Design and Construction Control of Warm Mix Epoxy Asphalt Mixture with Low Epoxy Content for Service Area Pavements

Abstract

1. Introduction

2. Physical Properties of Experimental Raw Materials

2.1. Asphalt Binder Materials

2.2. Aggregates

2.3. Mineral Powder

3. Design and Property Analysis of Warm Mix Epoxy Asphalt Mixture

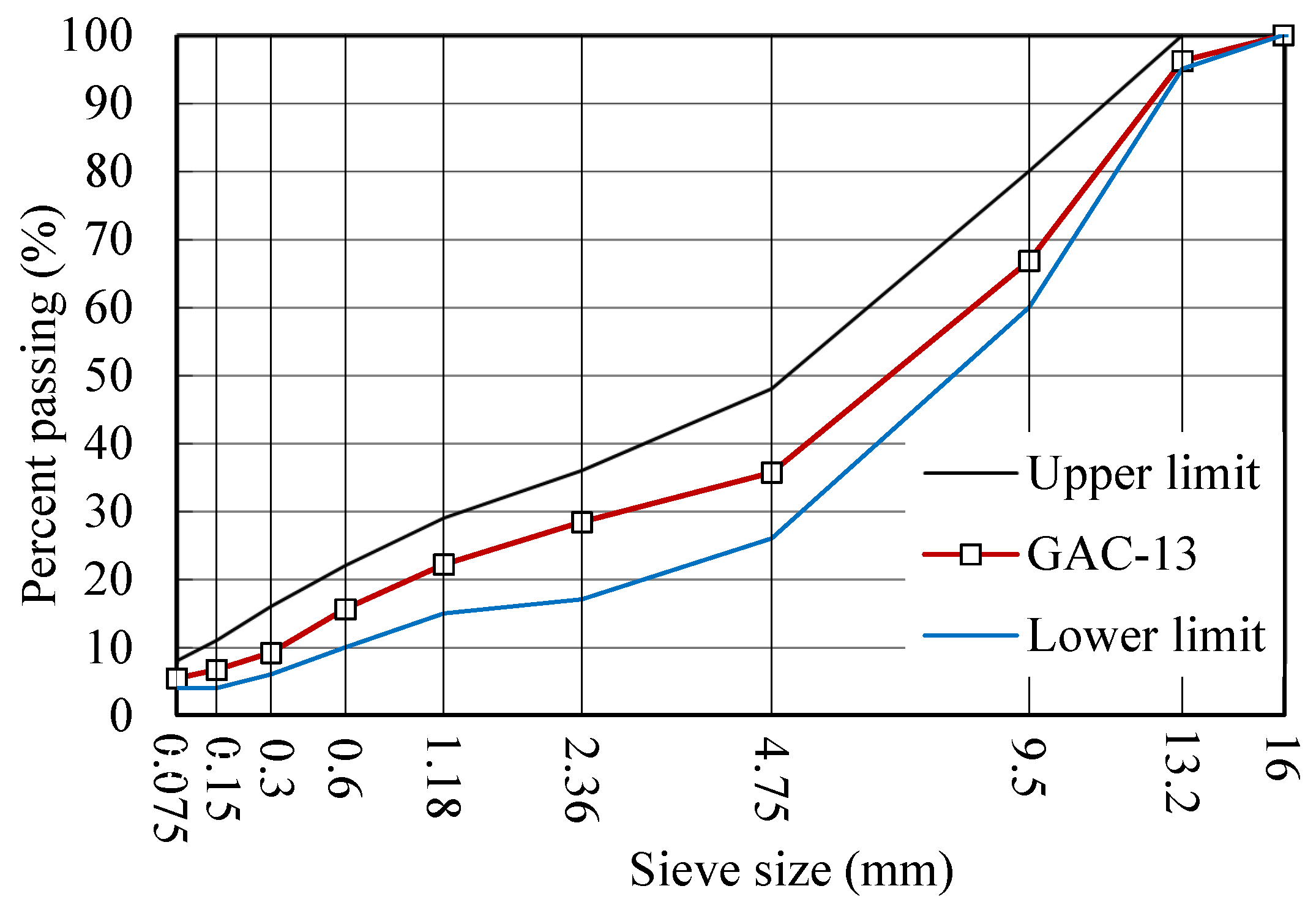

3.1. Mineral Aggregate Gradation Design

3.2. Comprehensive Property Analysis of Epoxy Asphalt Mixture

- (1)

- Mashall indicator analysis

- (2)

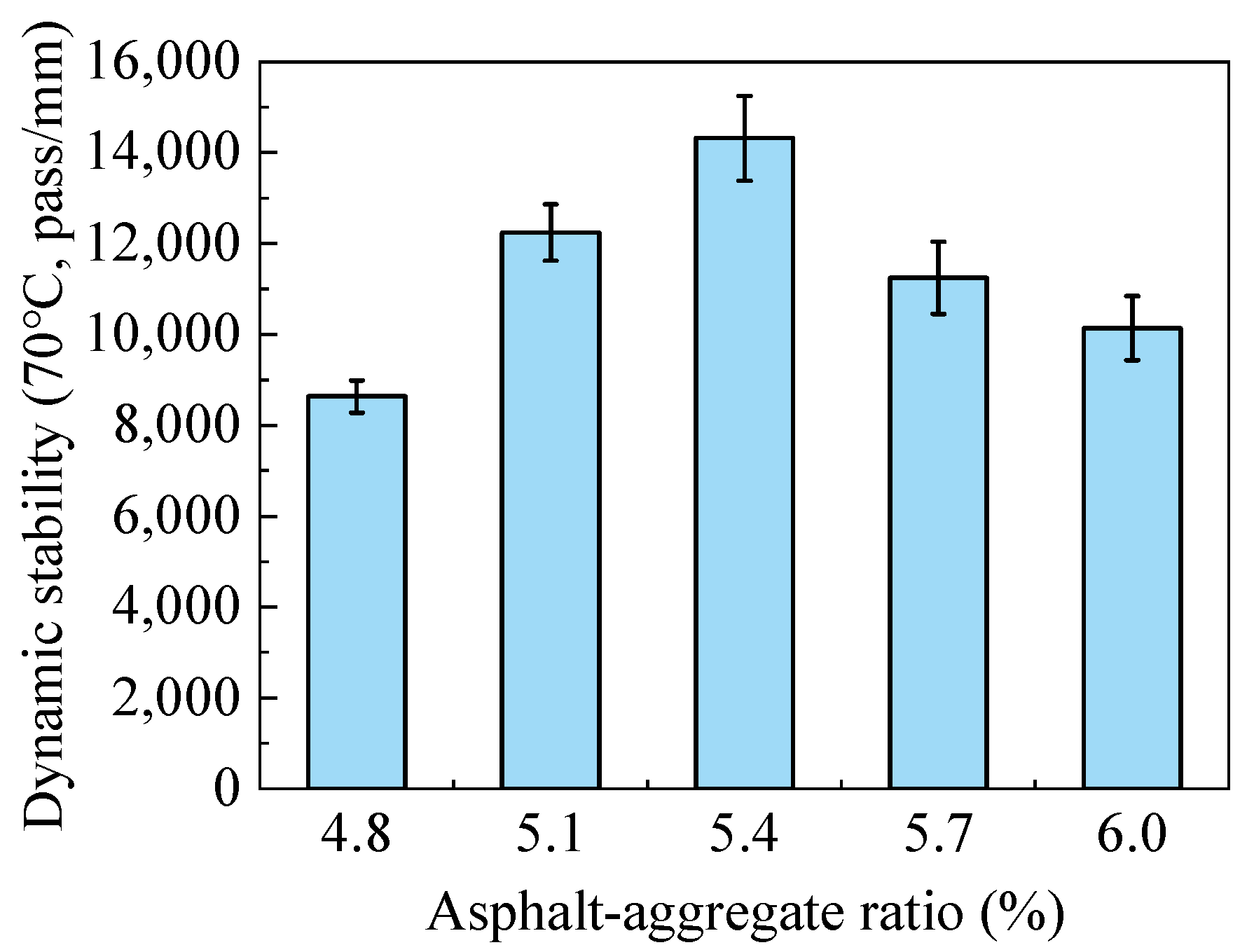

- High-temperature stability analysis

- (3)

