Improving Material Tracking for Sustainable Construction: A Standard Operating Procedure (SOP) Framework for Resource Efficiency

Abstract

1. Introduction

2. Literature Review

2.1. Material Tracking and Its Role in Sustainable Construction

2.2. Challenges in Material Management in Developing Contexts

2.3. Technological Innovations in Material Tracking

2.4. Standard Operating Procedures (SOPs) in Construction Logistics

2.5. Integration of Digital Tools with SOP Frameworks

2.6. Research Gaps and Contributions

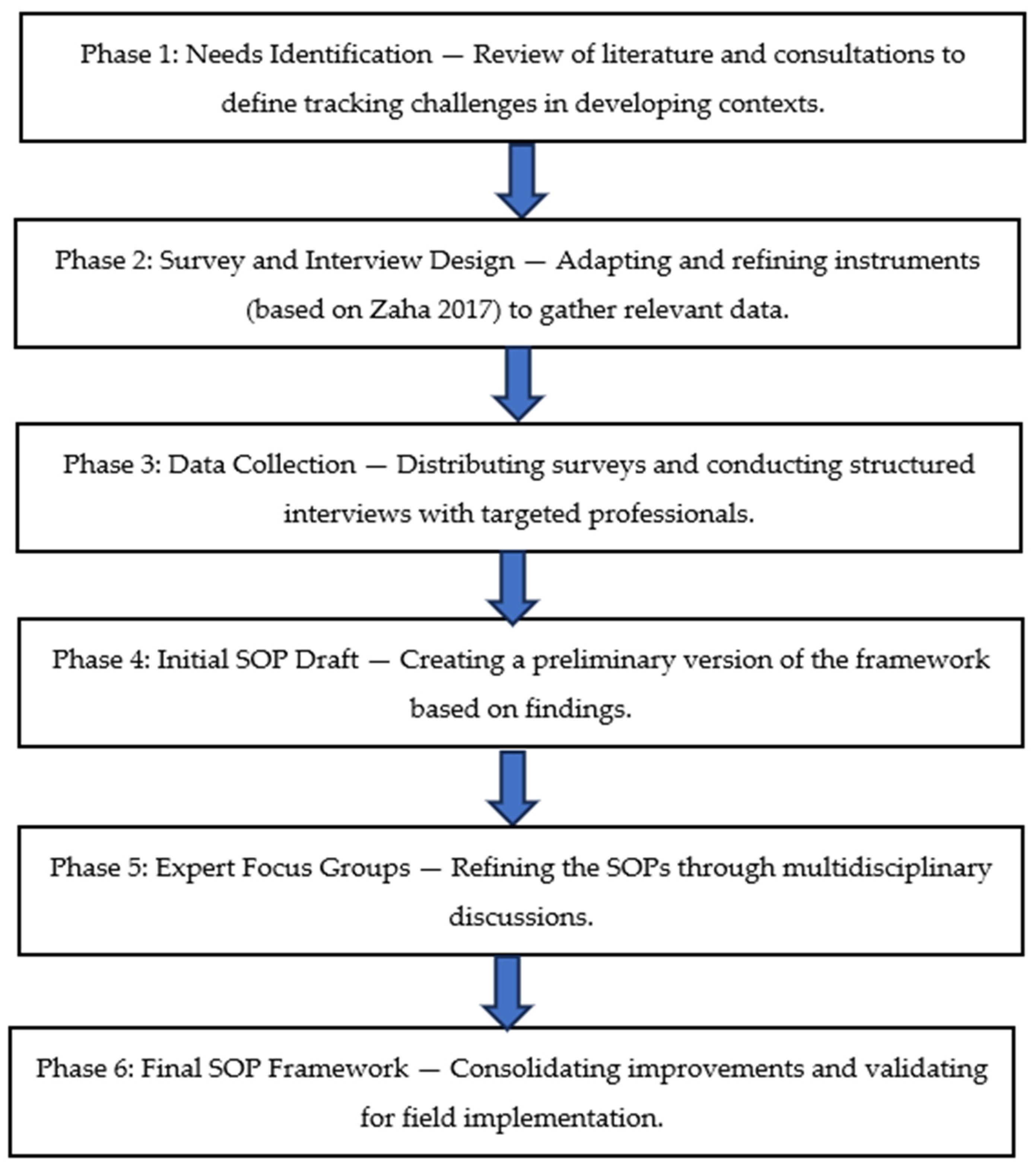

3. Research Methodology

3.1. Needs Identification

3.2. Survey and Interview Design

- Respondents’ background: Capturing roles, experience, and sector affiliation.

- Open-ended questions: Exploring inefficiencies in tracking and procurement.

- Likert-scale questions: Measuring agreement on challenges such as waste, over-ordering, and resource mismanagement.

- Close-ended questions: Identifying causes and frequency of material delays, cost overruns, and sustainability failures.

3.3. Data Collection

3.4. Initial SOP Draft Development

- Standardized protocols for receiving materials, quality verification, and dispatch;

- Integration of low-cost digital tools such as QR codes and mobile-accessible dashboards;

- Visual SOP templates and multilingual formats to enhance usability across diverse workforces.

