Research on Automated On-Site Construction of Timber Structures: Mobile Construction Platform Guided by Real-Time Visual Positioning System

Abstract

1. Introduction

2. Literature Review

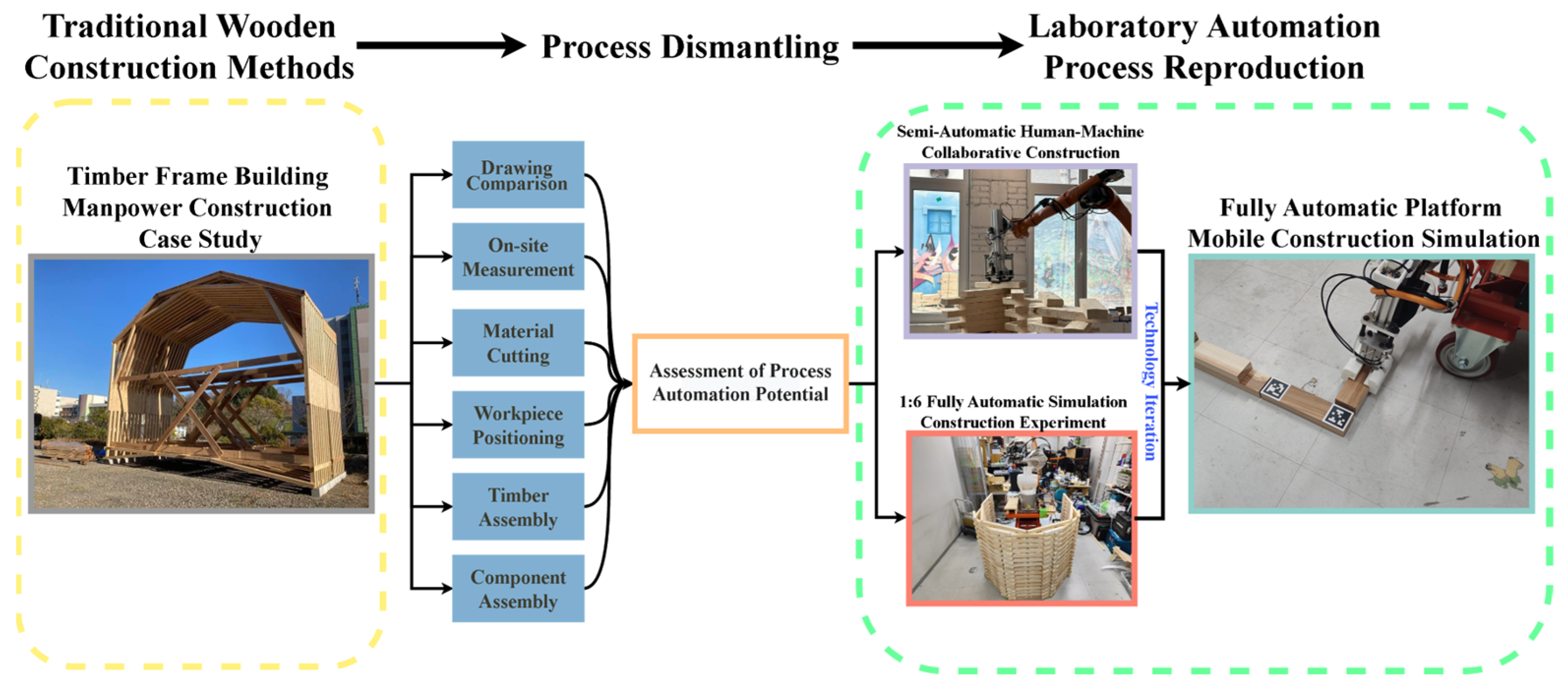

3. Methodology

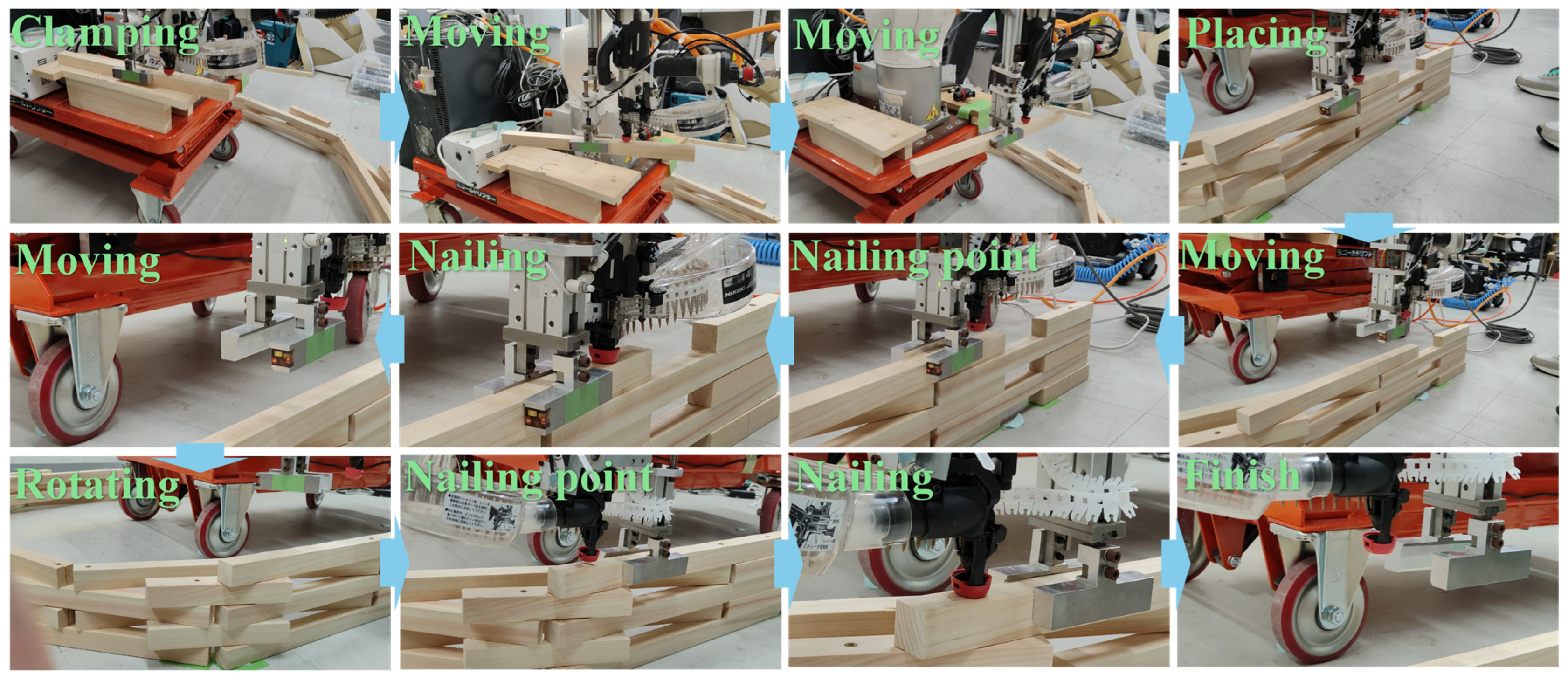

3.1. Analysis of Timber Construction Processes and Their Automation Methods

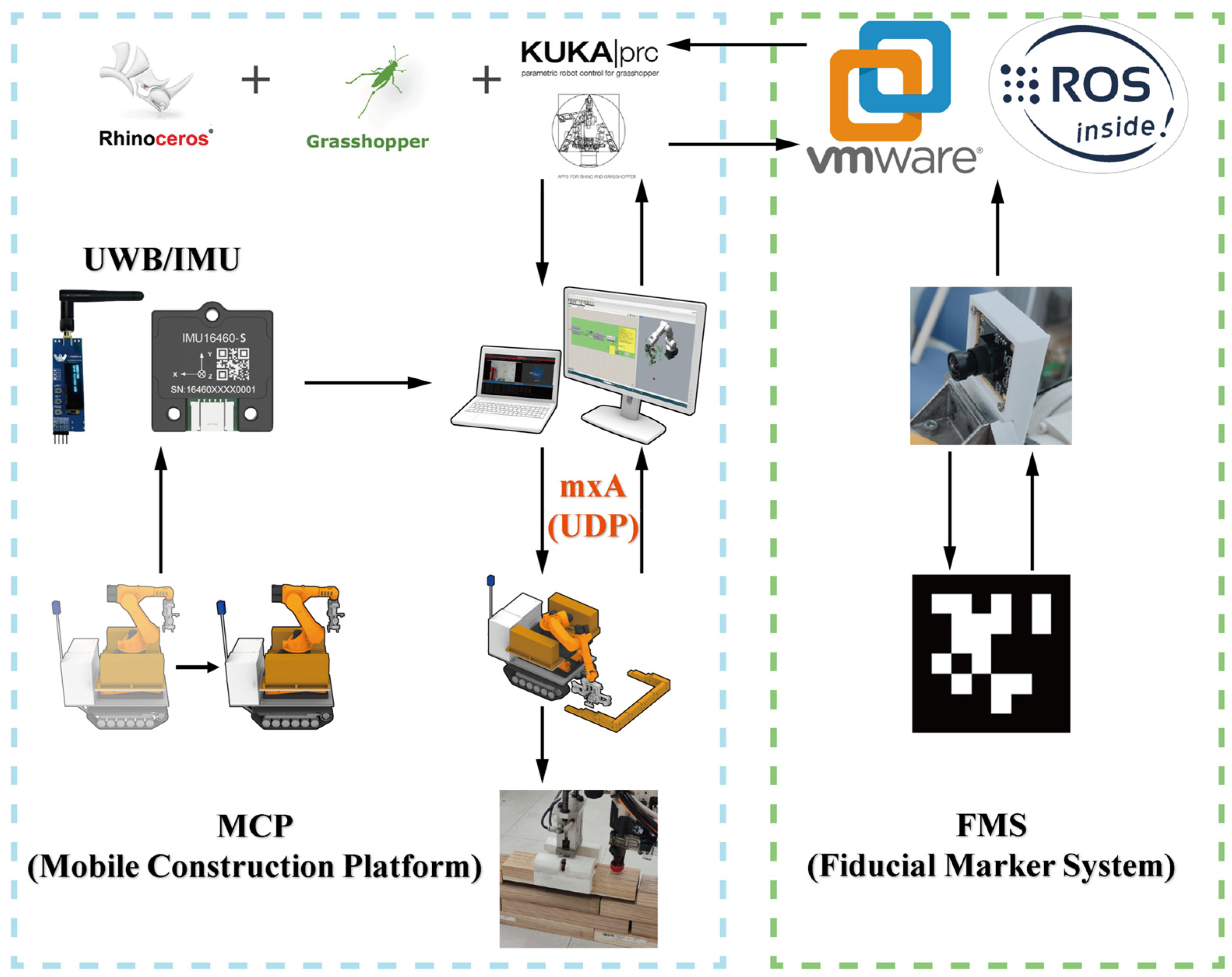

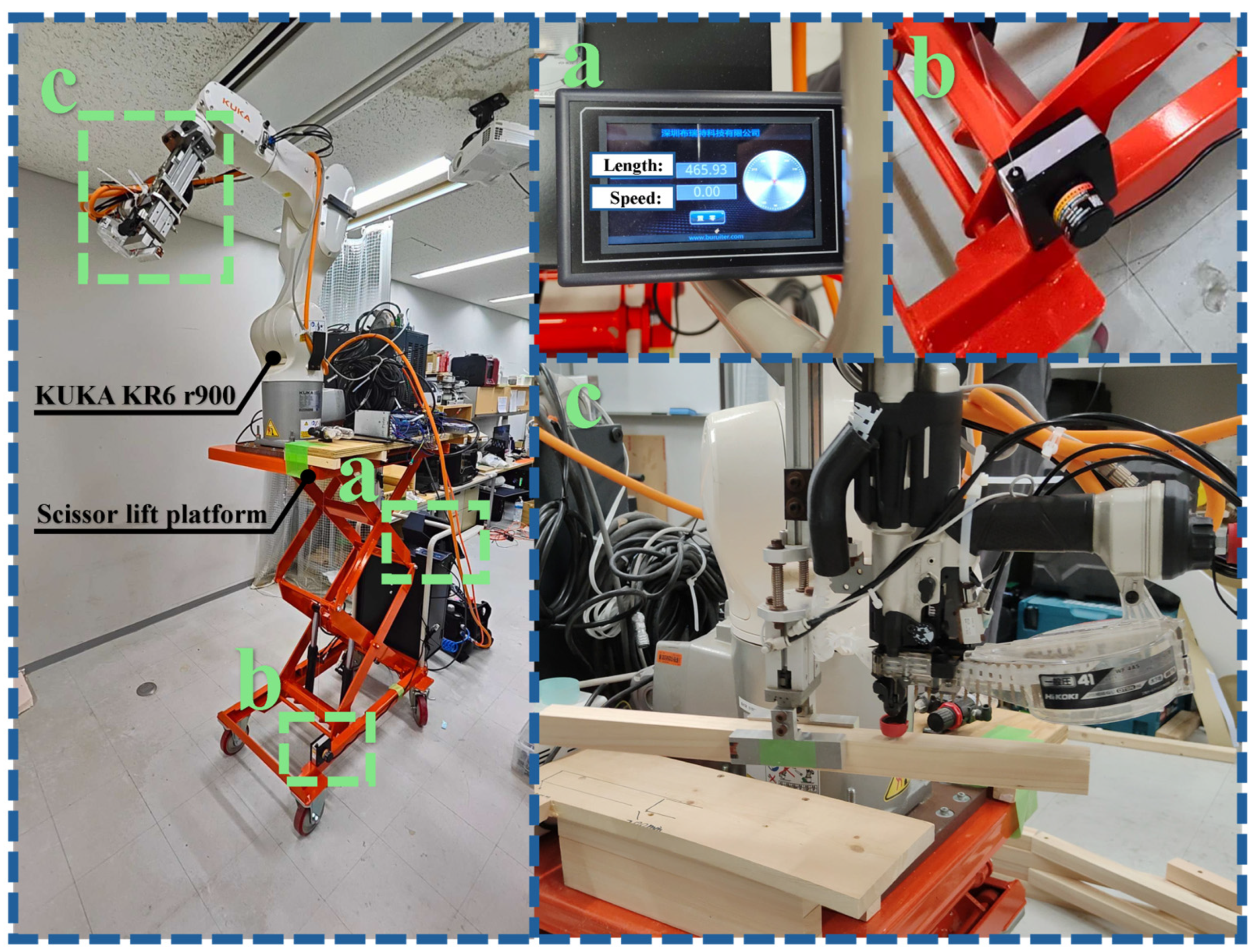

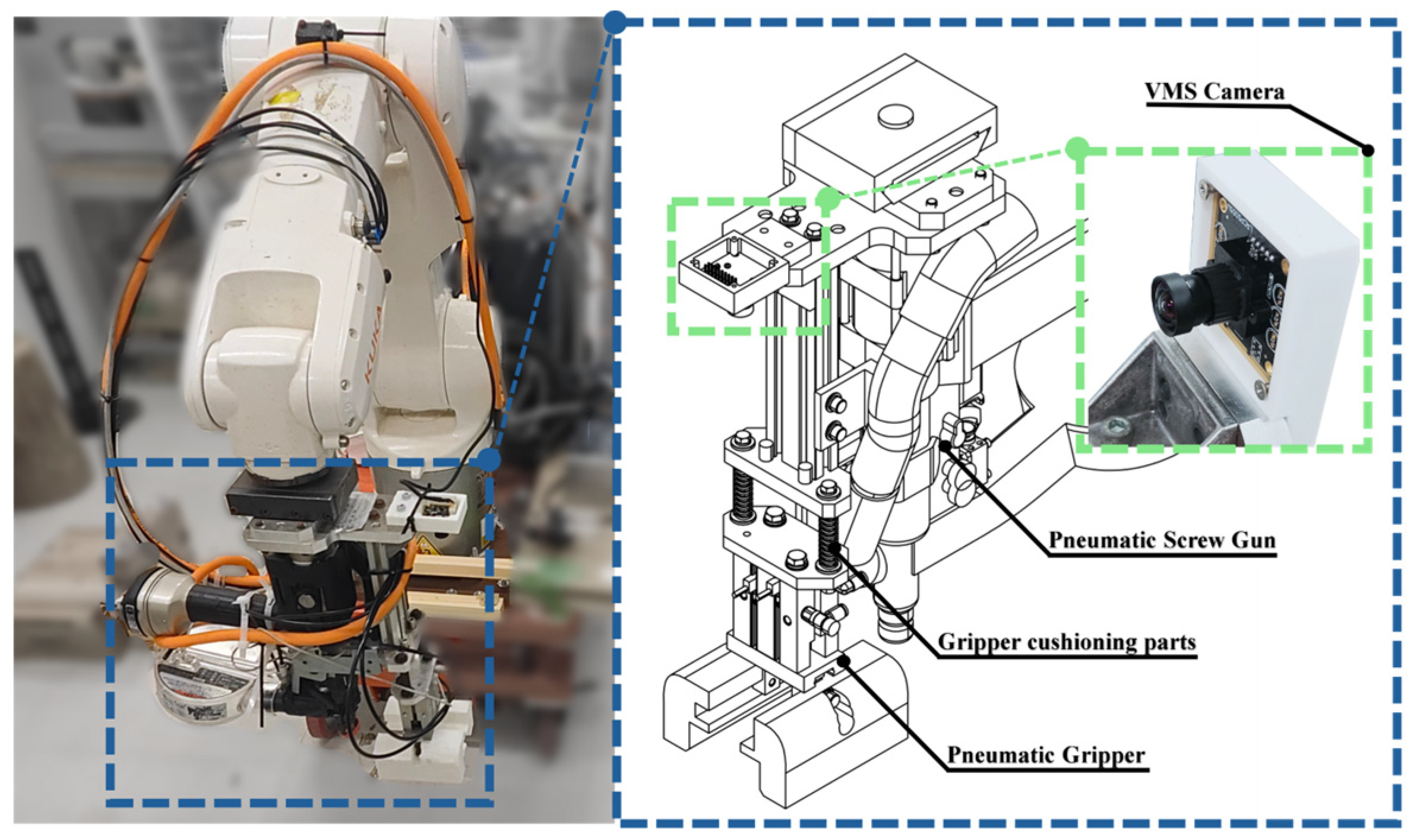

3.2. System Architecture Development

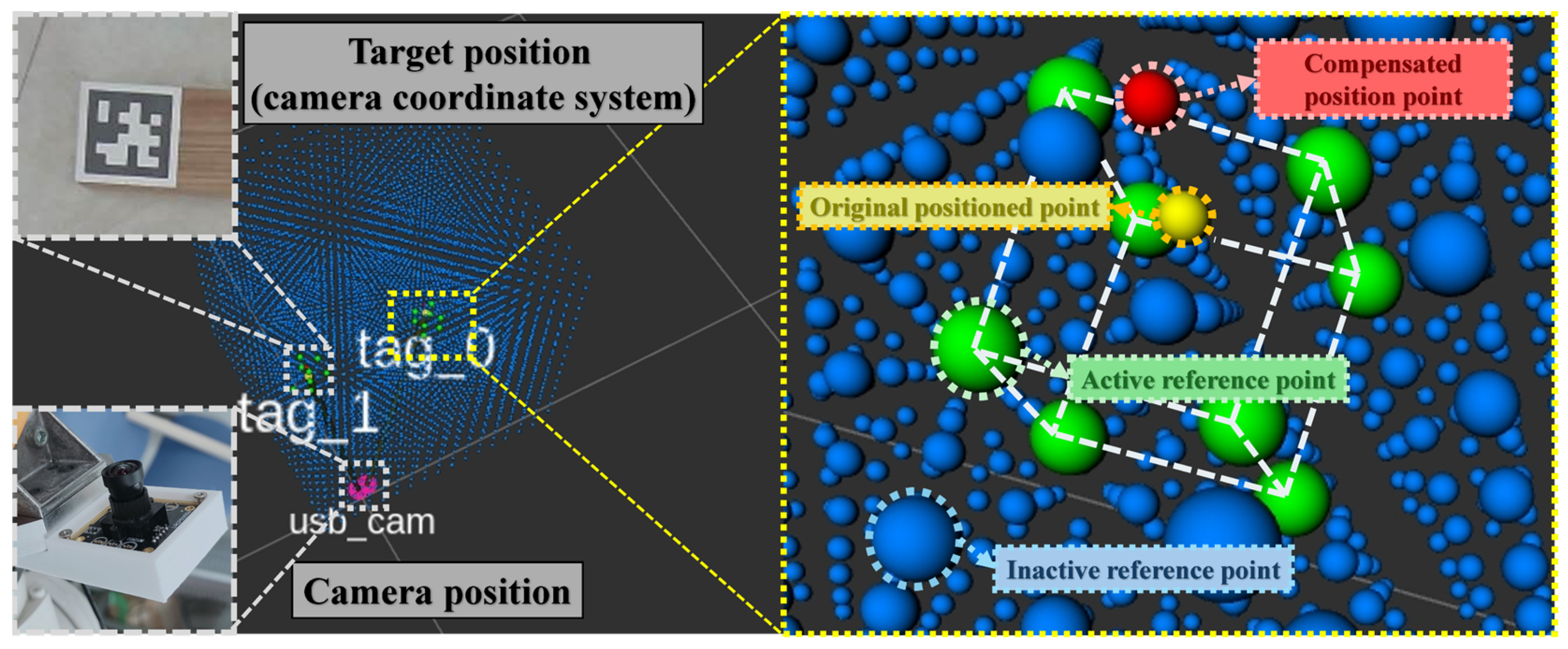

3.3. Design of the Self-Feedback Control System

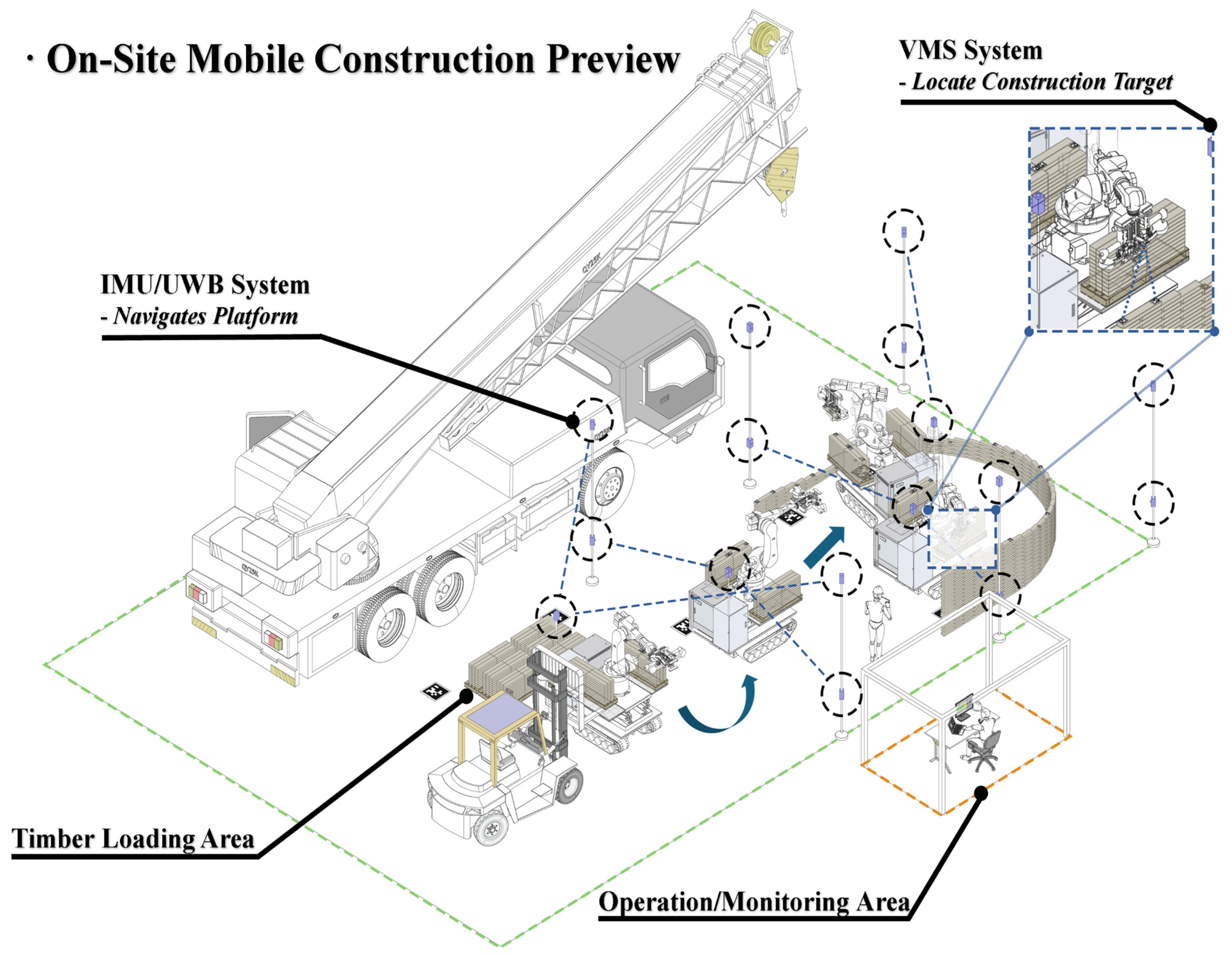

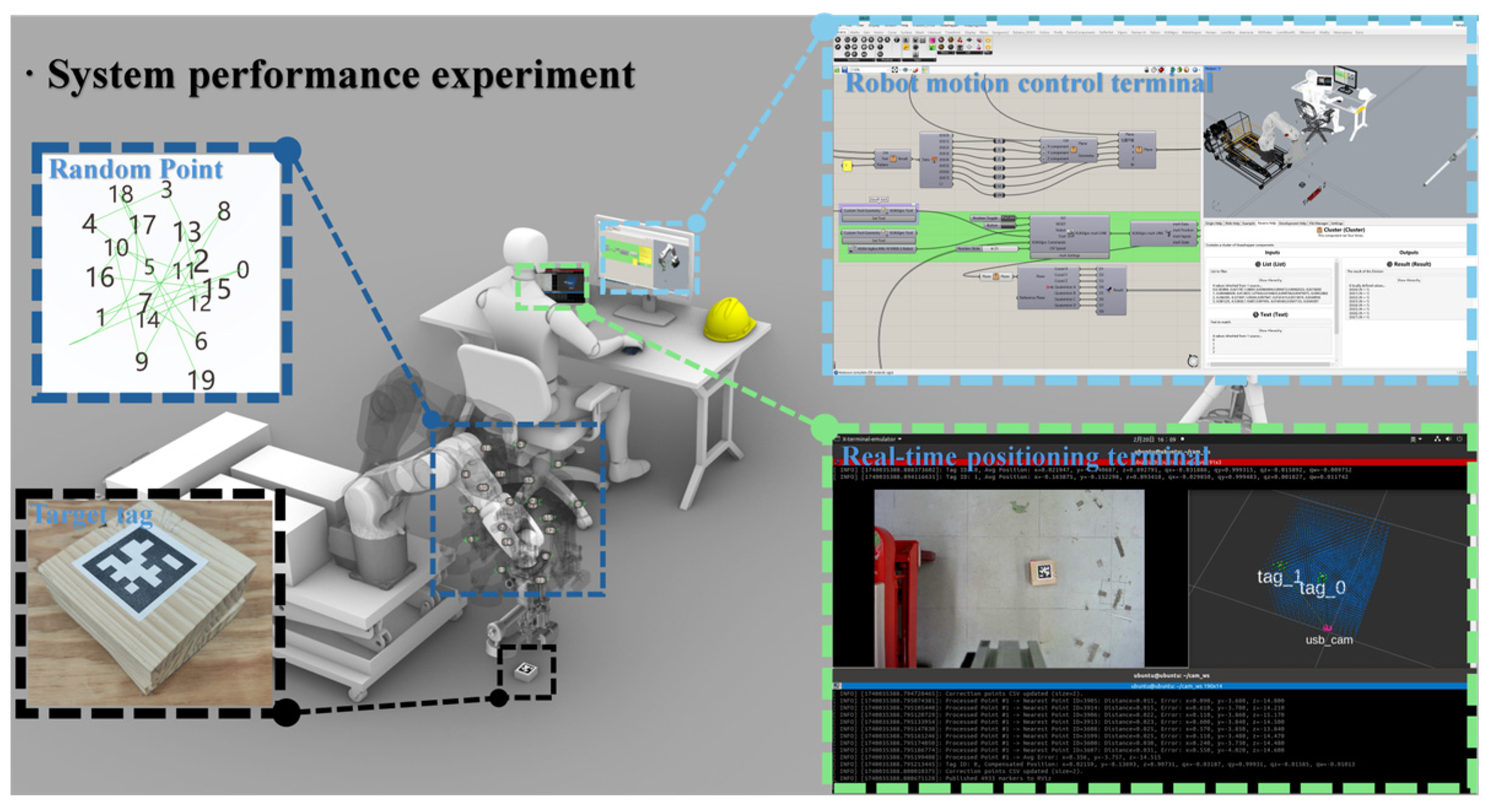

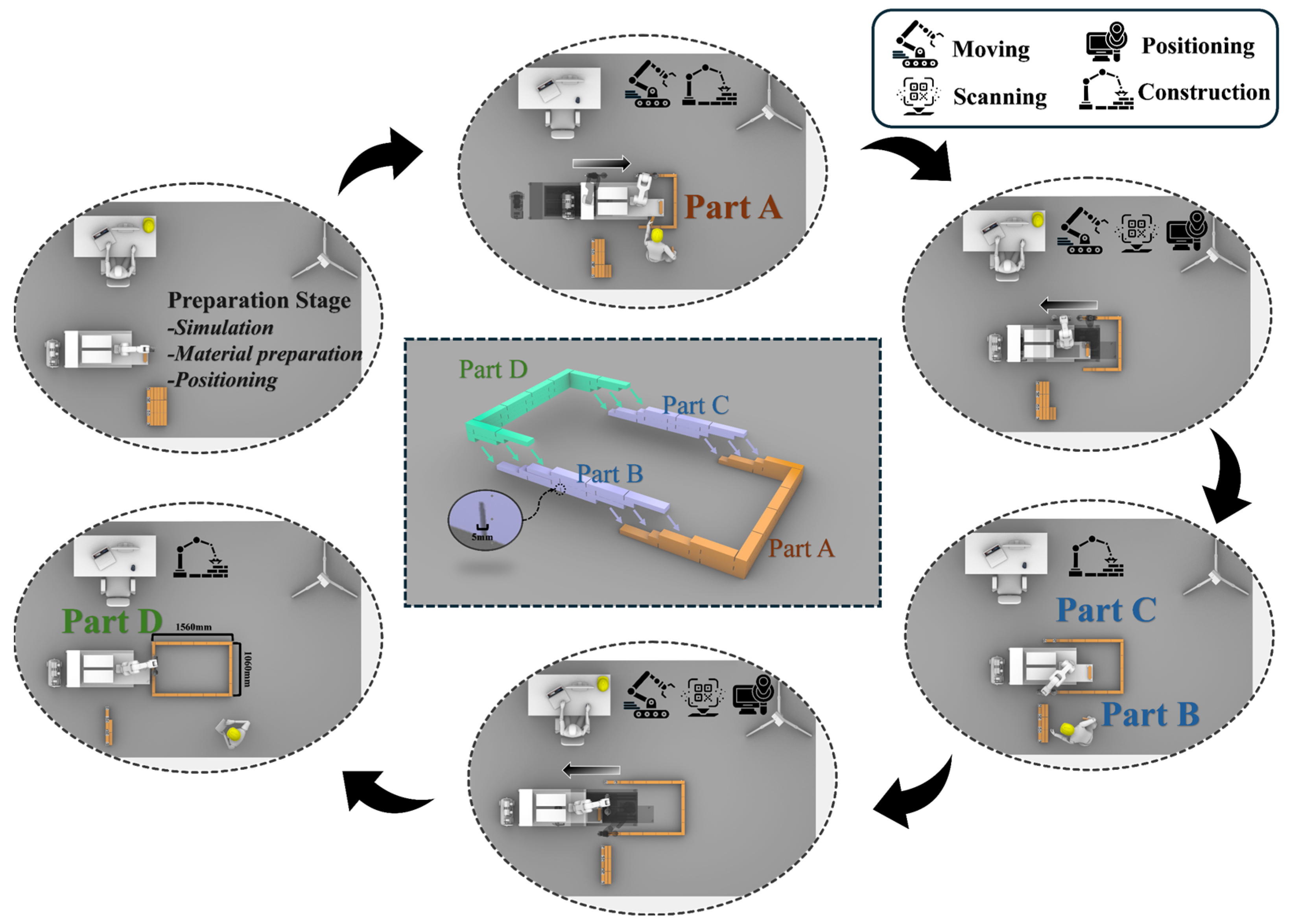

3.4. On-Site Construction Workflow Design and Performance Validation

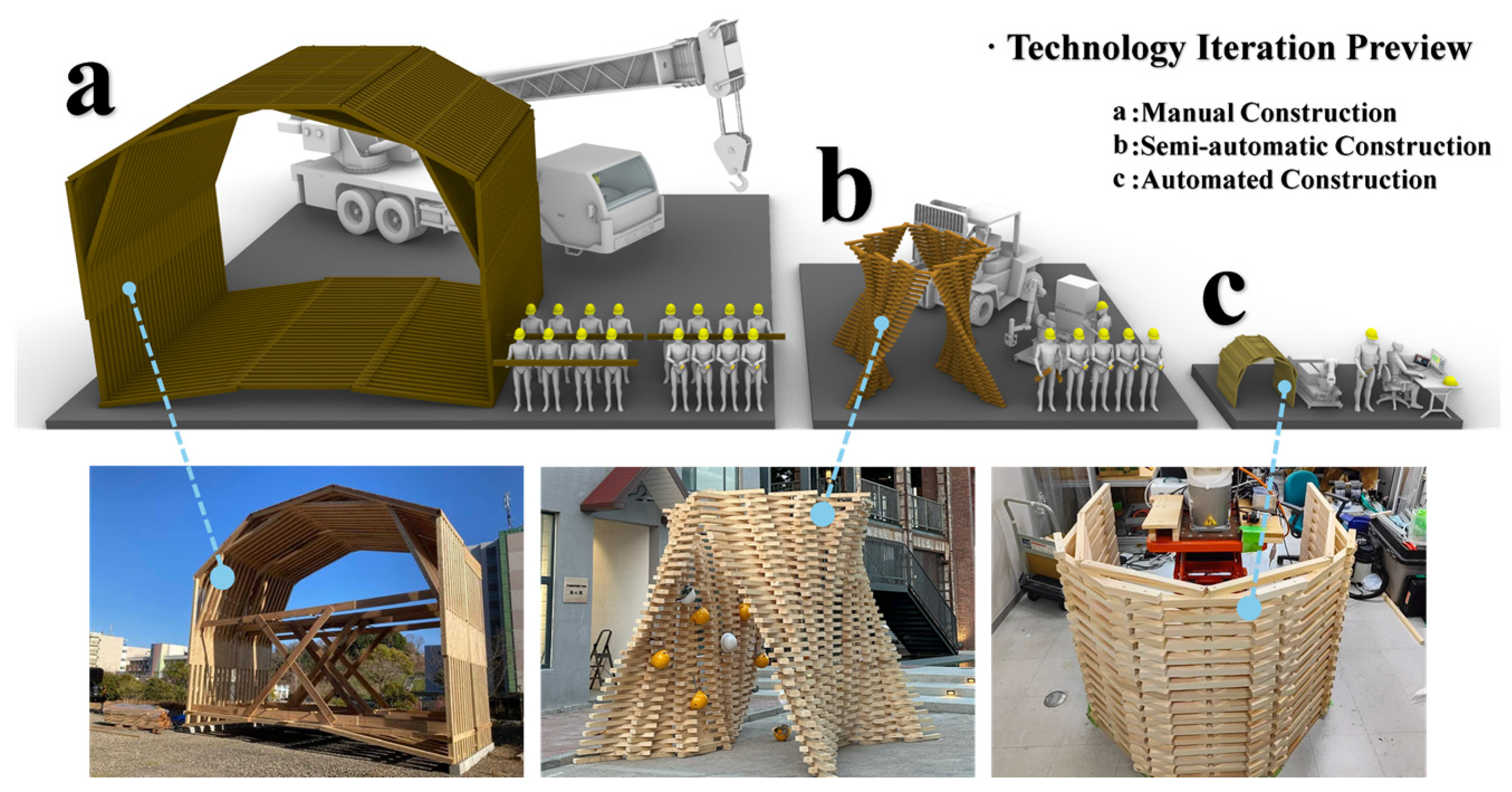

4. Construction Technology Dismantling and Iteration Review

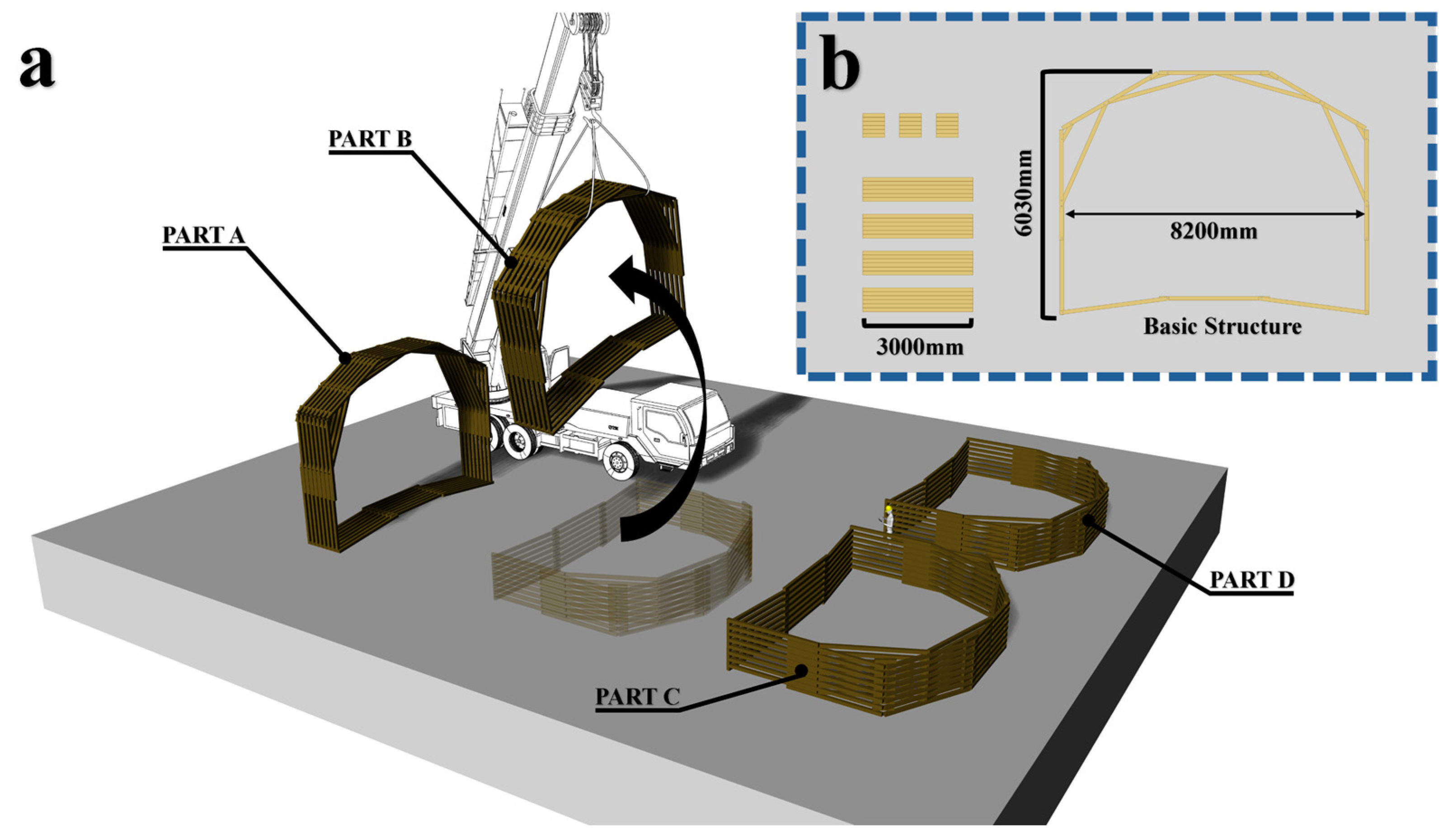

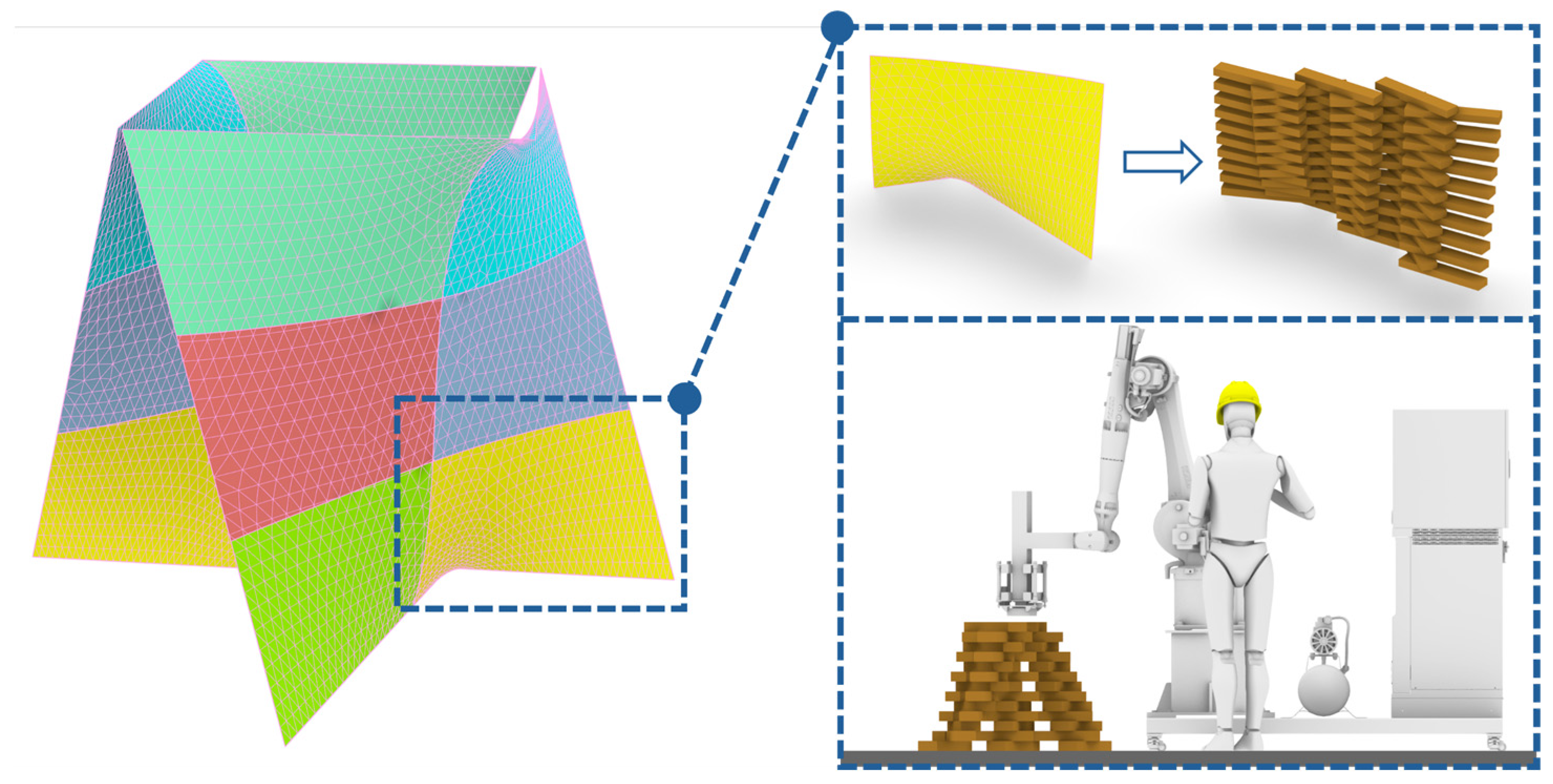