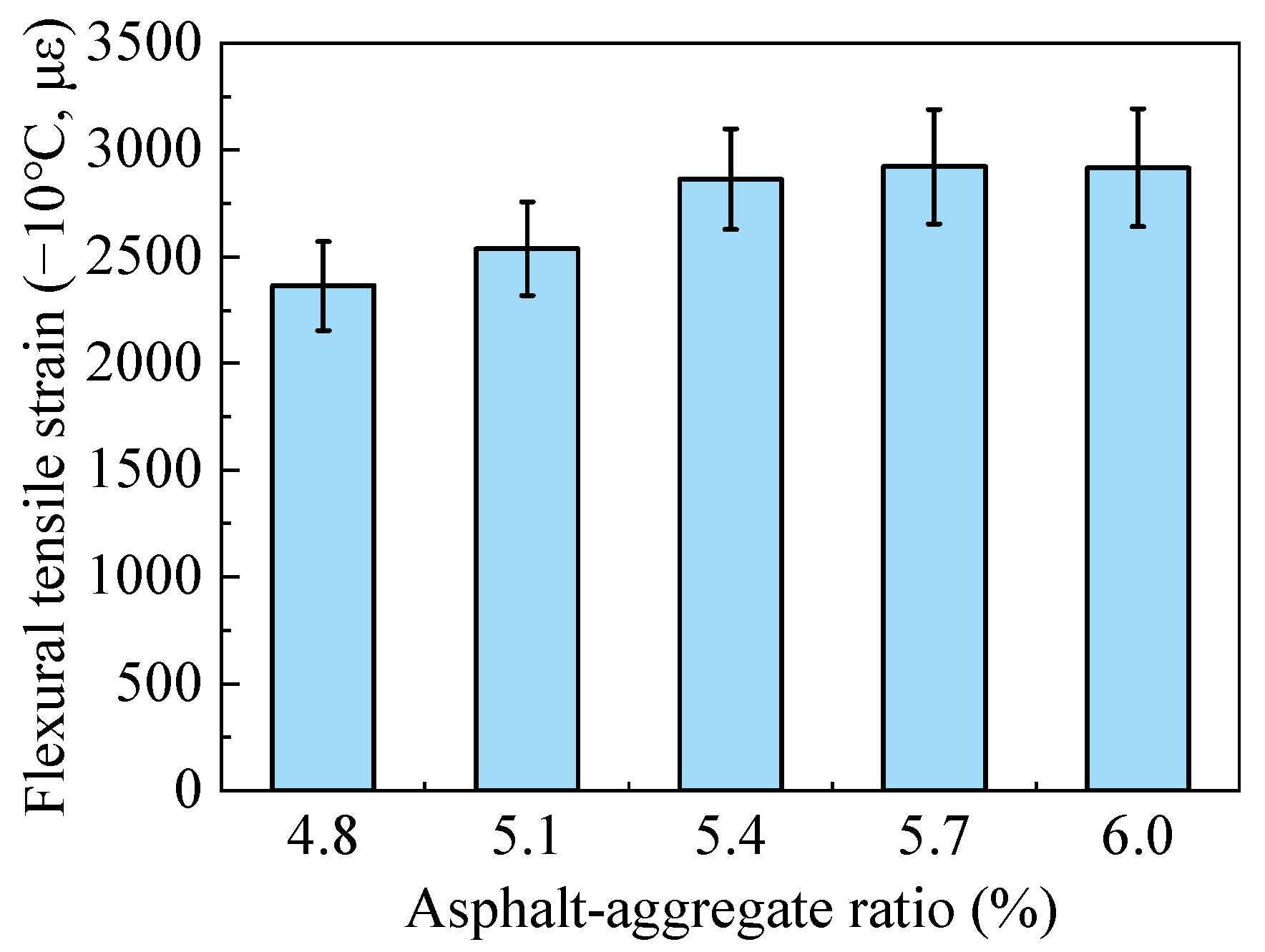

- Low-temperature crack resistance analysis

- (4)

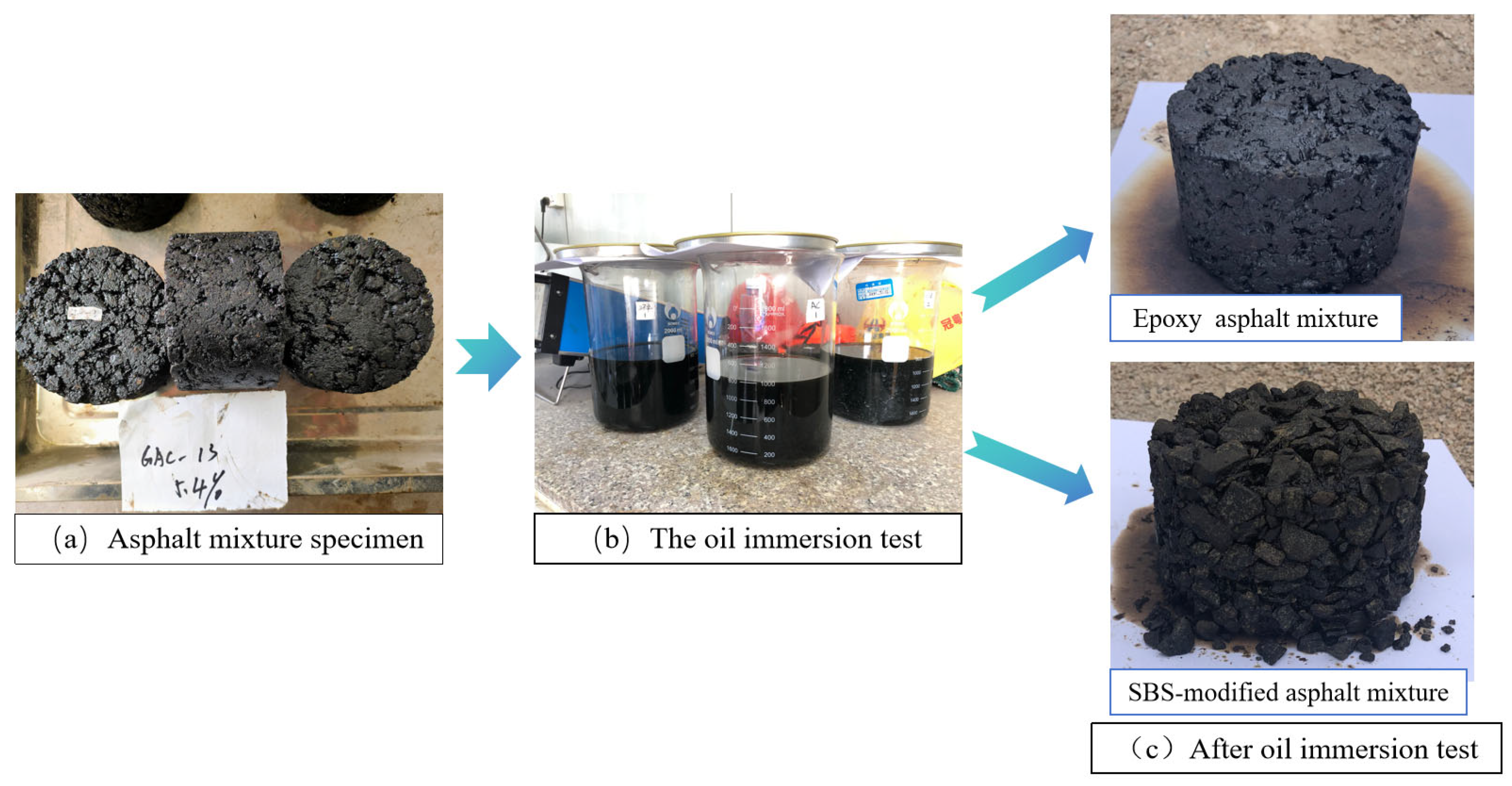

- Oil corrosion resistance analysis

- (5)

