Mechanical Performance of Prefabricated Monolithic Composite Columns with Reinforced ECC Precast Shell

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

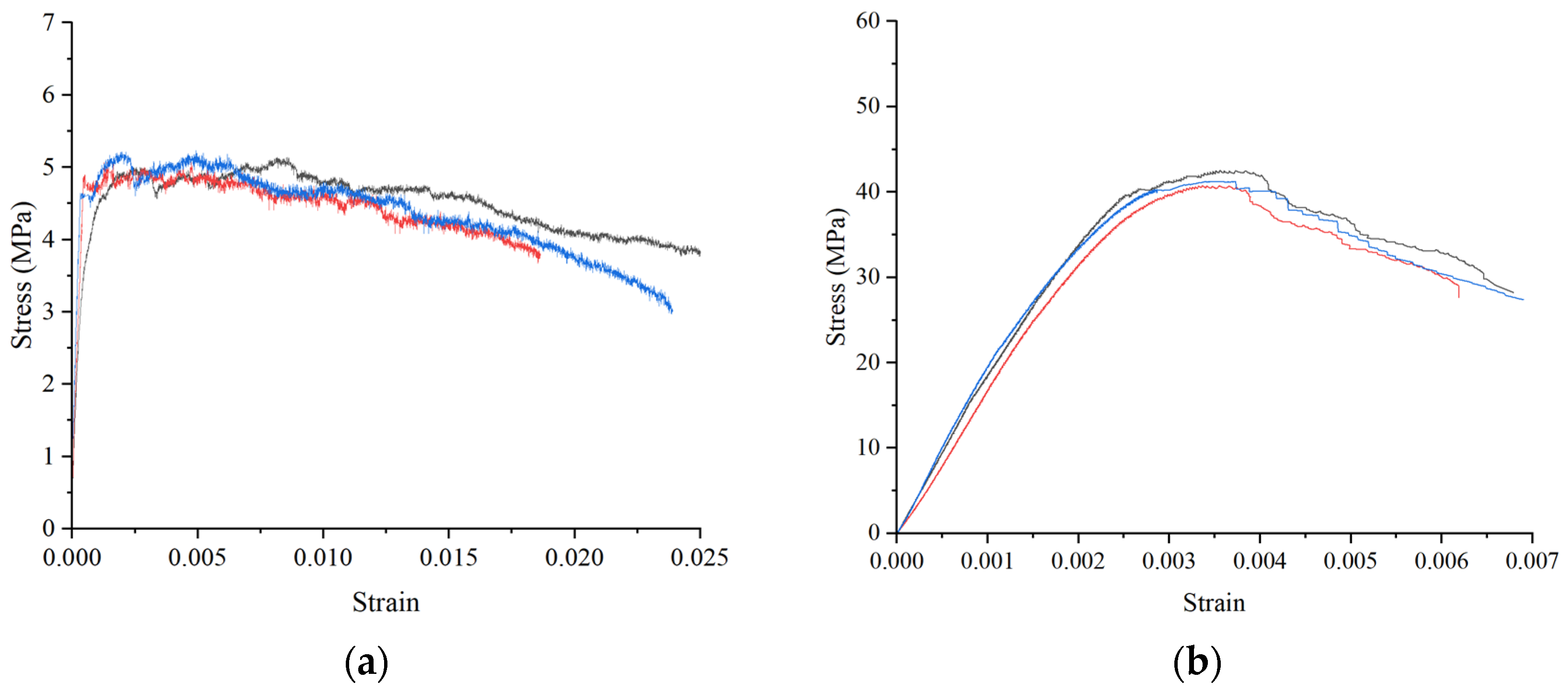

2.2. Materials

2.3. Test Setup and Instrument

3. Results and Discussion

3.1. Failure Pattern

- For specimen FRC-P-1, at an axial load of 1014.32 kN, initial vertical cracking appeared from the top of the column. The cracks developed with the increasing load. When the load reached 2448.84 kN, the vertical cracks on the right side of the specimen extended to the middle, and the transverse crack appeared at the edge of the column. The longitudinal reinforcement yielded at a load of 2625.80 kN. At the peak load, the transverse crack extended to the other side. The transverse cracks were connected with the vertical cracks on the left and right sides to form an “H” shape. Until the test stopped, the maximum crack width was about 3 mm. The final state is shown in Figure 4.

