Integrating Backscattered Electron Imaging and Multi-Feature-Weighted Clustering for Quantification of Hydrated C3S Microstructure

Abstract

1. Introduction

2. Experiment Program

3. Methodology

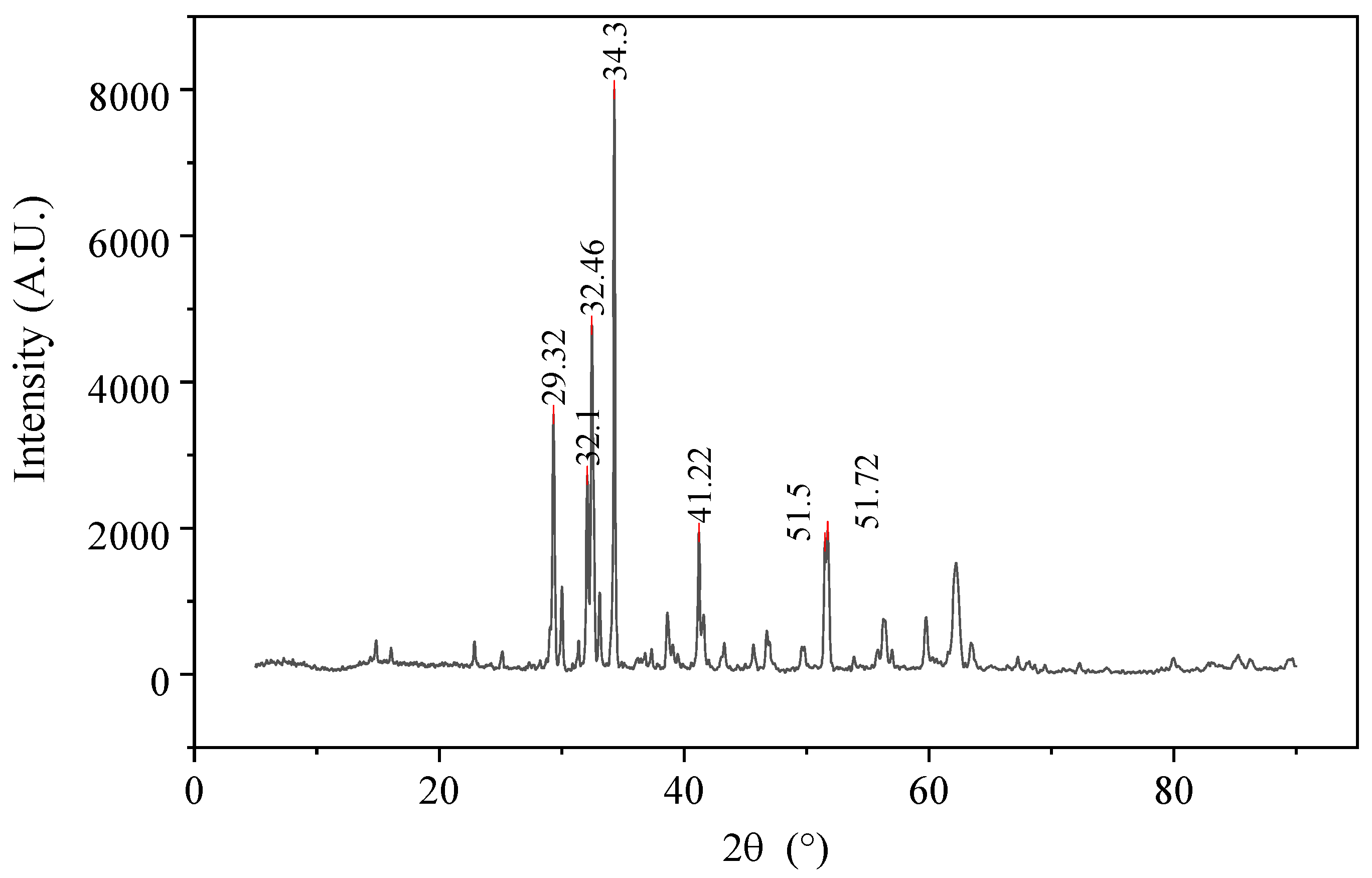

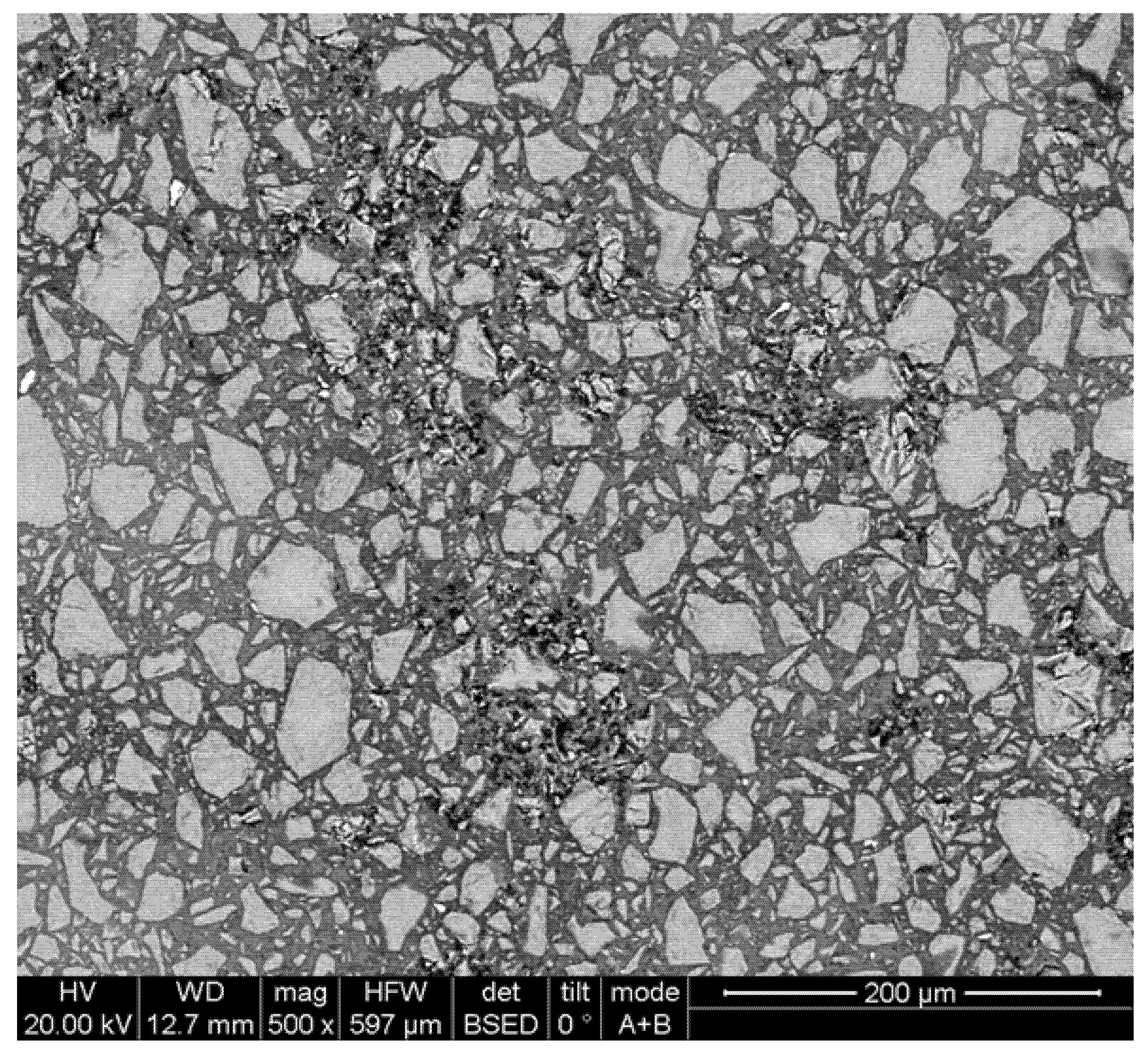

