Abstract

Composite reinforcement concrete square piles exhibit excellent bending resistance and deformation capacity, along with construction advantages such as ease of transportation. In recent years, they have been widely adopted in building pile foundation applications. However, their seismic behavior, particularly under multi-directional excitation, remains inadequately explored. This study employs large-scale shaking table tests to evaluate the seismic response of a single composite reinforcement square pile embedded in a soft clay foundation under different horizontal excitations (0° and 45°) and two distinct ground motions (Wenchuan Songpan and Chi-Chi) to assess directional anisotropy and resonance effects, with explicit consideration of soil–structure interaction (SSI). The key findings include the following: the dynamic earth pressure along the pile exhibits a distribution pattern of “large at the top, small at the middle and bottom”. And SSI reduced pile–soil compression by 20–30% under 45° excitation compared to 0°. The dynamic strain in outer longitudinal reinforcement in pile corners increased by 30–60% under 45° excitation compared to 0°. Under seismic excitation considering SSI, the bending moment along the pile exhibited an “upper-middle maximum” pattern, peaking at depths of 3–5 times the pile diameter. Axial forces peaked at the pile head and decreased with depth. While bending moment responses were consistent between 0° and 45° excitations, axial forces under 45° loading were marginally greater than those under 0°. The Chi-Chi motion induced a bending moment about four times greater than the Songpan motion, highlighting the resonance risks when the ground motion frequencies align with the pile–soil system’s fundamental frequency.

1. Introduction

Prestressed concrete pipe piles possess advantages such as high strength, standardized production, reliable quality, and low construction cost. In recent years, they have been widely used in industrial, civil, and municipal engineering projects [1,2,3]. However, due to their relatively small cross-sectional area, these piles often exhibit insufficient resistance to horizontal and bending loads, resulting in failure under combined axial compression and lateral seismic loading [4]. Compared with traditional pipe piles, prestressed concrete square piles not only retain the advantages of pipe piles, but also overcome their deficiencies in shear and bending capacity [5], while offering enhanced construction efficiency through ease of hoisting, transportation, and on-site stacking. Therefore, many scholars have conducted extensive research on the mechanical properties of prestressed concrete square piles.

Budek et al. [6] carried out quasi-static tests on prestressed concrete solid square piles and pipe piles and found that pipe piles exhibited poor energy dissipation and brittle failure. Consequently, pipe piles should ideally remain in the elastic range during seismic events, while solid square piles can be considered for seismic applications in the plastic range. Gong et al. [7] conducted cyclic loading experiments to study the seismic performance of prestressed concrete solid square piles. The results revealed that all specimens exhibited typical flexural failure characteristics. Under low axial force ratios, the failure mode of such piles was the tensile fracture of prestressed tendons, whereas under higher axial force ratios, failure was dominated by the crushing of the concrete in the compression zone. Ni et al. [8] performed quasi-static tests on the joints between prestressed hollow square piles and pile caps. They found that although diagonal loading represents the weak direction in static loading, the joints exhibited better deformation capacity and energy dissipation than those under principal axis loading. Liu et al. [9] conducted field tests under cyclic lateral loads on composite reinforcement concrete hollow square piles and observed that pure prestressed hollow square piles exhibited brittle failure, whereas the addition of non-prestressed reinforcement improved the ductility and lateral load-bearing capacity. Zheng et al. [10] conducted in situ quasi-static tests on composite reinforcement concrete hollow square piles under natural soil conditions. Through a comparative analysis of hysteresis curves, they demonstrated that incorporating non-prestressed reinforcement significantly improves the seismic performance of prestressed concrete piles, and that there exists an optimal non-prestressed reinforcement ratio. Xu et al. [11,12] conducted a series of full-scale bending and shear tests on composite reinforcement concrete prefabricated square piles. Their bending tests indicated that while prestressing increased the cracking load, it led to a decrease in the ultimate bending capacity. Shear tests revealed two failure modes: diagonal shear and flexural failure. Prestressing was found to inhibit crack propagation and raise the cracking shear force. Wang et al. [13] proposed a novel pile type—prestressed composite reinforcement solid square pile with steel strands—by combining the strengths of prestressed pipe piles, solid square piles, and steel strands. Full-scale bending tests and finite element simulations demonstrated that this new pile type achieves both high flexural capacity and excellent ductility. Parametric analysis was conducted through numerical simulations to identify the optimal reinforcement ratio. Composite reinforcement concrete square piles, as a category of prestressed square piles, integrate prestressed and non-prestressed reinforcement synergistically, achieving both a high crack resistance and energy dissipation capacity. However, most studies on the mechanical behavior of square piles have focused on unidirectional loading, with limited investigation into multidirectional responses. While the anisotropy of square cross-sections has been extensively investigated for reinforced concrete square columns [14,15,16,17], the direction of applied loading is found to have a significant effect on their load-bearing capacity and failure modes. Notably, since seismic excitation directions are inherently random, understanding directional effects is critical for prestressed square piles’ design.