- For specimen FRC-P-2, when the load was 679.77 kN, small vertical cracks occurred at the upper part. With the increasing load, continuous crack formation and extension were observed. When loading to 2652.38 kN, transverse cracking was initiated on one side of the column. The longitudinal reinforced bars yielded at 2908.29 kN. At peak load capacity, the transverse crack propagated through the full section width, and the vertical crack on the upper right side of one surface developed into the transverse crack. At test termination, the specimen exhibited a transverse crack present in the shell, and there was a vertical crack extending in the middle, as shown in Figure 5.

- When the load of specimen FRC-P-3 reached 1030.28 kN, transverse cracking was observed at three separate positions in the central region of the specimen. The longitudinal reinforced bars yielded at a load of 2039.07 kN. Upon reaching the ultimate load, a slender vertical crack appeared from the top surface to the central section. The edges and corners at the upper part were broken. The central transverse crack propagated through the entire cross-section, resulting in full penetration of both specimen surfaces. When the specimen failed, there were obvious vertical and transverse cracks in the mid-height region of the column, as illustrated in Figure 6. However, the ECC material of the shell did not fall off, and the specimen still maintained good integrity.

- For specimen RC-P-1, vertical cracks appeared at a load of 438.40 kN. The vertical cracks continued to occur and extend with the increase in load. The reinforced bar yielding was initiated at a measured load of 2406.67 kN. At 2549.28 kN, longitudinal cracks also developed in the specimen’s lower region. Simultaneously, existing vertical cracks propagated fully, creating a continuous through-fracture. When it reached the peak load, dense vertical cracks appeared in the concrete shell, and the concrete began to spall off. When the specimen failed, the longitudinal cracks propagated vertically between the column’s end regions, and the shell at the edges and corners broke and fell. Crushing occurred at the edges and corners of the lower side of the column (Figure 7a). Extensive concrete spalled off, and the reinforcement was exposed, as shown in Figure 7b.

- Vertical cracks began to appear at the bottom of specimen RC-P-2 at precisely 561.08 kN. Primary vertical cracks formed in the upper region at the load of 1325.52 kN. The longitudinal bars reached yielding when they reached 2788.29 kN. Upon reaching 3287.28 kN, transverse cracking and concrete extrusion occurred at the mid-height region, indicating compressive failure. The column exhibited diagonal crack failure. The column exhibited concrete cover spalling, resulting in the peeling of the shell (Figure 8a). In the end, the concrete at the edges and corners of the column cracked and spalled off. The steel bars were exposed. The final failure pattern and damage distribution are illustrated in Figure 8b.

- For column RC-P-3, the first visible vertical cracks formed at an applied load of 430.20 kN, and the vertical cracks began to propagate bidirectionally from the top and bottom toward the midspan when the load reached 1640.96 kN. The reinforced bars reached yielding at 1980.68 kN. At the ultimate load of 3014.24 kN, the main diagonal crack formed (Figure 9a), generating dense cracks around the vertical cracks, and the concrete began to fall off. When the test stopped, extensive concrete spalled off, resulting in full exposure of the reinforcement, as shown in Figure 9b.

- For specimen RC-1, vertical cracks occurred at the top of the column when the load reached 667.35 kN. At approximately 2621.15 kN, vertical cracks developed through the full specimen height, and the number of cracks increased. At 2654.32 kN, the reinforcement yielded. At the ultimate load of 3254.28 kN, the vertical cracks gradually developed to form oblique cracks. The concrete in the middle of the specimen was crushed, and the concrete began to spall off (Figure 10a). When the loading was stopped, vertical cracks at the upper and lower column regions progressively connected through diagonal fracture paths. A large amount of concrete fell off, exposing the longitudinal bars, as shown in Figure 10b.

