Abstract

This study investigated the effects of natural polysaccharides—guar gum (GG) and xanthan gum (XG)—on the properties and structure of illitic clay. Clay samples were prepared using five different GG and XG solutions, with polysaccharide concentrations of 0.5%, 1.0%, 1.5%, 2.0%, and 2.5%. The physical, mechanical, and hygroscopic properties of the samples were evaluated, along with water erosion resistance and structural characteristics, using SEM analysis. The addition of GG or XG significantly increased compressive strength and water erosion resistance, reduced shrinkage, and slightly improved the bulk density compared to the control clay sample. The results showed that compressive strength increased by 28–63% and 46–84% with the incorporation of GG and XG solutions, respectively. These findings suggest that environmentally friendly clay-based building materials can be effectively produced even using small amounts of natural polysaccharides.

1. Introduction

Unfired materials represent an eco-friendly building option that has regained popularity over the past decade. Typically, unfired clay materials are produced using raw materials such as clay, earth, and soil, along with various additives, including chemical stabilizers like cement [1,2,3], lime [4,5,6], gypsum [7,8,9], and natural fibers [10,11,12,13,14,15,16,17], and others [13,18,19,20,21]. Previous research [22,23,24,25,26,27,28] has demonstrated that biopolymers offer environmentally friendly alternatives and can be effectively used to enhance the properties of clay materials. Biopolymers can be classified into polysaccharides, proteins, lipids, and other complex molecules [29]. Some authors propose classifying biopolymers according to their nature, origin, and molecular structure [30], as well as their biodegradability [31,32].

Nakamatsu et al. [23] studied the effect of carrageenan on earthen construction, where the biopolymer was applied either as a coating layer or as an additive within the clayey matrix. Increases in compressive strength of up to 85% and tensile strength of up to 52% were observed. Additionally, even a 0.5% concentration of carrageenan solution provided improved protection against water erosion. The carrageenan admixture enhances durability by forming a water-repellent protective layer on the earthen surface and binding soil particles within the studied samples.

In the research [33], it was found that the highest compressive strength of 3.65 MPa and flexural strength of 0.58 MPa were achieved by using a 2.5% chitosan additive in soil samples. The soil strength achieved with a cement additive was even lower: Samples containing 2.5% chitosan exhibited, on average, 27% higher compressive strength and 11% higher flexural strength compared to samples stabilized with 8% cement after 28 days of curing. Mixing chitosan hydrogels with soil and water forms a structure that binds soil particles, thereby increasing the durability, as confirmed by immersion, suction, and contact test results. Chitosan-modified samples showed no visible cracks in contact and suction tests, similar to cement-stabilized samples, and had lower mass loss in immersion tests compared to unstabilized soil. Moreover, soil samples containing 2.5% chitosan exhibited significantly lower embodied energy (30.37 MJ/m3) and CO2 emissions (88.4 kg CO2/m3) compared to cement-stabilized mixtures (192.50 MJ/m3 and 145.43 kg CO2/m3) [33]. Aguilar et al. [34] also reported that 0.5% and 3% chitosan-coating solutions were effective in creating a water-repellent surface on the samples, with a contact angle of approximately 90°. The authors [23,34] suggested that the improvement in mechanical properties and durability is due to the strong adhesion of chitosan hydrogels to the surface of soil particles.

The study [24] presents findings aimed at improving the properties of earthen construction materials through the use of guar and xanthan gums as stabilizers. It was found that the compressive strength of the earth samples after 28 days increased by 30% and 50%, respectively, with the addition of 2% guar or xanthan gum, compared to soil stabilized with 8% cement. Additionally, using 2.5% xanthan gum increased the tensile strength of the soil samples by 38% after 28 days, compared to earth samples stabilized with 8% cement. Xanthan gum, as a natural stabilizer for different types of soils, was also studied by Chang et al. [25]. It was found that xanthan gum, together with fine soil particles, acts as a binder between coarse particles, significantly increasing the compressive strength of the studied soils. Research [26] demonstrated the application of thermo-gelling biopolymers (gellan and agar gum) for the stabilization of different soil types. The results showed that proper selection of the thermal treatment steps for the biopolymers is crucial. The compressive strength of the resulting soil materials reached 12 MPa, with a significant enhancement in their durability.

Research [35] highlighted the positive effects of combining natural fibers (5 mm and 15 mm lengths of palm and date palm fibers at dosages of 1.5% and 3%) with 1% to 2% biopolymers (xanthan gum and sodium hexametaphosphate) in the development of clay-based building materials. The addition of natural fibers alone negatively affected the sample structure, leading to reduced density and compressive strength. However, incorporating 1.5% fibers of 10 mm length in combination with 1% xanthan gum resulted in clay samples achieving a compressive strength of up to 4.5 MPa. This synergistic effect is attributed to the rough surface texture of the fibers, which promotes effective stress transfer between the fibers and the soil matrix.

This study introduces a novel approach to modifying unfired clay materials using two natural polysaccharides, guar gum (GG) and xanthan gum (XG), to enhance their mechanical strength, hygroscopic behavior, and durability. By systematically varying polysaccharide concentrations from 0.5% to 2.5%, the research offers a comparative analysis of their effects on physical and mechanical properties, water erosion resistance, and microstructural features. The innovation lies in the hypothesis that even low dosages of biodegradable and renewable additives may significantly improve the performance of unfired clay materials, suggesting their potential for sustainable and resilient building applications.

2. Materials and Methods

2.1. Materials

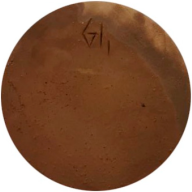

The clay used in this study was sourced from the “Palemono keramika” factory (Lithuania), where this clay is commonly used as a standardized raw material in the manufacture of fired clay-based products. The chemical and mineralogical composition of the studied clay is presented in Table 1 and Figure 1. The data indicate that illite, quartz, dolomite, kaolinite, feldspar, calcite, and chlorite are the predominant minerals. The composition of the studied clay is in good agreement with data reported for brickmaking clays (adobe, ceb, taipa bricks) in similar studies [36,37]. While a direct one-to-one comparison is not always possible due to regional and geological variations in clay deposits, the overall mineralogical profile (illite, quartz, and kaolinite phases) and oxide composition fall within the typical range observed for industrial clay materials used in brick production.

