Study on Seismic Performance of Reinforced Concrete Columns Reinforced with Steel Strip Composite Ultra–High–Performance Concrete

Abstract

1. Introduction

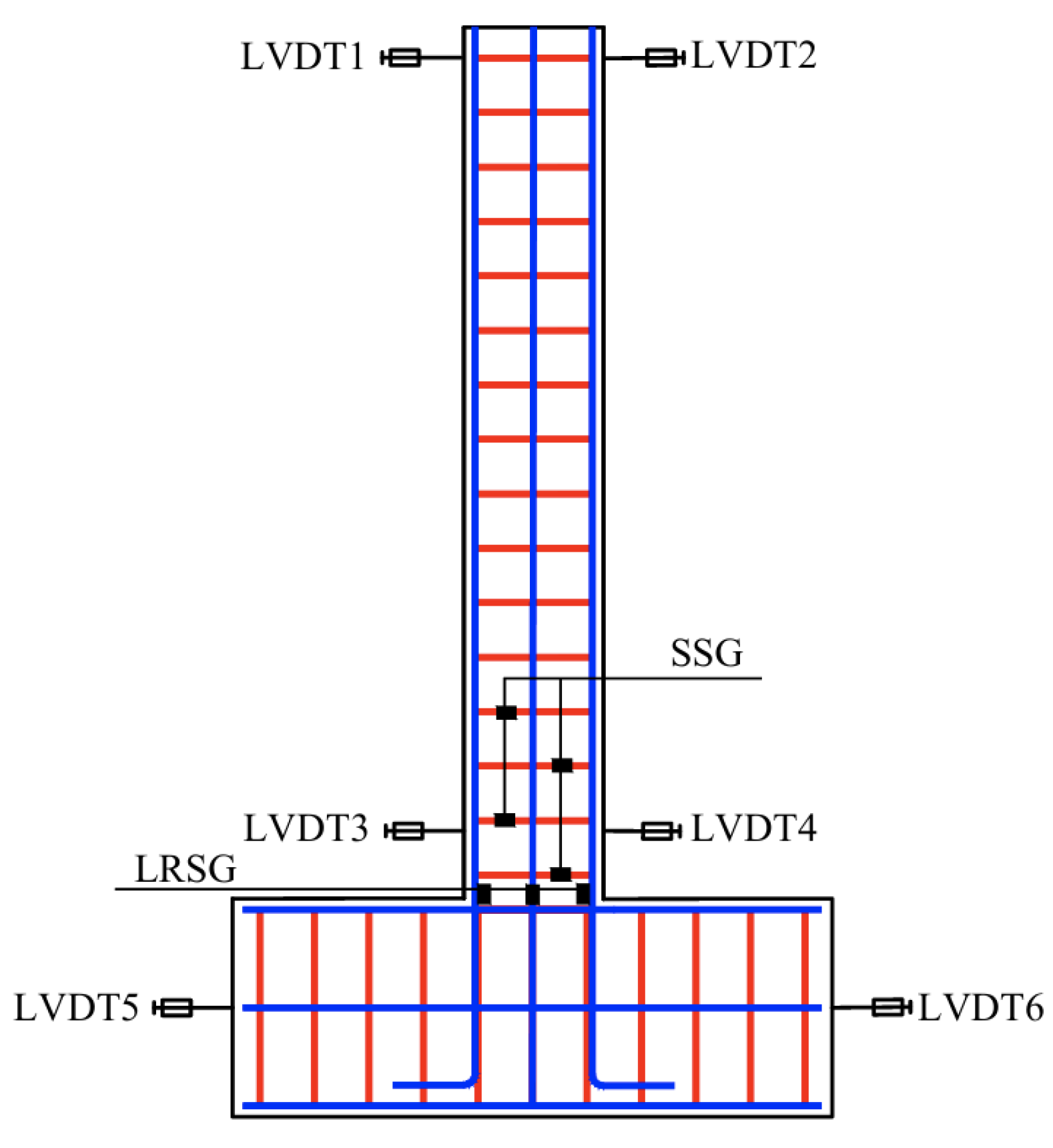

2. Test Program

2.1. Specimen Design and Retrofit Scheme

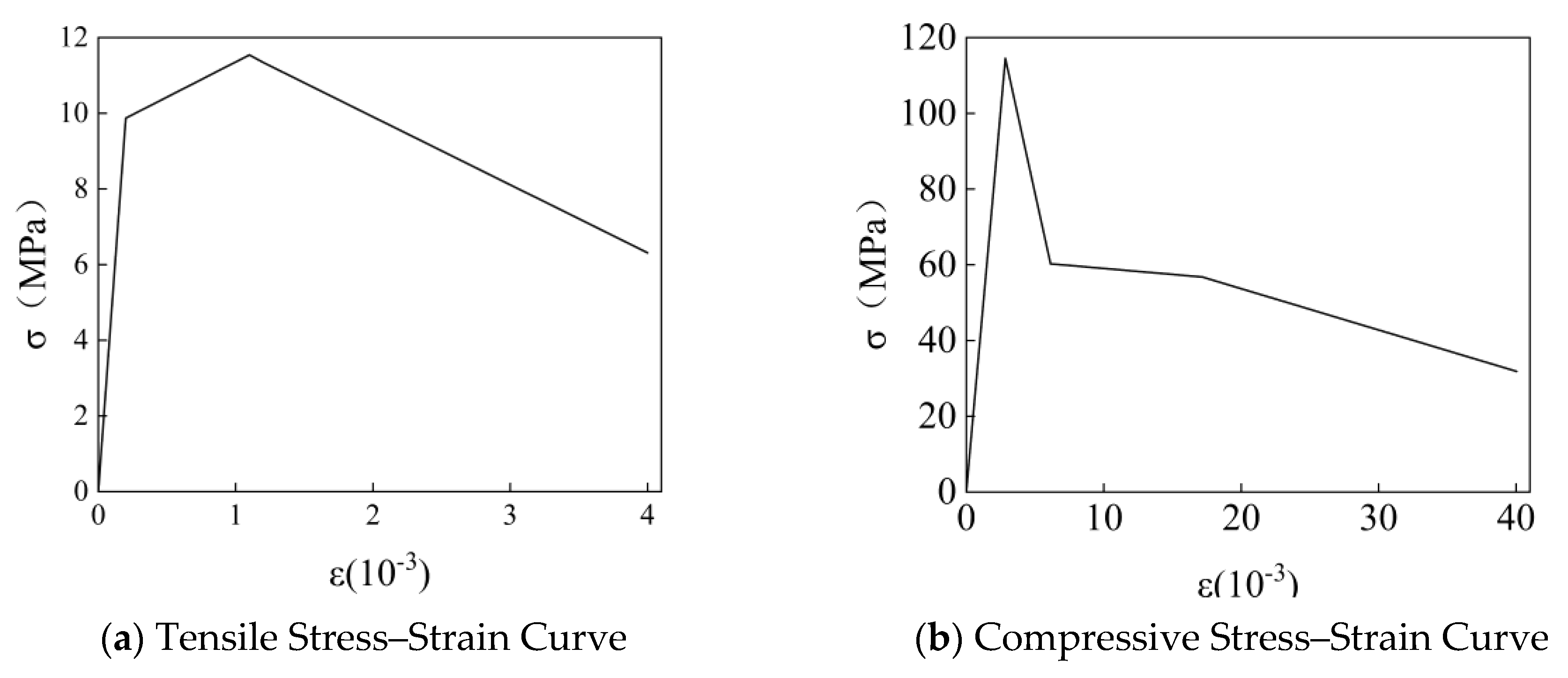

2.2. Properties of Material

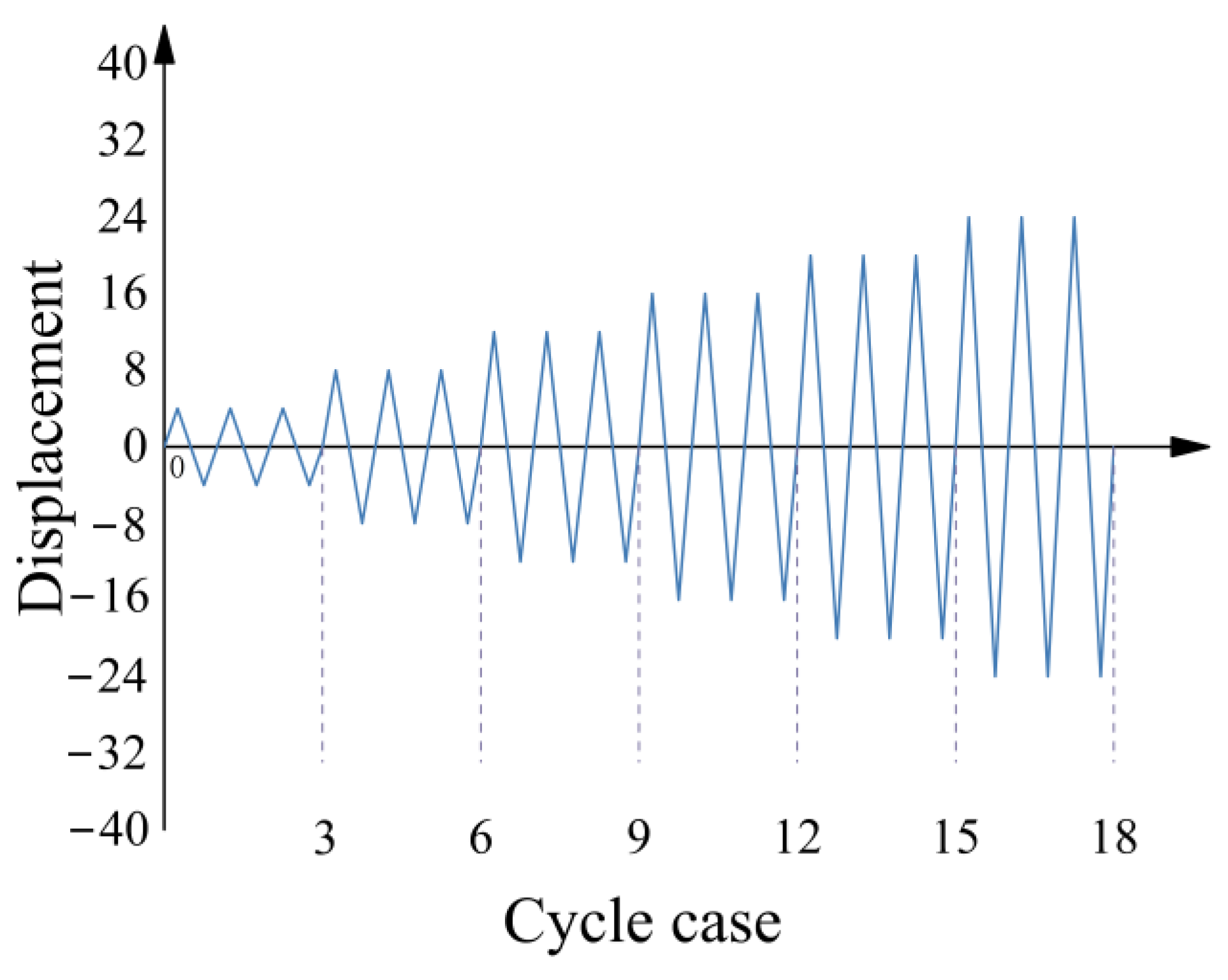

2.3. Test Device and Loading Procedure

3. Analysis and Discussion of Test Results

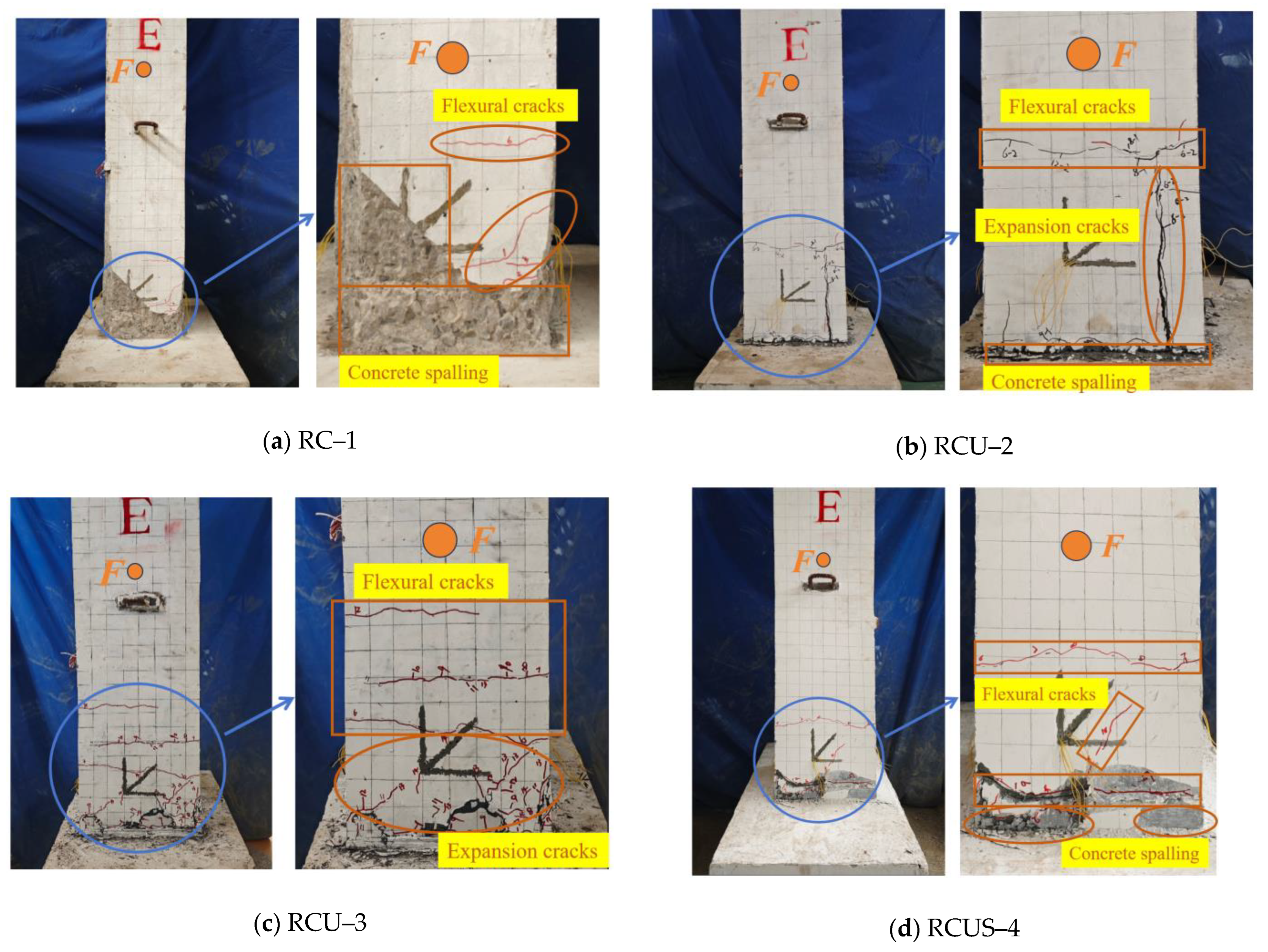

3.1. Damage Evolution of Columns

- (1)

- At a displacement of 15 mm, the first flexural crack appeared on the column body (width < 0.1 mm). As the displacement increased to 20 mm, a 45° inclined crack formed at the column base accompanied by concrete spalling. At 25 mm, extensive crushing of concrete occurred at the base. Final failure occurred at a displacement of 30 mm due to buckling of the longitudinal reinforcement, at which point the load had dropped below 85% of the peak value. This failure mode resulted from the high axial load ratio (0.4), which suppressed flexural crack development but intensified brittle crushing in the compression zone. The plastic hinge localized at the column base led to a sudden decline in load–bearing capacity.

- (2)

- In contrast, the UHPC–strengthened columns (RCU–2 and RCU–3) exhibited a mixed flexural–shear failure mode. RCU–2 developed vertical cracks at a displacement of 25 mm; at 50 mm, inclined cracks extended toward the mid–height of the column (width < 0.3 mm), and at 65 mm, debonding occurred at the interface between the UHPC layer and core concrete. In RCU–3, which had a thicker UHPC layer, inclined cracks were more uniformly distributed (spacing ~60 mm), and a dense network of microcracks (width < 0.2 mm) formed at the column base. These observations confirm that UHPC’s high tensile strength and the bridging effect of steel fibers effectively restrained crack propagation.