3.2. Load Deformation Analysis

- For specimen FRC-P-1, which used ECC material for the precast shell, the yield load increased by 6.36% compared with the specimen RC-P-1 with an RC precast shell, and the corresponding compressive strain increased by 20.42% in Table 5. Although peak load differences were negligible, FRC-P-1 showed a 23.62% higher compressive strain at the ultimate load. Compared with RC-P-2, FRC-P-2 exhibited a 7.96% higher yield load capacity and a 20.61% enhancement in the corresponding compressive strain. There was also an 8.97% increase in the compressive strain at peak load. For specimen FRC-P-3, the yield load slightly increased compared with RC-P-3, with a 7.54% increase in the corresponding compressive strain. At maximum load, specimen FRC-P-3 achieved a 13.31% greater compressive strain compared with the reference.

- Compared with RC precast shell composite columns, the deformation capacity of R/ECC precast shell composite column specimens was significantly improved without a sudden drop in load-bearing capacity. The R/ECC prefabricated shell provided additional confinement to the core concrete originating from the tensile strain-hardening characteristics of the ECC material beyond the confinement provided by the stirrups. The yielding of longitudinal reinforced bars was postponed, effectively enhancing the deformation capacity of the columns. The yield and ultimate load capacity of specimen FRC-P-1 were close to those of the cast-in-place specimen RC-1, with no significant difference in compressive strain. It indicated that the monolithic composite columns with prefabricated R/ECC shells exhibit essentially equivalent bearing capacity and deformation capability compared to the specimen RC-1.

- With the increase in the volumetric stirrup ratio, the ultimate load of the specimens increased slightly, and the deformation capacity was significantly enhanced. Compared with FRC-P-3, the volumetric stirrup ratio of FRC-P-1 increased by 0.31%, resulting in a 28.72% enhancement in yield load and a 46.14% improvement in compressive strain. The compressive strain at peak load increased by 24.75%. Compared with FRC-P-1, FRC-P-2 showed a 14.69% rise in yield load and a 24.20% improvement in corresponding compressive strain. At the ultimate load, the corresponding compressive strain improved by 13.25%. For the composite columns with RC precast shells, compared to RC-P-3, RC-P-1 exhibited a 22.32% increase in yield load and a 30.51% increase in corresponding compressive strain. The specimen RC-P-2, with a 0.43% higher volumetric stirrup ratio than RC-P-1, showed a 12.99% improvement in yield load and a 24.01% enhancement in corresponding compressive strain. The compressive strain at peak load increased by 31.41%. It showed that the influence of ECC materials on both yield capacity and compressive ductility of composite columns varied depending on the volumetric stirrup ratio.

3.3. Strain Analysis

3.3.1. Stirrup Strain

- When the load was less than 500 kN, the development trends of stirrup strain for specimens FRC-P-1 and RC-P-1 were basically the same. For loads from 500 kN to the peak load, the stirrup strains of specimen FRC-P-1 were consistently lower than those of specimen RC-P-1 at equivalent loading stages. The stirrup strain of specimen FRC-P-1 showed a sudden increase in growth rate at the load level of 2294.28 kN, while the stirrup strain of column RC-P-1 exhibited a similar sudden increase at a load of 2065.87 kN. The stirrups in specimen RC-P-1 yielded at the peak load point, whereas those in specimen FRC-P-1 did not. After the peak load, specimen RC-P-1 exhibited brittle post-peak behavior, while the stirrup strain of specimen FRC-P-1 increased rapidly, and the curve declined more slowly. Compared with specimen RC-P-1, the stirrup strain of specimen FRC-P-1 at the peak load was reduced by 22.28%.