3.5. Expert Focus Groups and Refinement

- Modular SOP design adaptable to project size and complexity;

- Use of visual aids and simplified language to improve comprehension;

- Inclusion of multilingual formats and mobile accessibility for broader usability;

- Emphasis on real-time feedback loops via automated dashboards and QR tracking.

3.6. Final SOP Framework

- Simplicity: Clear, concise procedures were developed to minimize training requirements, especially in environments where digital literacy may be limited.

- Practicality: The modular structure allows SOPs to be selectively applied based on the type, scale, and resource availability of each project.

- Sustainability: Each process step was designed to reduce material waste, limit redundant transportation, and enhance accuracy in forecasting and inventory control.

4. Results

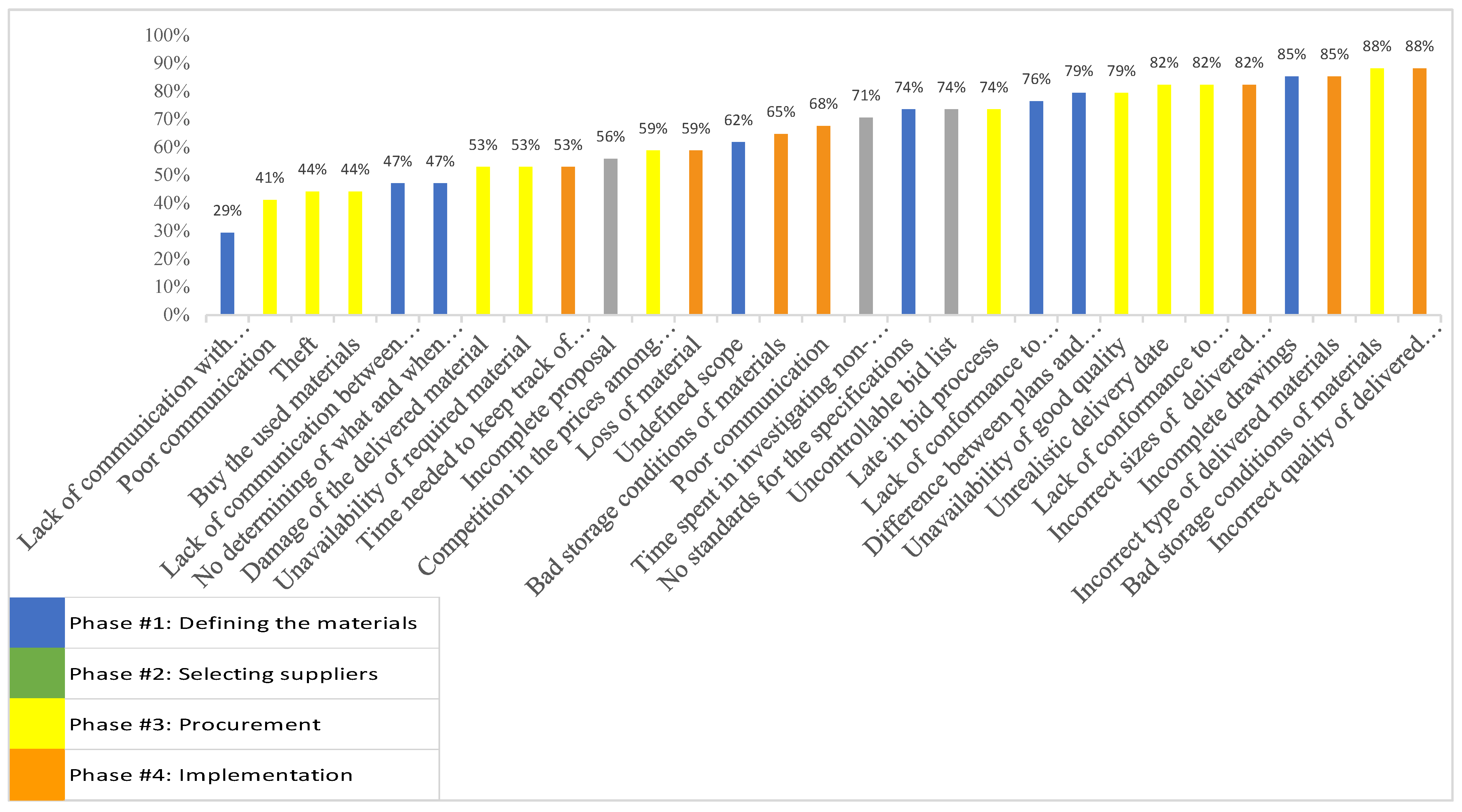

4.1. Survey Findings: Critical Factors and Obstacles in Material Tracking

4.1.1. Key Factors Influencing Material Tracking

4.1.2. Obstacles Across Project Phases

4.1.3. Comparative Insights Across Project Categories

4.2. Interview Insights

- Lack of Integration Between Office and Site Operations: Respondents consistently noted a disconnection between office-based planning tools (such as Primavera) and real-time operations at construction sites. While many companies maintain digital records in the office, these data are rarely shared effectively with site teams, resulting in delays, duplicated efforts, and limited tracking accuracy.

