Lateral Deformation Mechanisms of Piles in Coastal Regions Under Seawall Surcharge Loading and Mitigation Using Deep Cement Mixing (DCM) Piles

Abstract

1. Introduction

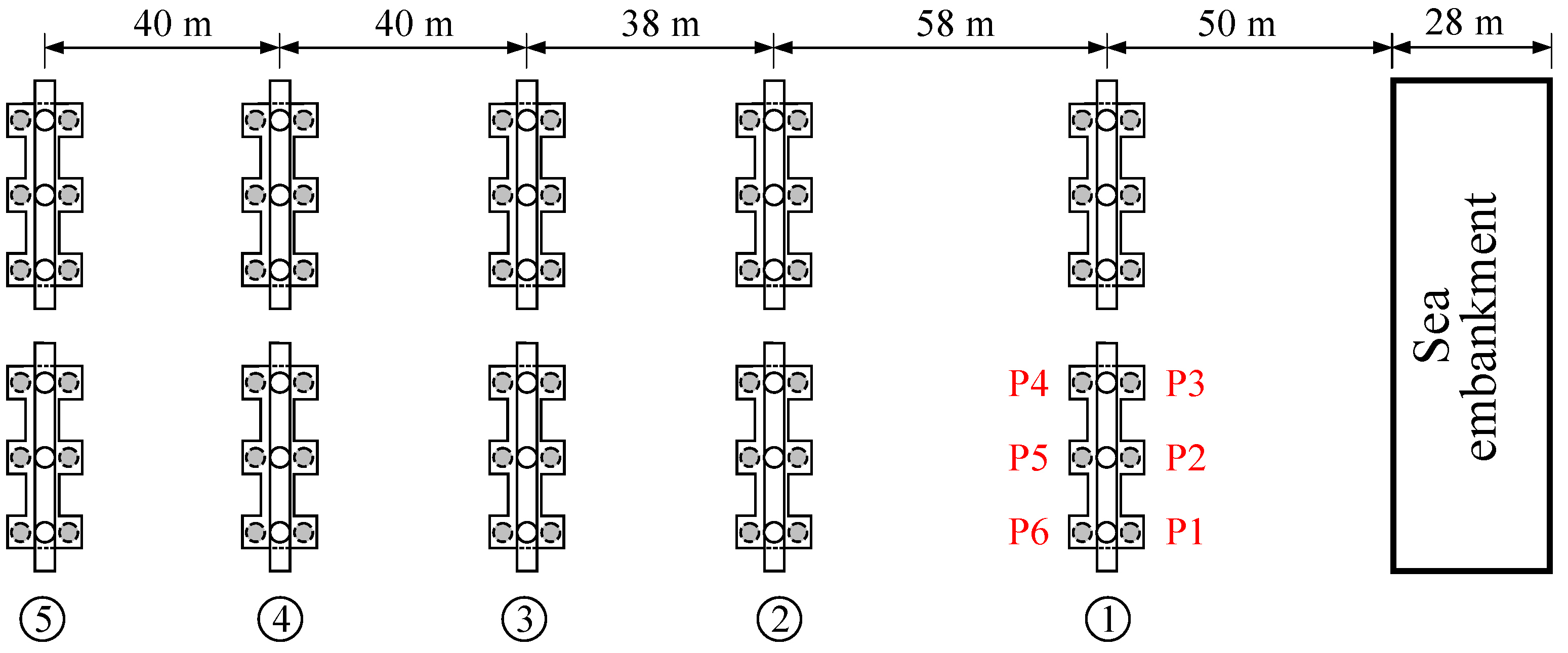

2. Site and Structural Details

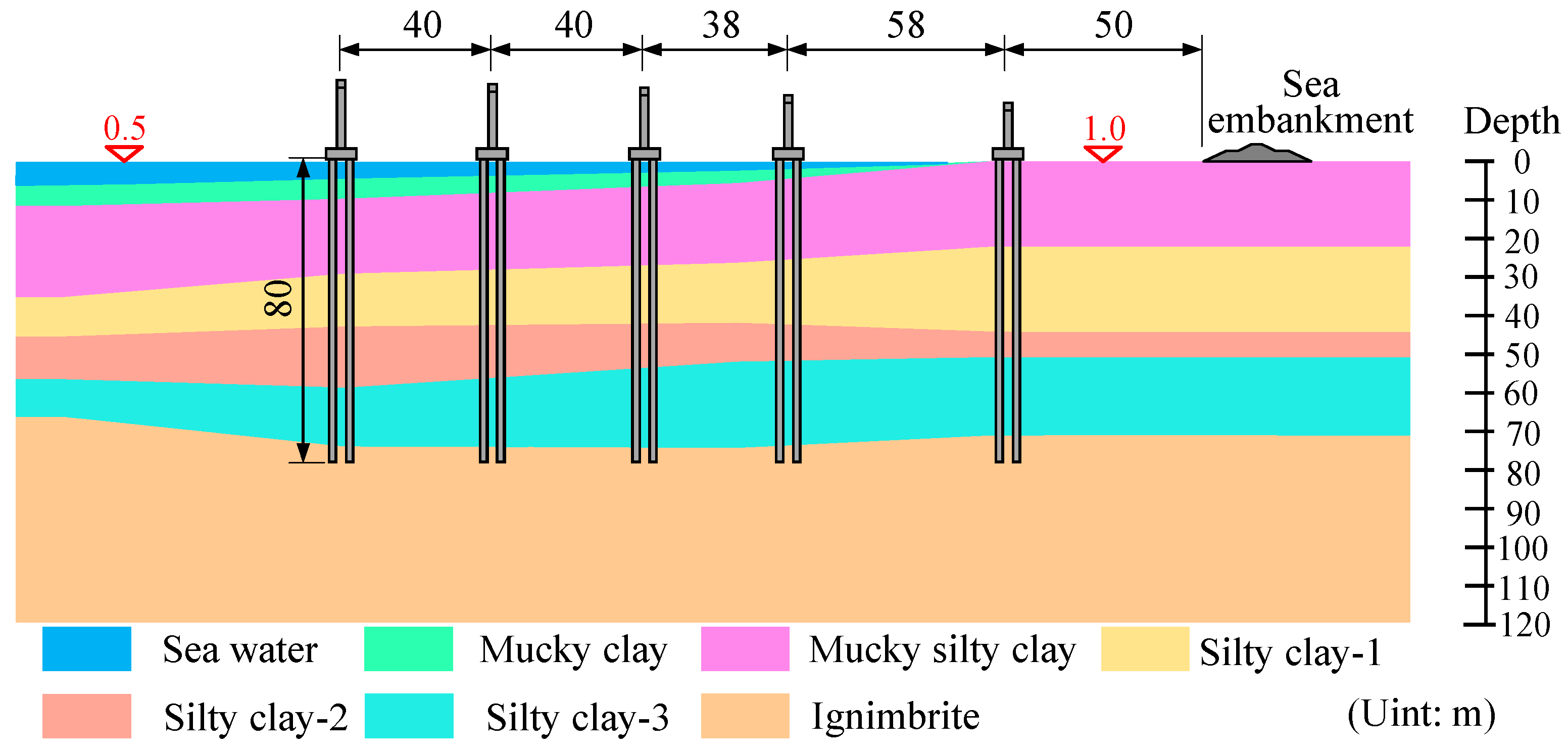

2.1. Geological Conditions

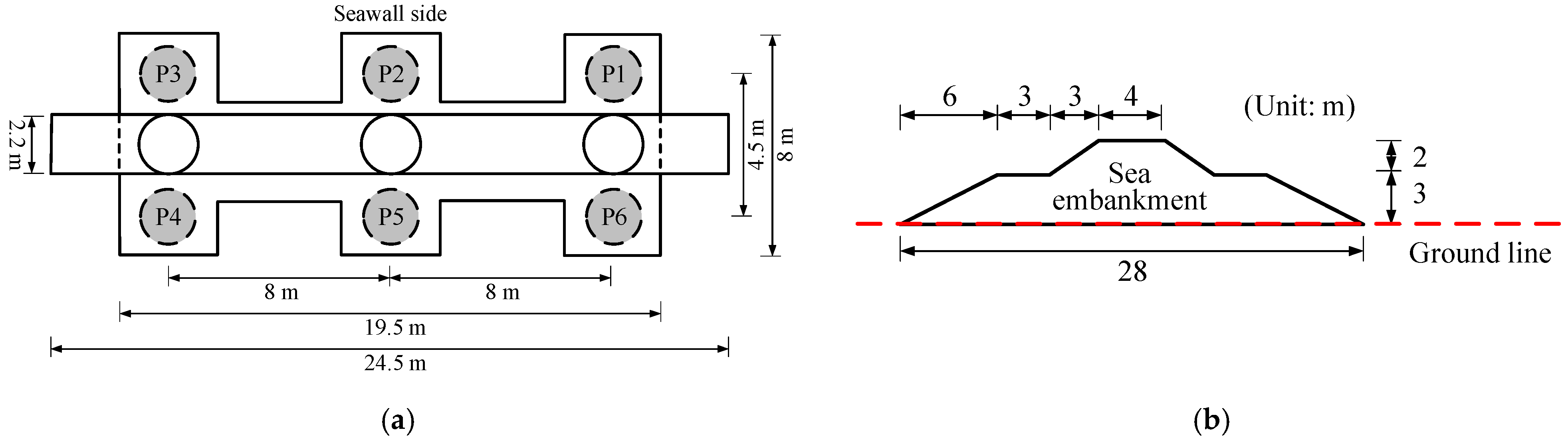

2.2. Bridge and Seawall Configuration

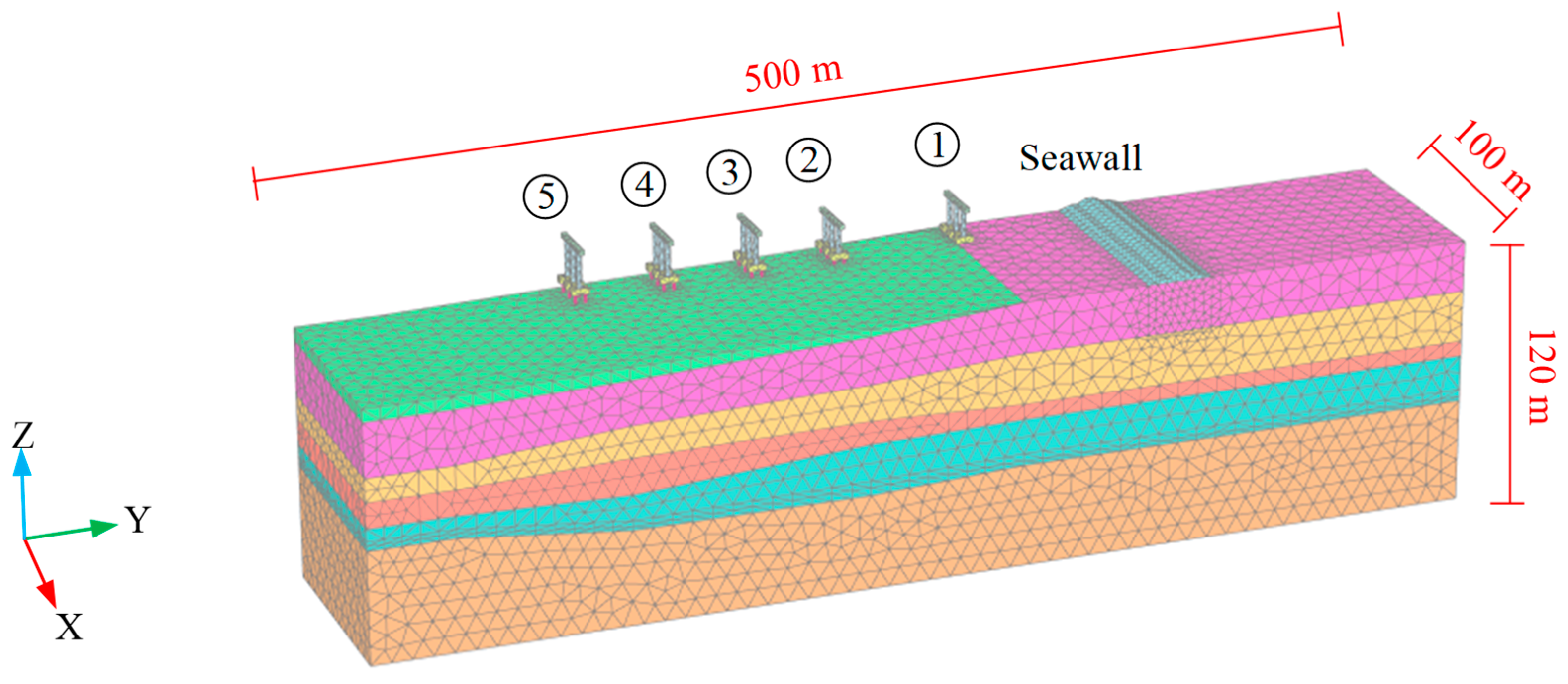

3. Numerical Modeling Framework

3.1. Soil Parameters

3.2. Structural Modeling Methodology

3.3. Boundary Conditions and Mesh Discretization

3.4. Analysis Step

- (1)

- Geostatic stress equilibrium: As indicated by the geological cross-section showing a non-horizontal ground surface, the gravity loading approach in Plaxis was employed to achieve initial stress equilibrium. As illustrated in Figure 2, the groundwater table elevation was set at 1.0 m.

- (2)

- Activation of bridge pile foundations with pile caps, columns, and crossbeams. A uniform equivalent surface load of 186 kPa was applied to the crossbeams, and the construction stages of the bridge were not accounted for.

- (3)

- Construction of the first-stage seawall (3 m height) using consolidation analysis, with a construction duration of 10 days followed by a 10-day rest period.

- (4)

- Construction of the second-stage seawall (2 m height) using consolidation analysis, with a construction duration of 5 days.

- (5)

- Long-term consolidation phase post-seawall construction to investigate sustained effects on bridge pile foundations. A consolidation analysis was conducted over a total duration of 20 years with annual intervals, where each yearly increment was defined as 365 days.

