1. Introduction

The tensile strength of clay is rather low, and under arid conditions, it may readily become fragile. When exposed to external forces, it is susceptible to brittle failure, hence constraining the use of clay in projects with significant load-bearing demands. Consequently, it is imperative to strengthen the clay, augment its structure, and bolster its strength and stability to guarantee the project’s safety and stability.

Qi et al. [

1] investigated the reinforcement of mudstone slopes in tailings piles using xanthan gum, discovering that the incorporation of xanthan gum markedly diminishes the crack area following the shrinking and drying of mudstone, with the average enhancement efficiency exhibiting a positive correlation to the concentration, specifically within the range of 0.5% to 2% xanthan gum content. Upon surpassing 2%, a negative connection is observed, with the maximum average improvement efficiency being 45%. Zhang et al. [

2] indicated that a low liquid limit powdery soil is typically unsuitable for direct application as roadbed or slope soil. They conducted unconfined compressive strength tests to examine the impact of xanthan gum on the enhancement of low liquid limit powdery soil and discovered that a xanthan gum concentration of 2%, maintained for 7 days, results in a stabilization of the soil’s strength. Anandha et al. [

3] discovered that the incorporation of xanthan gum into the soil creates a gel covering on the surface and a gel plug within the soil matrix, which can markedly diminish the hydraulic conductivity of the soil. Zizzo et al. [

4] performed an experimental investigation to enhance soil resistance to cracking by dry cracking tests on kaolin, discovering that xanthan gum and recycled carpet fibers can augment soil strength and diminish cracking. Zhang et al. [

5] discovered that xanthan gum (XG) and junction cold gel (GG) significantly enhance the water retention capacity of sandy soils. These materials absorb water to create hydrogels and biofilms, which diminish the pore space between the soil particles, hence enhancing the water retention capacity of sandy soils. As the concentration of biopolymers rises, the water retention capacity of sandy soils correspondingly increases. The water retention capacity of sandy soils treated with knotted cold gel surpassed that of sandy soils treated with xanthan gum. Miao et al. [

6] conducted indoor dry and wet cycle tests on xanthan gum-enhanced expansive soil, quantitatively analyzing the entire crack development process using digital image processing technology (PCAS). They examined the effects of xanthan gum incorporation on the crack morphology and characteristic indices of the expansive soil, discovering that xanthan gum mitigated cracking primarily through two mechanisms: it formed a “bridge-link” structure with soil particles via bonding and cementation, and it obstructed the water contact with the soil particles through filling and film formation, thereby reducing the thickness of the hydration film of the clay minerals. Xanthan gum mitigates the cracking of expanded soil through two mechanisms: firstly, it establishes a “bridging” structure with soil particles via bonding and cementation, thereby enhancing the overall tensile strength of the soil; secondly, it obstructs water contact with soil particles through filling and film formation, consequently diminishing the thickness of the hydration film surrounding clay minerals. Wang et al. [

7] discovered that xanthan gum and guar gum interacted with soil minerals to create cement, thereby enhancing the bonding strength among soil particles, increasing soil cohesion, reducing the expansion and contraction of expansive soils, and improving both shear strength and unconfined compressive strength.

Jin et al. [

8] examined the evaporation and cracking properties of straw and polypropylene fiber-reinforced soils, discovering that the incorporation of natural and polypropylene fibers diminishes water evaporation and mitigates cracking, thereby offering a method for soil enhancement in arid regions. Wang et al. [

9] performed loose and undrained triaxial experiments, revealing that the incorporation of polypropylene fiber and fly ash into the roadbed soil enhances its ductility and stiffness, while also establishing a denser skeletal structure inside the soil. Zhao et al. [

10] enhanced soil using coconut fiber, discovering that the fiber substantially increases the soil’s shear strength by direct shear testing, hence promoting slope stability and presenting the extensive application potential. Estabragh et al. [

11] incorporated nylon fibers into clay soil and discovered that this addition markedly enhances the shear strength and friction angle of the soil matrix. Li [

12] consider fiber-reinforced soil functions as a composite material, with fibers imparting significant tensile strength. Randomly distributed fibers engage with the soil to enhance interfacial resistance and interlocking, hence augmenting soil strength. This research discusses the use of coir fibers into a xanthan gum and clay mixture to enhance the soil’s strength and reduce brittleness.

Anusudha et al. [

13] conducting indoor experiments on clay amended with coir fiber, discovering that the unconfined compressive strength of soil is significantly increased when coir fiber is added to it. The increase is directly proportional to the quantity of the fiber used. The peak compressive strength of the fiber-reinforced soil with 1.5% fiber content is more than twice that of the unreinforced soil. Moreover, the stiffness and ductility of the soil are quite improved with the use of natural fiber. Cao et al. [

14] used coir fiber to reinforce red clay, and the results showed that the incorporation of coir fiber can improve the strength and ductility of red clay.

Previous studies only reflected in the improvement of soil by fiber or xanthan gum alone, studying its mechanical properties and micro-mechanisms, or considering the study of improved soil under a single maintenance method; in this paper, we combine the two materials and consider the strength change, stress–strain trend, damage morphology, and micro-analysis of improved soil under different maintenance methods.

The double-helix structure of xanthan gum can form a three-dimensional network in solution, dispersing coir fibers, preventing aggregation, and enhancing the homogeneity and stability of composites. Its good fluidity improves the processing performance, reduces resistance, and facilitates the mixing and molding of fibers with other matrices. The hydroxyl and carboxyl groups of xanthan gum can form hydrogen bonds with the hydroxyl groups on the surface of coir fiber to enhance the bonding force; the negative side-chain charge interacts with the positive charge on the surface of coir fiber to produce electrostatic interactions, which further stabilizes the structure and enhances the performance of the composite material. The combination of the two materials synergistically enhances the mechanical properties of the clay and necessitates an in-depth study.