The primary methodologies for evaluating the seismic performance of pile foundations include quasi-static tests, numerical simulations, and shaking table tests. Existing studies on the seismic performance evaluations of prestressed square piles predominantly rely on cyclic quasi-static tests. While such tests provide insights into structural behavior under repetitive loading, they inherently neglect the critical soil–pile interaction mechanisms present in real-world engineering scenarios. Furthermore, although advanced numerical simulations of soil–pile structure interaction have been developed, their accuracy is constrained by soil constitutive modeling, spatial variations in ground excitation, and its associated uncertainties [18]. In contrast, shaking table tests offer a more comprehensive approach by incorporating essential ground motion characteristics including frequency, amplitude, and duration—thereby enabling realistic simulations of seismic effects on pile foundations [19,20,21].

Although numerous researchers have conducted shaking table tests to investigate the seismic response of pile foundations, the majority of studies have focused on traditional pipe piles, with very few addressing square pile configurations. The following section reviews recent advancements in shaking table tests investigating the seismic performance of pipe pile foundations. Zhao et al. [22] conducted shaking table tests on high-cap pile group foundations. Based on an elastic similarity model with a geometric scale of 1/8, micro-concrete was used to fabricate model piles. The tests demonstrated that high-cap pile systems exhibited two bending extreme points: one at the pile head connected to the cap and another 1.5D–2D pile diameter below the ground surface. In contrast, low-cap piles showed a single bending extreme point at the pile head. Additionally, lateral dynamic earth pressure was more effectively mobilized in low-cap pile systems. Feng et al. [23] performed shaking table tests on socketed single piles with a geometric similarity ratio of 1/30. Model piles were fabricated using materials identical to those of the prototype piles. The results indicated that the acceleration time history response at the pile top closely matched the input seismic motion, with peak values significantly exceeding those at the pile base. Under different types of ground motions, the bending moment distribution along the pile exhibited a “3-shaped” pattern. Zhang et al. [24] investigated the dynamic response of prestressed high-strength concrete (PHC) pipe piles through shaking table tests. By focusing on key physical similarity ratios, a geometric scale of 1/3 was adopted and equivalent flexural and shear capacities were ensured. The model piles were constructed using prototype materials. The study revealed that compared to near-field ordinary ground motions, near-field pulse-type motions induced larger peaks in the dynamic time history curves at the pile head. The bending moment distribution followed a “larger in the upper-middle, smaller at both ends” pattern, and the dynamic earth pressure increased with seismic intensity, primarily driven by relative pile–soil displacement. In conclusion, shaking table tests serve as an effective methodology for replicating seismic responses and investigating the dynamic behavior of piles.

To address the existing research gaps in composite reinforcement concrete square piles’ seismic behavior, this study conducts large-scale shaking table experiments on composite-reinforced square pile foundations. Given the inherent geometric anisotropy of square cross-sections—exhibiting distinct mechanical behaviors along the principal axis (0°) versus the diagonal axis (45°)—the experiments systematically evaluate multi-directional dynamic responses under horizontal seismic excitation. The outcomes aim to provide actionable insights for optimizing the engineering design and applications of composite reinforcement concrete square piles.

2. Shake Table Test Design

2.1. Test Overview

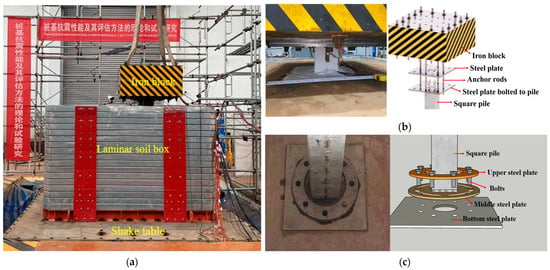

The experiment employed a three-directional six-degree-of-freedom shaking table with a total payload capacity of 20 tons, coupled with a bidirectional laminar shear soil container. To investigate the seismic response of composite reinforcement concrete square piles in soft clay foundations, a single model pile was tested on a shake table. A laminated shear box was used as the model boundary, with the soil container bolted to the table surface, as shown in Figure 1a. The container measured 2.0 m (length) × 1.9 m (width) × 1.85 m (height). To simulate the inertial forces generated by the superstructure, a single mass block (6 tons, designed within the shaking table’s payload constraints) was fixed to the pile top via anchor rods, as shown in Figure 1b. To avoid the failure of the pile-bearing capacity, the pile tip was fixed to the container base, as shown in Figure 1c.

Figure 1.

Photographs of shake table test setup. (a) Global view. (b) Pile top–superstructure connection (connection between pile and upper structure). (c) Pile tip–base connection(connection between pile and table base).

2.2. Similarity Design and Model Pile Fabrication

The prototype composite reinforcement concrete square pile is a prestressed concrete steel strand square pile with a 400 mm × 400 mm cross-section and C70-grade concrete. The prestressed reinforcement included eight AS9.5 steel strands, while non-prestressed reinforcement included four hot-rolled ribbed bars with a diameter of 18 mm. Spiral stirrups were 4 mm cold-drawn steel wire spaced at 100 mm intervals.

