Bibliometric Analysis of the Intersection of Circular Economy, Prefabrication, and Modularity in the Building Industry

Abstract

1. Introduction

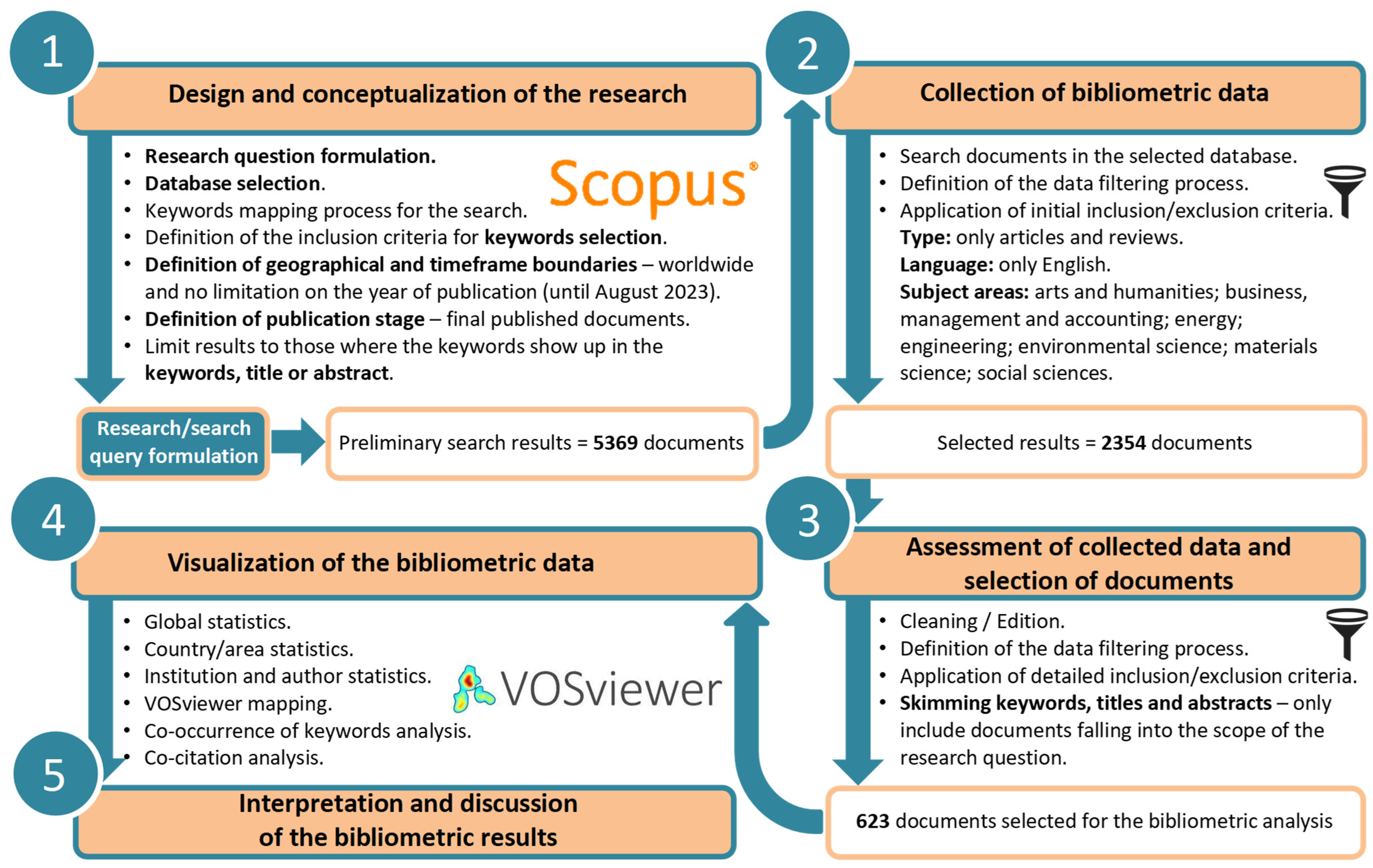

2. Framework: Bibliometric Analysis and Systematic Review

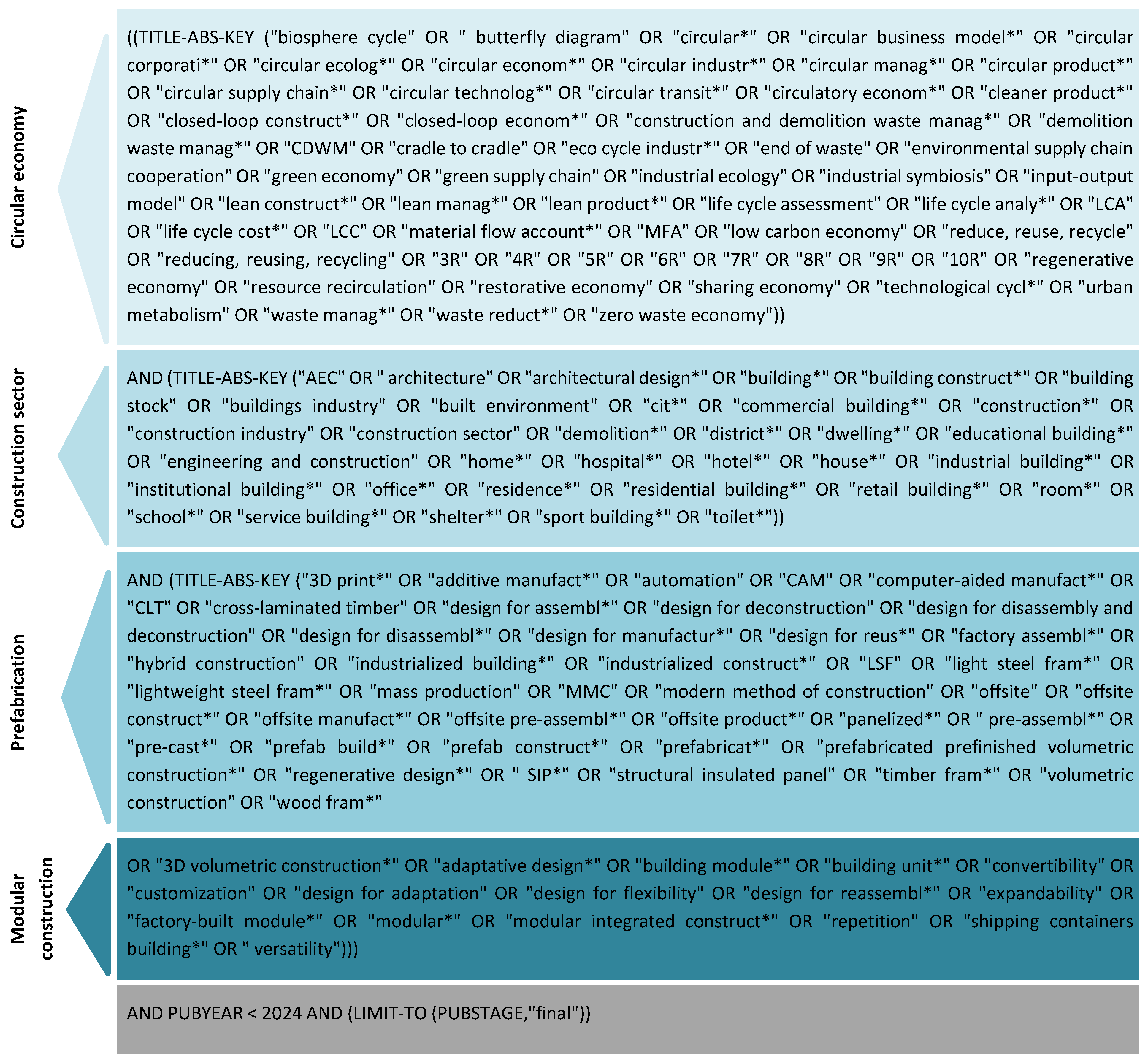

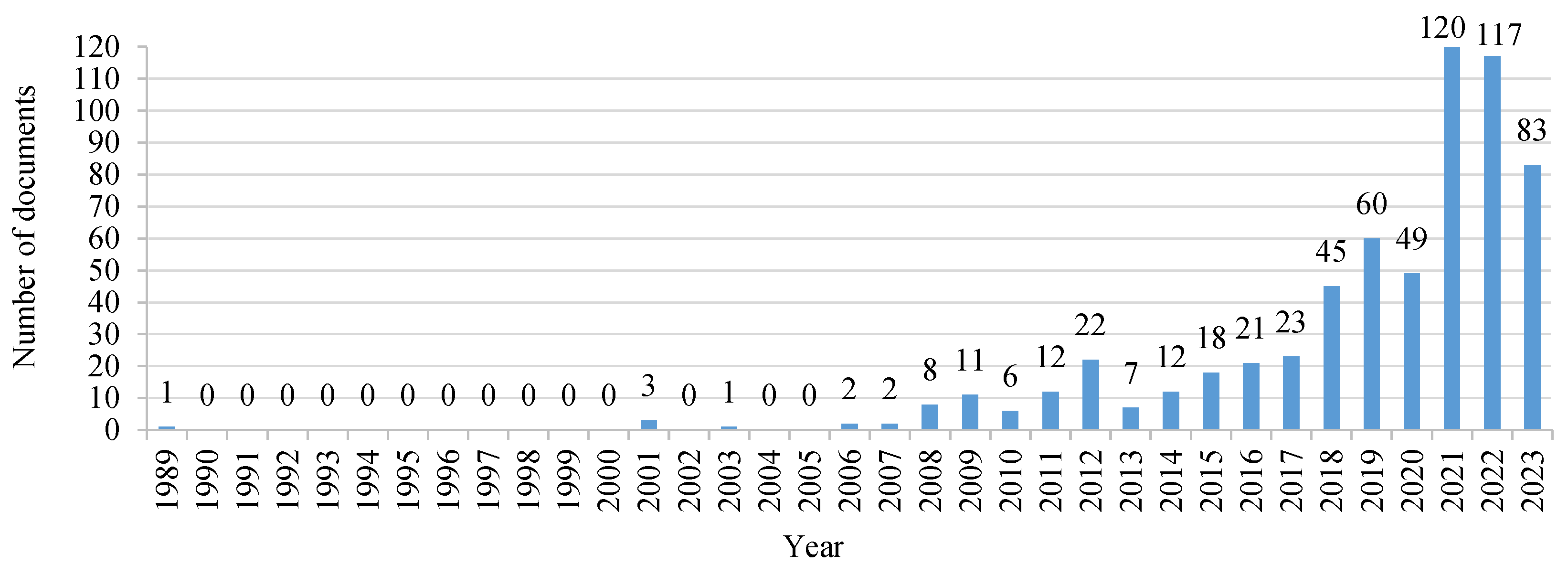

3. Methodology

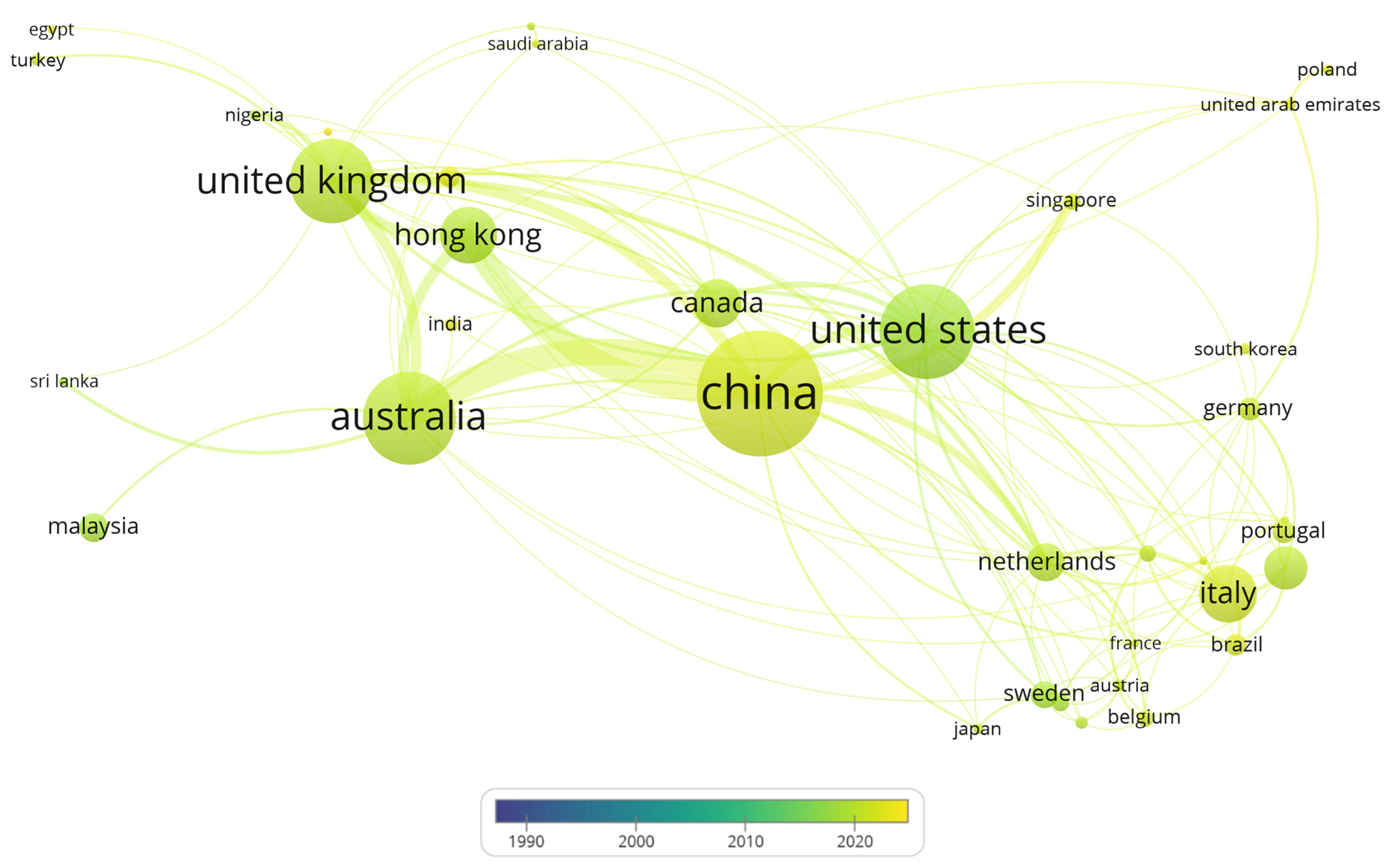

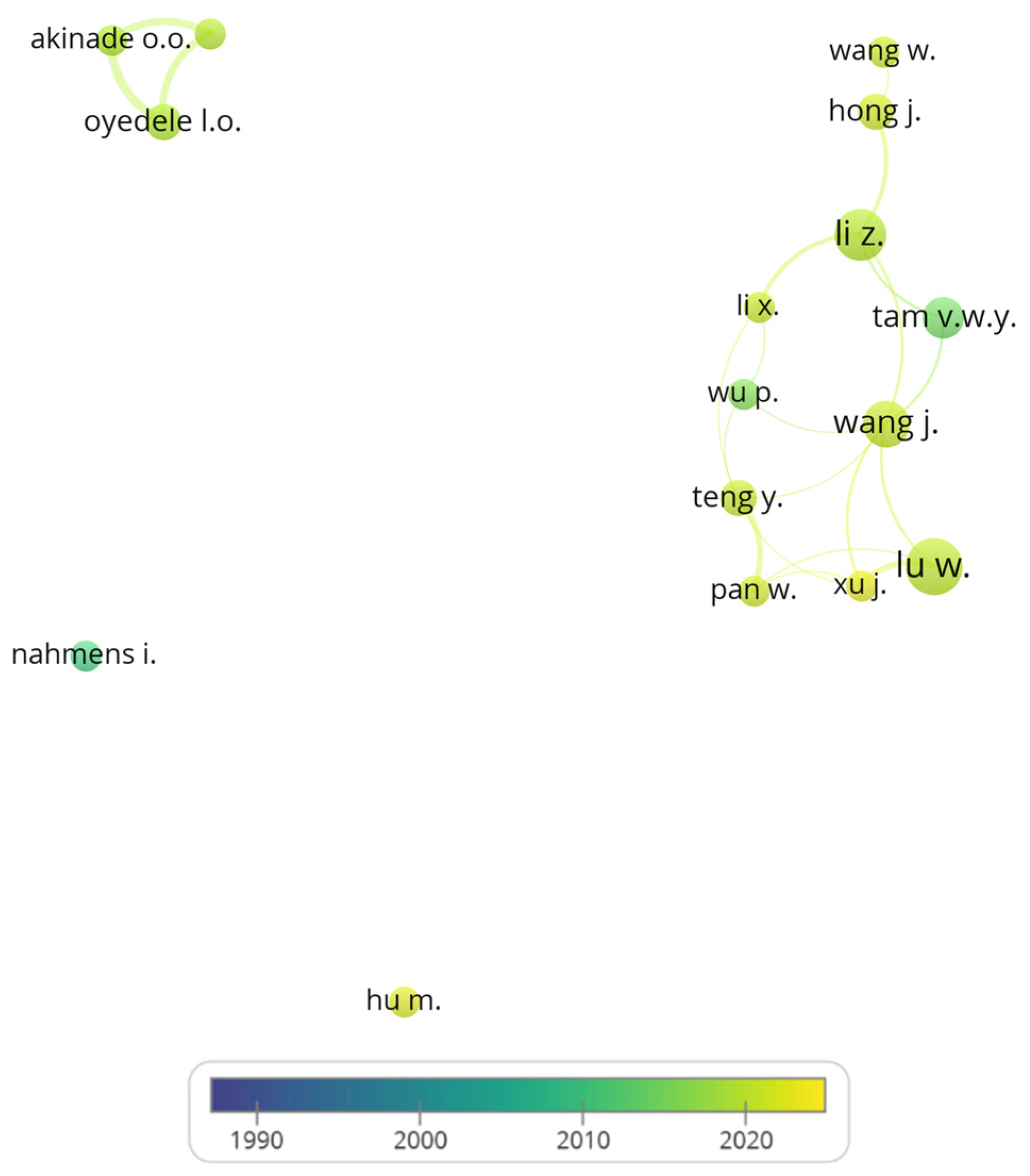

4. General Mapping of the Bibliometric Results

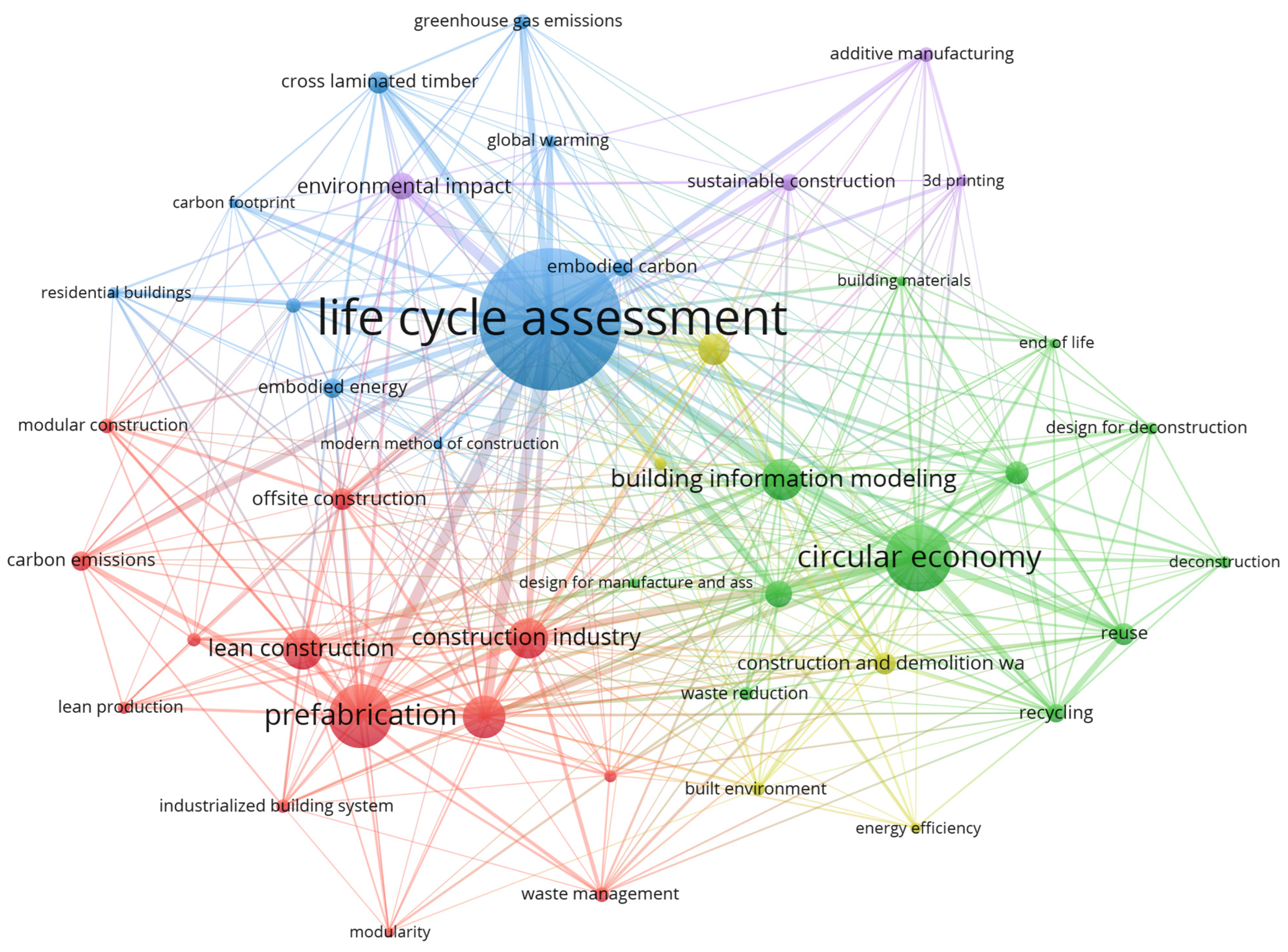

- The red cluster (cluster #1) focuses on prefabrication and modularity, including terms such as “Prefabrication”, “Offsite construction”, “Modularity”, “Modular construction”, “Industrialized building system”, “Lean construction”, and “Lean production”.

- The green cluster (cluster #2) centers on strategies for CE in the construction sector, with terms like “Circular economy”, “Building information modeling”, “Design for disassembly”, “Design for deconstruction”, “Reuse”, and “Recycling”.

- The blue cluster (cluster #3) is concerned with energy and environmental LCA, including terms such as “Life cycle assessment”, “Carbon footprint”, “Embodied carbon”, “Embodied energy”, “Global warming”, “Climate change”, and “Greenhouse gas emissions”.

- The yellow cluster (cluster #4) is primarily associated with “Life cycle costing”.

- Lastly, the purple cluster (cluster #5) includes terms related to “3D printing” and “Additive manufacturing”.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AEC | architecture, engineering and construction |

| AI | artificial intelligence |

| BIM | building information modelling |