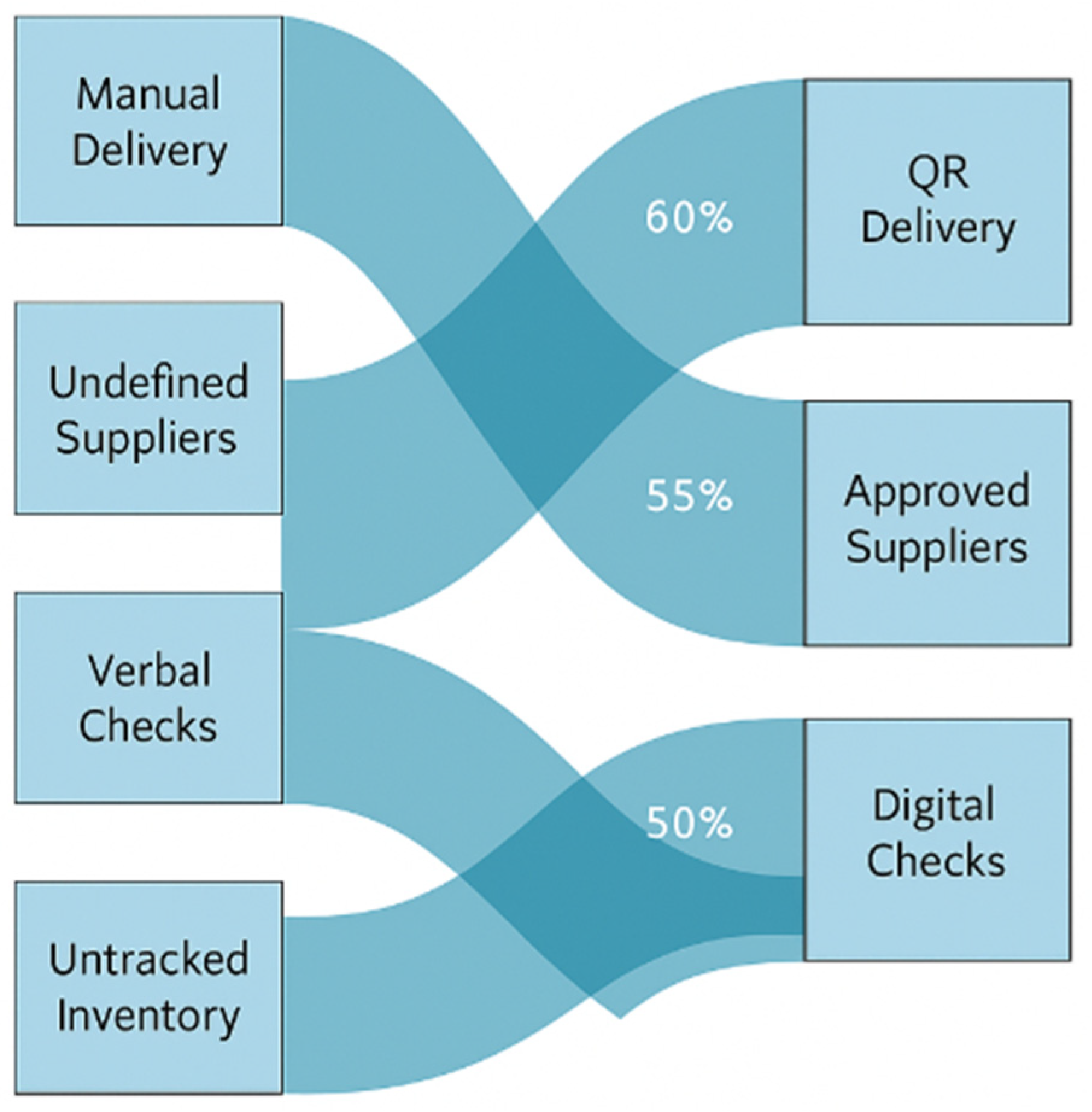

- Manual and Paper-Based Tracking Still Prevails: Despite awareness of digital tools, most participants reported that their organizations still rely heavily on Excel sheets, paper-based logs, and informal verbal communication for material tracking. This practice increases the risk of errors, lost data, and inefficiencies in procurement and usage.

- Barriers to Digital Adoption: Interviewees highlighted several obstacles to adopting digital tracking systems, including limited internet access at construction sites, lack of IT infrastructure, and insufficient training for staff. These barriers were particularly acute in public sector projects and smaller private firms.

- Material Quality and Procurement Issues: A recurring concern was the delivery of materials that did not meet project specifications. Respondents emphasized that delays caused by rejections or returns are common and rarely logged systematically, which hinders continuous improvement in procurement planning.

- Need for a Centralized, Role-Based System: Several engineers recommended the development of a centralized platform that allows role-based access for different stakeholders—such as site engineers, procurement managers, and warehouse staff. This system should also be capable of generating automatic notifications to track updates, alert teams about delivery dates, and flag delays or inconsistencies.

- Support for SOP Framework: Respondents expressed support for the proposed SOP approach, especially the idea of linking standard procedures to an interactive tracking system that reflects the actual material workflow on-site. They noted that SOPs could help reduce confusion about responsibilities, improve accountability, and align staff with sustainability goals.

