Dynamic Tensile Response of Seawater Coral Aggregate Concrete (SCAC) in Saturated State: Experimental and Numerical Simulation Study

Abstract

1. Introduction

2. Experiment Setup

2.1. Specimen Preparation

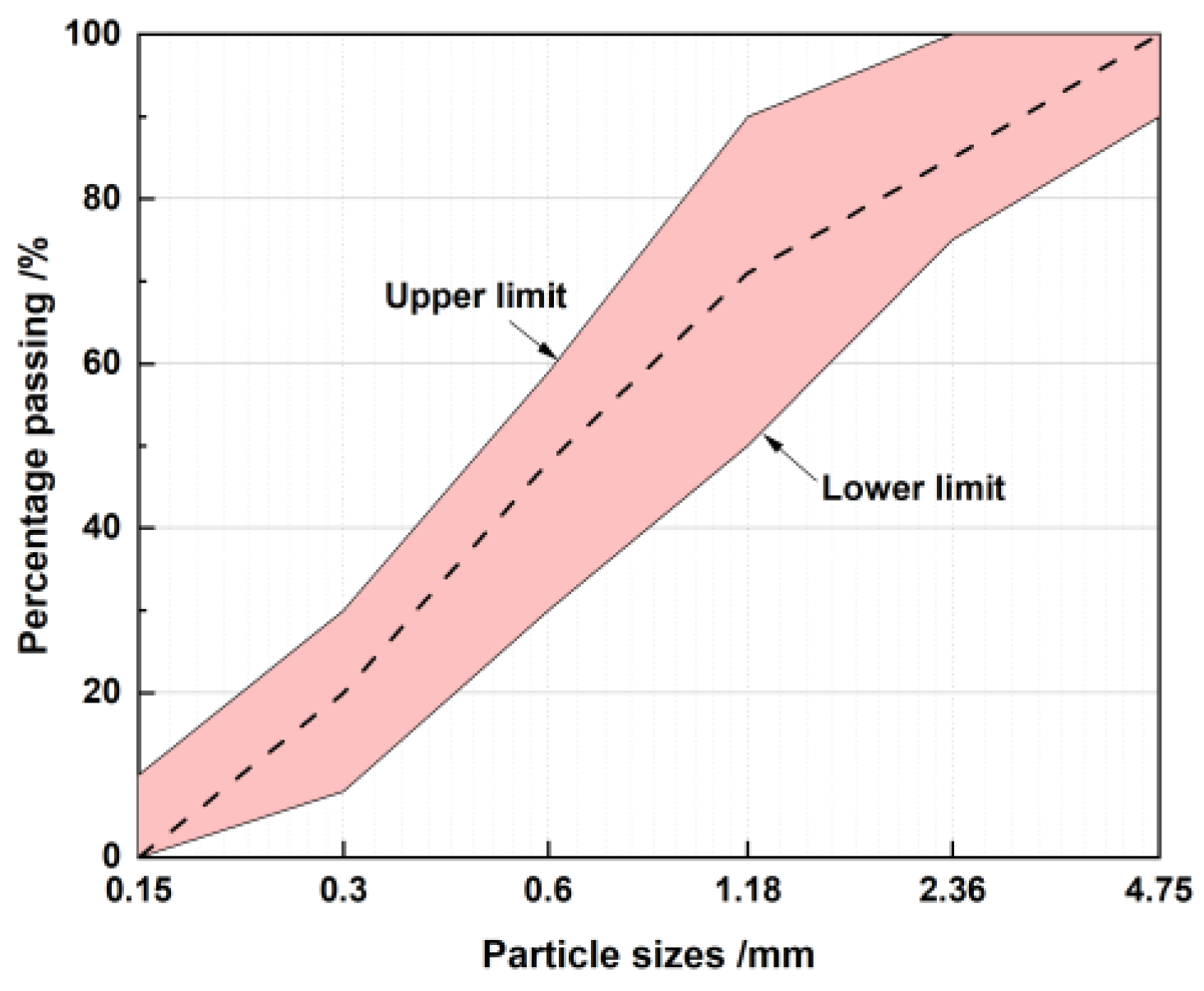

2.1.1. Materials

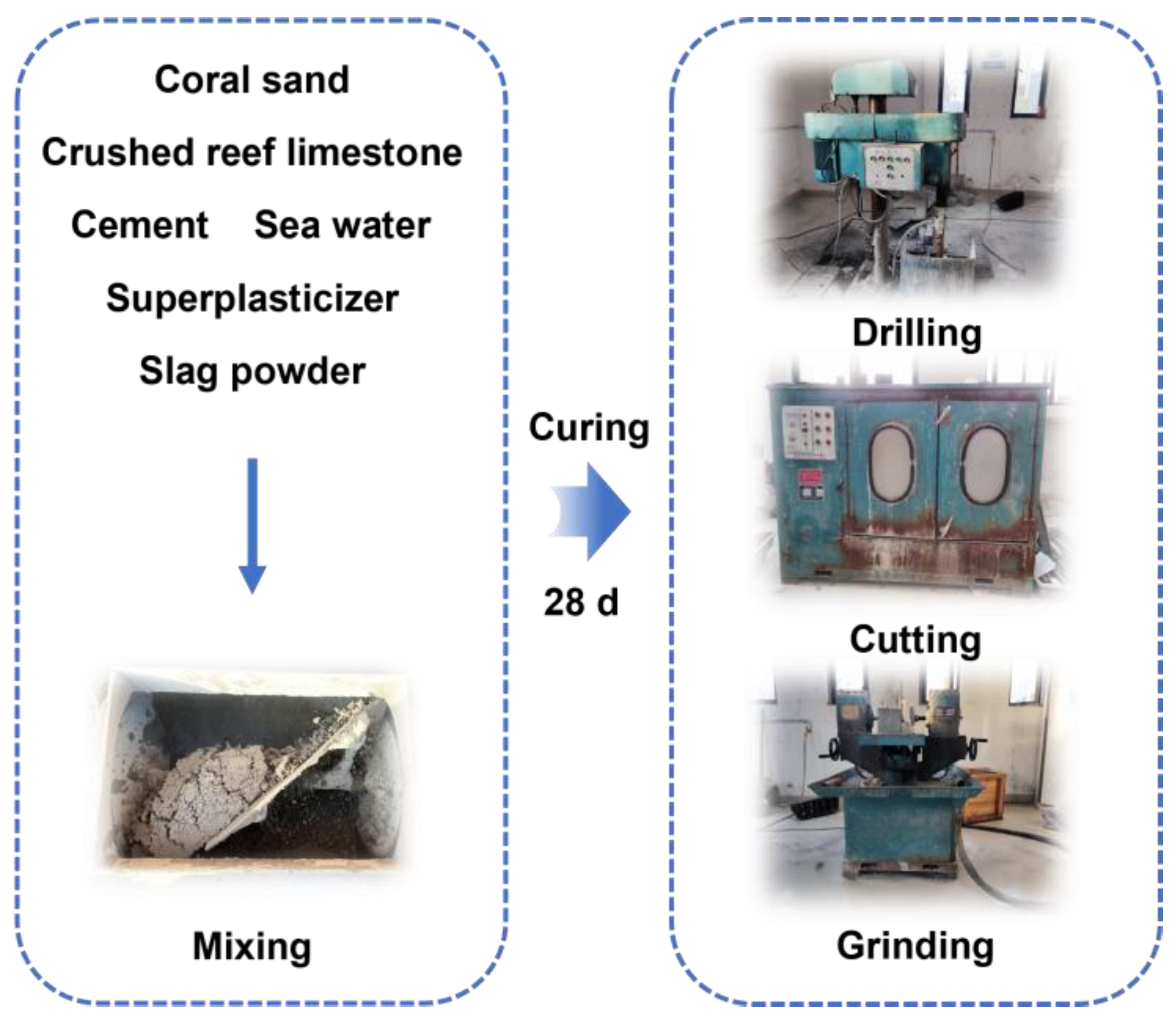

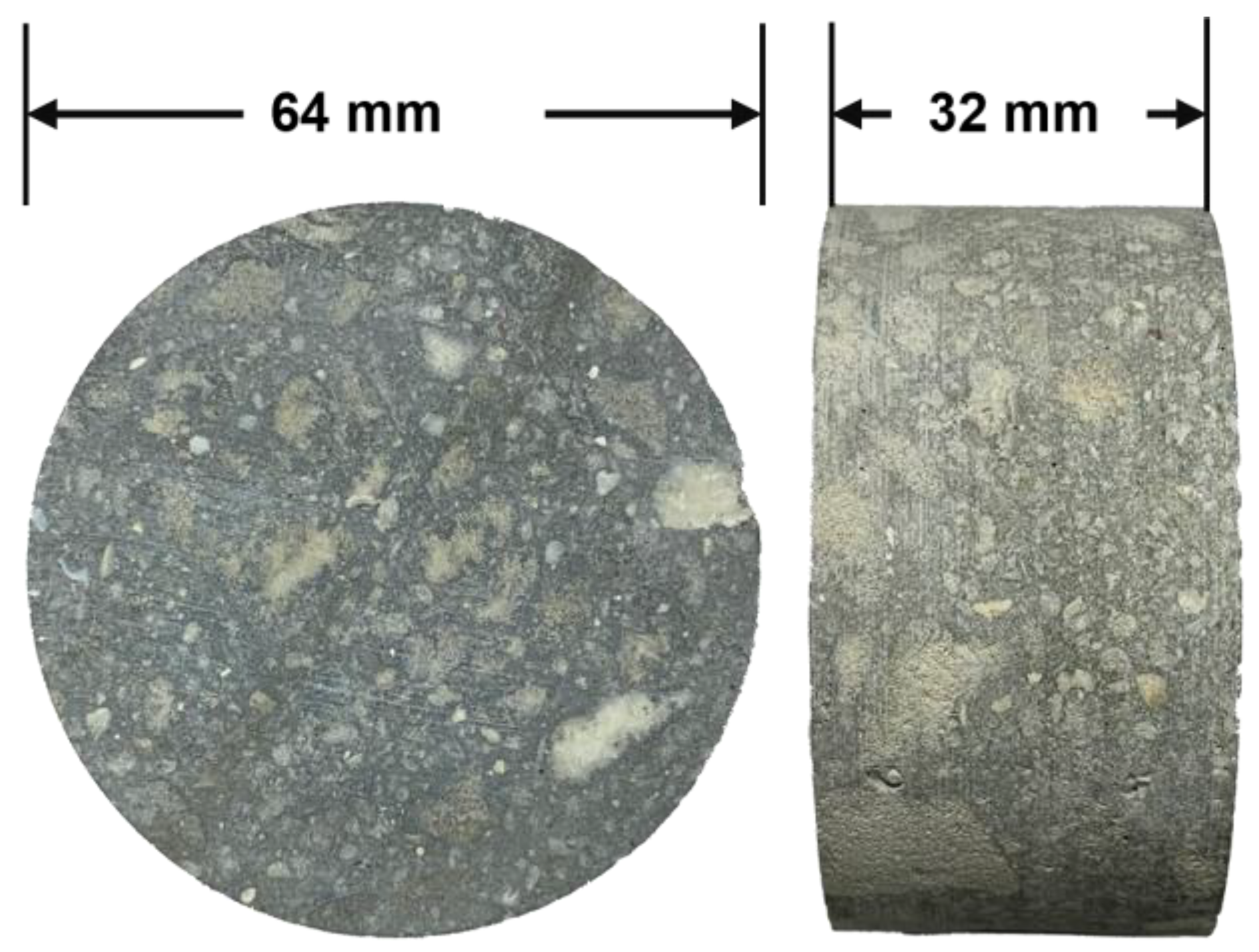

2.1.2. Production and Processing of SCAC Specimens

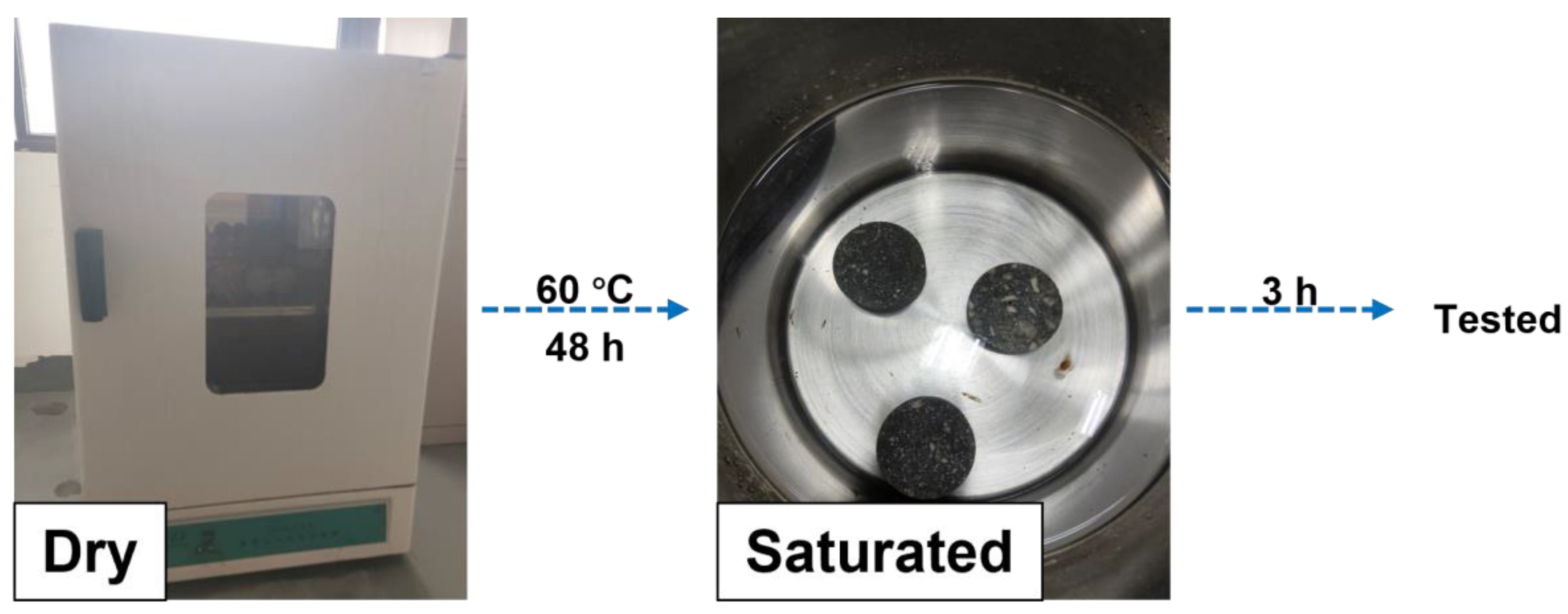