3. Test Results and Discussion

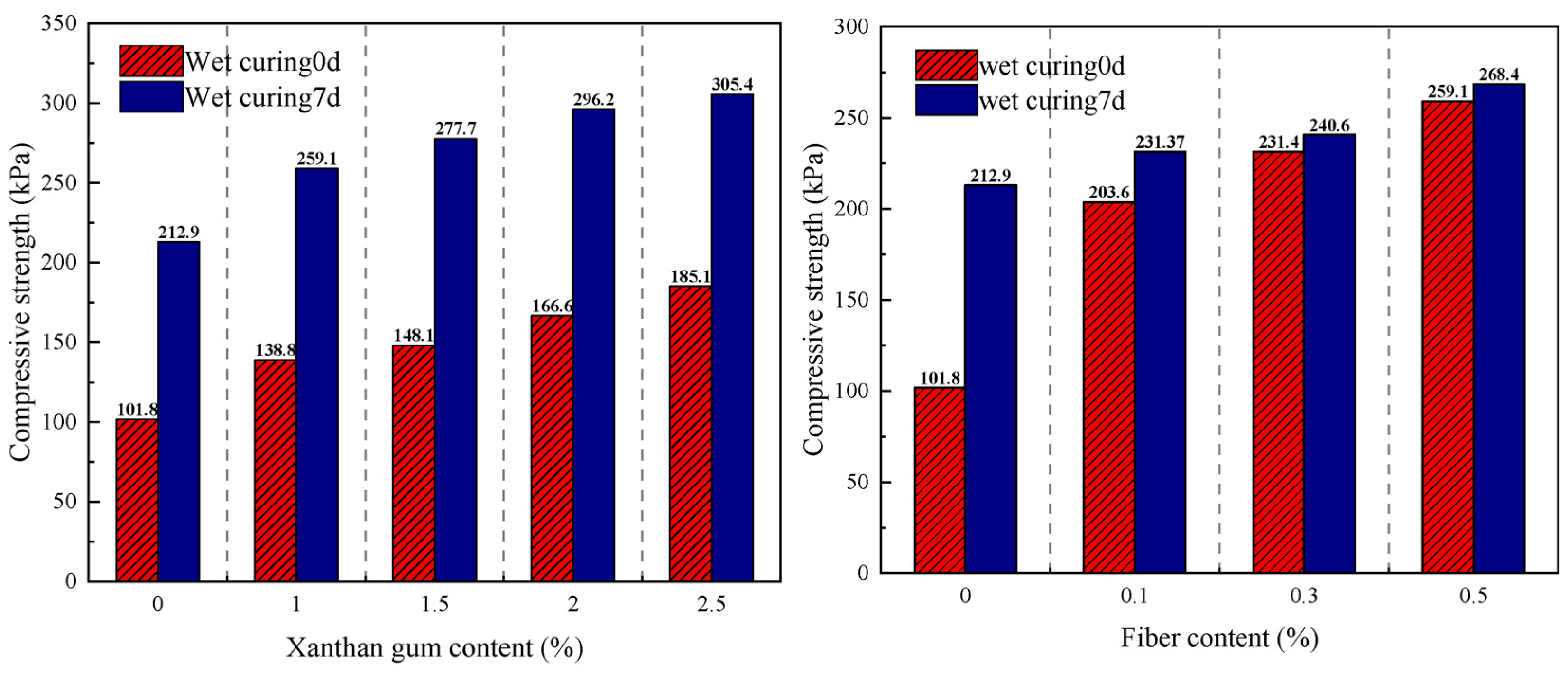

3.1. Effect of Xanthan Gum and Coconut Fiber on Soil Strength

Table 5 enumerates the compressive strength of the samples subjected to various beginning circumstances at 7 days and 28 days. The table indicates that, under uncured conditions, the unconfined compressive strength of soil enhanced with xanthan gum or coconut fiber alone can attain 185 kPa and 259 kPa, respectively. The unconfined compressive strength of the composite-improved soil exceeds that of the soil enhanced only with fiber or xanthan gum. As the quantities of fiber and xanthan gum rise, the unconfined compressive strength of fiber-reinforced clay significantly surpasses that of xanthan gum. The cementitious substance generated between the xanthan gum and the soil has not yet completely reacted; however, the friction between the fiber and the soil, along with the network structure established by the adhesion between the fiber and the xanthan gum, produces a locking force within the soil, thereby augmenting the compressive strength of the sample [

16]. Tang et al. [

17,

18], through the experimental study of this three-dimensional mesh structure, found that the fibers were interlinked with the soil to form a mesh structure. The gel formed by xanthan gum with water and soil can well connect the fiber roots and form a three-dimensional mesh structure. This increases the strength of the soil. Consequently, during brief curing durations, the cementing efficacy of xanthan gum in the soil remains inadequately harnessed, whereas the fibers predominantly contribute to the augmentation of soil strength in samples subjected to a limited curing time.

As the curing duration is established, the unconfined compressive strength of the specimen rises with the incorporation of fiber or xanthan gum. Following a 28-day curing period under arid conditions, with an XG concentration of 2.5%, the sample exhibits a compressive strength enhancement of 2316 kPa. Under dry curing circumstances, a 1% addition of XG resulted in an 11.31-fold increase in the unconfined compressive strength of the sample. A 2.5% addition led to a 12.52-fold increase. The augmentation of xanthan gum content correlates with the enhancement of the sample’s compressive strength and the degree of strength improvement.

Figure 5 illustrates that the compressive strength of the composite amended soil is higher than that of the soil amended with xanthan gum or coir fiber alone. So, composite materials have an enhancing effect on soil improvement.

Figure 6 illustrates that after a brief curing time, namely under wet conditions for seven days, the compressive strength of samples containing only fiber does not exhibit substantial enhancement. As the xanthan gum concentration rises, the compressive strength of the samples exhibits a notable alteration, suggesting that the curing duration positively influences the interaction of xanthan gum with the soil.

3.2. Analysis of the Efficiency of Strength Improvement in Materials

The following equation was used to evaluate the effect of xanthan gum and coconut fiber in increasing the strength of composite amended soils.

where

Wxg,

Wf represent the improvement percentages of the sample UCS by xanthan gum and coconut shell fiber, respectively.