| CAM | computer-aided manufacture |

| CDW | construction and demolition waste |

| CDWM | construction and demolition waste management |

| CE | circular economy |

| CLT | cross-laminated timber |

| DfA | design for assembly |

| DfAd | design for adaptability |

| DfD | design for deconstruction |

| DfDy | design for disassembly |

| DT | digital twin |

| EoL | end-of-life |

| GIS | geographic information system |

| ICT | information and communication technology |

| IoT | internet of things |

| LCA | environmental life cycle assessment |

| LCC | life cycle costing |

| LSF | lightweight steel framing |

| MFA | material flow analysis |

| MMC | modern method of construction |

| PfD | planning for deconstruction |

| S-LCA | social life cycle assessment |

| SIP | structural insulated panels |

References

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Sher, W.; Egbelakin, T. Circular economy pillars: A semi-systematic review. Clean Technol. Environ. Policy 2021, 23, 899–914. [Google Scholar] [CrossRef]

- Tokazhanov, G.; Galiyev, O.; Lukyanenko, A.; Nauyryzbay, A.; Ismagulov, R.; Durdyev, S.; Turkyilmaz, A.; Karaca, F. Circularity assessment tool development for construction projects in emerging economies. J. Clean. Prod. 2022, 362, 132293. [Google Scholar] [CrossRef]

- Luthin, A.; Traverso, M.; Crawford, R.H. Assessing the social life cycle impacts of circular economy. J. Clean. Prod. 2023, 386, 135725. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Uncertainty, variability, price changes and their implications on a regional building materials industry: The case of Swiss canton Argovia. J. Clean. Prod. 2022, 330, 129944. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Çimen, Ö. Construction and built environment in circular economy: A comprehensive literature review. J. Clean. Prod. 2021, 305, 127180. [Google Scholar] [CrossRef]

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A review of the circularity gap in the construction industry through scientometric analysis. J. Clean. Prod. 2021, 298, 126870. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W.; Hall, D. The transition to the circular economy of the construction industry: Insights into sustainable approaches to improve the understanding. J. Clean. Prod. 2022, 364, 132421. [Google Scholar] [CrossRef]

- Charef, R.; Lu, W. Factor dynamics to facilitate circular economy adoption in construction. J. Clean. Prod. 2021, 319, 128639. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Wijewickrama, M.K.C.S.; Rameezdeen, R.; Chileshe, N. Information brokerage for circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2021, 313, 127938. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Yu, Y.; Yazan, D.M.; Junjan, V.; Iacob, M.E. Circular economy in the construction industry: A review of decision support tools based on Information & Communication Technologies. J. Clean. Prod. 2022, 349, 131335. [Google Scholar] [CrossRef]

- Oorschot, L.; Asselbergs, T. New housing concepts: Modular, circular, biobased, reproducible, and affordable. Sustainability 2021, 13, 13772. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The Circular Economy in Detail. Available online: https://www.ellenmacarthurfoundation.org/the-circular-economy-in-detail-deep-dive (accessed on 21 November 2023).