2.1.3. The Water Saturation Treatment of SCAC Specimens

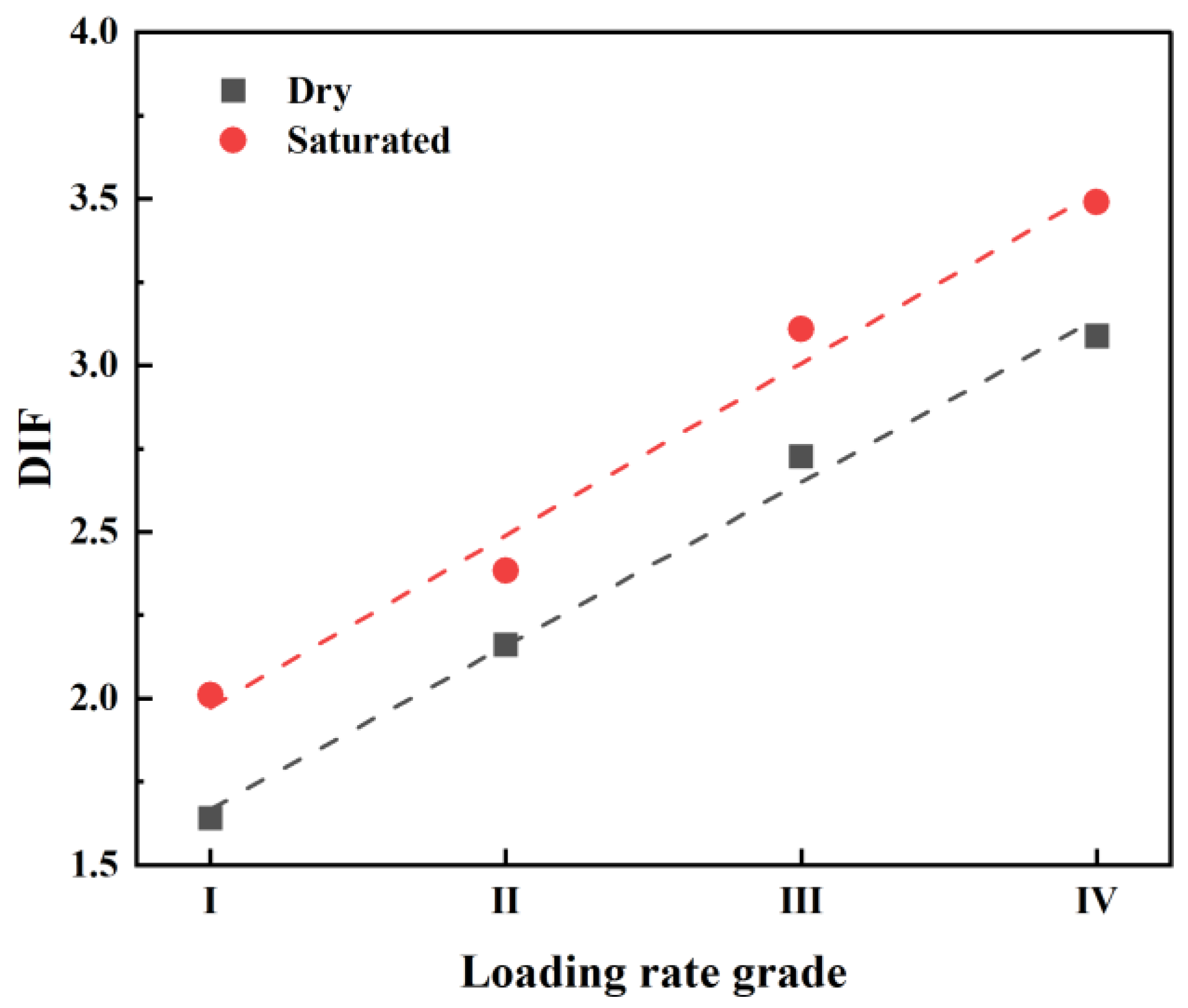

2.2. The Quasi-Static Brazilian Splitting Test

2.3. The Dynamic Brazilian Splitting Test

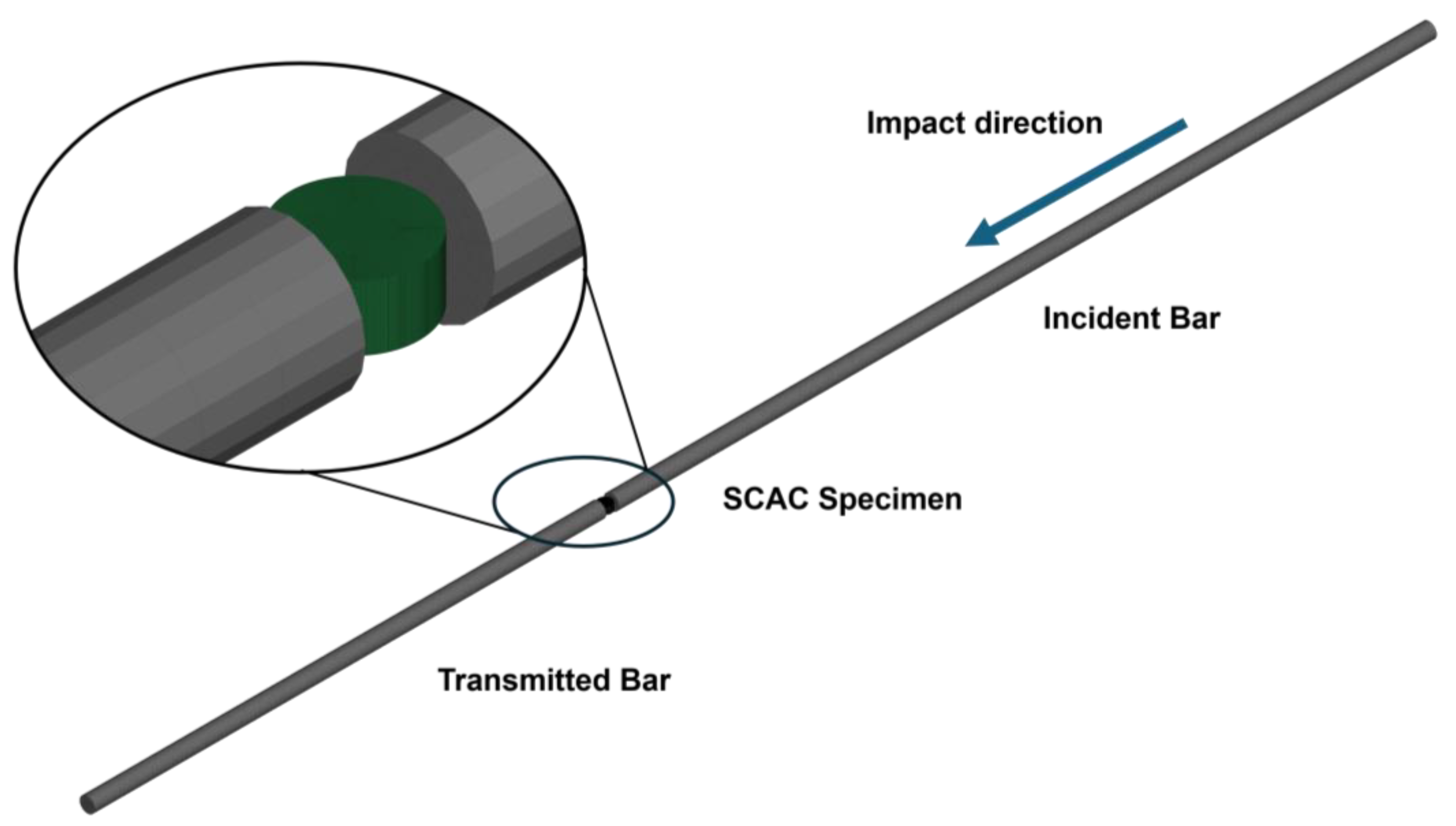

Configuration of the Testing System

3. Results and Discussion

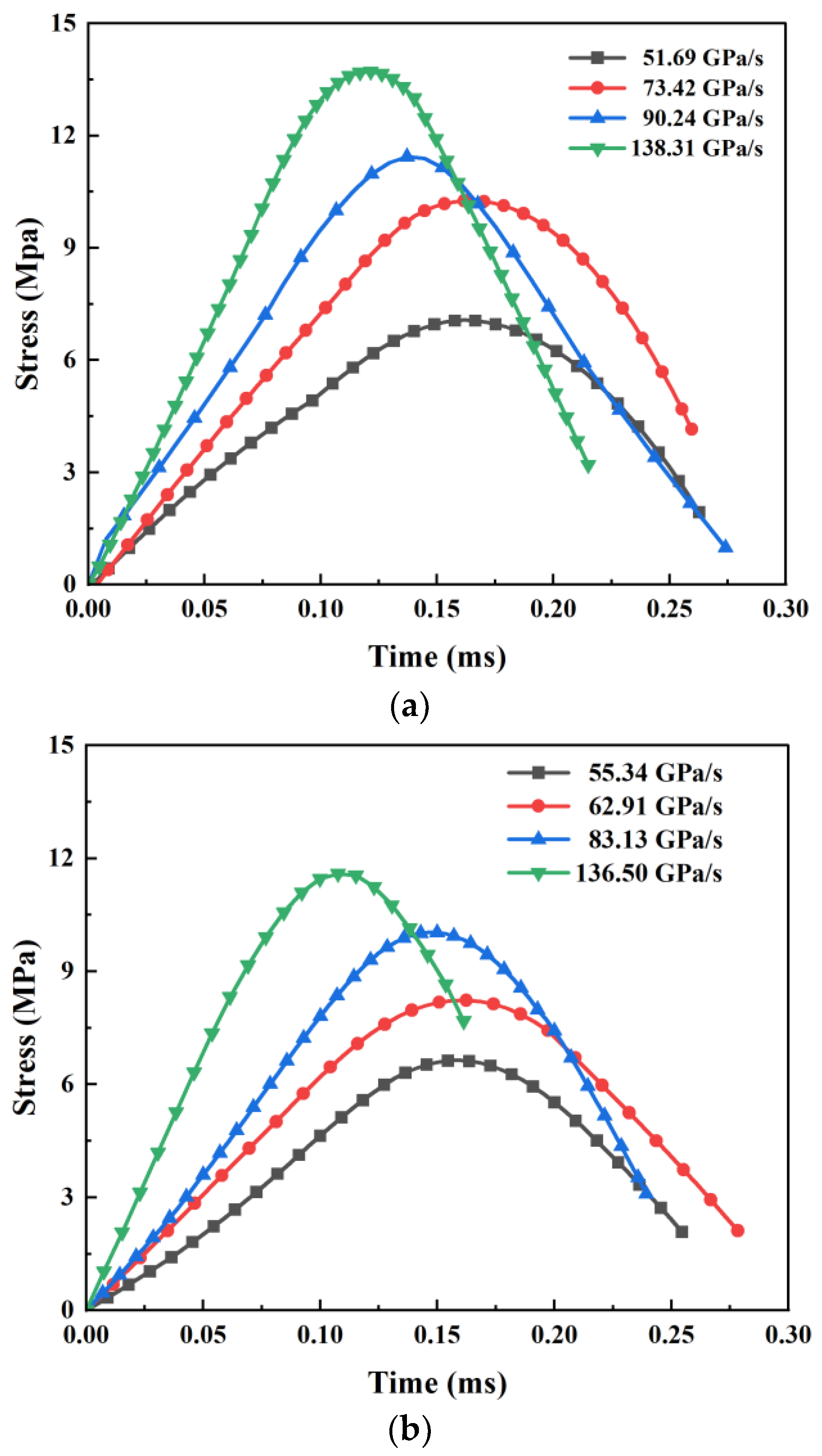

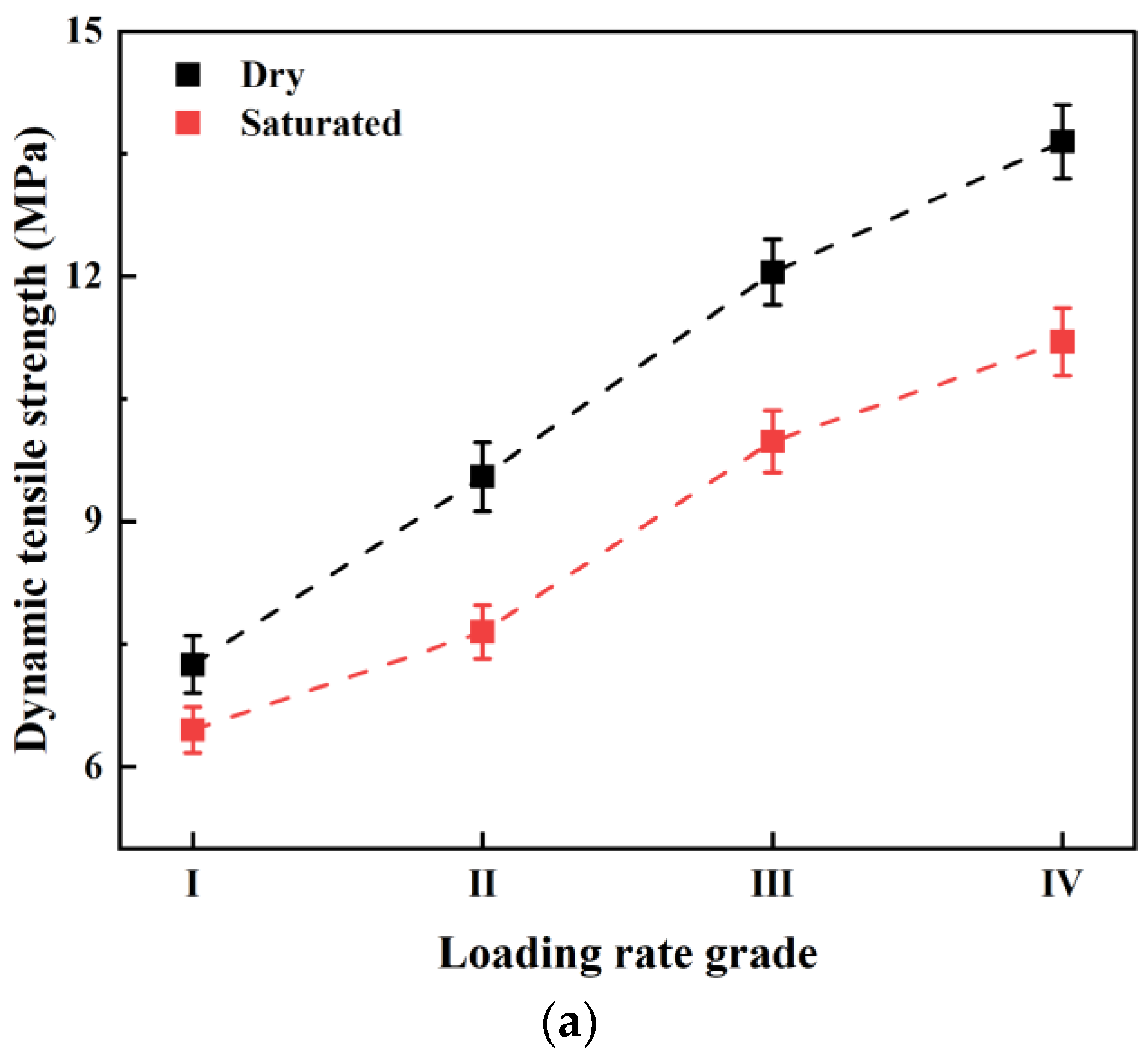

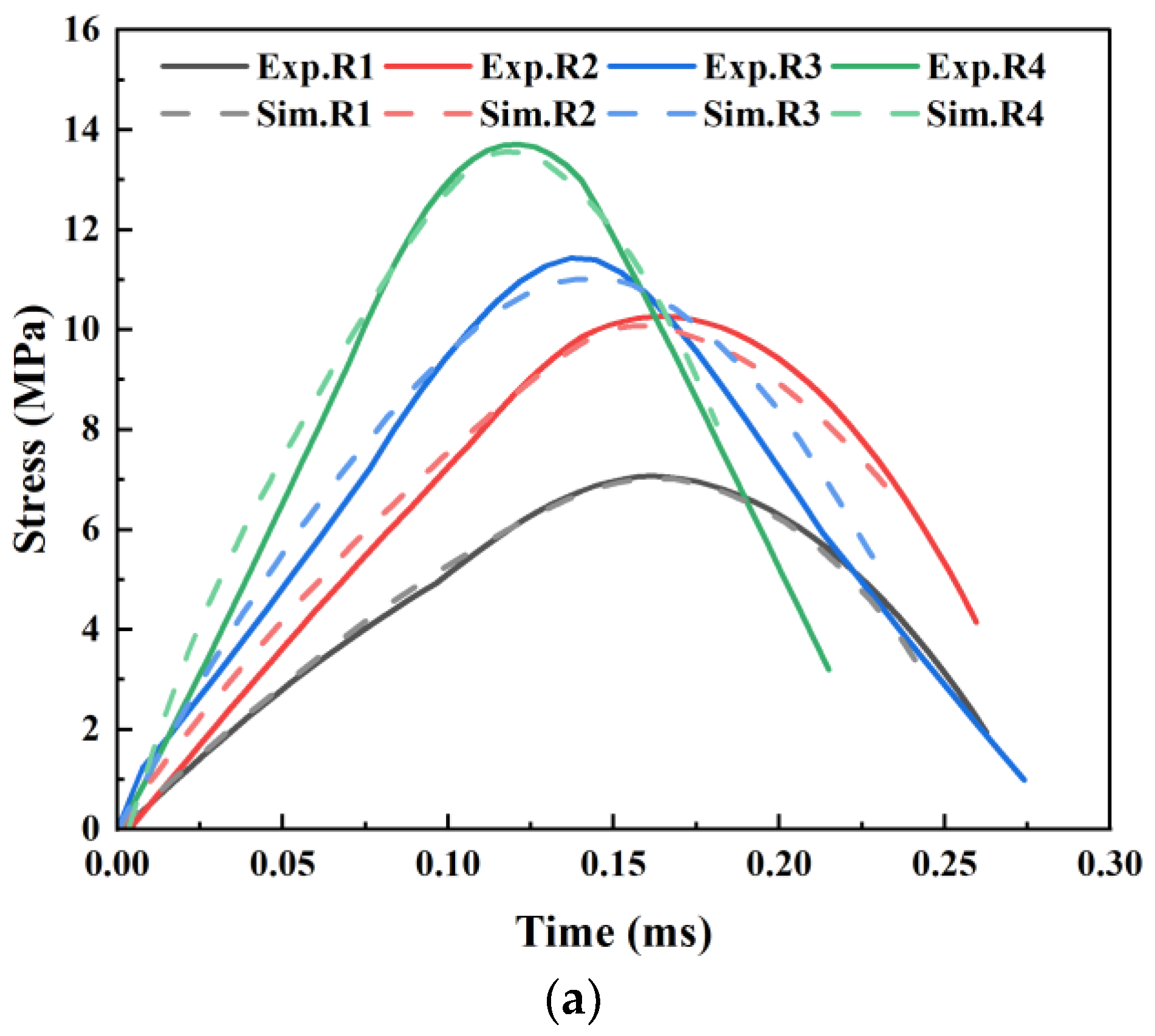