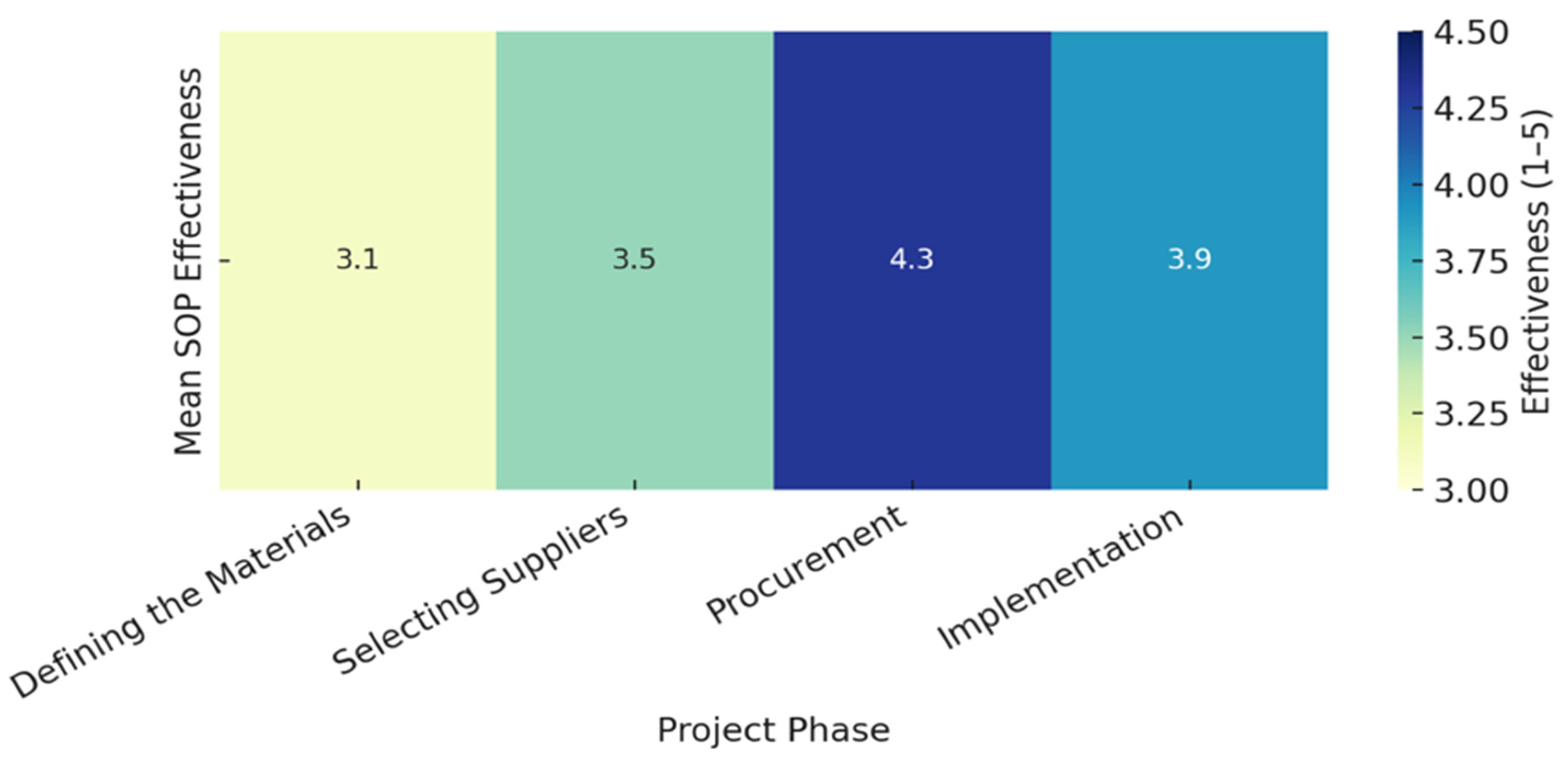

Statistical Summary of SOP Effectiveness and Stakeholder-Specific Obstacles

4.3. Key Revisions to SOP Framework Based on FGD Feedback

- 1-

- Key Insights from Experts:

- QR Code Integration: Experts emphasized that QR technology could significantly enhance material traceability, especially during the rebuilding phase in Syria. However, they cautioned against overloading QR codes with excessive information. Instead, they proposed using URLs embedded in the QR code, linking each material to a central database. For granular materials, where QR labeling is difficult, it was suggested to use physical signage placed near the material storage areas.

- Material Waste Monitoring: Experts highlighted the potential for the MTS to predict material waste by analyzing historical consumption data. They emphasized the need to automate waste tracking, particularly in public sector projects where current monitoring is largely manual and error prone.

- Need for Integration Across Office and Site: While some companies in the Gulf region already employ E-Systems, participants noted these often lack real-time integration between office planning and on-site execution. MTS was commended for addressing this gap by enabling bidirectional data sharing and operational updates.

- Benefits of Real-Time Tracking and Notifications: Experts noted that one of the MTS’s strengths is its ability to enhance communication across departments through automated notifications. This ensures timely procurement, reduces delays, and improves sustainability by minimizing rework and material loss.

- 2-

- Final Modifications Based on Expert Recommendations:

- Application Scope: Restrict the system’s implementation to medium and large-scale projects with complex material flows.