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P.; Tsavdaridis, K.D.; Poologanathan, K. Digitally enabled modular construction for promoting modular components reuse: A UK view. J. Build. Eng. 2021, 42, 102820. [Google Scholar] [CrossRef]

- Chippagiri, R.; Bras, A.; Sharma, D.; Ralegaonkar, R.V. Technological and sustainable perception on the advancements of prefabrication in construction industry. Energies 2022, 15, 7548. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, T.; Zhou, X.; Li, Z.; Jia, Y.; Ren, K.; Xu, T.; Li, C.; Hong, J. Life cycle environmental and cost assessment of prefabricated components manufacture. J. Clean. Prod. 2023, 415, 137888. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Stergioulas, L.K. Distributed manufacturing: A new digital framework for sustainable modular construction. Sustainability 2021, 13, 1515. [Google Scholar] [CrossRef]

- Chauhan, K.; Peltokorpi, A.; Lavikka, R.; Seppänen, O. The monetary and non-monetary impacts of prefabrication on construction: The effects of product modularity. Buildings 2022, 12, 459. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Developing critical success factors for integrating circular economy into modular construction projects in Hong Kong. Sustain. Prod. Consum. 2022, 29, 574–587. [Google Scholar] [CrossRef]

- Pasco, J.; Lei, Z.; Aranas, C. Additive manufacturing in off-site construction: Review and future directions. Buildings 2022, 12, 53. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building envelope prefabricated with 3D printing technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. Effects of Lean construction on sustainability of modular homebuilding. J. Archit. Eng. 2012, 18, 155–163. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. An empirical examination of the relationship between lean construction and safety in the industrialized housing industry. Lean Constr. J. 2009, 1–12. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Saari, R. A selective disassembly multi-objective optimization approach for adaptive reuse of building components. Resour. Conserv. Recycl. 2020, 154, 104605. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Driesser, M.; Kretschmann, T.; Walker, P.; Emmitt, S. A circular construction evaluation framework to promote designing for disassembly and adaptability. J. Clean. Prod. 2021, 316, 128122. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Wasim, M.; Vaz Serra, P.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction—A review. Int. J. Constr. Manag. 2022, 22, 3014–3022. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Hartmann, T. A framework for BIM-based disassembly models to support reuse of building components. Resour. Conserv. Recycl. 2021, 175, 105825. [Google Scholar] [CrossRef]

- Atmaca, N. Life-cycle assessment of post-disaster temporary housing. Build. Res. Inf. 2017, 45, 524–538. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Comparative life cycle energy and cost analysis of post-disaster temporary housings. Appl. Energy 2016, 171, 429–443. [Google Scholar] [CrossRef]

- Arslan, H. Re-design, re-use and recycle of temporary houses. Build. Environ. 2007, 42, 400–406. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Porras-Pereira, P.; Levinton, C. Circular economy and regenerative sustainability in emergency housing: Eco-efficient prototype design for subasi refugee camp in Turkey. Sustainability 2021, 13, 8100. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Wong, R.W.M.; Loo, B.P.Y. Sustainability implications of using precast concrete in construction: An in-depth project-level analysis spanning two decades. J. Clean. Prod. 2022, 378, 134486. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Gibb, A. Pre-Assembly in Construction (CRISP): A Review of Recent and Current Industry and Research Initiatives on Pre-Assembly in Construction. 2001. Available online: https://hdl.handle.net/2134/25702 (accessed on 1 August 2023).

- Lu, W.; Lee, W.M.W.; Xue, F.; Xu, J. Revisiting the effects of prefabrication on construction waste minimization: A quantitative study using bigger data. Resour. Conserv. Recycl. 2021, 170, 105579. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Tavares, V.; Calheiros, C.S.C.; Martins, I.B.; Maia, J.; Tsikaloudaki, K.; Fonseca, M.; Marchesi, M.; Laban, M.; Soares, N.; Santos, P.; et al. Modularity and Prefabrication. In Circular Economy Design and Management in the Built Environment; Springer: Berlin/Heidelberg, Germany, 2025; pp. 215–256. [Google Scholar] [CrossRef]

- Anastasiades, K.; Goffin, J.; Rinke, M.; Buyle, M.; Audenaert, A.; Blom, J. Standardisation: An essential enabler for the circular reuse of construction components? A trajectory for a cleaner European construction industry. J. Clean. Prod. 2021, 298, 126864. [Google Scholar] [CrossRef]

- Aziminezhad, M.; Taherkhani, R. BIM for deconstruction: A review and bibliometric analysis. J. Build. Eng. 2023, 73, 106683. [Google Scholar] [CrossRef]

- Allam, A.S.; Nik-Bakht, M. From demolition to deconstruction of the built environment: A synthesis of the literature. J. Build. Eng. 2023, 64, 105679. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.; Castro-Lacouture, D.; Hu, Y. Lean manufacturing applications in prefabricated construction projects. Autom. Constr. 2023, 150, 104790. [Google Scholar] [CrossRef]

- Barkhausen, R.; Rostek, L.; Miao, Z.C.; Zeller, V. Combinations of material flow analysis and life cycle assessment and their applicability to assess circular economy requirements in EU product regulations. A systematic literature review. J. Clean. Prod. 2023, 407, 137017. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P. Adopting artificial intelligence for enhancing the implementation of systemic circularity in the construction industry: A critical review. Sustain. Prod. Consum. 2023, 35, 509–524. [Google Scholar] [CrossRef]

- Kręt-Grześkowiak, A.; Baborska-Narożny, M. Guidelines for disassembly and adaptation in architectural design compared to circular economy goals—A literature review. Sustain. Prod. Consum. 2023, 39, 1–12. [Google Scholar] [CrossRef]

- Salvador, R.; Barros, M.V.; Pieroni, M.; Lopes Silva, D.A.; Freire, F.; De Francisco, A.C. Overarching Business Models for a Circular Bioeconomy: Systematising archetypes. Sustain. Prod. Consum. 2023, 43, 349–362. [Google Scholar] [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Oti-Sarpong, K.; Wuni, I.Y.; Tetteh, M.O. Systematic review on the integration of building information modelling and prefabrication construction for low-carbon building delivery. Build. Res. Inf. 2023, 51, 279–300. [Google Scholar] [CrossRef]

- Khan, A.A.; Yu, R.; Liu, T.; Gu, N.; Walsh, J. Volumetric modular construction risks: A comprehensive review and digital-technology-coupled circular mitigation strategies. Sustainability 2023, 15, 7019. [Google Scholar] [CrossRef]

- Hamida, M.B.; Jylhä, T.; Remøy, H.; Gruis, V. Circular building adaptability and its determinants—A literature review. Int. J. Build. Pathol. Adapt. 2022, 41, 47–69. [Google Scholar] [CrossRef]

- López-Guerrero, R.E.; Vera, S.; Carpio, M. A quantitative and qualitative evaluation of the sustainability of industrialised building systems: A bibliographic review and analysis of case studies. Renew. Sustain. Energy Rev. 2022, 157, 112034. [Google Scholar] [CrossRef]

- Horn, E.; Proksch, G. Symbiotic and regenerative sustainability frameworks: Moving towards circular city implementation. Front. Built Environ. 2022, 7, 780478. [Google Scholar] [CrossRef]

- Ahn, N.; Dodoo, A.; Riggio, M.; Muszynski, L.; Schimleck, L.; Puettmann, M. Circular economy in mass timber construction: State-of-the-art, gaps and pressing research needs. J. Build. Eng. 2022, 53, 104562. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. The ecodesign methodologies to achieve buildings’ deconstruction: A review and framework. Sustain. Prod. Consum. 2022, 30, 566–583. [Google Scholar] [CrossRef]

- Díaz-López, C.; Bonoli, A.; Martín-Morales, M.; Zamorano, M. Analysis of the scientific evolution of the circular economy applied to construction and demolition waste. Sustainability 2021, 13, 9416. [Google Scholar] [CrossRef]