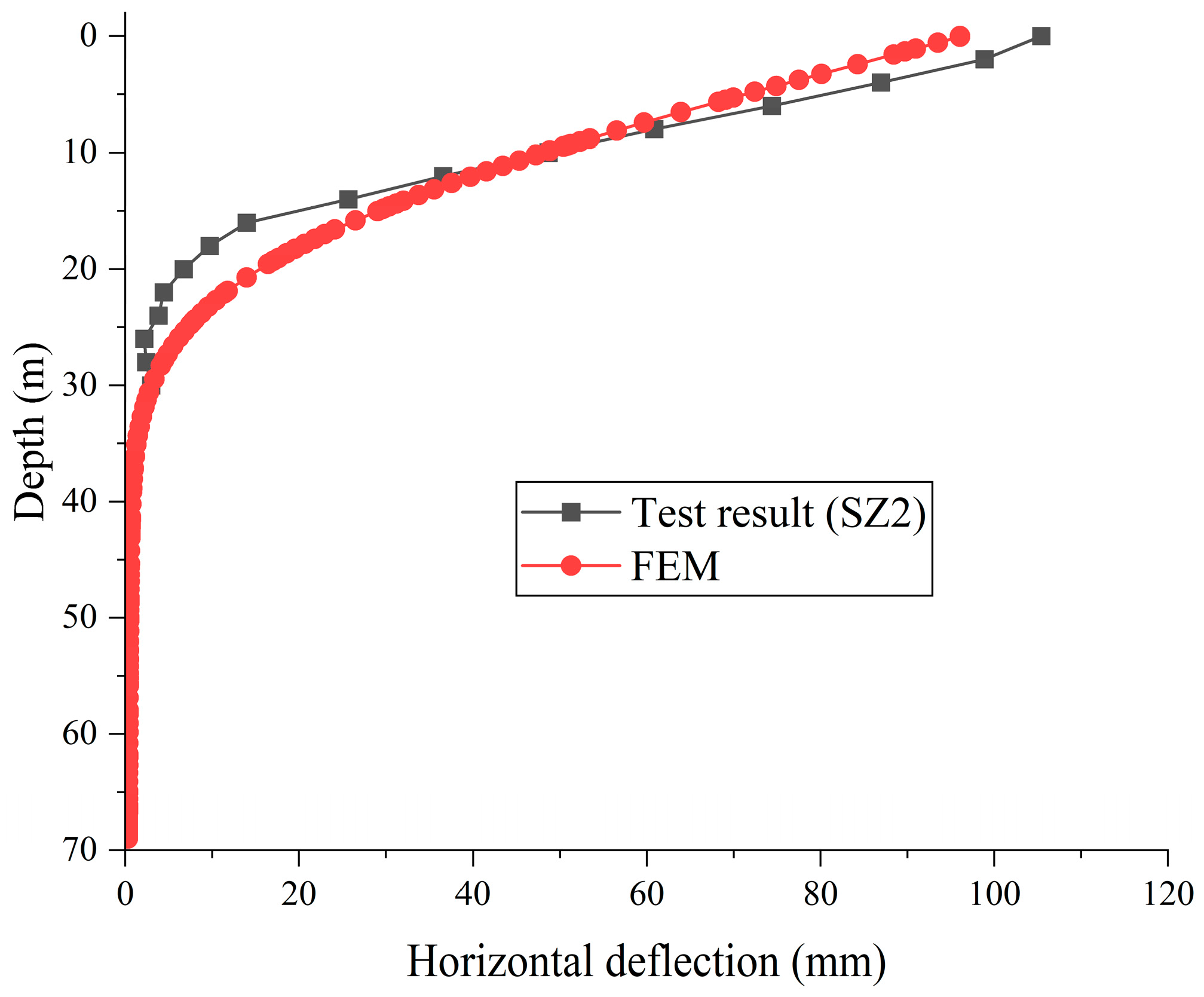

3.5. Numerical Simulation Validation

4. Results and Analysis

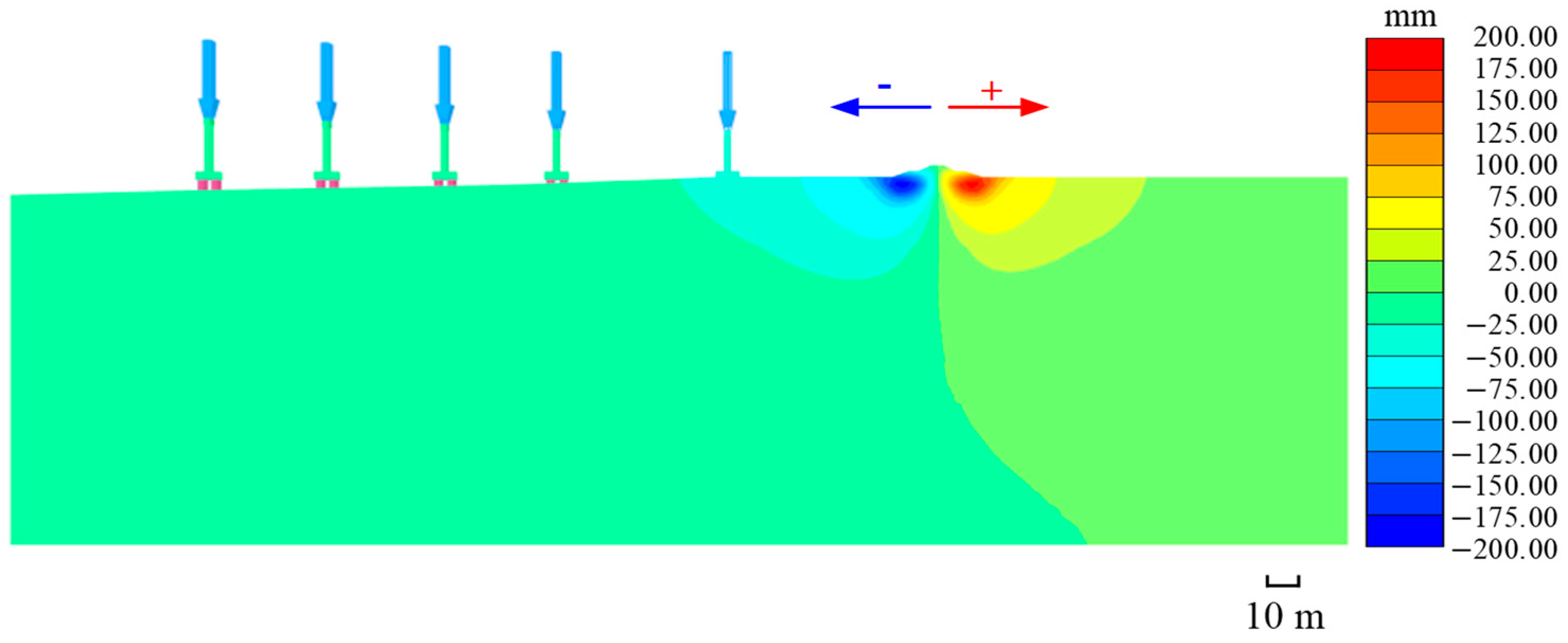

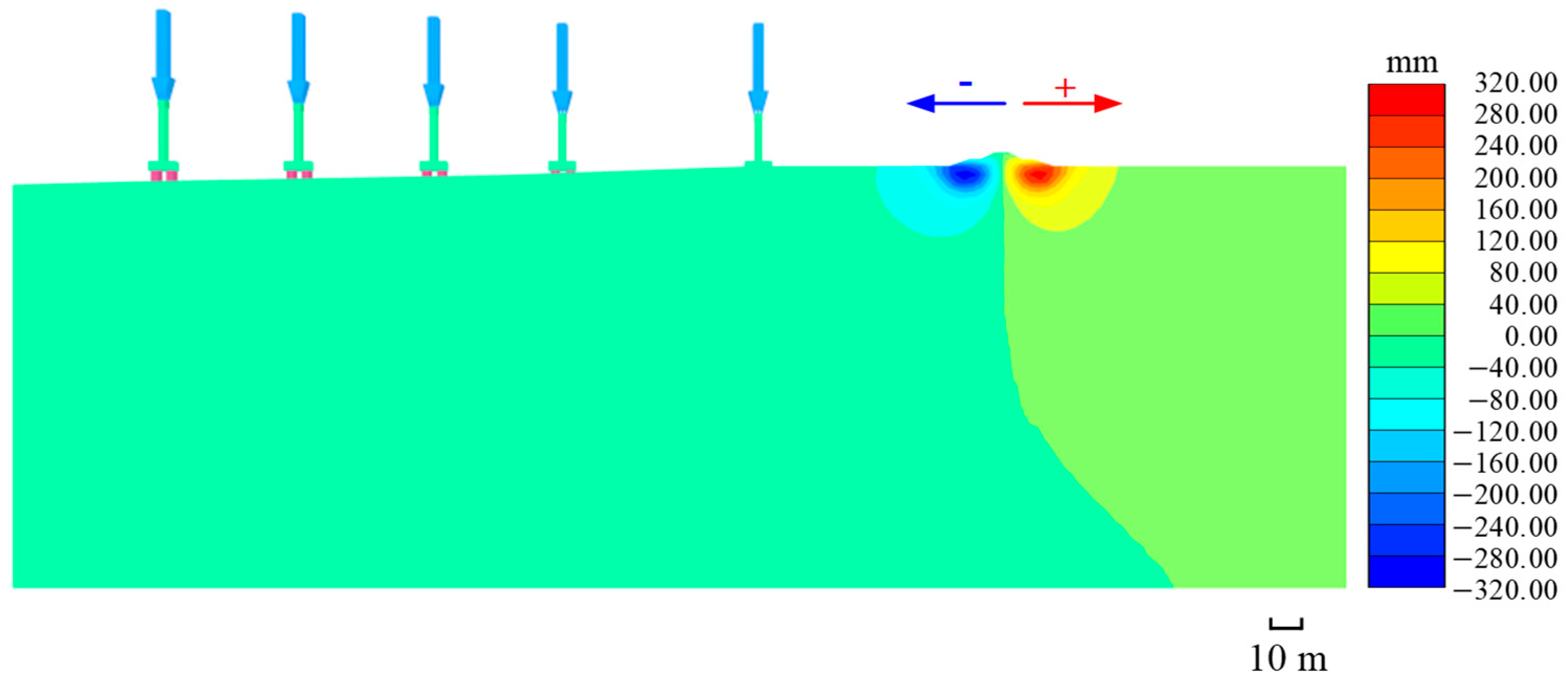

4.1. Influence Zone of Seawall

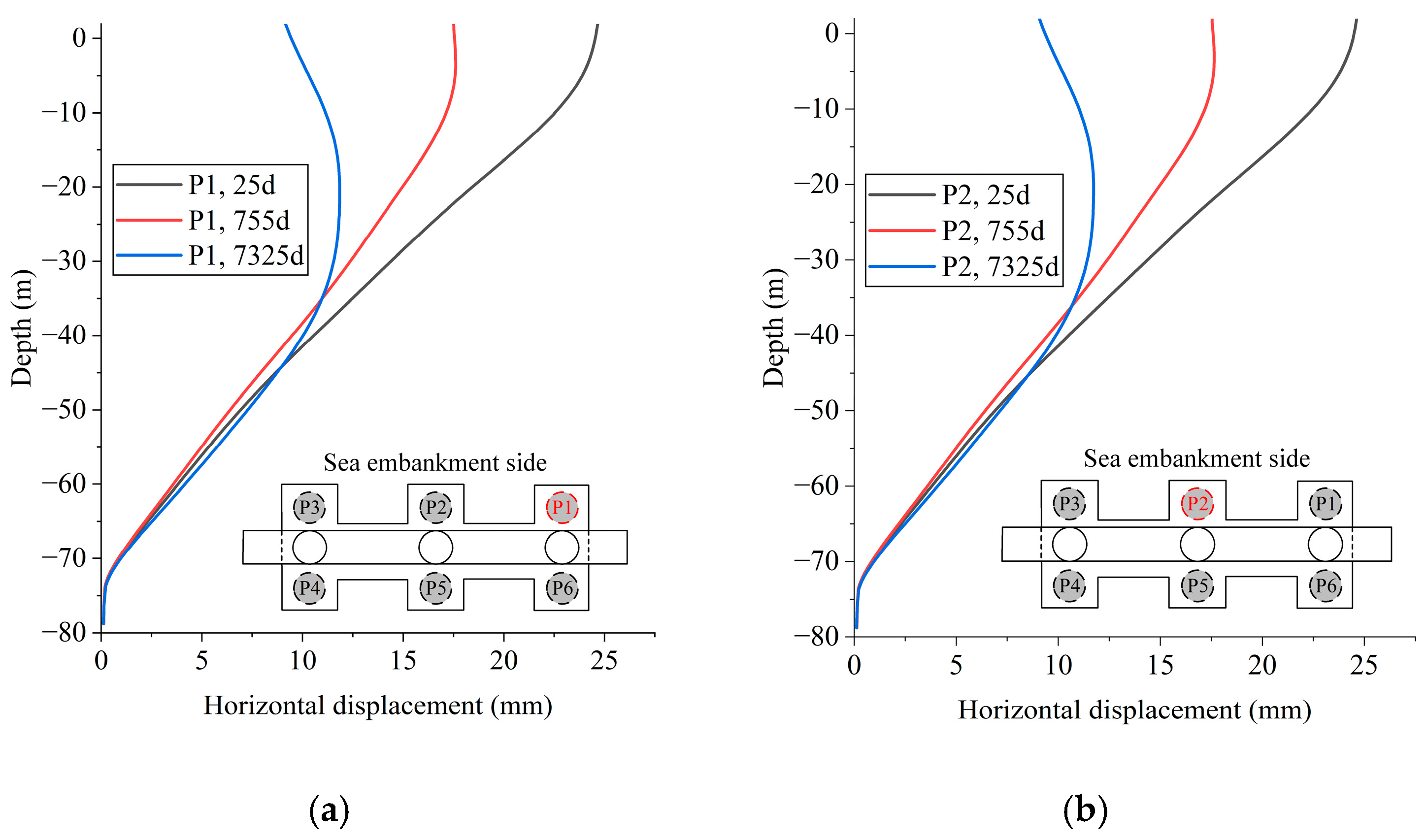