3.1. Stress–Time Curve and Tensile Strength

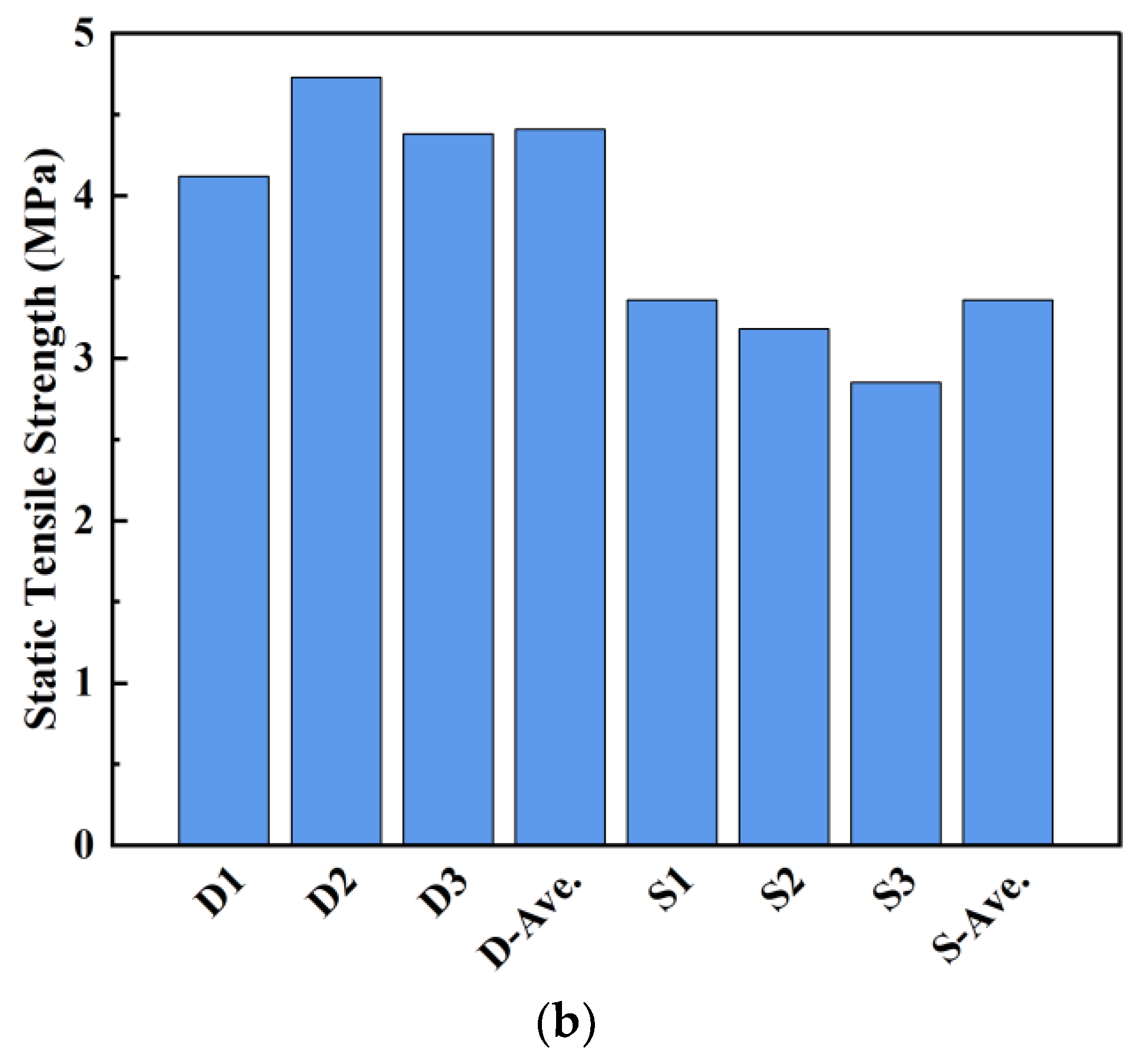

3.2. Sensitivity of Strain Rate

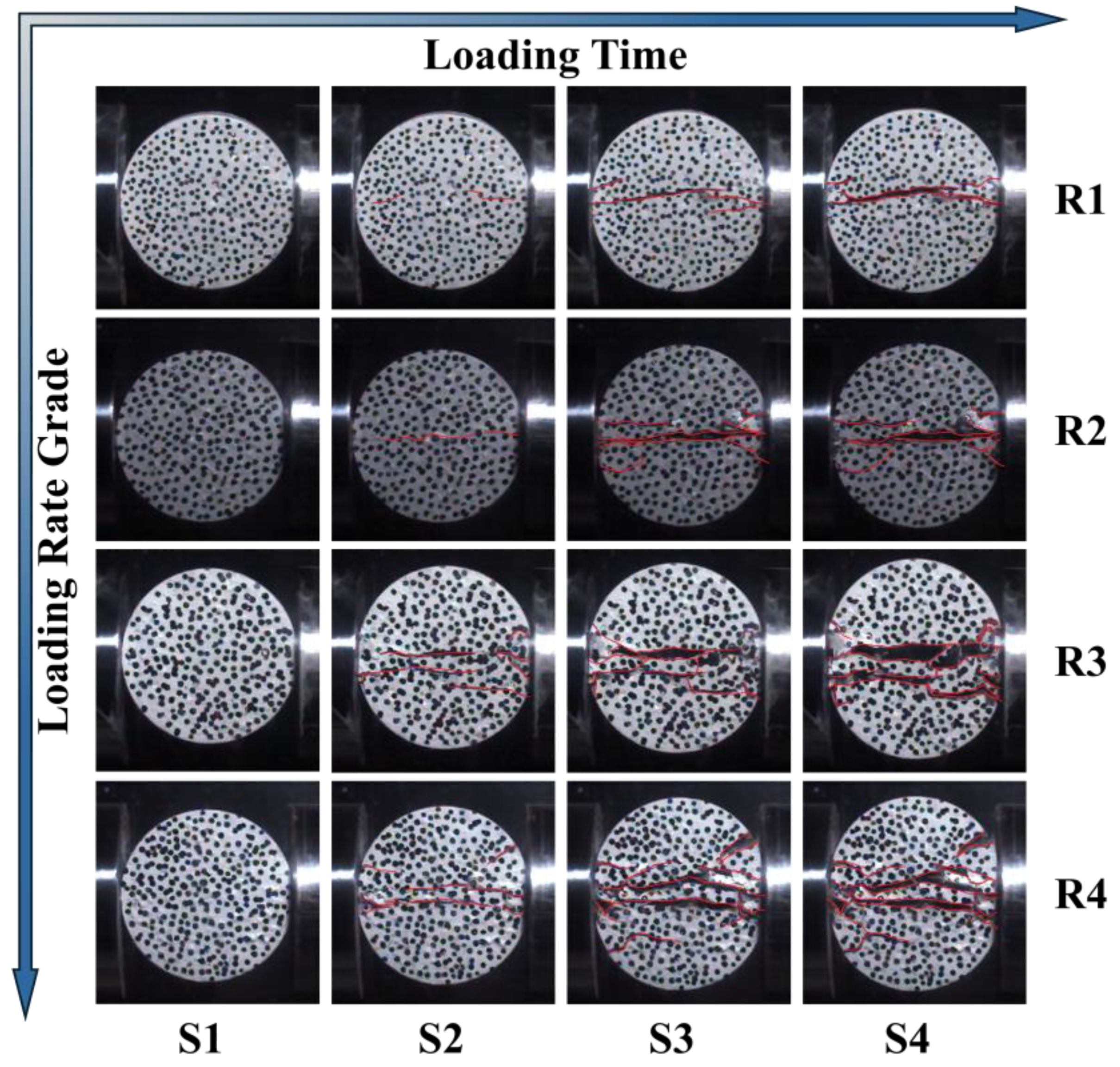

3.3. Dynamic Failure Process

3.4. Failure Patterns

4. Numerical Simulation

4.1. Modeling and Materials Setup

4.2. The Validity of the SHPB Simulation

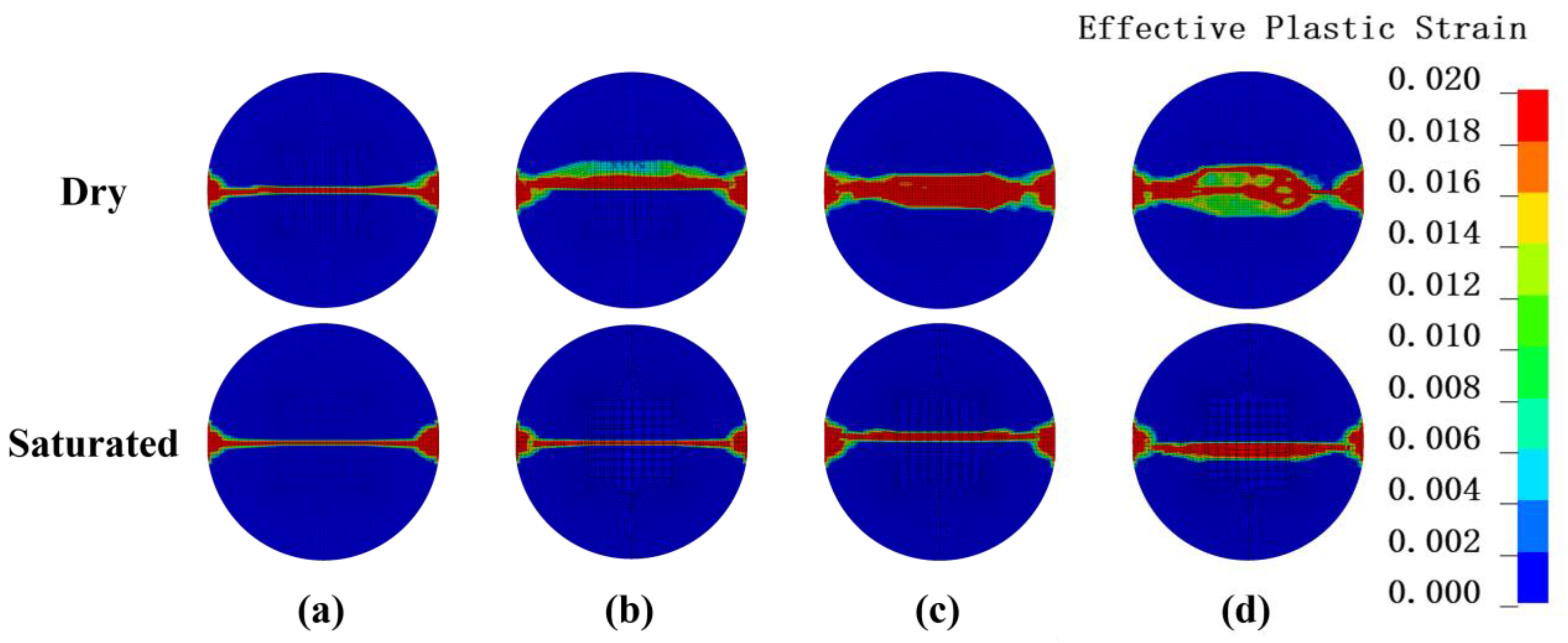

4.3. The Failure Patterns of SCACs in FEM

5. Conclusions

- Saturated SCAC specimens generally exhibited a reduction in dynamic tensile strength compared to their dry counterparts, with the reduction reaching up to 17.87%. This reduction was more pronounced at higher strain rates, aligning with trends observed in dynamic compression tests.

- Both dry and saturated SCAC specimens exhibited strain rate dependence, with dynamic tensile strength increasing as the strain rate rose. The saturated SCAC demonstrated a higher sensitivity to strain rate compared to the dry samples. The moisture content influenced the failure modes of SCAC under dynamic tension, with saturated specimens showing fewer cracks and a less pronounced failure pattern than the dry specimens.

- The numerical simulations performed with the Johnson–Holmquist Concrete (JHC) model aligned well with experimental observations, thereby confirming the reliability of the simulation outcomes. The comparison between experimental and simulated data supported the conclusion that saturation has a substantial impact on the mechanical properties of SCAC. Furthermore, the comparison between the numerical simulations and experimental results illustrates that adjusting material model parameters is an effective approach for simulating the behavior of saturated concrete or similar materials.

