Embodied Carbon Premium for Cantilevers

Abstract

1. Introduction

1.1. Aim and Scope

1.2. Notions and Definitions

1.3. Structure of the Paper

2. Cantilevers in Buildings

2.1. Literature Review

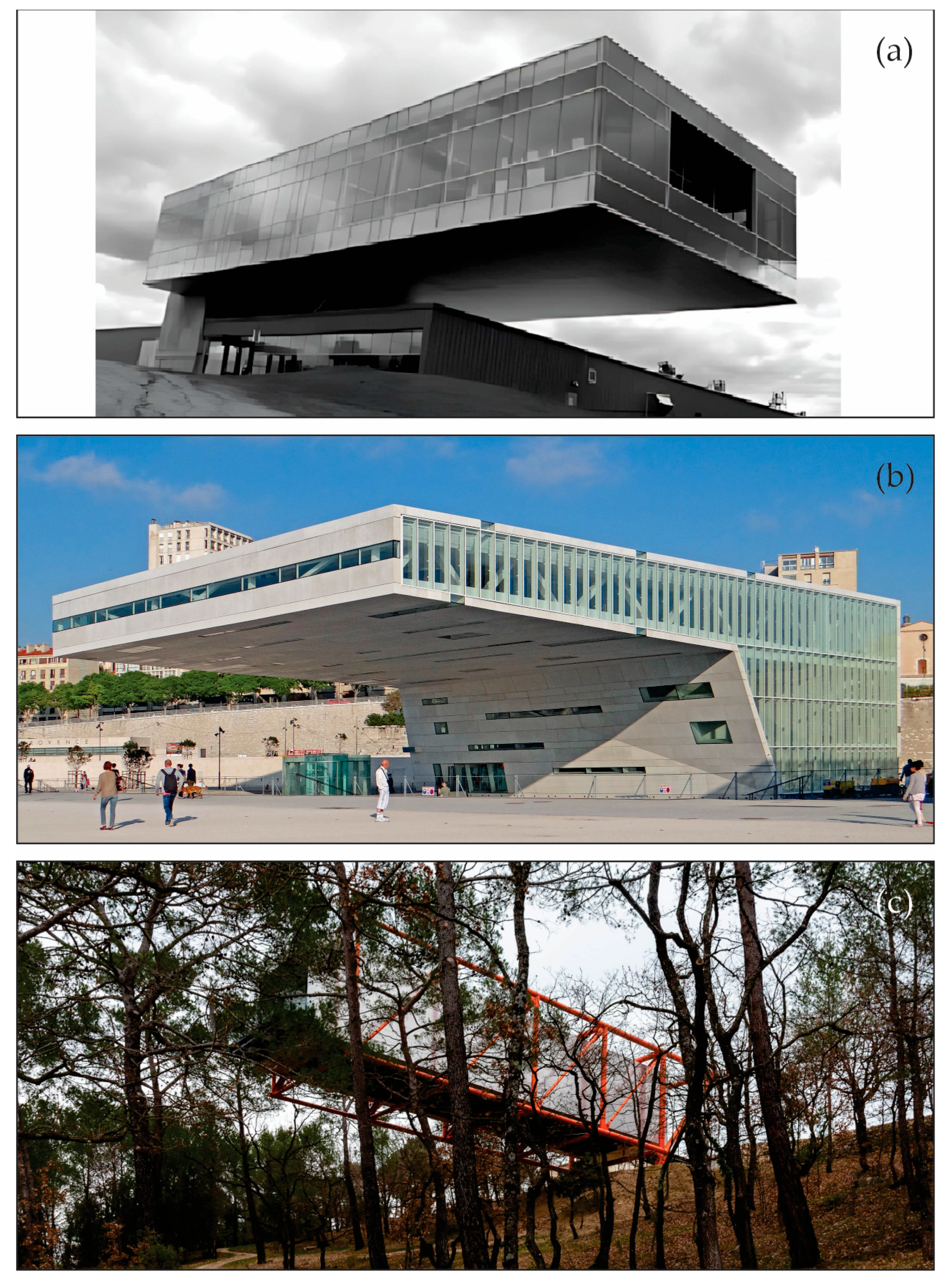

2.2. Cantilevers as an Architectural Trend

3. Melbourne School of Design Building: A Case Study

3.1. Design Intention