- Recommended epoxy asphalt mixture scheme

3.3. Viscosity Variety Analysis of Epoxy Asphalt

4. Construction Quality Control of Warm Mix Epoxy Asphalt Mixture

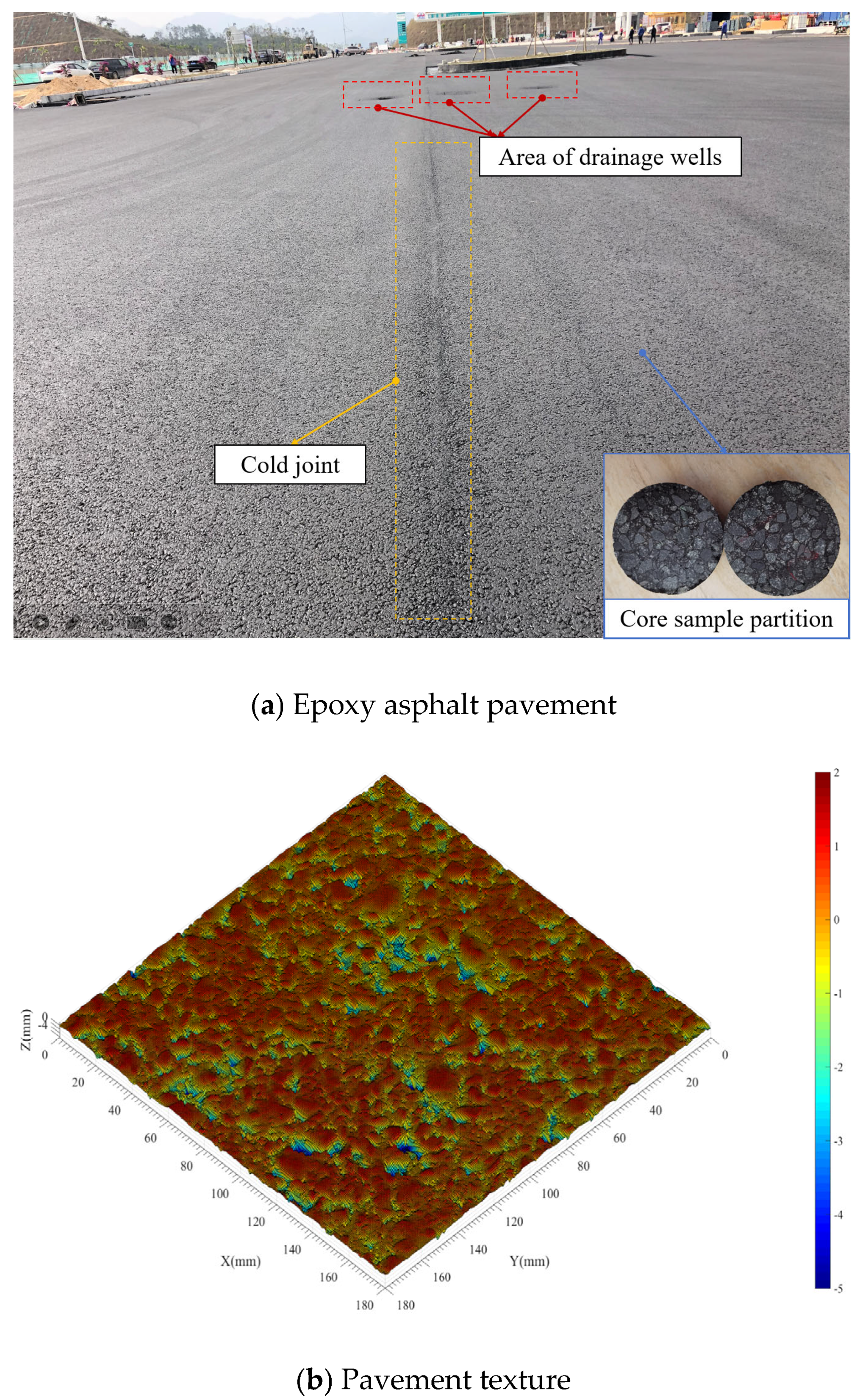

4.1. Project Profile

4.2. Preparation of Construction Machinery

4.3. Mixing and Transportation of Epoxy Asphalt Mixture

4.4. Distributing Construction of Epoxy Asphalt Bonding Treatment

4.5. Stability Control of Raw Material Mixing Production

4.6. Construction Available Time of Epoxy Asphalt Mixture

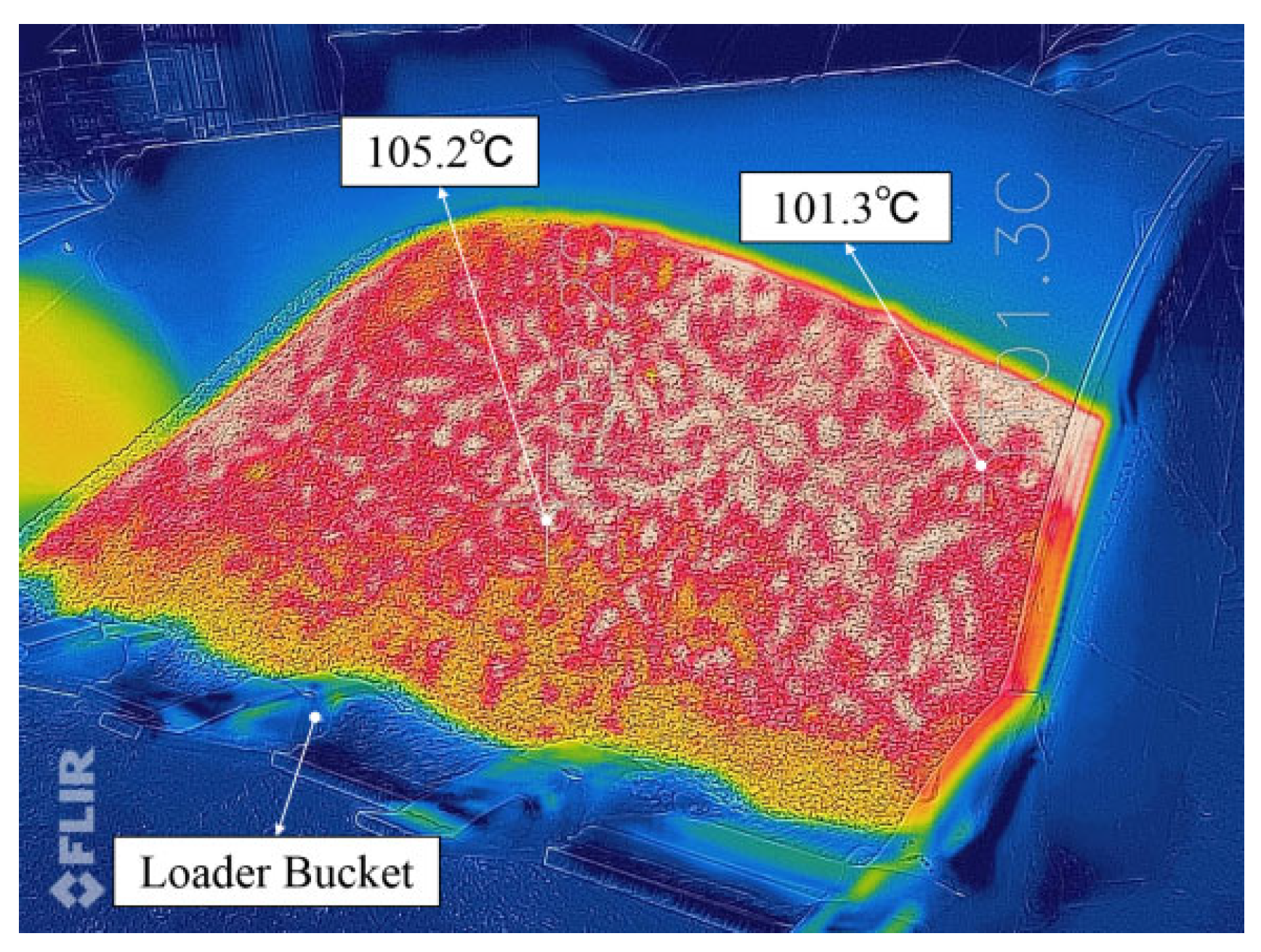

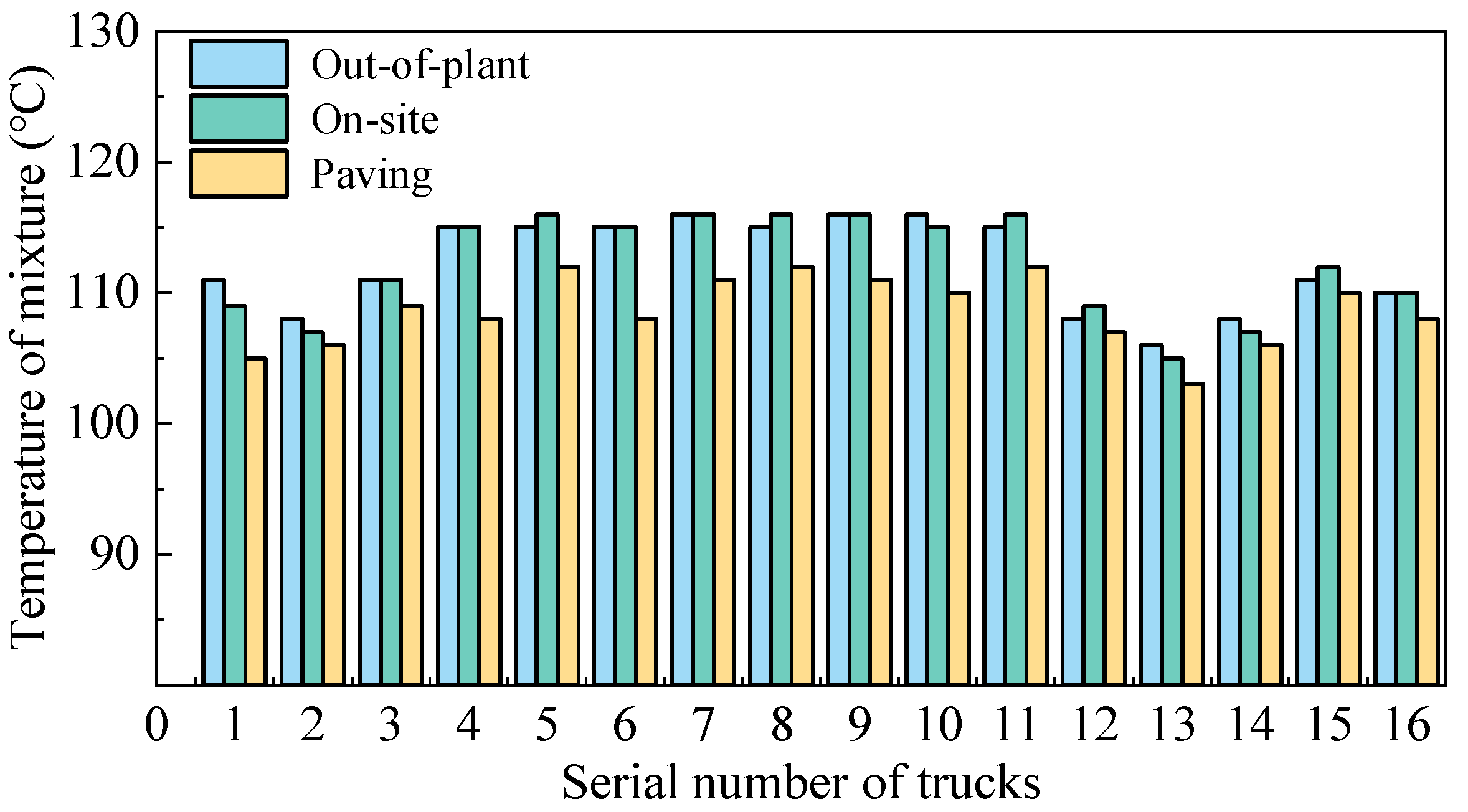

4.7. Construction Temperature Control of Epoxy Asphalt Mixture

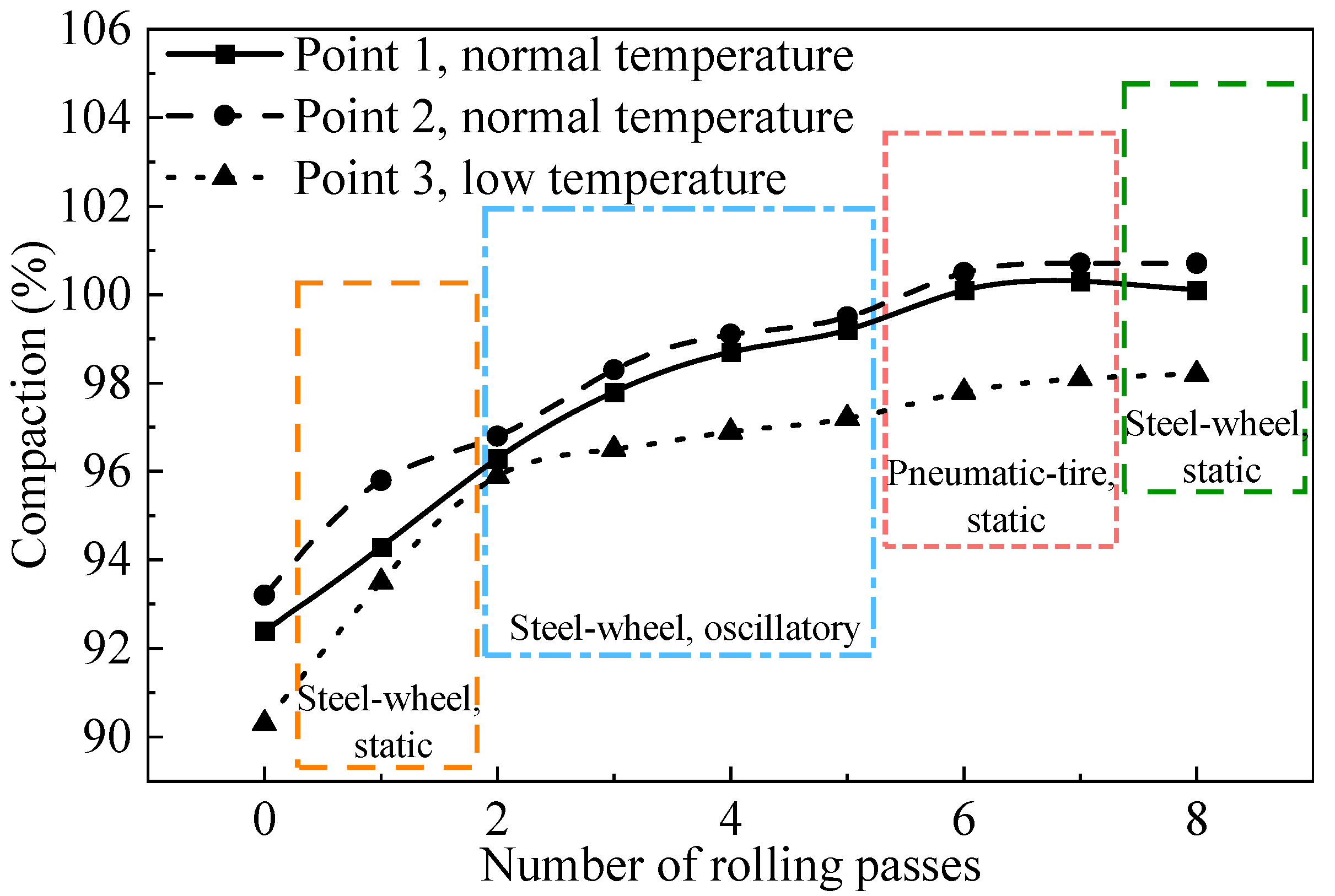

4.8. Compaction Process Control of Epoxy Asphalt Mixture

- (1)

- Under normal temperature conditions, after five passes of steel-wheel rolling (including the initial compaction), the compaction reached a stable state. Subsequently, two additional passes with the pneumatic-tire roller were sufficient to achieve peak compaction.

- (2)