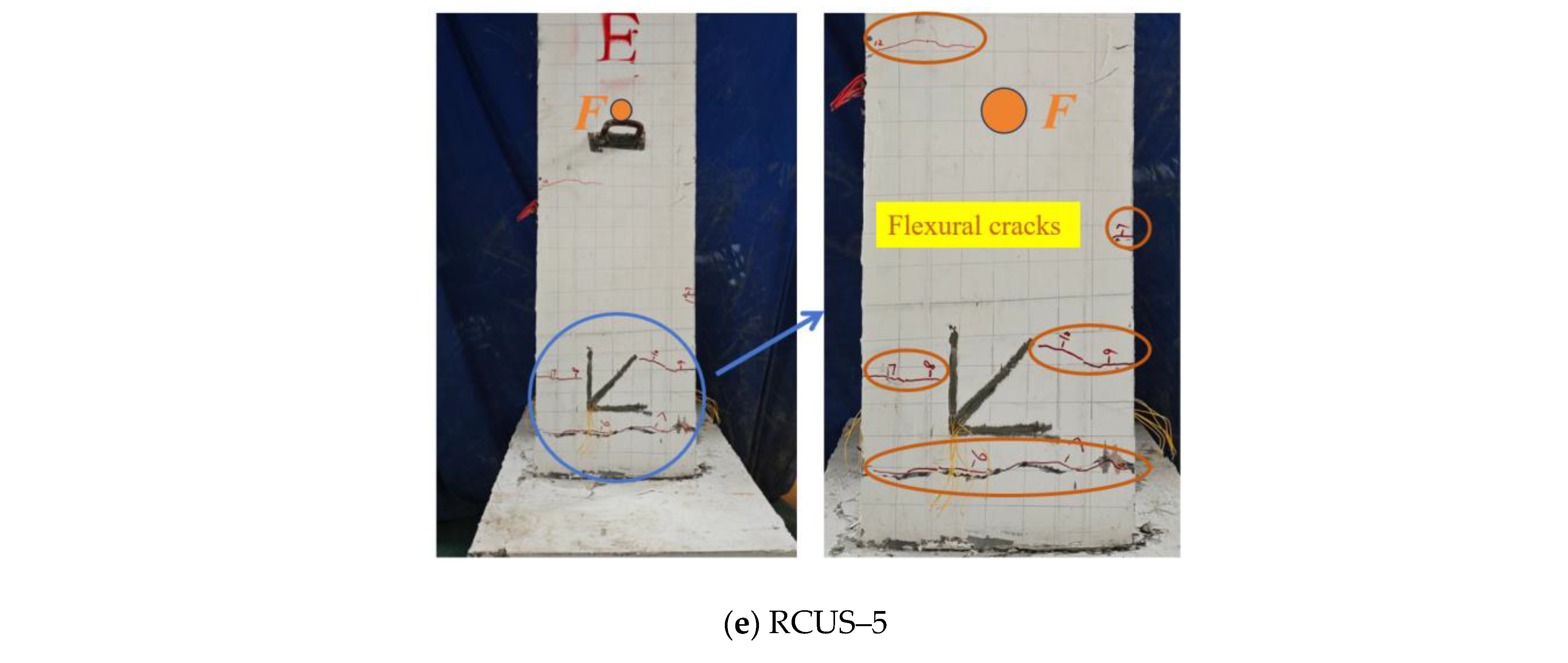

- (3)

- The UHPC–steel strip composite strengthened columns (RCUS–4 and RCUS–5) predominantly exhibited ductile flexural failure. RCUS–4 showed horizontal cracking at a displacement of 30 mm, with the steel strip reaching 60% of its yield strain. At 60 mm, the specimen reached a peak load of 333.19 kN, and the cracks presented as multiple fine cracks (maximum width 0.15 mm). For RCUS–5, the effect of the steel strips resulted in a 50% reduction in the number of cracks, with no through–cracks observed.

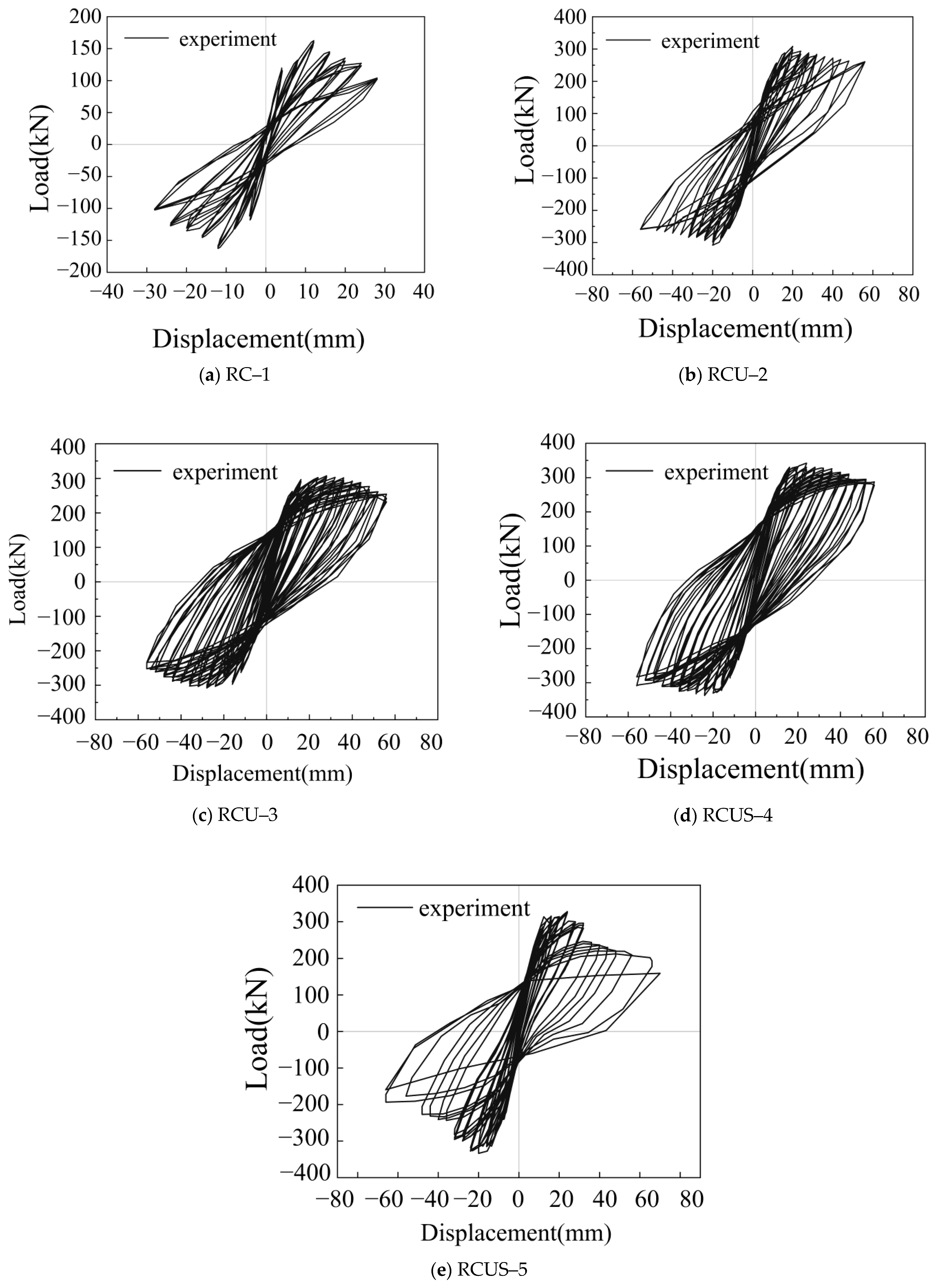

3.2. Hysteresis Curves

- (1)