In shaking table tests involving soil–pile structure interaction (SSI), achieving complete similarity between the model and prototype is challenging due to the multitude of physical variables influencing dynamic responses. To address this, an elastic similarity model was adopted for this study [25], prioritizing equivalence in elastic restoring forces and inertial forces. Key considerations included experimental objectives, shaking table specifications, and model fabrication feasibility. A geometric similarity ratio of 0.5 was selected, with elastic modulus and density similarity ratios fixed at 1.0. Using Buckingham’s π-theorem [26], additional similarity ratios for critical parameters were derived, as summarized in Table 1.

Table 1.

Similarity ratios of physical quantities in the model test system.

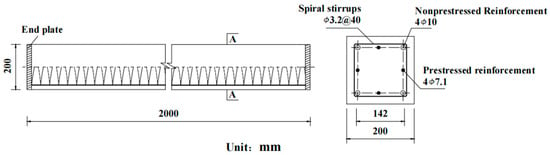

Guided by these similarity principles and equivalence criteria for flexural capacity and shear capacity [27], the model pile was designed with a 200 mm × 200 mm cross-section and a 29 mm concrete cover. The concrete retained the prototype’s C70 strength. As shown in Figure 2, the prestressed reinforcement consisted of four steel rods with a diameter of 7.1 mm. While the non-prestressed reinforcement included four hot-rolled steel bars with a diameter of 10 mm, spiral stirrups were fabricated from 3.2 mm galvanized iron wire spaced at 40 mm intervals.

Figure 2.

Dimension and reinforcement details of model pile (unit: mm).

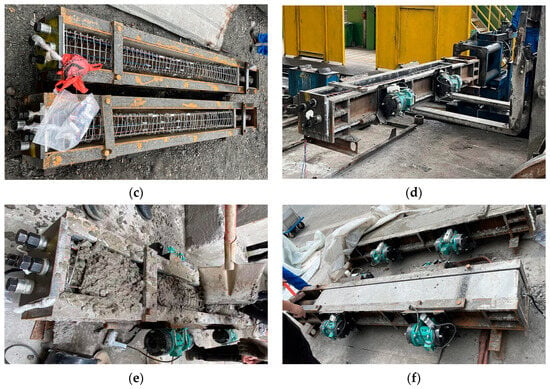

As illustrated in Figure 3, the fabrication process of the composite reinforcement concrete mold square pile included six steps: 1. fabrication of the mold for the model pile; 2. fabrication of the model pile steel cage; 3. installation of the cage into the mold; 4. tensioning of prestressed tendons and placement of vibrators; 5. pouring and vibrating the concrete; and 6. standard curing and removal of the mold.

Figure 3.

The composite reinforcement concrete square model pile fabrication process: (a) mold; (b) steel cage; (c) cage installation; (d) prestress tensioning; (e) concrete pouring; and (f) curing and demolding.

2.3. Model Soil Preparation

The model soil was prepared using in situ clay subjected to air-drying, mechanical crushing, and sieving (<2 mm particle size). Water was added to achieve a target moisture content of 23.12%, followed by layer-by-layer static compaction to a final height of 1.80 m. The physical parameters were determined through standardized geotechnical tests [28], with the results summarized in Table 2.

Table 2.

Physical parameters of model soil.

After soil compaction work, shear wave velocity () measurements were conducted to validate the dynamic similarity between the model and the prototype. The model foundation exhibited a of 95.7 m/s, closely aligning with the prototype’s site value of 106.7 m/s. This correspondence approximates the theoretical scaling relationship derived from the velocity similarity ratio ( = 1), confirming consistent shear stiffness characteristics under scaled conditions.

2.4. Test Instruments

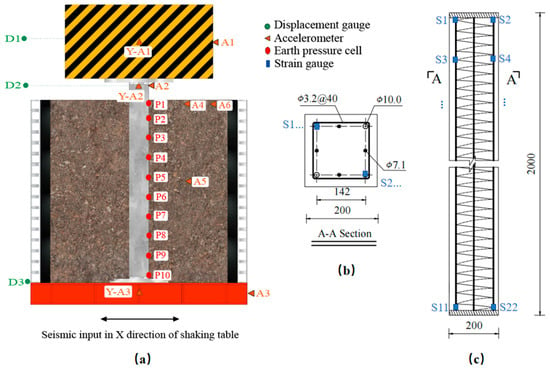

Sensors were arranged along the X and Y centerlines of the test setup, including accelerometers, displacement transducers, earth pressure cells, and strain gauges, as illustrated in Figure 4. Accelerometers (A1–A3 and YA1–YA3) were positioned at three critical locations: the superstructure, pile top, and container base. Additional accelerometers (A4 and A6) monitored the soil surface, while A5 was embedded at mid-soil depth. Three displacement transducers (D1–D3) monitored movement at the superstructure centroid, pile top, and container base. Ten earth pressure sensors (P1–P10) were uniformly distributed along the pile–soil interface on one side of the pile, spaced vertically at 200 mm intervals. For strain monitoring, 22 strain gauges (S1–S22) were affixed to longitudinal rebars on the pile’s outer periphery. These gauges were grouped in pairs at 11 cross-sections, spaced 200 mm apart vertically, enabling deformation measurements across critical pile segments (Figure 4b,c).

Figure 4.

