Valorization of Medical Waste in Cement-Based Construction Materials: A Systematic Review

Abstract

1. Introduction

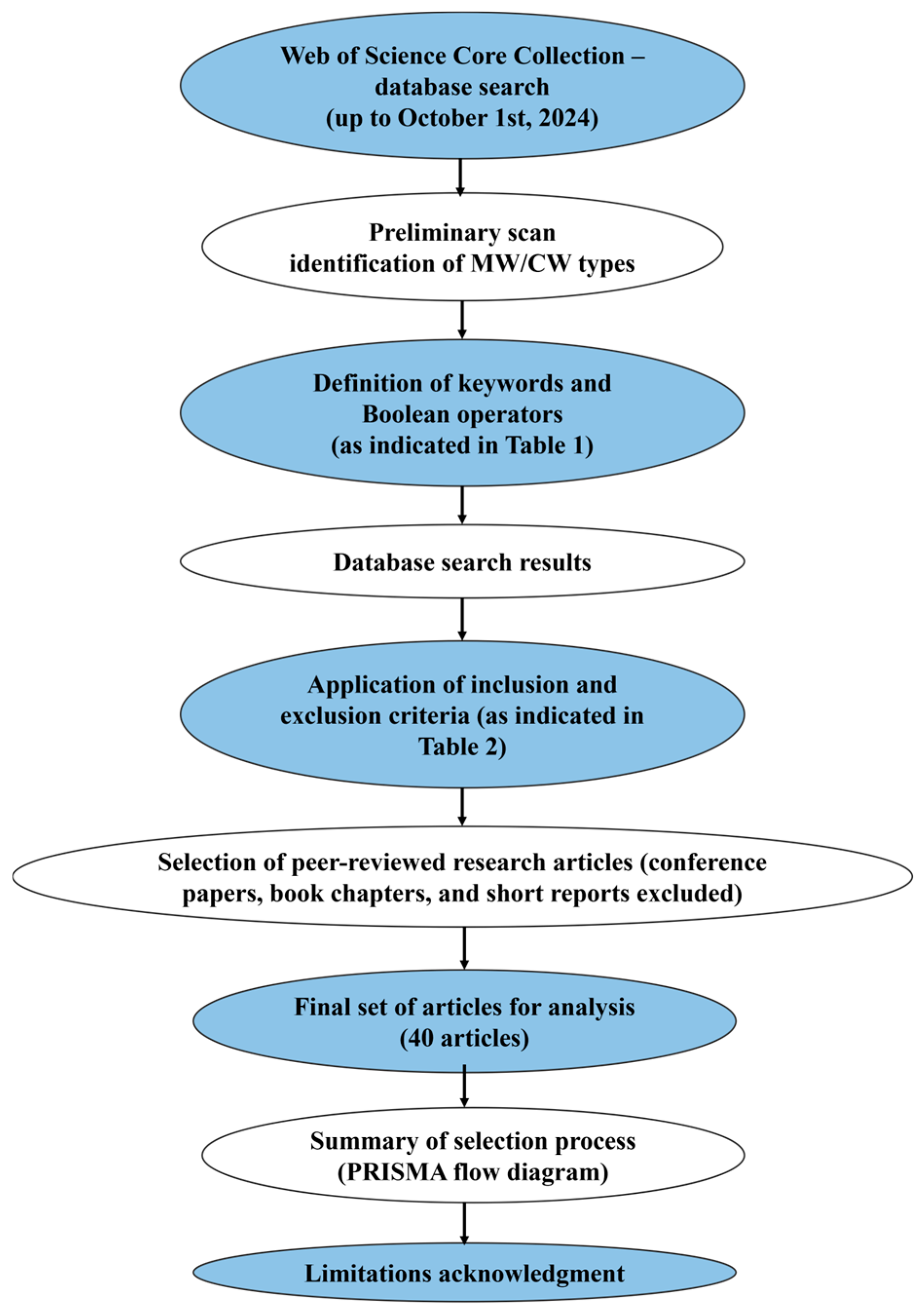

2. Search Strategy Methodology

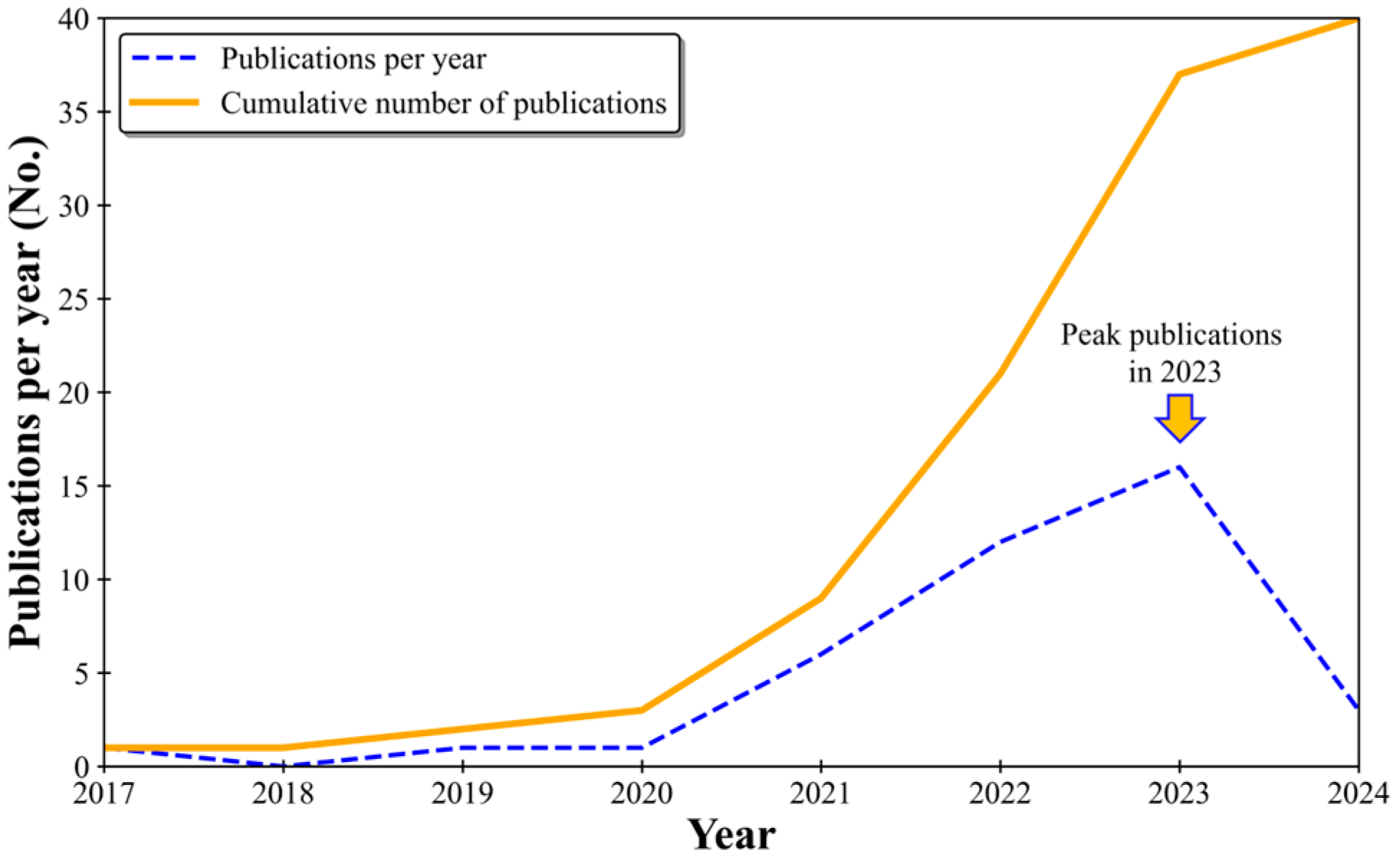

2.1. Bibliometric Assessment

Descriptive Analysis

2.2. Category Selection

3. Medical Wastes

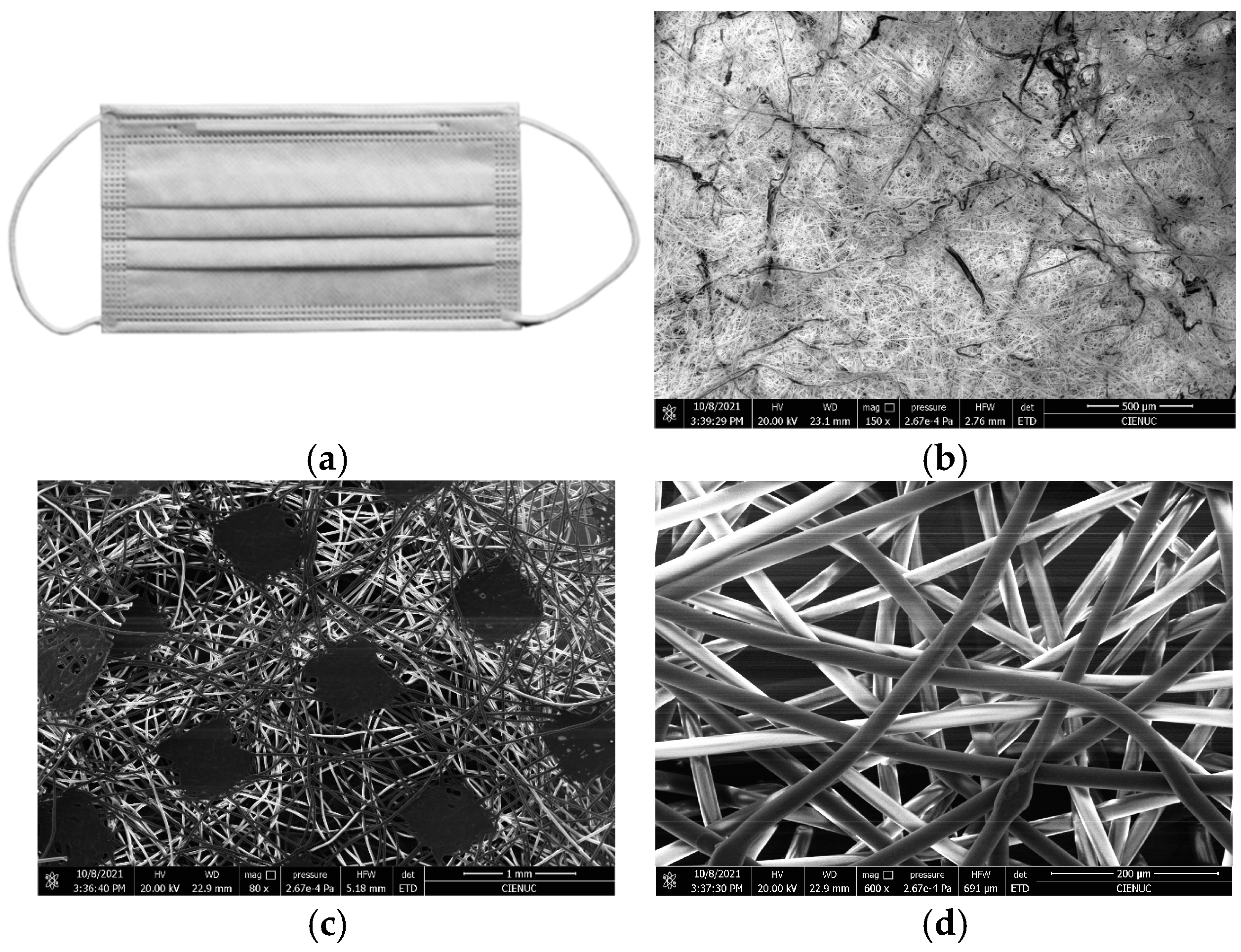

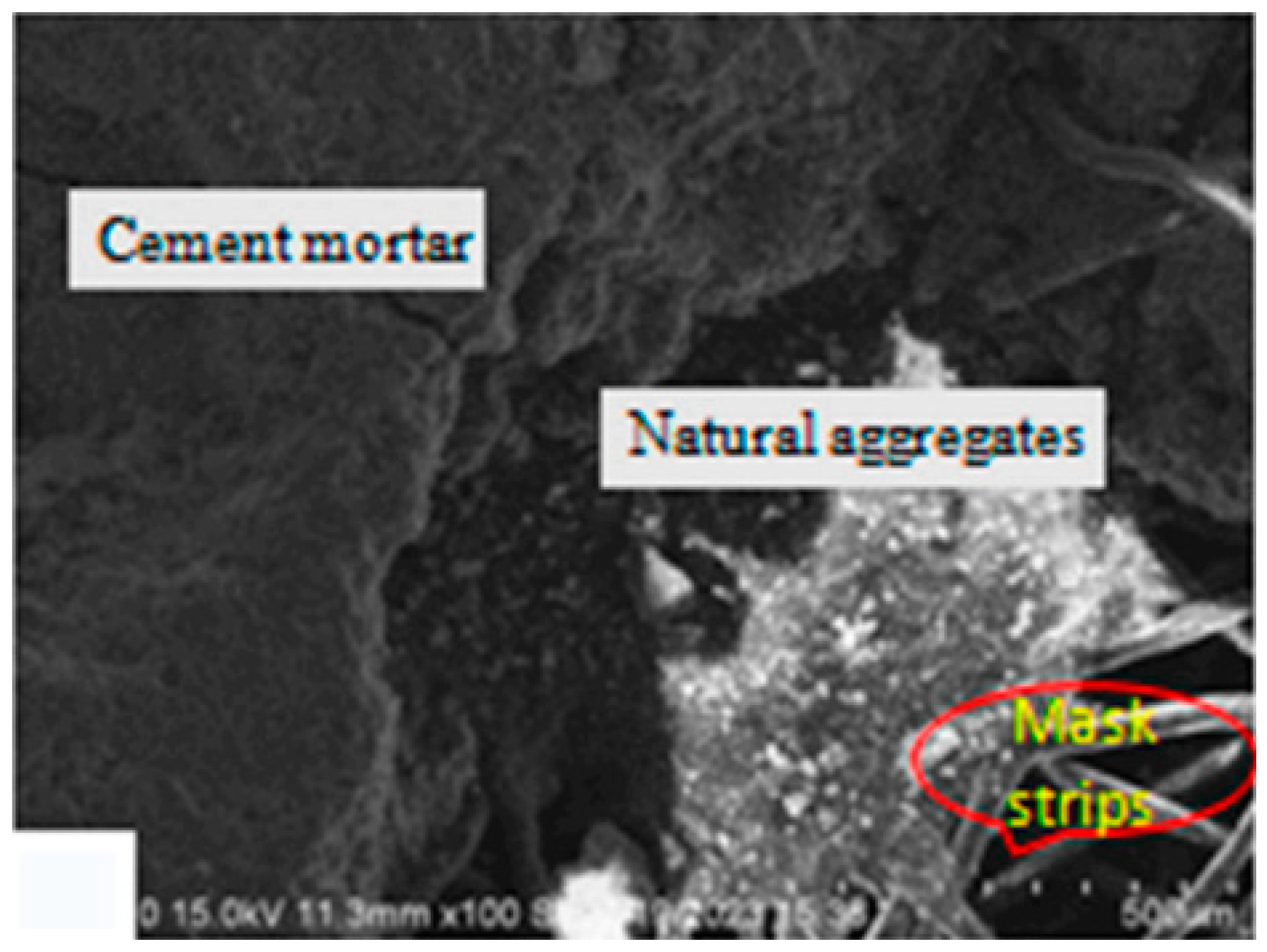

3.1. Face Masks (FMs)

3.1.1. FM Definition and Material Composition

3.1.2. FM Consumption Trends

3.1.3. Summary of FM Material Properties

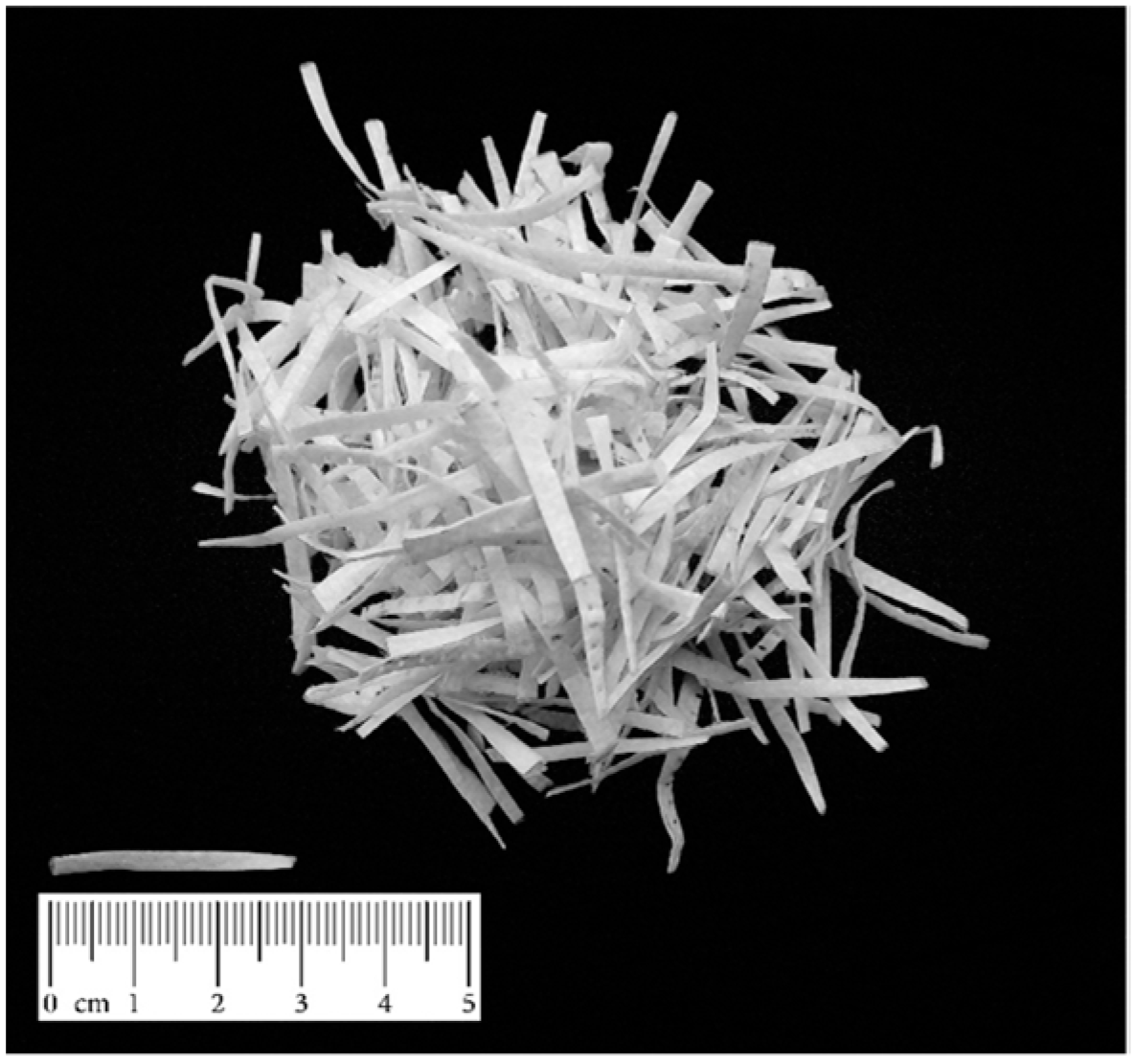

3.2. Needles (NDs)

3.2.1. ND Definition and Material Composition

3.2.2. ND Consumption Trends

3.2.3. Summary of ND Material Properties

3.3. Plastic Blisters (PBs)

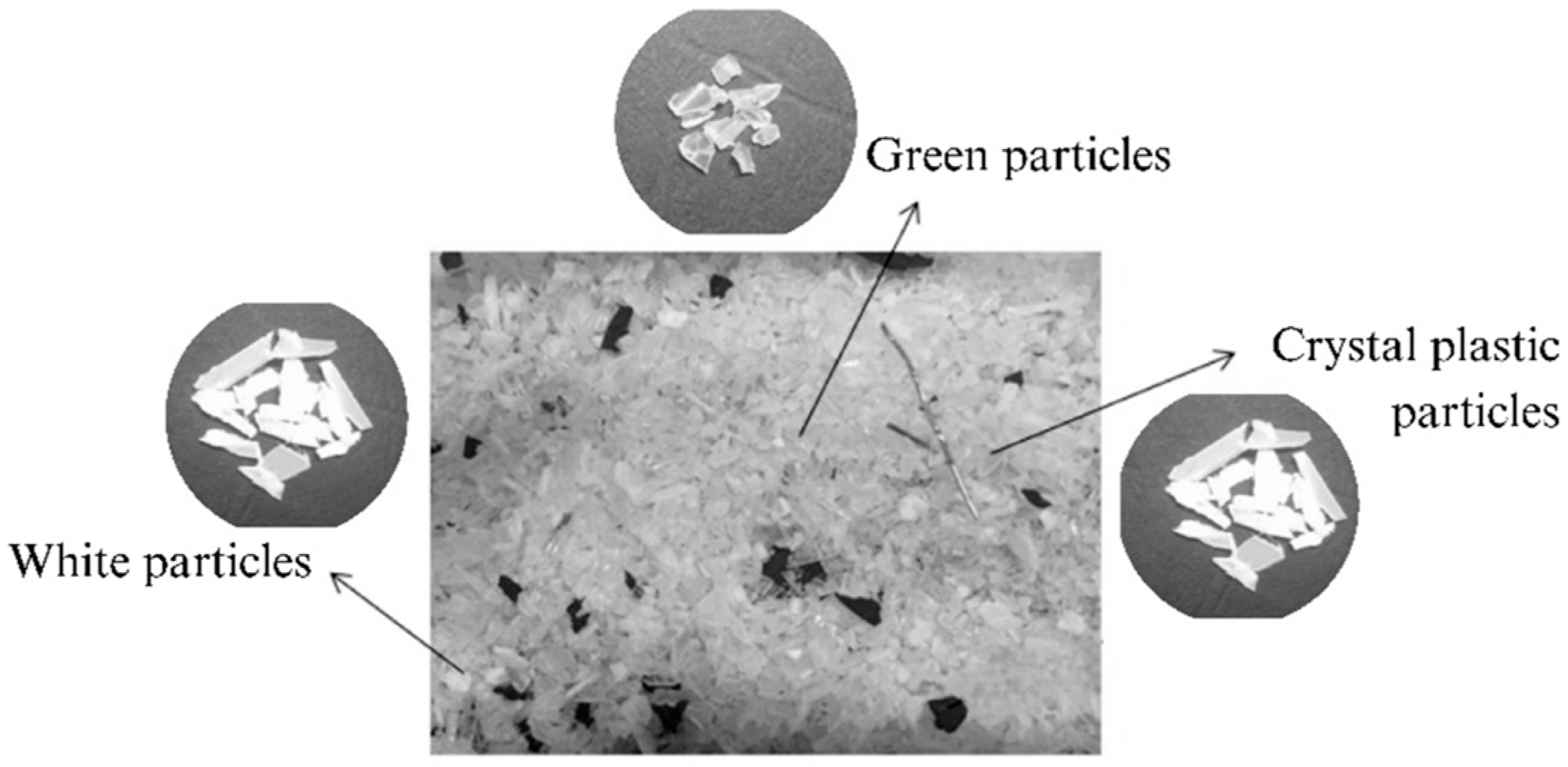

3.3.1. PB Definition and Material Composition

3.3.2. PB Consumption Trends

3.3.3. Summary of PB Material Properties

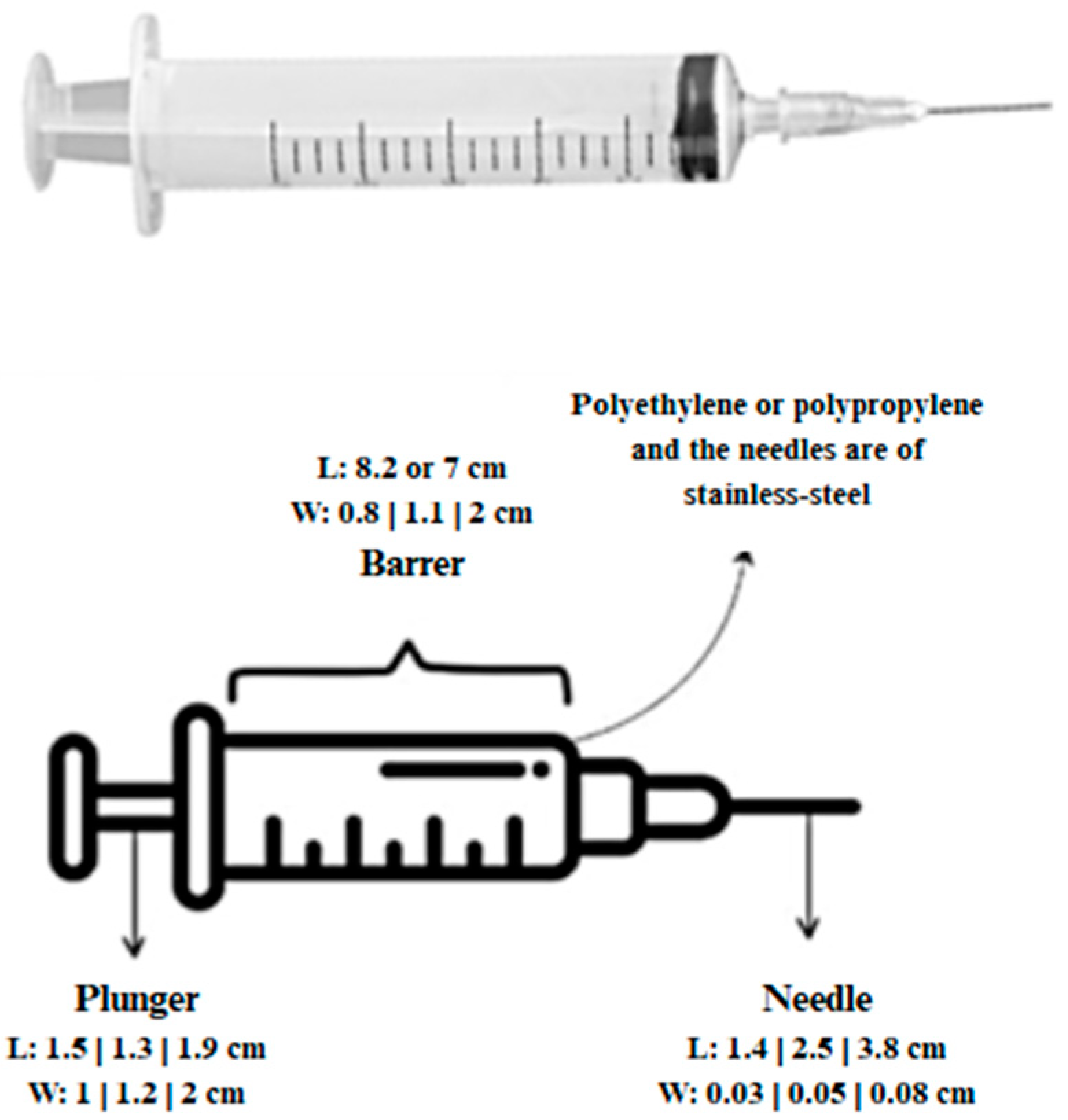

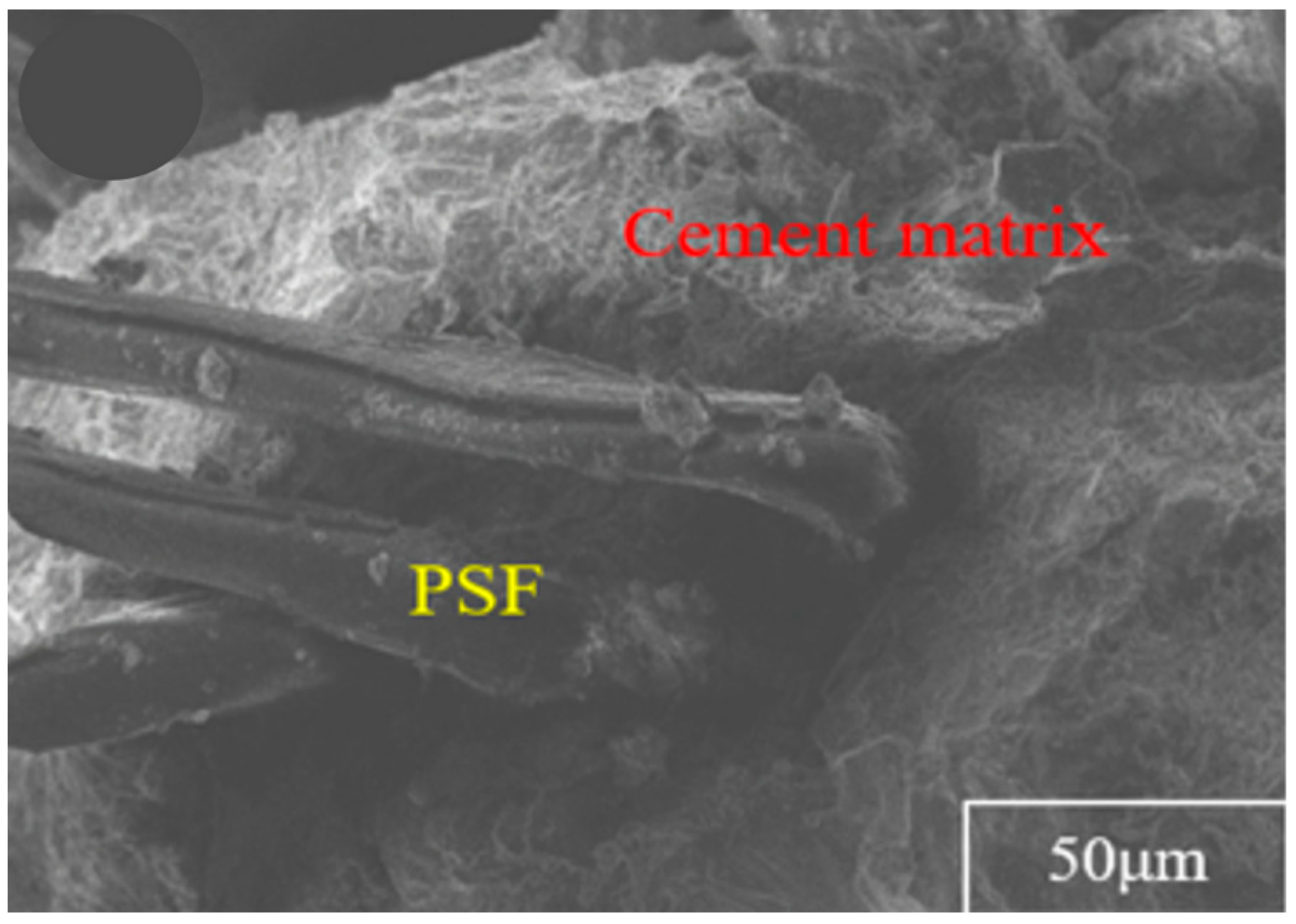

3.4. Plastic Syringes (PSGs)

3.4.1. PSG Definition and Material Composition

3.4.2. PSG Consumption Trends

3.4.3. Summary of PSG Material Properties

3.5. Medical Glass (MG)

3.5.1. MG Definition and Material Composition

3.5.2. MG Consumption Trends

3.5.3. Summary of MG Material Properties

3.6. Gloves (GLs)

3.6.1. GLs Definition and Material Composition

3.6.2. GLs Consumption Trends

