Abstract

With the advancement of space exploration, the development of sustainable construction technologies has become essential for the establishment of enduring extraterrestrial habitats. In Situ Resource Utilization (ISRU) assumes a pivotal role by facilitating the use of indigenous materials on celestial bodies such as the Moon and Mars, thereby reducing reliance on terrestrial resources. This review provides a comprehensive analysis of the latest ISRU-based construction technologies, with particular emphasis on biocementation techniques. It further examines the challenges associated with the application of biocementation in extreme space environments and outlines prospective research directions. The continued advancement of ISRU technologies through interdisciplinary collaboration remains crucial for the realization of viable and cost-efficient extraterrestrial construction solutions.

1. Introduction

As advancements in space exploration technology continue at an unprecedented pace, the concept of establishing extraterrestrial human settlements has evolved from a distant aspiration into a tangible research objective. Space agencies and research institutions across the globe are developing ambitious plans for lunar bases, Martian colonies, and even interstellar travel. These visionary efforts not only exemplify human ingenuity but also represent a critical step toward ensuring the long-term survival and development of human civilization beyond Earth. However, one of the primary obstacles to realizing these goals lies in the logistical and financial challenges of transporting vast quantities of construction materials from Earth into space, compounded by the energy-intensive nature of rocket launches and their significant environmental impacts [1,2,3,4,5].

Against this backdrop, ISRU has emerged as a key strategy for reducing the dependency on Earth-sourced materials for extraterrestrial construction. ISRU involves the extraction and conversion of local resources found on celestial bodies, such as the Moon or Mars, into usable construction materials and other vital resources. The development of ISRU technologies is essential for achieving long-term habitation on extraterrestrial surfaces, as it enables the creation of infrastructure, the production of life-supporting resources like oxygen and water, and the manufacture of fuel—all from locally sourced materials [6,7,8,9,10]. By leveraging the natural resources available in space, ISRU not only minimizes the need for costly resupply missions from Earth but also promotes sustainability in space missions. Unlocking the full potential of ISRU will enable future missions to become more autonomous and cost-effective, ultimately facilitating human expansion into the cosmos.

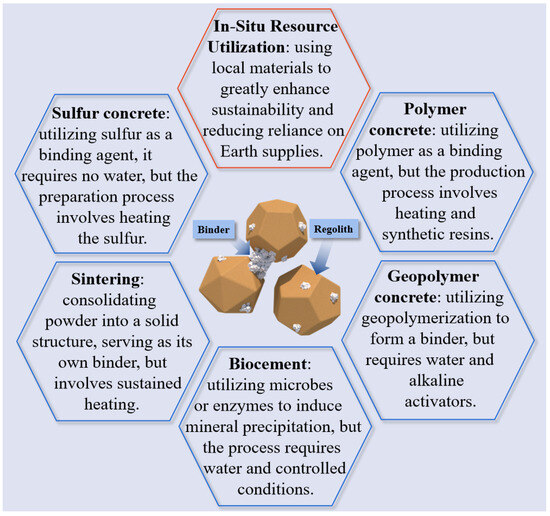

To date, a variety of ISRU-based construction techniques have been explored, focusing on the conversion of planetary regolith into durable building materials or its use in geotechnical engineering applications. Some of the most promising approaches include sulfur concrete, geopolymer concrete, sintering, and polymer concrete, each of which has its own unique technical characteristics. More recently, biocementation technologies have shown significant promise in utilizing regolith for space construction. Biocementation involves the use of microbial or enzymatic processes to induce precipitation, which acts as a binding agent that solidifies loose granular materials. The most widely studied forms of biocementation include microbially induced carbonate precipitation (MICP) and enzyme-induced carbonate precipitation (EICP), both of which have been successfully applied in terrestrial geotechnical construction environments [11,12,13,14,15]. These technologies are particularly attractive due to their low energy requirements, environmental sustainability, and potential for in situ applications in space. However, space biocement faces challenges in extreme environments, which could affect the efficacy of biocementation processes that rely on microorganisms or enzymes. Understanding the impact of these harsh conditions on biocementation is critical for optimizing its use in extraterrestrial environments.

This review examines the latest developments in ISRU-based construction technologies for space applications, as illustrated in Figure 1, with a particular focus on the advancements in biocementation. By analyzing current research trends and exploring the challenges and opportunities associated with biocement in space environments, this review aims to provide valuable insights for future research in extraterrestrial construction and geotechnical engineering. Through continuous technological innovation and interdisciplinary collaboration, we believe humanity will ultimately achieve stable and enduring extraterrestrial settlements, laying the foundation for new homes in the vast expanse of the universe.

Figure 1.

Current ISRU construction technologies and their characteristics.

2. Overview of Current Construction Technologies Based on In Situ Resource Utilization

2.1. Sulfur Concrete

Sulfur concrete can be produced using only sulfur and regolith as aggregate [16], offering a distinct advantage in extraterrestrial environments where water is scarce [17]. Unlike the hydration hardening process of traditional concrete, sulfur concrete hardens through a unique mechanism: sulfur melts and becomes liquid at 120 °C, transitions to a monoclinic crystalline form upon cooling to 114 °C, and finally adopts an orthorhombic state. This crystallization enhances its bonding with the aggregate, resulting in high strength [18]. The production of sulfur concrete on the Moon and Mars depends fundamentally on the availability of sulfur itself. Fortunately, sulfur is abundant on both these celestial bodies—especially on Mars, which is considered to be a sulfur-rich planet where sulfur cycling is a significant geochemical process [19,20,21,22,23]. The Martian surface contains large amounts of sulfates and sulfites, with sulfur concentrations that greatly exceed those found on Earth, the Moon, or various asteroids. Sulfur can be extracted from sulfides or sulfates through diverse chemical and physical processes; for instance, heating lunar regolith to 1100 °C can yield sulfur with a purity of 85–95% [24]. Sulfur may also be obtained from pyrite [25]. Additionally, sulfur is produced as a byproduct in processes that use Martian calcium sulfate dihydrate and gypsum to generate oxygen and water, with the resulting sulfur comprising up to 10% of the oxygen’s mass output [26].

The typical production process of sulfur concrete involves heating sulfur until it liquefies, mixing it with aggregate, pouring the mixture into molds, and then allowing it to harden. Maintaining a controlled heating temperature throughout this process is essential to keep the sulfur in its liquid state. Studies using the Martian soil simulant JSC Mars-1A indicate that the optimal mixture for producing Martian concrete is 50% sulfur and 50% simulant, with a maximum aggregate size of 1 mm. This Martian concrete formulation achieves compressive strengths exceeding 50 MPa, and its mechanical behavior under various loading conditions has been effectively simulated using the Lattice Discrete Particle Model. Additionally, the presence of metals in the Martian soil simulant contributes to concrete strength by reacting with sulfur to form sulfates and polysulfates [27]. Research has also investigated the effects of extreme space conditions, such as impacts and radiation, on sulfur concrete performance. Samples composed of 65% JSC-1 lunar regolith simulant and 35% sulfur were subjected to hypervelocity impact tests and space radiation exposure analyses. Detailed assessments of damage caused by such events can inform the design of future structures to minimize harmful impacts [28]. When magnetite is used as an aggregate, its rapid heating under microwave energy makes it an efficient heating source for casting Martian concrete. A lattice Boltzmann model was developed to determine the optimal microwave power and heating duration for casting Martian concrete. Experiments have measured the compressive strength and microstructure of microwave-cast Martian concrete, with the compressive strength of concrete produced using magnetite lunar aggregate simulant reaching 17.44 MPa [29].