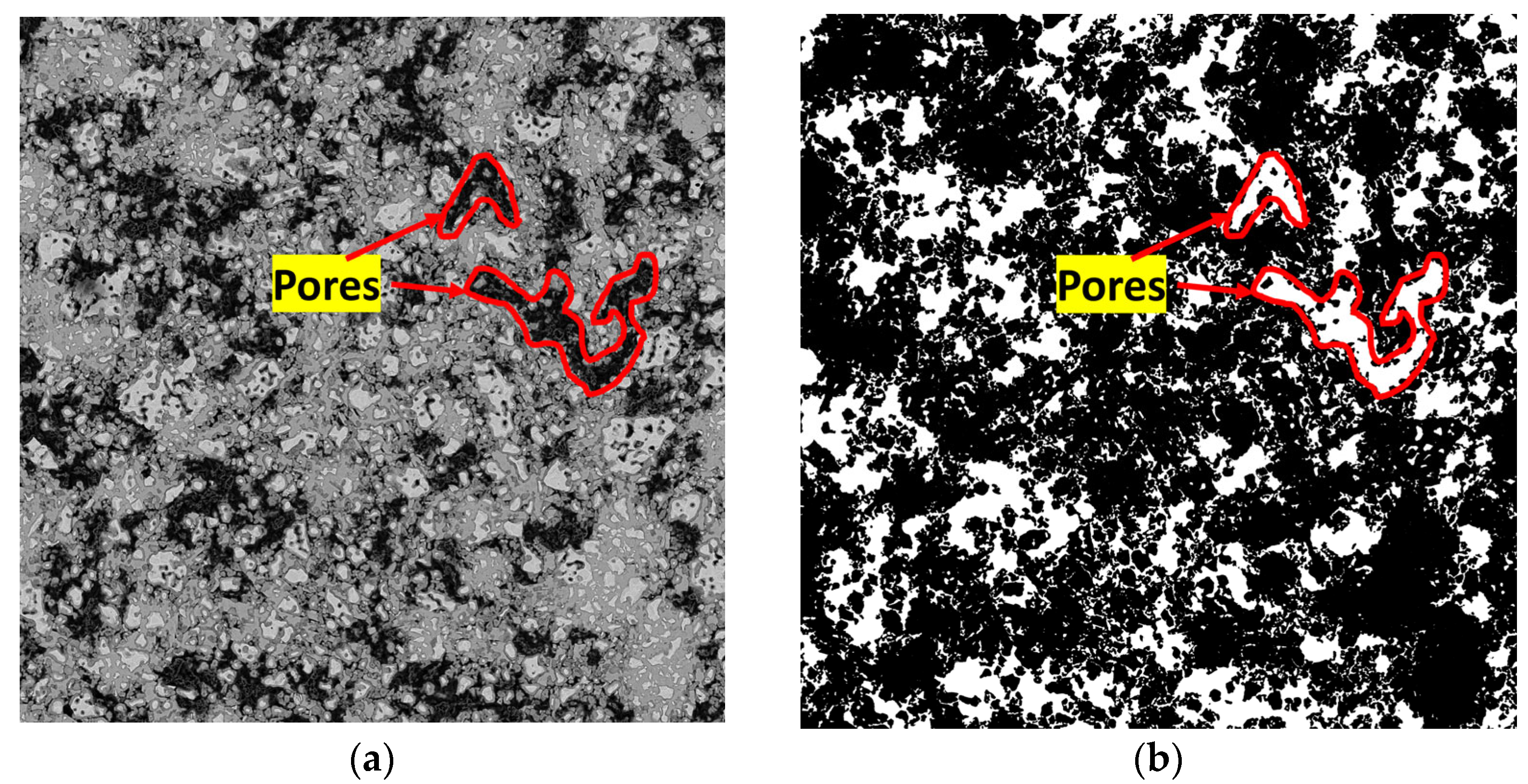

3.1. Correlation Between BSE Grayscale Values and Phase Composition in C3S Paste

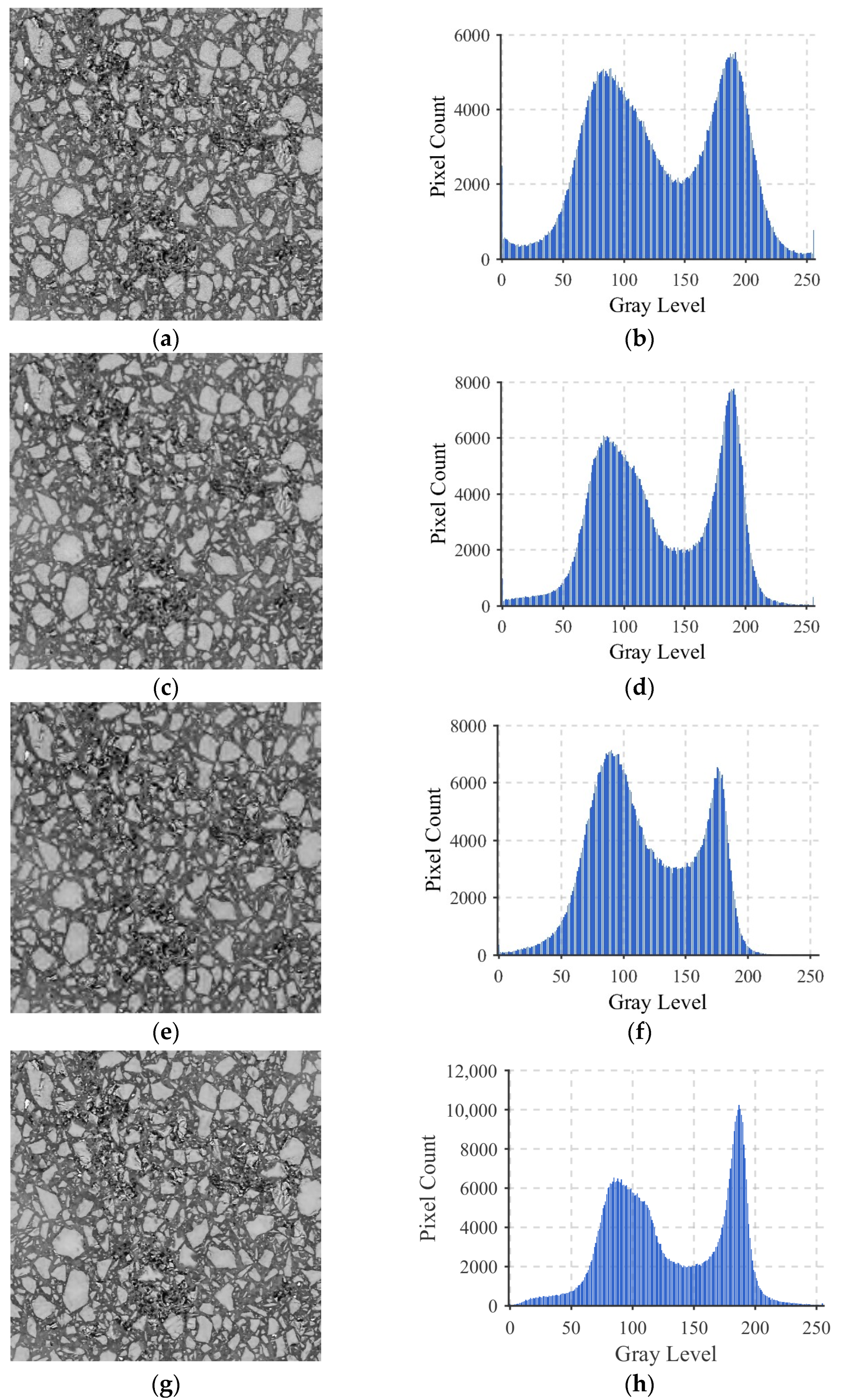

3.2. Image Denoising

- (1)

- Wavelet denoising

- (2)

- Median filtering

- (3)