- Under low-temperature conditions, compaction progressed more slowly. Even with the same number of rolling passes, the final compaction achieved was significantly lower than that under normal temperature conditions. The difference in final compaction was approximately 2.3%.

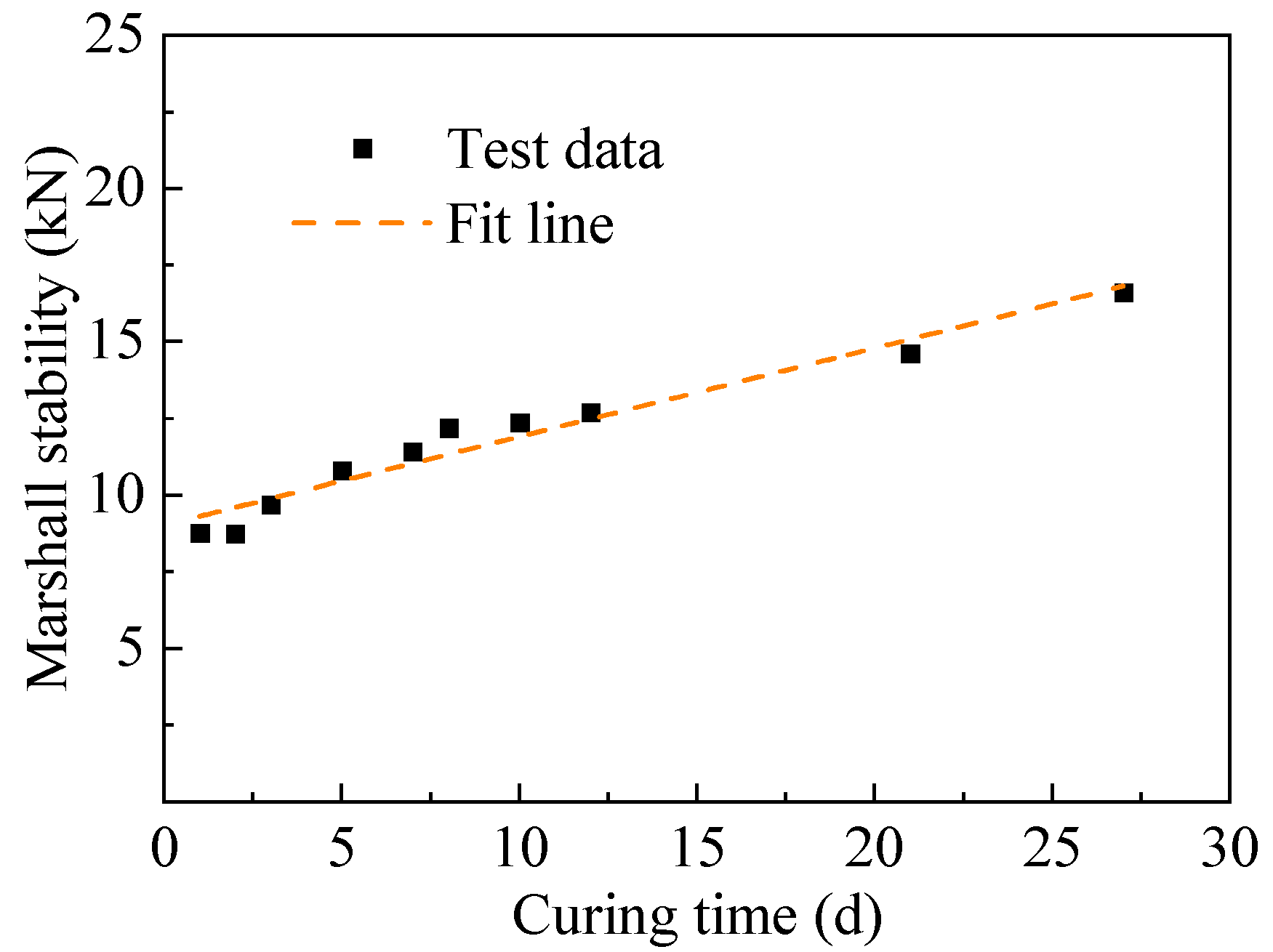

4.9. Determination of Curing Time for Epoxy Asphalt Mixture

5. Evaluation of Construction Quality for Warm Mix Epoxy Asphalt Pavement

6. Conclusions

- (1)

- The CAVF volumetric method for designing the gradation of warm mix epoxy asphalt mixtures effectively balances the mixture’s density and skid resistance. The high-temperature stability of the epoxy asphalt mixture exhibits significant non-linear characteristics with varying asphalt-aggregate ratios. When the asphalt-aggregate ratio is 5.4%, the dynamic stability of the GAC-13 mixture peaks at 70 °C. As the epoxy asphalt content increases, the low-temperature crack resistance of the mixture initially increases significantly and then stabilizes.

- (2)

- The structural strength and high-temperature stability of the warm mix epoxy asphalt mixtures are 2.13 times and 2.69 times greater, respectively, than those of the SBS-modified asphalt mixtures. The water stability and low-temperature crack resistance are also slightly superior to those of the SBS-modified asphalt mixtures. After oil immersion, the Marshall stability of the epoxy asphalt mixture samples reached 20 kN, with a residual stability of 50%. The oil resistance is significantly better than that of the SBS-modified asphalt mixtures, making it particularly suitable for service area parking lot pavements.

- (3)

- Viscosity tests of epoxy asphalt mixtures show that as the temperature decreases, the initial viscosity of the asphalt increases. Excessively high temperatures and prolonged reaction times can accelerate the curing reaction of the epoxy resin, leading to a rapid increase in asphalt viscosity. Therefore, the effective construction window for warm mix epoxy asphalt mixtures should be controlled within 100 min at temperatures between 100 °C and 120 °C.