3.6.3. Summary of GLs Material Properties

3.7. Medical Textiles (MTs)

3.7.1. MTs Definition and Material Composition

3.7.2. MTs Consumption Trends

3.7.3. Summary of MT Material Properties

3.8. Medical Waste Incineration Ash (MWIA)

3.8.1. Definition and Material Composition

3.8.2. MWIA Consumption Trends

3.8.3. Summary of MWIA Material Properties

4. Chemical and Physical Treatments

4.1. Protein Crosslinking Technique

4.2. Heat Treatment

4.3. Chemical Treatment

4.4. Gas Phase-Advanced Oxidation Process

4.5. Boiling

4.6. Graphene Oxide

4.7. Other Treatments

5. Bibliometric Analysis

5.1. Delimitations

5.2. Bibliometric Results

6. Applications of Medical Waste as CMs Within CB-CMs

6.1. Applications of Face Masks in CB-CMs

6.2. Applications of Needles in CB-CMs

6.3. Applications of Plastic Blisters in CB-CMs

6.4. Applications of Plastic Syringes in CB-CMs

6.5. Applications of Medical Glass in CB-CMs

6.6. Applications of Gloves in CB-CMs

6.7. Applications of Medical Textiles in CB-CMs

6.8. Applications of Medical Waste Incineration Ash in CB-CMs

6.9. Other Applications of MWs in CMs (Asphalt and Geopolymers)

7. Conclusions

- The inclusion of FMs in concrete generally has a positive impact on compressive strength, with improvements ranging from 5% up to 40%. Although some studies report decreases in compressive strength, these reductions are generally minor, rarely exceeding −8%. Overall, the evidence suggests that FMs have promising potential to enhance mechanical performance when appropriately processed and integrated.

- Regarding GLs, the results showed that, in general, GLs negatively affect compressive strength when incorporated into concrete and mortar, with reductions averaging 20%. However, other properties, such as tensile and flexural strength, exhibit positive effects, with increases up to 20% or more. These contrasting effects suggest that while GLs may compromise compressive performance, they can enhance other structural characteristics.

- Further investigation is required to assess the long-term performance of mortar incorporating GLs as fiber reinforcement. Durability concerns must be comprehensively analyzed to ensure that these MWs do not induce significant long-term performance reductions.

- It was demonstrated that MTs have significant potential as fiber reinforcement. However, for their widespread acceptance within the construction sector, more comprehensive long-term studies on mechanical and durability performance are essential, as only surgical gowns (SGs) have been investigated so far. Future studies should aim to assess the long-term integrity and functional stability of these materials under diverse environmental conditions to validate their reliability and ensure their suitability for structural applications.