- DCNN with guided filtering

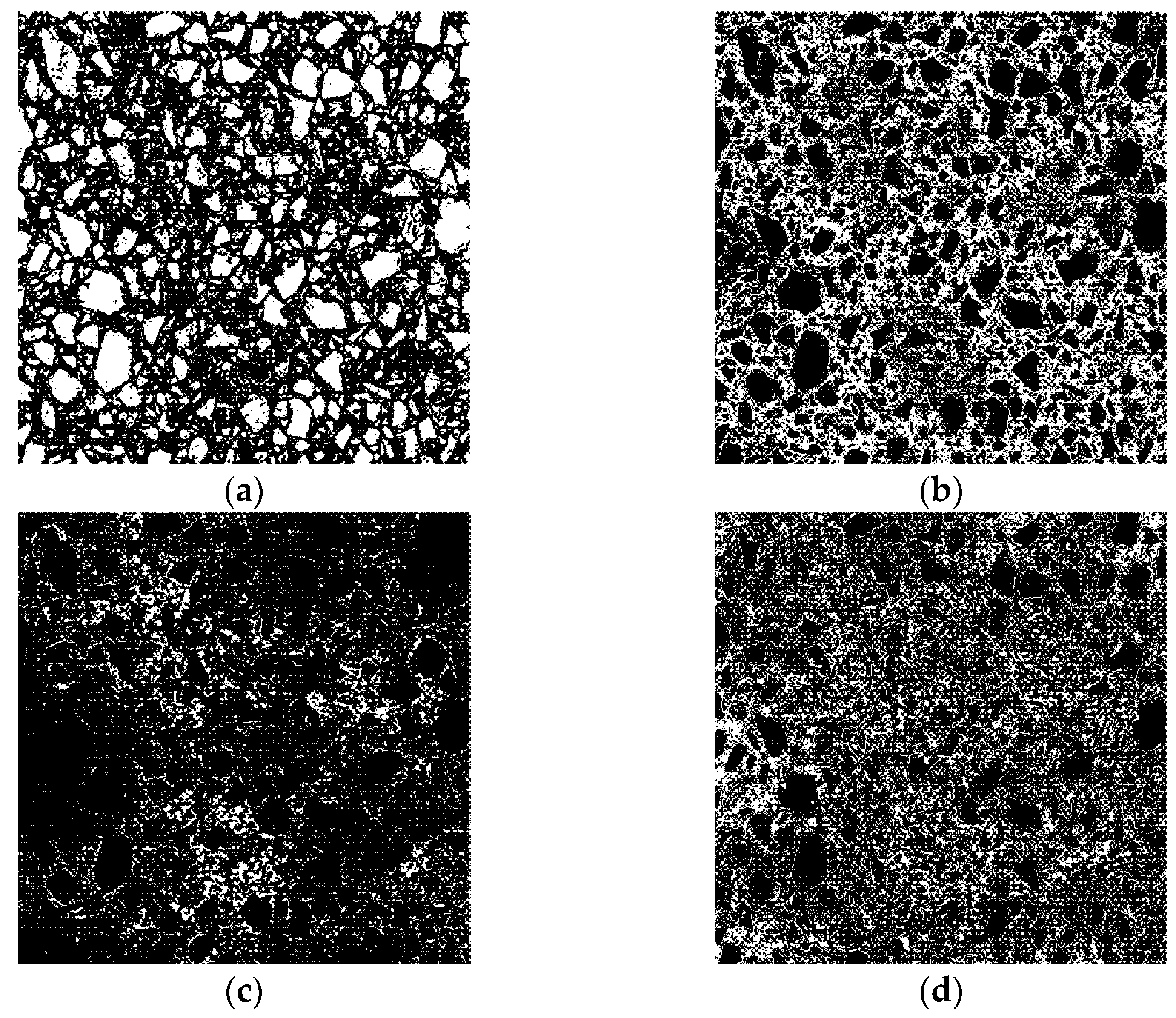

3.3. The Segmentation Method

3.3.1. K-Means Clustering

3.3.2. Weighted K-Means Clustering for Segmenting BSE Image of Hydrated C3S

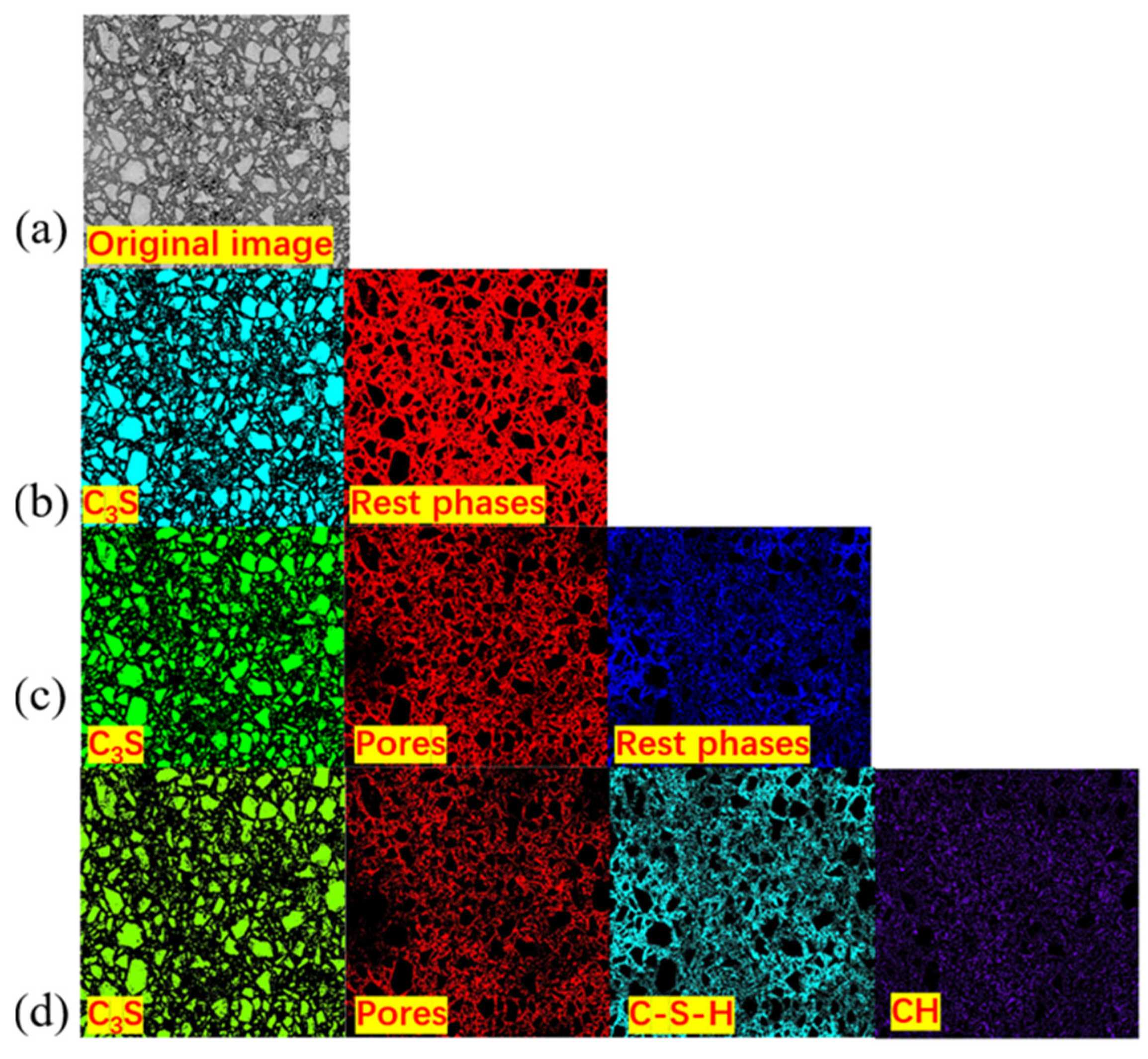

4. Results and Discussion

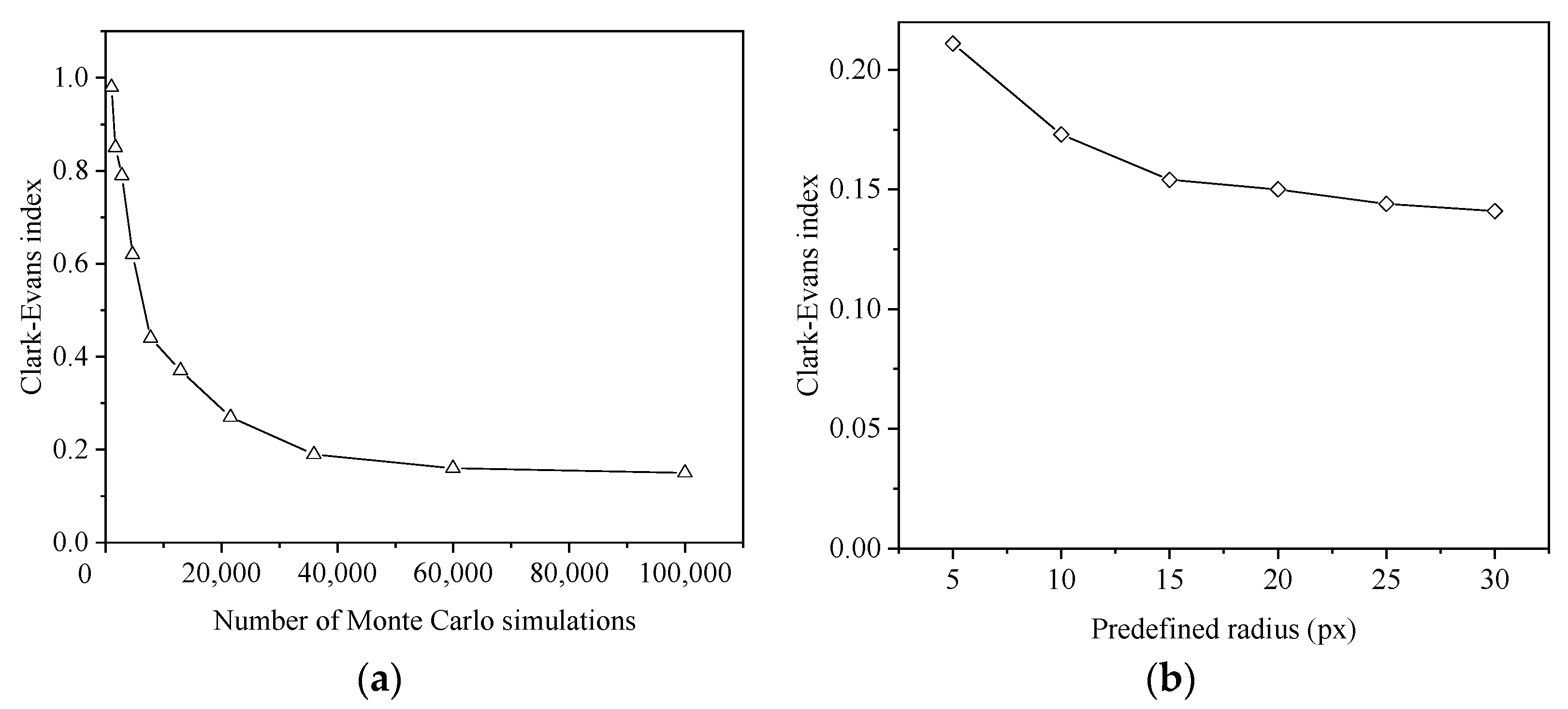

4.1. Sensitivity Analysis

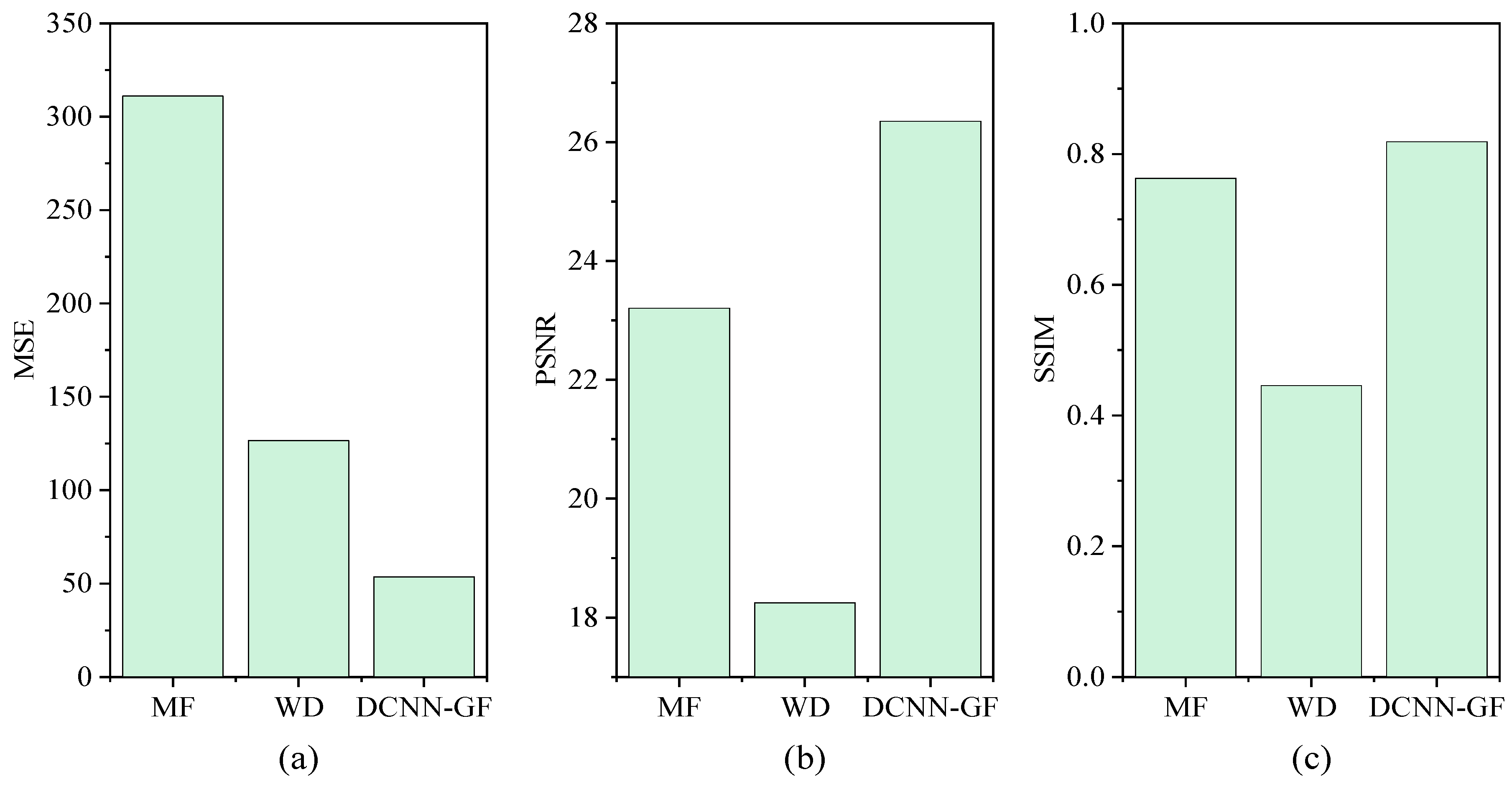

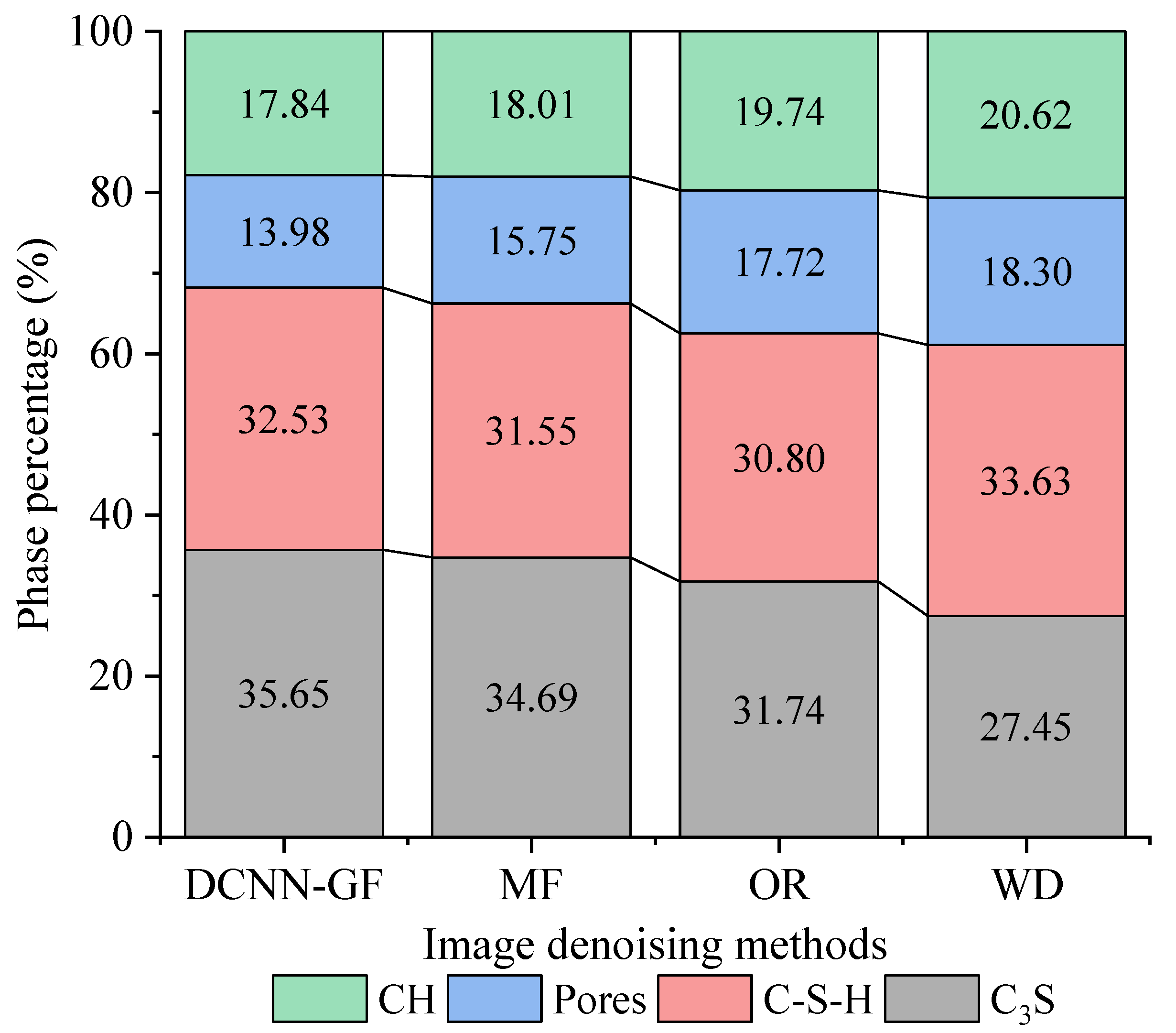

4.1.1. Influence of Image Denoising Method

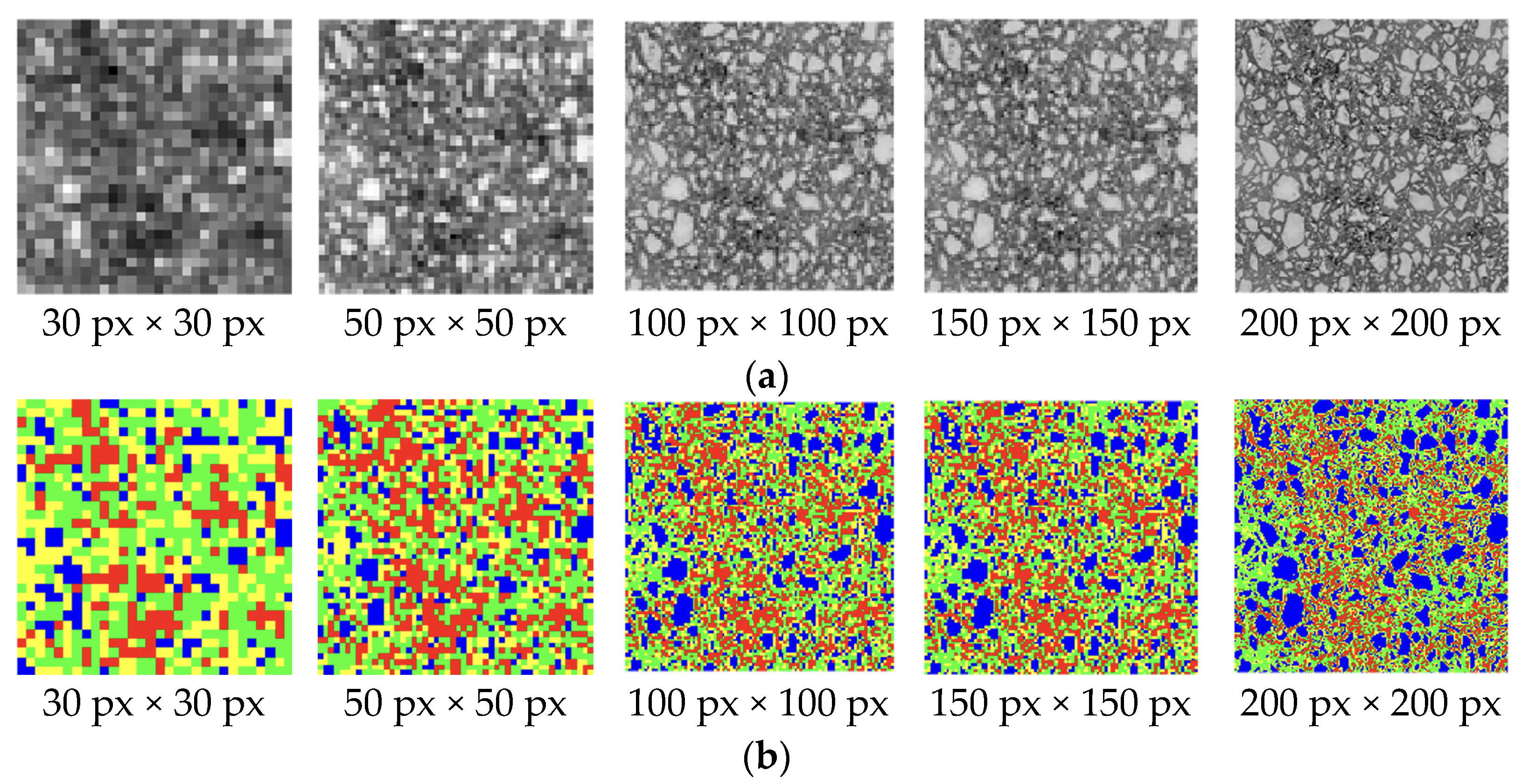

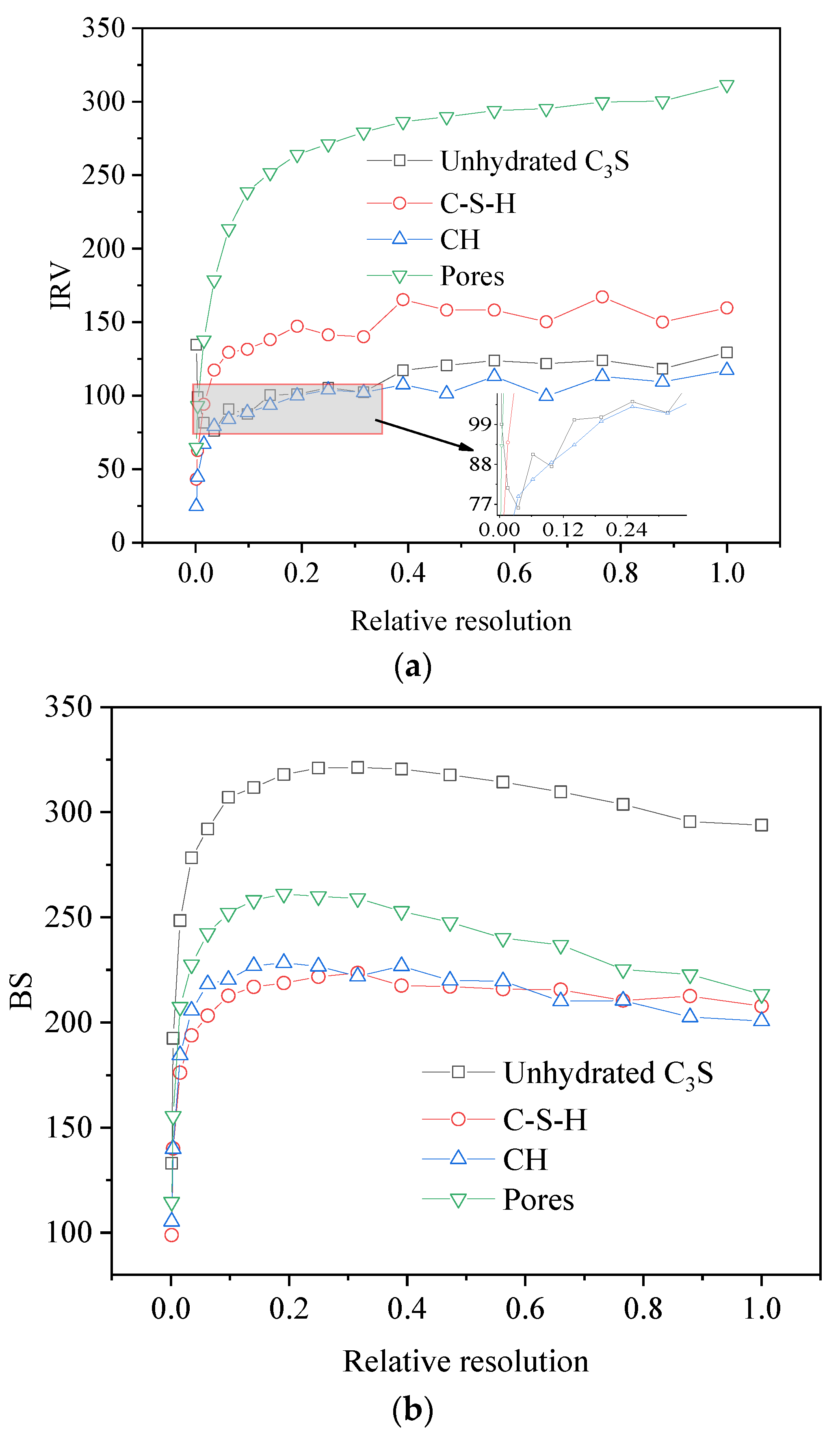

4.1.2. Influence of Image Resolution

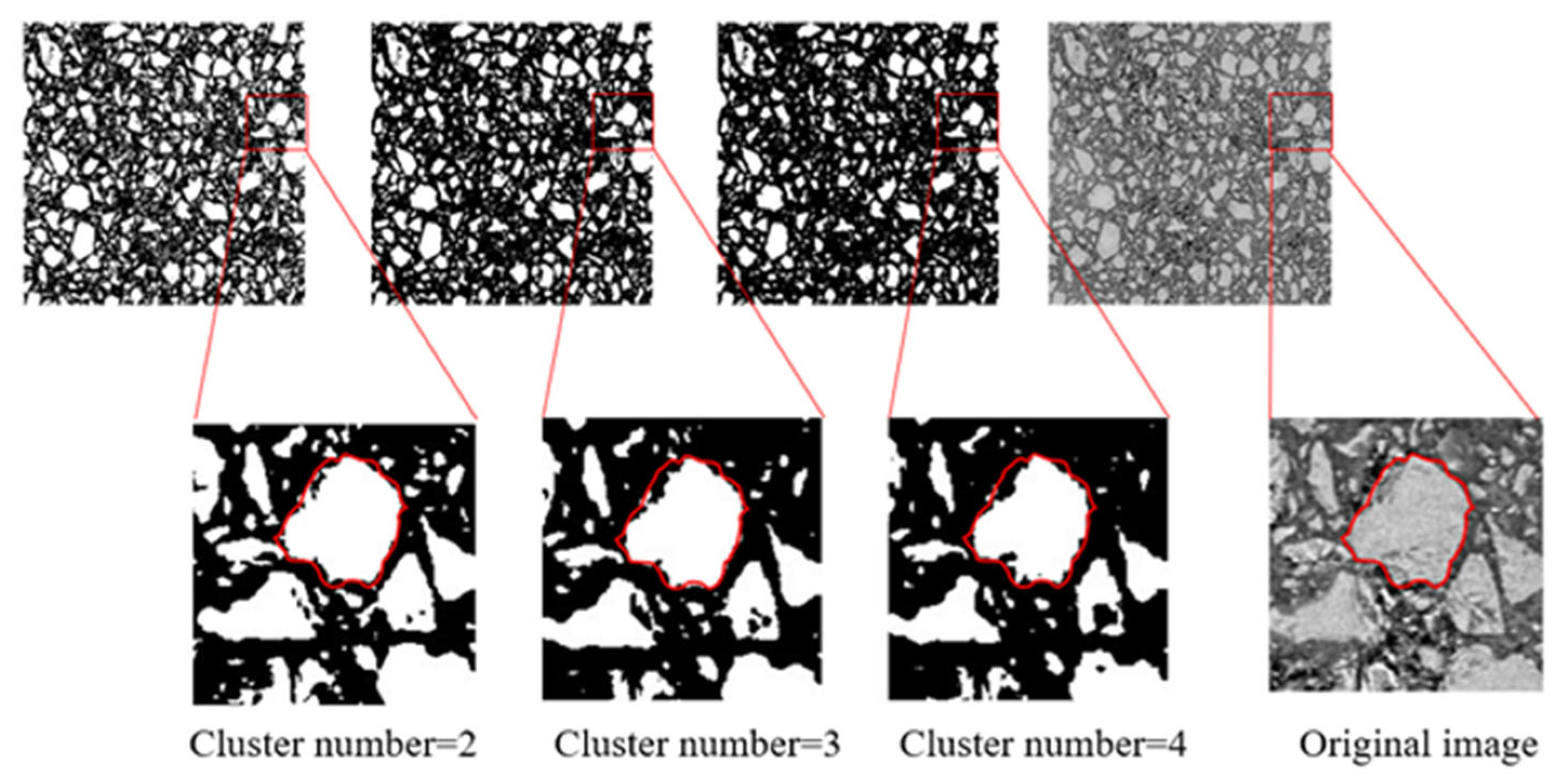

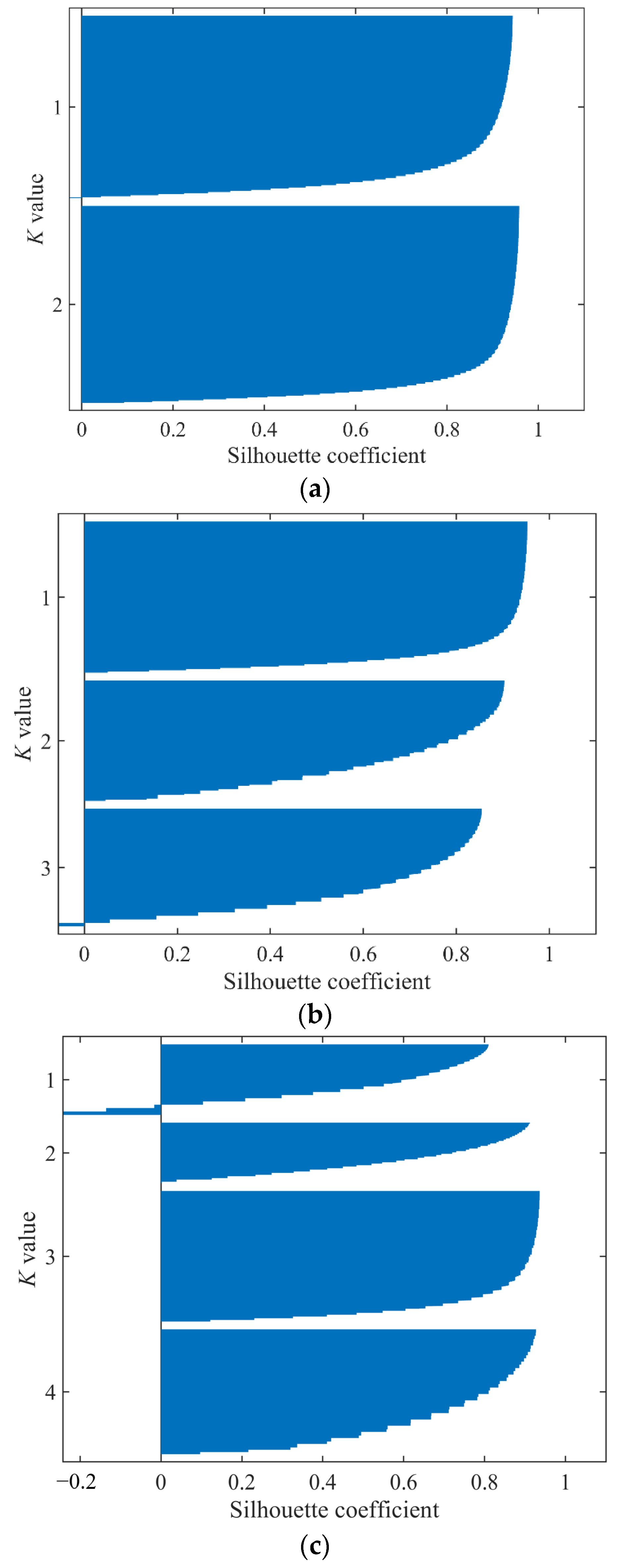

4.1.3. Influence of Cluster Number

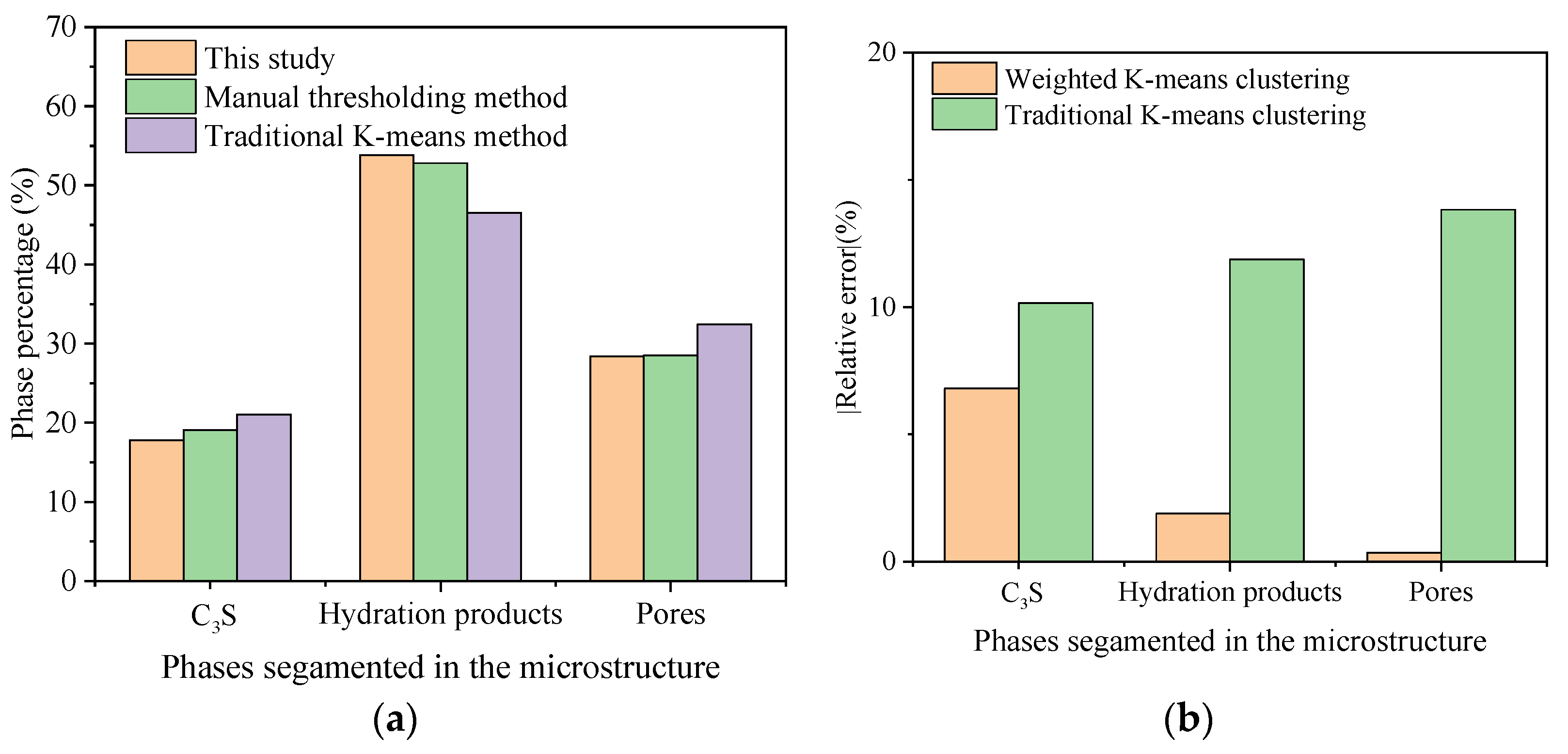

4.2. Validation

4.3. Applications