- When the load was less than 1000 kN, there was no significant difference in stirrup strain between specimen RC-P-2 and specimen FRC-P-2. From the load of 1000 kN to the peak load, the stirrup strain of specimen RC-P-2 began to exceed that of specimen FRC-P-2, and the difference gradually increased. Due to the high stirrup ratio of the two specimens, the stirrups of the two specimens did not yield at the ultimate load point. After that, the stirrup strain of specimen FRC-P-2 increased rapidly, and the curve declined more slowly than that of specimen RC-P-2.

- The stirrup strains of specimens RC-P-3 and FRC-P-3 yielded before the peak load. At the peak load point, the stirrup strain of specimen FRC-P-3 was 15.76% smaller than that of RC-P-3. Then, the load of specimen FRC-P-3 decreased more slowly than that of specimen RC-P-3. Because the volumetric stirrup ratios of specimens RC-P-3 and FRC-P-3 were smaller than those of other specimens, the stirrup strains of specimens RC-P-3 and FRC-P-3 were larger than those of other specimens. The confined effectiveness was relatively weaker.

3.3.2. Longitudinal Reinforced Bar Strain

- The longitudinal reinforcement strain in RC composite columns exhibited a slower growth trend with increasing stirrup ratios. At pre-peak loading stages, RC-P-3 developed the highest longitudinal reinforcement strains, whereas RC-P-2 maintained the lowest recorded values. As the loading approached its maximum load, specimen RC-P-2 displayed an accelerated strain development. At peak load, RC-P-1 exhibited an 8.85% greater longitudinal strain than RC-P-3, while RC-P-2 showed a 33.22% increase compared with RC-P-3. During the post-peak load stage, RC-P-2 maintained the most stable load-bearing behavior, with its load–strain curve descending much more slowly than that of other specimens.

- For R/ECC specimens, the development pattern of longitudinal reinforcement strain was similar to that of RC composite columns. However, distinct differences were observed in strain values at the maximum load point. Compared with FRC-P-3, FRC-P-1 exhibited a 9.36% improvement in longitudinal bar strain, while FRC-P-2 showed a more substantial 44.59% enhancement.

- Before the peak load point, the longitudinal reinforced bars’ strains in the composite column with the R/ECC prefabricated shell were lower than those in the RC counterpart at equivalent loading stages. When the stirrup ratio was relatively large, the longitudinal reinforcement strain value was quite different. The longitudinal strain difference between RC-P-3 and FRC-P-3, which had the smallest stirrup ratio, was relatively small, as shown in Figure 13. The ECC material delayed the yield time of the longitudinal reinforced bars. At equivalent longitudinal reinforcement strain levels, the R/ECC composite columns showed a 9.23% higher load-carrying capacity on average compared with RC counterparts. However, at the peak load, the corresponding strain of the longitudinal reinforced bars in the specimen FRC-P-1 was 6.68% larger than that of RC-P-1, the strain corresponding to the specimen FRC-P-2 was 15.21% larger than that of RC-P-2, and the strain of specimen FRC-P-3 was 6.18% larger than that corresponding to RC-P-3. The R/ECC composite columns exhibited better deformability than the RC composite columns. After the peak load, the curve decline of the R/ECC composite columns was slower compared with the RC prefabricated shell composite columns. This observation also showed that the volumetric stirrup ratio notably influenced the longitudinal reinforcement strain in R/ECC composite columns. It indicated effective cooperative behavior between the ECC precast shell and transverse reinforcement in providing complementary confinement.

3.3.3. Strains of Concrete and ECC Material

4. Conclusions

- The R/ECC prefabricated shell monolithic composite columns exhibited good mechanical properties under axial compression. The R/ECC composite columns exhibited excellent structural integrity throughout testing, and the final failure was manifested as transverse cracks in the shell but no spalling with characteristic ductile failure behavior. However, the RC composite columns showed a typical diagonal compression failure. The concrete spalled off, and the reinforced bars were exposed. The damage was serious.