- Further research on the implementation of MWIA as alternative supplementary cementitious material is strongly recommended. The current literature primarily focuses on compressive strength, while other essential properties remain largely unexplored, with limited or no supporting studies. Although the inclusion of MWIA has demonstrated a positive impact, the existing evidence is insufficient to establish definitive conclusions.

- While overall statistical heterogeneity was limited, mainly due to the small number of studies found in the literature, some variability emerged in most explored MWs. These differences point to gaps in the current literature and highlight the need for more focused, high-quality research to improve the consistency and comparability of future findings.

- Based on the currently available information, it remains challenging to determine whether CW can be definitively considered a sustainable alternative for CB-CM production. This uncertainty arises primarily from the lack of comprehensive studies establishing clear trends for each waste type. However, this emerging research area not only has the potential to significantly mitigate the environmental impact of CW pollution worldwide but also represents a promising step toward the development of more sustainable construction materials. Given its substantial environmental and industrial relevance, continued investigation into this topic is strongly encouraged.

- Regarding the potential use of MWIA, it can be incorporated into mortar and concrete mixtures; however, its effectiveness depends on the role it plays within the mixture. When used as a partial replacement for cement, MWIA generally does not improve mechanical performance. In contrast, when applied as a partial replacement for fine aggregate, particularly at low substitution levels, it can lead to improved or comparable mechanical properties.

- The use of MWIA in cementitious matrix blends leads to materials with slightly lower densities as their content increases. In addition, its reactivity, associated with quantities of reactive silica and alumina, plays a key role in improving mechanical performance. This incorporation not only contributes to the development of more sustainable materials but also offers a viable alternative for medical waste management, helping to reduce environmental pollution and conserve natural resources.

8. Future Recommendations

- MWIA in mortar;

- Nitrile GLs in mortar;

- Vinyl GLs in concrete;

- NDs in mortar;

- Other MTs in mortar and concrete;

- PSGs in mortar;

- MG in mortar;

- PBs in mortar.

- MG mixed with FMs;

- MG mixed with GLs;

- MWIA mixed with MTs;

- MWIA mixed with PBs;

- MWIA mixed with FMs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CAGR | Compound annual growth rate |

| CB-CM | Cement-based construction materials |

| CMs | Construction materials |

| CW | Clinical waste |

| FM | Face mask |

| GLs | Gloves |

| ITZ | Interfacial transition zone |

| IW | Industrial waste |

| MG | Medical glass |

| MWIA | Medical waste incineration ash |

| MT | Medical textile |

| MW | Medical waste |

| NC | Normal concrete |

| NDs | Needles |

| PBs | Plastic blisters |

| PE | Polyethylene |

| PP | Polypropylene |

| PPE | Personal protective equipment |

| PRISMA | Preferred reporting items for systematic reviews and meta-analyses |

| PSD | Particle size distribution |

| PVC | Polyvinyl chloride |

| PSG | Plastic syringe |

| RCPT | Rapid chloride permeability test |

| SC | Surgical cap |

| SCM | Supplementary cementitious material |

| SEM | Scanning electron microscopy |

| SG | Surgical gown |

| SLR | Scientific literature review |

| SEM-EDS | Scanning electron microscopy–energy dispersive spectroscopy |

| TOC | Total organic carbon |

| UPV | Ultrasonic pulse velocity |

| WHO | World Health Organization |

| WoS | Web of Science |

References

- Henley, R.; Ruiz, F.J. A Letter from Portland Cement Association Chair and Vice-Chair. America’s Cement Manufacturers Home Page. Available online: https://www.cement.org/ (accessed on 1 July 2024).

- Global Cement and Concrete Association. The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete. Concrete Roadmap Full Document GCCA Concrete Future-Roadmap to Net Zero, 2021. Available online: https://gccassociation.org/concretefuture/wp-content/uploads/2021/10/GCCA-Concrete-Future-Roadmap-Document-AW.pdf (accessed on 1 July 2024).

- International Energy Agency. Net Zero by 2050. A Roadmap for the Global Energy Sector; IEA Publications: Paris, France, 2021. [Google Scholar]

- Hasheminezhad, A.; King, D.; Ceylan, H.; Kim, S. Comparative life cycle assessment of natural and recycled aggregate concrete: A review. Sci. Total. Environ. 2024, 950, 175310. [Google Scholar] [CrossRef] [PubMed]

- Majhi, B.; Ranjan, R.; Mondal, S. Multi response optimization of recycled aggregate based alkali-activated concrete using Taguchi-Grey Relational Analysis Method. Constr. Build. Mater. 2024, 441, 137519. [Google Scholar] [CrossRef]

- Nadim, F.; Hasan, R.; Sobuz, H.R.; Ashraf, J.; Hasan, N.M.S.; Datta, S.D.; Islam, H.; Islam, A.; Awall, R.; Rahman, S.A.; et al. Effect of silica fume on the microstructural and mechanical properties of concrete made with 100% recycled aggregates. Rev. Constr. 2024, 23, 413–435. [Google Scholar] [CrossRef]

- Escamilla, E.Z.; Habert, G.; Wohlmuth, E. When CO2 counts: Sustainability assessment of industrialized bamboo as an alternative for social housing programs in the Philippines. Build. Environ. 2016, 103, 44–53. [Google Scholar] [CrossRef]

- Silva, Y.F.; Burbano-Garcia, C.; Araya-Letelier, G.; González, M. Short- and long-term experimental performance of concrete with copper slag: Mechanical and physical properties assessment. Case Stud. Constr. Mater. 2024, 20, e03302. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, K.-S.; Jung, S.S.; Hwang, J.I.; Choi, J.-S.; Sohn, I. Valorization of electric arc furnace primary steelmaking slags for cement applications. Waste Manag. 2015, 41, 85–93. [Google Scholar] [CrossRef]

- Zhang, L.; Ji, Y.; Huang, G.; Li, J.; Hu, Y. Modification and enhancement of mechanical properties of dehydrated cement paste using ground granulated blast-furnace slag. Constr. Build. Mater. 2018, 164, 525–534. [Google Scholar] [CrossRef]

- Filazi, A.; Demir, I.; Sevim, O. Enhancement on mechanical and durability performances of binary cementitious systems by optimizing particle size distribution of fly ash. Arch. Civ. Mech. Eng. 2020, 20, 58. [Google Scholar] [CrossRef]

- Demir, I.; Filazi, A.; Sevim, O.; Simsek, O. Influence of freeze–thaw cycling on properties of cementitious systems doped with fly ash having optimized particle size distribution. Arch. Civ. Mech. Eng. 2022, 22, 189. [Google Scholar] [CrossRef]

- Kumar, N.V.S. Crushed rock dust as filler material in concrete. Mater. Today: Proc. 2021, 43, 1714–1719. [Google Scholar] [CrossRef]

- De Oliveira, F.A.; Casagrande, C.A.; Marinho, É.P.; Jochem, L.F.; de Nóbrega, A.C.V. Blasted copper slag as artificial fines in ecofriendly concrete. Rev. Mater. 2022, 27, 1. [Google Scholar] [CrossRef]

- Morino, K.; Iwatsuki, E. Utilization of electric arc furnace oxidizing slag as concrete aggregate. In Minerals, Metals and Materials Society/AIME, REWAS’99: Global Symposium on Recycling, Waste Treatment and Clean Technology; Curran Associates, Inc.: Newry, UK, 1999; pp. 521–530. [Google Scholar]

- Najimi, M.; Pourkhorshidi, A.R. Properties of concrete containing copper slag waste. Mag. Concr. Res. 2011, 63, 605–615. [Google Scholar] [CrossRef]

- Velumani, M.; Nirmalkumar, K.; Yuvaraj, K. Copper slag and high-strength concrete. Mater. Today Proc. 2023, in press. [CrossRef]

- Antico, F.; Rojas, P.; Briones, F.; Araya-Letelier, G. Animal fibers as water reservoirs for internal curing of mortars and their limits caused by fiber clustering. Constr. Build. Mater. 2021, 267, 120918. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.C.; Parra, P.F.; Carrasco, M. Fiber-Reinforced Mortar Incorporating Pig Hair. Adv. Eng. Forum 2017, 21, 219–225. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Maturana, P.; Carrasco, M.; Antico, F.C.; Gómez, M.S. Mechanical-damage behavior of mortars reinforced with recycled polypropylene fibers. Sustainability 2019, 11, 2200. [Google Scholar] [CrossRef]

- El-Hawary, M.M.; Hamoush, S.A. Strength of concrete reinforced with treated feathers. Constr. Build. Mater. 1994, 8, 173–176. [Google Scholar] [CrossRef]

- Topçu, I.B.; Bilir, T.; Uygunoğlu, T. Effect of waste marble dust content as filler on properties of self-compacting concrete. Constr. Build. Mater. 2009, 23, 1947–1953. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D.; Ubysz, A. Investigating the effect of elevated temperatures on the utilization of demolished paving block powders as supplementary cementitious materials. Rev. De La Constr. 2024, 23, 151–163. [Google Scholar] [CrossRef]

- Guíñez, F.; María, H.S.; Araya-Letelier, G.; Lincoleo, J.; Palominos, F. Effect of mix dosage on rubberized concrete mechanical performance: A multivariable prediction model towards design provisions. J. Build. Eng. 2024, 90, 109451. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Health-Care Waste. 2023. Available online: https://www.who.int/news-room/fact-sheets/detail/health-care-waste (accessed on 29 September 2024).

- Citrón Hygiene. What Is Clinical Waste & Why Is Its Management Important? 2022. Available online: https://www.citronhygiene.co.uk/wp-content/uploads/2022/11/Citron-Hygiene-Printer-friendly-PDF-2022-05-12.pdf (accessed on 1 July 2024).

- United Nations Development Programme. Medical Waste: Why It Is so Important to Dispose of It Correctly. 2021. Available online: https://www.undp.org/kyrgyzstan/news/medical-waste-why-it-so-important-dispose-it-correctly (accessed on 22 October 2024).

- Environmental protection agency of United States. Medical Waste. 2024. Available online: https://www.epa.gov/rcra/medical-waste (accessed on 30 September 2024).

- Chartier, Y. Safe Management of Wastes from Health-Care Activities; World Health Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Hossain, S.; Santhanam, A.; Norulaini, N.N.; Omar, A.M. Clinical solid waste management practices and its impact on human health and environment—A review. Waste Manag. 2011, 31, 754–766. [Google Scholar] [CrossRef] [PubMed]

- Windfeld, E.S.; Brooks, M.S.-L. Medical waste management—A review. J. Environ. Manag. 2015, 163, 98–108. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Shortage of Personal Protective Equipment Endangering Health Workers Worldwide. 2020. Available online: https://www.who.int/news/item/03-03-2020-shortage-of-personal-protective-equipment-endangering-health-workers-worldwide (accessed on 29 September 2024).