4.1. Deconstruction of the Timber Construction Technology

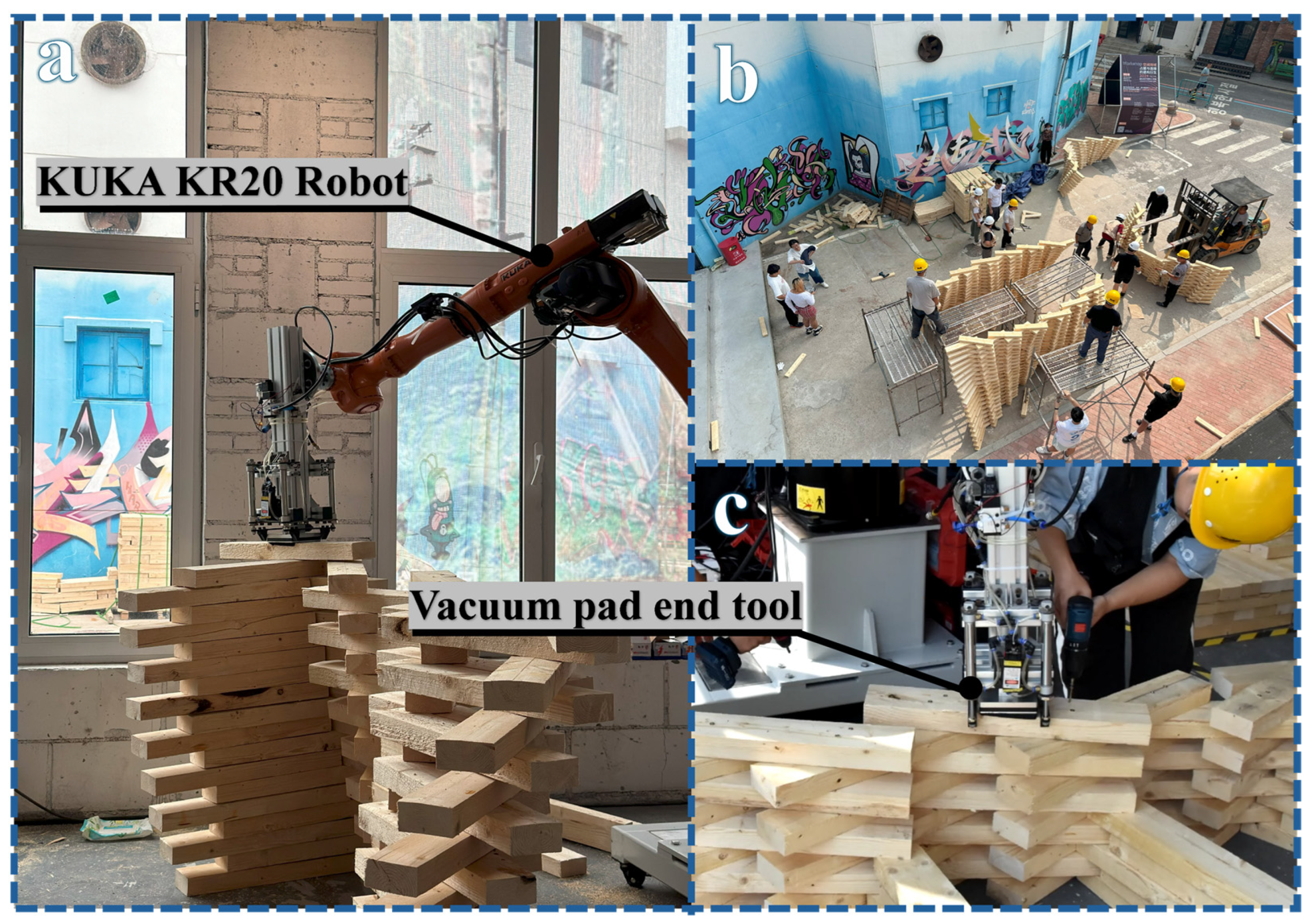

4.2. Exploration of Semi-Automated Timber Construction

4.3. Simulation of the Automated Timber Construction Process

4.4. Technology Iteration Analysis

5. Construction Workflow Design and Experimental Analysis

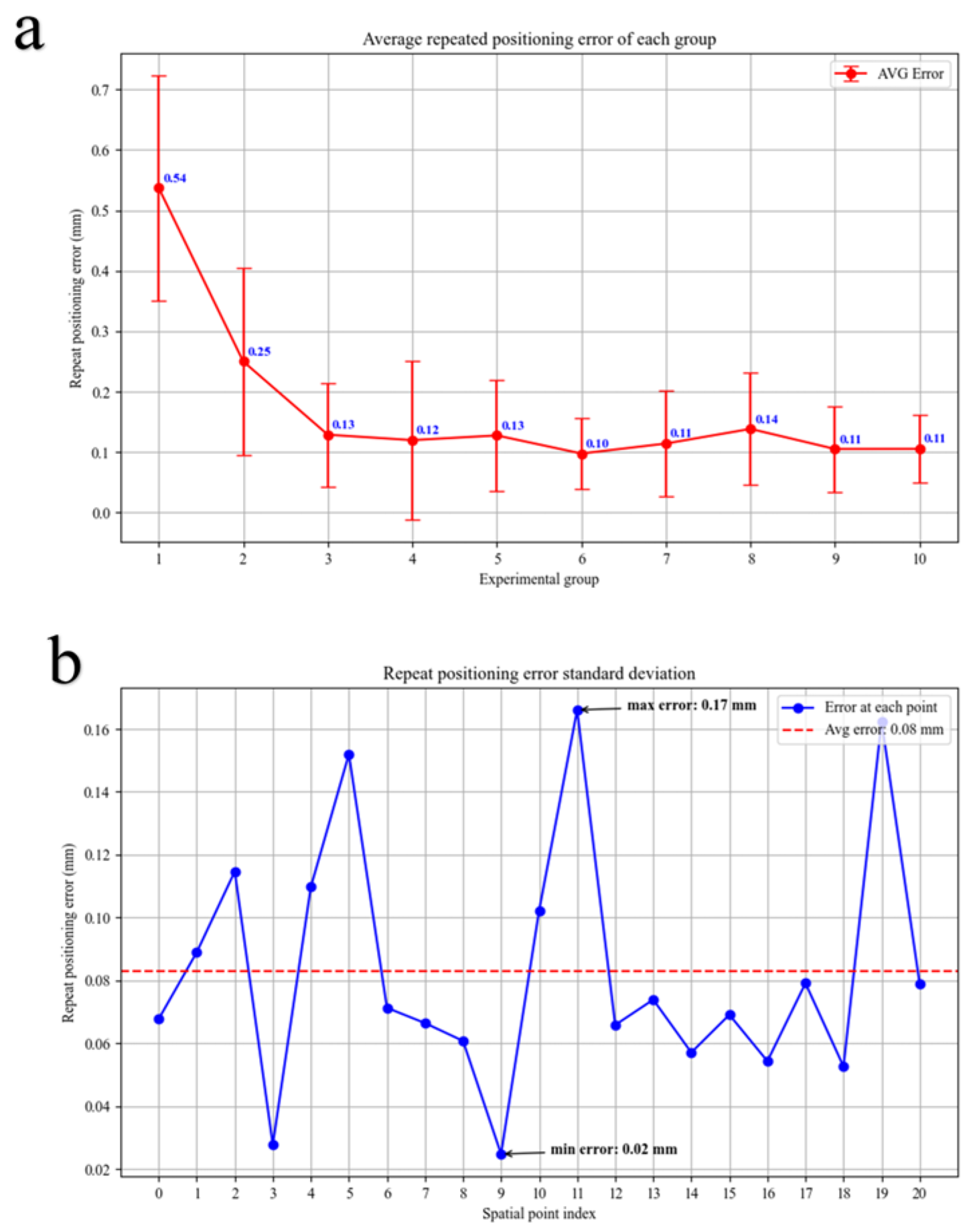

5.1. Performance Verification of the Visual Positioning System

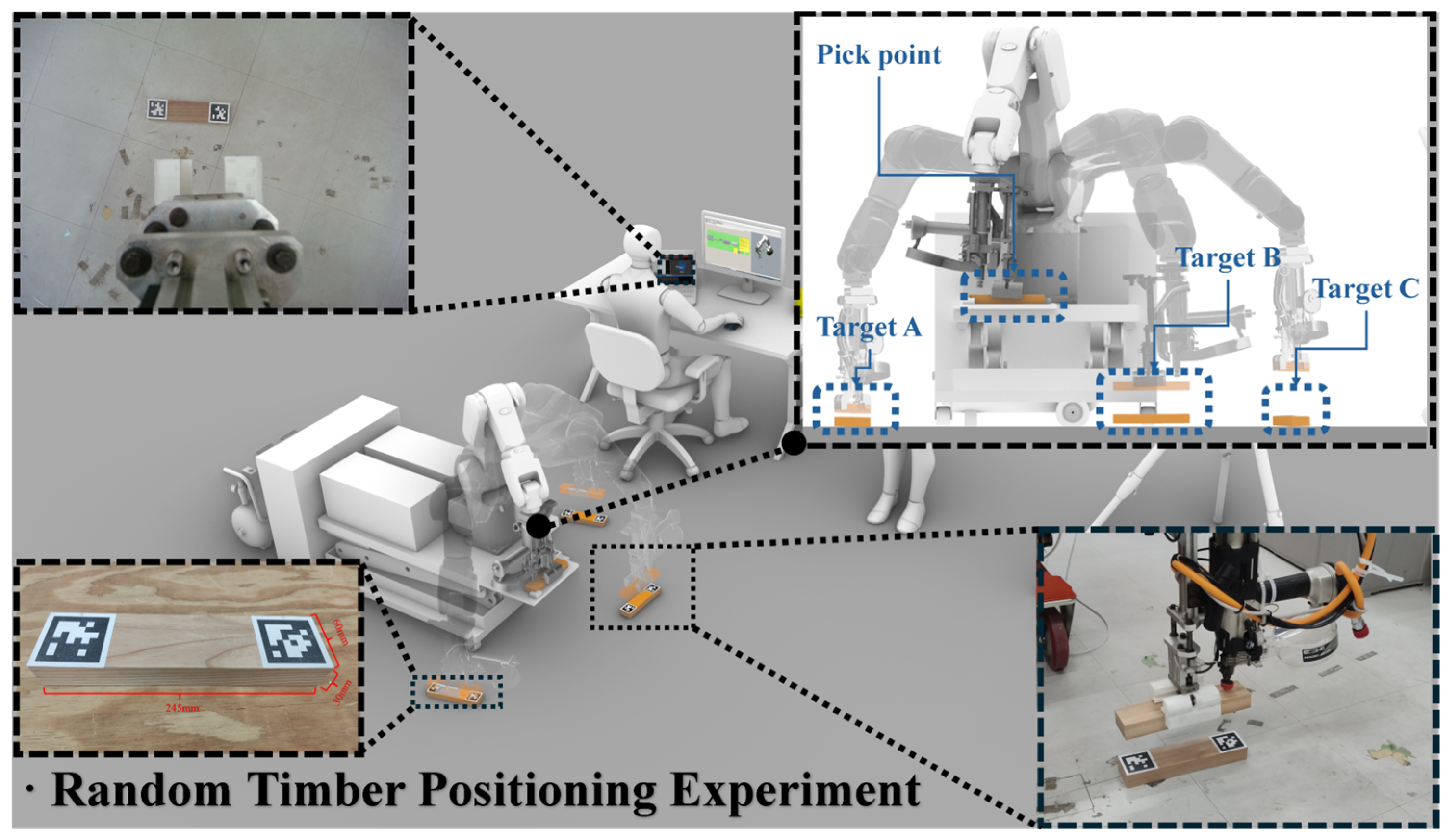

5.2. Random Timber Position Stacking Experiment

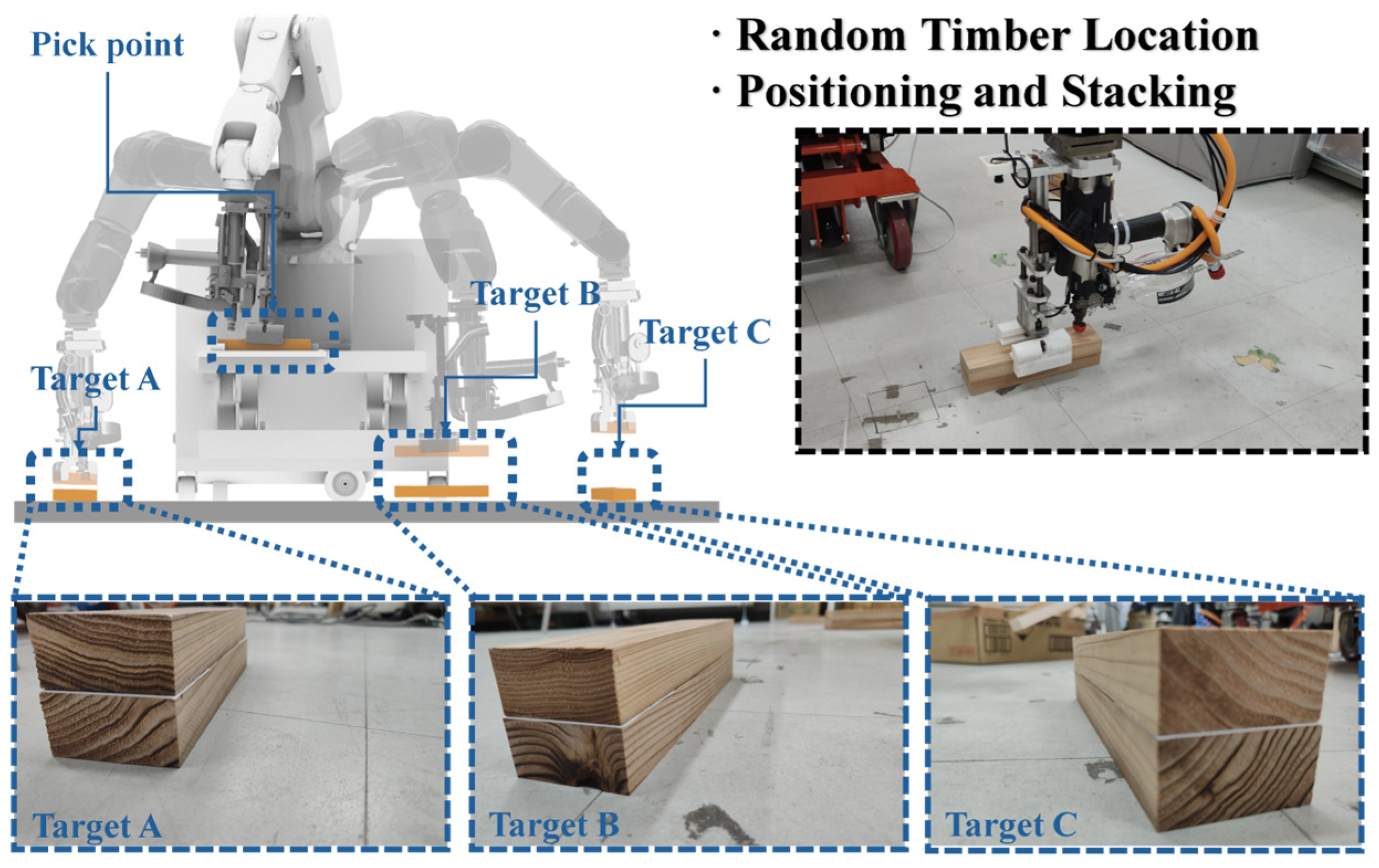

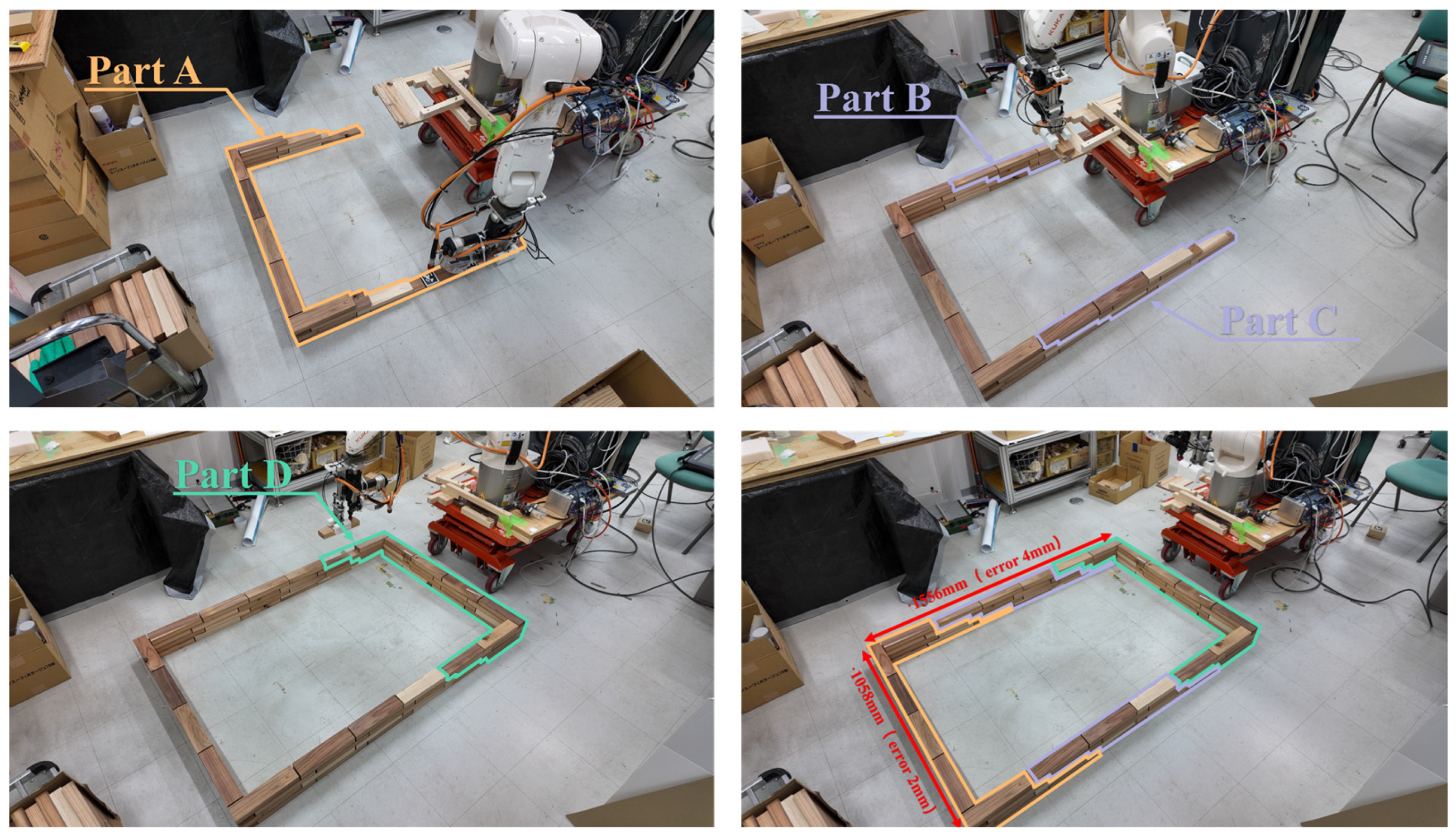

5.3. Simplified Timber Structure Assembly Experiment

5.4. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEC | Architecture, Engineering and Construction |

| MCP | Mobile Construction Platform |

| FMS | Fiducial Marker System |

| UWB | Ultra-Wideband |

| IMU | Inertial Measurement Unit |

| UDP | User Datagram Protocol |

| HGFS | Host–Guest File System |

| ATE | Absolute Trajectory Error |