- Compared to the specimens with an RC precast shell, the specimens that used ECC material for the precast shell showed improved deformability. The yield load increased slightly, and the corresponding compressive strain increased by 16.19% on average. Additionally, the compressive strain at the ultimate load improved by 15.30% on average. Using ECC material in the precast shell enhanced the restraint effect, thereby improving the deformability and integrity of the composite column.

- With the enhancement in the volumetric stirrup ratio, the deformability of the R/ECC prefabricated shell composite columns showed a measurable improvement. Compared with specimen FRC-P-3, the volumetric stirrup ratio of specimen FRC-P-1 increased by 0.31%, its yield load was enhanced by 28.72%, and the corresponding compressive strain increased by 46.14%. The compressive strain corresponding to the peak load showed a 24.75% enhancement. Compared with column FRC-P-1, the yield load of specimen FRC-P-2 increased by 14.69%, and the corresponding compressive strain increased by 24.20%. The corresponding compressive strain at the maximum load exhibited a 13.25% improvement. The experimental measurements showed that ECC materials’ enhancement effects on column yield strength and compressive strain varied with changes in the volumetric stirrup ratio.

- ECC materials could delay the yield time of the reinforced bars. Before the maximum load, the longitudinal reinforced bar strains in the composite column with the R/ECC precast shell were lower than those of the RC prefabricated shell composite columns at the equivalent load level. At equivalent longitudinal reinforced bar strain levels, the R/ECC precast shell composite column showed consistently higher load-bearing capacity than the RC precast shell counterpart. During the post-ultimate load stage, the R/ECC precast shell composite column exhibited a more gradual load degradation compared with the RC precast shell composite column system.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shan, B.; Xu, C.; Lai, D.D.; Xiao, Y.; Li, T.Y. Experimental research on compressive behavior of seawater and sea sand concrete-filled RPC tubes. Eng. Struct. 2020, 222, 111117. [Google Scholar] [CrossRef]

- Cai, J.M.; Pan, J.L.; Li, X.P. Behavior of ECC-encased CFST columns under axial compression. Eng. Struct. 2018, 171, 1–9. [Google Scholar] [CrossRef]

- Chen, G.P.; Wang, Y.L.; Yang, S.T. Elliptical FRP–concrete–steel double-skin tubular columns under cyclic compression: Fundamental characteristics and modeling. Eng. Struct. 2025, 326, 19517. [Google Scholar] [CrossRef]

- Bolina, F.L.; Gil, A.M.; Fernandes, B.; Hennemann, G.G.; Gonçalves, J.; Tutikian, B.F. Influence of design durability on concrete columns fire performance. J. Mater. Res. Technol. 2020, 9, 4968–4977. [Google Scholar] [CrossRef]

- Sheta, A.; Ma, X.; Zhuge, Y.; ElGawady, M.; Mills, J.E.; Abd-Elaal, E. Axial compressive behaviour of thin-walled composite columns comprise high-strength cold-formed steel and PE-ECC. Thin-Walled Struct. 2023, 184, 110471. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Bai, Y.L.; Han, S.W.; Milani, G.; Jin, X.J. Seismic behavior of novel resilient and corrosion-resistant composite columns using strain-hardening engineered cementitious composites and steel-FRP composite bars. Eng. Struct. 2024, 305, 117709. [Google Scholar] [CrossRef]

- Meda, A.; Mostosi, S.; Rinaldi, Z.; Paolo, R. Corroded RC columns repair and strengthening with high performance fiber rein-forced concrete jacket. Mater. Struct. 2016, 49, 1967–1978. [Google Scholar] [CrossRef]

- Zhang, R.; Hu, P.; Zheng, X.H.; Cai, L.; Guo, R.; Wei, D. Shear behavior of RC slender beams without stirrups by using precast U-shaped ECC permanent formwork. Constr. Build. Mater. 2020, 260, 120430. [Google Scholar] [CrossRef]