- Arumugam, G.; Priya, L.K.P.; Kusumo, C.M.L.; Mari, T. A Systematic Review and Analysis of 3D Printed Building Envelopes Inspired By Nature. J. Eng. Sci. Technol. 2021, 58–73. [Google Scholar]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Camana, D.; Manzardo, A.; Toniolo, S.; Gallo, F.; Scipioni, A. Assessing environmental sustainability of local waste management policies in Italy from a circular economy perspective. An overview of existing tools. Sustain. Prod. Consum. 2021, 27, 613–629. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, H.; Wang, Q.; Hua, T.; Xue, H. A review and scientometric analysis of global research on prefabricated buildings. Adv. Civ. Eng. 2021, 2021, 8869315. [Google Scholar] [CrossRef]

- O’Grady, T.; Minunno, R.; Chong, H.Y.; Morrison, G.M. Design for disassembly, deconstruction and resilience: A circular economy index for the built environment. Resour. Conserv. Recycl. 2021, 175, 105847. [Google Scholar] [CrossRef]

- Machado, N.; Morioka, S.N. Contributions of modularity to the circular economy: A systematic review of literature. J. Build. Eng. 2021, 44, 103322. [Google Scholar] [CrossRef]

- Charef, R.; Morel, J.C.; Rakhshan, K. Barriers to implementing the circular economy in the construction industry: A critical review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Zairul, M. The recent trends on prefabricated buildings with circular economy (CE) approach. Clean. Eng. Technol. 2021, 4, 100239. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Jin, R.; Hong, J.; Zuo, J. Environmental performance of off-site constructed facilities: A critical review. Energy Build. 2020, 207, 109567. [Google Scholar] [CrossRef]

- Akbarieh, A.; Jayasinghe, L.B.; Waldmann, D.; Teferle, F.N. BIM-based end-of-lifecycle decision making and digital deconstruction: Literature review. Sustainability 2020, 12, 2670. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Li, X.; Wu, G. A review of global lean construction during the past two decades: Analysis and visualization. Eng. Constr. Archit. Manag. 2019, 26, 1192–1216. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Ji, L.; Liu, C.; Huang, L.; Huang, G. The evolution of resources conservation and recycling over the past 30 years: A bibliometric overview. Resour. Conserv. Recycl. 2018, 134, 34–43. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Sonego, M.; Echeveste, M.E.S.; Galvan Debarba, H. The role of modularity in sustainable design: A systematic review. J. Clean. Prod. 2018, 176, 196–209. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and internet of things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- “Scopus”. Elsevier. Available online: http://www.scopus.com (accessed on 1 August 2023).

- “VOSviewer—Visualizing Scientific Landscapes”. Available online: https://www.vosviewer.com/ (accessed on 1 August 2023).

- Cabeza, L.F.; Chàfer, M.; Mata, É. Comparative analysis of web of science and scopus on the energy efficiency and climate impact of buildings. Energies 2020, 13, 409. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, P.S.; Habert, P.G. Regional environmental-economic assessment of building materials to promote circular economy: Comparison of three Swiss cantons. Resour. Conserv. Recycl. 2022, 181, 106247. [Google Scholar] [CrossRef]

- Böckin, D.; Willskytt, S.; André, H.; Tillman, A.M.; Ljunggren Söderman, M. How product characteristics can guide measures for resource efficiency—A synthesis of assessment studies. Resour. Conserv. Recycl. 2020, 154, 104582. [Google Scholar] [CrossRef]

- Sarja, A. Principles and Solutions of the New System Building Technology (TAT); Valtion teknillinen tutkimuskeskus. Tutkimuksia—Research Reports No. 662; VTT Technical Research Centre of Finland: Espoo, Finland, 1989. [Google Scholar]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An embodied carbon and energy analysis of modern methods of construction in housing: A case study using a lifecycle assessment framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the waste reduction potential of using prefabrication in building construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef] [PubMed]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input-output-based hybrid model. J. Clean. Prod. 2016, 112, 2198–2207. [Google Scholar] [CrossRef]

- Tam, V.W.Y. On the effectiveness in implementing a waste-management-plan method in construction. Waste Manag. 2008, 28, 1072–1080. [Google Scholar] [CrossRef] [PubMed]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, M.; Tam, V.W.Y.; Yi, G.; Tran, C.N.N. A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. J. Clean. Prod. 2018, 176, 676–692. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W.Y. Critical factors in effective construction waste minimization at the design stage: A Shenzhen case study, China. Resour. Conserv. Recycl. 2014, 82, 1–7. [Google Scholar] [CrossRef]

- Shadram, F.; Johansson, T.D.; Lu, W.; Schade, J.; Olofsson, T. An integrated BIM-based framework for minimizing embodied energy during building design. Energy Build. 2016, 128, 592–604. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Bilal, M.; Ajayi, S.O.; Owolabi, H.A.; Alaka, H.A.; Bello, S.A. Waste minimisation through deconstruction: A BIM based Deconstructability Assessment Score (BIM-DAS). Resour. Conserv. Recycl. 2015, 105, 167–176. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the impact of prefabrication on construction waste reduction: An empirical study in China. Resour. Conserv. Recycl. 2014, 91, 27–39. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction matters: Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Design issues of using prefabrication in hong kong building construction. Constr. Manag. Econ. 2010, 28, 1025–1042. [Google Scholar] [CrossRef]

- Dong, Y.H.; Jaillon, L.; Chu, P.; Poon, C.S. Comparing carbon emissions of precast and cast-in-situ construction methods—A case study of high-rise private building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

| Ref. | Authors | Journal | Year | Database | Review Period | Final Number of Documents | Contents and Main Contribution |

|---|---|---|---|---|---|---|---|

| [56] | Aziminezhad and Taherkhani | Journal of Building Engineering | 2023 | Scopus, Web of Science | 2012–August 2022 | 231 | This bibliometric study evaluates the research trends surrounding the integration of BIM and deconstruction. The findings highlight that earlier studies on BIM largely overlooked deconstruction. However, recent research has shown a growing interest in bridging the two fields. Key research gaps and critical areas for future investigation include effective design for deconstruction (DfD), end-of-life (EoL) performance assessment, and strategies for waste minimization. |

| [57] | Allam and Nik-Bakht | Journal of Building Engineering | 2023 | Scopus | 2015–February 2022 | 273 | This bibliometric analysis examines developed frameworks and tools for deconstruction across all life cycle stages, including the design, EoL, and second-life phases. Active research areas identified include architectural DfD, structural DfD, planning for deconstruction (PfD), post-deconstruction waste management, and the evaluation of second-life performance for materials and components. However, the study concludes that more attention is needed in several areas: the construction and operation/maintenance phases, which are crucial for facilitating EoL deconstruction; exploring the relationships between deconstruction planning and second-life performance; quantifying the impacts of various construction phases on deconstructability; and assessing the performance of facilities designed for deconstruction during the construction, operation, and maintenance phases. |

| [58] | Du et al. | Automation in Construction journal | 2023 | Scopus, Web of Science | Until June 2022 | 121 | This bibliometric search, quantitative analysis, and comprehensive literature classification reviews lean management practices and their application in prefabricated construction projects, systematically evaluating their impact on project improvement. The study proposes several strategies and potential research directions across five key dimensions: data-driven intelligent decision-making, construction sustainability, optimization of activity processes, adoption of lean construction principles, and other lean strategies related to prefabrication. |

| [59] | Barkhausen et al. | Journal of Cleaner Production | 2023 | Scopus, Web of Science | Until July 2022 | 44 | A PRISMA-based systematic review of studies integrating material flow analysis (MFA) and LCA, examining various levels of integration between the two methodologies, as well as differences in geographical and temporal scope and application fields, including construction (buildings), manufacturing, and waste management. |

| [60] | Oluleye et al. | Sustainable Production and Consumption | 2023 | Scopus | 2018–June 2022 | 30 | A systematic review assessing the potential of AI to support and enable CE practices in the building construction industry. |

| [61] | Kręt-Grześkowiak and Baborska-Narożny | Sustainable Production and Consumption | 2023 | Scopus, Web of Science | Until August 2022 | 70 | A systematic review aimed at establishing guidelines for DfDy and DfAd to support CE practices in architectural practice. |

| [5] | Luthin et al. | Journal of Cleaner Production | 2023 | Scopus, Web of Science, Google Scholar | Until January 2022 | 40 | A systematic review evaluating the current state-of-the-art in social circularity indicators and social life cycle assessment (S-LCA) methodologies within the context of CE. Training and education, job creation, and health and safety emerge as key CE indicators. Furthermore, future S-LCA studies should incorporate social circularity indicators to better assess CE strategies. |