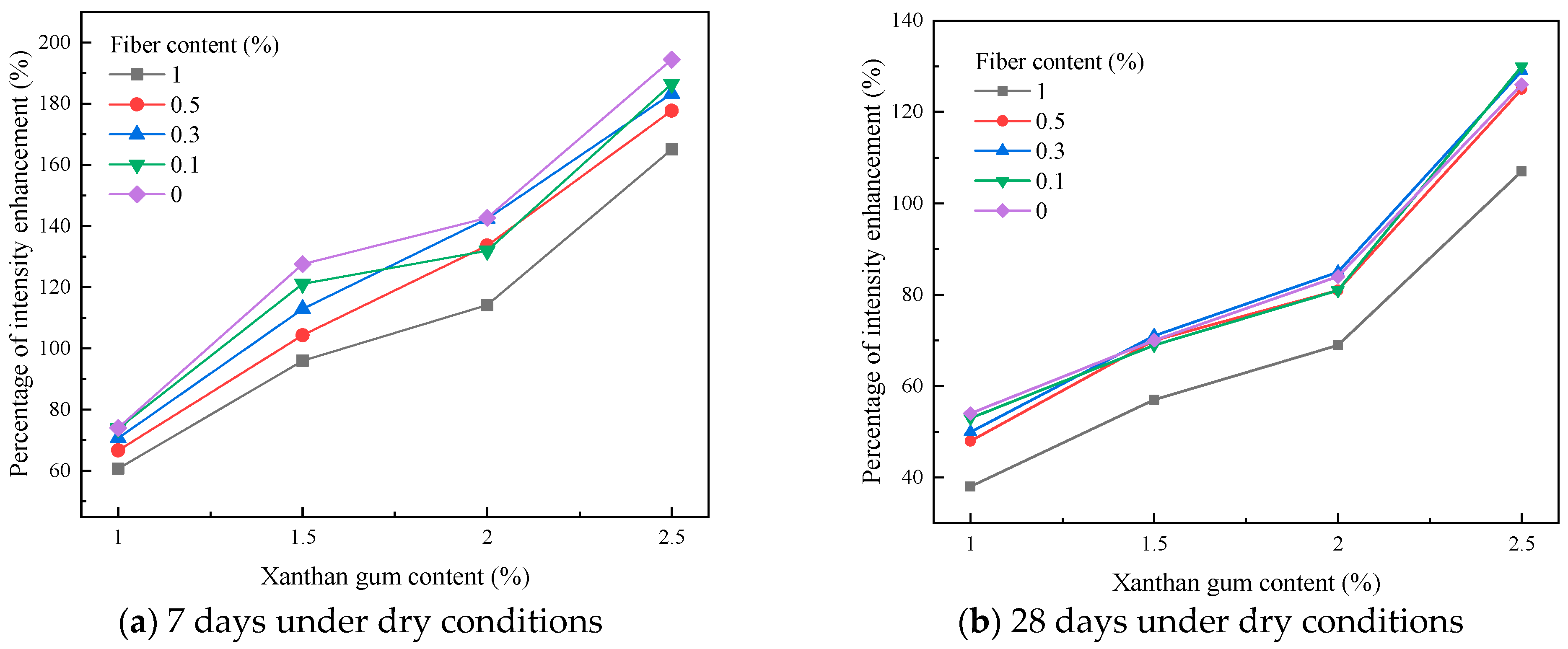

Figure 7 illustrates the impact of specimen strength increase efficiency using xanthan gum doping at a specified coir fiber doping level.

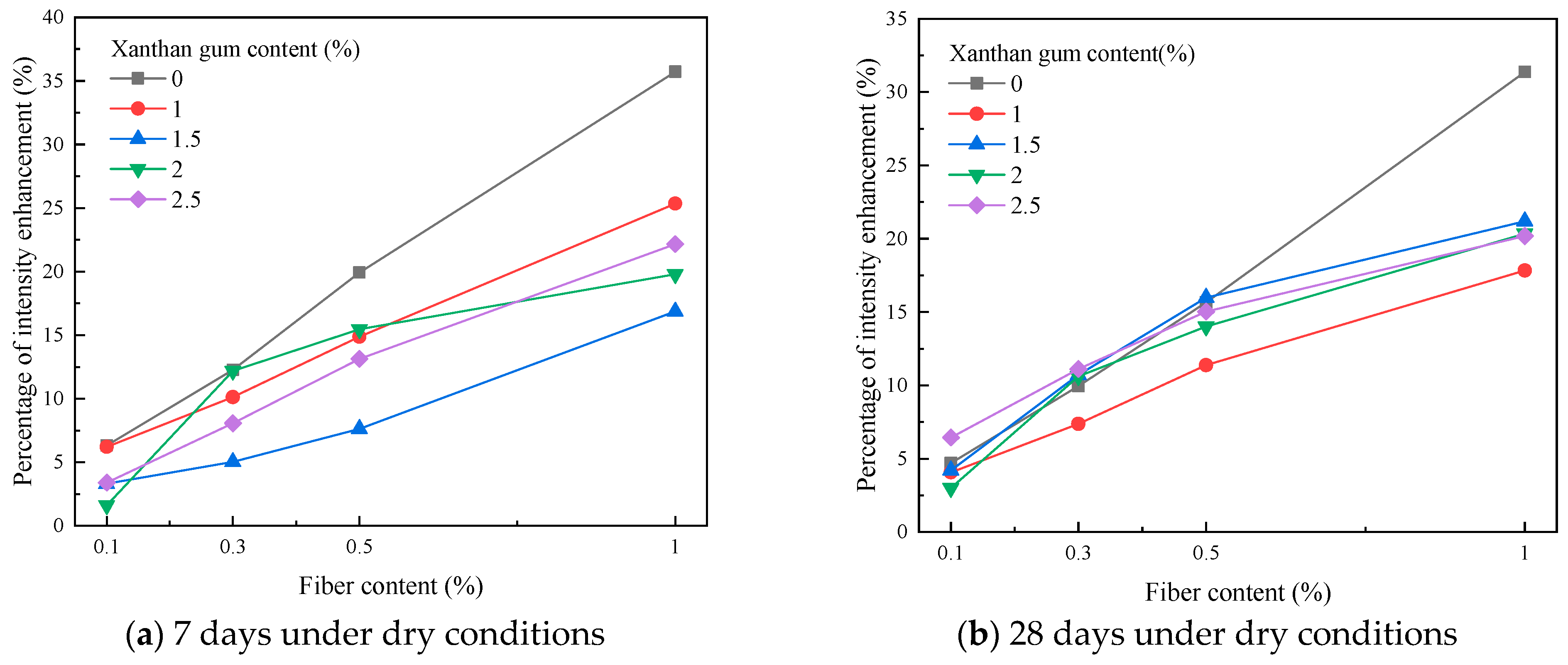

Figure 8 illustrates the effect of using xanthan gum at a specific xanthan gum doping level on the efficiency of specimen strength improvement. The efficacy of xanthan gum in enhancing specimen strength (

Wxg) is evidently proportional to its concentration, given a fixed fiber doping level. Similarly, at a specific xanthan gum concentration, the effectiveness of fiber in augmenting specimen strength (

Wf) also rises with increased fiber doping levels. It is evident that an increase in xanthan gum or fiber dosage enhances the interaction of the combined material with the soil matrix, hence improving the strength efficiency [

19].