- (4)

- Key construction processes were monitored, including infrared thermography, production data analysis from the mixing plant, transportation time statistics, and compaction measurements. Based on the results, it is recommended that the initial compaction temperature of the warm mix epoxy asphalt mixture be ≥100 °C, with at least six passes during the repeated compaction process. The final compaction temperature should be ≥70 °C to ensure a compaction rate of ≥98%.

- (5)

- Marshall stability tests of epoxy asphalt samples during ambient temperature curing showed that the initial stability is comparable to that of conventional modified asphalt mixtures. As curing time increases, the strength development rate is strongly correlated with temperature (R2 = 0.955). After 38 days of curing, the strength of the epoxy asphalt pavement structure reaches the design standard of 20 kN, allowing the road to be opened to traffic.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, S.; Li, R.; Zhu, H.Z.; Qin, Y.R.; Huang, C.X. Review of the state-of-the-art techniques for enhancing the toughness of thermosetting epoxy asphalt. Constr. Build. Mater. 2024, 449, 137660. [Google Scholar] [CrossRef]

- Xu, S.; Tang, G.M.; Pan, S.L.; Ji, Z.Y.; Fang, L.Z.; Zhang, C.L.; Cao, Z.L.; Zhou, X.X.; Jia, X.J. Application of reactive rejuvenator in aged SBS modified asphalt regeneration: A review. Constr. Build. Mater. 2024, 421, 135696. [Google Scholar] [CrossRef]

- Xie, H.F.; Li, C.X.; Wang, Q.J. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr. Build. Mater. 2022, 326, 126792. [Google Scholar] [CrossRef]

- Zhai, C.; Wu, W.; Xiao, Y.; Zhang, J.; Zhai, M. Jam traffic pattern of a multi-phase lattice hydrodynamic model integrating a continuous self-stabilizing control protocol to boycott the malicious cyber-attacks. Chaos Solitons Fract. 2025, 197, 116531. [Google Scholar] [CrossRef]

- Xiong, X.; Meng, A.; Lu, J.; Tan, Y.; Chen, B.; Tang, J.; Zhang, C.; Xiao, S.; Hu, J. Automatic detection and location of pavement internal distresses from ground penetrating radar images based on deep learning. Constr. Build. Mater. 2023, 411, 134483. [Google Scholar] [CrossRef]

- Xiong, X.; Tan, Y. Pixel-Level patch detection from full-scale asphalt pavement images based on deep learning. Int. J. Pavement Eng. 2023, 24, 2180639. [Google Scholar] [CrossRef]

- Shi, L.W.; Guo, H.J.; Zeng, G.D.; Zhou, R.; Li, X.X.; Lin, B.H.; Liang, H.H. Key parameters and effects in image processing and aggregate–aggregate contact calculation of asphalt mixtures. Measurement 2025, 239, 115439. [Google Scholar] [CrossRef]

- Wang, H.Z.; Liu, Y.X.; Li, J.; Liu, S.A.; Yang, J.; Luo, S.; Huang, W. Environmental life cycle assessment of bridge deck pavement and case studies of two bridges in China. Case Stud. Constr. Mater. 2023, 18, e02115. [Google Scholar] [CrossRef]

- Huang, P.; Wang, T.L.; Zhou, Y.X.; Fan, Y.L.; Wu, Y.; Wang, H.Z.; Yang, J.; Huang, W. Piezoresistive response of MWCNTs/Epoxy mixtures with load-sensing capability. Constr. Build. Mater. 2024, 438, 137203. [Google Scholar] [CrossRef]

- Li, K.; Xie, J.G.; Liu, Y.P.; Tan, Y.W.; Pan, Y.Q. Development and evaluation of roadway-oriented epoxy-modified asphalt binders and mixtures. Constr. Build. Mater. 2024, 418, 135398. [Google Scholar] [CrossRef]

- Gong, J.; Liu, Y.; Wang, Q.J.; Xi, Z.H.; Cai, J.; Ding, G.W.; Xie, H.F. Performance evaluation of warm mix asphalt additive modified epoxy asphalt rubbers. Constr. Build. Mater. 2019, 204, 288–295. [Google Scholar] [CrossRef]

- Haibara, Y.; Ge, H.B. Effects of Epoxy Resin System and Ingredient Content on the Properties of Asphalt and Its Mixtures. J. Mater. Civ. Eng. 2025, 37, 04024440. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.D.; Yang, Y.M.; Huang, Q.B.; Zhang, X.F. Effect of Curing Reaction Behaviors of Warm Mix Epoxy Asphalt Concrete on Its Field Compaction Characteristics Using Discrete-Element Method. J. Mater. Civ. Eng. 2022, 34, 04022092. [Google Scholar] [CrossRef]

- Huang, Q.B.; Qian, Z.D.; Yang, Y.M.; Zheng, D. Investigation of warm mix epoxy asphalt compaction with gyratory compactor and charge coupled photoelectric imaging. Constr. Build. Mater. 2021, 271, 121506. [Google Scholar] [CrossRef]

- Chen, F.; Min, Z.H.; Li, M.Y.; Shi, Z.Y.; Zhao, Y.Q.; Feng, J.L. Preparation and Performance Evaluation of Warm-Mixed Epoxy Asphalt Ultrathin Overlay by Post-Doping Method. J. Mater. Civ. Eng. 2024, 36, 04024145. [Google Scholar] [CrossRef]

- Jiang, X.J.; Huang, W.; Luo, S.; Wei, Y.; Kong, W.Y.; Du, K.J. Numerical analysis of the effects of subgrade settlement on top-down cracking in epoxy asphalt pavement. Sci. China Technol. Sci. 2024, 67, 3308–3320. [Google Scholar] [CrossRef]

- Fan, C.; Chen, H.; Lin, F.; Li, W.; Xiong, X.; Chen, B.; Yu, H. Impact of curing time and temperature on bond performance of epoxy resin adhesives for steel bridge decks. Polymers 2025, 17, 1018. [Google Scholar] [CrossRef]

- Min, Y.T.; Qian, Z.D.; Hu, B.Y.; Zhang, H.C.; Xie, Z.M.; Wang, D. Analysis of the recyclability of thermosetting pavement materials: A case study of reclaimed epoxy asphalt pavement (REAP). Constr. Build. Mater. 2025, 466, 140294. [Google Scholar] [CrossRef]

- Quan, X.J.; Chen, X.; Chen, Y.; Ma, T.; Gu, L.H.; Shi, S. Study the epoxy resin content on the performance of hot-mix epoxy asphalt binder and mixture used in steel deck pavement. Int. J. Pavement Eng. 2025, 26, 2449567. [Google Scholar] [CrossRef]

- Wu, W.J.; Fu, Z.Y.; Jiang, W. Developing a novel sustainable and durable self-luminous pavement material with solar energy absorption capability. Constr. Build. Mater. 2024, 445, 137934. [Google Scholar] [CrossRef]

- Chen, X.; Lin, Z.X.; Ma, T.; Gu, L.H.; Chen, Y.; Shi, S. Study on Hot-Mix Epoxy Resin Based on Glass Transition Temperature and Its Application for Steel Bridge Deck Pavement. J. Mater. Civ. Eng. 2024, 36, 04024239. [Google Scholar] [CrossRef]

- Zhang, Y.; Shi, X.M. Laboratory evaluation of a sustainable additive for anti-icing asphalt. Cold Reg. Sci. Technol. 2021, 189, 103338. [Google Scholar] [CrossRef]

- Zhang, W.; Zuo, S.; Zhang, K.; Luo, Y.F.; Zhu, L.L. Investigation of the interfacial bonding of new and old pavement materials for pothole applications: Bonding materials optimization, mechanical properties and structural performance. Constr. Build. Mater. 2024, 425, 135983. [Google Scholar] [CrossRef]