While sulfur concrete offers high strength and does not require water for production, its durability, especially in space environments [30], warrants further investigation. Under vacuum and elevated temperatures, the sublimation of sulfur in sulfur concrete becomes a significant concern. Research shows that in vacuum conditions, the sublimation rate of sulfur is 8000 times slower at −60 °C compared to 20 °C [31]. However, after exposure to vacuum at approximately 20 °C for 58 days, sulfur sublimates extensively, leading to a mass loss of about 30% from the initial weight. This sulfur loss creates voids and defects within the concrete matrix, which compromises its structural integrity. Sublimation rates increase drastically with temperature; for instance, it takes less than two hours to form a 1 cm sulfur layer at 120 °C, while at 15 °C, this process spans 3.7 years [32]. Furthermore, temperature cycling also significantly impacts the durability of sulfur concrete. During hardening, sulfur cools and crystallizes: at 114 °C, it crystallizes into monoclinic sulfur with a 7% volume contraction, and at 96 °C, monoclinic sulfur transforms into orthorhombic sulfur, leading to an additional 6% volume reduction. This shrinkage induces internal stresses, which negatively affect the material’s durability [33,34,35,36,37]. Samples exposed to temperature cycles ranging from room temperature to −191 °C exhibit strength reductions of at least fivefold compared to non-cycled samples. Microscopic analysis of fracture surfaces indicates significant debonding between SiO2 aggregate particles and sulfur, attributed to the substantial difference in thermal expansion coefficients. This differential expansion and contraction produce internal defects and cracks, compromising the macro-mechanical properties of sulfur concrete [38]. To address these durability challenges, research is focusing on optimizing combinations of sulfur, aggregate, and various additives. The interaction of these additives with sulfur and aggregate holds promise for enhancing the longevity of sulfur-based concrete in harsh environments [39,40,41,42,43].

2.2. Polymer Concrete

Another form of space concrete that eliminates the need for water is polymer concrete, which uses polymers instead of cement paste and water to bond the aggregates. The general preparation method for polymer concrete involves heating the concrete mixture to melt the polymer, thereby bonding the aggregates and fillers. Thus, the method of heating and the source of the polymer become especially critical.

By applying a 230 °C heating plate to the top of the sample, polyethylene is melted and bonded with lunar soil to form lunar concrete composed of 10% polymer and 90% lunar soil, achieving compressive strengths between 12.6 and 12.9 MPa [44]. Additionally, an investigation into bottom-up heating, performed at 200 °C instead of 230 °C within a vacuum chamber simulating lunar conditions, revealed that while the compressive strength was lower than that of the top-down heating method (maximum strength reaching 5.7 MPa), the bottom-up heating method allowed for curing at double the speed [45]. Through the thermal treatment of soil mixed with recycled polyethylene powder using solar energy, bricks with sufficient compressive strength can be produced. Bricks with a polymer content of 5% achieved strengths between 1 and 2 MPa, while those with 10% polymer reached between 3 and 8 MPa [46].

Since polymers are generally transported from Earth, researchers have studied key processing parameters in polymer concrete preparation to minimize the adhesive content and, consequently, the burden on space transportation. Pre-mixed JSC-1A lunar regolith simulant particles and a small amount of polymer binder are compacted quasi-statically, achieving a closely packed structure where large binder droplets fragment. As compaction pressure increases further, larger capillary forces encourage the binder to spread around the contact points of filler particles, forming polymer micro-agglomerates. With a binder content as low as 2 wt% to 5 wt%, this process can produce flexural strengths comparable to, or even surpassing, typical reinforced concrete [47]. Moreover, studies have proposed that hydrogen obtained by electrolyzing water from Martian soil could catalytically reduce atmospheric CO2 to produce CH4. The conversion of CH4 to C2H4, based on catalytic oxidation at temperatures between 800 and 900 °C, represents the next step in producing polyethylene from Martian resources, with the final step involving the catalytic linkage of C2H4 monomers. Samples of synthesized polyethylene mixed with JSC Mars-1 simulated Martian regolith and exposed to a 500 MeV/u 56Fe beam demonstrated their effectiveness in attenuating incident radiation, achieving the basic requirements for passive radiation shielding. These samples also withstood impact loads equivalent to 7 km/s micrometeoroid impacts. Simulations and experiments have shown that ballistic impact resistance under high-velocity conditions is proportional to the polyethylene binder content in the composite material. JSC Mars-1 simulant bricks shattered completely upon impact, with compressive strains generated by shockwave propagation exceeding the failure strain of Martian simulant bricks. However, composite bricks containing 40 wt% polyethylene sustained only minimal damage under similar impact conditions [48].

One of the primary limitations of polymer concrete in extraterrestrial applications may be its durability under extreme temperature conditions. Some studies have examined these composites printed at −30 °C and subjected to weekly lunar thermal cycling, ranging from 127 °C during the lunar day to −190 °C at night. Findings confirmed that thermal stresses lead to physical and chemical degradation. Therefore, further research into the long-term durability of polymer concrete in extreme environments is essential for future applications [49].

2.3. Geopolymer Concrete

Geopolymers are a class of inorganic polymers that serve as cementitious binders and can be combined with aggregates from regolith to produce geopolymer concrete. Their production involves a geosynthesis process with three main stages: alkali activation, where monomers are generated through the dissolution of amorphous aluminosilicates; reorientation, in which these monomers are transported, oriented, and condensed; and polycondensation, through which the material hardens into an inorganic polymer structure [50]. Lunar regolith contains abundant alumina and silica oxides with a chemical composition similar to the requirements for geopolymers [51], suggesting its potential for in situ production. Additionally, the presence of alkali metals on the Moon allows for the local production of alkaline activators [52]. Given the challenges in water extraction on the Moon, despite evidence of lunar water resources, minimizing water use or developing water recycling techniques within the production process is still essential.

The Si/Al ratio influences the properties of geopolymers, making the choice of a suitable simulant important [53,54,55,56,57]. Volcanic ash, due to its comparable chemical and mineralogical composition, suggests that lunar regolith’s alkali activation could be similar. Potential lunar cement materials have been prepared by using volcanic ash and sodium hydroxide solution as activators. Geopolymer samples made from volcanic ash exhibited compressive strengths of 45.53 MPa after 24 h under vacuum conditions and 44.95 MPa after 30 freeze–thaw cycles in liquid nitrogen. Notably, 98.61% of the water used in the process could be recovered [58]. Additional studies have shown that the simulant DNA-1, which mimics the lunar mare regolith, can act as an effective water-reducing agent and retarder when urea is added, by breaking hydrogen bonds and delaying setting time, reducing the water requirement by up to 32% for achieving similar workability [59]. Other studies have explored using glass meteoritic powder and sodium hydroxide as activators to create geopolymers and proposed a process for geopolymer concrete production on the Moon, which incorporates a water recycling system. In this process, prepared geopolymer concrete is placed in a vacuum curing chamber, where a condensation recovery system collects and reuses evaporated water [60].

However, current research has found that the Martian environment may impose certain limitations on geopolymer concrete. Lunar regolith simulants generally have smaller particle sizes and higher degrees of geopolymerization [61]. In contrast, the high iron content in Martian soil results in geopolymers with lower compressive strengths than those produced from lunar soil simulants [62]. Additionally, the high concentration of carbon dioxide in the Martian atmosphere has been shown to reduce the strength of geopolymers due to carbonation [63,64,65,66,67], which could hinder the application of geopolymer concrete on Mars.