The analysis of the strength enhancement efficiency graphs for 7 days and 28 days reveals a decline in the interaction efficiency at 28 days relative to 7 days. It is evident that the cementation between xanthan gum and soil particles is largely achieved within 7 days for specimens cured in a dry environment. Despite the operating efficiency value at 28 days being inferior to that at 7 days, its efficacy is enhanced, suggesting that an extended maintenance time can further augment the interaction between the composite material and soil particles. The strength efficiency of samples, when mixing identical quantities of material over the same maintenance duration, varies. When (xg1%, f1%) is cured under dry conditions for 7 days, its compressive strength can attain 1795 kPa, whereas the compressive strengths of (xg1%, f0%) and (xg0%, f1%) are 1432 kPa and 1117 kPa, respectively. The efficiency improvement rates are 95.97% and 25.35%, respectively. The maximum compressive strength after 28 days of curing for (xg1%, f1%), (xg1%, f0%), and (xg0%, f1%) is 2002 kPa, 1699 kPa, and 1453 kPa, respectively. The efficiency improvement rates are 56.57% and 17.83%, respectively. It can be inferred that, under dry curing circumstances, xanthan gum exhibits superior efficacy in enhancing sample strength.

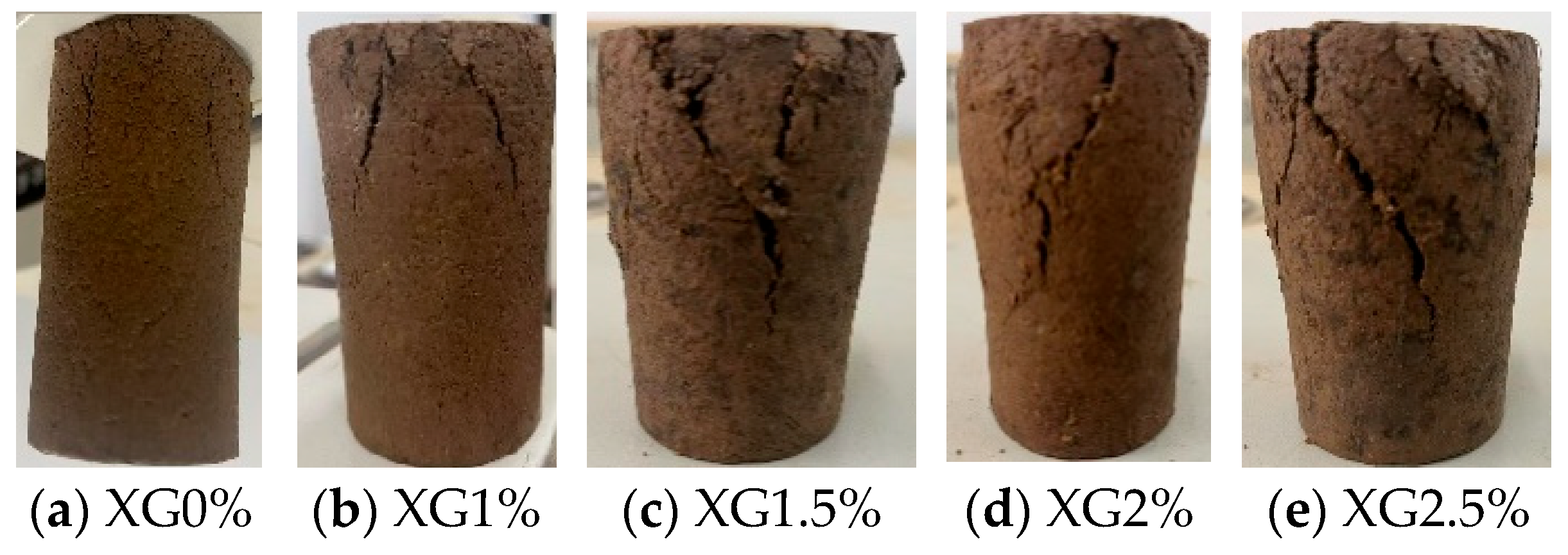

3.3. Failure Pattern

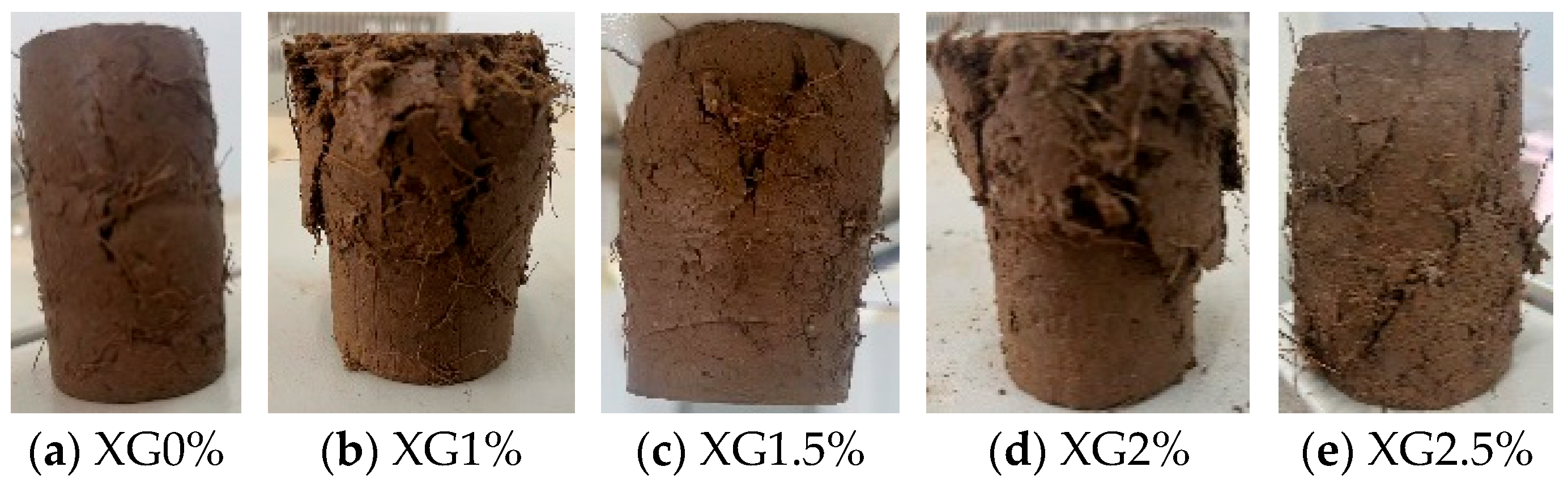

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 illustrate the failure modes of soil specimens subjected to conventional 28-day wet curing conditions. The untreated soil and the xanthan gum-treated soil display comparable damage patterns. Improved soil displays prominent fissures during uniaxial compression, creating a shear failure surface with an inclination angle ranging from 60° to 90°. No lateral bulging was observed in the sample, rather, axial damage was distinctly evident, marked by a significant and widespread primary crack, indicative of typical brittle failure. Upon examination, their stress–strain curves showed considerable resemblance, resulting in the conclusion that the incorporation of xanthan gum, in the absence of fiber blending, did not modify the soil’s brittleness. Under wet curing conditions for 28 days (i.e., enclosed in sealed bags), a specific quantity of moisture was preserved in the samples, hence demonstrating the traits of plastic deformation.