Schematic of shake table test: (a) front view, (b) pile section, and (c) pile reinforcement.

2.5. Input Motion and Test Protocol

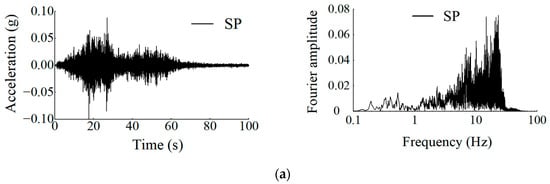

Two actual earthquake records were selected: the Wenchuan Songpan (SP) high-frequency ground motion and the Chi-Chi (CC) low-frequency motion. SP is from the 2008 Wenchuan earthquake (Mw = 7.9, 184.4 km); CC is from the 1999 Chi-Chi earthquake (Mw = 6.2, 85.4 km). The dominant frequency of CC (4.7 Hz) closely matches the pile’s natural frequency (3.1 Hz), while SP’s dominant frequency is 23.3 Hz. Figure 5 shows the time histories and Fourier spectra of the selected records.

Figure 5.

Time histories and frequency content of input ground motion. (a) SP. (b) CC.

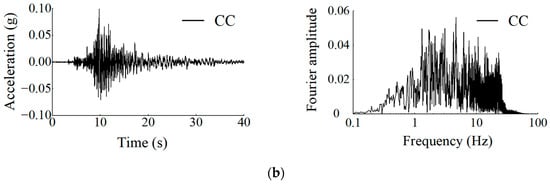

For 0° loading, input was applied in X only. For 45° loading, input was applied in both X and Y scaled by , as shown in Figure 6.

Figure 6.

Shaking table loading mechanism for seismic actions at different orientations. (a) 0° orientation. (b) 45° orientation.

Peak ground accelerations (PGAs) were set at 0.05 g and 0.10 g. White noise (WN) was used to assess the natural frequency of the test model before ground motion loading. Table 3 lists the test cases.

Table 3.

Test cases.

3. Experimental Results and Analysis

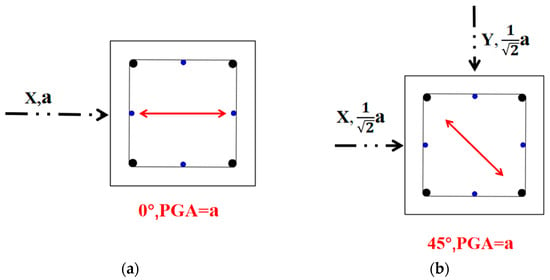

3.1. Dynamic Characteristics of the System

Figure 7 shows the changes in the natural frequencies of the pile–superstructure system and the foundation soil under white noise excitation. Within the seismic intensity of 0.1 g, the natural frequencies of the pile–superstructure system and soil exhibited no significant attenuation after multiple test cases.

Figure 7.

The change in the natural frequency of the system.

The frequency deviation of the pile–superstructure system was less than 0.1 Hz (within 3% fluctuation), and that of the foundation soil was less than 0.5 Hz (within 4%). These results indicate that the model system experienced no obvious cumulative damage and remained in the linear elastic range during testing.

3.2. Seismic Response of Foundation Soil

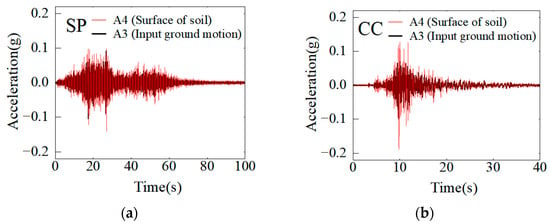

Figure 8 compares the acceleration time histories of the soil surface (A4) and shaking table base (A3) under 0° horizontal SP and CC excitation at 0.1 g PGA. While the waveform exhibited similar shapes, the soil surface experienced significant acceleration amplification relative to the base input. Quantitatively, the peak ground acceleration (PGA) amplification factors reached 1.37 for the SP motion and 1.88 for the CC motion.

Figure 8.

Comparison of acceleration time history curves. (a) SP. (b) CC.

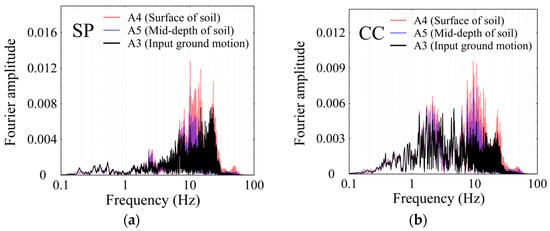

Figure 9 presents the Fourier amplitude spectra at three distinct depths (A4: surface of soil, A5: mid-depth of soil, and A3: shaking table base). The frequency content of the seismic waves underwent significant changes during their propagation toward the ground surface. Notably, frequency components within the 8–15 Hz range exhibited pronounced amplification at the soil surface (A4), closely aligned with the soil’s natural frequency of 12 Hz. This frequency-selective amplification mechanism confirms that soft clay foundations preferentially amplify seismic energy within their resonance band.

Figure 9.

Comparison of acceleration Fourier spectra. (a) SP. (b) CC.