4.2. Horizontal Displacement of Piles

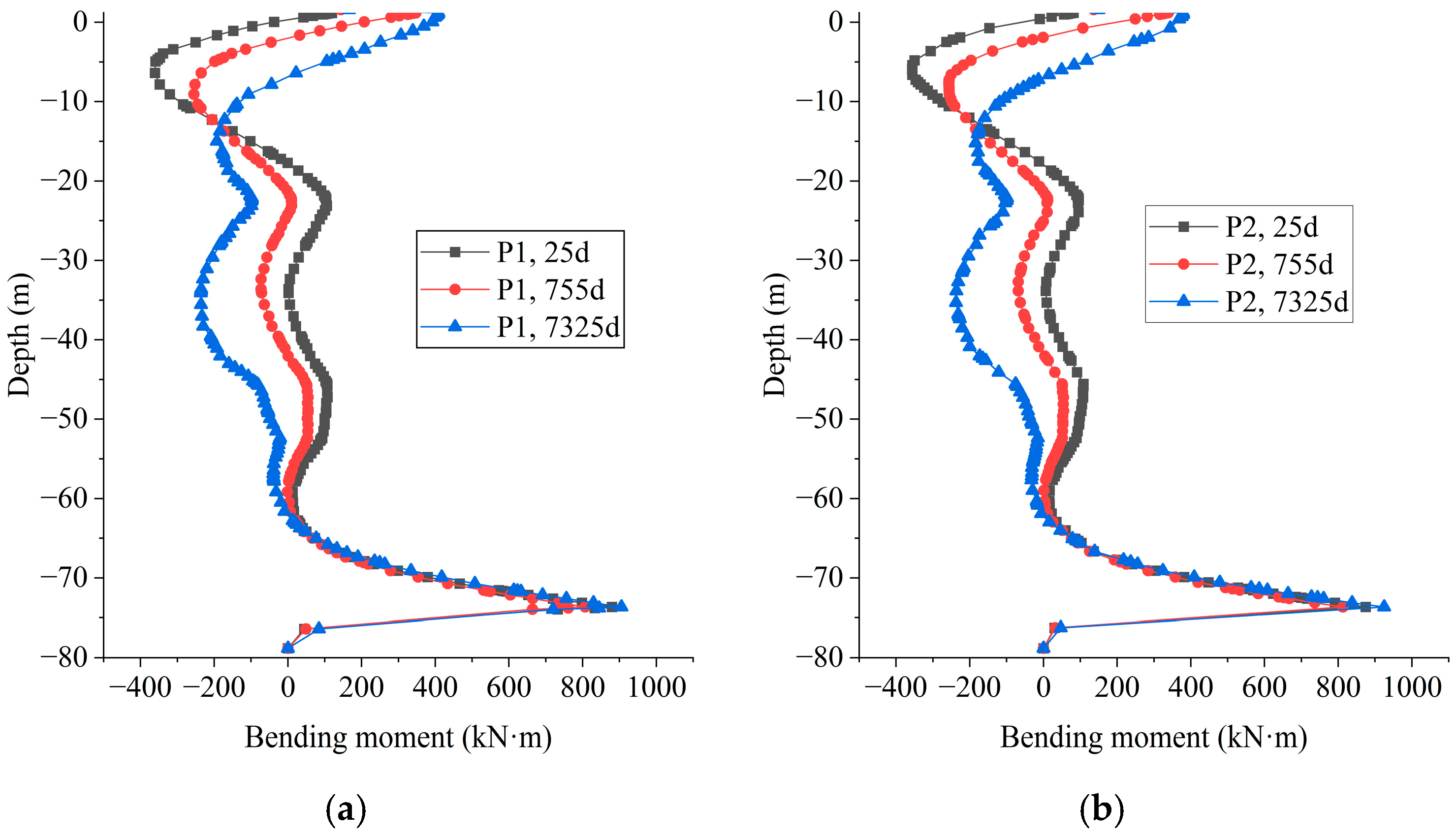

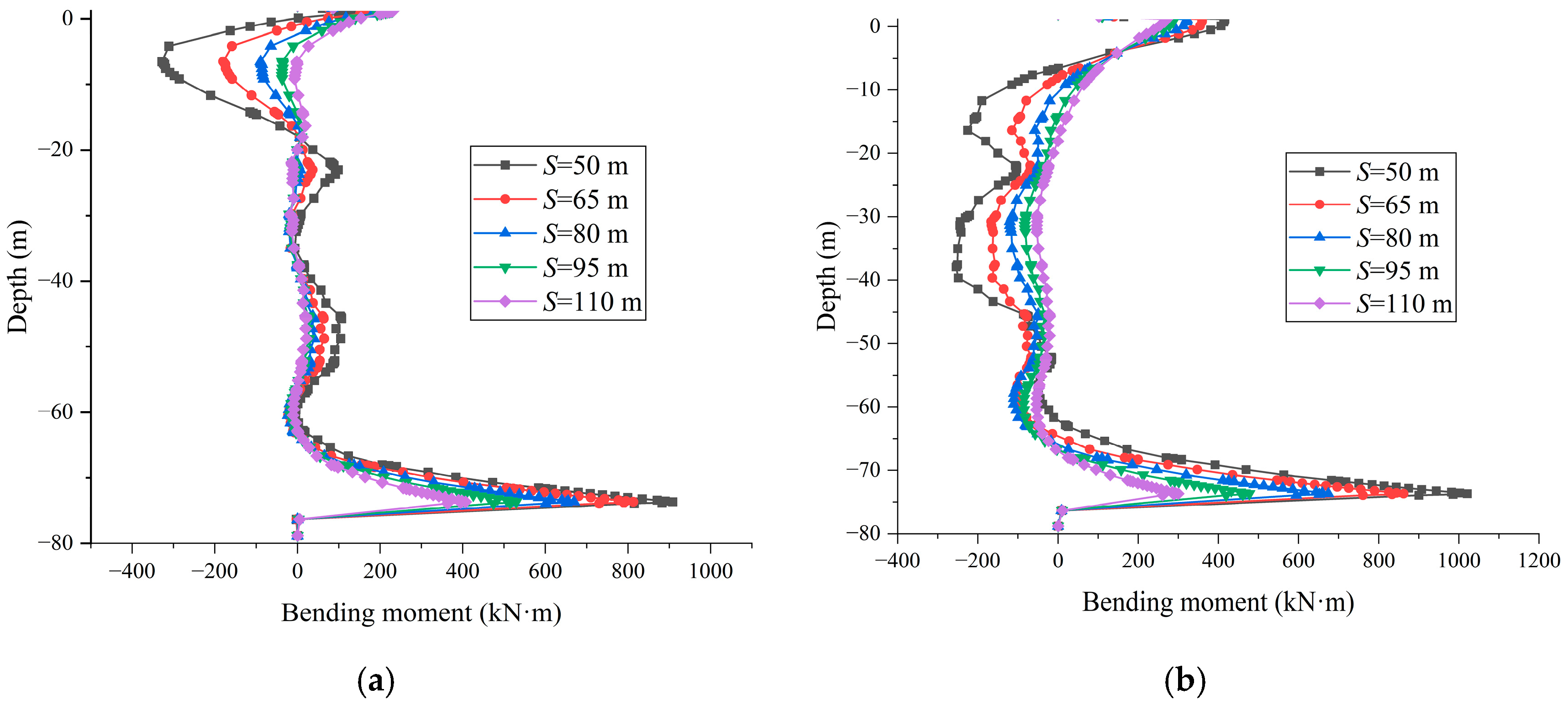

4.3. Bending Moments in Piles

4.4. Analysis of Influencing Factors

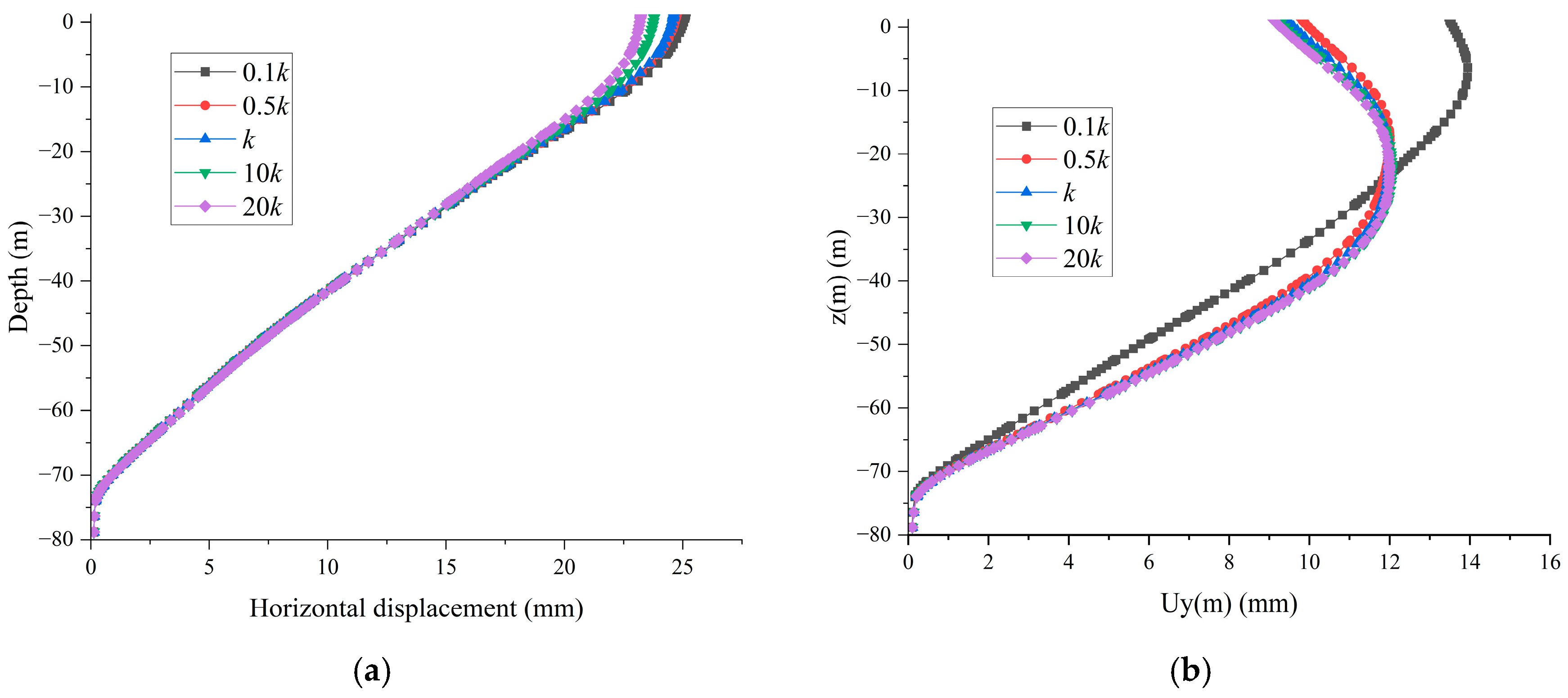

4.4.1. Permeability Coefficient

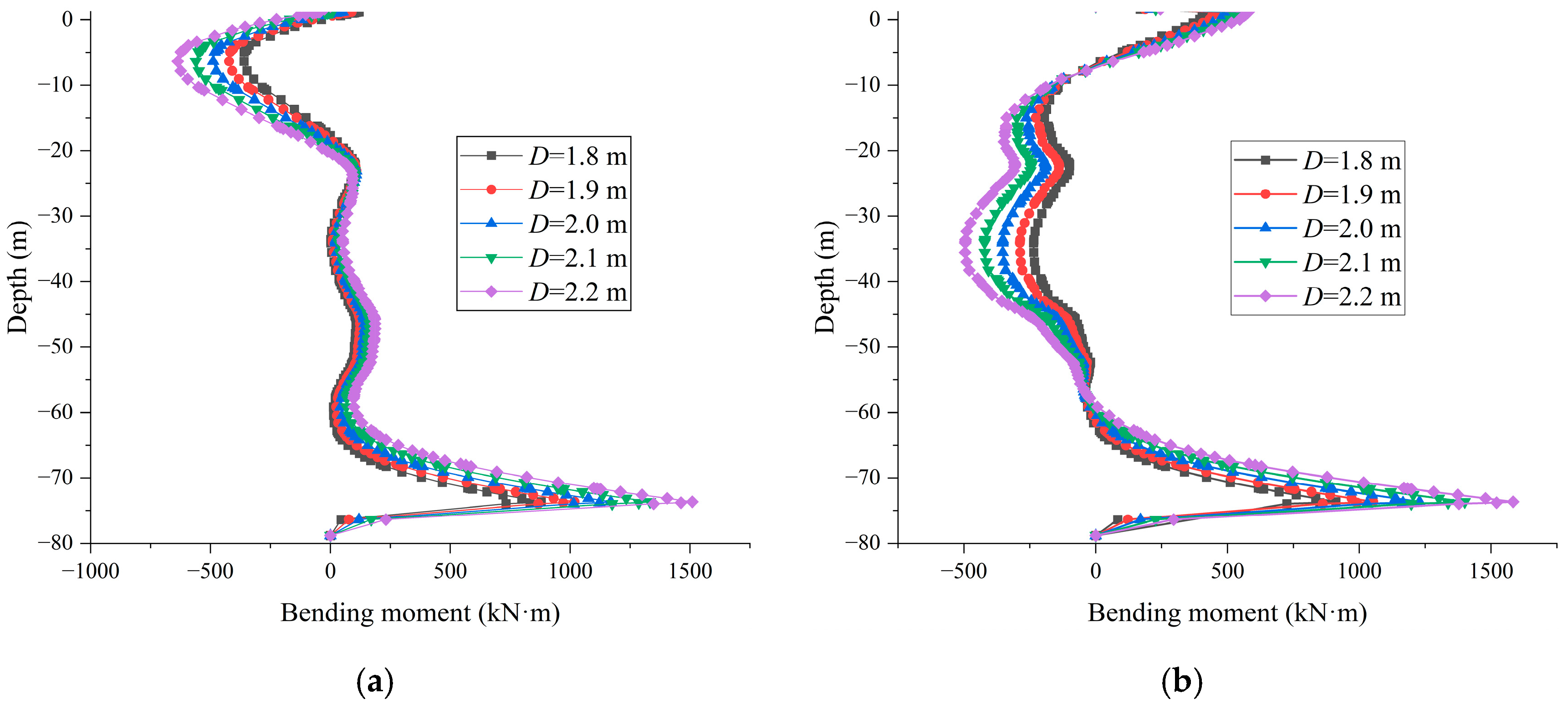