With a longer curing time, the colloidal substance generated by xanthan gum progressively attaches to soil particles, creating an internal bonding solid that the diminishes crack size. As the fibers are incrementally introduced, they function as a binding agent inside the soil. At this point, damage to the samples is infrequently detected, and sporadic swelling occurs, when the volume at both ends surpasses that of the central region. As the fiber content rises, a gel-like substance develops among the fibers, xanthan gum, and soil, resulting in a robust network structure that fortifies the sample’s strength. As the axial pressure escalates, no more cracks manifest in the sample. With the increase in axial pressure, no more cracks manifest in the sample, which subsequently begins to compress, demonstrating considerable plastic deformation at this juncture. This discovery aligns with the studies conducted by Liu et al. [

20], resulting in the conversion of substantial fissures into smaller ones.

In humid regions, soil absorbs moisture and expands, resulting in increased particle separation and alterations in its structure and qualities. Clay swells upon water absorption and softening, resulting in less strength, whereas moist circumstances augment the soil’s flexibility. During unconfined compression, the soil exhibits lateral expansion deformation under applied stress, rather than failing along a defined shear plane, demonstrating traits of plastic expansion damage. In wet protection, the force disseminates laterally, resulting in expansion-type damage marked by a substantial center and a diminutive end. Prolonging the curing duration will modify the internal composition of the soil. In soil mixed with a curing agent, the interaction between xanthan gum and coconut fiber during wet curing may alter the failure mode from brittle shear failure to multi-shear conical failure. The emergence of several fissures within the soil matrix results in increased anisotropy; these fissures are constrained by robust particle bonds during the expansion phase, leading to persistent directional alterations and finally creating a multi-crack conical damage surface.

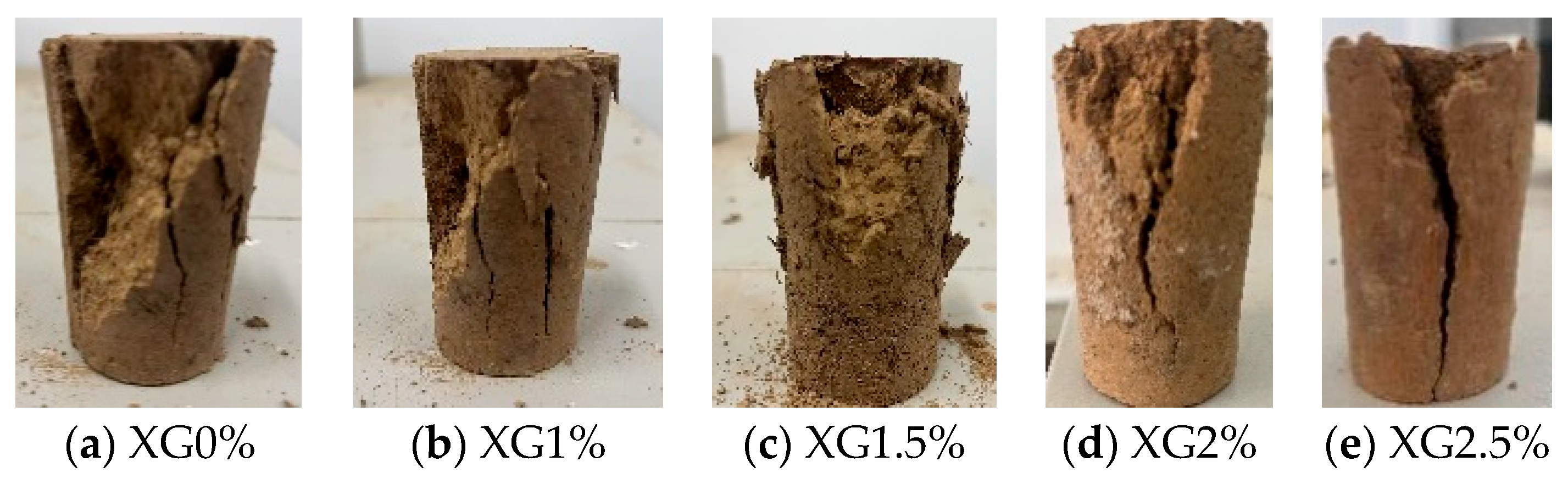

Figure 14,

Figure 15,

Figure 16,

Figure 17 and

Figure 18 illustrate the soil damage morphology during 28-day air-dry conservation settings, indicating that the samples exhibited increased brittleness throughout curing. The brittle behavior was more evident in samples with increased biopolymer concentration. The picture illustrates the transition from the brittle damage pattern of low xanthan gum–fiber soil mixtures to the ductile damage pattern of high xanthan gum–fiber soil mixtures in the samples. This indicates that the quantity of coir fibers is crucial for diminishing brittleness and enhancing ductility. In conclusion, the incorporation of xanthan gum altered the brittleness and strength of the soils, whereas the fibers enhanced their ductility.