2.4. Sintering

Sintering can be employed to manufacture structural components in dry environments, involving the compaction of regolith into the desired shape of the structural element. This compaction results in reduced porosity and limits shrinkage, thereby decreasing the energy (and duration) required for the sintering process. The compacted regolith is subsequently heated using an energy source, such as amplified (concentrated) sunlight, microwaves, or lasers. Through sintering, the particles bond together while simultaneously decreasing porosity until a dense medium is formed. The efficiency of sintering for producing construction materials is higher than that of melting, as it can be achieved at temperatures significantly below the material’s melting point (approximately 50–70%), yet it still demands substantial energy. This factor is particularly critical for applications on the Moon and Mars, where resources and conditions are constrained. Due to the thin atmospheres of the Moon and Mars, which do not reflect and absorb significant amounts of energy, solar sintering emerges as the primary viable processing method in these environments. To enhance the collection of solar energy, solar concentrators/collectors/furnaces can be utilized to gather and focus sunlight.

Utilizing a high-flux solar furnace, light can be focused and layered sintering of lunar regolith can be achieved. By depositing layers of 0.1 mm thickness, brick-shaped components can be sintered within approximately 5 h [68]. The use of a solar simulator allows for additive manufacturing of interlocking components from JSC-2A lunar regolith simulant. Experimental data is further integrated into finite element calculations, and structural analyses indicate that specific geometries can be constructed without the need for additional binding materials. These interlocking components hold the potential to form structures that protect pressurized inflatable habitats from radiation and micro-meteorite impacts or to create non-pressurized shelters for robotic machinery [69]. Furthermore, the study investigates the impact of simulant composition on sintering by examining the sintering or melting behaviors of four different lunar simulants at varying temperatures. It was discovered that the glass transition temperature of the lunar simulant was the lowest, thus melting first and playing a critical role in the simulated sintering process [70].

However, challenges remain in the current sintering techniques. The use of lasers or microwaves for sintering consumes a particularly high amount of energy, while solar sintering systems require additional complex maintenance, including cleaning lunar dust from mirrors and lenses to maintain concentrator efficiency and managing positioning controls to maintain the necessary focal point relative to the sun and the solar concentrator’s movement [71].

3. Current Research Status of Space Biocement

Biocement technology primarily encompasses two methods: MICP and EICP. MICP utilizes specific microorganisms, whereas EICP employs free enzymes. The reaction is typically achieved through the urease pathway, wherein urea is decomposed to produce ammonia and carbon dioxide, thereby increasing the alkalinity of the solution and facilitating the combination of calcium ions and carbonate ions to form calcium carbonate precipitates at the microscale. These precipitates can serve as binding materials, thus enhancing the geotechnical properties of soil in a controlled manner to achieve the desired response. The effectiveness and feasibility of this technology have been validated on Earth, with applications including foundation reinforcement [72,73,74,75,76], brick manufacturing [77,78,79,80,81], and erosion control [82,83,84,85,86], while also demonstrating potential for space applications [87].

Current research into the application of biocement in space has shown promise. Studies indicate that MICP technology mediated by Sporosarcina pasteurii can effectively consolidate lunar and Martian regolith simulants into brick-like structures with satisfactory structural strength. The potential effects of supplementing nickel to enhance urease activity may further improve the entire MICP process. The addition of the natural polymer guar gum facilitates a strong binding with soil particles through electrostatic interactions and additional hydrogen bonds, while the introduction of larger molecules may increase bacterial metabolic activity, thereby synergizing MICP. Samples augmented with 1% guar gum and 10 mM nickel exhibited the highest average compressive strength. However, results suggest that the treatment effects of Martian simulant soil are inferior compared to those of Lunar simulant soil. Fe and Mg are essential metal ions needed for bacterial growth, yet their concentrations are limited. The significantly higher presence of metals like Fe and Mg in Martian simulant soil may create a less than ideal environment for bacterial growth [88]. Building upon the addition of guar gum, incorporating short-cut glass fibers into the samples, while somewhat reducing compressive strength—by nearly 30% in some cases—significantly increased strain under maximum load. This toughening effect may be attributed to the formation of a network by the chopped glass fibers, which delays the occurrence of sample fracture. This preliminary observation warrants further careful consideration and may provide a pathway to enhance the toughness of space bricks. Moreover, the primary advantage of glass fibers lies in improving the workability of the final samples. In contrast to samples without glass fibers, which were found to be difficult to process and prone to breakage, glass fiber-reinforced samples maintained their integrity during machining, with material being removed in powder form rather than as continuous fragments, allowing for the production of free shapes without the need for custom casting molds [89].

Research has also investigated the biocementation of Martian regolith simulants using the microalga Thraustochytrium striatum. This study examined the effects of various biogrouting methods and calcium sources on the unconfined compressive strength and hydraulic conductivity of biocemented Martian regolith simulants columns. In the presence of urea and CaCl2, Thraustochytrium striatum can induce biocementation. The research further found that Thraustochytrium striatum could generate CaCO3 precipitate from calcium acetate by degrading it into CO32− and forming CaCO3 with Ca2+, even in the absence of urea. In this process, calcium acetate serves a dual role as both an organic carbon source and calcium source. Therefore, utilizing acetate from simulated anaerobic digestion of kitchen waste can avoid the ammonia emissions associated with traditional MICP, contributing to a cleaner cementation process [90]. Additionally, response surface methodology was employed to optimize the influence of three factors—cell biomass loading, nutrient loading, and particle size—on the unconfined compressive strength of Martian regolith simulants columns. Although nutrient loading did not show a consistent trend regarding its effect on unconfined compressive strength, the overall unconfined compressive strength of the columns increased with rising cell biomass loading, with medium-sized Martian regolith simulants achieving the strongest biocemented columns. The maximum unconfined compressive strength reached 603.83 kPa when the particle size was 0.25 to 0.425 mm, cell biomass loading was 3.8 g/100 mL, and nutrient loading was 5.83/14.18 (CaCl2/urea) g/100 mL [91].

In parallel, novel methods have emerged that further enhance the sustainability of space biocementation. In particular, recent efforts have focused on integrating waste-derived materials into the biocementation process to maximize resource efficiency and reduce reliance on Earth-supplied inputs. One study proposed a biocarbonation technique using magnesium oxide for lunar regolith molding [92]. This method utilizes Sporosarcina pasteurii and urea pre-hydrolysis to form hydrated magnesium carbonates such as hydromagnesite and dypingite. This study achieved an unconfined compressive strength of approximately 10 MPa after 24 h of curing. Scanning electron micrographs and carbonate content analyses confirmed the formation of well-structured precipitates at optimal urea (1.0 mol/L) and MgO (15%) concentrations. This approach effectively combines microbial processes with inorganic precursors to create high-strength regolith composites. Building upon the theme of sustainable material sourcing, another innovative study employed enzyme-induced calcium phosphate precipitation using crude soybean enzymes and calcium and phosphorus extracted from kitchen waste bones [93]. This strategy demonstrates how organic waste streams can be repurposed for extraterrestrial construction. Conducted under both normal and microgravity conditions, the study confirmed that calcium phosphate precipitation remains effective even in microgravity environments. Notably, the near-neutral pH of the reaction environment facilitated the ionic conversion of ammonia and enabled direct precipitation of hydroxyapatite. Scanning electron micrographs and X-ray diffraction analyses revealed no significant morphological or structural differences between the two gravity conditions. This work highlights the feasibility of producing sustainable, ammonia-free biocement in space while addressing waste management challenges and reducing the need for additional chemical inputs.