4.4.2. Stiffness of the Pile

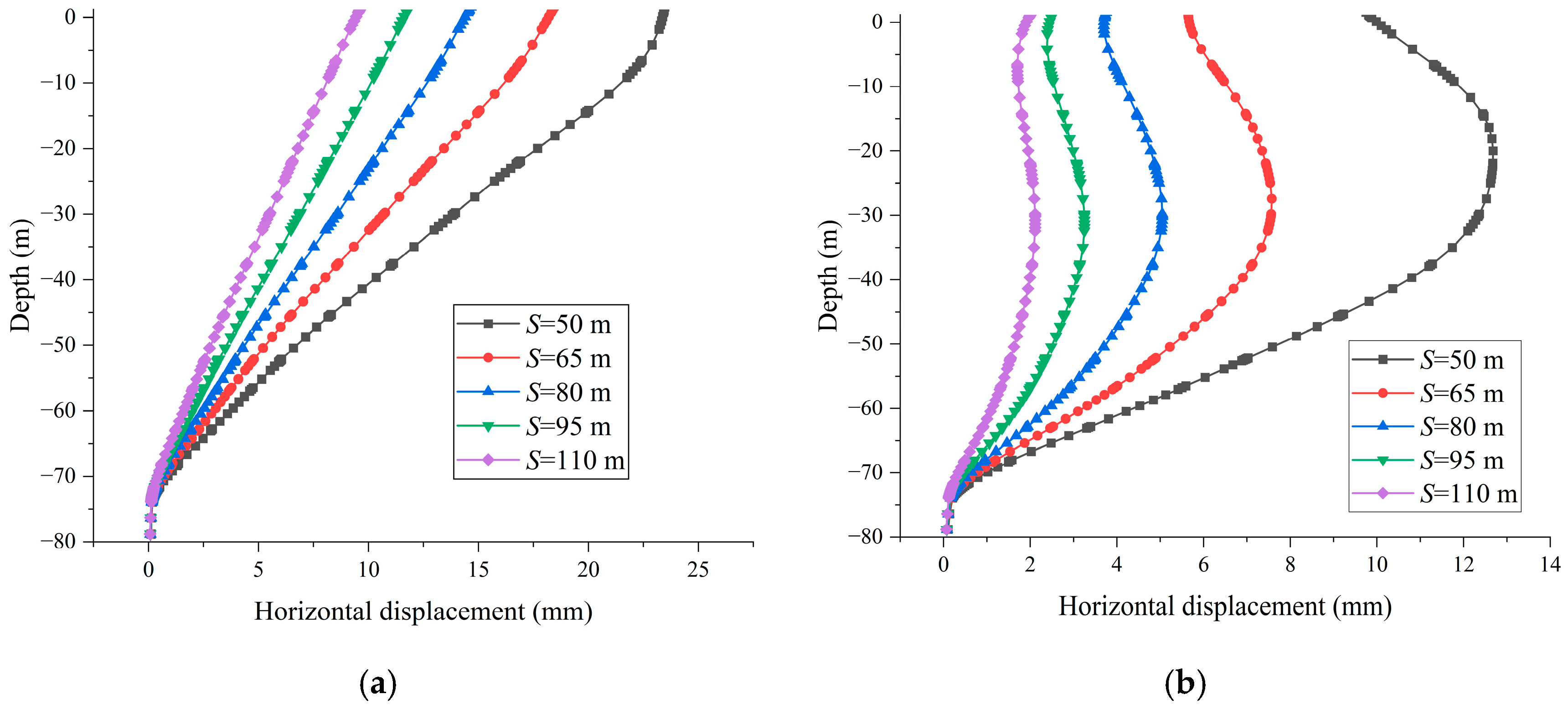

4.4.3. Seawall–Pile Separation Distance

5. Application of DCM Piles for Seawall Support

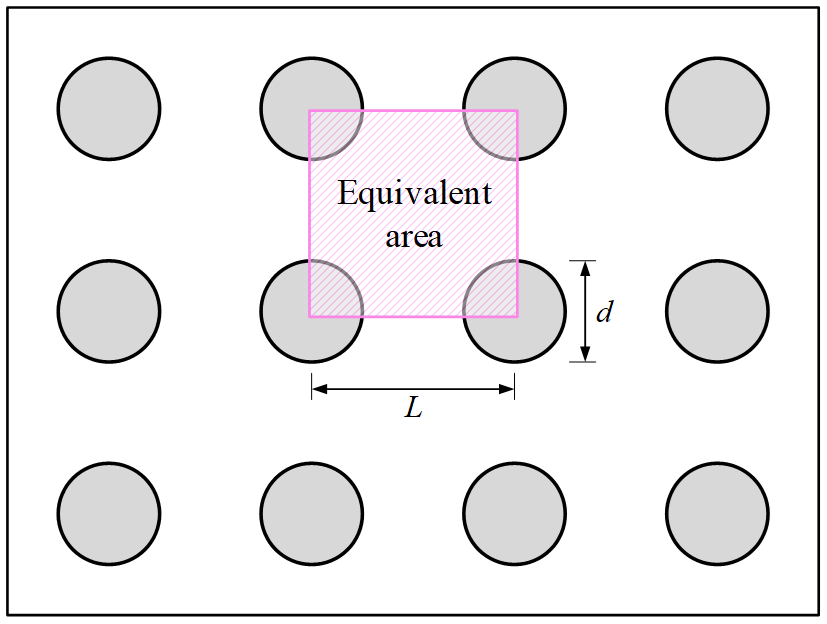

5.1. Parameters and Modeling of DCM Piles

5.2. Parametric Studies