Throughout the desiccation process, the soil mass expels moisture and contracts, resulting in a reduction in interparticle distance and the formation of microfractures therein. As drying progresses, these micro-cracks enlarge, stretch, and gradually develop into larger fissures. Drying maintenance will cause the soil structure to exhibit pronounced fissures, compromising its integrity and uniformity. Dry maintenance will diminish the flexibility of the soil and augment its brittleness. When exposed to external force, it is easier to develop a shear band in a specific direction, resulting in the specimen sustaining damage along the shear band, exhibiting distinct characteristics of brittle shear failure. The cementation among xanthan gum soil particles is augmented, resulting in increased soil strength and greater brittleness, with damage occurring along the shear surface at an inclination of approximately (45° + φ/2).

3.4. Stress–Strain Curves of Xanthan Gum and Coir Fiber Amended Soil

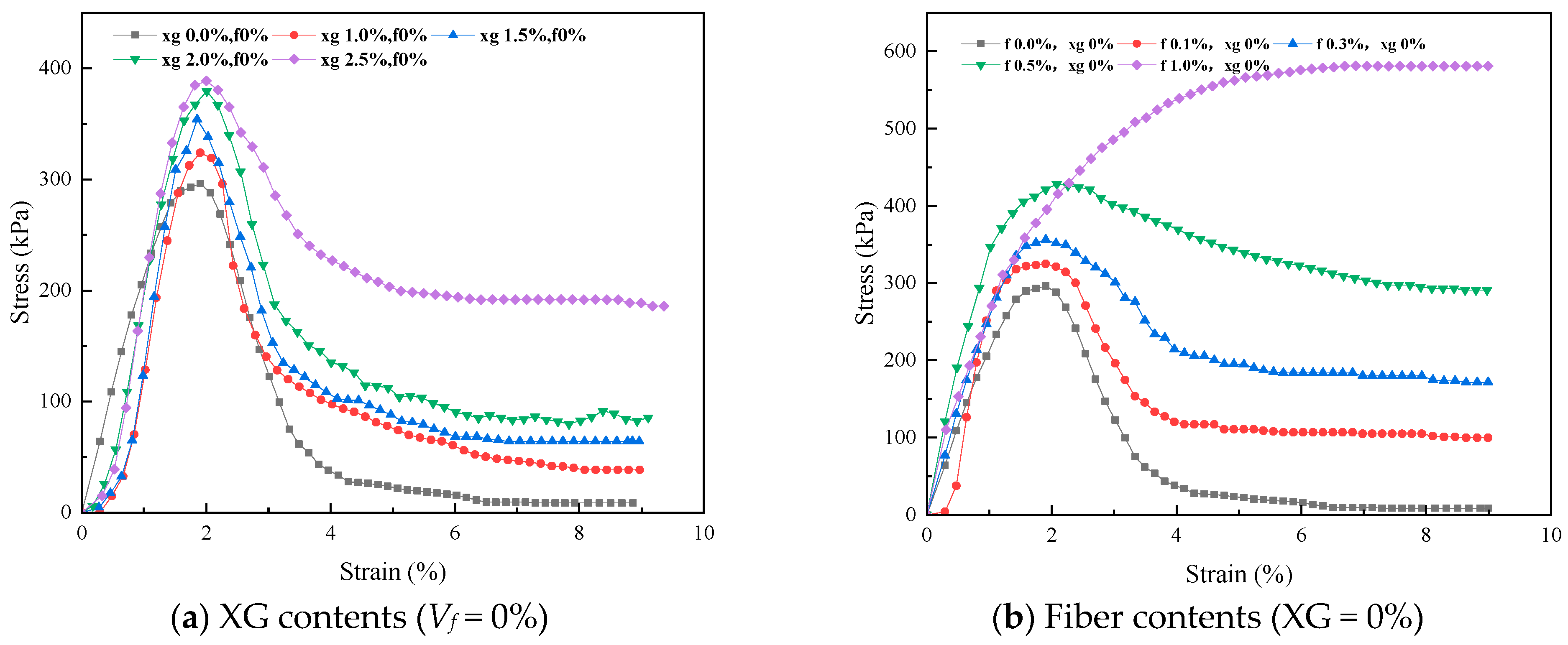

Figure 19 and

Figure 20 illustrate the stress–strain curves of samples subjected to two distinct curing conditions: dry and wet curing for a duration of 28 days.

Figure 19 unequivocally demonstrates that samples with xanthan gum display elevated peak stress following 28 days of wet curing. This indicates that prolonging the curing duration may facilitate interactions between xanthan gum and soil particles, so strengthening their bond and improving compressive strength. Furthermore, an increase in xanthan gum concentration markedly improves the sample strength during the curing process. For example, the maximum stress of the sample combined at a ratio of XG 2.5% and F 0.1% rose by 232 kPa after 28 days of wet curing, but the maximum stress of the sample combined at XG 1.0% and F 0.1% grew by merely 111 kPa. This suggests that an extended curing duration facilitates the greater incorporation of xanthan gum into the soil.

The anionic carboxyl (-COOH) and hydroxyl (-OH) groups in xanthan gum’s structure can interact with soil cations (e.g., Na

+, K

+, Ca

2+, etc.), resulting in the formation of ionic or hydrogen bonds. The deprotonated carboxyl groups of xanthan gum generate negative charges, which attract cations in the soil and facilitate their exchange with negatively charged clay minerals. This interaction can modify the surface charge characteristics of soil particles, facilitating particle aggregation. Furthermore, when xanthan gum dissolves in water, it produces a viscous hydrogel that occupies the voids between soil particles, establishing an interconnected network structure. This structure boosts the soil strength and stiffness while simultaneously reducing hydraulic conductivity, hence raising peak stress [

21,

22].

Figure 20 illustrates the stress–strain curves of the specimens cured in dry circumstances for 28 days.

Figure 19a and

Figure 20a demonstrate that the incorporation of xanthan gum markedly increases the peak stress of the specimens.