| LOS | Line-of-Sight |

| NLOS | Non-Line-of-Sight |

| ESKF | Error-State Kalman Filter |

References

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Chai, H.; So, C.; Yuan, P.F. Manufacturing Double-Curved Glulam with Robotic Band Saw Cutting Technique. Autom. Constr. 2021, 124, 103571. [Google Scholar] [CrossRef]

- Orlowski, K. Automated Manufacturing for Timber-Based Panelised Wall Systems. Autom. Constr. 2020, 109, 102988. [Google Scholar] [CrossRef]

- Krieg, O.D.; Lang, O. Adaptive Automation Strategies for Robotic Prefabrication of Parametrized Mass Timber Building Components. In Proceedings of the 2019 36th ISARC, Banff, AB, Canada, 21–24 May 2019. [Google Scholar]

- Wagner, H.J.; Alvarez, M.; Kyjanek, O.; Bhiri, Z.; Buck, M.; Menges, A. Flexible and Transportable Robotic Timber Construction Platform—TIM. Autom. Constr. 2020, 120, 103400. [Google Scholar] [CrossRef]

- Younis, A.; Dodoo, A. Cross-Laminated Timber for Building Construction: A Life-Cycle-Assessment Overview. J. Build. Eng. 2022, 52, 104482. [Google Scholar] [CrossRef]

- Hemmati, M.; Messadi, T.; Gu, H.; Seddelmeyer, J.; Hemmati, M. Comparison of Embodied Carbon Footprint of a Mass Timber Building Structure with a Steel Equivalent. Buildings 2024, 14, 1276. [Google Scholar] [CrossRef]

- ARUP-Embodied-Carbon-Timber. 07762000-RP-SUS-0002. 5 June 2023. Available online: https://www.istructe.org/IStructE/media/Public/Resources/ARUP-Embodied-carbon-timber_1.pdf (accessed on 25 March 2025).

- Drewniok, M.; Campbell, J.; Orr, J. SI for the Paper: The Lightest Beam Method—A Methodology to Find Ultimate Steel Savings and Reduce Embodied Carbon in Steel Framed Buildings. 2020. Available online: https://www.repository.cam.ac.uk/handle/1810/307047 (accessed on 25 March 2025).

- Kanagaraj, B.; Anand, N.; Samuvel Raj, R.; Lubloy, E. Techno-Socio-Economic Aspects of Portland Cement, Geopolymer, and Limestone Calcined Clay Cement (LC3) Composite Systems: A-State-of-Art-Review. Constr. Build. Mater. 2023, 398, 132484. [Google Scholar] [CrossRef]