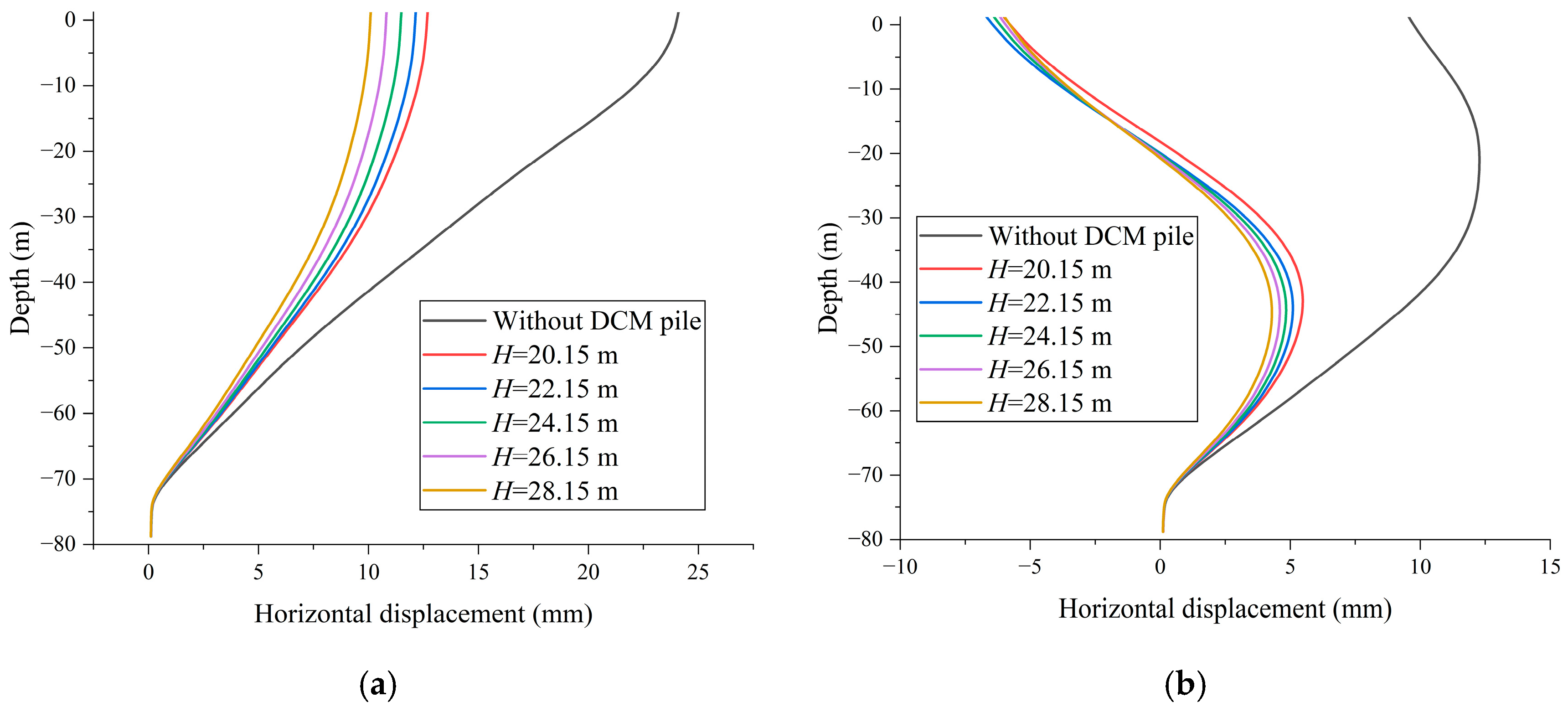

5.2.1. DCM Pile Length (H)

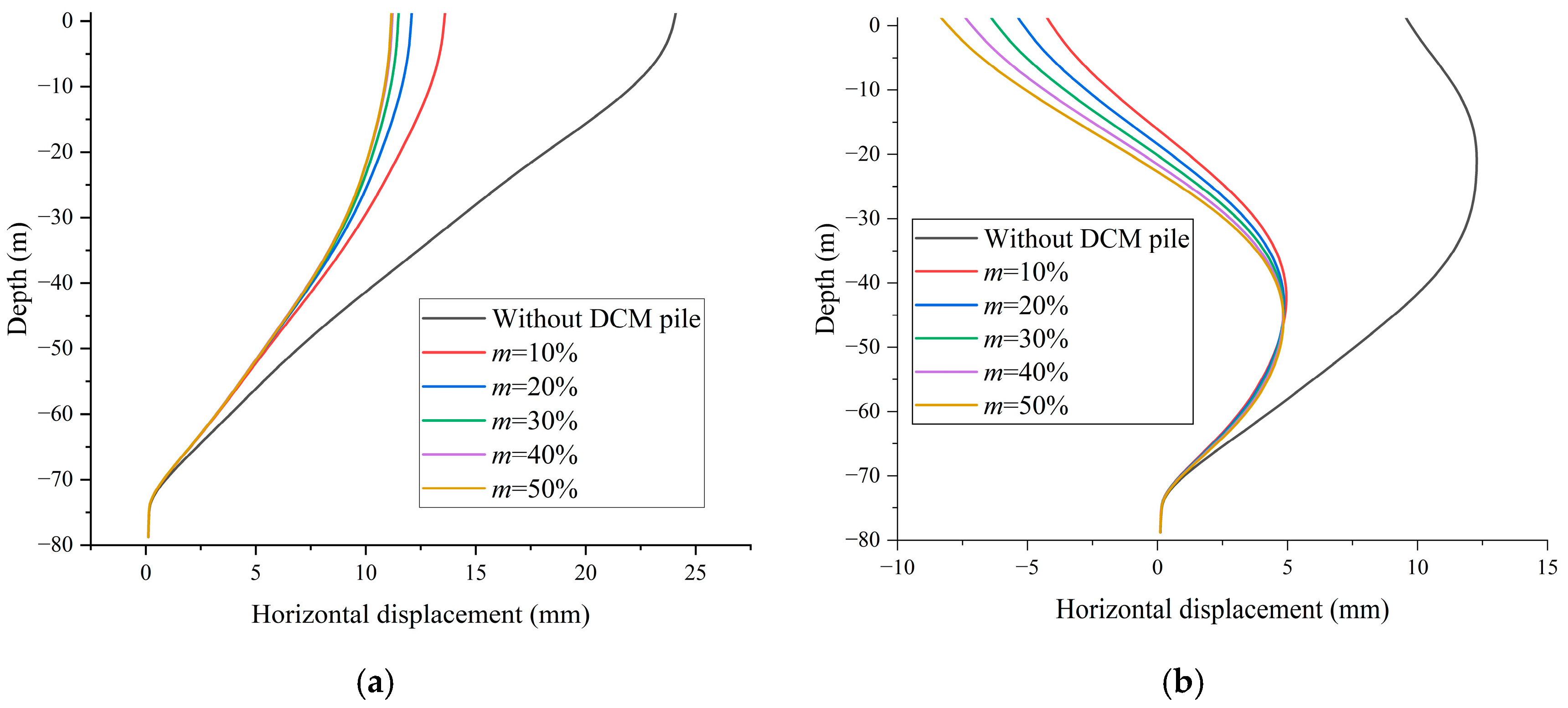

5.2.2. Area Replacement Ratio (m)

5.2.3. Elastic Modulus of DCM Pile (EDCM)

6. Conclusions

- (1)

- After seawall completion (25 days), the short-term maximum horizontal displacement of adjacent piles (25 mm) was observed at the pile head. Concurrently, the maximum negative bending moment (380 kN·m) occurred within shallow soft soil layers, while the peak positive bending moment (900 kN·m) developed at the rock–soil interface.