While sustainability and in situ resource utilization are critical considerations, the mechanical performance of biocemented structures remains equally vital for ensuring long-term durability and structural integrity in extraterrestrial environments. Mechanical integrity remains a core concern in space biocement research. One study investigated failure mechanisms in MICP-based space bricks using numerical lattice network models [94]. It demonstrated how pore–microcrack interactions govern crack propagation and failure in porous media. Simulations and experiments revealed that higher porosity correlates with reduced compressive strength and increased crack branching. These findings underscore the importance of optimizing microstructural design to improve the mechanical robustness of biocemented materials in space applications.

Currently, research on biocement technology for space applications is still extremely limited, with many critical issues remaining unresolved. Although previous studies have attempted to verify the feasibility of biocement under simulated lunar and Martian regolith conditions, truly adaptable technological solutions for extreme space environments are still scarce. The impacts of low gravity, high radiation, and extreme temperature fluctuations on microbial activity, enzyme stability, and reaction efficiency, as well as the durability of samples after solidification, are all important research directions that urgently need to be addressed.

4. Future Directions for Biocement Based on In Situ Resource Utilization

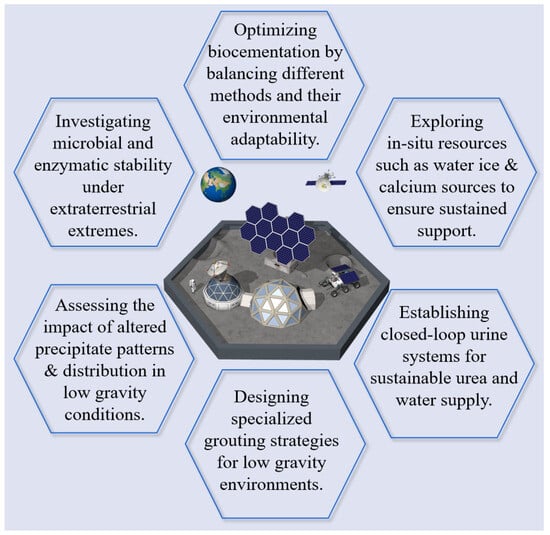

While biocement technology has successfully achieved consolidation under laboratory conditions, its practical application in the field of ISRU still faces significant challenges, as shown in Figure 2. The biocementation process requires a substantial amount of water, presenting a critical challenge for implementing biocement on the Moon and Mars. However, recent studies have discovered the presence of water ice on the lunar surface, which may provide an in situ resource for future biocementation. In biocement processes, urea is a key component for calcium carbonate formation, typically decomposing into ammonia and carbon dioxide with the aid of urease. Research suggests that urea from human or animal urine can serve as a raw material for biocementation [95,96,97,98,99]. Future missions could consider establishing urine collection and processing systems within space stations or lunar bases, thus providing a source of both urea and water.

Figure 2.

Current challenges in ISRU-based biocementation.

Simultaneously, the injection methods for grouting in microgravity environments require specific design to ensure efficient delivery of reactants, microorganisms, or enzymes under low-gravity conditions. Additionally, the distribution of calcium carbonate significantly impacts consolidation effectiveness [100,101,102,103,104]; hence, the precipitation patterns and distribution of biocement under microgravity are likely to differ considerably from those on Earth. As such, testing under extraterrestrial environments, particularly microgravity or low-gravity conditions, is essential to evaluate, optimize, and achieve the desired bioconsolidation effects.

The extreme conditions on the Moon and Mars may negatively impact microbial and enzymatic stability and activity, as well as the durability of biocement. To enable practical application of this technology in space environments, simulation systems replicating these harsh conditions must be developed. Future research should incorporate multi-factor coupled experimental designs to comprehensively evaluate the effects of extreme environmental factors such as high radiation and large temperature fluctuations on enzyme activity, precipitation kinetics, and overall consolidation performance. Microorganisms would need to overcome multiple stressors to survive and remain active. Certain microbial species have developed survival strategies, such as forming cysts and spores to protect cells from extreme conditions, expressing repair enzymes to mitigate environmental damage, and adjusting cell membrane composition to adapt to low temperatures or low water activity. These strategies enhance microbial resilience in harsh environments, making future research on selecting and optimizing microorganisms suited to these extreme conditions, and exploring their long-term survival mechanisms in space, a crucial focus. Compared to microorganisms, EICP technology may be better suited for space missions, as enzymes are easier to store and transport, and EICP does not rely on active cells, eliminating the need for oxygen. Applications under extreme temperatures are increasingly explored, suggesting its adaptability to the rigors of space. Additionally, crude enzymes derived from plants have been investigated extensively; when combined with space agriculture, plants used for crude enzyme extraction could also provide oxygen and nutrients.

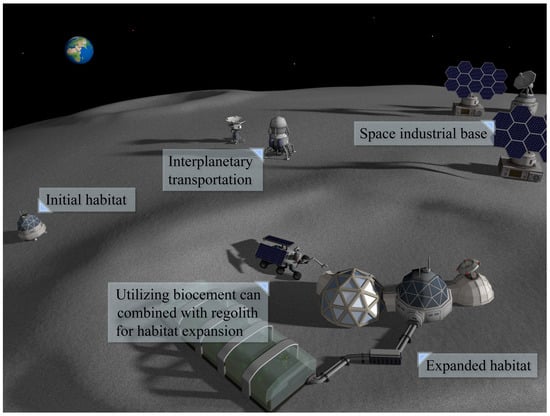

In the practical application of space construction materials, it is particularly important to recognize that any material intended for use in inhabited extraterrestrial environments must comply with stringent health standards [105]. Future research should incorporate health risk assessments into the evaluation of ISRU-derived construction materials. The discovery and efficient utilization of in situ resources on the Moon and Mars could significantly enhance the feasibility of biocementation. Future research should explore how to obtain and utilize these resources sustainably in extreme environments, advancing space construction and resource management. Additionally, combining biocement with other existing materials may address the limitations of single-material approaches, ultimately improving the overall performance of construction materials under extreme space conditions and enabling the expansion of extraterrestrial habitats, as illustrated in Figure 3.

Figure 3.

Schematic illustration of the potential expansion of extraterrestrial habitats enabled by biocementation based on in situ resource utilization.

5. Conclusions

This review synthesizes the various construction technologies based on ISRU for space applications, highlighting the potential to diminish reliance on terrestrial resources and mitigate transportation costs and environmental impacts by leveraging local materials from celestial bodies such as the Moon and Mars. Numerous ISRU construction technologies demonstrate their applicability in extraterrestrial environments, particularly recent advancements in biocementation techniques, which have been successfully implemented under laboratory conditions using lunar and Martian simulants. However, the practical application of biocementation in extreme space environments currently faces significant challenges. Therefore, future research must further investigate the material requirements, the effects of low-gravity conditions on injection methods and precipitation patterns, as well as the influence of extreme conditions on the stability of microorganisms and enzymes and the corresponding durability of samples. Continuous technological innovation and interdisciplinary collaboration will be essential for advancing the application of biocement technology in space, thereby laying the foundational technological groundwork for humanity’s establishment of new habitats in the cosmos.