- Abualia, A.; Liu, J.; Mohammad, L.N.; Cooper, S.B. Effect of High Polymer, Crumb Rubber, and Epoxy-Modified Asphalt Binders on Laboratory Performance of Open-Graded Friction Course Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2024, 36, 11981241254387. [Google Scholar] [CrossRef]

- Ye, F.L.; Ding, X.H.; Ma, T.; Ye, Z.Y.; Su, Z.Z.; Zhang, S.Q. Application research of epoxy resin mortar composite encapsulated piezoelectric ultrasonic sensors in monitoring dynamic modulus of asphalt concrete. Measurement 2025, 246, 116642. [Google Scholar] [CrossRef]

- Cui, P.D.; Wu, S.P.; Liu, Q.T.; Wang, F.S. Artificial neural network modeling for predicting surface texture and its attenuation of micro-surfacing containing steel slag aggregates. Constr. Build. Mater. 2022, 346, 128504. [Google Scholar] [CrossRef]

- Gong, J.; Liu, Y.; Jiang, Y.J.; Wang, Q.J.; Xi, Z.H.; Cai, J.; Xie, H.F. Performance of epoxy asphalt binder containing warm-mix asphalt additive. Int. J. Pavement Eng. 2021, 22, 223–232. [Google Scholar] [CrossRef]

- Li, X.D.; Luo, C.X.; Wang, S.H.; Long, X.; Wang, Y.; Li, J.; He, M. Study of Low-Content Epoxy Asphalt Mixture Applied to the Road. Buildings 2024, 14, 443. [Google Scholar] [CrossRef]

- Ma, C.; Peng, J.H.; Guo, Z.G.; Shi, J.Y.; Yu, F.; Zhou, H.J.; Dong, B.Q.; Du, Y.L. Property evaluation of magnesia-based cement emulsified asphalt mortar (MCAM) as pavement repair material. Int. J. Pavement Eng. 2023, 24, 2209264. [Google Scholar] [CrossRef]

- Ren, H.S.; Qian, Z.D.; Huang, W.; Bo, W.; Chen, T.J.; Cao, H.B. Evaluation of fracture behavior in asphalt concrete through the combination of semi-circular bending test and digital image correlation technology. Constr. Build. Mater. 2024, 451, 138854. [Google Scholar] [CrossRef]

- Song, Y.; Xu, H.Q.; Wu, S.P.; Xie, J.; Chen, A.Q.; Lv, Y.; Cheng, Y.X.; Li, Y.Y. High-quality utilization of reclaimed asphalt pavement (RAP) in asphalt mixture with the enhancement of steel slag and epoxy asphalt. Constr. Build. Mater. 2024, 445, 137963. [Google Scholar] [CrossRef]

- Wang, L.G.; Zhang, Z.R.; Liu, W.Y.; Wu, M.F.; Shi, J.Y.; Yan, K.Z. Effects of Epoxy Resin Value on Waterborne-Epoxy-Resin-Modified Emulsified Asphalt Mixture Performance. Appl. Sci. 2024, 14, 1353. [Google Scholar] [CrossRef]

- Wang, Q.C.; Min, Z.H.; Cheng, L.; Zhang, Y.; Sun, J.; Wong, Y.D.; Shao, K.M. An epoxy asphalt with polyethylene glycol chains for porous mixtures containing reclaimed asphalt pavement. Case Stud. Constr. Mater. 2024, 20, e02972. [Google Scholar] [CrossRef]

- Xu, Y.; Fan, Z.Q.; Wang, Z.H.; Shan, H.R.; Lyu, X.; Liu, Z.D.; Xu, S.F. Research on anti-shear performance of waterproof adhesive layer (WAL) in polyurethane-mixture steel-bridge pavement structure. Constr. Build. Mater. 2024, 417, 135314. [Google Scholar] [CrossRef]

- Yao, Y.Q.; Yang, J.G.; Gao, J.; Zheng, M.L.; Song, L.; Xu, J.; Sun, C. RAP chunks produced in cold milling operation of asphalt pavement: Evaluation, mechanism, and engineering investigation in China. J. Traffic Transp. Eng. 2024, 11, 972–1000. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Lu, Z.Y.; Chen, A.Q.; Wu, S.P.; Feng, J.L.; Xu, H.Q.; Li, Y.Y. Study on the Performance of Epoxy-Modified Asphalt and Steel Slag Ultra-Thin Friction Course. Materials 2024, 17, 4513. [Google Scholar] [CrossRef]

- Zhao, R.K.; Jing, F.; Li, C.X.; Wang, R.; Xi, Z.H.; Cai, J.; Wang, Q.J.; Xie, H.F. Phase-separated microstructures and viscosity-time behavior of graphene nanoplatelet modified warm-mix epoxy asphalt binders. Mater. Struct. 2022, 55, 248. [Google Scholar] [CrossRef]

- Zhuang, Y.Z.; Liu, K.; Zhan, X.L. Analysis of Mechanical Response of Epoxy Asphalt-Repaired Pavement in Pothole Interface on Steel Bridge Deck under Coupled Temperature-Dynamic Loading. Buildings 2024, 14, 599. [Google Scholar] [CrossRef]

- Suo, Z.; Bao, X.; Nie, L.; Yan, Q.; Qi, K. Optimization Design of Mix Proportion of Large Stone Permeable Mixture Based on Target Air Voids. Buildings 2021, 11, 514. [Google Scholar] [CrossRef]

- Zhu, L.Y.; Jing, H.; Luo, C.J.; Li, M.R.; Deng, J.L.; Yan, L.K. Modification of epoxy asphalt by low-doping PE-GMA and PE-MAH. J. Appl. Polym. Sci. 2024, 141, e55143. [Google Scholar] [CrossRef]

- Yoo, P.J.; Eom, B.S.; Park, K.S.; Kim, D.H. Aggregate pre-coating approach using rubber- and silane-coupled thermoset polymer and emulsion for warm-mix asphalt mixtures. Constr. Build. Mater. 2017, 152, 708–714. [Google Scholar] [CrossRef]

- GB/T 22314-2008; Plastics—Polyacrylamide—Determination for Residual Acrylamide. National Standards of the People’s Republic of China: Beijing, China, 2008.

- JTG E40-2007; Test Methods of Soils for Highway Engineering. National Standards of the People’s Republic of China: Beijing, China, 2007.

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. National Standards of the People’s Republic of China: Beijing, China, 2005.

- Sun, Y.; He, D.P. High and Low-Temperature Performance Evaluation and Microanalysis of SMCSBS Compound-Modified Asphalt. Materials 2021, 14, 771. [Google Scholar] [CrossRef] [PubMed]

- Min, Y.T.; Zhang, Y.H.; Qian, Z.D.; Zhang, H.C.; Hu, B.Y.; Xie, Y.X.; Zhang, X.F. Performance evaluation and feasibility study on reuse of reclaimed epoxy asphalt pavement (REAP). Constr. Build. Mater. 2024, 450, 138653. [Google Scholar] [CrossRef]

- Chen, B.; Xiong, C.; Li, W.; He, J.R.; Zhang, X.N. Assessing surface texture features of asphalt pavement based on three-dimensional laser scanning technology. Buildings 2021, 11, 623. [Google Scholar] [CrossRef]