- Stakeholder Definition: Clearly assign roles and responsibilities to each project stakeholder within the MTS database.

- Warehouse Integration: Allow for integration of both formal warehouses and informal on-site storage areas regardless of their structure or location.

- Sub-Warehouse Tracking: Include sub-warehouse tracking within the system to accommodate multiple storage points on large sites.

- GPS Tracking: Incorporate GPS tools to monitor vehicle movements during material transportation and delivery.

- Material Expiration Dates: Track storage duration and manage expiration-sensitive materials to reduce waste and prevent material degradation.

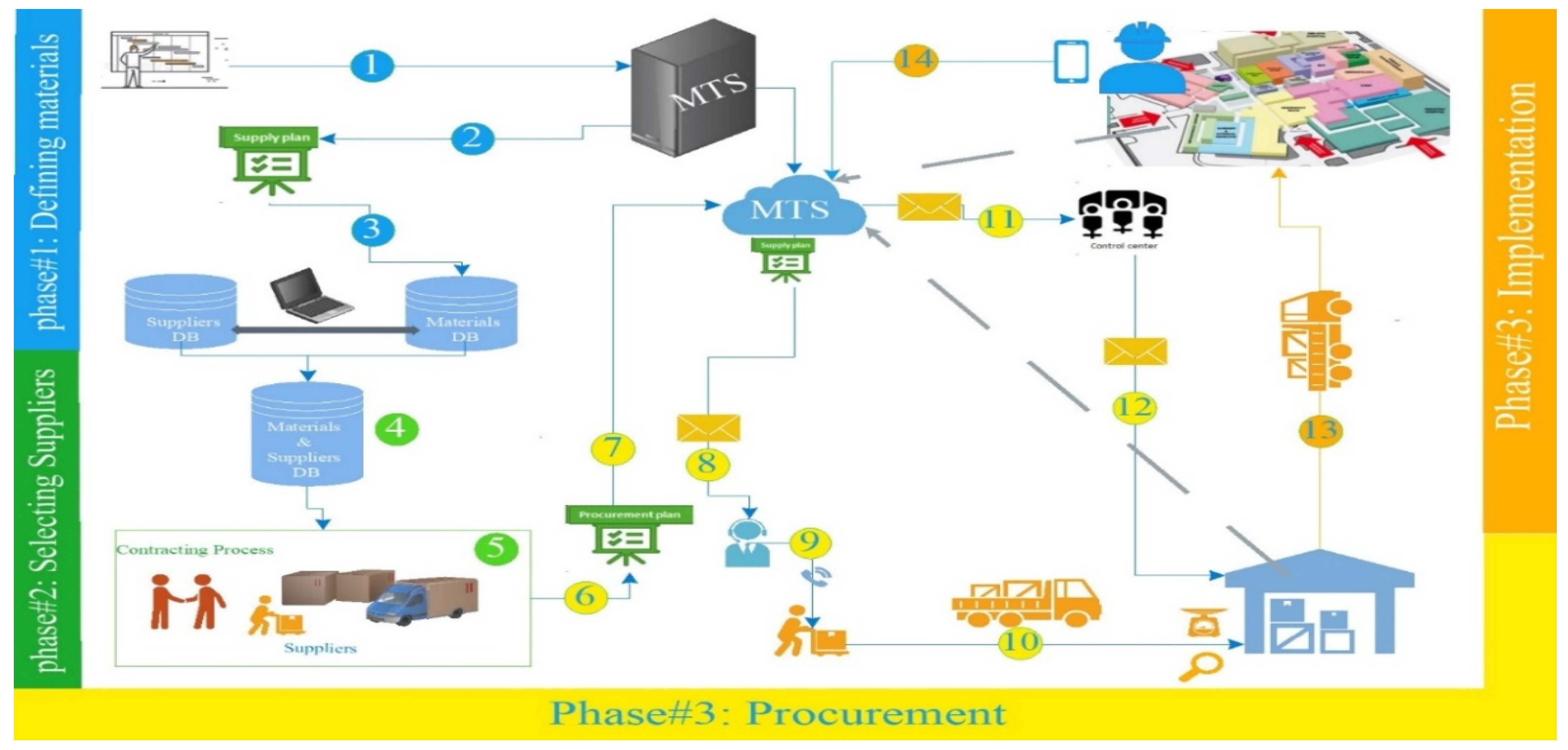

4.4. Finalized SOP Framework Snapshot

- A centralized MTS cloud platform that functions as the main dashboard and processing database;

- QR-coded materials cards that allow real-time tracking of material status and movement;

- Automated interdepartmental notifications to trigger procurement, delivery, or corrective actions;

- Visual SOP templates available in multilingual formats for field usability;

- Integrated data-sharing capabilities for decision-making across teams and project phases.

- (1)

- Fixed data including codes, material names, and specifications;

- (2)

- Variable Data A (e.g., estimated delivery and consumption dates, quantities, costs);

- (3)

- Variable Data B capturing supplier-related data and contract updates.

5. Discussion

- SDG 9: Industry, Innovation and Infrastructure—through digital enhancement of construction workflows.

- SDG 11: Sustainable Cities and Communities—by promoting resource-efficient construction practices.