Author Contributions

Z.Y.: Conceptualization, manuscript writing and reviewing, funding acquisition; S.K.: Resources. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data availability is not applicable to this article as no new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Neukart, F. Towards Sustainable Horizons: A Comprehensive Blueprint for Mars Colonization. Heliyon 2024, 10, e26180. [Google Scholar] [CrossRef] [PubMed]

- Dominguez Calabuig, G.J.; Wilson, A.; Bi, S.; Vasile, M.; Sippel, M.; Tajmar, M. Environmental Life Cycle Assessment of Reusable Launch Vehicle Fleets: Large Climate Impact Driven by Rocket Exhaust Emissions. Acta Astronaut. 2024, 221, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, L.; Li, Y.; Sun, Q.; Sun, M.; Huang, Y.; Li, Z.; Tang, D.; Wang, Y.; Xiao, L. In-Situ Utilization of Regolith Resource and Future Exploration of Additive Manufacturing for Lunar/Martian Habitats: A Review. Appl. Clay Sci. 2022, 229, 106673. [Google Scholar] [CrossRef]

- Rivera-Ingraham, G.A.; Andrade, M.; Vigouroux, R.; Solé, M.; Brokordt, K.; Lignot, J.-H.; Freitas, R. Are We Neglecting Earth While Conquering Space? Effects of Aluminized Solid Rocket Fuel Combustion on the Physiology of a Tropical Freshwater Invertebrate. Chemosphere 2021, 268, 128820. [Google Scholar] [CrossRef]

- Dallas, J.A.; Raval, S.; Alvarez Gaitan, J.P.; Saydam, S.; Dempster, A.G. The Environmental Impact of Emissions from Space Launches: A Comprehensive Review. J. Clean. Prod. 2020, 255, 120209. [Google Scholar] [CrossRef]

- Hoffman, J.A.; Hecht, M.H.; Rapp, D.; Hartvigsen, J.J.; SooHoo, J.G.; Aboobaker, A.M.; McClean, J.B.; Liu, A.M.; Hinterman, E.D.; Nasr, M.; et al. Mars Oxygen ISRU Experiment (MOXIE)—Preparing for Human Mars Exploration. Sci. Adv. 2022, 8, eabp8636. [Google Scholar] [CrossRef]

- Ellery, A. Leveraging in Situ Resources for Lunar Base Construction. Can. J. Civ. Eng. 2022, 49, 657–674. [Google Scholar] [CrossRef]

- Kruyer, N.S.; Realff, M.J.; Sun, W.; Genzale, C.L.; Peralta-Yahya, P. Designing the Bioproduction of Martian Rocket Propellant via a Biotechnology-Enabled in Situ Resource Utilization Strategy. Nat. Commun. 2021, 12, 6166. [Google Scholar] [CrossRef]

- Naser, M.Z. Space-Native Construction Materials for Earth-Independent and Sustainable Infrastructure. Acta Astronaut. 2019, 155, 264–273. [Google Scholar] [CrossRef]

- Wasilewski, T.G. Evaluation of Drilling-Based Water Extraction Methods for Martian ISRU from Mid-Latitude Ice Resources. Planet. Space Sci. 2018, 158, 16–24. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Liu, Y.; Sun, X.D.; Zeng, W.; Xing, H.P.; Lin, J.Z.; Kang, S.B.; Yu, L. Application of Microbially Induced Calcium Carbonate Precipitation (MICP) Technique in Concrete Crack Repair: A Review. Constr. Build. Mater. 2024, 411, 134313. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, C.-S.; Jiang, N.-J.; Pan, X.-H.; Liu, B.; Wang, Y.-J.; Shi, B. Microbial-induced Carbonate Precipitation (MICP) Technology: A Review on the Fundamentals and Engineering Applications. Environ. Earth Sci. 2023, 82, 229. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Liu, Y.; Liu, L.; Yan, B.; Li, L.; Meng, H.; Hang, L.; Qi, Y.; Wu, M.; Gao, Y. Recent Development on Optimization of Bio-Cementation for Soil Stabilization and Wind Erosion Control. Biogeotechnics 2023, 1, 100022. [Google Scholar] [CrossRef]

- Fu, T.; Saracho, A.C.; Haigh, S.K. Microbially Induced Carbonate Precipitation (MICP) for Soil Strengthening: A Comprehensive Review. Biogeotechnics 2023, 1, 100002. [Google Scholar] [CrossRef]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Beecham, S. Enzyme Induced Calcium Carbonate Precipitation and Its Engineering Application: A Systematic Review and Meta-Analysis. Constr. Build. Mater. 2021, 308, 125000. [Google Scholar] [CrossRef]

- Snehal, K.; Sinha, P.; Chaunsali, P. Development of Waterless Extra-Terrestrial Concrete Using Martian Regolith. Adv. Space Res. 2024, 73, 933–944. [Google Scholar] [CrossRef]

- Giwa, I.; Dempsey, M.; Fiske, M.; Kazemian, A. 3D Printed Sulfur-Regolith Concrete Performance Evaluation for Waterless Extraterrestrial Robotic Construction. Autom. Constr. 2024, 165, 105571. [Google Scholar] [CrossRef]

- Rasheed, M.F.; Rahim, A.; Irfan-ul-Hassan, M.; Ali, B.; Ali, N. Sulfur Concrete Made with Waste Marble and Slag Powders: 100% Recycled and Waterless Concrete. Environ. Sci. Pollut. Res. 2022, 29, 65655–65669. [Google Scholar] [CrossRef]

- Ding, S.; Dasgupta, R.; Tsuno, K. Sulfur Concentration of Martian Basalts at Sulfide Saturation at High Pressures and Temperatures—Implications for Deep Sulfur Cycle on Mars. Geochim. Cosmochim. Acta 2014, 131, 227–246. [Google Scholar] [CrossRef]

- Gaillard, F.; Michalski, J.; Berger, G.; McLennan, S.M.; Scaillet, B. Geochemical Reservoirs and Timing of Sulfur Cycling on Mars. Space Sci. Rev. 2013, 174, 251–300. [Google Scholar] [CrossRef]

- King, P.L.; McLennan, S.M. Sulfur on Mars. Elements 2010, 6, 107–112. [Google Scholar] [CrossRef]

- Righter, K.; Pando, K.; Danielson, L.R. Experimental Evidence for Sulfur-Rich Martian Magmas: Implications for Volcanism and Surficial Sulfur Sources. Earth Planet. Sci. Lett. 2009, 288, 235–243. [Google Scholar] [CrossRef]

- Halevy, I.; Zuber, M.T.; Schrag, D.P. A Sulfur Dioxide Climate Feedback on Early Mars. Science 2007, 318, 1903–1907. [Google Scholar] [CrossRef]

- Gracia, V.; Casanova, I. Sulfur Concrete: A Viable Alternative for Lunar Construction. Space 98; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 585–591. [Google Scholar] [CrossRef]

- Barkatt, A.; Okutsu, M. Obtaining Elemental Sulfur for Martian Sulfur Concrete. J. Chem. Res. 2022, 46, 17475198221080729. [Google Scholar] [CrossRef]

- Naser, M.Z. Extraterrestrial Construction Materials. Prog. Mater. Sci. 2019, 105, 100577. [Google Scholar] [CrossRef]

- Wan, L.; Wendner, R.; Cusatis, G. A Novel Material for in Situ Construction on Mars: Experiments and Numerical Simulations. Constr. Build. Mater. 2016, 120, 222–231. [Google Scholar] [CrossRef]

- Toutanji, H.A.; Evans, S.; Grugel, R.N. Performance of Lunar Sulfur Concrete in Lunar Environments. Constr. Build. Mater. 2012, 29, 444–448. [Google Scholar] [CrossRef]