3.3. Dynamic Soil Pressure at the Pile–Soil Interface

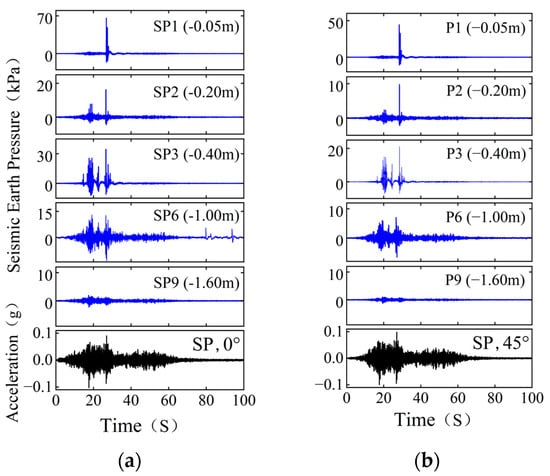

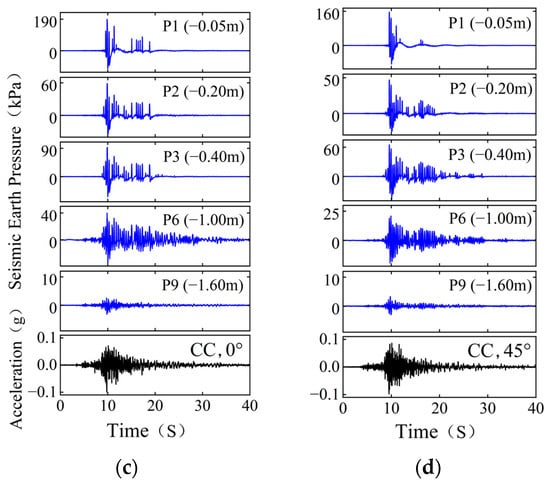

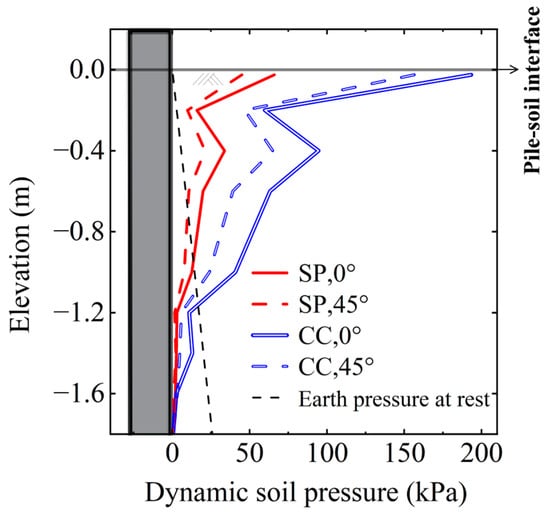

Figure 10 illustrates dynamic earth pressure time histories at various depths along the pile under 0.1 g SP and CC excitation in both 0° and 45° directions.

Figure 10.

Time history curves of dynamic soil pressure. (a) SP—0°. (b) SP—45°. (c) CC—0°. (d) CC—45°.

Near the pile bottom, the response patterns of dynamic earth pressure closely mirrored the input ground motion waveforms, indicating a negligible influence from superstructure inertia. As the elevation increased, the amplitudes of positive soil pressure progressively intensified, and the time histories transitioned to a cyclic pattern, alternating between zero and positive values—reflecting the repeated intermittent interfacial detachment and recontact between the pile and surrounding soil during seismic loading.

Figure 11 compares the maximum dynamic earth pressure distribution along the pile against the static earth pressure profile [29] (dashed line). The dynamic pressure envelopes exhibited a nonlinear “top-heavy” distribution. Notably, CC excitation induced greater pressures than SP, indicating that the ground motion type significantly affects the pile–soil interface behavior.

Figure 11.

Dynamic soil pressure envelopes.

Under 45° loading, dynamic pressures were marginally lower at all depths compared to at 0° excitation. For instance, the peak pressure at the soil surface (−0.05 m) under CC and SP motions decreased by 28.8% and 20.5%, respectively. This reduction stems from the multidirectional compressive engagement of all four pile sides at 45°, in contrast to the two-side contact under 0° loading. The increased interfacial contact area under diagonal excitation promotes force redistribution and localized stress dissipation.