- When the UHPC reinforcement layer thickness increases by 10 mm, the hysteresis loops of the UHPC–strengthened and UHPC–steel strip composite–reinforced specimens become fuller, with less decay in resistance at each load level and no significant pinching effect. This is primarily due to the increased thickness of the UHPC reinforcement layer, which enlarges the leverage of the reinforcing bars, thereby increasing their contribution to internal force distribution.

- (2)

- In UHPC–steel strip composite–reinforced specimens, compared to those with the same UHPC reinforcement thickness, the number of hysteresis loops increases slightly, and the loop areas become more pronounced. This suggests that the steel strip composite reinforcement enhances the confinement of the core concrete, limiting its lateral expansion. However, after the steel strip composite reinforcement, increasing the thickness of the UHPC layer does not result in a significant increase in peak load. While the number of hysteresis loops remains unchanged, their shape becomes fuller, and the energy dissipation capability improves. This indicates that the steel strip has already provided sufficient confinement, and further increasing the UHPC reinforcement thickness only enhances the plastic deformation capacity of the component without significantly improving the peak load.

3.3. Skeleton Curves and Ductility Index

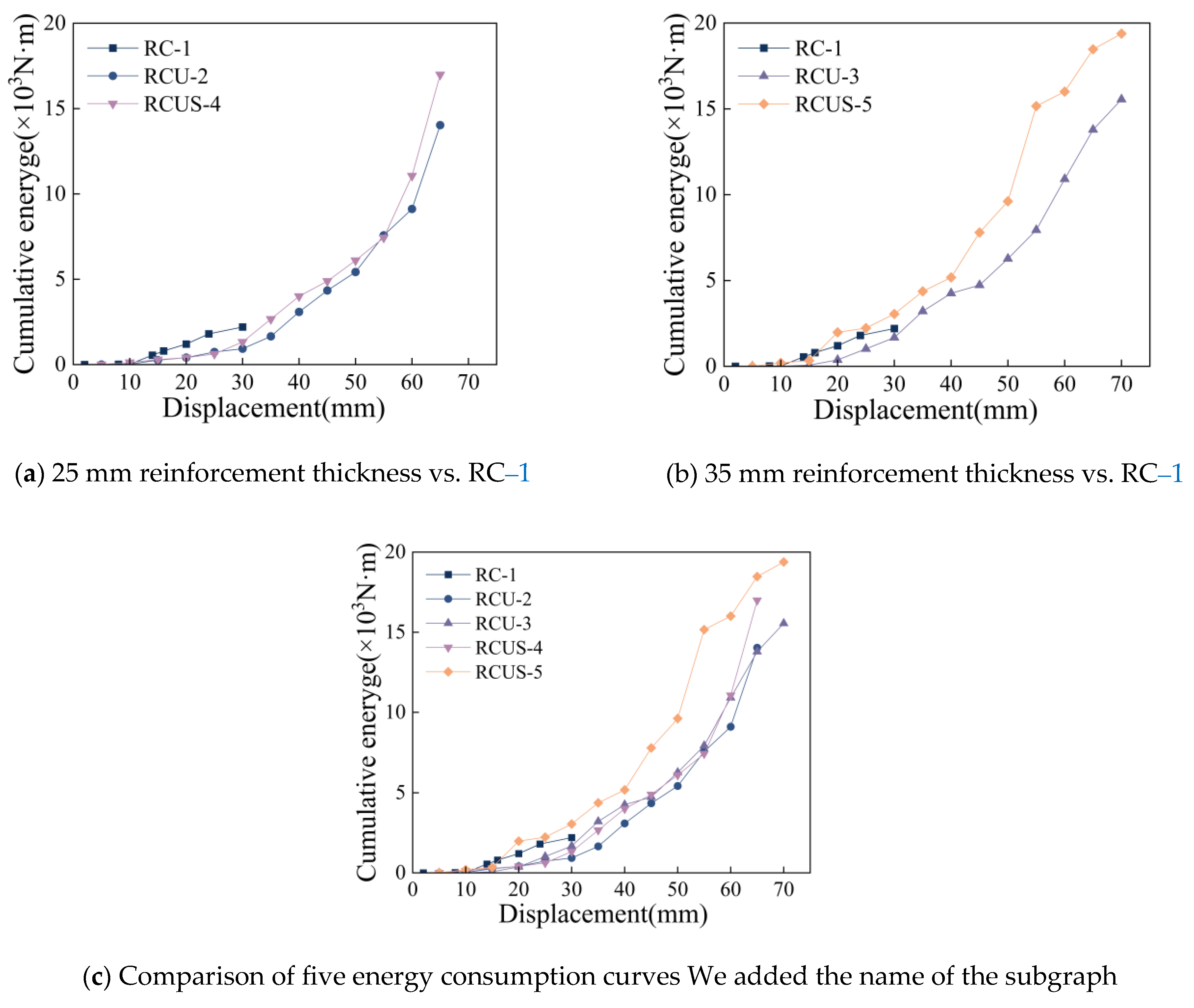

3.4. Energy Dissipation

3.5. Stiffness

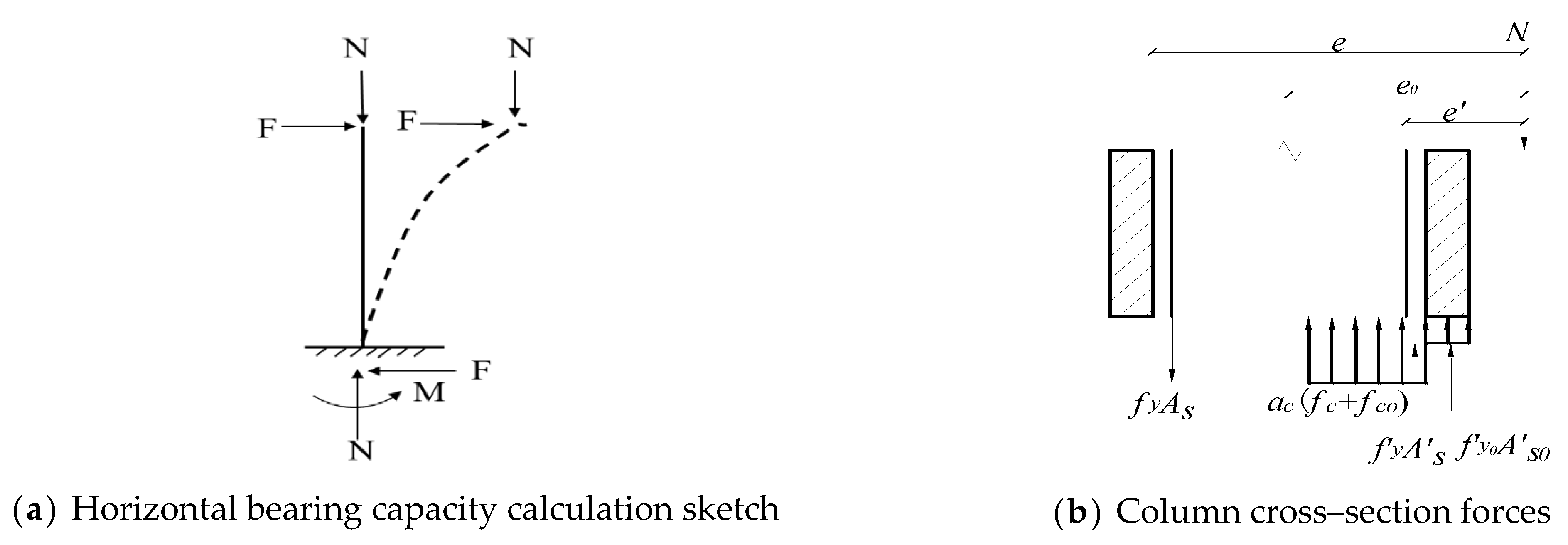

4. Bearing Capacity Calculation

4.1. Basic Assumptions of the Theoretical Model

4.2. Limit Relative Depth of Compression Zone

4.3. Balanced Flexural Capacity Calculation

5. Discussion and Conclusions

5.1. Discussion

- (1)

- ACI 318–19 emphasizes the importance of structural ductility design, requiring components to possess sufficient deformation capacity within the plastic hinge region. In this study, the UHPC–composite steel strip reinforcement significantly improved the displacement ductility coefficient (e.g., RCUS–5 with μ = 6.28), meeting the ductility requirements of ACI 318. However, the code does not explicitly permit the use of UHPC and steel strip composite reinforcement, necessitating adjustments in equivalent stirrup ratios or material properties to comply with existing provisions. Eurocode 8 requires structures to exhibit a “strong column–weak beam” mechanism and sufficient energy dissipation capacity. In this study, the hysteresis loops of the UHPC–composite reinforced columns are more pronounced, and energy dissipation capacity has been enhanced, which aligns with the energy dissipation requirements of Eurocode 8.