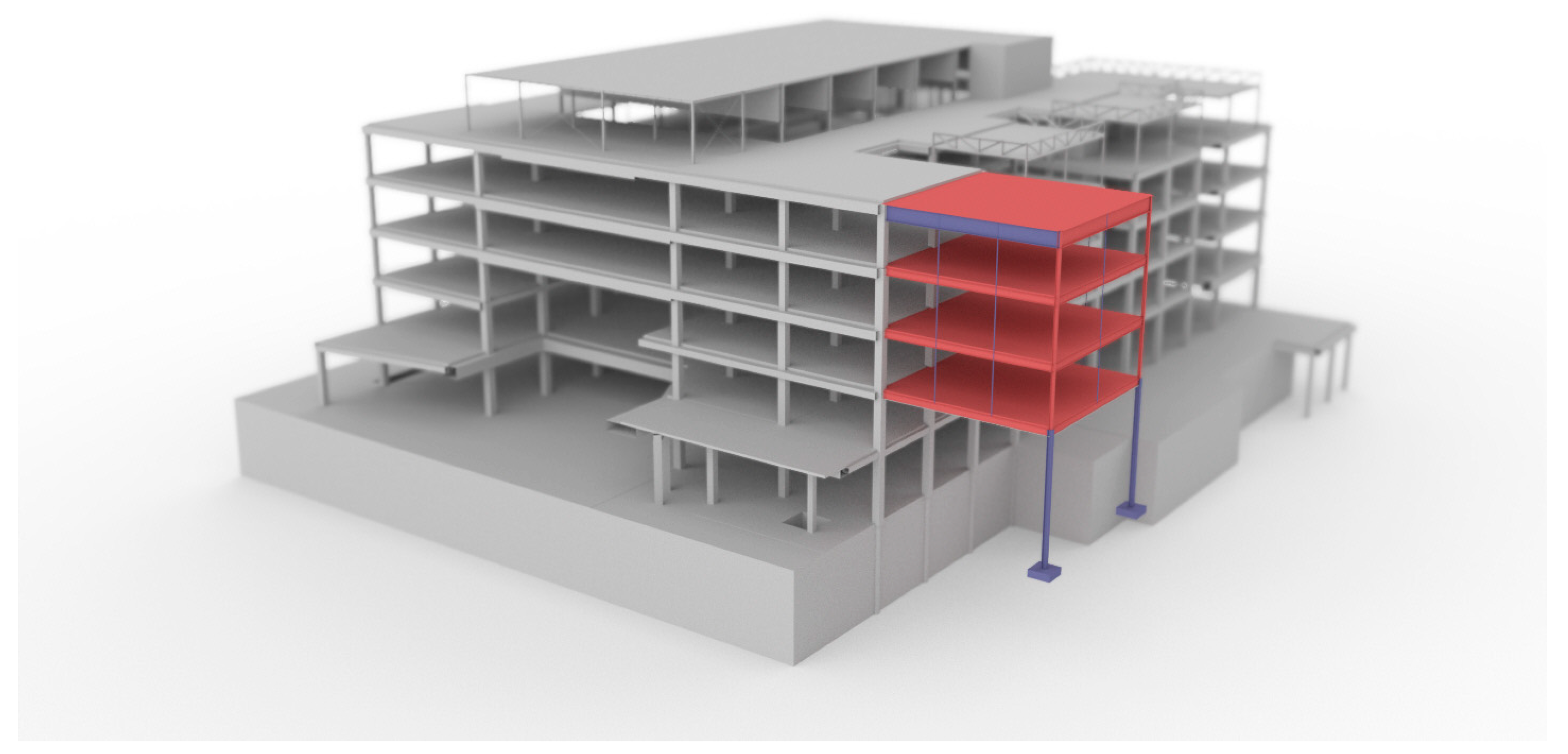

3.2. Description of the MSD Building’s Structural System

4. Research Method

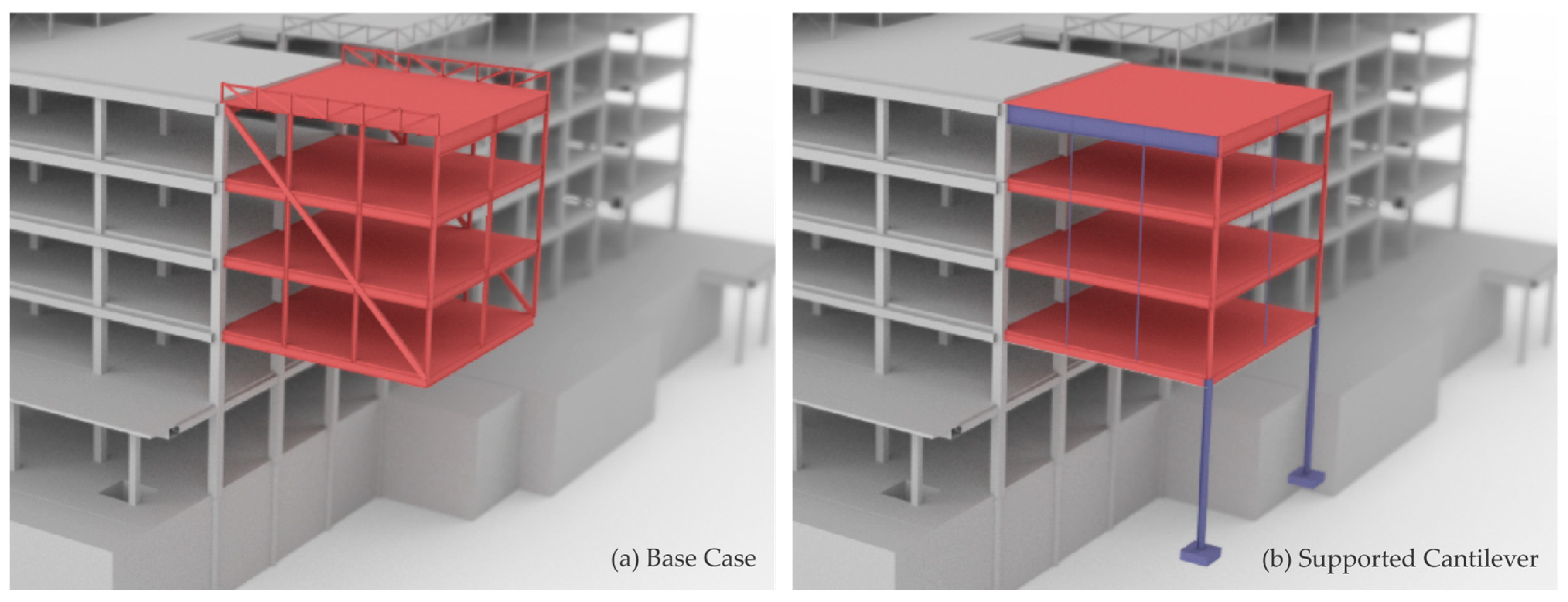

4.1. Design Scenarios

4.2. Structural Modelling

- Adjustments were made to account for the net changes in the volumes of structural steel, ensuring an accurate reflection of modifications from the base case to the alternative design.