- Wang, R.R.; Zhao, Y.Q.; Babich, A.; Senk, D.; Fan, X.Y. Hydrogen Direct Reduction (H-DR) in Steel Industry—An Overview of Challenges and Opportunities. J. Clean. Prod. 2021, 329, 129797. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Willmann, J.; Knauss, M.; Bonwetsch, T.; Apolinarska, A.A.; Gramazio, F.; Kohler, M. Robotic Timber Construction—Expanding Additive Fabrication to New Dimensions. Autom. Constr. 2016, 61, 16–23. [Google Scholar] [CrossRef]

- Möller, C.; Schmidt, H.C.; Koch, P.; Böhlmann, C.; Kothe, S.-M.; Wollnack, J.; Hintze, W. Machining of Large Scaled CFRP-Parts with Mobile CNC-Based Robotic System in Aerospace Industry. Procedia Manuf. 2017, 14, 17–29. [Google Scholar] [CrossRef]

- Parikh, P.; Kalamdane, S.; Rasal, A.; Mundada, K.; Kalshetti, U. SPArK-Bot: An Educational Robotic Platform. In Proceedings of the 2022 IEEE Global Engineering Education Conference (EDUCON), Tunis, Tunisia, 28–31 March 2022; pp. 1628–1633. [Google Scholar]