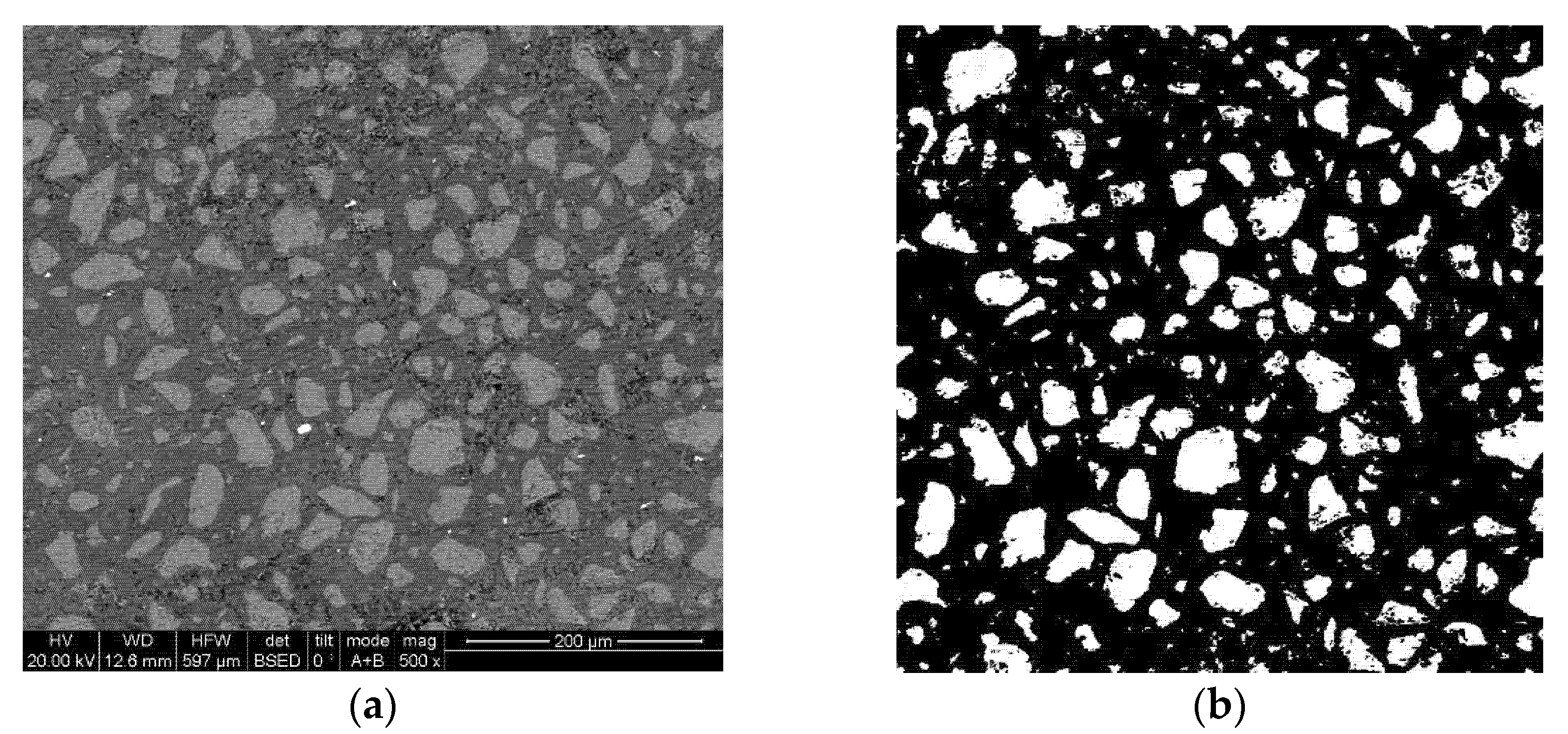

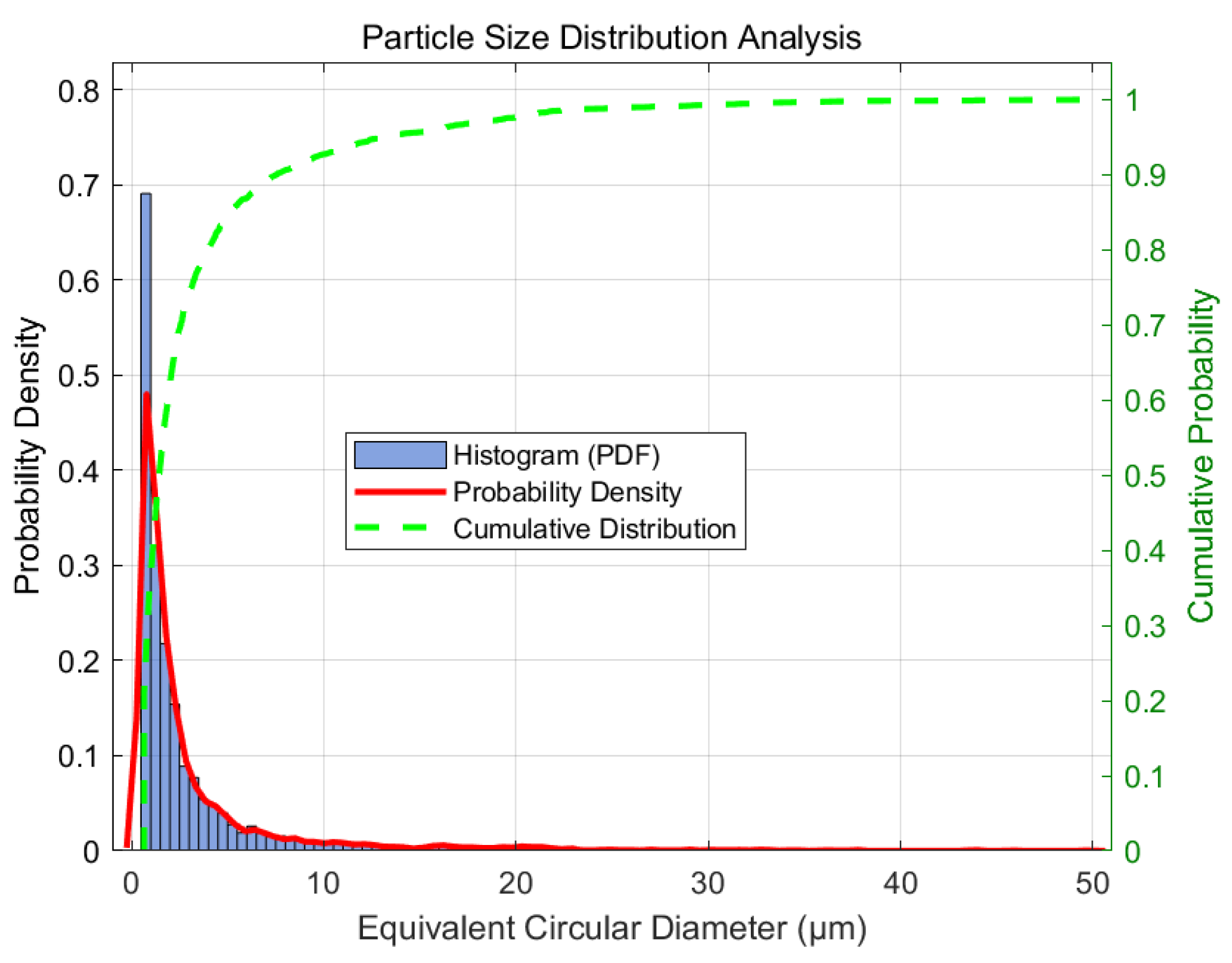

4.3.1. Estimating Particle Size Distribution During the Hydration

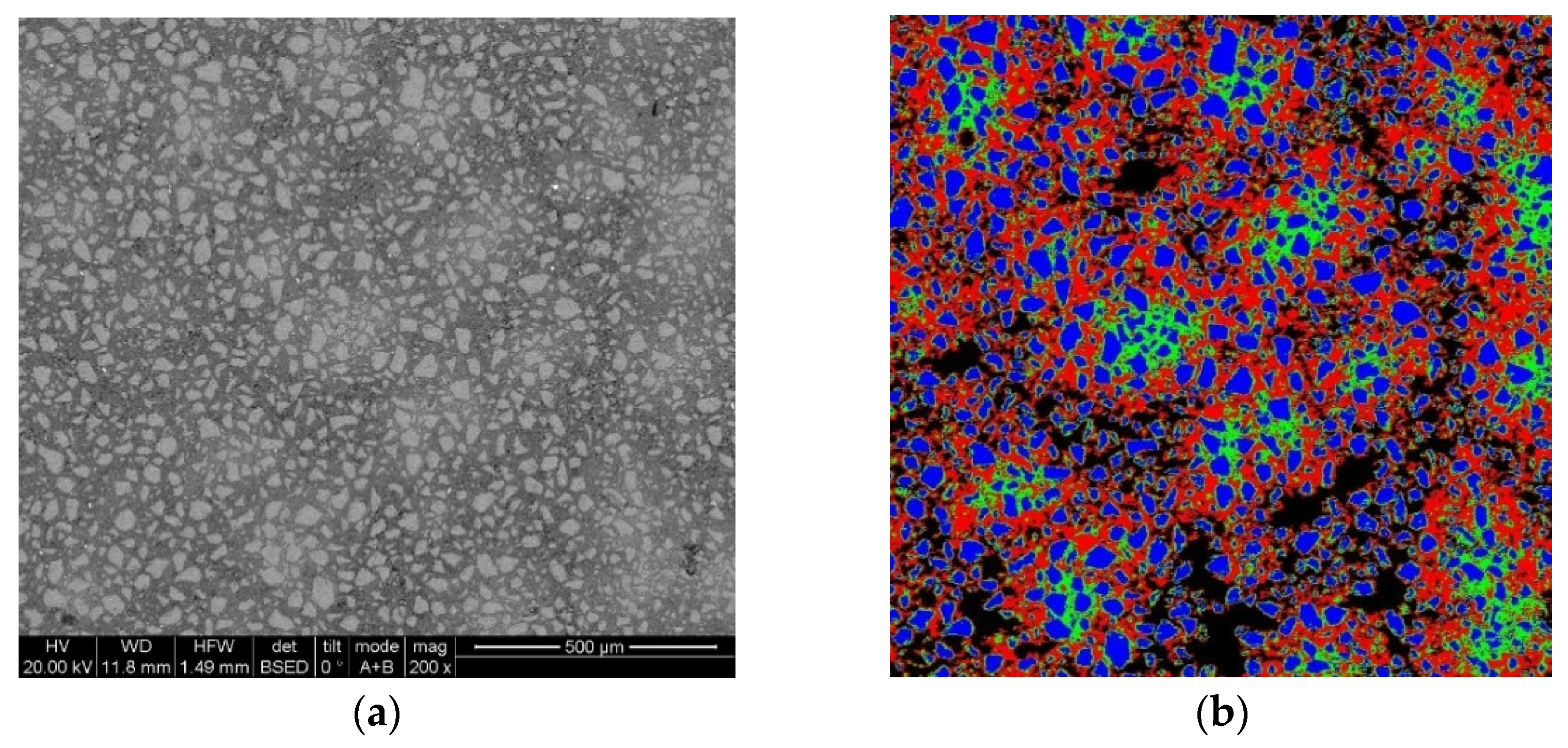

4.3.2. Distribution of CH

4.3.3. Pore Parameters

5. Extensions of Proposed Method

6. Limitations of This Study

7. Conclusions

- (1)

- The superior performance of DCNN-GF (MSE: 53.52, PSNR: 26.35 dB, SSIM: 0.8187) stems from its hybrid architecture. DCNN’s multi-scale feature extraction preserves phase boundaries, while GF adaptively smooths high-frequency noise without blurring textural details. This dual mechanism makes DCNN-GF uniquely suited for hydration kinetics studies requiring precise phase quantification (e.g., residual C3S evolution and C-S-H gel). In contrast, WD prioritizes pore network analysis