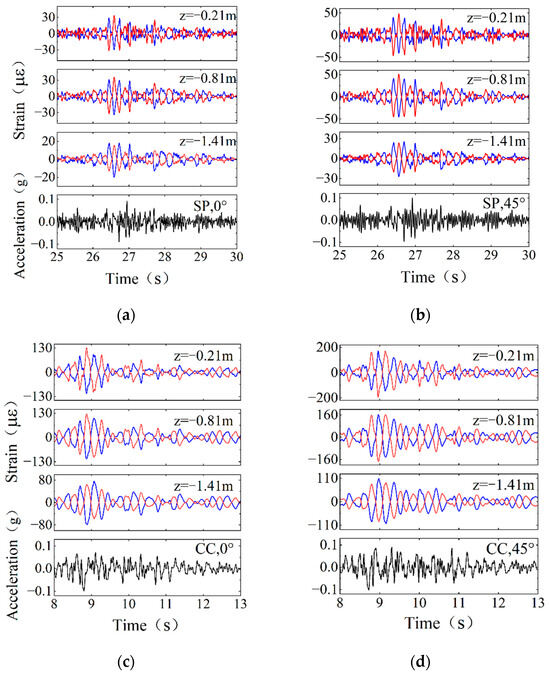

3.4. Response of Outer Longitudinal Reinforcement

Figure 12 displays the dynamic strain time histories of the outer longitudinal reinforcements at both sides of the pile under 0° and 45° SP and CC ground motions, captured near the peak acceleration phase of the input seismic excitation. As exemplified by the cross-section at −0.21 m elevation, the red and blue curves represent the strain data from gauge S5 and processed data from gauge S6, respectively. The strain profiles at all monitored elevations exhibited comparable amplitudes but opposite phases between opposed reinforcements, indicating that during seismic loading, the pile consistently maintained that one side was in tension and the other in compression due to dynamic bending. This behavior demonstrates that the pile deformation was predominantly flexural under seismic excitation.

Figure 12.

Dynamic strain on the outer edge steel bars. (a) SP—0°. (b) SP—45°. (c) CC—0°. (d) CC—45°. Red/blue lines show strain time histories of opposite-side longitudinal reinforcements (exemplified at −0.21 m: S5/S6 data).

The strain magnitudes under CC excitation significantly exceeded those observed under SP loading. For instance, at the elevation −0.81 m under 0° excitation, the peak strain reached 121.2 × 10−6 for CC motion, compared to only 35.6 × 10−6 for SP motion. This is attributed to resonance, as the predominant frequency of CC (4.7 Hz) was closer to the pile’s fundamental frequency (3.1 Hz) than that of SP (23.3 Hz).

Statistical analysis further revealed that strains under 45° loading exceeded those under 0° by 30–60%. This directional sensitivity stems from differences in reinforcement engagement: in 0° loading, three longitudinal bars (two non-prestressed and one prestressed) were positioned farthest from the neutral axis and collectively resisting deformation. Under 45° loading, only one non-prestressed bar was positioned farthest from the neutral axis and bore the majority of the flexural strain. These result in the amplified deformation of the outer longitudinal reinforcements at both sides of the pile under 45° loading.

3.5. Internal Force Response of the Pile

The bending moments (M) and axial forces (N) of the pile body caused by seismic excitation were calculated from strain data using the following equations:

In the formulas, E is the elastic modulus, I is moment of inertia, A is the cross-sectional area, ε1 and ε2 are the paired strain readings, and r is the distance from the neutral axis to the bar.

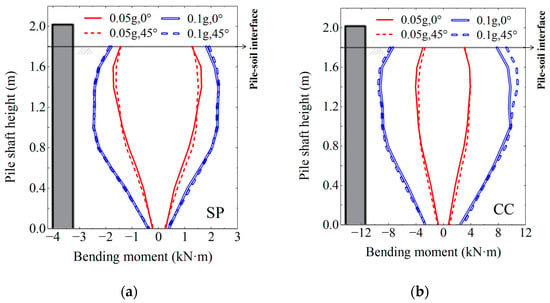

Figure 13 shows the bending moment envelopes. The pile exhibited a distribution of large moments in the upper-middle portion and small moments at the ends. The maximum moment occurred at 3–5 times the pile diameter from the top.

Figure 13.

Bending moment envelopes of square pile. (a) SP. (b) CC.

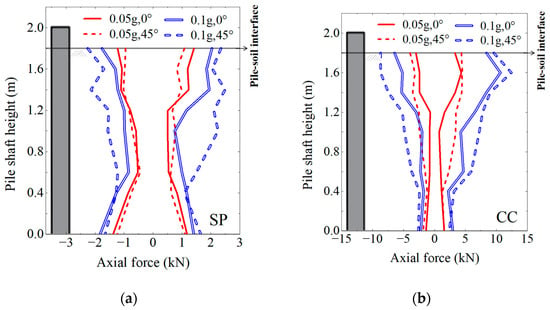

Figure 14 shows the axial force envelopes, with the largest axial force at the pile top, gradually decreasing with depth. That is because under SSI, the dynamic axial force in the pile is primarily governed by the overturning moment of the superstructure and the reaction of the surrounding soil.

Figure 14.

Axial force envelopes of square pile. (a) SP. (b) CC.

The Chi-Chi (CC) ground motion induced significantly larger internal forces than the Songpan (SP) motion, primarily due to the resonance effects. For instance, under the 0.1 g PGA condition, the maximum bending moment generated by the CC motion reached 10.86 kN·m, approximately four times greater than the 2.30 kN·m observed under the SP motion.

The bending moment profiles were similar under 0° and 45° inputs due to the pile’s symmetric cross-section and reinforcement layout. However, the axial forces were obviously higher under seismic loading at 45°, and the increase was less than 50%, primarily due to the increased instability of the mass block. This is because seismic excitation at 45° induces greater deformation in the outer edge reinforcement of the square pile, leading to more pronounced pile body distortion. As a result, the upper mass block becomes more unstable, thereby triggering a stronger dynamic axial force response.