- Modifications in the volumes of reinforced concrete elements were calculated. This included accounting for the corresponding steel reinforcement and post-tensioning tendons, with adherence to specifications from structural drawings and employing average reinforcing rates for each structural element type.

- The elimination of the cantilever removed the necessity to counteract a significant tension force within the lateral system. Consequently, the flat post-tensioned tendons on Storey 5, previously compensating for this force, were excluded from the total material volume.

- Axial demand variations for all reinforced concrete columns were analysed between the two design options, using data from the structural models. Adjustments in the column sectional areas were made based on these demand changes, accurately reflecting increases or decreases in the total concrete volume.

- For the two remaining reinforced concrete cores, analyses of bending, shear, and torsion variations between the design options were conducted. This led to adjustments in the quantities of steel reinforcement required to meet the new demands. Bending moments were addressed by reconfiguring them into tension–compression couples in each direction, with the variation in force accounted for by the addition or subtraction of reinforcing steel. The shear design provisions of AS3600 [59] were employed to calculate the necessary adjustments in transverse reinforcement for the shear and torsion demands.

4.3. Quantifying the Embodied Carbon of the MSD Building’s Structural System

- The process analysis approach, which represents a bottom-up approach that studies the series of processes that, together, form the life cycle of a product or service. This detailed analysis, while offering high precision, might not encompass the entirety of complex supply chains, potentially leading to an underestimation of embodied carbon due to systemic incompleteness and various forms of truncation, including upstream, downstream, and sideways truncation [61];

- Environmentally extended input–output (EEIO) analysis offers a macro-economic perspective, correlating financial transactions with physical material flows [62,63]. It integrates data from economic input–output tables with environmental metrics, thereby enabling the quantification of environmental impacts throughout intricate supply chains. This method, while comprehensive, may lack the detail required to distinguish between different actors within an industry or products within a product group;

- Hybrid analysis, which merges process data with EEIO data to ensure both specificity and comprehensiveness in the analysis of products or services [64].