- SDG 12: Responsible Consumption and Production—via waste reduction and optimized material usage.

6. Conclusions and Recommendations

- Policy Integration: Regulatory bodies should consider incorporating the framework into national construction guidelines to standardize material tracking practices and foster accountability across public and private sectors.

- Capacity Building: Construction companies are encouraged to train procurement officers, site engineers, and warehouse managers in the use of the MTS, with an emphasis on digital literacy and sustainability awareness.

- Gradual Adoption: The SOPs’ modular structure supports phased implementation. Small and medium-sized enterprises can begin with core components such as procurement and inventory control and gradually adopt the full workflow.

- Cross-Sector Collaboration: Continued development and adaptation of the framework will benefit from collaboration among construction firms, IT developers, and academic institutions, particularly in post-conflict reconstruction settings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SOP | Standard Operating Procedure |

| MTS | Materials tracking system |

| BIM | Building Information Modeling |

| BoQ | Bill of Quantities |

| FGD | Focus group discussion |

| IoT | Internet of Things |

| QR | Quick Response |

| SDGs | Sustainable Development Goals |

References

- Kasim, N.; Kusumaningtias, R.B.; Sarpin, N.B. Enhancing material tracking practices of material management in construction project. Int. J. Sustain. Constr. Eng. Technol. 2019, 10, 61–73. [Google Scholar] [CrossRef]

- Adam, A.; Josephson, P.-E.; Lindahl, G. Aggregation of factors causing cost overruns and time delays in large public construction projects: Trends and implications. Eng. Constr. Archit. Manag. 2017, 24, 393–406. [Google Scholar] [CrossRef]

- Van, B.P.; Peansupap, V. Confirmatory analysis on factors influencing the material management effectiveness in construction projects. Eng. Constr. Archit. Manag. 2024, 31, 2536–2562. [Google Scholar] [CrossRef]

- Guerlain, C.; Renault, S.; Ferrero, F. Understanding construction logistics in urban areas and lowering its environmental impact: A focus on construction consolidation centres. Sustainability 2019, 11, 6118. [Google Scholar] [CrossRef]

- Hammoudi, M.; Shibani, A. Enhancing the Syrian construction industry through augmented reality: Applications and challenges. Int. J. BIM Eng. Sci. 2024, 8, 47–57. [Google Scholar] [CrossRef]

- Maya, R.A. Proposed framework for professional management to Syrian construction projects. Tishreen Univ. J. Eng. Sci. Ser. 2020, 42, 25–40. [Google Scholar]

- Shaheen, H.; Al-Shihabi, T. Study the suppliers’ work reality in the Syrian construction projects related to their work challenges and selection criteria. Al-Baath Univ. J. Eng. Sci. Ser. 2022, 44, 59–80. [Google Scholar]

- Shaheen, H.; Al-Shihabi, T. The highest-affect phase on materials management effectiveness in Syrian construction projects. J. Damascus Univ. Eng. Sci. Ser. 2022, 38, 23–44. [Google Scholar]

- Kasim, N. Intelligent materials tracking system for construction projects management. J. Eng. Technol. Sci. 2015, 47, 218–230. [Google Scholar] [CrossRef]

- Chen, X.; Li, H.; Wong, J.K.W.; Su, Y.; Xu, Z. Implementation of technologies in the construction industry: A systematic review. Eng. Constr. Archit. Manag. 2021, 29, 3181–3209. [Google Scholar] [CrossRef]

- Zaher, M.; Greenwood, D.; Marzouk, M. Mobile augmented reality applications for construction projects. Constr. Innov. 2018, 18, 152–166. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Shafiq, N.; Khan, A.M. Integration of passive RFID for small-scale construction project management. Data Inf. Manag. 2023, 7, 100055. [Google Scholar] [CrossRef]

- Nakanishi, Y.; Kaneta, T.; Nishino, S. A review of monitoring construction equipment in support of construction project management. Front. Built Environ. 2022, 7, 632593. [Google Scholar] [CrossRef]

- Babaeian Jelodar, M.; Shu, F. Innovative use of low-cost digitization for smart information systems in construction projects. Buildings 2021, 11, 270. [Google Scholar] [CrossRef]

- Abdul Rahman, I.; Memon, A.H.; Abdul Azis, A.A.; Abdullah, N.H. Modeling causes of cost overrun in large construction projects with partial least square-SEM approach: Contractor’s perspective. Res. J. Appl. Sci. Eng. Technol. 2013, 6, 1963–1972. [Google Scholar] [CrossRef]

- Fauziyah, S.; Sholeh, M.N.; Dharmo, B.; Purba, P.; Sutanto, H. Material tracking system of the supply chain in engineering procurement construction (EPC). AIP Conf. Proc. 2019, 2114, 030007. [Google Scholar] [CrossRef]

- Ibrahim, O.A.; Mohammed, I.A.; Varouqa, I.F. Materials management on construction sites using RFID technique. Int. J. Sci. Technol. Res. 2020, 9, 1576–1580. [Google Scholar]

- Sundquist, V.; Gadde, L.E.; Hulthén, K. Reorganizing construction logistics for improved performance. Constr. Manag. Econ. 2017, 36, 49–65. [Google Scholar] [CrossRef]