4. Conclusions

To investigate the dynamic response characteristics of the composite reinforcement concrete square pile embedded in clay foundations under horizontal seismic excitation from different directions (0° principal axis and 45° diagonal direction), large-scale shaking table tests were conducted. The influence of both the seismic input direction and ground motion type on the seismic behavior of the composite reinforcement square pile was analyzed. The main conclusions are as follows:

- Amplification and filtering effects exist in clay foundations under seismic excitation. The surface acceleration is amplified compared to the base input, particularly enhancing components near its natural frequency;

- Under horizontal seismic loading, dynamic earth pressure along the pile exhibits a ‘large at the top, small at the bottom’ distribution pattern. Near the ground surface, due to the intermittent contact and separation between the pile and soil, the time history of dynamic earth pressure fluctuates periodically between zero and positive values. Furthermore, under 45° seismic excitation, the intensity of pile–soil compressive interaction is marginally weakened by approximately 20% to 30%;

- The 45° loading direction is more sensitive to the deformation of the outer reinforcement bars at the pile corners. Compared to the 0° direction, the dynamic strain response of the outer longitudinal reinforcement under 45° seismic excitation increased by approximately 30% to 60%;

- Considering soil–structure interaction (SSI), the seismic bending envelopes along the pile exhibit a distribution pattern of ‘larger at the upper-middle section, smaller at both ends’, with peak values occurring at a location 3–5 times the pile diameter from the top. Additionally, the bending moment responses are generally consistent between 0° and 45° due to the pile’s symmetric shape and reinforcement layout;

- Considering SSI, the maximum axial force occurs near the pile top. Additionally, compared to 0°, 45° seismic excitation results in a larger axial force response (less than 50%), indicating more significant pile deformation and the reduced stability of the superstructure mass under diagonal excitation;

- The internal force response of the pile is influenced by the input ground motion type: the Chi-Chi (CC) ground motion, with a predominant frequency closer to the natural frequency of the pile, induces significantly greater internal forces than the Songpan (SP) motion. For instance, under the 0.1 g PGA, the bending moment of the pile induced by the CC ground motion was approximately four times greater than that induced by the SP ground motion.

While this study advanced the understanding of the multi-directional seismic responses (0° and 45°) of single composite-reinforced square piles under medium- and low-intensity excitation (PGA ≤ 0.1 g), it did not address two critical aspects: pile group interaction effects and damage progression under high-intensity excitation. To bridge these gaps, future work should integrate the following: (1) High-intensity multi-directional tests. Conduct shaking table tests on pile groups subjected to extreme seismic inputs to quantify the damage initiation thresholds, including concrete crushing, rebar buckling, and prestress loss. (2) Group effect mechanisms. Analyze load-sharing behaviors, soil–pile kinematic constraints, and progressive failure patterns in clustered configurations. These efforts will enable the development of robust design frameworks for composite reinforcement concrete square pile foundations in seismically active regions.

Author Contributions

Conceptualization, G.G.; methodology, G.G. and C.F.; validation, G.G. and C.F.; formal analysis, C.F., K.C. and K.F.; investigation, C.F., K.C. and K.F.; resources, G.G.; data curation, C.F.; writing—original draft preparation, C.F.; writing—review and editing, G.G.; visualization, C.F.; supervision, G.G.; project administration, G.G.; funding acquisition, G.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Housing and Urban-Rural Development Science and Technology Program Project (2021-K-030).

Data Availability Statement

The original contributions of this study are thoroughly detailed in this manuscript. For further inquiries, please contact the corresponding author directly.

Acknowledgments

The input earthquake motion data of Songpan in this study are provided by the Strong Motion Observation Center, Institute of Engineering Mechanics, China Earthquake Administration.

Conflicts of Interest

Authors Gang Gan and Kepeng Chen were employed by the company The Architectural Design & Research Institute of Zhejiang University Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wang, Y.; Sang, S.; Zhang, M. Investigation on in-situ test of penetration characteristics of open and closed PHC pipe piles. Soils Found. 2021, 61, 960–973. [Google Scholar] [CrossRef]

- Ding, X.; Gao, J.; Li, S. Application analysis of PHC pile and CFG pile on sandy ground in Xi’an area. J. Ground Improv. 2023, 5, 498–505. [Google Scholar]

- Hou, Z.; Liu, Y.; Han, Z. Experimental study of the bearing characteristics of a novel energy-saving and environmentally friendly pile: Drilling with prestressed concrete pipe cased piles. Int. J. Geomech. 2024, 24, 04024035. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Liu, K. Seismic performance of prestressed high-intensity concrete pile. J. Hebei Univ. Technol. 2013, 42, 99–103. [Google Scholar]

- Xu, Q.B. Composite Reinforced Concrete Prefabricated Square Pile; Zhejiang University Architectural Design and Research Institute Co., Ltd.: Hangzhou, China, 27 April 2016. [Google Scholar]