- Chen, B.; Wang, X.Y.; Li, Z.H.; Chen, K.; Li, W.X.; Chen, Z.C.; Xiong, X.T. Spatial distribution characteristics and mechanical properties of artificial coarse aggregates with different morphologies in asphalt mixtures. Case Stud. Constr. Mater. 2025, 5, e04667. [Google Scholar] [CrossRef]

| Project | Unit | Requirement | Result | Method |

|---|---|---|---|---|

| Appearance | - | Light yellow | Qualified | Visualization |

| Viscosity (120 °C) | 20 ± 10 | 21.8 | GB/T 22314-2008 [42] | |

| Water content | % | ≤0.15 | 0.08 | |

| Chroma | Gardner | ≤4 | 2.2 | |

| Density (20 °C) | 1.15 ± 0.15 | 1.14 | ||

| Flash point (open cup) | ≥200 | 285 |

| Project | Unit | Requirement | Result | Method |

|---|---|---|---|---|

| Appearance | - | Brownish black | Qualified | Visualization |

| Acid value | ≤150 | 90 | GB/T 22314-2008 [42] | |

| Flash point (open cup) | ≥220 | 316 | ||

| Water content | % | ≤0.5 | 0.2 | |

| Viscosity (120 °C) | >320 | 2012 | ||

| Density | 1.00 ± 0.15 | 1.01 |

| Project | Unit | Requirement | Result | Method |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 40~60 | 52 | JTG E40-2007 [43] |

| Penetration index (PI) | - | ≥0 | 0.35 | |

| Ductility (5 °C, 5 cm/min) | cm | ≥25 | 28 | |

| Softening point TR&B | °C | ≥75 | >90 | |

| Flash point | °C | ≥230 | 342 | |

| Solubility | % | ≥99 | 99.8 | |

| Storage stability (163 °C, 48 h, Softening point Difference) | °C | ≤2 | 0.8 | |

| Elastic recovery (25 °C) | % | ≥95 | 96 |

| Project | Unit | Requirement | Result | Method |

|---|---|---|---|---|

| Crushing value | % | ≤18 | 8.6 | JTG E42-2005 [44] |

| LA abrasion loss | % | ≤22 | 9.2 | |

| Apparent relative density | - | ≥2.6 | 2.922 | |

| Water content | % | ≤1 | 0.2 | |

| Adhesion level | - | ≥5 | 5 | |

| Particle content (<0.075 mm, washing) | % | ≤0.8 | 0.3 | |

| Soft rock content | % | ≤1 | 0.2 | |

| Polished stone value | BPN | ≥42 | 45 |

| Project | Unit | Requirement | Result | Method |

|---|---|---|---|---|

| Apparent relative density | ≥2.5 | 2.918 | JTG E42-2005 [44] | |

| Ruggedness (>0.3 mm) | % | ≤12 | 3.2 | |

| Sand equivalent | % | ≥65 | 71 | |

| Methylene blue value | ≤2.5 | 1.2 | ||

| Angularity (flow time) | s | ≥30 | 48 |

| Project | Unit | Requirement | Result | Method |

|---|---|---|---|---|

| Appearance | - | No Agglomeration | Qualified | Visualization |

| Apparent relative density | ≥2.5 | 2.717 | JTG E42-2005 [44] | |

| Water content | % | ≤1 | 0.6 | |

| Particle size: <0.6 mm | % | 100 | 100 | |

| <0.15 mm | % | 90~100 | 96.6 | |

| <0.075 mm | % | 75~100 | 86.7 | |

| Hydrophilicity coefficient | - | ≤1 | 0.64 | |

| Methylene blue value | ≤8 | 2.6 |

| Asphalt-Aggregate Ratio (%) | Gmb | Gmm | VV (%) | VMA (%) | VFA (%) | FN (kN) | FL (0.1 mm) |

|---|---|---|---|---|---|---|---|

| 4.8 | 2.559 | 2.683 | 4.6 | 14.5 | 68.0 | 10.1 | 28.8 |

| 5.1 | 2.560 | 2.671 | 4.1 | 14.7 | 71.9 | 10.8 | 29.1 |

| 5.4 | 2.561 | 2.659 | 3.7 | 14.9 | 75.3 | 11.7 | 30.2 |

| 5.7 | 2.563 | 2.648 | 3.2 | 15.1 | 78.8 | 11.2 | 31.6 |

| 6.0 | 2.576 | 2.637 | 2.3 | 14.9 | 84.6 | 10.6 | 33.3 |

| Requirement | - | - | ≤5 | ≥14 | ≥75 | ≥7.5 | 20~50 |

| Project | Unit | Epoxy Asphalt Mixture | SBS-Modified Asphalt Mixture | Requirement |

|---|---|---|---|---|

| Mashall stability | kN | 30.6 | 14.34 | ≥7.5 |

| Void content | % | 3.7 | 3.8 | ≤5 |

| Vapor Fraction of Asphalt | % | 75.3 | 75.1 | ≥75 |

| Immersion Mashall Residue stability ratio | % | 95.1 | 91.8 | ≥90 |

| Freeze–thaw tensile strength ratio | % | 94 | 90.2 | ≥80 |

| Flexural tensile strain | με | 2863 | 2558.0 | ≥2000 |

| Dynamic stability (70 °C) | pass/mm | 14,319 | 5329 | ≥5000 |

| Texture depth | mm | 1.1 | 1.08 | ≥0.8 |

| Compaction Stage | Number of Passes |

|---|---|

| Initial rolling | 1 Pass, static, 2 steel-wheel (2 drum) rollers |

| Repeated rolling | 2~3 Passes, oscillatory, 2 steel-wheel (2 drum) rollers 2 Pass, static, 1 pneumatic-tire roller |

| Finish rolling | 1~2 Passes, static, 2 steel-wheel (2 drum) rollers |

| Indicator | Design (%) | Item | Average (%) | Max (%) | Min (%) |

|---|---|---|---|---|---|

| 0~3.5 mm | 26 | Actual Value | 25.99 | 26.56 | 24.84 |

| RE | −0.04 | 2.11 | −4.67 | ||

| 3.5~6 mm | 6 | Actual Value | 6.00 | 6.13 | 5.70 |

| RE | 0.00 | 2.12 | −5.26 | ||

| 6~11 mm | 32 | Actual Value | 32.03 | 33.18 | 31.64 |

| RE | 0.09 | 3.56 | −1.14 | ||

| 11~16 mm | 32 | Actual Value | 31.98 | 32.87 | 30.62 |

| RE | −0.06 | 2.65 | −4.51 | ||

| Mineral powder | 4 | Actual Value | 4.00 | 4.17 | 3.89 |

| RE | 0.00 | 4.08 | −2.83 | ||

| Asphalt-aggregate ratio | 5.4 | Actual Value | 5.39 | 5.63 | 5.20 |

| RE | −0.19 | 4.09 | −3.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Chen, K.; Xiong, X.; Deng, Y.; Chen, Z.; Li, W.; Yu, H. Design and Construction Control of Warm Mix Epoxy Asphalt Mixture with Low Epoxy Content for Service Area Pavements. Buildings 2025, 15, 1673. https://doi.org/10.3390/buildings15101673

Chen B, Chen K, Xiong X, Deng Y, Chen Z, Li W, Yu H. Design and Construction Control of Warm Mix Epoxy Asphalt Mixture with Low Epoxy Content for Service Area Pavements. Buildings. 2025; 15(10):1673. https://doi.org/10.3390/buildings15101673

Chicago/Turabian StyleChen, Bo, Kai Chen, Xuetang Xiong, Yi Deng, Zicong Chen, Weixiong Li, and Huayang Yu. 2025. "Design and Construction Control of Warm Mix Epoxy Asphalt Mixture with Low Epoxy Content for Service Area Pavements" Buildings 15, no. 10: 1673. https://doi.org/10.3390/buildings15101673

APA StyleChen, B., Chen, K., Xiong, X., Deng, Y., Chen, Z., Li, W., & Yu, H. (2025). Design and Construction Control of Warm Mix Epoxy Asphalt Mixture with Low Epoxy Content for Service Area Pavements. Buildings, 15(10), 1673. https://doi.org/10.3390/buildings15101673