5. Results

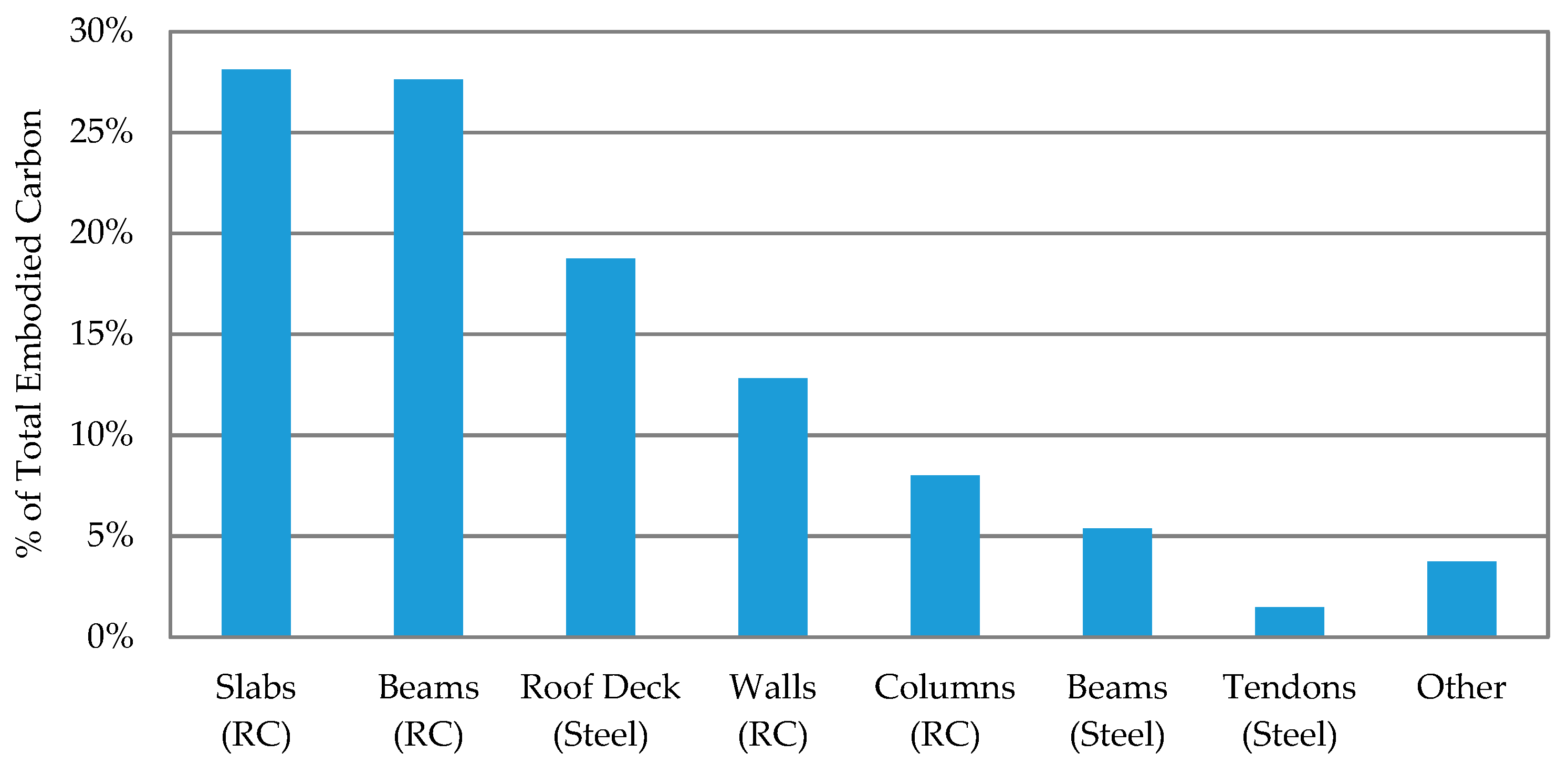

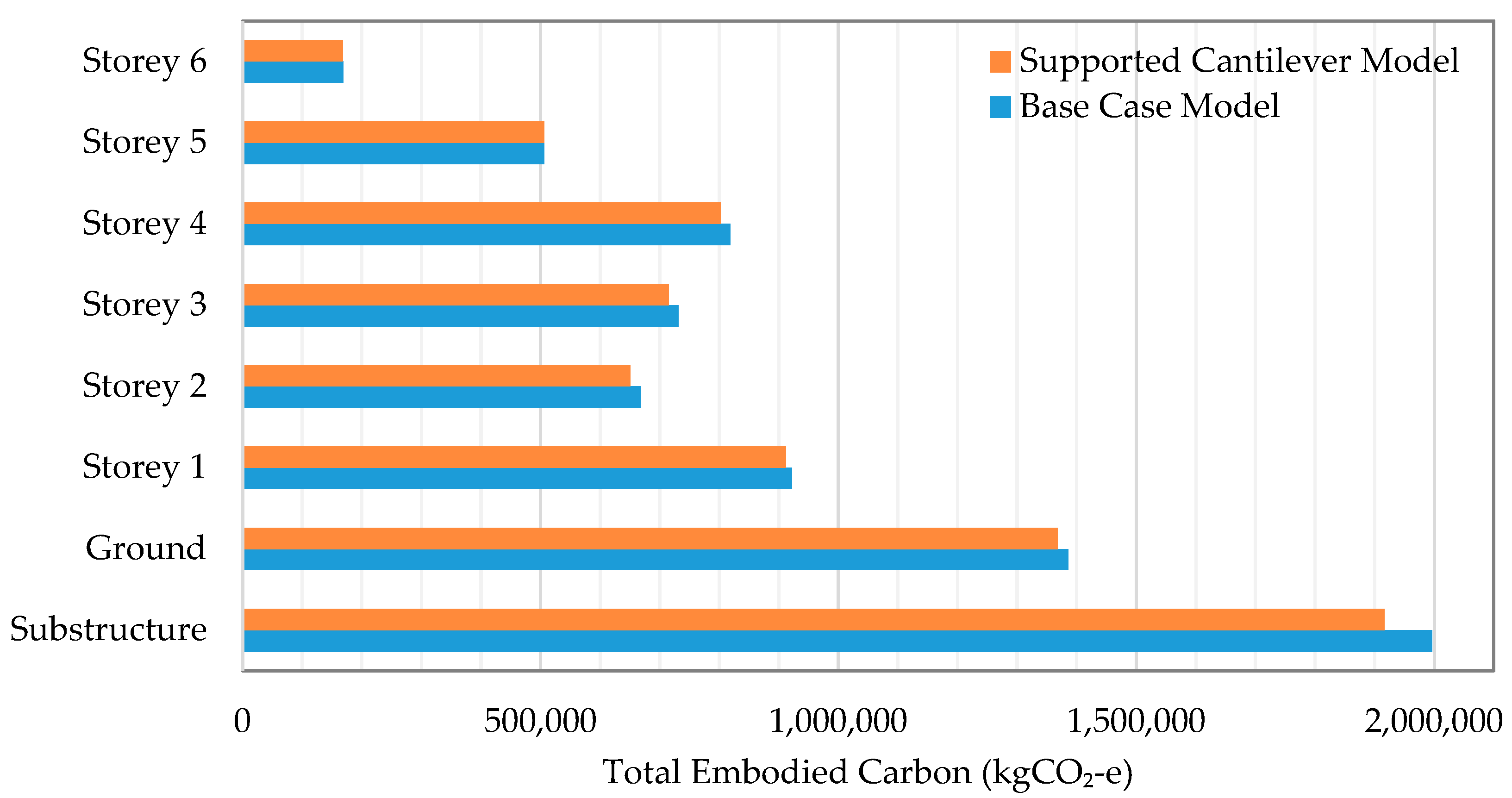

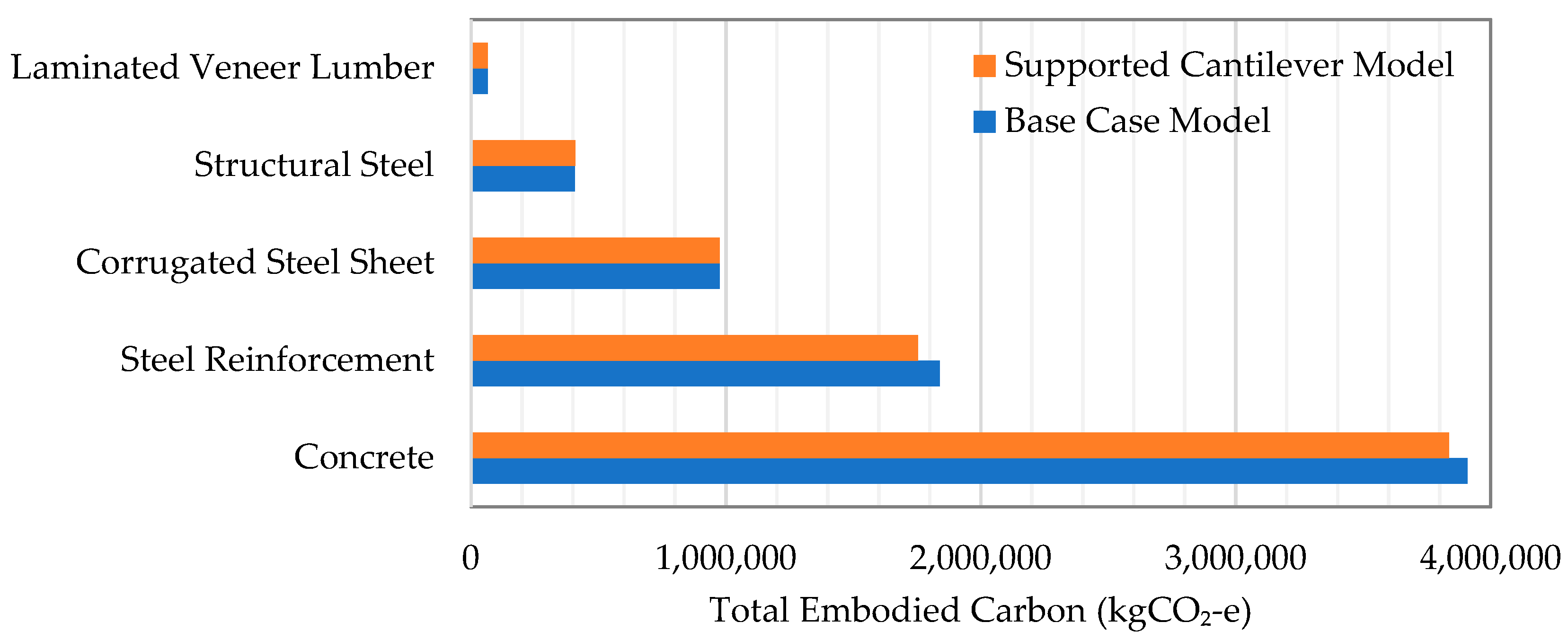

5.1. Embodied Carbon of the Base Case Model of the MSD Building’s Structural System

5.2. Embodied Carbon of the Supported Cantilever Model of the MSD Building’s Structural System

5.3. Influence of Life Cycle Inventory Analysis Approaches on the Embodied Carbon Premium for Cantilevers

6. Discussion

7. Implications and Significance of the Research

7.1. Implications for Design Practitioners

7.2. Implications for Design Pedagogues

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hoesung, L.; Katherine, C.; Dipak, D.; Gerhard, K.; Aditi, M.; Peter, T.; Christopher, T.; José, R.; Paulina, A.; Ko, B.; et al. Climate Change 2023: Synthesis Report, in Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland, 2023; pp. 35–115. [Google Scholar]

- UNEP. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; Dean, B., Dulac, J., Petrichenko, K., Graham, P., Eds.; United Nations Environment Programme: Nairobi, Kenya, 2022. [Google Scholar]

- Crawford, R.H.; Treloar, G. Validation of the use of Australian input-output data for building embodied energy simulation. In IBPSA 2003, Proceedings of the Eighth International Building Performance Simulation Association Conference on Building Simulation: For better Building Design, Eindhoven, The Netherlands, 11–14 August 2003; IBPSA: Toronto, ON, Canada, 2003. [Google Scholar]