Table 1.

Chemical composition of clay.

Figure 1.

XRD analysis of clay (□—illite, ◊—quartz, ○—dolomite, ●—kaolinite, ▪—feldspar, ∆—calcite, ♦—chlorite).

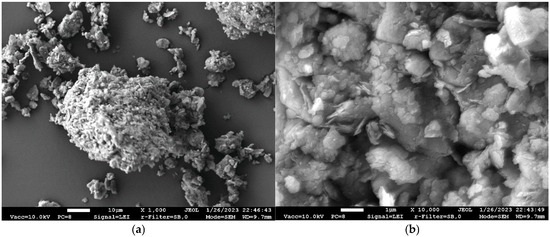

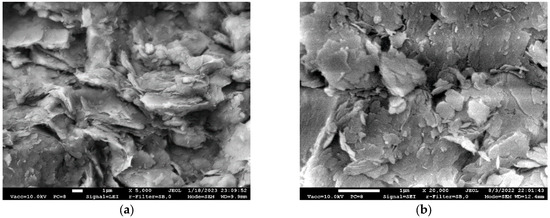

The particle size of the clay is as follows: >50 µm—4.34%, 50–10 µm—13.42%, 10–5 µm—16.56%, 5–1 µm—24.50%, <1 µm—41.18%. About 95% of clay particles are smaller than 50 μm, which may indicate good clay plasticity. Atterberg limits of clay are liquid limit 34%, plastic limit 16%, and plasticity index 18.0. The structure of the clay is shown in Figure 2. The layered clay particles are thin, with sizes ranging from approximately 0.3 to 1.2 µm, and are clumped together into agglomerates measuring 5 to 30 µm.

Figure 2.

SEM image of clay: (a,b) clay particle.

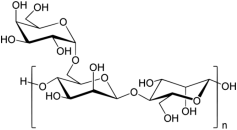

Xanthan gum (XG) and guar gum (GG) biopolymers were supplied in powder form by “Riposantas” and “Lerochem” companies, respectively, both based in Lithuania. Both GG and XG are classified as natural polysaccharides [38]. Guar gum is a plant-derived polysaccharide extracted from the seeds of the guar plant, primarily composed of galactomannans along with varying amounts of water, proteins, fibers, and ash [39]. Xanthan gum is an anionic polysaccharide of microbial origin, typically produced through the fermentation of glucose or sucrose by Xanthomonas campestris [40]. The characteristics of the studied polysaccharides are presented in Table 2.

Table 2.

Characteristics of the studied polysaccharides.

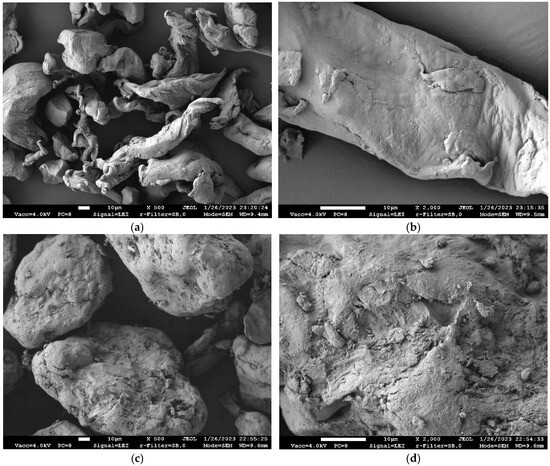

While observing microstructure, it can be noted that GG is characterized by more elongated particles, smooth surface, granular structure, good separated from each other, with the particles ranging from 10 μm to 80 μm (Figure 3a,b). On the other hand, XG exhibits more rounded particles with smooth surfaces and a granular structure that is well-separated. The particle sizes of XG range up to 90 μm (Figure 3c,d).

Figure 3.

SEM image of GG (a,b) and XG (c,d).

2.2. Mixture and Sample Preparation

XG was dissolved in 80 °C water under constant stirring at 100 rpm for 5 min, ensuring complete dissolution of the XG and the formation of a uniform aqueous solution. The same procedure was applied for GG, but using room-temperature water (22 °C). The polysaccharides studied had a high molar mass (GG = 532.68 g/mol and XG = 239.37 g/mol), so the GG and XG concentration in the solution was limited to a maximum of 2.5% w/v (0.5%, 1%, 1.5%, 2%, and 2.5%) to achieve a homogeneous solution. The characteristics of aqueous guar gum (GG) and xanthan gum (XG) solutions at various concentrations (0.5–2.5%) are summarized in Table 3. GG solutions exhibit a yellow-white color, while XG solutions appear yellow-brown. For both polysaccharides, increasing concentration results in noticeable changes in pH and a substantial rise in viscosity.

Table 3.

Characteristics of GG and XG solutions.

As the GG concentration increases from 0.5% to 2.5%, the pH rises from 7.7 to 8.4. In contrast, increasing the XG concentration leads to a decrease in pH from 8.3 to 7.4. Viscosity measurements indicate that XG produces higher viscosity at lower concentrations (0.5–1.0%) due to its rigid helical structure. In comparison, GG exhibits exponential thickening at concentrations above 1.5%, attributed to the formation of entangled networks by its flexible polymer chains. XG shows a more gradual increase in viscosity, maintaining pseudoplastic behavior throughout, whereas GG displays a sharp rise beyond its critical overlap concentration. At 2.5%, the maximum viscosity reaches 1032.6 mPa·s for GG and 708.5 mPa·s for XG.