- (2)

- Following 20 years of soft soil consolidation, the long-term maximum horizontal displacement of adjacent piles diminished to 12 mm, with the displacement peak shifting to the mid-pile region. During this prolonged consolidation phase, the critical negative bending moment migrated to mid-depth silty clay layers, reducing to 190 kN·m. Notably, the rock–soil interface maintained a consistent positive bending moment of approximately 900 kN·m throughout the monitoring period.

- (3)

- Parametric analysis revealed the limited sensitivity of pile lateral deformation to variations in soft soil permeability coefficients. However, increasing the pile’s stiffness and expanding the seawall–pile clearance distance demonstrated significant efficacy in mitigating both short-term (25-day) and long-term (20-year) horizontal displacements. Notably, displacement reduction through increased spacing exhibited superior performance, achieving over 72% attenuation in maximum lateral displacement.

- (4)

- Using DCM piles to support the seawall effectively reduces its impact on the horizontal deformations of adjacent piles. Parametric analysis of DCM piles shows that longer DCM pile lengths yield better mitigation effects on short- and long-term deformations of adjacent horizontal piles. Threshold values exist for the area replacement ratio (30%) and elastic modulus (40.5 MPa) in reducing the horizontal displacements of adjacent piles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Deng, H.; Dai, G.; Zhu, M.; Gong, W.; Azadi, M.R. Study on the influence of unsymmetrical surcharge on adjacent pile foundations in a coastal soft soil area. Soil Dyn. Earthq. Eng. 2025, 194, 109365. [Google Scholar] [CrossRef]

- Berrill, J.; Christensen, S.; Keenan, R.; Okada, W.; Pettinga, J. Case study of lateral spreading forces on a piled foundation. Geotechnique 2001, 51, 501–517. [Google Scholar] [CrossRef]

- Jones, C.A.; Stewart, D.I.; Danilewicz, C.J. Bridge distress caused by approach embankment settlement. Proc. Inst. Civ. Eng.-Geotech. Eng. 2008, 161, 63–74. [Google Scholar] [CrossRef]

- De Beer, E. The effects of horizontal loads on piles, due to surcharge or seismic effects. In Proceedings of the 9th ICSMFE, Tokyo, Japan, 10–15 July 1977; pp. 547–558. [Google Scholar]

- Asgari, A.; Ahmadtabar Sorkhi, S.F. Wind turbine performance under multi-hazard loads: Wave, wind, and earthquake effects on liquefiable soil. Results Eng. 2025, 26, 104647. [Google Scholar] [CrossRef]

- Li, S.; Wei, L.; Niu, J.; Deng, Z.; Wu, B.; Qian, W.; He, F. Time-dependent deviation of bridge pile foundations caused by adjacent large-area surcharge loads in soft soils and its preventive measures. Front. Struct. Civ. Eng. 2024, 18, 184–201. [Google Scholar] [CrossRef]

- Li, H.-q.; Wei, L.-m.; Feng, S.-y.; Chen, Z. Behavior of Piles Subjected to Surcharge Loading in Deep Soft Soils: Field Tests. Geotech. Geol. Eng. 2019, 37, 4019–4029. [Google Scholar] [CrossRef]

- Yang, M.; Shangguan, S.; Li, W.; Zhu, B. Numerical Study of Consolidation Effect on the Response of Passive Piles Adjacent to Surcharge Load. Int. J. Geomech. 2017, 17, 04017093. [Google Scholar] [CrossRef]

- Ye, X.; Wu, J.; Li, G. Time-dependent field performance of PHC pile-cap-beam-supported embankment over soft marine clay. Transp. Geotech. 2021, 26, 100435. [Google Scholar] [CrossRef]

- Leoni, M.; Karstunen, M.; Vermeer, P. Anisotropic creep model for soft soils. Géotechnique 2008, 58, 215–226. [Google Scholar] [CrossRef]

- Pan, J.L.; Goh, A.T.; Wong, K.S.; Teh, C.I. Model tests on single piles in soft clay. Can. Geotech. J. 2000, 37, 890–897. [Google Scholar] [CrossRef]

- Bian, X.; Liang, Y.; Zhao, C.; Dong, L.; Cai, D. Centrifuge testing and numerical modeling of single pile and long-pile groups adjacent to surcharge loads in silt soil. Transp. Geotech. 2020, 25, 100399. [Google Scholar] [CrossRef]

- Wang, L.Z.; Chen, K.X.; Hong, Y.; Ng, C.W.W. Effect of consolidation on responses of a single pile subjected to lateral soil movement. Can. Geotech. J. 2015, 52, 769–782. [Google Scholar] [CrossRef]

- Ellis, E.; Springman, S. Modelling of soil–structure interaction for a piled bridge abutment in plane strain FEM analyses. Comput. Geotech. 2001, 28, 79–98. [Google Scholar] [CrossRef]

- Kelesoglu, M.K.; Springman, S.M. Analytical and 3D numerical modelling of full-height bridge abutments constructed on pile foundations through soft soils. Comput. Geotech. 2011, 38, 934–948. [Google Scholar] [CrossRef]

- Koronides, M.; Michailides, C.; Stylianidis, P.; Onoufriou, T. Numerical Study of the Nonlinear Soil–Pile–Structure Interaction Effects on the Lateral Response of Marine Jetties. J. Mar. Sci. Eng. 2024, 12, 2075. [Google Scholar] [CrossRef]

- Asgari, A.; Ranjbar, F.; Bagheri, M. Seismic resilience of pile groups to lateral spreading in liquefiable soils: 3D parallel finite element modeling. Structures 2025, 74, 108578. [Google Scholar] [CrossRef]

- Wei, G.; Qi, Y.; Chen, C.; Zhang, S.; Qian, C.; Zhou, J. Analysis of the protective effect of setting isolation piles outside the foundation pit on the underpass tunnel side. Transp. Geotech. 2022, 35, 100791. [Google Scholar] [CrossRef]

- Wu, P.-C.; Feng, W.-Q.; Yin, J.-H. Numerical study of creep effects on settlements and load transfer mechanisms of soft soil improved by deep cement mixed soil columns under embankment load. Geotext. Geomembr. 2020, 48, 331–348. [Google Scholar] [CrossRef]

- Lin, K.Q.; Wong, I.H. Use of Deep Cement Mixing to Reduce Settlements at Bridge Approaches. J. Geotech. Geoenviron. Eng. 1999, 125, 309–320. [Google Scholar] [CrossRef]

- Yin, J.-H.; Fang, Z. Physical Modeling of a Footing on Soft Soil Ground with Deep Cement Mixed Soil Columns under Vertical Loading. Mar. Georesour. Geotechnol. 2010, 28, 173–188. [Google Scholar] [CrossRef]

- Shen, H.; Li, X.; Duan, R.; Zhao, Y.; Zhao, J.; Che, H.; Liu, G.; Xue, Z.; Yan, C.; Liu, J.; et al. Quality evaluation of ground improvement by deep cement mixing piles via ground-penetrating radar. Nat. Commun. 2023, 14, 3448. [Google Scholar] [CrossRef] [PubMed]

- Le Hello, B.; Villard, P. Embankments reinforced by piles and geosynthetics—Numerical and experimental studies dealing with the transfer of load on the soil embankment. Eng. Geol. 2009, 106, 78–91. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Du, Y.-J.; Yi, Y.-L.; Puppala, A.J. Field investigations on performance of T-shaped deep mixed soil cement column–supported embankments over soft ground. J. Geotech. Geoenviron. Eng. 2012, 138, 718–727. [Google Scholar] [CrossRef]

- Nunez, M.; Briançon, L.; Dias, D. Analyses of a pile-supported embankment over soft clay: Full-scale experiment, analytical and numerical approaches. Eng. Geol. 2013, 153, 53–67. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, C.; Liu, Y.; Zhang, D.; Sun, Y.; Zhou, P. Load Transfer and Performance Evaluation of the Composite Foundation Reinforced by Penetrated PCCSs and Partially Penetrated DCM Columns under Embankment Loads. Int. J. Geomech. 2025, 25, 05024014. [Google Scholar] [CrossRef]