- (2)

- The steel strip–UHPC composite reinforcement technique proposed in this study demonstrates significant advantages in practical engineering applications. In terms of construction efficiency, the installation of steel strips is approximately 40% faster than traditional steel jackets. When combined with prefabricated UHPC components, the construction period can be significantly shortened. From an economic perspective, material costs are reduced by approximately 30% and 22% compared to FRP and steel jackets, respectively, while life–cycle maintenance costs are lowered by over 50%. This technique is particularly suitable for the rapid seismic retrofitting of columns with high axial load ratios (0.3–0.5). By employing a standardized construction process—including pre–tension control between 20–30 kN and an interface roughness of Ra ≥ 50 μm—the method achieves substantial seismic upgrading with minimal interference to the appearance of historic buildings, as the reinforcement layer is only 25–35 mm thick. Overall, the approach reduces seismic retrofit costs by approximately 35–40% and offers considerable potential for widespread engineering application.

- (3)

- The UHPC–composite steel band reinforcement achieves a simultaneous enhancement of stiffness, initial strength, and ductility through the synergistic interaction of materials and construction. Under service–level events, the reinforced structure not only maintains a high elastic stiffness but also effectively addresses accidental overloading through ductility design, in accordance with modern seismic codes (such as ACI 318 and Eurocode 8), which require a “strong column–weak beam” mechanism and energy dissipation. Future research could further quantify the changes in stiffness at the service level, optimizing the reinforcement layer thickness and steel band layout to balance economic and performance demands.

5.2. Conclusions

- (1)

- The failure modes of the reinforced specimens have significantly improved. Compared to the unreinforced specimens, the reinforced specimens exhibit bending–shear failure, with fine diagonal cracks appearing at the bottom of the UHPC–strengthened specimens. In comparison to the UHPC–strengthened specimens, the UHPC–composite steel strip reinforced specimens show only a few diagonal cracks, indicating that both UHPC reinforcement and UHPC–composite steel strip reinforcement can improve the failure modes of the specimens. However, the UHPC–composite steel strip reinforcement is more effective in restraining the initiation and propagation of cracks.