Clay and polysaccharide (GG and XG) mixtures were prepared by adding free water to achieve a plasticity of 18. The mixtures were stored in a desiccator for 24 h. Formed samples (60 × 30 × 18 mm prisms for physical–mechanical property testing, 100 × 10 mm cylinders for hygroscopic testing, and water erosion testing) were dried for 8–10 days under laboratory conditions at 20 ± 2 °C and 50 ± 5% of relative humidity. The composition of the obtained clay–polysaccharide mixtures is provided in Table 4.

Table 4.

Characteristics of clay–polysaccharide mixture.

2.3. Methods

A wavelength dispersive X-ray fluorescence spectrometer (Rigaku ZSX Primus IV), equipped with an Rh target, end window, and 4 kW X-ray tube, was used to determine the chemical composition of the raw material. The mineralogical composition was analyzed using an X-ray diffractometer with copper anticathode, a nickel filter (DRON-7). The structure of the clay, GG, and XG was examined using scanning electron microscopy (SEM) with a JEOL SM-7600F (JEOL Ltd., Tokyo, Japan). The bulk density and shrinkage of the samples were evaluated according to LST EN 772-13:2003 [41] and ASTM C326-09 [42] standards, respectively. The Atterberg limits of the clay were determined in accordance with the ASTM D4318 [43] standard. The compressive strength characteristics were evaluated according to the DIN 18945 [44] standard (test procedure DIN EN ISO 7500-1:2004-11 [45]). The DIN 18945:2013-08 [46] standard, specifically designed for clay samples, was used in this research to classify the obtained clay-based composites based on their compressive strength. The classification criteria were as follows:

- Class 2: Suitable for low-load height construction (e.g., huts, sheds) or secondary structures, with mean compressive strength—2.5 MPa and smallest single compressive strength value—2.0 MPa;

- Class 3: For non-load-bearing structures or high-rise walling, with mean compressive strength—3.8 MPa and smallest single compressive strength value—3.0 MPa;

- Class 4: Intended for inner walls, low-rise walls, or middle-rise buildings, with mean compressive strength—5.0 MPa and smallest single compressive strength value—4.0 MPa;

- Class 5: For load-bearing walls and inner walls, with mean compressive strength—6.3 MPa and smallest single compressive strength value—5.0 MPa;

- Class 6: For load-bearing walls and inner walls, with mean compressive strength—7.5 MPa and smallest single compressive strength value—6.0 MPa.

The hygroscopic tests of the clay samples were checked in accordance with the ISO 24353:2008 [47] and ISO 12571:2013 [48] standards. Changes in mass, representing moisture uptake, were recorded over a one-hour period using a laboratory balance with an accuracy of ±0.01 g. The hygroscopicity of the samples was measured using a MEMMERT HPP110eco climate chamber, under the following testing program:

- Step 1 (mass stabilization): temperature—22 °C, relative humidity—50%, time—24 h;

- Step 2 (moisture adsorption): temperature—22 °C, relative humidity—75%, time—12 h;

- Step 3 (moisture desorption): temperature—22 °C, relative humidity—50%, time—12 h.

It should be noted that only the active moisture exchange phases (Steps 2 and 3) will be presented in further results (Section 3.2). Step 1, the mass stabilization phase, serves only to establish a consistent baseline mass prior to measurement and is not typically included in graphical result presentations.

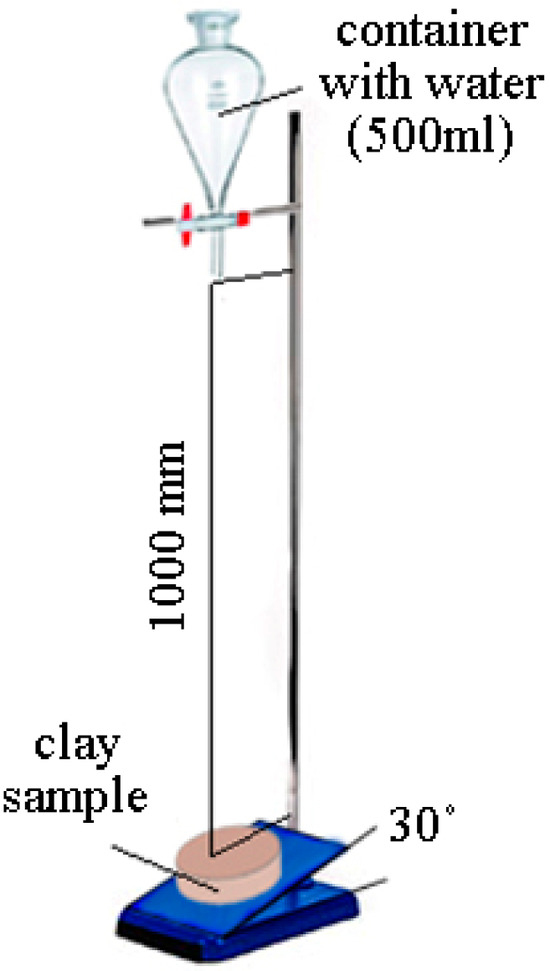

The durability of the clay materials was assessed by their resistance to water erosion, using the Geelong method as specified in the UNE R41410:2008 [49] and NZS 4298:1998 [50] standards. The water erosion resistance was determined in accordance with NZS 4298:1998 [50]. The test procedure involved tilting the samples at a 30° angle and dripping 500 mL of water from a height of 100 cm on the sample surface (Figure 4). The maximum duration of the test is 10 min. After 5 and 10 min, the samples were inspected for visible defects such as cracks, holes, or other changes.

Figure 4.

Water erosion tests.

To ensure the accuracy and reproducibility of the results, a minimum of three repeated tests and measurements were performed for each evaluation of physical and mechanical properties, hygroscopic behavior, and water erosion resistance of the studied clay materials.