- Chu, B.; Jung, K.; Lim, M.-T.; Hong, D. Robot-Based Construction Automation: An Application to Steel Beam Assembly (Part I). Autom. Constr. 2013, 32, 46–61. [Google Scholar] [CrossRef]

- Melenbrink, N.; Werfel, J.; Menges, A. On-Site Autonomous Construction Robots: Towards Unsupervised Building. Autom. Constr. 2020, 119, 103312. [Google Scholar] [CrossRef]

- Bock, T.; Linner, T. Construction Robots: Elementary Technologies and Single-Task Construction Robots; Cambridge University Press: Cambridge, UK, 2016; ISBN 978-1-107-07599-3. [Google Scholar]

- Castro-Lacouture, D. Construction Automation. In Springer Handbook of Automation; Nof, S.Y., Ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1063–1078. ISBN 978-3-540-78831-7. [Google Scholar]

- Bock, T.; Linner, T. Site Automation: Automated/Robotic On-Site Factories, 1st ed.; Cambridge University Press: Cambridge, UK, 2015; ISBN 978-1-107-07597-9. [Google Scholar]

- Bechthold, M. The Return of the Future: A Second Go at Robotic Construction. Archit. Des. 2010, 80, 116–121. [Google Scholar] [CrossRef]

- Ardiny, H.; Witwicki, S.; Mondada, F. Are Autonomous Mobile Robots Able to Take Over Construction? A Review. Int. J. Robot. 2015, 4, 10–21. [Google Scholar]

- Helm, V.; Ercan, S.; Gramazio, F.; Kohler, M. Mobile Robotic Fabrication on Construction Sites: DimRob. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 4335–4341. [Google Scholar]

- Andres, J.; Bock, T.; Gebhart, F.; Steck, W. First Results of the Development of the Masonry Robot System ROCCO: A Fault Tolerant Assembly Tool. In Automation and Robotics in Construction Xi; Elsevier: Amsterdam, The Netherlands, 1994; pp. 87–93. ISBN 978-0-444-82044-0. [Google Scholar]

- Robots on Construction Sites: The Potential and Challenges of On-Site Digital Fabrication|Science Robotics. Available online: https://www.science.org/doi/abs/10.1126/scirobotics.aan3674 (accessed on 1 March 2025).