but results in partial loss of solid phase information. These results establish a selection criterion: DCNN-GF for reaction front analysis, as well as WD for durability-related pore network modeling;

- (2)

- For IRV, low resolutions cause particle misidentification, mid resolutions optimize boundary clarity, while high resolutions introduce microstructural noise. Pores exhibit the highest IRV due to multi-scale networks. C-S-H stabilizes above 0.25 resolution through fractal aggregation, while CH stabilizes via crystal saturation. For BS, optimal boundary detection occurs at medium image relative resolutions (0.14–0.56), with C3S peaking at 0.25–0.56, C-S-H at 0.32, and CH at 0.19. Pores show a linear BS decline due to fractal complexity;

- (3)

- Silhouette analysis (average: 0.70–0.84) validates robust clustering when the number of clusters is 2–4. The Clark–Evans index of CH (0.426) reveals non-classical nucleation mechanisms in C3S hydration. Unlike Portland cement systems, where CH randomly precipitates within pore spaces, C3S-derived CH forms distinct nucleation centers within the microstructure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hache, E.; Simoën, M.; Seck, G.S.; Bonnet, C.; Jabberi, A.; Carcanague, S. The impact of future power generation on cement demand: An international and regional assessment based on climate scenarios. Int. Econ. 2020, 163, 114–133. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997. [Google Scholar]

- Wu, S.; Wang, X.; Shen, D.; Sun, K.; Zhu, J. Simulation analysis on hydration kinetics and microstructure development of tricalcium silicate considering dissolution mechanisms. Constr. Build. Mater. 2020, 249, 118535. [Google Scholar] [CrossRef]

- Wang, X.; Shen, D.; Tao, S.; Liu, R.; Wu, S. Estimation of chloride diffusivity in hydrated tricalcium silicate using a hydration-diffusion integrated method. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2025, 40, 49–64. [Google Scholar] [CrossRef]

- Camerini, R.; Poggi, G.; Ridi, F.; Baglioni, P. The kinetic of calcium silicate hydrate formation from silica and calcium hydroxide nanoparticles. J. Colloid Interface Sci. 2022, 605, 33–43. [Google Scholar] [CrossRef]

- Liu, X.; Feng, P.; Cai, Y.; Yu, X.; Liu, Q. Carbonation behaviors of calcium silicate hydrate (C-S-H): Effects of aluminum. Constr. Build. Mater. 2022, 325, 126825. [Google Scholar] [CrossRef]