3. Results and Discussion

3.1. Physical and Mechanical Characteristics

The physical and mechanical characteristics of the samples are presented in Table 5. The addition of GG or XG reduces the shrinkage of the samples, while the density of the specimens slightly increases. When comparing the results of previous studies, it can be noted that the effect of biopolymers on the density of clay-based materials can vary: The authors of [51] reported a decrease in density, whereas in other studies [52,53], an opposite trend was observed—a slight increase in density. This effect may be related to the optimal water content (OWC) required to form a plastic clay-based mass during the preparation stage of such materials. It is well known that biopolymers increase the OWC value, as the addition of biopolymers reduces the amount of free water in the clay–water system by attracting and binding free water molecules, forming a gel-like solution [51,54]. In addition, when distributed within the clay matrix, biopolymers may contribute to reduced shrinkage by partially occupying morphological features typical of clay composites, such as pores, voids, and internal cracks [26]. However, it should be noted that aggressive drying of such materials can, on the contrary, lead to extensive shrinkage, even resulting in the formation of major shrinkage defects such as cracks, which makes the clay materials unsuitable for use in construction [55].

Table 5.

The physical–mechanical characteristics.

Moreover, the addition of GG and XG significantly enhances the compressive strength of the samples. It was found that the compressive strength of the specimens increased by 28.6–63.5% when the GG content in the clay mixture was 0.5–2.5%. With the introduction of 0.5–2.5% XG, the compressive strength increased by 46.0–84.1%. This phenomenon indicates that the structure of the clay samples changes, as the incorporation of GG and XG additives promotes better adhesion between clay particles, leading to the partial or complete closure of pores and voids between the clay particles. As a result, the compressive strength and water erosion resistance of the specimens increased (Table 5). This result aligns with findings reported in the literature [23,24,25,26,33,52], which indicate that the use of biopolymers in clay mixtures improves the mechanical properties of clay materials [24,33,52] and reduces water erosion [26,34]. The literature suggests that this improvement is due to the modified clay structure, which becomes more homogeneous and cohesive, and the clay particles are brought closer together [56,57,58]. GG and XG are evenly distributed within the clay matrix and readily adhere to the surfaces of clay particles through different physical and chemical interactions [59]. Furthermore, the formation of hydrogels and the reduction in pores/voids contribute to the improved strength parameters of clay specimens [60].

The elastic modulus of clay samples modified with aqueous GG and XG solutions shows a clear increasing trend with rising biopolymer concentrations (0.5–2.5%). In GG-modified clay, the elastic modulus increases from 241.1 Pa (Control clay) to 279.2 Pa at 2.5% GG content. Similarly, XG-modified clay exhibits an elastic modulus increase, reaching 283.6 Pa at the maximum polymer concentration. This improvement is attributed to the formation of polymer networks that coat clay particles, fill voids, and form cross-linking bonds, thereby reinforcing the clay matrix. The higher elastic modulus observed in XG-modified samples compared to GG may be explained by XG’s stronger anionic interactions and pseudoplastic behavior, which enhance particle bonding and resistance to deformation. Similar effects were reported by Fatehi et al. [61], who observed a 309% increase in the elastic modulus of expansive clay treated with 1.5% GG after 60 days of curing, attributed to hydrogel-induced densification and pore space reduction. Likewise, Hamza et al. found that 1.5% XG increased the elastic modulus by over 500% [51], while 1.5% GG resulted in an increase of more than 210% [62], due to the formation of additional hydrogen bonds within the soil structure.

The addition of GG or XG to clay mixtures significantly reduces the shrinkage of the specimens compared to the control samples. Shrinkage is associated with water loss and the amount of voids within the clay mixture [63,64,65]. The results, specified in Table 3, demonstrated that as the concentration of GG or XG increased from 0.5% to 2.5%, the shrinkage of the specimens decreased to 3.8–4.7% (GG additive) and 4.7–4.0% (XG additive). This represents a shrinkage reduction of 25–39% (for GG) and 25–36% (for XG), respectively, compared to the control sample—6.3%. Various studies [53,66,67] have declared that the use of biopolymers can reduce the shrinkage of clay materials due to the formation of additional hydrogen bonds within the clay structure. Additionally, biopolymer solutions envelop clay particles, preventing them from moving closer to each other [26].

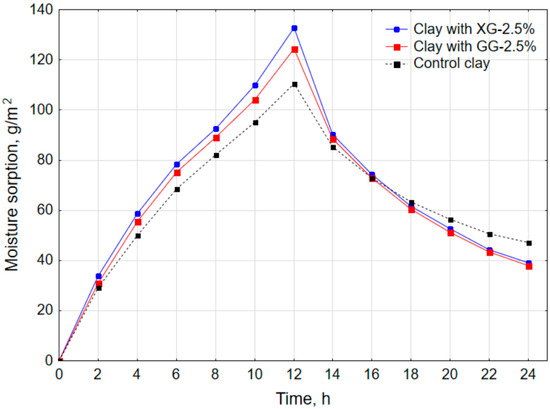

3.2. Hygroscopic Characteristics

Figure 5 illustrates the effect of the biopolymers xanthan gum (XG) and guar gum (GG) on the moisture-buffering capacity of clay materials. The maximum moisture adsorption occurred at the 12 h mark, which, according to the adopted methodology, corresponds to the end of the second stage—moisture adsorption. The control sample exhibited a moisture uptake of 110.7 g/m2, whereas the clay samples modified with GG and XG adsorbed 124.3 g/m2 and 132.8 g/m2, respectively, reflecting a 12% and 20% increase in moisture adsorption capacity. Notably, although the XG- and GG-modified clay materials absorbed more ambient moisture, they also released more moisture during the third stage of the experiment—desorption. Between 12 and 24 h, the control sample released approximately 57% of the previously adsorbed moisture (from 0 to 12 h), while the samples containing 2.5% XG and GG desorbed around 70% of the previously absorbed moisture. A similar effect of biopolymers on the moisture-buffering capacity of clay-based materials was reported in [54], where the addition of 2% XG and GG led to a 75% and 50% increase in moisture sorption, respectively. These results highlight the potential of GG and XG to enhance the moisture-buffering capacity of clay by modifying the sorption–desorption dynamics. However, it is important to note that the extent of this effect also strongly depends on the base material, especially the specific type of clay used.