- Dixit, M.K.; Fernández-Solís, J.L.; Lavy, S.; Culp, C.H. Identification of parameters for embodied energy measurement: A literature review. Energy Build. 2010, 42, 1238–1247. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings–The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- World Green Building Council. Bringing embodied carbon upfront. In Advancing Net. Zero; World Green Building Council: London, UK, 2019; p. 35. [Google Scholar]

- Helal, J. Towards a comprehensive framework for integrating embodied environmental flow assessment into the structural design of tall buildings. In Faculty of Architecture, Building and Planning; University of Melbourne: Melbourne, Australia, 2022. [Google Scholar]

- Dario, T.; Antony, W.; Olivier, V.; Nicoleta, P.; Donald, W.D. Life Cycle Assessment of Tall Building Structural Systems; CTBUH: Chicago, IL, USA, 2015. [Google Scholar]

- Foraboschi, P.; Mercanzin, M.; Trabucco, D. Sustainable structural design of tall buildings based on embodied energy. Energy Build. 2014, 68, 254–269. [Google Scholar] [CrossRef]

- Moussavi Nadoushani, Z.S.; Akbarnezhad, A. Effects of structural system on the life cycle carbon footprint of buildings. Energy Build. 2015, 102, 337–346. [Google Scholar] [CrossRef]

- Du, P.; Wood, A.; Stetphens, B.; Song, X. Life-cycle energy implications of downtown high-rise vs. suburban low-rise living: An overview and quantitative case study for Chicago. Buildings 2015, 5, 1003–1024. [Google Scholar] [CrossRef]

- Helal, J.; Stephan, A.; Crawford, R.H. The influence of life cycle inventory approaches on the choice of structural systems to reduce the embodied greenhouse gas emissions of tall buildings. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032028. [Google Scholar] [CrossRef]