- Wu, P.-C.; Yin, J.-H.; Feng, W.-Q.; Chen, W.-B. Experimental study on geosynthetic-reinforced sand fill over marine clay with or without deep cement mixed soil columns under different loadings. Undergr. Space 2019, 4, 340–347. [Google Scholar] [CrossRef]

- Phutthananon, C.; Jongpradist, P.; Jongpradist, P.; Dias, D.; Jamsawang, P.; Bergado, D.T. Performance-based design optimization of embankments resting on soft soil improved with T-shaped and conventional DCM columns. Acta Geotech. 2021, 16, 3301–3326. [Google Scholar] [CrossRef]

- Yapage, N.; Liyanapathirana, D. A parametric study of geosynthetic-reinforced column-supported embankments. Geosynth. Int. 2014, 21, 213–232. [Google Scholar] [CrossRef]

- Li, W.; Zhang, J.; Chen, H.; Ni, J.; Zhang, D. Quantitative Study on the Impact of Surcharge on Nearby Foundations. Buildings 2024, 14, 1596. [Google Scholar] [CrossRef]

- Ghiasi, V.; Eskandari, S. Comparing a single pile’s axial bearing capacity using numerical modeling and analytical techniques. Results Eng. 2023, 17, 100893. [Google Scholar] [CrossRef]

- Jala, Y.; Sawant, V.A.; Mishra, A. Development of p-y curves from numerical study of long piles in sandy slope. Ocean Eng. 2025, 319, 120275. [Google Scholar] [CrossRef]

- Jamsawang, P.; Yoobanpot, N.; Thanasisathit, N.; Voottipruex, P.; Jongpradist, P. Three-dimensional numerical analysis of a DCM column-supported highway embankment. Comput. Geotech. 2016, 72, 42–56. [Google Scholar] [CrossRef]

- Brinkgreve, R.; Kumarswamy, S.; Swolfs, W.; Waterman, D.; Chesaru, A.; Bonnier, P. PLAXIS 2016; PLAXIS Bv: Delft, The Netherlands, 2016; pp. 1–16. [Google Scholar]

- Ren, Y.; Chen, Z.; Zhu, W. A Numerical Study of the Lateral Load-Sharing Mechanism of the Pile Cap in a 3 × 3 Pile Group. Buildings 2025, 15, 1431. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.; Souri, A.; Voyiadjis, G.; Rosti, F. Comparison of static lateral behavior of three pile group configurations using three-dimensional finite element modeling. Can. Geotech. J. 2018, 55, 107–118. [Google Scholar] [CrossRef]

- Yoo, C. Interaction between tunneling and bridge foundation—A 3D numerical investigation. Comput. Geotech. 2013, 49, 70–78. [Google Scholar] [CrossRef]

- Tschuchnigg, F.; Schweiger, H. The embedded pile concept–Verification of an efficient tool for modelling complex deep foundations. Comput. Geotech. 2015, 63, 244–254. [Google Scholar] [CrossRef]

- Shen, B.; Mao, D.; Ding, Y.; Wang, L.; Li, Z. A numerical analysis of inclination and rectification of ramp-bridge piers adjacent to surcharge load in soft clay area. Sci. Rep. 2023, 13, 9614. [Google Scholar] [CrossRef]

- Jamsawang, P.; Bergado, D.T.; Voottipruex, P. Chapter 2—Full-Scale Tests on Stiffened Deep Cement Mixing Piles Including Three-Dimensional Finite Element Simulation. In Ground Improvement Case Histories; Indraratna, B., Chu, J., Rujikiatkamjorn, C., Eds.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 31–77. [Google Scholar]

- Tyagi, A.; Zulkefli, M.F.B.; Pan, Y.; Goh, S.-H.; Lee, F.-H. Failure Modes of Tunnels with Improved Soil Surrounds. J. Geotech. Geoenviron. Eng. 2017, 143, 04017088. [Google Scholar] [CrossRef]

- Rashid, A.S.; Faizi, K.; Armaghani, D.J.; Nazir, R. Deformation Model of Deep Soil Mixing Using Finite Element Method. J. Teknol. (Sci. Eng.) 2015, 74, 165–170. [Google Scholar] [CrossRef][Green Version]

- Wijerathna, M.; Liyanapathirana, D.S. Numerical Simulation of DCM Column-Supported Embankments Using Simplified Plane-Strain Models; Springer: Singapore, 2018; pp. 434–441. [Google Scholar]

- Yapage, N.N.S.; Liyanapathirana, D.S.; Kelly, R.B.; Poulos, H.G.; Leo, C.J. Numerical Modeling of an Embankment over Soft Ground Improved with Deep Cement Mixed Columns: Case History. J. Geotech. Geoenviron. Eng. 2014, 140, 04014062. [Google Scholar] [CrossRef]

- Rogbeck, Y. Reinforced piled embankments in Sweden-design aspects. In Proceedings of the 6th International Conference on Geosynthetics, Atlanta, GA, USA, 25–29 March 1998. [Google Scholar]

- Yin, J.-H. Stress-strain-strength characteristics of soft Hong Kong marine deposits without or with cement treatment. Lowl. Technol. Int. 2001, 3, 1–13. [Google Scholar]

| Soil | (kN/m3) | Es (kPa) | Cohesion c (kPa) | Friction Angle φ (°) | Permeability Coefficient k (m/d) |

|---|---|---|---|---|---|

| Mucky clay | 17.9 | 2720 | 12.3 | 9.0 | 0.423 × 10−3 |

| Mucky silty clay | 18.3 | 2660 | 13.7 | 10.3 | 0.588 × 10−3 |

| Silty clay-1 | 19.0 | 4720 | 34.3 | 11.5 | 8.640 × 10−3 |

| Silty clay-2 | 19.7 | 6050 | 55.6 | 15.8 | 8.640 × 10−3 |

| Silty clay-3 | 20.1 | 7120 | 51.4 | 15.8 | 8.640 × 10−3 |

| Ignimbrite | 22.2 | – | 300.0 | 40.0 | – |

| Soil | Mucky Clay | Mucky Silty Clay | Silty Clay | Silty Clay | Silty Clay | Ignimbrite |

|---|---|---|---|---|---|---|

| Constitutive Model | HS | HS | HS | HS | HS | Mohr–Coulomb |

| (kN/m3) | 17.9 | 18.3 | 19.0 | 19.7 | 20.1 | 22 |

| E (kPa) | – | – | – | – | – | 1 × 106 |

| ν | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 |

| (kPa) | 2720 | 2660 | 4720 | 6050 | 7120 | – |

| (kPa) | 2720 | 2660 | 4720 | 6050 | 7120 | – |

| (kPa) | 13,600 | 13,300 | 23,600 | 30,250 | 35,600 | – |

| m | 0.80 | 0.80 | 0.75 | 0.75 | 0.75 | – |

| (kPa) | 100 | 100 | 100 | 100 | 100 | – |

| c (kPa) | 12.3 | 13.7 | 34.3 | 55.6 | 51.4 | 300 |

| φ (°) | 9.0 | 10.3 | 11.5 | 15.8 | 15.8 | 40 |

| Structures | (kN/m3) | E (MPa) | ν | c (kPa) | φ (°) |

|---|---|---|---|---|---|

| Pile | 25 | 31.5 × 103 | 0.15 | - | - |

| Pile cap, column, and crossbeam | 33.5 × 103 | ||||

| Seawall | 20 | 20 | 0.25 | 30 | 20 |

(kN/m3) | Ee (MPa) | ν | ce (kPa) | φe (°) | k (m/d) | |

|---|---|---|---|---|---|---|

| DCM pile in mucky silty clay | 20 | 14.05 | 0.15 | 35.69 | 39.0 | 0.588 × 10−3 |

| DCM pile in silty clay | 20 | 15.45 | 0.15 | 50.11 | 39.2 | 8.640 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, F.; Chen, Z.; Deng, H.; Zhu, W. Lateral Deformation Mechanisms of Piles in Coastal Regions Under Seawall Surcharge Loading and Mitigation Using Deep Cement Mixing (DCM) Piles. Buildings 2025, 15, 1936. https://doi.org/10.3390/buildings15111936

Huang F, Chen Z, Deng H, Zhu W. Lateral Deformation Mechanisms of Piles in Coastal Regions Under Seawall Surcharge Loading and Mitigation Using Deep Cement Mixing (DCM) Piles. Buildings. 2025; 15(11):1936. https://doi.org/10.3390/buildings15111936

Chicago/Turabian StyleHuang, Fei, Zhiwei Chen, Huiyuan Deng, and Wenbo Zhu. 2025. "Lateral Deformation Mechanisms of Piles in Coastal Regions Under Seawall Surcharge Loading and Mitigation Using Deep Cement Mixing (DCM) Piles" Buildings 15, no. 11: 1936. https://doi.org/10.3390/buildings15111936

APA StyleHuang, F., Chen, Z., Deng, H., & Zhu, W. (2025). Lateral Deformation Mechanisms of Piles in Coastal Regions Under Seawall Surcharge Loading and Mitigation Using Deep Cement Mixing (DCM) Piles. Buildings, 15(11), 1936. https://doi.org/10.3390/buildings15111936