Figure 5.

Moisture sorption of the clay materials.

3.3. Water Erosion

According to the water erosion standard (NZS 4298:1998 [50]), all samples, including the control sample, belong to Class 2 on the erodibility index (where 0 ≤ pit depth (mm) < 5), which represents the highest quality classification. However, it should be noted that the damaged surface area of the samples containing GG and XG additives showed significantly less damage after 5 or 10 min of testing. Additionally, the depth of the pits in these samples was much smaller compared to the control samples (Table 6). Other authors [23,34] have also indicated that biopolymer additives can effectively enhance the water erosion resistance of clay materials.

Table 6.

Evaluation of the clay surfaces after the water erosion test.

3.4. Structure of Clay Materials

Figure 6 illustrates the microstructure of the untreated, control clay samples. The surface morphology exhibits distinct, well-defined agglomerates of clay particles, displaying a sharp and textured relief. These agglomerates are clearly discernible, with uniformly distributed interparticle pores and voids. The clay platelets range in size from 0.5 to 5 μm, while the pore diameters measure between 0.3 and 0.5 μm (Figure 6a,b).

Figure 6.

Surface morphology of the control sample: (a) control clay surface at 5000 magnification and (b) control surface at 20,000 magnification.

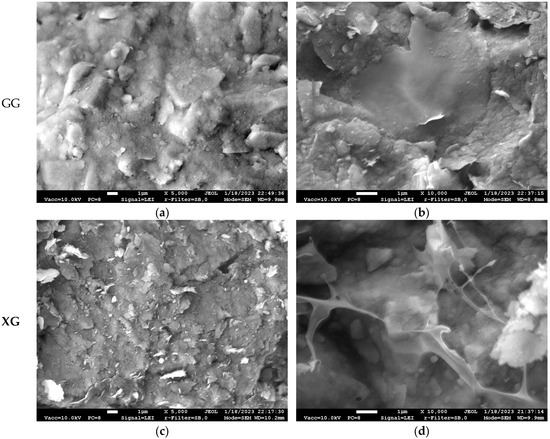

Figure 7a–d presents the surface morphologies of clay samples modified with guar gum (GG) and xanthan gum (XG), revealing significant structural alterations of the clay surface induced by biopolymer incorporation. These changes are also reflected in the experimental results for compressive strength (Table 5) and water erosion resistance (Table 6). The biopolymer-modified samples exhibit a denser and more interconnected structure, which enhances the overall performance of the material.

Figure 7.

Surface morphology of the clay, modified with guar gum (GG) and xanthan gum (XG): (a) GG-2.5 surface at 5000 magnification, (b) GG-2.5 surface at 10,000 magnification, (c) XG-2.5 surface at 5000 magnifications, and (d) XG-2.5 surface at 10,000 magnifications.

When examining the microstructure of the clay sample with 2.5% GG addition, it was observed that the biopolymer formed a gel-like structure on the clay surface, covering its aggregates, thereby significantly smoothing the entire clay structure (Figure 7a). The guar gum solution enhances the overall surface morphology by forming an additional layer and filling the pores and voids within the clay structure, resulting in a more uniform and homogeneous surface. At higher SEM magnification (Figure 7b), the effects of guar gum become more evident, also revealing good adhesion between the clay particles and the guar gum solution.

The surface of the clay sample with 2.5% XG addition (Figure 7c) also appears more homogeneous compared to the control sample (Figure 6a). Upon closer observation, various filamentous, net-like biopolymer structures can be seen within the clay matrix, interconnecting the clay aggregates (Figure 7d). The lengths of these threads range from 2 μm to 10 μm, and they are distributed throughout the entire volume of the clay matrix (Figure 7d).

A similar effect was observed in the research [23,24,25,26,34,68], when the biopolymers coating the surface of the clayey aggregates, increasing the contact area between the particles, which leads to more interconnected and cohesive structures. Researchers [25,38,68] also highlighted the differing interaction mechanisms of plant-based (guar gum) and microbial-based (xanthan gum) biopolymers with clayey materials, describing guar gum as forming a “coating” on clay particles, while xanthan gum exhibits direct interactions through “web-like” linkages.

The development of a three-dimensional biopolymer network structure (both “coats” and “web-linkages”) within the pore spaces of a clay matrix is a complex process driven by molecular interactions, physicochemical bonding, and the unique structural properties of both clay and biopolymers [69,70,71]. When biopolymers like xanthan gum or guar gum are introduced to a clay–water system, they first disperse and hydrate, forming viscous, gel-like solutions [72] that consequently fill the internal pore spaces of the clay matrix. Researchers [73,74] also postulated that characteristics of water–polymer solutions, such as viscosity, pH, and electrostatic charge, may play a crucial role in facilitating effective clay–biopolymer interactions.

Anionic xanthan gum, characterized by its rigid helical structure and carboxyl groups, interacts with clay surfaces primarily through cationic bridging (via divalent cations such as Ca2+) and electrostatic attraction to the positively charged edges of clay platelets [69,70,71,73]. In contrast, neutral guar gum forms hydrogen bonds between its hydroxyl groups and the surfaces of clay minerals, while also creating physical entanglements due to its high molecular weight [53,75]. These interactions are facilitated by the high surface area and layered structure of clays, which offer abundant binding sites for biopolymer adsorption. Moreover, the clays’ high cation exchange capacity and swelling potential enable biopolymers to modify the microstructure, enhancing their cohesiveness and thereby increasing resistance to mechanical stress and water exposure.