Figure 19b and

Figure 20b demonstrate that the fiber retain residual stress following the compression and destruction of the specimens. During a 28-day dry curing process, the moisture in the gum gel will progressively evaporate, concurrently resulting in the formation of a solid gum film. These solidified films can tightly adhere soil particles and fiber, so markedly improving the bonding strength between them, which contributes to an increase in the peak stress of the specimens [

23].

Under dry curing circumstances, the gum film may experience shrinkage and become brittle, with this brittleness becoming more pronounced as the curing duration and gum quantity rise.

Figure 4 illustrates that, irrespective of the gum quantity, the stress–strain curves exhibit a softening effect post-peak stress when fiber content escalates. After the specimen’s stress attains its maximum value, an increased compressive strain can more efficiently leverage the tensile characteristics of the fiber, resulting in the improved ductility of the samples and subsequently augmenting the residual stress post-damage [

24].

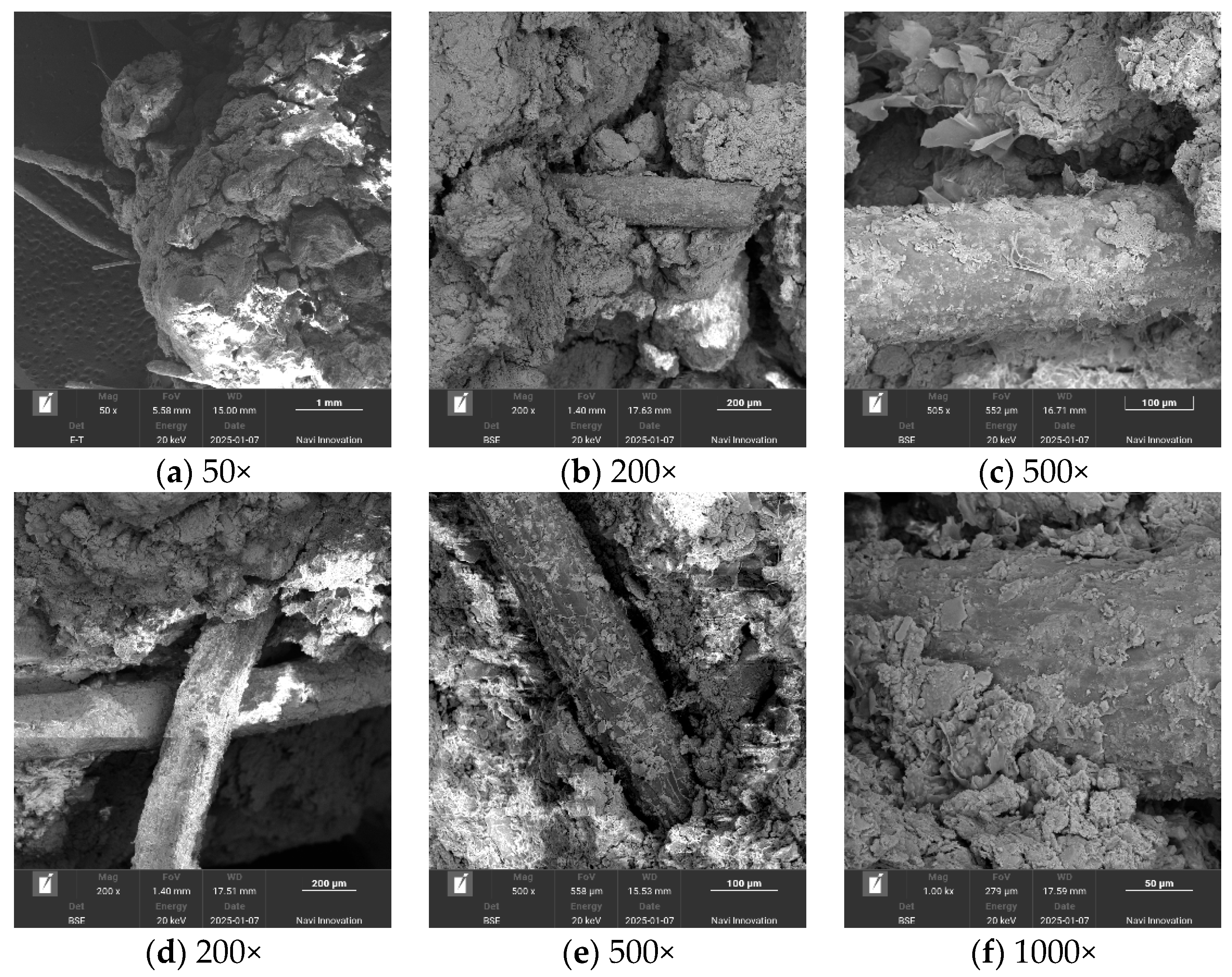

3.5. Microanalysis

Figure 21a–c illustrate the interior morphology of the soil samples at magnifications of 50×, 200×, and 500×, respectively. The bonding blocks formed between the xanthan gum and the soil particles are relatively distributed, making it challenging to join the soil particles. The reduced concentration of xanthan gum results in an increased number of voids in the material. Scattered xanthan gum gels are affixed to the fiber.

Figure 21d–f illustrate the internal morphology of the soil examined at magnifications of 200×, 500×, and 1000×. As the xanthan gum level increases, it binds the soil particles to create gel agglomerates, filling the interstitial spaces and thereby improving the specimen’s compressive strength. The fiber’s surface is partially devoid of its cuticle covering, revealing a distinct and organized depression that facilitates interfacial interaction between the coconut fiber surface and the xanthan gum. The coarse texture of the coconut shell fiber is evident, together with the presence of gelatinous substances, suggesting that the incorporation of coconut shell fiber positively influences the adhesion among soil particles.