- Zaha, A. The impact of Material Management on Construction Project Delivery in Maldives. Master’s Thesis, Universiti Tunku Abdul Rahman, Kampar, Malaysia, 2017. [Google Scholar]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Fredriksson, A.; Janné, M.; Rudberg, M. Characterizing third-party logistics setups in the context of construction. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 325–349. [Google Scholar] [CrossRef]

- Akinradewo, O.I.; Awodele, O.A.; Akinradewo, O.F. Bill of material and labour template for construction information management. J. Eng. Proj. Prod. Manag. 2021, 11, 52–60. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.-H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Grau, D.; Caldas, C.H.; Haas, C.T.; Goodrum, P.M.; Gong, J. Assessing the impact of materials tracking technologies on construction craft productivity. Autom. Constr. 2009, 18, 903–911. [Google Scholar] [CrossRef]

- Salah, M.; Elmasry, M.; Mashhour, I.M.; Amer, N. A framework for assessing sustainability of construction projects. Cleaner Eng. Technol. 2023, 13, 100626. [Google Scholar] [CrossRef]

- Jaselskis, E.J.; El-Misalami, T. Implementing radio frequency identification in the construction process. J. Constr. Eng. Manag. 2003, 129, 680–688. [Google Scholar] [CrossRef]

- Tan, P.X.; Kasim, N.; Zainal, R.; Musa, S.M.S.; Noh, H.M. Study on barcoding implementation for improving materials tracking at construction site. Res. Manag. Technol. Bus. 2021, 2, 722–733. [Google Scholar]

- Garcia-Lopez, N.P.; Fischer, M.A. A system to track work progress at construction jobsites. In Proceedings of the 2014 Industrial and Systems Engineering Research Conference, Montreal, QC, Canada, 31 May–3 June 2014. [Google Scholar]

- Moselhi, O.; El-Omari, S. Integrating bar coding and RFID to automate data collection from construction sites. In Proceedings of the Joint International Conference on Computing and Decision Making in Civil and Building Engineering, Montréal, QC, Canada, 14–16 June 2006. [Google Scholar]

- Young, D.A.; Haas, C.T.; Goodrum, P.; Caldas, C. Improving construction supply network visibility by using automated materials locating and tracking technology. J. Constr. Eng. Manag. 2011, 137, 1170–1178. [Google Scholar] [CrossRef]

- Kasim, N.; Shamsuddin, A.; Zainal, R.; Kamarudin, N.C. Implementation of RFID technology for real-time materials tracking process in construction projects. In Proceedings of the 2012 IEEE Colloquium on Humanities, Science and Engineering (CHUSER), Kota Kinabalu, Malaysia, 3–4 December 2012; pp. 699–703. [Google Scholar] [CrossRef]

- Chong, H.-Y.; Wong, J.S.; Wang, X. An explanatory case study on cloud computing applications in the built environment. Autom. Constr. 2014, 44, 152–162. [Google Scholar] [CrossRef]

- Zhu, X.; Mukhopadhyay, S.K.; Kurata, H. A review of RFID technology and its managerial applications in different industries. J. Eng. Technol. Manag. 2012, 29, 152–167. [Google Scholar] [CrossRef]

- Lee, J.H.; Song, J.H.; Oh, K.S.; Gu, N. Information lifecycle management with RFID for material control on construction sites. Adv. Eng. Inform. 2013, 27, 108–119. [Google Scholar] [CrossRef]

- Nasr, E.; Shehab, T.; Vlad, A. Tracking systems in construction: Applications and comparisons. In Proceedings of the 49th ASC Annual International Conference, San Luis Obispo, CA, USA, 10–13 April 2013; Associated Schools of Construction: Loveland, CO, USA, 2013. [Google Scholar]

- Ayinla, K.O.; Adamu, Z. Bridging the digital divide gap in BIM technology adoption. Eng. Constr. Archit. Manag. 2018, 25, 1398–1416. [Google Scholar] [CrossRef]

- Lu, W.; Huang, G.Q.; Li, H. Scenarios for applying RFID technology in construction project management. Autom. Constr. 2011, 20, 101–106. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Song, J.; Haas, C.T.; Caldas, C.; Ergen, E.; Akinci, B. Automating the task of tracking the delivery and receipt of fabricated pipe spools in industrial projects. Autom. Constr. 2006, 15, 166–177. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. BIM log mining: Exploring design productivity characteristics. Autom. Constr. 2020, 109, 102997. [Google Scholar] [CrossRef]

- Rowley, J. Designing and using research questionnaires. Manag. Res. Rev. 2014, 37, 308–330. [Google Scholar] [CrossRef]

- Maguire, M.; Delahunt, B. Doing a Thematic Analysis: A Practical, Step-by-Step Guide for Learning and Teaching Scholars. AISHE-J. 2017, 9, 3351. [Google Scholar]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef]

- Suprayoga, G.B.; Bakker, M.; Witte, P.; Spit, T. A Systematic Review of Indicators to Assess the Sustainability of Road Infrastructure Projects. Eur. Transp. Res. Rev. 2020, 12, 19. [Google Scholar] [CrossRef]