- Helal, J.; Stephan, A.; Crawford, R.H. The influence of structural design methods on the embodied greenhouse gas emissions of structural systems for tall buildings. Structures 2020, 24, 650–665. [Google Scholar] [CrossRef]

- Mavrokapnidis, D.; Mitropoulou, C.C.; Lagaros, N.D. Environmental assessment of cost optimized structural systems in tall buildings. J. Build. Eng. 2019, 24, 100730. [Google Scholar] [CrossRef]

- Norman, J.; MacLean, H.L.; Kennedy, C.A. Comparing High and Low Residential Density: Life-Cycle Analysis of Energy Use and Greenhouse Gas Emissions; American Society of Civil Engineers: Reston, VA, USA, 2006; p. 10. [Google Scholar]

- Treloar, G.J.; Fay, R.; Ilozor, B.; Lovet, P. An analysis of the embodied energy of office buildings by height. Facilities 2001, 19, 204. [Google Scholar] [CrossRef]

- Helal, J.; Stephan, A.; Crawford, R.H. Integrating embodied greenhouse gas emissions assessment into the structural design of tall buildings: A framework and software tool for design decision-making. Energy Build. 2023, 297, 113462. [Google Scholar] [CrossRef]

- Helal, J.; Mehdipanah, A.; Stephan, A.; Lumantarna, E.; Crawford, R.H. Embodied greenhouse gas emissions of structural systems for tall buildings: Is there a premium for plan irregularity? In Architectural Science and User Experience: How Can Design Enhance the Quality of Life, Proceedings of the 55th International Conference of the Architectural Science Association 2022, Perth, Australia, 1–2 December 2022; Izadpanahi, P., Perugia, F., Eds.; Curtin University: Perth, Australia, 2022; pp. 273–283. [Google Scholar]

- Brown, N.C.; Mueller, C.T. Design for structural and energy performance of long span buildings using geometric multi-objective optimization. Energy Build. 2016, 127, 748–761. [Google Scholar] [CrossRef]

- Khan, F.R. Current trends in concrete high-rise buildings. In Symposium on Tall Buildings with Particular Reference to Shear Wall Structures; Pergamon: Southampton, UK, 1967; pp. 571–590. [Google Scholar]

- Allacker, K. Sustainable building: The development of an evaluation method. Diss. Abstr. Int. 2010, 71, 420. [Google Scholar]

- Oregi, X.; Hernandez, P.; Gazulla, C.; Isasa, M. Integrating Simplified and Full Life Cycle Approaches in Decision Making for Building Energy Refurbishment: Benefits and Barriers. Buildings 2015, 5, 354–380. [Google Scholar] [CrossRef]

- EN 15978:2011; Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. European Committee for Standardization, BSI Standards: London, UK, 2011.

- Gibbons, O.; Orr, J. How to Calculate Embodied Carbon; The Institution of Structural Engineers: London, UK, 2022; pp. 1–68. [Google Scholar]

- Dahlstrøm, O.; Sørnes, K.; Eriksen, S.T.; Hertwich, G. Life cycle assessment of a single-family residence built to either conventional- or passive house standard. Energy Build. 2012, 54, 470–479. [Google Scholar] [CrossRef]

- Crowther, P. Design for disassembly to recover embodied energy. In Proceedings of the 16th Annual Conference on Passive and Low Energy Architecture, Brisbane, Australia, 22–24 September 1999; PLEA: Melbourne, Australia; Brisbane, Australia; Cairns, Australia, 1999. [Google Scholar]

- Winistorfer, P.; Chen, Z.; Lippke, B.; Stevens, N. Energy consumption and greenhouse gas emissions related to the use, maintenance, and disposal of a residential structure. Wood Fiber Sci. 2007, 37, 128–139. [Google Scholar]

- Petroski, H. Engineering: The Cantilever. Am. Sci. 2007, 95, 394–397. [Google Scholar] [CrossRef]

- Moon, K.S. Cantilever Architecture; Routledge: New York, NK, USA, 2019; p. 266. [Google Scholar]

- Fang, D.; Brown, N.; Det Wolf, C.; Mueller, C. Reducing embodied carbon in structural systems: A review of early-stage design strategies. J. Build. Eng. 2023, 76, 107054. [Google Scholar] [CrossRef]

- Basbagill, J.; Flager, F.; Letpech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Gauch, H.L.; Hawkins, W.; Ibell, T.; Allwood, J.; Dunant, C. Carbon vs. cost option mapping: A tool for improving early-stage design decisions. Autom. Constr. 2022, 136, 104178. [Google Scholar] [CrossRef]

- Hawkins, W.; Peters, A.; Mander, T. A weight off your mind: Floor loadings and the climate emergency. Struct. Eng. 2021, 99, 18–20. [Google Scholar] [CrossRef]

- RJC Engineers, Embodied Carbon in Residential Structures a Toronto Based Case Study; RJC Engineers: Vancouver, BC, Canada, 2023; p. 13.