- Omer, S.-E. Timber Construction and Robots. In Proceedings of the New Technologies, Development and Application; Karabegović, I., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 163–169. [Google Scholar]

- Apolinarska, A.A.; Pacher, M.; Li, H.; Cote, N.; Pastrana, R.; Gramazio, F.; Kohler, M. Robotic Assembly of Timber Joints Using Reinforcement Learning. Autom. Constr. 2021, 125, 103569. [Google Scholar] [CrossRef]

- Martinez, P.; Livojevic, M.; Jajal, P.; Aldrich, D.R.; Al-Hussein, M.; Ahmad, R. Simulation-Driven Design of Wood Framing Support Systems for Off-Site Construction Machinery. J. Constr. Eng. Manag. 2020, 146, 04020075. [Google Scholar] [CrossRef]

- Kyjanek, O.; Al Bahar, B.; Vasey, L.; Wannemacher, B.; Menges, A. Implementation of an Augmented Reality AR Workflow for Human Robot Collaboration in Timber Prefabrication. In Proceedings of the 2019 36th ISARC, Banff, AB, Canada, 21–24 May 2019. [Google Scholar]

- Thoma, A.; Adel, A.; Helmreich, M.; Wehrle, T.; Gramazio, F.; Kohler, M. Robotic Fabrication of Bespoke Timber Frame Modules. In Proceedings of the Robotic Fabrication in Architecture, Art and Design 2018, Zurich, Switzerland, 10–15 September 2018; Willmann, J., Block, P., Hutter, M., Byrne, K., Schork, T., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 447–458. [Google Scholar]

- Kunic, A.; Naboni, R.; Kramberger, A.; Schlette, C. Design and Assembly Automation of the Robotic Reversible Timber Beam. Autom. Constr. 2021, 123, 103531. [Google Scholar] [CrossRef]

- Hittawe, M.M.; Sidibé, D.; Beya, O.; Mériaudeau, F. Machine Vision for Timber Grading Singularities Detection and Applications. J. Electron. Imaging 2017, 26, 063015. [Google Scholar] [CrossRef]

- Lussi, M.; Sandy, T.; Dorfler, K.; Hack, N.; Gramazio, F.; Kohler, M.; Buchli, J. Accurate and Adaptive in Situ Fabrication of an Undulated Wall Using an On-Board Visual Sensing System. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 3532–3539. [Google Scholar]

- Dörfler, K.; Sandy, T.; Giftthaler, M.; Gramazio, F.; Kohler, M.; Buchli, J. Mobile Robotic Brickwork. In Robotic Fabrication in Architecture, Art and Design 2016; Reinhardt, D., Saunders, R., Burry, J., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 204–217. ISBN 978-3-319-26378-6. [Google Scholar]

- Giftthaler, M.; Sandy, T.; Dörfler, K.; Brooks, I.; Buckingham, M.; Rey, G.; Kohler, M.; Gramazio, F.; Buchli, J. Mobile Robotic Fabrication at 1:1 Scale: The In Situ Fabricator. Constr. Robot. 2017, 1, 3–14. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D Printing for Construction Based on a Complex Wall of Polymer-Foam and Concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Subrin, K.; Bressac, T.; Garnier, S.; Ambiehl, A.; Paquet, E.; Furet, B. Improvement of the Mobile Robot Location Dedicated for Habitable House Construction by 3D Printing. IFAC-PapersOnLine 2018, 51, 716–721. [Google Scholar] [CrossRef]

- Keating, S.J. From Bacteria to Buildings: Additive Manufacturing Outside the Box. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2016. [Google Scholar]

- Gawel, A.; Siegwart, R.; Hutter, M.; Sandy, T.; Blum, H.; Pankert, J.; Kramer, K.; Bartolomei, L.; Ercan, S.; Farshidian, F.; et al. A Fully-Integrated Sensing and Control System for High-Accuracy Mobile Robotic Building Construction. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 4–8 November 2019; pp. 2300–2307. [Google Scholar]

- Buchli, J.; Giftthaler, M.; Kumar, N.; Lussi, M.; Sandy, T.; Dörfler, K.; Hack, N. Digital in Situ Fabrication—Challenges and Opportunities for Robotic in Situ Fabrication in Architecture, Construction, and Beyond. Cem. Concr. Res. 2018, 112, 66–75. [Google Scholar] [CrossRef]

- Kramberger, A.; Kunic, A.; Iturrate, I.; Sloth, C.; Naboni, R.; Schlette, C. Robotic Assembly of Timber Structures in a Human-Robot Collaboration Setup. Front. Robot. AI 2022, 8, 768038. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, Y.; Yun, X. Effect of the Dynamic Interaction on Coordinated Control of Mobile Manipulators. IEEE Trans. Robot. Autom. 1996, 12, 816–824. [Google Scholar] [CrossRef]

- High Accuracy Mobile Robotic System for Machining of Large Aircraft Components. Available online: https://www.sae.org/publications/technical-papers/content/2016-01-2139/ (accessed on 1 March 2025).

- Jiang, Z.-H. Workspace Trajectory Control of Flexible Robot Manipulators Using Neural Network and Visual Sensor Feedback. In Proceedings of the 2015 IEEE 28th Canadian Conference on Electrical and Computer Engineering (CCECE), Halifax, NS, Canada, 3–6 May 2015; pp. 1502–1507. [Google Scholar]

- Chai, H.; Wagner, H.J.; Guo, Z.; Qi, Y.; Menges, A.; Yuan, P.F. Computational Design and On-Site Mobile Robotic Construction of an Adaptive Reinforcement Beam Network for Cross-Laminated Timber Slab Panels. Autom. Constr. 2022, 142, 104536. [Google Scholar] [CrossRef]

- Tahri, O.; Usman, M.; Demonceaux, C.; Fofi, D.; Hittawe, M. Fast Earth Mover’s Distance Computation for Catadioptric Image Sequences. In Proceedings of the 2016 IEEE International Conference on Image Processing (ICIP), Phoenix, AZ, USA, 25–28 September 2016; IEEE: Phoenix, AZ, USA, 2016; pp. 2485–2489. [Google Scholar]

- Bouman, A.; Ginting, M.F.; Alatur, N.; Palieri, M.; Fan, D.D.; Touma, T.; Pailevanian, T.; Kim, S.-K.; Otsu, K.; Burdick, J.; et al. Autonomous Spot: Long-Range Autonomous Exploration of Extreme Environments with Legged Locomotion. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 2518–2525. [Google Scholar]

- Heesterman, M.; Sweet, K. Robotic Connections: Customisable Joints for Timber Construction. Blucher Des. Proc. 2018, 5, 644–652. [Google Scholar]

- Guo, H.; Song, S.; Yin, H.; Ren, D.; Zhu, X. Optimization of UWB Indoor Positioning Based on Hardware Accelerated Fuzzy ISODATA. Sci. Rep. 2024, 14, 17985. [Google Scholar] [CrossRef]

- Yang, M.; Yang, E. Two-Stage Multi-Sensor Fusion Positioning System with Seamless Switching for Cooperative Mobile Robot and Manipulator System. Int. J. Intell. Robot. Appl. 2023, 7, 275–290. [Google Scholar] [CrossRef]

- Lee, D.; Jung, M.; Yang, W.; Kim, A. LiDAR Odometry Survey: Recent Advancements and Remaining Challenges. Intell. Serv. Robot. 2024, 17, 95–118. [Google Scholar] [CrossRef]

- Analysis and Mitigation of Shared Resource Contention on Heterogeneous Multicore: An Industrial Case Study. Available online: https://arxiv.org/html/2304.13110v3 (accessed on 29 April 2025).

- López-Cerón, A.; Cañas, J.M. Accuracy Analysis of Marker-Based 3D Visual Localization. 2016. Available online: https://ruc.udc.es/dspace/bitstream/handle/2183/29246/2016_LopezCeron_Alberto_Accuracy-analysis-marker-3D-visual-localization.pdf?sequence=3&isAllowed=y (accessed on 25 March 2025).

- Tan, S.; Srinivasaragavan, A.; Iturralde, K.; Holst, C. Enhanced Precision in Built Environment Measurement: Integrating AprilTags Detection with Machine Learning. In Proceedings of the 2024 Proceedings of the 41st ISARC, Lille, France, 3–5 June 2024. [Google Scholar]

- Shi, X.; Wang, C.; Phillips, T.K.; Sun, C.; Zhou, H.; Zhao, W.; Cui, W.; Wan, D. Research on Positioning and Simulation Method for Autonomous Mobile Construction Platform. Buildings 2024, 14, 1196. [Google Scholar] [CrossRef]

| Scheme | Typical Planar Accuracy * | Update Rate | Environmental Dependence | Main Advantages/Disadvantages |

|---|---|---|---|---|

| UWB + IMU fusion | 5–10 cm (LOS) | 100–200 Hz | Anchors must be deployed; NLOS error ↑ | Low cost; independent of lighting/texture; NLOS bias can be suppressed by IMU [49] |

| FMS marker-based vision (end effector) | ≤5 mm @ 1.2 m | 30–120 Hz | Markers must remain in view | Sub-millimeter precision at close range; affected by occlusion and illumination; complements UWB/IMU [50] |

| LiDAR-inertial odometry/LiDAR-SLAM | 2–5 cm ATE (indoor datasets) | 10–30 Hz | Requires dense point clouds; vulnerable to strong reflections or dust/fog | Insensitive to lighting; drift accumulates over distance; LiDAR is expensive and computation-intensive [51] |

| Vision/visual-inertial SLAM | ≈3 cm ATE (EuRoC, OVSLAM) | 20–100 Hz | Sensitive to lighting/texture; dynamic scenes may cause failures | Camera-only hardware; mature open-source software; can lose tracking under low-feature or lighting changes [52] |

| Error Type | Mean | Std. Dev. | RMSE |

|---|---|---|---|

| EX | −0.13 | 0.31 | 0.34 |

| EY | −0.39 | 0.25 | 0.46 |

| EZ | 0.51 | 0.76 | 0.91 |

| ED | 1.01 | 0.38 | 1.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, K.; Shi, X.; Wan, D.; Zhou, H.; Zhao, W.; Sun, C.; Du, P.; Fukuda, H. Research on Automated On-Site Construction of Timber Structures: Mobile Construction Platform Guided by Real-Time Visual Positioning System. Buildings 2025, 15, 1594. https://doi.org/10.3390/buildings15101594

Bi K, Shi X, Wan D, Zhou H, Zhao W, Sun C, Du P, Fukuda H. Research on Automated On-Site Construction of Timber Structures: Mobile Construction Platform Guided by Real-Time Visual Positioning System. Buildings. 2025; 15(10):1594. https://doi.org/10.3390/buildings15101594

Chicago/Turabian StyleBi, Kang, Xinyu Shi, Da Wan, Haining Zhou, Wenxuan Zhao, Chengpeng Sun, Peng Du, and Hiroatsu Fukuda. 2025. "Research on Automated On-Site Construction of Timber Structures: Mobile Construction Platform Guided by Real-Time Visual Positioning System" Buildings 15, no. 10: 1594. https://doi.org/10.3390/buildings15101594

APA StyleBi, K., Shi, X., Wan, D., Zhou, H., Zhao, W., Sun, C., Du, P., & Fukuda, H. (2025). Research on Automated On-Site Construction of Timber Structures: Mobile Construction Platform Guided by Real-Time Visual Positioning System. Buildings, 15(10), 1594. https://doi.org/10.3390/buildings15101594