- Considering the observed reduction in dynamic tensile performance under saturated conditions, special attention should be given to the dynamic tensile response of water-saturated SCAC in island reef engineering, particularly for structures subjected to tensile loads in such moisture-rich environments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, A.; Lyu, B.; Zhang, Z.; Liu, K.; Xu, H.; Sun, D. The Development of Coral Concretes and Their Upgrading Technologies: A Critical Review. Constr. Build. Mater. 2018, 187, 1004–1019. [Google Scholar] [CrossRef]

- Cai, Y.; Ren, H.; Long, Z.; Guo, R.; Du, K.; Chen, S.; Zheng, Z. Comparison Study on the Impact Compression Mechanical Properties of Coral Aggregate Concrete and Ordinary Portland Concrete. Structures 2022, 44, 1403–1415. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Wang, Q.; Shah, K.W.; Wang, W. Design and Properties of Seawater Coral Aggregate Alkali-Activated Concrete. J. Sustain. Cem. Based Mater. 2022, 11, 187–201. [Google Scholar] [CrossRef]

- Meng, Q.; Dong, Y.; Li, H.; Cui, L. Static and Dynamic Compressive Performance of Coral Reef Limestone: Interpretations of Rate Effect from Laboratory Tests. Bull. Eng. Geol. Environ. 2024, 83, 194. [Google Scholar] [CrossRef]

- Xu, X.; Chi, L.; Yang, J.; Lv, N. Investigation on the Deformation and Failure Characteristics of Concrete in Dynamic Splitting Tests. Materials 2022, 15, 1681. [Google Scholar] [CrossRef]

- Yu, Q.; Chen, Z.; Yang, J.; Rong, K. Numerical Study of Concrete Dynamic Splitting Based on 3D Realistic Aggregate Mesoscopic Model. Materials 2021, 14, 1948. [Google Scholar] [CrossRef]

- Luo, Y.; Li, S.; Gong, H.; Song, X.; Fan, R.; Zhang, J. Dynamic properties and fragmentation fractal characteristics of water-saturated reef limestone concrete under impact loading. Constr. Build. Mater. 2023, 397, 132417. [Google Scholar] [CrossRef]

- Liu, J.; Ou, Z.; Peng, W.; Guo, T.; Deng, W.; Chen, Y. Literature review of coral concrete. Arab. J. Sci. Eng. 2018, 43, 1529–1541. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P.; Han, Y.; Hao, R.; Liu, W. Dynamic Compressive Properties of Seawater Coral Aggregate Concrete (SCAC) Reinforced with Mono or Hybrid Fibers. Constr. Build. Mater. 2022, 340, 127801. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Z.; Zhang, Y.; Fang, Q.; Yu, H.; Jiang, C. Mesoscopic Characteristics and Macroscopic Mechanical Properties of Coral Aggregates. Constr. Build. Mater. 2021, 309, 125125. [Google Scholar] [CrossRef]

- Ma, L.; Li, Z.; Liu, J.; Duan, L.; Wu, J. Mechanical Properties of Coral Concrete Subjected to Uniaxial Dynamic Compression. Constr. Build. Mater. 2019, 199, 244–255. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Sun, H.; Sun, Y.; Wang, Q. Effects of Coral, Recycled and Natural Coarse Aggregates on the Mechanical Properties of Concrete. Constr. Build. Mater. 2018, 192, 330–347. [Google Scholar] [CrossRef]

- Liu, B.; Zhou, J.; Wen, X.; Guo, J.; Deng, Z.; Hu, X. Mechanical Performance and Failure Criterion of Coral Concrete under Combined Compression-Shear Stresses. Constr. Build. Mater. 2021, 288, 123050. [Google Scholar] [CrossRef]

- Ma, H.; Yue, C.; Yu, H.; Mei, Q.; Chen, L.; Zhang, J.; Zhang, Y.; Jiang, X. Experimental Study and Numerical Simulation of Impact Compression Mechanical Properties of High Strength Coral Aggregate Seawater Concrete. Int. J. Impact Eng. 2020, 137, 103466. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, J.; Yu, H.; Fang, Q.; Chen, L.; Yue, C. Experimental and Mesoscopic Investigation on the Dynamic Properties of Coral Aggregate Concrete in Compression. Sci. China Technol. Sci. 2021, 64, 1153–1166. [Google Scholar] [CrossRef]

- Guo, R.; Ou, C.; Ma, L.; Long, Z.; Xu, F.; Yin, C. Experimental Study on Impact Performance of Seawater Sea-Sand Concrete with Recycled Aggregates. Sustain. Mater.Technol. 2024, 41, e01060. [Google Scholar] [CrossRef]

- Guo, J.; Yu, H.; Ma, H.; Quan, S.; Liu, T.; Dai, X. Impact Toughness Analysis and Numerical Simulation of Coral Aggregate Concrete at Various Strength Grades: Experimental and Data Investigations. Buildings 2024, 14, 1605. [Google Scholar] [CrossRef]

- Yue, C.; Ma, H.; Yu, H.; Zhang, J.; Chen, L.; Mei, Q.; Tan, Y.; Liu, T. Experimental and Three-Dimensional Mesoscopic Simulation Study on Coral Aggregate Seawater Concrete with Dynamic Direct Tensile Technology. Int. J. Impact Eng. 2021, 150, 103776. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, J.; Fang, Q.; Yu, H.; Ma, H. 3D Mesoscopic Modelling on the Dynamic Properties of Coral Aggregate Concrete under Direct Tension. Eng. Fract. Mech. 2021, 247, 107636. [Google Scholar] [CrossRef]

- Ma, H.; Wu, Z.; Yu, H.; Zhang, J.; Yue, C. Experimental and Three-Dimensional Mesoscopic Investigation of Coral Aggregate Concrete under Dynamic Splitting-Tensile Loading. Mater. Struct. 2020, 53, 12. [Google Scholar] [CrossRef]

- Peng, Y.; Yu, L.; Qian, J.; Li, W.; Zhang, T.; Zhou, L. Dynamic Tensile Behavior and Crack Propagation in Coral Aggregate Seawater Shotcrete: Experimental Investigation and Numerical Simulation. Cem. Concr. Compos. 2025, 159, 106010. [Google Scholar] [CrossRef]

- Wang, Y.; Qiao, P.; Sun, J.; Chen, A. Influence of Fibers on Tensile Behavior of Ultra-High Performance Concrete: A Review. Constr. Build. Mater. 2024, 430, 136432. [Google Scholar] [CrossRef]

- Grote, D.L.; Park, S.W.; Zhou, M. Dynamic Behavior of Concrete at High Strain Rates and Pressures: I. Experimental Characterization. Int. J. Impact Eng. 2001, 25, 869–886. [Google Scholar] [CrossRef]

- Xue, W.; Min, T.; Alam, M.S.; Fan, H.; Liu, L. Evolution Characteristics and Mechanism of Concrete Performance under Water Pressure Environment: A Comprehensive Review. Struct. Concr. 2023, 24, 6338–6369. [Google Scholar] [CrossRef]

- Zhang, X.; Chiu, Y.-W.; Hao, H.; Cui, J. Dynamic Enhancing Effect of Free Water on the Dynamic Tensile Properties of Mortar. Mater. Struct. 2023, 56, 123. [Google Scholar] [CrossRef]

- Xie, F.; Jin, Z.; Yang, T.; Han, X.; Chen, X.; Zhang, Y. Dynamic Splitting Tensile Strength of Precast Concrete Samples with Varying Moisture Contents. J. Mater. Civ. Eng. 2024, 36, 4023547. [Google Scholar] [CrossRef]