| [62] | Salvador et al. | Sustainable Production and Consumption | 2023 | Scopus, Web of Science, ScienceDirect | Until September 2021 | 29 | A systematic review discussing business models for a circular bioeconomy, focusing on resource efficiency optimization, biorefinery creation, value recovery from waste, resource exchange, innovation in bio-based and renewable resources, development of feasible service- and result-oriented value offers, and the enhancement of the local economy. This study, limited in geographical scope, considers only environmental aspects. |

| [63] | Yevu et al. | Building Research & Information | 2023 | Scopus | Not provided | 69 | A systematic review assessing the integration of prefabrication and BIM. Six key integration application categories are discussed: visualization and real-time monitoring, energy and environmental assessment, parametric design optimization, automation in modelling, BIM-prefabrication modifications, and information mapping. |

| [64] | Khan et al. | Sustainability | 2023 | Scopus, Web of Science | 2010–January 2023 | 91 | A PRISMA-based systematic review to identify critical risk factors in volumetric modular construction across project stages (including design and planning, offsite manufacturing, transport and logistics, and onsite assembly) and project attributes (including implementation and scheduling, supply chain and financial concerns, safety and ergonomics, and civil and structural aspects). Digital technology-driven circular strategies are proposed to mitigate the identified risks. |

| [19] | Yu et al. | Journal of Cleaner Production | 2022 | Web of Science | 2010–November 2021 | 62 | A review of CE-oriented decision support tools leveraging information and communication technologies (ICTs). Seven ICT solutions aligned with various construction life cycle phases are discussed, including BIM, geographic information systems (GISs), radio frequency identification, big data analytics, IoT, blockchain technology, and modelling and simulation. |

| [65] | Hamida et al. | International Journal of Building Pathology and Adaptation | 2022 | Scopus, Web of Science | Until March 2021 | 104 | A PRISMA-based systematic review assessing how adaptability can foster more circularity-oriented models. The review identifies ten key design and operational factors that enhance building resilience, create value, and reduce waste: configuration flexibility, product dismantlability, asset multi-usability, design regularity, functional convertibility, material reversibility, building maintainability, resource recovery, volume scalability, and asset refitability. |

| [66] | López-Guerrero et al. | Renewable and Sustainable Energy Reviews | 2022 | Scopus, Web of Science, Google Scholar, Engineering Village, Emerald Insight | 2008–February 2021 | 67 | A bibliometric review evaluating the sustainability of industrialized systems compared to traditional building systems. The review concludes that most studies focus primarily on environmental indicators, with limited attention given to economic and social indicators. Additionally, certain indicators, such as water usage, acidification potential, reusability, and the level of prefabrication, have been insufficiently studied. |

| [67] | Horn and Proksch | Frontiers in Built Environment | 2022 | Not provided | Not provided | 84 | A review evaluating sustainability frameworks and strategies to support the implementation of circular city goals for sustainable urban futures. The review explores several key domains, including circular cities, the food–water–energy nexus, CE, bioeconomy, industrial symbiosis, and regenerative design. |

| [68] | Ahn et al. | Journal of Building Engineering | 2022 | Web of Science, Google Scholar | 2010–December 2021 | 90 | A systematic review of CE practices in mass timber construction. |

| [11] | Charef et al. | Journal of Cleaner Production | 2022 | Scopus, Google Scholar, University library | Not provided | Not provided | An overview of key sustainable approaches that support the transition to a circular construction industry. Forty-two approaches within the construction sector were categorized into seven groups, with their differences and similarities evaluated using a text mining method. The authors also provided a force-directed graph illustrating the diversity of approaches and their interrelationships, along with a taxonomy of asset life cycle strategies in the context of CE. |

| [69] | Munaro et al. | Sustainable Production and Consumption | 2022 | Scopus, Web of Science | 1995–2019 | 288 | A bibliometric review assessing how the construction sector applies ecodesign methods to facilitate building deconstruction. Design for adaptability (DfAd) and design for disassembly (DfDy) were identified as the two most inclusive and sustainable ecodesign methods for deconstruction. The review also concluded that further research is needed on ecodesign methods, deconstruction strategies, material reuse, and life cycle assessment tools. |

| [70] | Díaz-López et al. | Sustainability | 2021 | Scopus, Web of Science | 1993–2020 | 1440 | A PRISMA-based systematic review and bibliometric analysis evaluating the current state of CE research applied to construction and demolition waste (CDW). |

| [71] | Arumugam et al. | Journal of Engineering Science and Technology | 2021 | Scopus | 2011–2021 | 66 | A PRISMA-based systematic review of nature-inspired 3D printed building envelopes. |

| [13] | Norouzi et al. | Journal of Building Engineering | 2021 | Scopus, Web of Science | 2005–2020 | 7005 | A bibliometric analysis of the application of CE in the building sector. The review concludes that research hotspots requiring further investigation include the development and use of alternative construction materials, the creation of circular business models, and the integration of smart cities and Industry 4.0 technologies with CE. |

| [14] | Wijewickrama et al. | Journal of Cleaner Production | 2021 | Scopus, Web of Science, Google Scholar, ScienceDirect | 2002–2020 | 125 | A systematic review evaluating how new information brokers can bridge gaps between parties in the circular supply chain within the construction industry, preventing the loss of valuable information. |

| [72] | Schuldt et al. | Automation in Construction | 2021 | Scopus | 1998–2019 | 297 | A PRISMA-based systematic review assessing the viability of 3D-printed construction in remote, isolated, or expeditionary environments as an alternative to conventional methods. The review identifies several key areas for future research to ensure the technology’s feasibility, including cost and environmental life cycle assessments, printing full-scale structures and components with locally sourced materials in uncontrolled environments, establishing standards for 3D printing, and automating additional construction processes. |

| [73] | Camana et al. | Sustainable Production and Consumption | 2021 | Scopus, Web of Science | 2010–2020 | 609 | A systematic review and bibliometric analysis (using Italy as a case study) to assess the applicability of key environmental assessment tools related to CE—including industrial ecology, life cycle thinking, footprints, and material and energy flow analyses—in evaluating the sustainability of local circular actions within the European CE framework and measuring the performance of CE policies. |

| [74] | Liu et al. | Advances in Civil Engineering | 2021 | Web of Science | 2010–2019 | 1224 | A bibliometric analysis of global research on prefabricated buildings. |

| [75] | O’Grady et al. | Resources, Conservation & Recycling | 2021 | Scopus, Web of Science, ScienceDirect | Not provided | 496 | A systematic review assessing how design, disassembly, deconstruction, and material resilience are defined within the context of CE. |

| [76] | Machado and Morioka | Journal of Building Engineering | 2021 | Web of Science | Until June 2020 | 49 | A systematic review discussing the contribution of modularity to CE. The review concludes that while the link between modularity and CE has become more evident in recent years, further research is needed to validate the key benefits and barriers of modularity in promoting CE within the building industry and to drive behavioral changes among stakeholders. |

| [10] | Antwi-Afari et al. | Journal of Cleaner Production | 2021 | Scopus | Until February 2020 | 25 | A bibliometric analysis to identify circularity gaps in the construction industry, key areas of influence, emerging research topics, and CE approaches. |

| [9] | Çimen | Journal of Cleaner Production | 2021 | Ebscohost | 2008–April 2020 | 238 | A systematic survey of construction and the built environment under CE principles. The author concludes that the diversity of stakeholders, their motivations, and their influence across various project life cycle stages must be considered; flexible buildings with adaptive reuse and modularity can enhance efficiency and health benefits when aligned with CE principles; and cities adopting a CE require a system dynamics approach to effectively understand urban transitions under varying policies and regulations. |

| [77] | Charef et al. | Sustainability | 2021 | Scopus, Google Scholar | Not provided | 41 | A systematic review identifying and discussing the key barriers hindering the transition to a CE in the construction sector. The authors categorize these barriers into six areas: organizational, economic, technical, social, political, and environmental. |

| [78] | Zairul | Cleaner Engineering and Technology | 2021 | Scopus, Web of Science, Mendeley | 2015–2021 | 36 | A survey of recent trends in prefabrication within the building industry, considering CE approaches. The authors conclude that there is a need to design new business models that integrate CE principles into the prefabrication of buildings. |

| [79] | Kedir and Hall | Journal of Cleaner Production | 2021 | Scopus, Web of Science | Not provided | 86 | A systematic survey identifying key opportunities for resource efficiency in industrialized housing construction, including CE concepts, value chain coordination, and socio-economic impacts. |