- Li, H.; Meng, H.; Lan, M.; Zhou, J.; Xu, M.; Zhao, X.; Xiang, B. Development of a Novel Material and Casting Method for in Situ Construction on Mars. Powder Technol. 2021, 390, 219–229. [Google Scholar] [CrossRef]

- Khitab, A.; Anwar, W.; Mehmood, I.; Kazmi, S.M.S.; Munir, M.J. Lunar Concrete: Prospects and Challenges. Astron. Rep. 2016, 60, 306–312. [Google Scholar] [CrossRef]

- Shahsavari, M.H.; Karbala, M.M.; Iranfar, S.; Vandeginste, V. Martian and Lunar Sulfur Concrete Mechanical and Chemical Properties Considering Regolith Ingredients and Sublimation. Constr. Build. Mater. 2022, 350, 128914. [Google Scholar] [CrossRef]

- Grugel, R.N.; Toutanji, H. Sulfur “Concrete” for Lunar Applications—Sublimation Concerns. Adv. Space Res. 2008, 41, 103–112. [Google Scholar] [CrossRef]

- Zamani, M.N.; Noor, N.M.; Umar, S.; Shah, M.S.A.; Yahaya, N.; Kim, J.H.-J.; Teng, N.C. Laboratory Studies on the Mechanical Properties of Sulphur-Based Construction Material at Simulated Martian Temperatures. Acta Astronaut. 2024, 221, 163–179. [Google Scholar] [CrossRef]

- Liu, J.; Yan, C.; Li, J.; Zhang, J.; Liu, S. Investigation on the Mechanical Properties and Strengthening Mechanism of Solid-Waste–Sulfur-Based Cementitious Composites. Materials 2023, 16, 1203. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Kalb, P.D.; Milian, L.; Northrup, P.A. Characterization of a Sustainable Sulfur Polymer Concrete Using Activated Fillers. Cem. Concr. Compos. 2016, 67, 20–29. [Google Scholar] [CrossRef]

- Vlahovic, M.M.; Martinovic, S.P.; Boljanac, T.D.; Jovanic, P.B.; Volkov-Husovic, T.D. Durability of Sulfur Concrete in Various Aggressive Environments. Constr. Build. Mater. 2011, 25, 3926–3934. [Google Scholar] [CrossRef]

- Mohamed, A.-M.O.; El Gamal, M. Sulfur Based Hazardous Waste Solidification. Environ. Geol. 2007, 53, 159–175. [Google Scholar] [CrossRef]

- Grugel, R.N. Integrity of Sulfur Concrete Subjected to Simulated Lunar Temperature Cycles. Adv. Space Res. 2012, 50, 1294–1299. [Google Scholar] [CrossRef]

- Wang, Q.; Snoeck, D. To Boldly Go Where No One Has Gone before: Sulfur Concrete, a Promising Construction Material Fulfilling the Demands for a Sustainable Future on Celestial Objects: A Review. Mater. Today 2024, 72, 301–317. [Google Scholar] [CrossRef]

- Amanova, N.; Turaev, K.; Shadhar, M.H.; Tadjixodjayeva, U.; Jumaeva, Z.; Berdimurodov, E.; Eliboev, I.; Hosseini-Bandegharaei, A. Sulfur-Based Concrete: Modifications, Advancements, and Future Prospects. Constr. Build. Mater. 2024, 435, 136765. [Google Scholar] [CrossRef]

- Dobrosmyslov, S.S.; Zadov, V.E.; Nazirov, R.A.; Nagibin, G.E.; Voronin, A.S.; Simunin, M.M.; Fadeev, Y.V.; Khartov, S.V. High Strength Construction Material Based on Sulfur Binder Obtained by Physical Modification. Buildings 2022, 12, 1012. [Google Scholar] [CrossRef]

- Gwon, S.; Ahn, E.; Shin, M. Water Permeability and Rapid Self-Healing of Sustainable Sulfur Composites Using Superabsorbent Polymer and Binary Cement. Constr. Build. Mater. 2020, 265, 120306. [Google Scholar] [CrossRef]

- Mohamed, A.-M.O.; Gamal, M.E. Hydro-Mechanical Behavior of a Newly Developed Sulfur Polymer Concrete. Cem. Concr. Compos. 2009, 31, 186–194. [Google Scholar] [CrossRef]

- Sik Lee, T.; Lee, J.; Yong Ann, K. Manufacture of Polymeric Concrete on the Moon. Acta Astronaut. 2015, 114, 60–64. [Google Scholar] [CrossRef]

- Lee, J.; Ann, K.Y.; Lee, T.S.; Mitikie, B.B. Bottom-up Heating Method for Producing Polyethylene Lunar Concrete in Lunar Environment. Adv. Space Res. 2018, 62, 164–173. [Google Scholar] [CrossRef]

- Varela Miranda, L.; Valdes, J.R.; Cortes, D.D. Solar Bricks for Lunar Construction. Constr. Build. Mater. 2017, 139, 241–246. [Google Scholar] [CrossRef]

- Chen, T.; Chow, B.J.; Zhong, Y.; Wang, M.; Kou, R.; Qiao, Y. Formation of Polymer Micro-Agglomerations in Ultralow-Binder-Content Composite Based on Lunar Soil Simulant. Adv. Space Res. 2018, 61, 830–836. [Google Scholar] [CrossRef]

- Sen, S.; Carranza, S.; Pillay, S. Multifunctional Martian Habitat Composite Material Synthesized from in Situ Resources. Adv. Space Res. 2010, 46, 582–592. [Google Scholar] [CrossRef]

- Marnot, A.; Milliken, J.; Cho, J.; Lin, Z.; Wong, C.; Jones, J.M.; Hill, C.; Brettmann, B. Thermal Weathering of 3D-Printed Lunar Regolith Simulant Composites. ACS Appl. Eng. Mater. 2024, 2, 2016–2026. [Google Scholar] [CrossRef]

- Hu, Z.; Shi, T.; Cen, M.; Wang, J.; Zhao, X.; Zeng, C.; Zhou, Y.; Fan, Y.; Liu, Y.; Zhao, Z. Research Progress on Lunar and Martian Concrete. Constr. Build. Mater. 2022, 343, 128117. [Google Scholar] [CrossRef]

- Zheng, X.; Zhao, C.; Sun, X.; Dong, W. Lunar Regolith Geopolymer Concrete for In-Situ Construction of Lunar Bases: A Review. Polymers 2024, 16, 1582. [Google Scholar] [CrossRef]

- Matta, M.; Smith, S.; Baumgardner, J.; Wilson, J.; Martinis, C.; Mendillo, M. The Sodium Tail of the Moon. Icarus 2009, 204, 409–417. [Google Scholar] [CrossRef]

- Liu, J.; Doh, J.-H.; Dinh, H.L.; Ong, D.E.L.; Zi, G.; You, I. Effect of Si/Al Molar Ratio on the Strength Behavior of Geopolymer Derived from Various Industrial Waste: A Current State of the Art Review. Constr. Build. Mater. 2022, 329, 127134. [Google Scholar] [CrossRef]

- Dehghani, A.; Aslani, F.; Ghaebi Panah, N. Effects of Initial SiO2/Al2O3 Molar Ratio and Slag on Fly Ash-Based Ambient Cured Geopolymer Properties. Constr. Build. Mater. 2021, 293, 123527. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhang, W.; Li, Z.; Zhang, Y.; Li, Y.; Ren, Y. Effects of Si/Al Ratio on the Efflorescence and Properties of Fly Ash Based Geopolymer. J. Clean. Prod. 2020, 244, 118852. [Google Scholar] [CrossRef]