- Srinivas, S.; Tiffin, C.; Wingo, L.; Yang, F. Embodied carbon reduction roadmap–Strategies and policies for the state of California. ARUP 2023, 1, 14. [Google Scholar]

- Llago Acero, R.; García Rodríguez, P. El Centro de Diseño de Barcelona. Hormigón Y Acero 2015, 66, 55–67. [Google Scholar] [CrossRef]

- Setareh, M.; Asce, M. Vibrations due to Walking in a Long-Cantilevered Office Building Structure. J. Perform. Constr. Facil. 2012, 26, 255–270. [Google Scholar] [CrossRef]

- Safdie, M. Case Study, Marina Bay Sands, Singapore. CTBUH J. 2011, 2011, 12–17. [Google Scholar]

- McCafferty, P.; Brodkin, D.; Farnsworth, D.; Scott, D. Engineering an Icon–The Marina Bay Sands Integrated Resort. In Structure; National Council of Structural Engineers Associations: Chicago, IL, USA; ASCE’s Structural Engineering Institute: Reston, VA, USA; Council of American Structural Engineers: New York, NY, USA, 2011; pp. 29–33. [Google Scholar]

- Beydoun, K.H.; Hussein, J.; Salamet, A. Power of cantilever design in the contemporary architecture. Arch. Plan. J. 2021, 27, 1. [Google Scholar] [CrossRef]

- Guinness World Records. Longest Cantilever Roof. 2011; Busan Metropolitan City, Coop Himmelb(l)lau|Wolf d. Prix/w. Dreibholz & Partner Zt Gmbh Prix. Available online: https://www.guinnessworldrecords.com/world-records/longest-cantilever-roof#:~:text=The%20roof%20of%20the%20Busan,weighs%206%2C376%20(metric)%20tons (accessed on 6 February 2024).

- Guinness World Records. Tallest Cantilevered Building. 2019 Central Park Tower, Extell Development Company. Available online: https://www.guinnessworldrecords.com/world-records/69359-tallest-cantilevered-building#:~:text=The%20tallest%20cantilevered%20building%20is,88%20m%20(290%20ft) (accessed on 6 February 2024).

- Setareh, M.; Lovelace, M. Vibration Analysis and Design of a Structure Subjected to Human Walking Excitations. Shock. Vib. 2010, 17, 257173. [Google Scholar] [CrossRef]

- Dalbéra, J.-P. La Villa Méditerranée (Marseille). 2014. Available online: https://www.flickr.com/photos/dalbera/14043594049 (accessed on 6 February 2024).

- Poggi, J Richard Rogers Gallery, Château La Coste. 2022. Available online: https://www.flickr.com/photos/jacqueline_poggi/51938956327 (accessed on 6 February 2024).

- The University of Melbourne. The University of Melbourne Strategic Plan: Growing Esteem; The University of Melbourne: Melbourne, VIC, Australia, 2015; pp. 1–32. [Google Scholar]

- The University of Melbourne. MSD Building Architectural Design Competition. 2014. Available online: https://msd.unimelb.edu.au/about/msd-building/competition (accessed on 5 February 2024).

- Monahan, T. Flexible space & built pedagogy: Emerging IT embodiments. Inventio 2002, 4, 1–19. [Google Scholar]

- Elkington, S.; Bligh, B. Future Learning Spaces: Space, Technology and Pedagogy. Ph.D. Thesis, University of York, Heslington, UK, 2019; pp. 1–69. [Google Scholar]

- Luz, A. The [design of] educational space: A process-centred built pedagogy. In DS 46, Proceedings of the E&PDE 2008, the 10th International Conference on Engineering and Product Design Education, Barcelona, Spain, 4–5 September 2008; Universitat Politecnica de Catalunya: Barcelona, Spain, 2008. [Google Scholar]

- Oblinger, D. Learning Spaces; Educause: Washington, DC, USA, 2006; Volume 444. [Google Scholar]

- University of Auckland. Sir. Owen G. Glenn Building. 2018. Available online: https://www.auckland.ac.nz/en/business/about-business-school/our-faculty/oggb.html (accessed on 5 February 2024).

- Gardiner, B.; Charing, S.; Mullumby, N.; Kealy, K. Built pedagogy and architectural design in the architecture library of the Melbourne School of Design. In Proceedings of the Architectural Science Association (ANZAScA) 2015 Conference 49th International Conference of the Architectural Science Association: Living and Learning-Research for a Better Built Environment, Melbourne, Australia, 2–4 December 2015. [Google Scholar]

- Sturm, S.; Turner, S. Life and Death and the University. Crit. Educ. 2020, 11, 1–13. [Google Scholar]

- Hermon, P.; Hayndes, R. Review of Life Cycle Assessment–Faculty of Architecture, Building and Planning; University of Melbourne, eTool PTY LTD: Melbourne, VIC, Australia, 2014; pp. 1–102. [Google Scholar]

- Computers and Structures Inc. ETABS. 2018. Available online: https://www.csiamerica.com/products/etabs/releases#17-17.0.0 (accessed on 10 December 2019).

- AS/NZS: 1170.2:2002; AS/NZS 1170.2:2002–Structural Design Actions: Wind Actions. Standards Australia International: Wellington, Sydney, 2002.

- AS/NZS 1170.0:2002-AS/NZS 1190.3:2003; AS/NZS 1170.4:2002: Structural Design Actions: Earthquake Actions. Standards Australia International: Sydney, Australia; Standards New Zealand: Wellington, New Zealand, 2011.

- AS 3600-2009; AS 3600-2009–Concrete Structures. 4th ed. Standards Australia: Homebush, Australia, 2009.

- AS 4100-1998; AS 4100-1998–Steel Structures. Standards Australia: Homebush, Australia, 1998.