- Mazzei, H.G.; Specchia, S. Latest insights on technologies for the treatment of solid medical waste: A review. J. Environ. Chem. Eng. 2023, 11, 109309. [Google Scholar] [CrossRef]

- Arcuri, C.; Luciani, F.; Piva, P.; Bartuli, F.N.; Ottria, L.; Mecheri, B.; Licoccia, S. Medical waste to energy: Experimental study. J. Oral Implant. 2013, 6, 83–88. [Google Scholar] [CrossRef]

- Dharmaraj, S.; Ashokkumar, V.; Chew, K.W.; Chia, S.R.; Show, P.L.; Ngamcharussrivichai, C. Novel strategy in biohydrogen energy production from COVID—19 plastic waste: A critical review. Int. J. Hydrogen Energy 2022, 47, 42051–42074. [Google Scholar] [CrossRef]

- Zhou, J.; Ayub, Y.; Shi, T.; Ren, J.; He, C. Sustainable co-valorization of medical waste and biomass waste: Innovative process design, optimization and assessment. Energy 2024, 288, 129803. [Google Scholar] [CrossRef]

- Li, S.; Chen, H.; Gao, Y.; Fan, L.; Pan, P.; Xu, G. A novel waste-to-energy system based on sludge hydrothermal treatment and medical waste plasma gasification and integrated with the waste heat recovery of a cement plant. Energy 2024, 305, 132358. [Google Scholar] [CrossRef]

- Akyıldız, A.; Köse, E.T.; Yıldız, A. Compressive strength and heavy metal leaching of concrete containing medical waste incineration ash. Constr. Build. Mater. 2017, 138, 326–332. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Dehestani, M. Influence of Latex and Vinyl Disposable Gloves as Recycled Fibers in 3D Printing Sustainable Mortars. Sustainability 2022, 14, 9908. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Roychand, R.; Saberian, M.; Li, J.; Zhang, G.; Setunge, S. A sustainable approach on the utilisation of COVID-19 plastic based isolation gowns in structural concrete. Case Stud. Constr. Mater. 2022, 17, e01408. [Google Scholar] [CrossRef]

- Koniorczyk, M.; Bednarska, D.; Masek, A.; Cichosz, S. Performance of concrete containing recycled masks used for personal protection during coronavirus pandemic. Constr. Build. Mater. 2022, 324, 126712. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Opulencia, M.J.C.; Chandra, T.; Chandra, S.; Muda, I.; Dias, R.; Chetthamrongchai, P.; Jalil, A.T. An Environmentally Friendly Solution for Waste Facial Masks Recycled in Construction Materials. Sustainability 2022, 14, 8739. [Google Scholar] [CrossRef]

- Paul, S.C.; Santo, A.H.; Nahid, S.A.; Majumder, A.R.; Al Mamun, F.; Basit, A.; Babafemi, A.J. Potential Use of COVID-19 Surgical Masks and Polyethylene Plastics in Developing Sustainable Concrete. J. Compos. Sci. 2023, 7, 402. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Content Analysis. Forum: Qualitative Social Research 1. 2000. Available online: https://www.qualitative-research.net/index.php/fqs/article/view/1089/2386 (accessed on 1 July 2024).

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Hou, Y.; Jia, L.; Ma, W.; Hao, J.L. Analysing the factors affecting medical waste generation in China. Sustain. Chem. Pharm. 2023, 32, 100975. [Google Scholar] [CrossRef]

- Goswami, M.; Goswami, P.J.; Nautiyal, S.; Prakash, S. Challenges and actions to the environmental management of Bio-Medical Waste during COVID-19 pandemic in India. Heliyon 2021, 7, e06313. [Google Scholar] [CrossRef] [PubMed]

- Asim, N.; Badiei, M.; Sopian, K. Review of the valorization options for the proper disposal of face masks during the COVID-19 pandemic. Environ. Technol. Innov. 2021, 23, 101797. [Google Scholar] [CrossRef]

- Akarsu, C.; Madenli, Ö.; Deveci, E.Ü. Characterization of littered face masks in the southeastern part of Turkey. Environ. Sci. Pollut. Res. 2021, 28, 47517–47527. [Google Scholar] [CrossRef]

- Qi, K.; Da, W.; Azmier, M.; Chun, S. Valorizing disposable face masks into non-condensable hydrocarbon gases via optimal reactor configurations in thermal pyrolysis. J. Anal. Appl. Pyrolysis 2023, 175, 106164. [Google Scholar] [CrossRef]

- Aziz, T.; Hossain, S.S.; Hasan, A.; Mohiuddin, M.A. Utilization of face masks and ladle furnace slag in concrete: Insights from experimental study. Clean. Eng. Technol. 2023, 15, 100653. [Google Scholar] [CrossRef]

- Pourebrahimi, S. Upcycling face mask wastes generated during COVID-19 into value-added engineering materials: A review. Sci. Total. Environ. 2022, 851, 158396. [Google Scholar] [CrossRef]

- Tan, K.Q.; Ahmad, M.A.; Da Oh, W.; Low, S.C. Valorization of hazardous plastic wastes into value-added resources by catalytic pyrolysis-gasification: A review of techno-economic analysis. Renew. Sustain. Energy Rev. 2023, 182, 113346. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Fei, M.-E.; Shi, X. Upcycling waste mask PP microfibers in portland cement paste: Surface treatment by graphene oxide. Mater. Lett. 2022, 318, 132238. [Google Scholar] [CrossRef]

- Chen, Y.; Luo, W.; Meng, F.; Zhou, T.; Lai, F.; Zhao, Z.; Liu, Y.; Li, J. Sustainable application study of disposable medical waste masks in cement based on green Fenton reaction. J. Appl. Polym. Sci. 2023, 141, e55049. [Google Scholar] [CrossRef]

- Naaman, A.E. Engineered Steel Fibers with Optimal Properties for Reinforcement of Cement Composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Roychand, R.; Zhang, G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021, 296, 126460. [Google Scholar] [CrossRef] [PubMed]

- Rajeev, P.; Ramesh, A.; Navaratnam, S.; Sanjayan, J. Using Fibre recovered from face mask waste to improve printability in 3D concrete printing. Cem. Concr. Compos. 2023, 139, 105047. [Google Scholar] [CrossRef]

- KMed (Liaoning Kangyi Medical Equipment Co.). Hypodermic Needles Types. 2020. Available online: https://www.kmedhealth.com/hypodermic-needles-types/ (accessed on 1 October 2024).

- Arslanov, K.M.; Khabirov, A.I.; Khamitova, G.M. Medical Waste Disposal Regulation in International Laws. HELIX 2019, 9, 5335–5338. [Google Scholar] [CrossRef]

- Markets And Markets. Needles Market Growth. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/needles-market-223979930.html#:~:text=Needles%20Market%20Overview%20and%20Growth,well%20as%20growing%20elderly%20population (accessed on 1 October 2024).

- Hamada, L.K.; Ismail, Z.Z. Sustainable Approach for Recycling Medical Waste Needles to Partially Replace Aggregate in Lightweight Concrete Production. Adv. Sci. Technol. Res. J. 2021, 15, 166–173. [Google Scholar] [CrossRef]

- Çapkın, I.Y.; Gökelma, M. A review on characterization and recyclability of pharmaceutical blisters. Clean. Waste Syst. 2023, 4, 100082. [Google Scholar] [CrossRef]

- Rimšaitė, A.; Mumladze, T.; Denafas, G. Feasibilities of Aluminium Recovery from Combined Packaging Waste, SSRG International Journal of Agriculture & Environmental Science (SSRG-IJAES) 6. 2019. Available online: http://www.internationaljournalssrg.org (accessed on 1 October 2024).

- Ron, P. Pharmaceutical Blister Packaging. 2000. Available online: https://pharmanet.com.br/pdf/blister.pdf (accessed on 1 July 2024).

- Kremser, K.; Schön, H.; Gerl, P.; Gómez, M.Á.V.; Espinosa, D.R.; Morandini, A.; Argilés, M.P.; Martínez, B.M.; Guebitz, G.M. Pharmaceutical blister waste recycling using biogenic sulfuric acid: Effect of sulfur source and blister material on bioleaching efficiency. Hydrometallurgy 2023, 221, 106124. [Google Scholar] [CrossRef]

- Dalal, S.P.; Dalal, P.; Motiani, R.; Solanki, V. Experimental investigation on recycling of waste pharmaceutical blister powder as partial replacement of fine aggregate in concrete. Resour. Conserv. Recycl. Adv. 2022, 14, 200076. [Google Scholar] [CrossRef]

- Reddy, K.C. Effect of solid waste on concrete performance: Innovative use of recycled and secondary materials. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Australian Government. Department of Health and Aged Care, Review of Plastic Syringes. 2024. Available online: https://www.tga.gov.au/how-we-regulate/supply-therapeutic-good/supply-medical-device/medical-device-post-market-reviews/review-plastic-syringes (accessed on 2 October 2024).

- Rashidi, M.; Joshaghani, A.; Ghodrat, M. Towards eco-flowable concrete production. Sustainability 2020, 12, 1208. [Google Scholar] [CrossRef]

- Future Market Insights Inc. Plastic Syringe Market Outlook (2025 to 2035). 2023. Available online: https://www.futuremarketinsights.com/reports/plastic-syringe-market (accessed on 2 October 2024).

- Jiang, X.; An, C.; Li, C.; Fei, Z.; Jin, Y.; Yan, J. Fusibility of medical glass in hospital waste incineration: Effect of glass components. Thermochim. Acta 2009, 491, 39–43. [Google Scholar] [CrossRef]

- Abdellatief, M.; Adel, B.; Alanazi, H.; Tawfik, T.A. Multiscale optimization analysis of high strength alkali-activated concrete containing waste medical glass under exposure to carbonation and elevated temperatures. Dev. Built Environ. 2024, 19, 100492. [Google Scholar] [CrossRef]

- Xiao, R.; Jiang, X.; Wang, Y.; He, Q.; Huang, B. Experimental and Thermodynamic Study of Alkali-Activated Waste Glass and Calcium Sulfoaluminate Cement Blends: Shrinkage, Efflorescence Potential, and Phase Assemblages. J. Mater. Civ. Eng. 2021, 33, 04021312. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Sivapriya, S.V.; Hariraj, M.J.; Rajarajan, T.; Kumar, S.V. Effect of discarded smooth and rough glass waste on mechanical properties of cement concrete. J. Constr. 2024, 23, 522–537. [Google Scholar] [CrossRef]

- Gökşen, Y.; Durak, U.; Ilkentapar, S.; Atabey, I.I.; Kaya, M.; Karahan, O.; Atis, C.D. Synergistic effect of waste glass powder and fly ash on some properties of mortar and notably suppressing alkali-silica reaction. Rev. Constr. 2023, 22, 419–430. [Google Scholar] [CrossRef]

- Ho, L.S.; Huynh, T.-P. Recycled waste medical glass as a fine aggregate replacement in low environmental impact concrete: Effects on long-term strength and durability performance. J. Clean. Prod. 2022, 368, 133144. [Google Scholar] [CrossRef]

- Guo, P.; Meng, W.; Nassif, H.; Gou, H.; Bao, Y. New perspectives on recycling waste glass in manufacturing concrete for sustainable civil infrastructure. Constr. Build. Mater. 2020, 257, 119579. [Google Scholar] [CrossRef]

- Missoum, S.; Kacimi, L.; Kaci, A. Elaboration of geopolymer binder from pharmaceutical glass waste and optimization of its synthesis parameters. J. Mater. Cycles Waste Manag. 2021, 23, 1201–1218. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Roychand, R.; Saberian, M.; Li, J.; Zhang, G. Application of COVID-19 single-use shredded nitrile gloves in structural concrete: Case study from Australia. Sci. Total. Environ. 2022, 812, 151423. [Google Scholar] [CrossRef]

- Global Market Insights. Medical Gloves Market Size & Share—Trends Report, 2032. 2024. Available online: https://www.gminsights.com/industry-analysis/medical-gloves-market (accessed on 21 October 2024).