Thus, the obtained effects demonstrate that xanthan gum and guar gum biopolymers offer a sustainable and effective approach to clay modification, with distinct microstructural interactions that enhance both physical, mechanical properties and durability, while preserving the environmental potential. The combination of the specific clay and biopolymers shows particular promise due to their synergistic effects, potentially delivering improved performance at lower polymer concentrations compared to untreated clay materials.

4. Conclusions

Polysaccharides such as guar gum (GG) and xanthan gum (XG) have demonstrated the ability to modify the structure of clay, resulting in enhanced compressive strength and improved resistance to water erosion. These improvements are attributed to the formation of additional clay–polysaccharide interactions via cross-links, strong chemical bonds, and particle aggregation, which collectively enhance the cohesiveness of the clay matrix.

Comparing clay bricks, which contain 0.5–2.5% GG or XG, with control clay bricks showed that compressive strength increased 24.6–58.5% and 41.5–78.5%, respectively.

The control sample exhibited a moisture uptake of 110.7 g/m2, whereas the clay samples modified with GG and XG adsorbed 124.3 g/m2 and 132.8 g/m2, respectively, reflecting a 12% and 20% increase in moisture adsorption capacity. These results highlight the potential of GG and XG to enhance the moisture-buffering capacity of clay by modifying the sorption–desorption dynamics.

It is also important to note that the damaged surface area observed in the water erosion test was significantly smaller for samples containing GG and XG additives after 5 or 10 min of testing, indicating that these biopolymers can effectively enhance the water erosion resistance of unfired clay materials.

Author Contributions

Conceptualization, O.K. and V.K.; methodology, O.K., V.K. and Y.T.; software, Y.T.; validation, O.K., V.K. and V.V.; formal analysis, O.K., V.K., Y.T., V.V. and I.D.; investigation, O.K., V.K., Y.T., V.V. and I.D.; data curation, O.K. and V.K.; writing—original draft preparation, O.K., Y.T., V.V. and I.D.; writing—review and editing, O.K., V.K., Y.T., V.V. and I.D.; visualization, Y.T.; supervision, O.K., V.K. and V.V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Inga Daščioraitė was employed by the “Expertus Vilnensis” Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationship that could be construed as a potential conflict of interest.

References

- Islam, M.S.; Tausif-E-Elahi, A.R.; Shahriar, K.; Nahar, T.R.H. Strength and durability characteristics of cement-sand stabilized earth blocks. J. Mater. Civ. Eng. 2020, 32, 04020087. [Google Scholar] [CrossRef]

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S. Engineering characteristics of compressed earth blocks stabilized with cement and fly ash. Constr. Build. Mater. 2021, 277, 122367. [Google Scholar] [CrossRef]

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S.; Mehzabin, F.; Mumtaz, N. Suitability of fly ash and cement for fabrication of compressed stabilized earth blocks. Constr. Build. Mater. 2020, 263, 120935. [Google Scholar] [CrossRef]

- Ouedraogo, K.A.J.; Aubert, J.E.; Tribout, C.; Escadeillas, G. Is stabilization of earth bricks using low cement or lime contents relevant? Constr. Build. Mater. 2020, 236, 117578. [Google Scholar] [CrossRef]

- Ciancio, D.; Beckett, C.T.S.; Carraro, J.A.H. Optimum lime content identification for lime-stabilised rammed earth. Constr. Build. Mater. 2014, 53, 59–65. [Google Scholar] [CrossRef]

- Ávila, F.; Puertas, E.; Gallego, R. Mechanical characterization of lime-stabilized rammed earth: Lime content and strength development. Constr. Build. Mater. 2022, 350, 128871. [Google Scholar] [CrossRef]

- Mattone, M.; Rescic, S.; Fratini, F.; Manganelli Del Fà, R. Experimentation of Earth-Gypsum Plasters for the Conservation of Earthen Constructions. Int. J. Archit. Herit. 2017, 11, 763–772. [Google Scholar] [CrossRef]

- Zak, P.; Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. The influence of natural reinforcement fibers, gypsum and cement on compressive strength of earth bricks materials. Constr. Build. Mater. 2016, 106, 179–188. [Google Scholar] [CrossRef]

- Pimraksa, K.; Chindaprasirt, P. Lightweight bricks made of diatomaceous earth, lime and gypsum. Ceram. Int. 2009, 35, 471–478. [Google Scholar] [CrossRef]

- Meena, S.K.; Sahu, R.; Ayothiraman, R. Utilization of Waste Wheat Straw Fibers for Improving the Strength Characteristics of Clay. J. Nat. Fibers. 2021, 18, 1404–1418. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Turco, C.; Paula Junior, A.C.; Teixeira, E.R.; Mateus, R. Optimisation of Compressed Earth Blocks (CEBs) using natural origin materials: A systematic literature review. Constr. Build. Mater. 2021, 309, 125140. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Critical review of recent development in fiber reinforced adobe bricks for sustainable construction. Front. Struct. Civ. Eng. 2020, 14, 839–854. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Afzali, M.; Madadipour, M. Experimental investigation on mud bricks reinforced with natural additives under compressive and tensile tests. Constr. Build. Mater. 2017, 142, 137–147. [Google Scholar] [CrossRef]

- Giroudon, M.; Laborel-Préneron, A.; Aubert, J.E.; Magniont, C. Comparison of barley and lavender straws as bioaggregates in earth bricks. Constr. Build. Mater. 2019, 202, 254–265. [Google Scholar] [CrossRef]

- Gandia, R.M.; Gomes, F.C.; Corrêa, A.A.R.; Rodrigues, M.C.; Mendes, R.F. Physical, mechanical and thermal behavior of adobe stabilized with glass fiber reinforced polymer waste. Constr. Build. Mater. 2019, 222, 168–182. [Google Scholar] [CrossRef]

- Kolathayar, S.; Prasannan, S.; Sharma, A.K. Strength Tests and Model Experiments on Soil Reinforced with Areca and PVA Fibers. Lect. Notes Civ. Eng. 2020, 85, 147–153. [Google Scholar] [CrossRef]