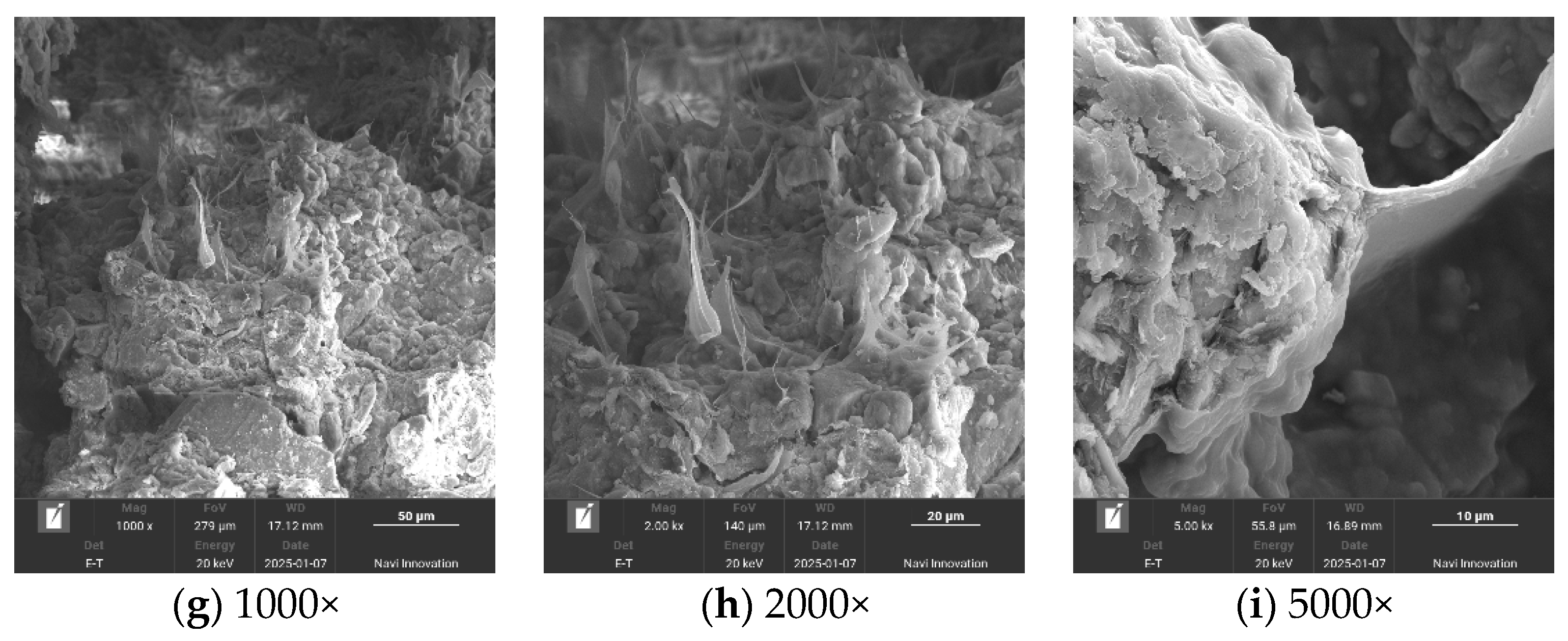

The fiber facilitates the distribution of xanthan gum and soil particle gels within the soil (illustrated in

Figure 21g–i, where the hydrogel is magnified 5000 times to reveal internal details), providing a framework for the agglomerates formed by soil particles and xanthan gum, which adhere to the surface of the coconut shell fiber, creating a cohesive soil structure and coconut shell fiber that serves an adhesive function. Additionally, the rough surface of the coconut shell fiber generates frictional force when the soil structure is subjected to stress, exerting a restraining influence on the soil body and resisting deformation. The fiber’s binding action on soil particles improves the stability of the soil structure. Consequently, the fiber can influence the likelihood of the abrupt displacement of soil particles under axial load [

25]. The xanthan gum in the specimen binds easily to smaller soil particles, while the woven network structure of the coconut shell fiber more effectively stabilizes bigger soil particles, hence enhancing the specimen’s strength.

4. Conclusions

The research used a mixture of xanthan gum and coconut shell fiber to enhance the clay, examining the associated mechanical properties of the soil. The effects on the mechanical properties of the subgrade and slope soils in engineering were evaluated, offering a viable solution for subgrade deterioration and slope instability in various locations of the country. The primary conclusions are as follows:

(1) The unconfined linear compressive strength of xanthan gum alone or in coir fiber-treated soils increased with its concentration. Notably, the unconfined compressive strength of coir fiber-treated clays surpassed that of xanthan gum at a curing duration of 0 days, indicating that the unconfined compressive strength of the specimens was governed by the coir fibers in the untreated specimens.

(2) Xanthan gum can create a rigid film and enhance the compressive strength of the specimen within 7 days of conditioning in dry settings; however, 28 days of conditioning in wet conditions is necessary to optimize the gel’s effect.

(3) Xanthan gum influences the compressive strength of the specimen and the extent of strength enhancement, whereas coir fibers augment the specimen’s strength, transform its brittleness into ductility, and impart residual strength post-failure. The incorporation of xanthan gum altered the soil’s strength and brittleness, while the inclusion of fibers modified its toughness.

(4) The xanthan gum or coconut fiber is utilized to enhance the specimen’s strength through the incorporation of additional materials, and the strengthening efficacy after 28 days under dry conditions is inferior to that observed at 7 days. The xanthan gum’s contribution to the specimen is predominantly realized within the first 7 days. During the subsequent 7 to 28 days, xanthan gum’s influence diminishes, yet it continues to facilitate the incremental strength enhancement of the specimen.

(5) Xanthan gum incorporated into the soil will generate a gel-like layer, uniformly covering the surface and occluding the pores, thus stabilizing the soil structure. Fiber is incorporated into the soil to create a conducive environment for the gelling material, facilitating the adhesion of the product to the growth, and thereby resulting in a strong bond between the fibers and the soil. Additionally, the fiber establishes a spatial mesh structure within the soil, which mitigates cracking and enhances the soil’s resistance to deformation. The coconut fiber primarily serves a reinforcing function, while xanthan gum acts as a curing agent, their combined action alters the intrinsic properties of the soil.

In this paper, the long-term durability of xanthan gum in saturated environments is not considered, and we discuss the mechanical properties of xanthan gum at an optimal water content. In subsequent studies we can consider the mechanical properties and durability of xanthan gum-amended soils when the water content is too high, and investigate whether xanthan gum is effective in improving soil properties at a high water content.

(1) The effect of xanthan gum on the strength of improved soil is most significant near the optimal water content. At this time, xanthan gum can give full play to its role in filling the pores and enhancing the inter-particle bonding, so that the strength of the soil body reaches a high level.

(2) The strength of xanthan gum-amended soils decreases dramatically when the water content is too high, especially near saturation. This is because excess moisture weakens the bond between the xanthan gum and the soil particles, and also causes the gel structure of the xanthan gum to become loose due to water absorption and expansion, thus reducing the overall strength of the soil.