- Global Market Insights. Isoprene Rubber Latex Market Size & Share Report—2032. 2024. Available online: https://www.gminsights.com/industry-analysis/isoprene-rubber-latex-irl-market (accessed on 21 October 2024).

- Global Market Insights. Nitrile Butadiene Rubber Latex Market Size & Share Report—2032. 2024. Available online: https://www.gminsights.com/industry-analysis/nitrile-butadiene-rubber-nbr-latex-market (accessed on 21 October 2024).

- Ran, T.; Pang, J.; Liu, Y.; Zou, J.; Cai, F. Improving concrete fatigue resistance with COVID-19 rubber gloves: An innovative sustainable approach. Case Stud. Constr. Mater. 2023, 18, e01914. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Dehestani, M. On the possibility of using waste disposable gloves as recycled fibers in sustainable 3D concrete printing using different additives. Sci. Rep. 2023, 13, 10812. [Google Scholar] [CrossRef]

- Afolabi, L.O.; Elfaghi, A.M.; Alomayri, T.; Arogundade, A.I.; Mahzan, S.; Isa, N.M.; Saw, C.L.; Otitoju, T.A. Thermal energy storage phase change material cement mortar incorporated with clinical waste composites. Int. J. Energy Res. 2021, 45, 13575–13590. [Google Scholar] [CrossRef]

- Al Biajawi, M.I.; Embong, R.; Muthusamy, K.; Ismail, N.; Johari, I. Assessing the performance of concrete made with recycled latex gloves and silicone catheter using ultrasonic pulse velocity. Mater. Today Proc. 2023, 109, 32–40. [Google Scholar] [CrossRef]

- Qin, Y. Medical Textile Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–243. [Google Scholar]

- Scott, C.A.; Saber, D.A.; Neivandt, D.J. Engineering a compostable isolation gown to reduce hospital-derived synthetic waste accumulation in landfill. Environ. Technol. Innov. 2024, 35, 103663. [Google Scholar] [CrossRef]

- Rutala, W.A.; Weber, D.J. A review of single-use and reusable gowns and drapes in health care. Infect. Control. Hosp. Epidemiol. 2001, 22, 248–257. [Google Scholar] [CrossRef]

- Grand View Research. Medical Textiles Market Size, Share & Growth Report, 2030. 2022. Available online: https://www.grandviewresearch.com/industry-analysis/medical-textiles-market (accessed on 21 October 2024).

- Global Market Insigths. Medical Clothing Market Size, Report & Future Trends, 2032. 2024. Available online: https://www.gminsights.com/industry-analysis/medical-clothing-market (accessed on 21 October 2024).

- Global Market Insights. Hospital Gowns Market Size, Growth Analysis 2024–2032. 2024. Available online: https://www.gminsights.com/industry-analysis/hospital-gowns-market (accessed on 21 October 2024).

- Ran, T.; Pang, J.; Zou, J. An Emerging Solution for Medical Waste: Reuse of COVID-19 Protective Suit in Concrete. Sustainability 2022, 14, 10045. [Google Scholar] [CrossRef]

- Troynikov, O.; Nawaz, N.; Watson, C. Medical protective clothing. In Protective Clothing: Managing Thermal Stress; Woodhead Publishing: Sawston, UK, 2014; pp. 192–224. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, G.; Zhang, X.; He, S.; Xu, W.; Zhang, X.; Zhong, S. Resource utilization of medical waste incineration fly ash to activate peroxydisulfate for tetracycline degradation: Synergy between adsorption and PDS activation. Environ. Res. 2024, 258, 119488. [Google Scholar] [CrossRef]

- Jang, Y.-C.; Lee, C.; Yoon, O.-S.; Kim, H. Medical waste management in Korea. J. Environ. Manag. 2006, 80, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Huang, Y.; Pang, J.; Li, Z.; Zhu, Z.; Cheng, H.; Gao, J.; Zuo, W.; Zhou, H. A study of the stabilization and solidification of heavy metals in co-vitrification of medical waste incineration ash and coal fly ash. Waste Manag. 2024, 186, 46–54. [Google Scholar] [CrossRef]

- Katare, K.N.; Samaiya, N.K.; Murthy, Y.I. Experimental Investigations of Binary Blended Concrete Containing Incinerated Biomedical Waste Ash. Int. J. Civ. Eng. 2023, 10, 9–22. [Google Scholar] [CrossRef]

- Ahmed, T.; Al Biruni, M.T.; Azad, S.; Hasan, M. Medical waste incineration fly ash as an effective adsorbent for removing dyes from textile effluent and methylene blue from synthetic aqueous solutions. Case Stud. Chem. Environ. Eng. 2024, 9, 100681. [Google Scholar] [CrossRef]

- Manjunath, B.; Di Mare, M.; Ouellet-Plamondon, C.M.; Bhojaraju, C. Exploring the potential use of incinerated biomedical waste ash as an eco-friendly solution in concrete composites: A review. Constr. Build. Mater. 2023, 387, 131595. [Google Scholar] [CrossRef]

- Katare, K.N.; Samaiya, N.K.; IyerMurthy, Y. Strength and durability properties of concrete using incinerated biomedical waste ash. Environ. Eng. Res. 2023, 28, 220024. [Google Scholar] [CrossRef]

- Silva, A.L.P.; Prata, J.C.; Walker, T.R.; Campos, D.; Duarte, A.C.; Soares, A.M.; Barcelò, D.; Rocha-Santos, T. Rethinking and optimising plastic waste management under COVID-19 pandemic: Policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Sci. Total. Environ. 2020, 742, 140565. [Google Scholar] [CrossRef]

- Peng, J.; Wu, X.; Wang, R.; Li, C.; Zhang, Q.; Wei, D. Medical waste management practice during the 2019–2020 novel coronavirus pandemic: Experience in a general hospital. Am. J. Infect. Control 2020, 48, 918–921. [Google Scholar] [CrossRef]

- Global Market Insights. Medical Waste Management Market Size, Share Report—2032. 2023. Available online: https://www.gminsights.com/industry-analysis/medical-waste-management-market (accessed on 21 October 2024).

- Grand View Research. Medical Waste Management Market Size, Share Report 2030. 2022. Available online: https://www.grandviewresearch.com/industry-analysis/medical-waste-management-market (accessed on 21 October 2024).

- Kaur, H.; Siddique, R.; Rajor, A. Influence of incinerated biomedical waste ash on the properties of concrete. Constr. Build. Mater. 2019, 226, 428–441. [Google Scholar] [CrossRef]

- Chakravarthy, H.G.N.; Seenappa, K.M.; Naganna, S.R.; Pruthviraja, D. Machine Learning Models for the Prediction of the Compressive Strength of Self-Compacting Concrete Incorporating Incinerated Bio-Medical Waste Ash. Sustainability 2023, 15, 13621. [Google Scholar] [CrossRef]

- Matalkah, F. Recycling of hazardous medical waste ash toward cleaner utilization in concrete mixtures. J. Clean. Prod. 2023, 400, 136736. [Google Scholar] [CrossRef]

- Suresh, K.A.; Muthukannan, M.; Arun, K.K.; Chithambar, G.A.; Kanniga, D.R. Influence of incinerated biomedical waste ash and waste glass powder on the mechanical and flexural properties of reinforced geopolymer concrete. Aust. J. Struct. Eng. 2022, 23, 254–268. [Google Scholar] [CrossRef]

- Kumar, A.S.; Muthukannan, M.; Devi, R.K.; Arunkumar, K.; Ganesh, A.C. Reduction of hazardous incinerated bio-medical waste ash and its environmental strain by utilizing in green concrete. Water Sci. Technol. 2021, 84, 2780–2792. [Google Scholar] [CrossRef] [PubMed]

- Arunachalam, S.K.; Muthiah, M.; Rangaswamy, K.D.; Kadarkarai, A.; Arunasankar, C.G. Improving the structural performance of reinforced geopolymer concrete incorporated with hazardous heavy metal waste ash. World J. Eng. 2022, 19, 808–821. [Google Scholar] [CrossRef]

- Oke, I.A.; Lukman, S.; Ismail, A.; Fehintola, E.O.; Amoko, J.S. Removal of lead ions from water and wastewaters electrochemically. In Water Purification; Elsevier: Amsterdam, The Netherlands, 2017; pp. 643–691. [Google Scholar] [CrossRef]

- ThermoFisher Scientific. Overview of Crosslinking and Protein Modification—CO, (n.d.). Available online: https://www.thermofisher.com/ht/en/home/life-science/protein-biology/protein-biology-learning-center/protein-biology-resource-library/pierce-protein-methods/overview-crosslinking-protein-modification.html (accessed on 22 October 2024).

- Suwandittakul, P.; Montha, S.; Na Ubol, P.; Kongkaew, C.; Kositanont, C. Toxicity reduction of natural rubber gloves using protein crosslinking technique. J. Appl. Polym. Sci. 2023, 140, e54110. [Google Scholar] [CrossRef]

- Sales, E.; Mulatier, N.; Wittmann, L.; Fernandes, A.; Vacher, B.; Penuelas, J. Effect of dry heat treatment between room temperature and 160 °C on surgical masks. Mater. Lett. 2022, 308, 131270. [Google Scholar] [CrossRef]

- Yan, S.; Stackhouse, C.A.; Waluyo, I.; Hunt, A.; Kisslinger, K.; Head, A.R.; Bock, D.C.; Takeuchi, E.S.; Takeuchi, K.J.; Wang, L.; et al. Reusing Face Covering Masks: Probing the Impact of Heat Treatment. ACS Sustain. Chem. Eng. 2021, 9, 13545–13558. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Riyanto, R.; Asrel; Jatnika, Y. Treatment of Bottom Ash Medical Waste (BAMW) from Hospital Infectious Waste into Paving Block Products. EKSAKTA J. Sci. Data Anal. 2024, 5, 175–185. [Google Scholar] [CrossRef]

- Al Biruni, M.T.; Sarker, H.S.; Charu, W.U.S.; Ahmed, T. Sustainable use of medical waste incineration fly ash in compressed stabilized earth blocks. Constr. Build. Mater. 2024, 452, 138886. [Google Scholar] [CrossRef]

- Ababneh, A.; Al-Rousan, R.; Gharaibeh, W.; Abu-Dalo, M. Recycling of pre-treated medical waste fly ash in mortar mixtures. J. Mater. Cycles Waste Manag. 2020, 22, 207–220. [Google Scholar] [CrossRef]

- Hasani, M.; Campbell, T.; Wu, F.; Warriner, K. Decontamination of N95 and surgical masks using a treatment based on a continuous gas phase-Advanced Oxidation Process. PLoS ONE 2021, 16, e0248487. [Google Scholar] [CrossRef]

- Gilbertson, J.; Quintanar-Solares, M.; Liland, F.; Niermeyer, S. High-level disinfection of re-usable neonatal resuscitation equipment through boiling and steaming. J. Hosp. Infect. 2020, 106, 721–725. [Google Scholar] [CrossRef] [PubMed]

- Faridi-Majidi, R.; Norouz, F.; Boroumand, S.; Tabatabaei, S.N.; Faridi-Majidi, R. Decontamination Assessment of Nanofiber-based N95 Masks. Environ. Sci. Pollut. Res. 2022, 29, 80411–80421. [Google Scholar] [CrossRef]

- Erdiaw-Kwasie, M.O.; Abunyewah, M.; Baah, C. A systematic review of the factors—Barriers, drivers, and technologies—Affecting e-waste urban mining: On the circular economy future of developing countries. J. Clean. Prod. 2024, 436, 140645. [Google Scholar] [CrossRef]

- Macquarie University Library. Systematic Reviews, PRISMA Flow Diagram and Diagram Generator Tool. 2024. Available online: https://libguides.mq.edu.au/systematic_reviews/prisma_screen (accessed on 30 September 2024).