- Mattone, R. Sisal fibre reinforced soil with cement or cactus pulp in bahareque technique. Cem. Conc. Compos. 2025, 27, 611–616. [Google Scholar] [CrossRef]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Bellotto, M.; Woloszyn, M.; Dotelli, G. Natural additives and biopolymers for raw earth construction stabilization—A review. Constr. Build. Mater. 2021, 304, 124507. [Google Scholar] [CrossRef]

- Nakamatsu, J.; Kim, S.; Ayarza, J.; Ramírez, E.; Elgegren, M.; Aguilar, R. Eco-friendly modification of earthen construction with carrageenan: Water durability and mechanical assessment. Constr. Build. Mater. 2017, 139, 193–202. [Google Scholar] [CrossRef]

- Muguda, S.; Booth, S.J.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Mechanical properties of biopolymer-stabilised soil-based construction materials. Géotech. Lett. 2017, 7, 309–314. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.C. Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Courteille, E. 3D printing of earth-based materials: Processing aspects. Constr. Build. Mater. 2018, 172, 670–676. [Google Scholar] [CrossRef]

- Keita, I.; Sorgho, B.; Dembele, C.; Plea, M.; Zerbo, L.; Guel, B.; Ouedraogo, R.; Gomina, M.; Blanchart, P. Ageing of clay and clay-tannin geomaterials for building. Constr. Build. Mater. 2014, 61, 114–119. [Google Scholar] [CrossRef]

- Vissac, A.; Bourgès, A.; Gandreau, D.; Anger, R.; Fontaine, R. Argiles & Biopolymères, les Stabilisants Naturels Pour la Construction en Terre; CRAterre: Grenoble, France, 2017. [Google Scholar]

- Singh, R.; Gautam, S.; Sharma, B.; Jain, P.; Chauhan, K.D. Chapter 2—Biopolymers and their classifications. In Biopolymers and Their Industrial Applications. From Plant, Animal, and Marine Sources, to Functional Products; Thomas, S., Gopi, S., Amalraj, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 21–44. [Google Scholar] [CrossRef]

- Niaounakis, M. (Ed.) Biopolymers: Reuse, Recycling, and Disposal; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Khademian, E.; Salehi, E.; Sanaeepur, H.; Galiano, F.; Figoli, A. A systematic review on carbohydrate biopolymers for adsorptive remediation of copper ions from aqueous environments-part A: Classification and modification strategies. Sci. Total Environ. 2020, 738, 139829. [Google Scholar] [CrossRef]

- Ilman, B.; Balkis, A.P. Sustainable biopolymer stabilized earthen: Utilization of chitosan biopolymer on mechanical, durability, and microstructural properties. J. Build. Eng. 2023, 76, 107220. [Google Scholar] [CrossRef]

- Aguilar, R.; Nakamatsu, J.; Ramírez, E.; Elgegren, M.; Ayarza, J.; Kim, S.; Pando, M.A.; Ortega-San-Martin, L. The potential use of chitosan as a biopolymer additive for enhanced mechanical properties and water resistance of earthen construction. Const. Build. Mater. 2016, 114, 625–637. [Google Scholar] [CrossRef]

- Benzerara, M.; Guihéneuf, S.; Belouettar, R.; Perrot, A. Combined and synergic effect of algerian natural fibres and biopolymers on the reinforcement of extruded raw earth. Constr. Build. Mater. 2021, 289, 123211. [Google Scholar] [CrossRef]

- Costa, C.; Arduin, D.; Rocha, F.; Velosa, A. Adobe Blocks in the Center of Portugal: Main Characteristics. Int. J. Archit. Herit. 2021, 3, 467–578. [Google Scholar] [CrossRef]

- Wang, S.; Gainey, L.; Wang, X.; Mackinnon, I.D.R.; Xi, Y. Influence of palygorskite on in-situ thermal behaviours of clay mixtures and properties of fired bricks. Appl. Clay Sci. 2022, 216, 106384. [Google Scholar] [CrossRef]

- Nasrollahzaded, M.; Sajjadi, M.; Nezafat, Z.; Shafiei, N. Chapter 3—Polysaccharides biopolymer chemistry. In Biopolymer-Based Metal Nanoparticle Chemistry for Sustainable Applications. Classification, Properties and Synthesis; Nasrollahzaded, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Sharma, G.; Sharma, S.; Kumar, A.; Al-Muhtaseb, A.H.; Naushad, M.; Ghfar, A.A.; Mola, G.T.; Stadler, F.G. Guar gum and its composites as potential materials for diverse applications: A review. Carbohydr. Polym. 2018, 199, 534–545. [Google Scholar] [CrossRef]

- Nsengiyumva, E.M.; Alexandridis, P. Xanthan gum in aqueous solutions: Fundamentals and applications. Int. J. Bio. Macromol. 2022, 216, 583–604. [Google Scholar] [CrossRef]

- LST EN 772-13:2003; Methods of Test for Masonry Units—Part 13: Determination of Net and Gross Dry Density of Masonry Units. LST Standards Board: Vilnius, Lithuania, 2003.

- ASTM C326-09; Standard Test Method for Drying and Firing Shrinkages of Ceramic Whiteware Clays. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- DIN 18945; Earth blocks—Terms and Definitions, Requirements, Test Methods. Beuth Verlag GmbH: Berlin, Germany, 2003.

- DIN EN ISO 7500-1:2004-11; Metallic Materials—Verification of Static Uniaxial Testing Machines—Part 1: Tension/Compression Testing Machines—Verification and Calibration of the Force-Measuring System. Beuth Verlag GmbH: Berlin, Germany, 2004.

- DIN 18945:2013-08; Earth Blocks—Terms and Definitions, Requirements, Test Methods. Beuth Verlag GmbH: Berlin, Germany, 2013.