- (2)

- The increased thickness of the UHPC reinforcement layer effectively enhances the seismic performance of the structure. With an increase of 10 mm in the UHPC reinforcement layer thickness, the peak load of the UHPC–strengthened specimens increased by 6.06%, the displacement ductility improved by 17.23%, and the energy dissipation capacity increased by 18.21%. For the UHPC–composite steel strip reinforced specimens, the peak load increased by 2.22%, the displacement ductility improved by 9.98%, and the energy dissipation capacity increased by 14.09%. Furthermore, the hysteresis loops became more complete, and the stiffness degradation was significantly improved.

- (3)

- Compared to specimens strengthened solely with UHPC, the composite specimens reinforced with steel bands exhibited increases in peak load of 10.36% and 6.36% for reinforcement layer thicknesses of 25 mm and 35 mm, respectively. The ductility coefficients increased by 29.47% and 21.47%, accompanied by significant enhancements in energy dissipation capacity. The hysteresis loops became larger and more stable, indicating further improvements in energy absorption and stiffness degradation. Moreover, under the same seismic performance requirements, the inclusion of steel bands effectively reduced the required thickness of the UHPC layer, demonstrating a strong synergistic effect among the three components.

- (4)

- Based on moment equilibrium, the proposed calculation formula for the horizontal ultimate bending capacity yields a calculation value with an error within 15% of the experimental values, demonstrating good agreement. This formula provides theoretical guidance for engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- GB 50010—2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- ACI 318–19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019; pp. 435–454. [CrossRef]

- Lubkowski, Z.A.; Duan, X. EN1998 Eurocode 8: Design of Structures for Earthquake Resistance; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Li, H.; Xiao, S.; Huo, L. Damage investigation and analysis of engineering structures in the Wenchuan earthquake. J. Build. Struct. 2008, 9, 10–19. [Google Scholar]

- Miller, D.K. Lessons learned from the Northridge earthquake—ScienceDirect. Eng. Struct. 1998, 20, 249–260. [Google Scholar] [CrossRef]

- Sezen, H.; Whittaker, A.S.; Elwood, K.J.; Mosalam, K.M. Performance of reinforced concrete buildings during the August 17, 1999 Kocaeli, Turkey earthquake, and seismic design and construction practise in Turkey. Eng. Struct. 2003, 25, 103–114. [Google Scholar] [CrossRef]

- Fu, T.; Wang, K.; Zhu, Z.; Ren, X.; Li, Y.; Xu, L.; Meng, L.; Sun, Z. Seismic performance of prefabricated square hollow section piers strengthened by jacketing using UHPC and high–strength steel. Structures 2023, 47, 449–465. [Google Scholar] [CrossRef]

- Nuroji, N.; Hung, C.C.; Prasetya, B.H.; Han, A. The Behavior of Reinforced Concrete Members with Section Enlargement Using Self–Compacting Concrete. Int. Rev. Civ. Eng. (IRECE) 2020, 11, 121. [Google Scholar] [CrossRef]

- Belal, M.F.; Mohamed, H.M.; Morad, S.A. Behavior of reinforced concrete columns strengthened by steel jacket. HBRC J. 2015, 11, 201–212. [Google Scholar] [CrossRef]

- Pudjisuryadi, P.; Tavio Suprobo, P. Performance of Square Reinforced Concrete Columns Externally Confined by Steel Angle Collars Under Combined Axial and Lateral Load. Procedia Eng. 2015, 125, 1043–1049. [Google Scholar] [CrossRef]

- Iacobucci, R.D.; Sheikh, S.A.; Bayrak, O. Retrofit of Square Concrete Columns with Carbon Fiber–Reinforced Polymer for Seismic Resistance. ACI Struct. J. 2003, 100, 785–794. [Google Scholar]

- Kang, L.; Bang, L.; Soo, S. A Seismic Strengthening Technique for Reinforced Concrete Columns Using Sprayed FRP. Polymers 2016, 8, 107. [Google Scholar] [CrossRef]

- Xia, Z.; Lin, L.; Zhang, J.; Jiang, S. Seismic performance of underwater RC bridge piers strengthened with self–compacting concrete–filled BFRP jacket. Structures 2022, 39, 637–652. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial bond properties between normal strength concrete substrate and ultra–high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- John, S.K.; Cascardi, A.; Verre, S.; Nadir, Y. Rc–columns subjected to lateral cyclic force with different frcm–strengthening schemes: Experimental and numerical investigation. Bull. Earthq. Eng. 2025, 23, 1561–1590. [Google Scholar] [CrossRef]

- Alhoubi, Y.; El Refai, A.; Abed, F.; El–Maaddawy, T.; Tello, N. Strengthening pre–damaged rc square columns with fabric–reinforced cementitious matrix (frcm): Experimental investigation. Compos. Struct. 2022, 294, 115784. [Google Scholar] [CrossRef]

- Farzad, M.; Shafieifar, M.; Azizinamini, A. Experimental and numerical study on bond strength between conventional concrete and Ultra High–Performance Concrete (UHPC). Eng. Struct. 2019, 186, 297–305. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Li, H. Comparative studies of the effect of ultrahigh–performance concrete and normal concrete as repair materials on interfacial bond properties and microstructure. Eng. Struct. 2020, 222, 111122. [Google Scholar] [CrossRef]

- Aboukifa, M.; Moustafa, M.A. Experimental seismic behavior of ultra–high performance concrete columns with high strength steel reinforcement. Eng. Struct. 2021, 232, 111885. [Google Scholar] [CrossRef]

- Guan, D.; Chen, Z.; Liu, J.; Lin, Z.; Guo, Z. Seismic performance of precast concrete columns with prefabricated UHPC jackets in plastic hinge zone. Eng. Struct. 2021, 245, 112776. [Google Scholar] [CrossRef]

- Shao, Y.; Kuo, C.W.; Hung, C.C. Seismic performance of full–scale UHPC–jacket–strengthened RC columns under high axial loads. Eng. Struct. 2021, 243, 112657. [Google Scholar] [CrossRef]