- Salem, S.; Eissa, E.; Zarif, E.; Sherif, S.; Shazly, M. Influence of Moisture Content on the Concrete Response under Dynamic Loading. Ain Shams Eng. J. 2023, 14, 101976. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Zhao, X.; Hong, M.; Guo, B.; Yuan, Q.; Niu, D. Water Saturation Effect on the Dynamic Mechanical Behaviour and Scaling Law Effect on the Dynamic Strength of Coral Aggregate Concrete. Cem. Concr. Compos. 2021, 120, 104034. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, H.; Liu, Y.; Gan, J.; Tang, L. Pore Characteristics and Mechanical Behaviors of Autoclaved Aerated Concrete Produced from Coal Bottom Ash and Tailings. Eng. Rep. 2024, 6, e12834. [Google Scholar] [CrossRef]

- García, V.J.; Márquez, C.O.; Zúñiga-Suárez, A.R.; Zuñiga-Torres, B.C.; Villalta-Granda, L.J. Brazilian Test of Concrete Specimens Subjected to Different Loading Geometries: Review and New Insights. Int. J. Concr. Struct. Mater. 2017, 11, 343–363. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, W.; He, B.; Zhu, X.; Jiang, Z. Compressive Behaviour and Microstructure of Geopolymer Mortar Subjected to Cryogenic Freeze-Thaw Cycle: Effects of Cycles and Polypropylene Fiber. Cem. Concr. Compos. 2024, 149, 105505. [Google Scholar] [CrossRef]

- Zhu, H.; Xiong, Z.; Song, Y.; Zhou, K.; Su, Y. Effect of Expansion Agent and Glass Fiber on the Dynamic Splitting Tensile Properties of Seawater–Sea-Sand Concrete. Buildings 2024, 14, 217. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Shi, C.; Chen, X. Experimental and Numerical Study on Tensile Strength and Failure Pattern of High Performance Steel Fiber Reinforced Concrete under Dynamic Splitting Tension. Constr. Build. Mater. 2020, 259, 119796. [Google Scholar] [CrossRef]

- Cui, J.; Shi, Y.; Sun, T.; Zhang, X.; Li, M.; Guan, X. Influence of Water Saturation on Dynamic Tensile and Compressive Behaviors of Concrete. J. Mater. Civ. Eng. 2024, 36, 4024144. [Google Scholar] [CrossRef]

- Wang, H.; Jin, W.; Li, Q. Saturation Effect on Dynamic Tensile and Compressive Strength of Concrete. Adv. Struct. Eng. 2009, 12, 279–286. [Google Scholar] [CrossRef]

- Jin, L.; Du, X.; Ma, G. Macroscopic Effective Moduli and Tensile Strength of Saturated Concrete. Cem. Concr. Res. 2012, 42, 1590–1600. [Google Scholar] [CrossRef]

- Xie, F.; Jin, Z.; Yang, T.; Han, X.; Chen, X.; Zhang, Y. Experimental Study of Dynamic Splitting-Tensile Properties of Precast Concrete Samples under Different Strain Rates. Constr. Build. Mater. 2023, 372, 130748. [Google Scholar] [CrossRef]

- Ma, H.; Guo, J.; Liu, T.; Yu, H.; Zhang, J.; Wu, Z.; Yue, C.; Mei, Q. Experimental and Numerical Studies on the Mechanical Behaviors of Basic Magnesium Sulfate Cement Concrete under Dynamic Split-Tension. J. Build. Eng. 2023, 77, 107525. [Google Scholar] [CrossRef]

- Man, K.; Song, Z.; Liu, X. Dynamic Tensile Test of Granite and Its Tensile Sensitivity. Adv. Civ. Eng. 2020, 2020, 8837865. [Google Scholar] [CrossRef]

- Zhao, X.; Li, H.; Wang, C. Quasi-Static and Dynamic Compressive Behavior of Ultra-High Toughness Cementitious Composites in Dry and Wet Conditions. Constr. Build. Mater. 2019, 227, 117008. [Google Scholar] [CrossRef]

- Ou, C.; Guo, R.; Ma, L.; Long, Z.; Xu, F.; Yin, C. Experimental Investigation on the Dynamic Tensile Characteristics and Microstructure of Recycled Coral Aggregate Concrete (RCAC). Eng. Fail. Anal. 2025, 167, 109057. [Google Scholar] [CrossRef]

- Lv, N.; Wang, H.; Rong, K.; Chen, Z.; Zong, Q. The Numerical Simulation of Large Diameter Split Hopkinson Pressure Bar and Hopkinson Bundle Bar of Concrete Based on Mesoscopic Model. Constr. Build. Mater. 2022, 315, 125728. [Google Scholar] [CrossRef]

- Ma, H.; Tan, Y.; Yu, H.; Yue, C.; Zhang, Y. Dynamic Impact Compressive Behavior Investigation of Sisal Fiber-Reinforced Coral Seawater Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2023, 38, 1034–1043. [Google Scholar] [CrossRef]

- Holmquist, T.J.; Johnson, G.R. A Computational Constitutive Model for Glass Subjected to Large Strains, High Strain Rates and High Pressures. J. Appl. Mech. 2011, 78, 051003. [Google Scholar] [CrossRef]

- Wang, C.; Song, R.; Wang, G.; Zhang, S.; Cao, X.; Wei, P. Modifications of the HJC (Holmquist-Johnson-Cook) Model for an Improved Numerical Simulation of Roller Compacted Concrete (RCC) Structures Subjected to Impact Loadings. Materials 2020, 13, 1361. [Google Scholar] [CrossRef]

- Huang, R.; Hu, L.; Qin, J.; Jiang, D.; Meng, L. Effect of Free Water on the Mechanical Properties and Blast Resistance of Concrete. KSCE J. Civ. Eng. 2021, 25, 3084–3096. [Google Scholar] [CrossRef]

| NaCl | MgCl·6H2O | Na2SO4 | CaCl2 | KCl |

|---|---|---|---|---|

| 24.5 | 11.1 | 4.1 | 1.2 | 0.7 |

| Cement | Coral Sand | Crushed Reef-Limestone | Seawater | Superplasticizer | Slag Powder |

|---|---|---|---|---|---|

| 590 | 700 | 780 | 260 | 5.1 | 185 |

| Elastic Modulus/GPa | Density/g∙cm−3 | Poisson’s Ratio |

|---|---|---|

| 210 | 7.83 | 0.3 |

| (kg/m3) | fc (GPa) | ft (GPa) | A | B | N | C | ||

|---|---|---|---|---|---|---|---|---|

| Dry | 2040 | 16.16 | 0.041 | 0.00441 | 0.30 | 0.83 | 0.87 | 0.0061 |

| Saturated | 2099 | 12.51 | 0.032 | 0.00313 | 0.46 | 0.72 | 0.61 | 0.0063 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Mu, C.; Qin, Y.; Zhou, H.; Xie, Q. Dynamic Tensile Response of Seawater Coral Aggregate Concrete (SCAC) in Saturated State: Experimental and Numerical Simulation Study. Buildings 2025, 15, 1897. https://doi.org/10.3390/buildings15111897

Li R, Mu C, Qin Y, Zhou H, Xie Q. Dynamic Tensile Response of Seawater Coral Aggregate Concrete (SCAC) in Saturated State: Experimental and Numerical Simulation Study. Buildings. 2025; 15(11):1897. https://doi.org/10.3390/buildings15111897

Chicago/Turabian StyleLi, Rui, Chaomin Mu, Yulin Qin, Hui Zhou, and Quanmin Xie. 2025. "Dynamic Tensile Response of Seawater Coral Aggregate Concrete (SCAC) in Saturated State: Experimental and Numerical Simulation Study" Buildings 15, no. 11: 1897. https://doi.org/10.3390/buildings15111897

APA StyleLi, R., Mu, C., Qin, Y., Zhou, H., & Xie, Q. (2025). Dynamic Tensile Response of Seawater Coral Aggregate Concrete (SCAC) in Saturated State: Experimental and Numerical Simulation Study. Buildings, 15(11), 1897. https://doi.org/10.3390/buildings15111897