- ISO 24353:2008; Hygrothermal Performance of Building Materials and Products—Determination of Moisture Adsorption/Desorption Properties in Response to Humidity Variation. International Organization for Standardization: Geneva, Switzerland, 2008.

- ISO 12571:2013; Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties. International Organization for Standardization: Geneva, Switzerland, 2013.

- UNE R41410:2008; Earth for Construction. Compressed Earth Blocks. Definitions and Characteristics. AENOR: Madrid, Spain, 2008.

- NZS 4298:1998; Materials and Workmanship for Earth Buildings. Standards New Zealand: Wellington, New Zealand, 1998.

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, Z.; Rehman, Z. Strengthening potential of xanthan gum biopolymer in stabilizing weak subgrade soil. Clean Techn. Environ. Policy 2022, 24, 2719–2738. [Google Scholar] [CrossRef]

- Trambitski, Y.; Kizinievič, O.; Kizinievič, V. Modification of clay materials with retrograded starch hydrogel. Constr. Build. Mater. 2022, 314, 125619. [Google Scholar] [CrossRef]

- Dove, C.; Bradley, F.; Patwardhan, S. Seaweed biopolymers as additives for unfired clay bricks. Mater. Struct. 2016, 49, 4463–4481. [Google Scholar] [CrossRef]

- Muguda, S.; Lucas, G.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Bruno, A.W.; Gallipoli, D. Durability and hygroscopic behaviour of biopolymer stabilised earthen construction materials. Constr. Build. Mater. 2020, 259, 119725. [Google Scholar] [CrossRef]

- Alhaik, G.; Ferreira, M.; Dubois, V.; Wirquin, E.; Tilloy, S.; Monflier, E.; Aouad, G. Enhance the rheological and mechanical properties of clayey materials by adding starches. Constr. Build. Mater. 2017, 139, 602–610. [Google Scholar] [CrossRef]

- Bozyigit, I.; Javadi, A.; Altun, S. Strength properties of xanthan gum and guar gum treated kaolin at different water contents. J. Rock Mech. Geotech. Eng. 2021, 13, 1160–1172. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Awraheem, M.H.; Khalaf, M.M. Geotechnical properties of a low-plasticity clay with biopolymer. J. Mater. Civ. Eng. 2018, 30, 04018170. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Majid, M.Z.A.; Rashid, A.S.A. Xanthan gum biopolymer: An eco-friendly additive for stabilization of tropical organic peat. Environ. Earth Sci. 2016, 75, 825. [Google Scholar] [CrossRef]

- Mahamaya, M.; Das, S.K.; Reddy, K.R.; Jain, S. Interaction of biopolymer with dispersive geomaterial and its characterization: An eco-friendly approach for erosion control. J. Clean. Prod. 2021, 312, 127778. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, L.; Budhu, M. Biopolymer stabilization of mine tailings. J. Geotech. Geoenviron. 2013, 139, 1802–1807. [Google Scholar] [CrossRef]

- Fatehi, E.H.; Ong, D.E.L.; Yu, J.; Chang, I. The Effects of Particle Size Distribution and Moisture Variation on Mechanical Strength of Biopolymer-Treated Soil. Polymers 2023, 15, 1549. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Salman, M. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Techn. Environ. Policy. 2023, 25, 1699–1719. [Google Scholar] [CrossRef]

- Gualtieri, A.F.; Ricchi, A.; Gualtieri, M.L.; Maretti, S.; Tamburini, M. Kinetic study of the drying process of clay bricks. J. Therm. Anal. Calorim. 2016, 123, 153–167. [Google Scholar] [CrossRef]

- Scherer, G.W. Theory of drying. J. Am. Ceram. Soc. 1990, 73, 3–14. [Google Scholar] [CrossRef]

- Zaccaron, A.; Nandi, V.S.; Bernardin, A.M. Fast drying for the manufacturing of clay ceramics using natural clays. J. Build. Eng. 2021, 33, 101877. [Google Scholar] [CrossRef]

- Sorgho, B.; Zerbo, L.; Keita, I.; Dembele, C.; Plea, M.; Sol, V.; Gomina, M.; Blanchart, P. Strength and creep behavior of geomaterials for building with tannin addition. Mater. Struct. 2014, 47, 937–946. [Google Scholar] [CrossRef]

- Hataf, N.; Ghadir, P.; Ranjbr, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 267. [Google Scholar] [CrossRef] [PubMed]

- Theng, B.K.G. Formation and properties of clay-polymer complexes, Interactions of clay minerals with naturally occurring polymers. In Developments in Clay Science; Theng, B.K.G., Ed.; Elsevier: Amsterdam, The Netherlands, 2012; Volume 4, pp. 351–383. [Google Scholar]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. Biopolymers as Green Binders for Soil Improvement in Geotechnical Applications: A Review. Geosciences 2021, 11, 291. [Google Scholar] [CrossRef]

- Trambitski, Y.; Kizinievič, O.; Gaspar, F.; Kizinievič, V.; Valente, J. Eco-friendly unfired clay materials modified by natural polysaccharides. Constr. Build. Mater. 2023, 400, 132783. [Google Scholar] [CrossRef]

- Pasqui, D.; De Cagna, M.; Barbucci, R. Polysaccharide-Based Hydrogels: The Key Role of Water in Affecting Mechanical Properties. Polymers 2012, 4, 1517–1534. [Google Scholar] [CrossRef]

- Liu, P. Polymer modified clay minerals: A review. Appl. Clay Sci. 2007, 38, 64–76. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Y.; Laskowski, J.S. The adsorption of polysaccharides onto mineral surfaces: An acid/base interaction. Int. J. Miner. Process. 2000, 60, 229–245. [Google Scholar] [CrossRef]

- Nascimento, M.G. Introductory Chapter: Polymers and Clays—A Fruitful Combination. Clay and Clay Minerals. Intech Open. 2021. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).