- Lima, L.; Trindade, E.; Alencar, L.; Alencar, M.; Silva, L. Sustainability in the construction industry: A systematic review of the literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Win, T.T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef]

- Avudaiappan, S.; Cendoya, P.; Arunachalam, K.P.; Maureira-Carsalade, N.; Canales, C.; Amran, M.; Parra, P.F. Innovative Use of Single-Use Face Mask Fibers for the Production of a Sustainable Cement Mortar. J. Compos. Sci. 2023, 7, 214. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; He, J.; Shi, X. Graphene Oxide–Pretreated Waste Medical Mask Microfiber-Reinforced Cement Composites: Frost Damage Modeling and Chloride Migration. J. Mater. Civ. Eng. 2024, 36. [Google Scholar] [CrossRef]

- Durmuş, G.; Çelik, D.N.; Demircan, R.K.; Kaplan, G. Effect of waste COVID-19 face masks on self-compacting high-strength mortars exposed to elevated temperature. Ain Shams Eng. J. 2023, 14, 102058. [Google Scholar] [CrossRef]

- Zhang, F.; Li, X.; Wang, D. Mechanical behavior of self-compacting recycled concrete reinforced with recycled disposable medical mask fiber. Constr. Build. Mater. 2024, 429, 136314. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; He, J.; Qian, S.; Shi, X. Recycled mask polypropylene microfibers benefit tensile properties and prevent thermally induced spalling of high-strength engineered cementitious composite (HS-ECC). J. Clean. Prod. 2024, 457, 142476. [Google Scholar] [CrossRef]

- Koniorczyk, M.; Bednarsk, D.; Omrani, I.A.N.; Masek, A.; Cichosz, S. Performance of concrete containing recycled masks used for personal protection during SARS-CoV-2 coronavirus pandemic. Cem. Wapno Beton 2022, 27, 2–13. [Google Scholar] [CrossRef]

- Mohan, H.T.; Jayanarayanan, K.; Mini, K. A sustainable approach for the utilization of PPE biomedical waste in the construction sector. Eng. Sci. Technol. Int. J. 2022, 32, 101060. [Google Scholar] [CrossRef]

- Ahmad, J.; Burduhos-Nergis, D.D.; Arbili, M.M.; Alogla, S.M.; Majdi, A.; Deifalla, A.F. A Review on Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced Concrete. Buildings 2022, 12, 1951. [Google Scholar] [CrossRef]

- Nehvi, R.; Kumar, P.; Nahvi, U.Z. Sharda university Effect of Different Percentages of Polypropylene Fibre (Recron 3s) on the Compressive, Tensile and Flexural Strength of Concrete. Int. J. Eng. Res. 2016, 5, 124–130. [Google Scholar]

- Ramgopal, L.; Gandhimathi, R.; Dhipanaravind, S.; Rao, G.M.; Thenmozhi, S.; Adethya, V.S. An investigation of the bio-medical waste ash on cement mortar bricks. Mater. Today Proc. 2024, 103, 463–468. [Google Scholar] [CrossRef]

- Liu, F.; Liu, H.-Q.; Wei, G.-X.; Zhang, R.; Zeng, T.-T.; Liu, G.-S.; Zhou, J.-H. Characteristics and Treatment Methods of Medical Waste Incinerator Fly Ash: A Review. Processes 2018, 6, 173. [Google Scholar] [CrossRef]

- El-Amaireh, N.A.A.; Al-Zoubi, H.; Al-Khashman, O.A. Hospital waste incinerator ash: Characteristics, treatment techniques, and applications (A review). J. Water Health 2023, 21, 1686–1702. [Google Scholar] [CrossRef]

- Memon, S.A.; Sheikh, M.A.; Paracha, M.B. Utilization of hospital waste ash in concrete. Mehran Univ. Res. J. Eng. Technol. 2013, 32, 1–8. [Google Scholar]

- Rachmawati, S.; Chairani, E.; Suryadi, I. Life cycle analysis and environmental cost-benefit assessment of utilizing hospital medical waste into heavy metal safe paving blocks. AIMS Environ. Sci. 2024, 11, 665–681. [Google Scholar] [CrossRef]

- Chowdhury, R.; Al Biruni, M.T.; Afia, A.; Hasan, M.; Islam, M.R.; Ahmed, T. Medical Waste Incineration Fly Ash as a Mineral Filler in Dense Bituminous Course in Flexible Pavements. Materials 2023, 16, 5612. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Wu, S.; Liu, Q.; Xie, J.; Yang, C.; Wang, F.; Wan, P. Recycling waste disposable medical masks in improving the performance of asphalt and asphalt mixtures. Constr. Build. Mater. 2022, 337, 127621. [Google Scholar] [CrossRef]

- Thoudam, K.; Hossiney, N.; Kumar, S.L.; Alex, J.; Prakasan, S.; Chandra, S.; Urs, Y.; Arunkumar, A.S. Recycled Surgical Mask Waste as a Resource Material in Sustainable Geopolymer Bricks. Recycling 2023, 8, 93. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Shen, D.; Ma, Y. Physical and mechanical properties of fly ash-based geopolymer with disposable medical mask reinforcement. J. Appl. Polym. Sci. 2024, 141, e55083. [Google Scholar] [CrossRef]

| Features | Inclusion Criteria | Exclusion Criteria |

|---|---|---|

| Type of research | Peer-reviewed research articles | Conference papers, book chapters, and short reports |

| Language | English | Other languages |

| Availability | Full: The complete research article is accessible, including all sections | Not available: Articles for which only abstracts or summaries are available but not the full text |

| Objective |

|

|

| l 1,2 (mm) | Height 2 (mm) | Width 2 (mm) | A 2 (mm2) | ¥ 2 (mm2) | (mm) | AR 2 | Density 1 (g/cm3) | Tensile Strength 1 (MPa) | Modulus of Elasticity 1 (GPa) | Melting Point 1 (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5~30 | 0.045 | 0.25–0.30 | 0.011–0.013 | 0.59–0.69 | 0.074–0.075 | 65.56–400 | 0.91 [57] | 4.25 [57] | 0.26 ± 0.02 [58] | 160 [57] |

| Gauge | Length (mm) | Weight (g) |

|---|---|---|

| 16~30 [59] | 40–48 [59] | 25–30 [59] |

| Gauge | Length (mm) | Volumetric Mass Density (kg/m3) |

|---|---|---|

| 16~30 [59] | 5–15 [62] | 1455 [62] |

| Specific Gravity | Water Absorption (%) | Maximum Size (mm) |

|---|---|---|

| 0.97 | 0.1 | 4.75 |

| Density (kg/m3) | Fineness Modulus |

|---|---|

| 2486 [78] | 3.37 [78] |

| Density (kg/dm3) | Specific Gravity | D50-PSD (µm) | Blaine Specific Surface Area (m2/kg) |

|---|---|---|---|

| 2.48 [78]–2.50 [80] | 2.03–2.23 [73] | 30 [80] | 402 [80] |

| Tensile Strength (MPa) | Tensile Strength at Break (MPa) | Rupture Force (N) | Elongation at Break (%) |

|---|---|---|---|

| 2.73 | 2.71 | 4.15 | 103.55 |

| Specific Gravity | l 1 (mm) | Height 2 (mm) | Width 1 (mm) | A 1 (mm2) | ¥ 1 (mm2) | (mm) | AR 2 |

|---|---|---|---|---|---|---|---|

| 1.26 | 15 | 0.08–0.13 | 5 | 0.4–0.65 | 10.16–10.26 | 0.15–0.25 | 100–160 |

| Water Absorption (%) | Maximum Size (mm) |

|---|---|

| 8% | 5 |

| Breaking Force 1 (N) | Elongation at Break 1 (%) | Specific Gravity 1 | Water Absorption 1 (%) | AR 1 | l 1 (mm) | Height 2 (mm) | Width 1 (mm) | A 1 (mm2) | ¥ 1 (mm2) | (mm) | AR 2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 183 | 42 | 0.93 | 7.6 | 5 | 20 | 0.1–0.5 | 4 | 0.4–2 | 8.2–9 | 0.19–0.8 | 105.2–125 |

| Specific Gravity | Fineness Modulus | Water Absorption by Mass (%) | Water Absorption (%) | Specific Gravity | Bulk Density (kg/m3) |

|---|---|---|---|---|---|

| 2.48 [108] | 3.17 [108] | 4.89 [108] | 3.9 [109] | 2.54 [109] | 1415 [109] |

| Density (kg/m3) | Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Electrical Conductivity (dS/m) | pH | TOC * (mg/kg) | Bulk Density (g/cm3) | Water Absorption (%) | Nitrate (mg/L) | Fineness Modulus |

|---|---|---|---|---|---|---|---|---|---|

| 3390.4 [38] | 0.003 [38] | 3.991 [38] | 8.55 [38] | 10.88 [38] –11.63 [103] | 7097 [38] | 0.68 [103] | 3.01 [103] | 27.80 [103] | 3.14 [103] |

| MW | Set of Keywords and Boolean Operators | Data Results–WoS (No.) |

|---|---|---|

| General search | (“Medical waste” OR “clinical waste”) AND (“construction material” OR cement paste OR mortar OR concrete) | 40 |

| FM | (“facemask” OR “surgical mask” OR “medical mask”) AND (“construction material” OR cement paste OR mortar OR concrete) | 19 |

| NDs | (“needles”) AND (“medical waste” OR “clinical waste”) AND (“construction material” OR cement paste OR mortar OR concrete) | 1 |

| PBs | (“pharmaceutical blisters”) AND (“medical waste” OR “clinical waste”) AND (“construction material” OR cement paste OR mortar OR concrete) | 1 |

| PSGs | (“plastic syringes”) AND (“medical waste” OR “clinical waste”) AND (“construction material” OR cement paste OR mortar OR concrete) | 2 |

| MG | (“medical glass” OR “pharmaceutical glass”) AND (“construction material” OR cement paste OR mortar OR concrete) | 4 |

| GLs | (“surgical gloves” OR “latex gloves” OR “gloves”) AND (“construction material” OR cement paste OR mortar OR concrete) | 42 |

| MT | (“medical textile” OR “surgical gowns” OR “protective suit” OR “surgical caps”) AND (“construction material” OR cement paste OR mortar OR concrete) | 3 |

| MWIA | (“medical waste incineration ash” OR “biomedical waste ash” OR “medical waste ash”) AND (“construction material” OR cement paste OR mortar OR concrete) | 19 |

| Total results | 131 | |

| Type of Matrix | % of Fiber | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties | Citation Article |

|---|---|---|---|---|---|

| Cement paste | 0.1% (vol.) | - | Compressive strength 67~/−6%/0.1% Splitting tensile strength 8~/+47%/0.1% | - | [54] |

| Mortar | 0.5% (wt.) | - | Compressive strength 30~/−21%/0.5% Flexural strength 4~/−38.4%/0.5% | - | [55] |