- Mirzahosseini, H.; Mirhosseini, S.M.; Zeighami, E. Progressive collapse assessment of reinforced concrete (RC) buildings with high-performance fiber-reinforced cementitious composites (HPFRCC). Structures 2023, 49, 139–151. [Google Scholar] [CrossRef]

- Yin, S.P.; Wang, C.L.; Wang, C.C.; Cong, X. Flexural performance of TRC permanent formwork reinforced concrete beams with different dimensions. J. Build. Struct. 2021, 42, 291–301. [Google Scholar] [CrossRef]

- Zhang, P.; Xu, F.; Liu, Y.; Sheikh, S.A. Shear behaviour of composite beams with permanent UHPC formwork and high-strength steel rebar. Constr. Build. Mater. 2022, 352, 128951. [Google Scholar] [CrossRef]

- Liang, X.W.; Wang, P.; Xu, M.X.; Yu, J.; Li, L. Flexural behavior and capacity analysis of RC beams with permanent UHPC formwork. Eng. Mech. 2019, 36, 95–107. [Google Scholar] [CrossRef]

- Qiao, Z.; Pan, Z.F.; Xue, W.C.; Meng, S.P. Experimental study on flexural behavior of ECC/RC composite beams with U-shaped ECC permanent formwork. Front. Struct. Civ. Eng. 2019, 13, 1271–1287. [Google Scholar] [CrossRef]

- Pan, Z.; Zhu, Y.; Qiao, Z.; Meng, S.P. Seismic behavior of composite columns with steel reinforced ECC permanent formwork and infilled concrete. Eng. Struct. 2020, 212, 110541. [Google Scholar] [CrossRef]

- Liu, J.W. Seismic Behavior and Design Method of ECC/RC Composite Columns. Master’s Thesis, Southeast University, Nanjing, China, 2015. [Google Scholar]

- Liang, X.W.; Shi, J.C.; Yu, J.; Li, L. Seismic behavior of reinforced concrete columns with permanent template of Ultra-High-Performance Concrete. China Earthq. Eng. J. 2020, 42, 579–588. [Google Scholar]

- Zanuy, C.; Ulzurrun, G.S.D.; Curbach, M. Experimental determination of sectional forces in impact tests: Application to composite RC-HPFRCC beams. Eng. Struct. 2022, 256, 114004. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Khan, M.I. Behavioral response of reinforced concrete beams with ultra-ductile fiber-reinforced cementitious composite layers—Experiments, models and reinforcement limits. J. Build. Eng. 2023, 77, 107475. [Google Scholar] [CrossRef]

- Nguyen, D.L.; Thai, D.K.; Nguyen, H.T.T.; Nguyen, T.Q.; Le-Trung, K. Responses of composite beams with high-performance fiber-reinforced concrete. Constr. Build. Mater. 2021, 270, 121814. [Google Scholar] [CrossRef]

- Li, F.H.; Feng, Z.H.; Deng, K.L.; Yu, Y.J.; Hu, Z.M.; Jin, H.S. Axial behavior of reinforced PP-ECC column and hybrid NSC-ECC column under compression. Eng. Struct. 2019, 195, 223–230. [Google Scholar] [CrossRef]

- Lai, B.L.; Zhang, M.Y.; Zheng, X.F.; Chen, Z.P.; Zheng, Y.Y. Experimental study on the axial compressive behaviour of steel reinforced concrete composite columns with stay-in-place ECC jacket. J. Build. Eng. 2023, 68, 106174. [Google Scholar] [CrossRef]

- Sasikumar, P. Experimental study on the fully encased composite short columns made with high-strength fibre-reinforced concrete. Asian J. Civ. Eng. 2024, 25, 3239–3250. [Google Scholar] [CrossRef]

- Xu, X.F.; Jiang, Z.Q.; Wan, M.X.; Cui, S.A.; Liu, P.; Zeng, H.N. Experimental study on performance of reinforced concrete short columns repaired and strengthened with Basalt fiber ultra-high-performance concrete (BF-UHPC). Structures 2024, 62, 106170. [Google Scholar] [CrossRef]