- Tong, T.; Lei, H.; Yuan, S.; Liu, Z. Experimental investigation and seismic vulnerability assessment of low flexural strength rectangular bridge piers retrofitted with ultrahigh–performance concrete jackets. Eng. Struct. 2020, 206, 110132. [Google Scholar] [CrossRef]

- Hung, C.C.; Lin, C.C.; Do, T.D.D. Seismic rehabilitation of RC frames with innovative precast U–shaped UHPC jackets: Experimental evaluation and computational simulation. Eng. Struct. 2024, 318, 16. [Google Scholar] [CrossRef]

- Zhu, M. Seismic Performance of Reinforced Concrete Column Retrofitted with UHPC Jacketing Enhanced by Stainless Steel Matrix. Master’s Thesis, Southeast University, Nanjing, China, 2023. [Google Scholar]

- Ding, Y.; Zeng, B.; Zhou, Z.; Wei, Y.; Zhu, M. Seismic retrofitting of RC columns using stainless steel grid–reinforced UHPC jackets in plastic hinge zone. J. Build. Eng. 2024, 84, 108637. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Deng, M.; Dai, L. Experimental study on seismic behavior of RC columns strengthened with ultra–high performance concrete jacket. J. Build. Struct. 2023, 44, 88–98. [Google Scholar] [CrossRef]

- GB 50011—2010; Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2016. (In Chinese)

- GB 50367—2013; Code for Design of Strengthening Concrete Structure. China Architecture & Building Press: Beijing, China, 2013. (In Chinese)

- GB/T 50081—2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standards Press of China: Beijing, China, 2019. (In Chinese)

- GB/T 31387–2015; Reactive Powder Concrete. China Standard Press: Beijing, China, 2015. (In Chinese)

- T/CBMF 37–2018, T/CCPA 7–2018; Fundamental Characteristic and Test Methods of Ultra–High Performance Concrete. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- GB/T 228. 1—2021; Metallic Materials: Tensile Testing: Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021. (In Chinese)

- JGJ 101—2015; Code for Seismic Testing of Buildings. China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

| Specimens | Steel Strip Width/mm | Thickness of Steel Strip/mm | Number of Layers of Steel Strip | Steel Strip Spacing/mm | UHPC Reinforcement Thickness/mm | Axial Pressure Ratio |

|---|---|---|---|---|---|---|

| RC–1 | – | – | – | – | 0 | 0.4 |

| RCU–2 | – | – | – | – | 25 | 0.4 |

| RCU–3 | – | – | – | – | 35 | 0.4 |

| RCUS–4 | 32 | 0.8 | 1 | 150 | 25 | 0.4 |

| RCUS–5 | 32 | 0.8 | 1 | 150 | 35 | 0.4 |

| Type of Concrete | Compressive Strength of the Cube/MPa | Axial Compressive Strength of Cylinder/MPa | Elastic Modulus/GPa | Tensile Strength/MPa |

|---|---|---|---|---|

| C40 | 42.53 | 28.71 | 31.94 | 2.32 |

| UHPC | 134.82 | 116.74 | 45.01 | 11.31 |

| Type of Steel | Diameter/mm | Yield Strength/MPa | Ultimate Strength/MPa | Breaking Strain/% |

|---|---|---|---|---|

| C8 | 8 | 483 | 604 | 22 |

| C14 | 14 | 519 | 649 | 20 |

| C16 | 16 | 536 | 670 | 23 |

| Steel Strip Number | Failure Load/kN | Yield Strength/MPa | Ultimate Strength/MPa | Elastic Modulus/MPa |

|---|---|---|---|---|

| S1 | 18.18 | 642 | 732 | 1.79 × 105 |

| S1–1 | 17.45 | 613 | 699 | – |

| Specimen | Py/kN | Δy/mm | Pm/kN | Δm/mm | Δu/mm | μ |

|---|---|---|---|---|---|---|

| RC–1 | 130.48 | 6.93 | 174.53 | 14.92 | 28.97 | 4.18 |

| RCU–2 | 243.76 | 12.96 | 285.89 | 19.92 | 57.11 | 4.41 |

| RCU–3 | 247.96 | 12.57 | 303.21 | 24.04 | 64.95 | 5.17 |

| RCUS–4 | 266.43 | 11.02 | 315.51 | 23.99 | 62.94 | 5.71 |

| RCUS–5 | 270.94 | 11.04 | 322.52 | 24.01 | 69.28 | 6.28 |

| Specimen | Experimental Value/kN | Calculated Value/kN | Experimental Value/Calculated Value |

|---|---|---|---|

| RC–1 | 174.53 | 190.52 | 0.916 |

| RCU–2 | 285.89 | 312.33 | 0.915 |

| RCU–3 | 303.21 | 334.62 | 0.906 |

| RCUS–4 | 315.51 | 353.11 | 0.894 |

| RCUS–5 | 322.52 | 357.41 | 0.902 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chang, W.; Wang, Z.; Pan, M. Study on Seismic Performance of Reinforced Concrete Columns Reinforced with Steel Strip Composite Ultra–High–Performance Concrete. Buildings 2025, 15, 1762. https://doi.org/10.3390/buildings15111762

Liu X, Chang W, Wang Z, Pan M. Study on Seismic Performance of Reinforced Concrete Columns Reinforced with Steel Strip Composite Ultra–High–Performance Concrete. Buildings. 2025; 15(11):1762. https://doi.org/10.3390/buildings15111762

Chicago/Turabian StyleLiu, Xianhui, Wenlong Chang, Zihang Wang, and Meiqing Pan. 2025. "Study on Seismic Performance of Reinforced Concrete Columns Reinforced with Steel Strip Composite Ultra–High–Performance Concrete" Buildings 15, no. 11: 1762. https://doi.org/10.3390/buildings15111762

APA StyleLiu, X., Chang, W., Wang, Z., & Pan, M. (2025). Study on Seismic Performance of Reinforced Concrete Columns Reinforced with Steel Strip Composite Ultra–High–Performance Concrete. Buildings, 15(11), 1762. https://doi.org/10.3390/buildings15111762