| Mortar | 0.5% 1% 1.5% 2% (vol.) | - | Compressive strength 41~/+17%/1% Tensile strength 3~/+22%/1.5% Flexural strength 3~/+30%/1% | Sorptivity (mm/√sec) 0.0225/+28%/2% | [130] |

| Mortar | 0.10% 0.15% 0.20% 0.25% (vol.) | Bulk density (kg/m3) 2090~/−0.3%/0.15% (28d) | Compressive strength 47~/−14.5%/0.15% Tensile strength 2.7~/+44.8%/0.15% Flexural strength 7.24/+34.8%/0.15% | Water absorption (%) 3.8/+25.2%/0.25% (28d) | [129] |

| Concrete | 0.1% (vol.) | - | Compressive strength 81~/−8%/0.1% Splitting tensile strength 4.3~/+35%/0.1% | Freeze–thaw resistance NR/+15%/0.1% | [131] |

| Mortar | 0.3% 0.5% 0.8% 1% (wt.) | Dry bulk density (kg/m3) 2392/+0.4~/0.3% (28d) | Compressive strength 74.4/+0.5%~/0.3% Flexural strength 14.9/+26%~/0.3% | Water absorption (%) 1.79/−4.5%/0.3% (28d) Porosity (%) 3.16/+3%~/0.3% (28d) | [132] |

| Concrete | 0. 5% 1% 1.5% 2% (vol.) | Workability (mm) 125~/+0%/0.5% 125~/−40%/1% Density (kg/m3) 2360~/−19%/2% | Compressive strength 35~/−20%/0.5% Split tensile strength 2.4~/−11%/0.5% | Water absorption (%) 3.5~/+22% to +70%/0.5% to 2% | [43] |

| Concrete | 1% (wt.) | - | Compressive strength 67.25/+5%/1% Tensile strength 8.07/+3%~/1% | Frost resistance (measured with compressive strength in MPa) 72.48/+4.7%~/1% (100 freezing–thawing cycles) | [41] |

| Concrete | As fibers (F) 1% 1.5% 2% (vol.) | - | (F) Compressive strength 27.3/+11.7/2% Tensile strength 3.5~/+14.57/2% | (F) Chlorine permeability (RCPT charge in C) 3800~/−23.2/1.5% | [42] |

| As 1–2mm shredded FM (S) 0.75% 1% 1.5% (vol.) | (S) Compressive strength 27.3/+18.28%/1% Tensile strength 3.5~/+1.14%/1% 3.5~/−14.57%/1.5% | (S) Chlorine permeability (RCPT charge in C) 3800/−41.3%/1% | |||

| Concrete | 0.2% (fiber only) 0.1% 0.2% 0.3% (mixed w/recycled coarse aggregate) | Elastic modulus (GPa) 16.2~/+4.73%/0.2% Workability (mm) 690~/−3%~/0.2% | Compressive strength 41~/+12%~/0.2% Splitting tensile strength 3.2~/+3%~/0.2% Flexural strength 4~/+35%~/0.2% | - | [133] |

| Concrete | 0.3% 0.5% (vol.) | - | Compressive strength 96.4/−1.4%~/0.5% Tensile strength7.1/+11.3%/0.5% Tensile strain 2.03/+28.1%/0.5% First cracking strength 5.17/+0.4%~/0.3% | Average crack width (μm) 123.8/−53%~/0.5% (28d) | [134] |

| Concrete | 0.1% 0.15% 0.2% 0.25% (vol.) | Young modulus (GPa) 29.24/+3.3%/0.1% (28d) 29.24/−2.05%/0.15% (28d) * No significant influence was found regarding the Young modulus | Compressive strength 50.34/+17%~/0.2% Tensile strength 3.27/+12.23%/0.2% | UPV (m/s) 4590/+4%~/0.2% (28d) | [57] |

| Concrete | 1% 2% (vol.) | Permeable voids (%) 9.4/−4.4%~/1% 9.4/+12,7%~/2% | Compressive strength 33.5/+41%/1% Flexural strength 10.5/+21.9%/1% 10.5/+38%/2% Interlayer bond strength 1.4/+21.4%/1% | - | [58] |

| Concrete | 0.2% (vol.) | - | Compressive strength 67.25/+5.3%/0.2% Splitting tensile strength 8.13/−6.3%/0.2% | - | [135] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties (%) | Citation Article |

|---|---|---|---|---|---|

| Concrete | 2% 4% 6% 8% 10% (wt.) | Dry density (kg/m3) 2400/−1.5%/10% Slump (cm) 7.8~/−10.2%/10% | Compressive strength 45~/−1.4%/10% Flexural strength 6~/+18.3%/10% | Water absorption 2.09~/−9.6%/10% | [62] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties (%) | Citation Article |

|---|---|---|---|---|---|

| Concrete | 5% 10% 15% 20% (wt.) | - | Compressive strength 34~/+14.87%/10% Splitting tensile strength 3.14/+11.78%/10% Flexural strength 3.97/+10.33%/10% | - | [68] |

| Concrete | 5% 10% 15% 20% 25% 30% (wt.) | - | Compressive strength 33~/−10.8%/30% Flexural strength 7.6~/−23.36%/30% Tensile Strength 5.4~/−15.38%/30% | Water absorption 1.23/+5.6%/30% | [67] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties | Citation Article |

|---|---|---|---|---|---|

| Concrete | 10% 20% 30% 40% 50% (wt.) | Slump flow (mm) 650/+1.5%/10% (28d) L-box test (H2/H1) 0.95~/+5%~/10% (28d) | Compressive strength 47~/+1.5%~/20% Splitting tensile strength 4.2~/−2%~/20% Flexural strength 3.3~/+9%~/20% | - | [70] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (120d) | Durability Properties (120d) | Citation Article |

|---|---|---|---|---|---|

| Concrete | 20% 40% 60% 80% 100% (wt.) | - | Compressive strength 39.2/+12.3%/60% | Water absorption (%) 4.36/−10.84%/60% UPV (m/s) 4775/+2.6%/60% RCPT (coulombs) 709/−20.6%/60% Sulfate resistance (µm/m) 80/−20%/60% | [78] |

| Type of Matrix | % of Fiber | Physical Properties (28d) | Mechanical Properties (28d) | Durability Properties | Citation Article |

|---|---|---|---|---|---|

| Mortar | 0.1% 0.2% (vol.) | Workability (average spread diameter in mm) 204.1/+6.6%/0.2% Buildability index 17325/+331%/0.2% | Compressive strength (MPa) 68.8/−23%~/0.2% Maximum flexural force (N) 2128.8/+17%/0.1% Direct tensile force (N) 1173.3/+37.5%/0.1% | [39] | |

| Concrete | 0.5% 1% 1.5% 2% (vol.) | - | Compressive strength (MPa) 26.1/−21.9%/1% Total strain NR/+13.5%/0.5% (50 cycles) Plastic strain 0.59~/+43.8%/0.5% (50 cycles) | - | [85] |

| Concrete | 0.1% 0.2% (vol.) | Workability (mm) 204.1/+6.6%/0.2% Buildability index 17325/+361%~/0.2% Density (kg/m3) 2300~/+5%~/0.1% | Compressive strength (MPa) 68.8/−18%/0.2% Direct tensile force (N) 1173.3/+37.5/0.1% Ultimate bending force (flexural) 2099.3/+17%/0.1% | [86] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties (28d) | Citation Article |

|---|---|---|---|---|---|

| Mortar | 2.5% 5% 7.5% 10% (wt.) | Density (kg/m3) 2355.15/−3.4%/2.5% (28d) | Compressive strength 36.72/−27.5%/2.5% | Water absorption (%) 4.08/+79%~/10% UPV (km/s) 4.61/−16.5%/10% | [87] |

| Concrete | 0.1% 0.2% 0.3% (vol.) | Compressive strength 50.34/+22%~/0.2% Concrete’s Young mod-ulus (GPa) 29.24/+3.5%/0.2% | UPV (m/s) 4590/+1.15%/0.2% | [81] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties (28d) | Citation Article |

|---|---|---|---|---|---|

| Concrete | 2.5% 5% 7.5% 10% (wt.) | Compressive strength 37~/−86%/10% | Workability (mm) 110/−16%~/2.5% UPV (m/s) 3800/−17.3%/10% | [88] |

| Type of Matrix | % of Fiber | Physical Properties (28d) | Mechanical Properties (MPa) (28d) | Durability Properties (km/s) (28d) | Citation Article |

|---|---|---|---|---|---|

| Concrete | 0.2% 0.4% 0.6% 0.8% 1% (vol.) | Density (kg/m3) 2364/−1.5%/1% | Compressive strength 37/−7.3%/1% Splitting tensile strength (MPa) 3.12/+43.6%/1% | UPV 5400~/−12.5%~/1% | [95] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties | Citation Article |

|---|---|---|---|---|---|

| Mortar | 14.3% 20% 33.33% (wt.) | - | Compressive strength 37/−16%~/33.33% Flexural strength 1/−19%~/20% | - | [136] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties | Citation Article |

|---|---|---|---|---|---|

| Mortar | 40% (wt.) | - | Compressive strength NR/+60%/40% * | [110] | |

| Concrete | 40% (wt.) | - | Acid resistance NR/+47%/40% (28d) | [110] | |

| Concrete | 5% 10% 15% 20% 25% 30% 40% 50% (wt.) | - | Compressive strength 38~/+2.6%~/5% | - | [38] |

| Concrete | 2.5% 5% 7.5% 10% 12.5% (wt.) | - | Compressive strength 22.32/+20%/7.5% Split tensile strength 2.2/+17%/7.5% Flexural strength NR/+14%/7.5% | Workability (mm) 97/−13.3%/2.5% | [103] |

| Type of Matrix | % of Replacement | Physical Properties | Mechanical Properties (MPa) (28d) | Durability Properties (28d) | Citation Article |

|---|---|---|---|---|---|

| Concrete | 5% 10% 15% 20% (vol.) | - | Compressive strength 27~/+33.28%/5% Splitting tensile strength 2.4~/+15%/5% | Water absorption (%) 4.26/+4.2%/5% | [108] |

| Concrete | 10% 20% 30% (wt.) | Slump flow test (mm) 740/−1.3%/10% V-funnel test (sec) 8/−46%/10% | Compressive strength 30/−14.3%/10% | - | [109] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murillo, M.; Manzano, S.; Silva, Y.F.; Burbano-García, C.; Araya-Letelier, G. Valorization of Medical Waste in Cement-Based Construction Materials: A Systematic Review. Buildings 2025, 15, 1643. https://doi.org/10.3390/buildings15101643

Murillo M, Manzano S, Silva YF, Burbano-García C, Araya-Letelier G. Valorization of Medical Waste in Cement-Based Construction Materials: A Systematic Review. Buildings. 2025; 15(10):1643. https://doi.org/10.3390/buildings15101643

Chicago/Turabian StyleMurillo, M., S. Manzano, Y. F. Silva, C. Burbano-García, and G. Araya-Letelier. 2025. "Valorization of Medical Waste in Cement-Based Construction Materials: A Systematic Review" Buildings 15, no. 10: 1643. https://doi.org/10.3390/buildings15101643

APA StyleMurillo, M., Manzano, S., Silva, Y. F., Burbano-García, C., & Araya-Letelier, G. (2025). Valorization of Medical Waste in Cement-Based Construction Materials: A Systematic Review. Buildings, 15(10), 1643. https://doi.org/10.3390/buildings15101643