- Lahoti, M.; Wong, K.K.; Yang, E.-H.; Tan, K.H. Effects of Si/Al Molar Ratio on Strength Endurance and Volume Stability of Metakaolin Geopolymers Subject to Elevated Temperature. Ceram. Int. 2018, 44, 5726–5734. [Google Scholar] [CrossRef]

- He, P.; Wang, M.; Fu, S.; Jia, D.; Yan, S.; Yuan, J.; Xu, J.; Wang, P.; Zhou, Y. Effects of Si/Al Ratio on the Structure and Properties of Metakaolin Based Geopolymer. Ceram. Int. 2016, 42, 14416–14422. [Google Scholar] [CrossRef]

- Wang, K.; Lemougna, P.N.; Tang, Q.; Li, W.; Cui, X. Lunar Regolith Can Allow the Synthesis of Cement Materials with Near-Zero Water Consumption. Gondwana Res. 2017, 44, 1–6. [Google Scholar] [CrossRef]

- Pilehvar, S.; Arnhof, M.; Erichsen, A.; Valentini, L.; Kjøniksen, A. Investigation of Severe Lunar Environmental Conditions on the Physical and Mechanical Properties of Lunar Regolith Geopolymers. J. Mater. Res. Technol. 2021, 11, 1506–1516. [Google Scholar] [CrossRef]

- Wang, K.; Tang, Q.; Cui, X.; He, Y.; Liu, L. Development of Near-Zero Water Consumption Cement Materials via the Geopolymerization of Tektites and Its Implication for Lunar Construction. Sci. Rep. 2016, 6, 29659. [Google Scholar] [CrossRef]

- Alexiadis, A.; Alberini, F.; Meyer, M.E. Geopolymers from Lunar and Martian Soil Simulants. Adv. Space Res. 2017, 59, 490–495. [Google Scholar] [CrossRef]

- Mills, J.N.; Katzarova, M.; Wagner, N.J. Comparison of Lunar and Martian Regolith Simulant-Based Geopolymer Cements Formed by Alkali-Activation for in-Situ Resource Utilization. Adv. Space Res. 2022, 69, 761–777. [Google Scholar] [CrossRef]

- Zhao, C.; Li, Z.; Peng, S.; Liu, J.; Wu, Q.; Xu, X. State-of-the-Art Review of Geopolymer Concrete Carbonation: From Impact Analysis to Model Establishment. Case Stud. Constr. Mater. 2024, 20, e03124. [Google Scholar] [CrossRef]

- Li, F.; Chen, D.; Yang, Z.; Lu, Y.; Zhang, H.; Li, S. Effect of Mixed Fibers on Fly Ash-Based Geopolymer Resistance against Carbonation. Constr. Build. Mater. 2022, 322, 126394. [Google Scholar] [CrossRef]

- Pasupathy, K.; Sanjayan, J.; Rajeev, P. Evaluation of Alkalinity Changes and Carbonation of Geopolymer Concrete Exposed to Wetting and Drying. J. Build. Eng. 2021, 35, 102029. [Google Scholar] [CrossRef]

- Pasupathy, K.; Berndt, M.; Castel, A.; Sanjayan, J.; Pathmanathan, R. Carbonation of a Blended Slag-Fly Ash Geopolymer Concrete in Field Conditions after 8 Years. Constr. Build. Mater. 2016, 125, 661–669. [Google Scholar] [CrossRef]

- Bernal, S.A.; Mejía de Gutiérrez, R.; Provis, J.L. Engineering and Durability Properties of Concretes Based on Alkali-Activated Granulated Blast Furnace Slag/Metakaolin Blends. Constr. Build. Mater. 2012, 33, 99–108. [Google Scholar] [CrossRef]

- Meurisse, A.; Makaya, A.; Willsch, C.; Sperl, M. Solar 3D Printing of Lunar Regolith. Acta Astronaut. 2018, 152, 800–810. [Google Scholar] [CrossRef]

- Fateri, M.; Meurisse, A.; Sperl, M.; Urbina, D.; Madakashira, H.K.; Govindaraj, S.; Gancet, J.; Imhof, B.; Hoheneder, W.; Waclavicek, R.; et al. Solar Sintering for Lunar Additive Manufacturing. J. Aerosp. Eng. 2019, 32, 04019101. [Google Scholar] [CrossRef]

- Hintze, P.E.; Quintana, S. Building a Lunar or Martian Launch Pad with In Situ Materials: Recent Laboratory and Field Studies. J. Aerosp. Eng. 2013, 26, 134–142. [Google Scholar] [CrossRef]

- Lim, S.; Prabhu, V.L.; Anand, M.; Taylor, L.A. Extra-Terrestrial Construction Processes—Advancements, Opportunities and Challenges. Adv. Space Res. 2017, 60, 1413–1429. [Google Scholar] [CrossRef]

- Lai, H.-J.; Cui, M.-J.; Chu, J. Stress–Dilatancy Behavior of Biocementation-Enhanced Geogrid-Reinforced Sand. Int. J. Geomech. 2023, 23, 04023043. [Google Scholar] [CrossRef]

- Yan, Z.; Gowthaman, S.; Nakashima, K.; Kawasaki, S. Polymer-Assisted Enzyme Induced Carbonate Precipitation for Non-Ammonia Emission Soil Stabilization. Sci. Rep. 2022, 12, 8821. [Google Scholar] [CrossRef]

- Tang, C.-S.; Li, H.; Pan, X.-H.; Yin, L.-Y.; Cheng, L.; Cheng, Q.; Liu, B.; Shi, B. Coupling Effect of Biocementation-Fiber Reinforcement on Mechanical Behavior of Calcareous Sand for Ocean Engineering. Bull. Eng. Geol. Environ. 2022, 81, 163. [Google Scholar] [CrossRef]

- Xiao, Y.; Stuedlein, A.W.; Pan, Z.; Liu, H.; Matthew Evans, T.; He, X.; Lin, H.; Chu, J.; van Paassen, L.A. Toe-Bearing Capacity of Precast Concrete Piles through Biogrouting Improvement. J. Geotech. Geoenviron. Eng. 2020, 146, 06020026. [Google Scholar] [CrossRef]

- Xiao, Y.; He, X.; Evans, T.M.; Stuedlein, A.W.; Liu, H. Unconfined Compressive and Splitting Tensile Strength of Basalt Fiber–Reinforced Biocemented Sand. J. Geotech. Geoenviron. Eng. 2019, 145, 04019048. [Google Scholar] [CrossRef]

- Farajnia, A.; Shafaat, A.; Farajnia, S.; Sartipipour, M.; Khodadadi Tirkolaei, H. The Efficiency of Ureolytic Bacteria Isolated from Historical Adobe Structures in the Production of Bio-Bricks. Constr. Build. Mater. 2022, 317, 125868. [Google Scholar] [CrossRef]

- Arab, M.G.; Omar, M.; Almajed, A.; Elbaz, Y.; Ahmed, A.H. Hybrid Technique to Produce Bio-Bricks Using Enzyme-Induced Carbonate Precipitation (EICP) and Sodium Alginate Biopolymer. Constr. Build. Mater. 2021, 284, 122846. [Google Scholar] [CrossRef]