- Lu, T.; Wen, Y.; Guan, K.; Wang, B. Flexural performance analysis of composite beam with reinforced HPFRCC precast shell. Materials 2025, 18, 762. [Google Scholar] [CrossRef]

- Lu, T.; Guan, K.; Jin, H. Experimental study on bending performance of high-performance fiber-reinforced cement composite prefabricated monolithic composite beams. Buildings 2023, 13, 1744. [Google Scholar] [CrossRef]

- JCT 2461-2018; Standard Test Method for Mechanical Properties of Ductile Fiber-Reinforced Cementitious Composites. National Building Materials Industry Standard of China: Beijing, China, 2018.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- GB/T 228.1-2021; Standard Metallic Materials-Tensile Testing—Part 1: Method for Tests at Room Temperature. China Architecture & Building Press: Beijing, China, 2021.

| Number | Shell Material | Longitudinal Reinforcement (mm2) | Stirrup Spacing (mm) | Volumetric Stirrup Ratio (%) |

|---|---|---|---|---|

| FRC-P-1 | R/ECC | 904 | 70 | 1.05 |

| FRC-P-2 | R/ECC | 904 | 50 | 1.48 |

| FRC-P-3 | R/ECC | 904 | 100 | 0.74 |

| RC-P-1 | RC | 904 | 70 | 1.05 |

| RC-P-2 | RC | 904 | 50 | 1.48 |

| RC-P-3 | RC | 904 | 100 | 0.74 |

| RC-1 | Cast-in-place | 904 | 70 | 1.05 |

| Cement (g/L) | Fly Ash (g/L) | Quartz Sand (g/L) | PVA Fiber (g/L) | Water Reducer (g/L) | Water (g/L) |

|---|---|---|---|---|---|

| 630 | 630 | 406 | 20 | 15 | 436 |

| Length (mm) | Diameter (µm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|

| 12 | 40 | 1560 | 41 | 6.5 |

| Diameter (mm) | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|

| 6 | 442 | 544 |

| 12 | 453 | 592 |

| Number | Yield Point | Peak Load Point | ||

|---|---|---|---|---|

| Load (kN) | Compressive Strain (10−6) | Load (kN) | Compressive Strain (10−6) | |

| FRC-P-1 | 2624.80 | 7771.18 | 3199.82 | 9511.28 |

| FRC-P-2 | 3010.47 | 9652.34 | 3293.84 | 10,772.33 |

| FRC-P-3 | 2039.13 | 5317.33 | 3074.38 | 7624.52 |

| RC-P-1 | 2467.88 | 6453.33 | 3181.43 | 7693.67 |

| RC-P-2 | 2788.62 | 8002.67 | 3287.28 | 10,110.76 |

| RC-P-3 | 2017.45 | 4944.47 | 3014.24 | 6728.87 |

| RC-1 | 2654.32 | 7738.67 | 3254.28 | 9558.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.; Wang, B.; Jin, H. Mechanical Performance of Prefabricated Monolithic Composite Columns with Reinforced ECC Precast Shell. Buildings 2025, 15, 1777. https://doi.org/10.3390/buildings15111777

Lu T, Wang B, Jin H. Mechanical Performance of Prefabricated Monolithic Composite Columns with Reinforced ECC Precast Shell. Buildings. 2025; 15(11):1777. https://doi.org/10.3390/buildings15111777

Chicago/Turabian StyleLu, Tingting, Bin Wang, and Haowei Jin. 2025. "Mechanical Performance of Prefabricated Monolithic Composite Columns with Reinforced ECC Precast Shell" Buildings 15, no. 11: 1777. https://doi.org/10.3390/buildings15111777

APA StyleLu, T., Wang, B., & Jin, H. (2025). Mechanical Performance of Prefabricated Monolithic Composite Columns with Reinforced ECC Precast Shell. Buildings, 15(11), 1777. https://doi.org/10.3390/buildings15111777