- Crawford, R.H. Validation of a hybrid life-cycle inventory analysis method. J. Environ. Manag. 2008, 88, 496–506. [Google Scholar] [CrossRef]

- Leontief, W.W. Quantitative Input and Output Relations in the Economic Systems of the United States. Rev. Econ. Stat. 1936, 18, 105–125. [Google Scholar] [CrossRef]

- Lenzen, M. Errors in Conventional and Input-Output-based Life-Cycle Inventories. J. Ind. Ecol. 2000, 4, 127–148. [Google Scholar] [CrossRef]

- Crawford, R.H.; Bontinck, P.-A.; Stetphan, A.; Wiedmann, T.; Yu, M. Hybrid life cycle inventory methods—A review. J. Clean. Prod. 2018, 172, 1273–1288. [Google Scholar] [CrossRef]

- Treloar, G.J. Extracting Embodied Energy Paths from Input–Output Tables: Towards an Input–Output-based Hybrid Energy Analysis Method. Econ. Syst. Res. 1997, 9, 375–391. [Google Scholar] [CrossRef]

- Lenzen, M.; Crawford, R.H. The Path Exchange Method for Hybrid LCA. Environ. Sci. Technol. 2009, 43, 8251–8256. [Google Scholar] [CrossRef]

- Stephan, A.; Crawford, R.H.; Bontinck, P.-A. A model for streamlining and automating path exchange hybrid life cycle assessment. Int. J. Life Cycle Assess. 2019, 24, 237–252. [Google Scholar] [CrossRef]

- Crawford, R.H.; Stephan, A.; Prideaux, F. The EPiC database: Hybrid embodied environmental flow coefficients for construction materials. Resour. Conserv. Recycl. 2022, 180, 106058. [Google Scholar] [CrossRef]

- Robati, M.; Oldfield, P.; Netzhad, A.A.; Carmichael, D.G.; Kuru, A. Carbon value engineering: A framework for integrating embodied carbon and cost reduction strategies in building design. Build. Environ. 2021, 192, 107620. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy Build. 2017, 155, 404–413. [Google Scholar] [CrossRef]

- Moré, F.B.; Galindro, B.M.; Soares, S.R. Assessing the completeness and comparability of environmental product declarations. J. Clean. Prod. 2022, 375, 133999. [Google Scholar] [CrossRef]

- Structural Engineering Institute. Committing to Net. Zeo. 2019. Available online: https://se2050.org/ (accessed on 3 March 2021).

- Ministère de la Transition écologique and M.d.l.C.d. Territoires. Bâtiments à Energie Positive & Réduction Carbone. 2018. Available online: http://www.batiment-energiecarbone.fr/ (accessed on 3 March 2021).

- Ministerie van Binnenlandse Zaken en Koninkrijksrelaties. Bouwbesluit Online 2012. Available online: https://rijksoverheid.bouwbesluit.com/ (accessed on 3 March 2021).

- Ympäristöministeriö. Vähähiilisen Rakentamisen Tiekartta. 2017. Available online: https://ym.fi/vahahiilisen-rakentamisen-tiekartta (accessed on 3 March 2021).

- Architects Accreditation Council of Australia. National Standard of Competency for Architects 2021; Architects Accreditation Council of Australia: New South Wales, Australia, 2021; pp. 1–9. [Google Scholar]

| Storey | Embodied Carbon (kgCO2-e) | % of Total |

|---|---|---|

| Substructure 1 | 1,996,349 | 27.7% |

| Ground storey | 1,385,976 | 19.3% |

| Storey 1 | 921,626 | 12.8% |

| Storey 2 | 667,851 | 9.3% |

| Storey 3 | 731,959 | 10.2% |

| Storey 4 | 818,803 | 11.4% |

| Storey 5 | 506,310 | 7.0% |

| Roof | 168,732 | 2.3% |

| Material | Embodied Carbon (kgCO2-e) | % of Total |

|---|---|---|

| Concrete | 3,909,356 | 54.3% |

| Steel Reinforcement 1 | 1,839,523 | 25.6% |

| Corrugated Steel Sheet | 974,993 | 13.5% |

| Structural Steel | 407,334 | 5.7% |

| Laminated Veneer Lumber | 66,401 | 0.9% |

| Structural Subsystem | Embodied Carbon (kgCO2-e) | % of Total |

|---|---|---|

| Cantilever | 191,995 | 2.7% |

| Rest of Structural System | 7,005,612 | 97.3% |

| Element Type | Embodied Carbon (kgCO2-e) | %Δ |

|---|---|---|

| Walls (RC) | 508,111 | −23.8% |

| Beams (Steel) | 1,475,485 | +5.2% |

| Beams (RC) | 974,993 | +2.7% |

| Columns (RC) | 424,453 | +1.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helal, J.; Trabucco, D.; Ruggiero, D.; Miglietta, P.; Perrucci, G. Embodied Carbon Premium for Cantilevers. Buildings 2024, 14, 871. https://doi.org/10.3390/buildings14040871

Helal J, Trabucco D, Ruggiero D, Miglietta P, Perrucci G. Embodied Carbon Premium for Cantilevers. Buildings. 2024; 14(4):871. https://doi.org/10.3390/buildings14040871

Chicago/Turabian StyleHelal, James, Dario Trabucco, David Ruggiero, Paola Miglietta, and Giovanni Perrucci. 2024. "Embodied Carbon Premium for Cantilevers" Buildings 14, no. 4: 871. https://doi.org/10.3390/buildings14040871

APA StyleHelal, J., Trabucco, D., Ruggiero, D., Miglietta, P., & Perrucci, G. (2024). Embodied Carbon Premium for Cantilevers. Buildings, 14(4), 871. https://doi.org/10.3390/buildings14040871