- Li, Y.; Wen, K.; Li, L.; Huang, W.; Bu, C.; Amini, F. Experimental Investigation on Compression Resistance of Bio-Bricks. Constr. Build. Mater. 2020, 265, 120751. [Google Scholar] [CrossRef]

- Cheng, L.; Kobayashi, T.; Shahin, M.A. Microbially Induced Calcite Precipitation for Production of “Bio-Bricks” Treated at Partial Saturation Condition. Constr. Build. Mater. 2020, 231, 117095. [Google Scholar] [CrossRef]

- Bernardi, D.; DeJong, J.T.; Montoya, B.M.; Martinez, B.C. Bio-Bricks: Biologically Cemented Sandstone Bricks. Constr. Build. Mater. 2014, 55, 462–469. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Y.; Liu, B.; Cao, X.; Chen, J. Biocementation for Desert Sand against Wind-Induced Erosion with Different Treatment Processes. J. Soils Sediments 2024, 24, 3265–3275. [Google Scholar] [CrossRef]

- Fernández Rodríguez, R.; Cardoso, R. Study of Biocementation Treatment to Prevent Erosion by Concentrated Water Flow in a Small-Scale Sand Slope. Transp. Geotech. 2022, 37, 100873. [Google Scholar] [CrossRef]

- Hamid Lajevardi, S.; Shafiei, H. Investigating the Biological Treatment Effect on Fine-Grained Soil Resistance against Wind Erosion: An Experimental Case Study. Aeolian Res. 2023, 60, 100841. [Google Scholar] [CrossRef]

- Namdar-Khojasteh, D.; Bazgir, M.; Hashemi Babaheidari, S.A.; Asumadu-Sakyi, A.B. Application of Biocementation Technique Using Bacillus Sphaericus for Stabilization of Soil Surface and Dust Storm Control. J. Arid Land 2022, 14, 537–549. [Google Scholar] [CrossRef]

- Zomorodian, S.M.A.; Ghaffari, H.; O’Kelly, B.C. Stabilisation of Crustal Sand Layer Using Biocementation Technique for Wind Erosion Control. Aeolian Res. 2019, 40, 34–41. [Google Scholar] [CrossRef]

- Zuo, H.; Ni, S.; Xu, M. An Assumption of in Situ Resource Utilization for “Bio-Bricks” in Space Exploration. Front. Mater. 2023, 10, 1155643. [Google Scholar] [CrossRef]

- Dikshit, R.; Gupta, N.; Dey, A.; Viswanathan, K.; Kumar, A. Microbial Induced Calcite Precipitation Can Consolidate Martian and Lunar Regolith Simulants. PLoS ONE 2022, 17, e0266415. [Google Scholar] [CrossRef]

- Dikshit, R.; Dey, A.; Gupta, N.; Varma, S.C.; Venugopal, I.; Viswanathan, K.; Kumar, A. Space Bricks: From LSS to Machinable Structures via MICP. Ceram. Int. 2021, 47, 14892–14898. [Google Scholar] [CrossRef]

- Gleaton, J.; Lai, Z.; Xiao, R.; Chen, Q.; Zheng, Y. Microalga-Induced Biocementation of Martian Regolith Simulant: Effects of Biogrouting Methods and Calcium Sources. Constr. Build. Mater. 2019, 229, 116885. [Google Scholar] [CrossRef]

- Gleaton, J.; Lai, Z.; Xiao, R.; Zhang, K.; Chen, Q.; Zheng, Y. Optimization of Mechanical Strength of Biocemented Martian Regolith Simulant Soil Columns. Constr. Build. Mater. 2022, 315, 125741. [Google Scholar] [CrossRef]

- Shi, J.; Xiao, Z.; Xiao, Y.; Liu, H. Bio-Molding of Lunar Regolith with Bio-Carbonized Magnesium Oxide. Biogeotechnics 2024, 100159, in press. [Google Scholar] [CrossRef]

- Yan, Z.; Nakashima, K.; Takano, C.; Kawasaki, S. Kitchen Waste Bone-Driven Enzyme-Induced Calcium Phosphate Precipitation under Microgravity for Space Biocementation. Biogeotechnics 2024, 100156, in press. [Google Scholar] [CrossRef]

- Dawara, V.; Gupta, N.; Dey, A.; Kumar, A.; Viswanathan, K. Pore–Microcrack Interaction Governs Failure in Bioconsolidated Space Bricks. Ceram. Int. 2022, 48, 35874–35882. [Google Scholar] [CrossRef]

- Yang, Y.; Chu, J.; Cheng, L.; Liu, H. Utilization of Carbide Sludge and Urine for Sustainable Biocement Production. J. Environ. Chem. Eng. 2022, 10, 107443. [Google Scholar] [CrossRef]

- Crane, L.; Ray, H.; Hamdan, N.; Boyer, T.H. Enzyme-Induced Carbonate Precipitation Utilizing Fresh Urine and Calcium-Rich Zeolites. J. Environ. Chem. Eng. 2022, 10, 107238. [Google Scholar] [CrossRef]

- Comadran-Casas, C.; Schaschke, C.J.; Akunna, J.C.; Jorat, M.E. Cow Urine as a Source of Nutrients for Microbial-Induced Calcite Precipitation in Sandy Soil. J. Environ. Manag. 2022, 304, 114307. [Google Scholar] [CrossRef]

- Lambert, S.E.; Randall, D.G. Manufacturing Bio-Bricks Using Microbial Induced Calcium Carbonate Precipitation and Human Urine. Water Res. 2019, 160, 158–166. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-J.; Huang, Y.-H.; Chen, C.-C.; Maity, J.P.; Chen, C.-Y. Microbial Induced Calcium Carbonate Precipitation (MICP) Using Pig Urine as an Alternative to Industrial Urea. Waste Biomass Valorization 2019, 10, 2887–2895. [Google Scholar] [CrossRef]

- Yan, Z.; Nakashima, K.; Takano, C.; Kawasaki, S. Feasibility Study of Enhancing Enzyme-Induced Carbonate Precipitation with Eggshell Waste for Sand Solidification. Biogeotechnics 2024, 2, 100108. [Google Scholar] [CrossRef]

- Liu, J.; Li, G.; Li, X. Geotechnical Engineering Properties of Soils Solidified by Microbially Induced CaCO3 Precipitation (MICP). Adv. Civ. Eng. 2021, 2021, 6683930. [Google Scholar] [CrossRef]

- Almajed, A.; Abbas, H.; Arab, M.; Alsabhan, A.; Hamid, W.; Al-Salloum, Y. Enzyme-Induced Carbonate Precipitation (EICP)-Based Methods for Ecofriendly Stabilization of Different Types of Natural Sands. J. Clean. Prod. 2020, 274, 122627. [Google Scholar] [CrossRef]

- Xiao, Y.; Stuedlein, A.W.; Ran, J.; Evans, T.M.; Cheng, L.; Liu, H.; van Paassen, L.A.; Chu, J. Effect of Particle Shape on Strength and Stiffness of Biocemented Glass Beads. J. Geotech. Geoenviron. Eng. 2019, 145, 06019016. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-Mediated Soil Improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Wang, J.L.; Rosenbaum, J.J.; Prasad, A.N.; Raad, R.R.; Putman, E.J.; Harrington, A.D.; Aintablian, H.; Hynek, B.M. Potential Health Impacts, Treatments, and Countermeasures of Martian Dust on Future Human Space Exploration. GeoHealth 2025, 9, e2024GH001213. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).