- United Nations Economic and Social Commission for Western Asia (ESCWA). National Agenda for the Future of Syria: Economic Governance; United Nations ESCWA: Beirut, Lebanon, 2021. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations General Assembly: New York, NY, USA, 2015; Available online: https://sdgs.un.org/2030agenda (accessed on 10 April 2025).

| Item | Details |

|---|---|

| Total Respondents | 34 |

| Sector Affiliation | 45% Public Sector, 55% Private Sector |

| Civil Engineers | 73% of total respondents |

| Academic Qualifications | 6% PhD holders, 53% MSc holders |

| Experience Level | 74% with more than 10 years of professional experience |

| Number of Companies | 11 engineering firms |

| Projects Evaluated | 46 construction projects across six Syrian governorates |

| Project Type Distribution | 54% Residential, 41% Transportation, 4% Infrastructure |

| Geographic Coverage | Damascus, Rural Damascus, Tartous, Latakia, Hama, Al Suwayda |

| Phase | Defining the Materials | Selecting Suppliers | Procurement | Implementation |

|---|---|---|---|---|

| The weight (W) out of 1 | 0.28 | 0.10 | 0.38 | 0.24 |

| Impact (I) = Avg. % Respondents | 63% | 67% | 64% | 71% |

| The Effective Impact (Ieff) = W × I | 17% | 7% | 24% | 17% |

| Category | Dominant Challenge | SOP Implementation Pattern |

|---|---|---|

| Transportation | Logistics delays | Stronger in execution, weaker in handover |

| Residential | Inventory mismanagement | More QR-code adoption on-site |

| Public Projects | Procurement delays | Slower cycle, more SOP compliance |

| Private Projects | Inconsistent storage practices | Faster cycle, but variable compliance |

| Coastal Regions | Better supplier reliability | Higher digital tool usage |

| Rural Projects | Connectivity gaps | More procedural workarounds |

| Project Phase | Mean SOP Effectiveness (1–5) | Standard Deviation | N |

|---|---|---|---|

| Defining the Materials | 3.1 | 0.94 | 12 |

| Selecting Suppliers | 3.5 | 0.82 | 16 |

| Procurement | 4.3 | 0.58 | 22 |

| Implementation | 3.9 | 0.73 | 18 |

| Obstacle Description | Contractors (%) | Consultants (%) | Government Officials (%) |

|---|---|---|---|

| Incomplete SOP Documentation | 78 | 64 | 43 |

| Tracking System Inconsistencies | 69 | 55 | 34 |

| Delayed Procurement Approvals | 72 | 38 | 76 |

| Phase | SOP Focus Areas |

|---|---|

| Phase 1: Defining Materials | P#1—Extracting information from project plans (Primavera/BoQ) P#2—Preparing a supply plan |

| Phase 2: Selecting Suppliers | P#3—Generating material cards with cost/supplier data P#4—Assigning materials to suppliers P#5—Choosing procurement method |

| Phase 3: Procurement | P#6—Starting the procurement process P#7—Finalizing contracts P#8—Arranging delivery logistics P#9—Material receiving P#10—Quality and quantity verification |

| Phase 4: Implementation | P#11—Dispatching to site P#12—QR tracking and on-site placement P#13—Consumption recording P#14—Updating inventory and follow-up |

| Performance Indicator | Estimated Improvement | Source |

|---|---|---|

| Material waste reduction | 15–25% decrease | Expert focus group (n = 14) |

| Delivery time accuracy | 20–30% improvement | Site supervisor interviews (n = 9) |

| Procurement lead time | 10–15% reduction | Procurement officer responses (survey) |

| Inventory discrepancy rate | Reduction from ~18% to <8% | Internal warehouse reporting (3 sites) |

| Frequency of emergency reorders | ~40% decrease | Combined interview feedback |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, D.M.; Gáspár, L.; Shaheen, H.M.; Al-Shihabi, T.A.; Maya, R.A.; Pinto, F.S. Improving Material Tracking for Sustainable Construction: A Standard Operating Procedure (SOP) Framework for Resource Efficiency. Buildings 2025, 15, 1941. https://doi.org/10.3390/buildings15111941

Ahmad DM, Gáspár L, Shaheen HM, Al-Shihabi TA, Maya RA, Pinto FS. Improving Material Tracking for Sustainable Construction: A Standard Operating Procedure (SOP) Framework for Resource Efficiency. Buildings. 2025; 15(11):1941. https://doi.org/10.3390/buildings15111941

Chicago/Turabian StyleAhmad, Dema Munef, László Gáspár, Hummam Mohammed Shaheen, Talal Ahmad Al-Shihabi, Rana Ahmad Maya, and Francisco Silva Pinto. 2025. "Improving Material Tracking for Sustainable Construction: A Standard Operating Procedure (SOP) Framework for Resource Efficiency" Buildings 15, no. 11: 1941. https://doi.org/10.3390/buildings15111941

APA StyleAhmad, D. M., Gáspár, L., Shaheen, H. M., Al-Shihabi, T. A., Maya, R. A., & Pinto, F. S. (2025). Improving Material Tracking for Sustainable Construction: A Standard Operating Procedure (SOP) Framework for Resource Efficiency. Buildings, 15(11), 1941. https://doi.org/10.3390/buildings15111941