| [16] | Hossain et al. | Renewable and Sustainable Energy Reviews | 2020 | Scopus, Web of Science, Google Scholar | 2015–2019 | 66 | A systematic review identifying the main implications, considerations, contributions, and challenges of CE in the construction industry. The review discusses several challenges across various stages, including design, material selection, supply chain, business models, uncertainty and risk, collaboration among stakeholders, knowledge and understanding, relevant policies, integration of urban metabolism, and methodologies for CE evaluation. |

| [80] | Jin et al. | Energy & Buildings | 2020 | Scopus, Web of Science | Not provided | 43 | A bibliometric study on the environmental performance of offsite constructed facilities, concluding that LCA is commonly used to assess carbon emissions and energy consumption, while other environmental impact categories receive less focus. Sub-assembly components are frequently used as functional units, while volumetric construction is rarely considered. Research predominantly focuses on the manufacturing and construction stages, with the operation and EoL stages largely overlooked. The study identifies three key areas for future research: the development of sustainability rating systems, the application of the IoT for monitoring, and the creation of indicator systems for performance evaluation. |

| [81] | Akbarieh et al. | Sustainability | 2020 | Scopus, Web of Science | 2009–February 2019 | 88 | A bibliometric analysis and literature review assessing the use of BIM for selecting EoL scenarios to reduce CDW. |

| [8] | Benachio et al. | Journal of Cleaner Production | 2020 | Scopus, Web of Science, ScienceDirect | 2015–May 2019 | 45 | A systematic review evaluating the application of CE within the construction industry. Six key areas of research are discussed: the development of CE, material reuse, material stocks, CE in the built environment, LCA, and material passports. |

| [82] | Jin et al. | Resources, Conservation and Recycling | 2019 | Scopus | 2009–2018 | 370 | A bibliometric analysis evaluating the latest research on construction and demolition waste management, concluding that further investigation is needed into the integration of BIM and big data in this field. |

| [83] | Li et al. | Engineering, Construction and Architectural Management | 2019 | Scopus | 1997–2016 | 370 | A bibliometric analysis evaluating research trends in lean construction. |

| [7] | Corona et al. | Resources, Conservation and Recycling | 2019 | Web of Science | 2008–August 2018 | 72 | A survey of current methodological developments to identify circularity metrics for products and services, evaluate their validity based on a CE definition rooted in sustainability, and provide recommendations for measuring circularity. |

| [84] | Merli et al. | Journal of Cleaner Production | 2018 | Scopus, Web of Science | Until April 2017 | 565 | A systematic review of CE literature, identifying three main directions: the transformation of social and economic dynamics at the macro and administrative levels, the development of industrial symbiosis at the meso level, and the support of CE business models at the micro level. |

| [85] | Ji et al. | Resources, Conservation and Recycling | 2018 | Web of Science | 1988–August 2017 | 2368 | A bibliometric analysis assessing the evolution of research on resource conservation and recycling. |

| [86] | Jin et al. | Journal of Cleaner Production | 2018 | Scopus | 2008–February 2018 | 349 | A bibliometric analysis of the literature on offsite construction, highlighting several research gaps: the need to further integrate emerging digital construction technologies, combine the concepts of design for manufacturing (DfM) and design for assembly (DfA), and incorporate project delivery methods, lean construction practices, and sustainability metrics. |

| [87] | Sonego et al. | Journal of Cleaner Production | 2018 | Web of Science | Until March 2017 | 81 | A systematic review evaluating the role of modularity in the sustainable design of products throughout their life cycle. |

| [88] | Winans et al. | Renewable and Sustainable Energy Reviews | 2017 | Scopus, Google Scholar, ScienceDirect | Not provided | 150 | A review of the history (definitions, concepts, and principles) and applications of the CE concept, including policy instruments and approaches, value chains, material flows, and products, as well as technological, organizational, and social innovations. |

| [89] | Geissdoerfer et al. | Journal of Cleaner Production | 2017 | Web of Science | 1950–January 2016 | 67 | A bibliometric analysis and systematic review aimed at conceptually distinguishing the terms CE and sustainability and evaluating the various types of relationships between them. |

| [90] | D’Amato et al. | Journal of Cleaner Production | 2017 | Web of Science | 1990–2016 | 1943 | A bibliometric analysis examining the diversity within and between the concepts of CE, green economy, and bioeconomy. |

| [91] | Nobre and Tavares | Scientometrics | 2017 | Scopus | 2006–2015 | 70 | A bibliometric analysis of the application of big data and the IoT in CE. |

| [92] | Ghisellini et al. | Journal of Cleaner Production | 2016 | Web of Science, ScienceDirect | 2004–2014 | 155 | A review of the key features and perspectives of CE, including its origins, core principles, advantages, and drawbacks, as well as the modelling and implementation of CE at the micro, meso, and macro levels. |

| [93] | Lieder and Rashid | Journal of Cleaner Production | 2016 | Scopus, Web of Science | 1950–2015 | 158 | A systematic review exploring CE in the contexts of resource scarcity, waste generation, and economic benefits, particularly when considered together. A CE framework and practical implementation strategy are proposed, integrating three key aspects: environment, resources, and economic advantages. |

| [94] | Tukker | Journal of Cleaner Production | 2015 | Scopus | 2000–2012 | 278 | A bibliometric analysis and review of product-service systems for resource efficiency and CE. |

| [95] | Li et al. | Habitat International | 2014 | Scopus | 2000–2013 | 100 | A bibliometric analysis and review of research on the management of prefabricated construction. |

| Circular economy | Biosphere cycle, butterfly diagram; circular business model; circular corporation; circular ecology; circular industry; circular management; circular production; circular supply chain; circular technology; circular transition; circular value chain; circularity; circulatory economy; cleaner production; closed-loop construction; closed-loop economy; construction and demolition waste management; CDWM; cradle to cradle; eco cycle industry; end of waste; environmental supply chain cooperation; environmental supply chain cooperation; green economy; green supply chain; industrial ecology; industrial symbiosis; input-output model; lean construction; lean management; lean production; life cycle analysis; life cycle assessment; LCA; life cycle costing; LCC; material flow accounting; MFA; low carbon economy; reduce, reuse, recycle; 3R; 4R; 5R: 6R; 7R; 8R; 9R; 10R; regenerative economy; resource recirculation; restorative economy; sharing economy; technological cycle; urban metabolism; waste management; waste reduction; zero waste economy. |

| Construction sector | AEC; architecture, architectural design; building construction; building stock; buildings; buildings industry; buildings sector; built environment; city; commercial building; construction; construction industry; demolition; district; dwelling; educational building; engineering and construction; home; hospital; hotel; house; industrial building; institutional building; office; residence; residential building; retail building; school; rooms; service building; shelter; sport building, toilet. |

| Prefabrication | 3D printed; additive manufacturing; automation; CAM; computer-aided manufacture; CLT; cross-laminated timber; design for assembly; design for deconstruction; design for disassembly and deconstruction; design for disassembly; design for manufacture; design for reuse; factory assembly; hybrid construction; industrialized buildings; industrialized construction; LSF; light steel framing; lightweight steel framing; mass production; MMC; modern method of construction; offsite; offsite construction; offsite manufacturing; offsite pre-assembly; offsite production; panelized building; panelized construction; panelized prefabrication; preassembly; pre-cast production; prefab building; prefab construction; prefabricated; prefabricated prefinished volumetric construction; regenerative design; SIP; structural insulated panels; timber framing; volumetric construction, wood framing. |

| Modular construction | 3D volumetric construction; adaptative design; building module; building units; convertibility; customization; design for adaptation; design for flexibility; design for reassembly; expandability; factory-built modules; modular; modularity; modular integrated construction; repetition; shipping containers building; versatility. |

| Keyword | Description | Occurrences | Total Link Strength |

|---|---|---|---|

| 3d printing | 3D print; 3D printing; 3-D printing. | 12 | 30 |

| Additive manufacturing | Additive manufacturing; Additive manufacturing (AM). | 16 | 28 |

| Building information modeling | Building information modeling; Building information model/modeling (BIM); Building information modeling (BIM); Building information modelling; Building information modelling (BIM); Building information management (BIM); BIM. | 52 | 90 |

| Building materials | Building materials; Building material. | 10 | 30 |

| Buildings | Building; Buildings; Building construction; Building construction industry; Building industry. | 32 | 85 |

| Built environment | Built environment; Built-environment. | 15 | 28 |

| Carbon emissions | Carbon emission; Carbon emissions; Carbon emission intensity. | 23 | 39 |