- Budek, A.; Benzoni, G.; Priestley, M. Experimental Investigation of Ductility of In-Ground Hinges in Solid and Hollow Prestressed Piles; Structural Systems Research Project: San Diego, CA, USA, 1997. [Google Scholar]

- Gong, S.; Zhao, Y.; Fan, H. Experimental study on seismic performance of prestressed concrete solid square piles. Adv. Struct. Eng. 2024, 27, 2444–2462. [Google Scholar] [CrossRef]

- Ni, G.; Yang, J.; Pan, P. Quasi-static Tests of Pile-cap Connections for the prestressed Spun Concrete square piles. China Earthq. Eng. J. 2013, 35, 246–251. [Google Scholar]

- LIU, C.; HU, Q.; ZHENG, G. Experimental study on seismic performance of hollow square concrete pile with combined prestressed and non-prestressed steel bar. J. Build. Struct. 2020, 41, 166–175. [Google Scholar]

- Zheng, G.; Liu, C.; Liu, Y. Experimental study on horizontal bearing behaviors of different pile types of full-scale piles under reciprocating horizontal loads. Chin. J. Geotech. Eng. 2019, 41, 32–40. [Google Scholar]

- Xu, Q.B.; Chen, G.; He, J.F.; Gong, S.F.; Xiao, Z.B. Flexural performance experiment of connection joint for composite reinforcement concrete prefabricated square piles. J. Zhejiang Univ. Eng. Sci. 2017, 51, 1300–1308. [Google Scholar]

- Xu, Q.B.; Chen, G.; Gong, S.F. Experimental research on shear behavior of composite reinforcement concrete prefabricated square piles. Ind. Constr. 2017, 47, 102–108+165. [Google Scholar]

- Wang, H.Y.; Gan, G.; Zeng, K.; Chen, K.P.; Yu, X.D. Study on Flexural Performance of Prestressed Concrete Steel Strand Square Piles with Reinforcement. Buildings 2022, 12, 1801. [Google Scholar] [CrossRef]

- Du, H.B. Seismic performance of biaxially loaded reinforced concrete columns. J. Harbin Univ. Civ. Eng. Archit. 1999, 4, 47–52. [Google Scholar]

- Qiu, F.W.; Li, W.F. Bidirectional quasi-static test study on reinforced concrete columns. J. Build. Struct. 2001, 22, 26–31. [Google Scholar]

- Pham, T.P.; Li, B. Seismic behavior of reinforced concrete columns with light transverse reinforcement under different lateral loading directions. ACI Struct. J. 2013, 110, 833–843. [Google Scholar]

- Zhang, H.Y.; Qu, B.W.; Mao, C.X. Experimental study on seismic performance of reinforced concrete columns under horizontally bidirectional cyclic loading. China Civ. Eng. J. 2019, 52, 49–61+71. [Google Scholar]

- Çetindemir, O. A review of modeling issues on the seismic soil-pile-structure interaction. KSCE J. Civ. Eng. 2025, 28, 3359–3377. [Google Scholar] [CrossRef]

- Tokimatsu, K.; Suzuki, H.; Sato, M. Effects of inertial and kinematic interaction on seismic behavior of pile with embedded foundation. Soil Dyn. Earthq. Eng. 2005, 25, 753–762. [Google Scholar] [CrossRef]

- Wang, X.; Ye, A.; Shang, Y.; Zhou, L. Shake-table investigation of scoured RC pile-group-supported bridges in liquefiable and nonliquefiable soils. Earthq. Eng. Struct. Dyn. 2019, 48, 1217–1237. [Google Scholar] [CrossRef]

- Xu, C.S.; Jia, K.M.; Du, X.L.; Wang, Z.H.; Song, J.; Zhang, X.L. Review on seismic behavior of pile foundation subjected to liquefaction-induced lateral spreading. J. Disaster Prev. Mitig. Eng. 2021, 41, 768–791. [Google Scholar]

- Feng, Z.J.; Zhang, C.; He, J.B. Shaking table test on time-history response of rock-socketed single pile under strong earthquake. Rock Soil Mech. 2021, 42, 3227–3237. [Google Scholar]

- Zhao, X.G.; Gao, W.S. Experimental study on seismic response of pile group foundation with high-cap by shaking table. Build. Struct. 2019, 49, 120–129. [Google Scholar]

- Zhang, H.; Wang, F.; Lyu, Z.; Zhao, Z.; Liu, Z.; Mao, Z. Shake-table test on dynamic response of prestressed high-strength concrete pipe piles under soil-structure interaction. Soil Dyn. Earthq. Eng. 2023, 174, 108159. [Google Scholar] [CrossRef]

- Lin, G.; Zhu, T.; Lin, B. Similarity techniques for dynamic model tests of structures. J. Dalian Univ. Technol. 2000, 1, 1–8. [Google Scholar]

- Yang, J.; Lu, Z.; Li, P. Large-scale shaking table test on tall buildings with viscous dampers considering pile-soil-structure interaction. Eng. Struct. 2020, 220, 110960. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Standards Press: Beijing, China, 2015.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Standards Press: Beijing, China, 2019.

- GB 50007-2011; Code for Design of Building Foundation. China Standards Press: Beijing, China, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).