- Prabhu, A.; Dolado, J.S.; Koenders, E.A.B.; Zarzuela, R.; Mosquera, M.J.; Garcia-Lodeiro, I.; Blanco-Varela, M.T. A patchy particle model for C-S-H formation. Cem. Concr. Res. 2022, 152, 106658. [Google Scholar] [CrossRef]

- Kurdowski, W. Cement and Concrete Chemistry, 1st ed.; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Salah Uddin, K.M.; Izadifar, M.; Ukrainczyk, N.; Koenders, E.; Middendorf, B. Dissolution of portlandite in pure water: Part 1 molecular dynamics (MD) approach. Materials 2022, 15, 1404. [Google Scholar] [CrossRef]

- Izadifar, M.; Ukrainczyk, N.; Salah Uddin, K.M.; Middendorf, B.; Koenders, E. Dissolution of portlandite in pure water: Part 2 atomistic kinetic Monte Carlo (KMC) approach. Materials 2022, 15, 1442. [Google Scholar] [CrossRef]

- Shen, D.; Wang, X. Simulation on Hydration of Tricalcium Silicate in Cement Clinker, 1st ed.; Springer: Singapore, 2023. [Google Scholar]

- Taylor, H.F.W.; Mohan, K.; Moir, G.K. Analytical study of pure and extended portland cement pastes: I, pure Portland cement pastes. J. Am. Ceram. Soc. 1985, 68, 680–685. [Google Scholar] [CrossRef]

- Bentz, D.P.; Stutzman, P.E.; Haecker, C.; Remond, S. SEM/X-ray imaging of cement-based materials. In Proceedings of the 7th Euroseminar on Microscopy Applied to building Materials, Delft, Holland, 29 June–2 July 1999; pp. 457–466. [Google Scholar]

- Wong, H.S.; Head, M.K.; Buenfeld, N.R. Pore segmentation of cement-based materials from backscattered electron images. Cem. Concr. Res. 2006, 36, 1083–1090. [Google Scholar] [CrossRef]

- Gao, Y.; De Schutter, G.; Ye, G.; Huang, H.; Tan, Z.; Wu, K. Characterization of ITZ in ternary blended cementitious composites: Experiment and simulation. Constr. Build. Mater. 2013, 41, 742–750. [Google Scholar] [CrossRef]

- Scrivener, K.L. Backscattered electron imaging of cementitious microstructures: Understanding and quantification. Cem. Concr. Compos. 2004, 26, 935–945. [Google Scholar] [CrossRef]

- Chen, L.; Shan, W.; Liu, P. Identification of concrete aggregates using K-means clustering and level set method. Structures 2021, 34, 2069–2076. [Google Scholar] [CrossRef]

- Li, L.; Yang, J.; Shen, X. Measuring the hydration product proportion in composite cement paste by using quantitative BSE-EDS image analysis: A comparative study. Measurement 2022, 199, 111290. [Google Scholar] [CrossRef]

- Yu, Y.; Geng, G. Deep learning methods for phase segmentation in backscattered electron images of cement paste and SCM-blended systems. Cem. Concr. Compos. 2025, 155, 105810. [Google Scholar] [CrossRef]

- Sheiati, S.; Nguyen, H.; Kinnunen, P.; Ranjbar, N. Cementitious phase quantification using deep learning. Cem. Concr. Res. 2023, 172, 107231. [Google Scholar] [CrossRef]

- Ma, Y.; Qian, H.; Zou, D.; Zhou, A.; Liu, T.; Li, Y. Resolution enhancement of cementitious microstructure images and phases quantification using deep learning. Constr. Build. Mater. 2025, 461, 139909. [Google Scholar] [CrossRef]

- Abras, G.N.; Ballarin, V.L. A weighted K-means algorithm applied to brain tissue classification. J. Comput. Sci. Technol. 2005, 5, 121–126. [Google Scholar]

- Costoya Fernández, M.M. Effect of Particle Size on the Hydration Kinetics and Microstructural Development of Tricalcium Silicate. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2008. [Google Scholar]

- Young, J.F.; Hansen, W. Volume relationships for C-S-H formation based on hydration stoichiometries. MRS Online Proc. Libr. 1986, 85, 313. [Google Scholar] [CrossRef]

- Wei, D.; Rajashekar, U.; Bovik, A.C. 3.4-Wavelet denoising for image enhancement. In Handbook of Image and Video Processing, 2nd ed.; Bovik, A.L., Ed.; Academic Press: Burlington, VT, USA, 2005; pp. 157–165. [Google Scholar]

- Dinç, İ.; Dinç, S.; Sigdel, M.; Sigdel, M.S.; Aygün, R.S.; Pusey, M.L. Chapter 12-DT-Binarize: A decision tree based binarization for protein crystal images. In Emerging Trends in Image Processing, Computer Vision and Pattern Recognition; Deligiannidis, L., Arabnia, H.R., Eds.; Morgan Kaufmann: Boston, MA, USA, 2015; pp. 183–199. [Google Scholar]

- He, K.; Sun, J.; Tang, X. Guided image filtering. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 1397–1409. [Google Scholar] [CrossRef]

- MacQueen, J.B.; Le Cam, L.M.; Neyman, J. Some methods for classification and analysis of multivariate observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability, Berkeley, CA, USA, 21 June–18 July 1965 and 27 December 1965–7 January 1966; University of California Press: Berkeley, CA, USA, 1967; pp. 281–297. [Google Scholar]

- Poynton, C. Digital Video and HDTV: Algorithms and Interfaces, 1st ed.; Morgan Kaufmann: San Francisco, CA, USA, 2012. [Google Scholar]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 1st ed.; Pearson: Essex, UK, 2018. [Google Scholar]

- Horé, A.; Ziou, D. Image quality metrics: PSNR vs. SSIM. In Proceedings of the 2010 20th International Conference on Pattern Recognition, Istanbul, Turkey, 23–26 August 2010; pp. 2366–2369. [Google Scholar]

- Zhou, W.; Bovik, A.C.; Sheikh, H.R.; Simoncelli, E.P. Image quality assessment: From error visibility to structural similarity. IEEE Trans. Image Process. 2004, 13, 600–612. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zuo, W.; Chen, Y.; Meng, D.; Zhang, L. Beyond a Gaussian denoiser: Residual learning of deep CNN for image denoising. IEEE Trans. Image Process. 2017, 26, 3142–3155. [Google Scholar] [CrossRef]

- Oleschko, K. Delesse principle and statistical fractal sets: 1. Dimensional equivalents. Soil Tillage Res. 1998, 49, 255–266. [Google Scholar] [CrossRef]

- Kleiner, F.; Becker, F.; Rößler, C.; Ludwig, H.-M. A Python tool to determine the thickness of the hydrate layer around clinker grains using SEM-BSE images. J. Microsc. 2024, 294, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Kleiner, F. Large SEM-BSE Images of Hydrated Alite of Ages from 1 Day up to 1 Year. Zenodo. Available online: https://zenodo.org/records/8210797 (accessed on 6 July 2023).

- Kleiner, F. ELM/Measure_Hydrate_Layer: Release for Revision 1. Zenodo. Available online: https://zenodo.org/records/10659663 (accessed on 14 February 2024).

- Buades, A.; Coll, B.; Morel, J.M. Non-local means denoising. Image Process. Line 2011, 1, 208–212. [Google Scholar] [CrossRef]

- Kjellsen, K.O.; Justnes, H. Revisiting the microstructure of hydrated tricalcium silicate––A comparison to Portland cement. Cem. Concr. Compos. 2004, 26, 947–956. [Google Scholar] [CrossRef]

- Petrere, M. The variance of the index (R) of aggregation of Clark and Evans. Oecologia 1985, 68, 158–159. [Google Scholar] [CrossRef]

- Gao, X.; Liu, Q.-F.; Cai, Y.; Tong, L.-Y.; Peng, Z.; Xiong, Q.X.; De Schutter, G. A new model for investigating the formation of interfacial transition zone in cement-based materials. Cem. Concr. Res. 2025, 187, 107675. [Google Scholar] [CrossRef]

- Jain, R.; Kasturi, R.; Schunck, B.G. Machine Vision, 1st ed.; McGraw-Hill: London, UK, 1995. [Google Scholar]

- Termkhajornkit, P.; Vu, Q.H.; Barbarulo, R.; Daronnat, S.; Chanvillard, G. Dependence of compressive strength on phase assemblage in cement pastes: Beyond gel–space ratio—Experimental evidence and micromechanical modeling. Cem. Concr. Res. 2014, 56, 1–11. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, M.; Fang, G.; Bai, Y.; Zhang, Y. Modelling of capillary pore structure evolution in Portland cement pastes based on irregular-shaped cement particles. In Proceedings of the 6th International Conference on Durability of Concrete Structures, Leeds, UK, 18–20 July 2018; pp. 771–780. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Luo, Y. Integrating Backscattered Electron Imaging and Multi-Feature-Weighted Clustering for Quantification of Hydrated C3S Microstructure. Buildings 2025, 15, 1699. https://doi.org/10.3390/buildings15101699

Wang X, Luo Y. Integrating Backscattered Electron Imaging and Multi-Feature-Weighted Clustering for Quantification of Hydrated C3S Microstructure. Buildings. 2025; 15(10):1699. https://doi.org/10.3390/buildings15101699

Chicago/Turabian StyleWang, Xin, and Yongjun Luo. 2025. "Integrating Backscattered Electron Imaging and Multi-Feature-Weighted Clustering for Quantification of Hydrated C3S Microstructure" Buildings 15, no. 10: 1699. https://doi.org/10.3390/buildings15101699

APA StyleWang, X., & Luo, Y. (2025). Integrating Backscattered Electron Imaging and Multi-Feature-Weighted Clustering for Quantification of Hydrated C3S Microstructure. Buildings, 15(10), 1699. https://doi.org/10.3390/buildings15101699