| Carbon footprint | Carbon footprint. | 10 | 22 |

| Circular economy | Circular economy; Circular economy (CE); (CE). | 90 | 169 |

| Climate change | Climate change. | 16 | 38 |

| Construction and demolition waste | Construction and demolition waste; Construction and demolition waste (C&DW); Construction and demolition waste (CDW); CDW; C&D waste. | 26 | 47 |

| Construction industry | Construction industry; Construction industry (CI); Construction. | 51 | 101 |

| Construction waste | Construction waste. | 14 | 26 |

| Cross laminated timber | Cross laminated timber (CLT); CLT; Cross laminate timber; Cross laminated timber; Cross-laminated timber; Cross-laminated timber (CLT). | 25 | 47 |

| Deconstruction | Deconstruction. | 13 | 26 |

| Design for deconstruction | Design for deconstruction; Design for deconstruction (DfD). | 14 | 30 |

| Design for disassembly | Design for disassembly; Design for disassembling; Design for disassembly (DFD); Design-for-disassembly; DfD. | 27 | 67 |

| Design for manufacture and assembly | Design for manufacture and assembly; Design for manufacture and assembly (DfMA); Design for manufacturing and assembly; Design for manufacturing and assembly (DfMA); DfMA. | 11 | 23 |

| Embodied carbon | Embodied carbon; Embodied carbon (EC); Embodied carbon assessment. | 20 | 58 |

| Embodied energy | Embodied energy; Embodied energy (CED); Embodied energy (EE). | 22 | 50 |

| End of life | End of life; End-of-life; EoL. | 10 | 31 |

| Energy efficiency | Energy efficiency; Energy-efficiency. | 12 | 17 |

| Environmental impact | Environmental impact; Environmental impacts; Environmental impact assessment. | 32 | 60 |

| Global warming | Global warming; Global warming potential; Global warming potential (GWP). | 14 | 29 |

| Greenhouse gas emissions | GHG emissions; Greenhouse gas emissions; Greenhouse emission; Greenhouse gas; Greenhouse gas (GHG) emissions; Greenhouse gases; Green house gases (GHG). | 16 | 32 |

| Industrialized building system | Industrialised Building System; Industrial building system (IBS); Industrialized building system; Industrialised Building System (IBS); Industrialized building system (IBS); Industrialized building systems. | 15 | 25 |

| Lean construction | Lean construction; Lean construction (LC); Lean construction 4.0; Lean in construction; Lean-construction. | 51 | 59 |

| Lean production | Lean production; Lean production principles. | 14 | 18 |

| Life cycle assessment | Life cycle analysis (LCA); Life cycle analysis; Lifecycle analysis; Life-cycle analysis; Life cycle assessment (LCA); lifcycle assessment LCA; (LCA); Life cycle assessment; Lifecycle assessment; Life-cycle assessment; Life-cycle assessment (LCA); LCA method. | 210 | 355 |

| Life cycle costing | Life cycle cost (LCC); Life cycle cost; LCC; Life cycle cost analysis; Life cycle cost assessment; Life cycle cost assessment (LCCA); Life cycle costing; Life cycle costing (LCC); Life-cycle cost; Life-cycle cost assessment; Life-cycle costing; Life-cycle costs; Lifecycle costs (LCC). | 38 | 68 |

| Modern method of construction | Modern construction systems; Modern method of construction; Modern methods of construction; Modern methods of construction (MMC). | 10 | 26 |

| Modular construction | Modular construction | 17 | 28 |

| Modularity | Modular; Modularity. | 10 | 17 |

| Offsite construction | Off-site; Offsite construction; Off-site construction; Offsite construction (OSC); Off-site construction (OSC). | 26 | 57 |

| Prefabrication | Prefabricated; Prefabricated; Prefabrication; Pre-fabrication; Prefabricated architecture (prefab); Prefabricated building; Prefabricated buildings; Prefabricated building project; Prefabricated buildings and walls. | 83 | 136 |

| Recycling | Recycle; Recycling. | 21 | 62 |

| Residential buildings | Residential; Residential building; Residential buildings; Residential homes. | 12 | 29 |

| Reuse | Reuse; Re-use; Re-using. | 25 | 70 |

| Sustainability | Sustainability; Sustainable. | 53 | 99 |

| Sustainable buildings | Sustainable building; Sustainable buildings. | 13 | 24 |

| Sustainable construction | Sustainable construction; Sustainable constructions. | 20 | 36 |

| Sustainable development | Sustainable development. | 15 | 28 |

| Waste management | Waste management; Waste management (WM). | 17 | 35 |

| Waste reduction | Waste minimisation; Waste minimization; Waste reduction. | 15 | 31 |

| Rank | Citations | Authors | Year | Journal | Journal H-Index | Cluster | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | 622 | Allwood et al. | 2011 | Resources, Conservation and Recycling | 218 | #2 | [105] |

| 2 | 525 | Wu et al. | 2016 | Automation in Construction | 200 | #2, #4, #5 | [106] |

| 3 | 422 | Tam et al. | 2007 | Building and Environment | 221 | #1, #2 | [107] |

| 4 | 396 | Monahan and Powell | 2011 | Energy and Buildings | 246 | #3 | [108] |

| 5 | 378 | Jaillon et al. | 2009 | Waste Management | 239 | #1, #2 | [109] |

| 6 | 319 | Labonnote et al. | 2016 | Automation in Construction | 200 | #5 | [110] |

| 7 | 310 | Aye et al. | 2012 | Energy and Buildings | 246 | #1, #2, #3 | [111] |

| 8 | 302 | Kamali and Hewage | 2016 | Renewable and Sustainable Energy Reviews | 464 | #1, #3 | [47] |

| 9 | 216 | Cao et al. | 2015 | Journal of Cleaner Production | 354 | #1, #3 | [112] |

| 10 | 201 | Jin et al. | 2018 | Journal of Cleaner Production | 354 | #1 | [86] |

| 11 | 198 | Jin et al. | 2019 | Resources, Conservation and Recycling | 218 | #2, #4 | [82] |

| 12 | 183 | Akanbi et al. | 2018 | Resources, Conservation and Recycling | 218 | #2 | [113] |

| 13 | 178 | Hong et al. | 2016 | Journal of Cleaner Production | 354 | #1, #3 | [114] |

| 14 | 171 | Tam | 2008 | Waste Management | 239 | #2, #4 | [115] |

| 15 | 151 | Robertson et al. | 2012 | Buildings | 71 | #3 | [116] |

| 16 | 149 | Ding et al. | 2018 | Journal of Cleaner Production | 354 | #2 | [117] |

| 17 | 147 | Wang et al. | 2014 | Resources, Conservation and Recycling | 218 | #2 | [118] |

| 18 | 144 | Shadram et al. | 2016 | Energy and Buildings | 246 | #2, #3 | [119] |

| 19 | 144 | Akinade et al. | 2015 | Resources, Conservation and Recycling | 218 | #2 | [120] |

| 20 | 144 | Li et al. | 2014 | Resources, Conservation and Recycling | 218 | #1 | [121] |

| 21 | 144 | Nahmens et al. | 2012 | Journal of Architectural Engineering | 46 | #1 | [33] |

| 22 | 141 | Agustí-Juan and Habert | 2017 | Journal of Cleaner Production | 354 | #3, #5 | [122] |

| 23 | 140 | Quale et al. | 2012 | Journal of Industrial Ecology | 141 | #1, #3 | [123] |

| 24 | 140 | Jaillon and Poon | 2010 | Construction Management and Economics | 116 | #1, #5 | [124] |

| 25 | 137 | Dong et al. | 2015 | Construction and Building Materials | 293 | #1, #3 | [125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares, N.; Tavares, V. Bibliometric Analysis of the Intersection of Circular Economy, Prefabrication, and Modularity in the Building Industry. Buildings 2025, 15, 1923. https://doi.org/10.3390/buildings15111923

Soares N, Tavares V. Bibliometric Analysis of the Intersection of Circular Economy, Prefabrication, and Modularity in the Building Industry. Buildings. 2025; 15(11):1923. https://doi.org/10.3390/buildings15111923

Chicago/Turabian StyleSoares, Nelson, and Vanessa Tavares. 2025. "Bibliometric Analysis of the Intersection of Circular Economy, Prefabrication, and Modularity in the Building Industry" Buildings 15, no. 11: 1923. https://doi.org/10.3390/buildings15111923

APA StyleSoares, N., & Tavares, V. (2025). Bibliometric Analysis of the Intersection of Circular Economy, Prefabrication, and Modularity in the Building Industry. Buildings, 15(11), 1923. https://doi.org/10.3390/buildings15111923