A Comprehensive Review of the Advances, Manufacturing, Properties, Innovations, Environmental Impact and Applications of Ultra-High-Performance Concrete (UHPC)

Abstract

1. Introduction

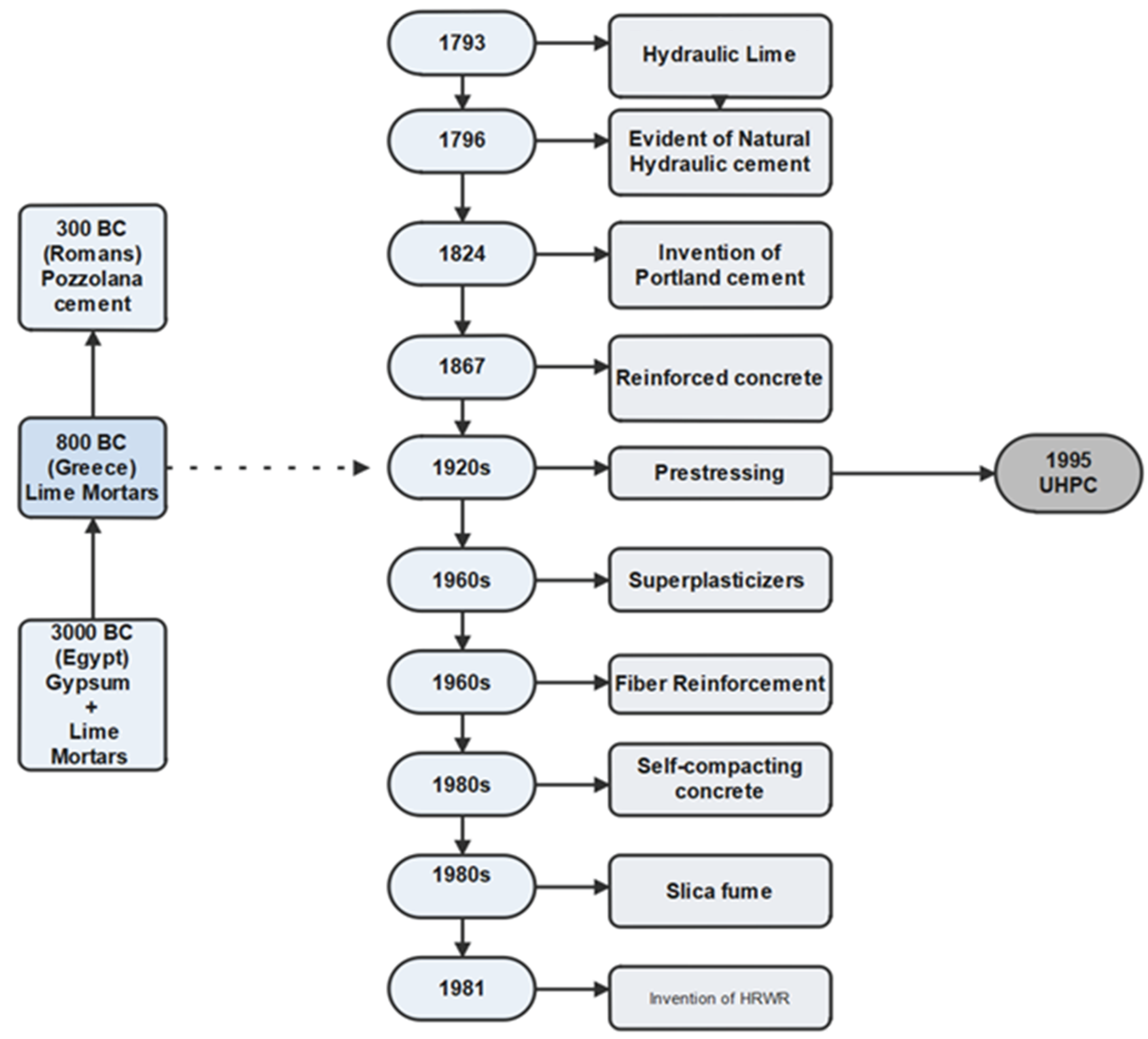

History of UHPC

2. Manufacturing and Design of UHPC

2.1. Composition of UHPC

- Low Water-Cement Ratio. Maintaining a very low water-cement ratio, typically between 0.20 to 0.25, is crucial. This helps in achieving a compact and robust structure through hydration. The low ratio reduces capillary pores, enhances ductility and prevents brittle collapse.

- High Particle Packing Density. Utilizing fine binder materials promotes high particle packing density, minimizing water demand in the fresh mixture. This not only improves compressive strength but also influences the brittleness of the concrete.

- Optimal Superplasticizer Dosage. Employing a high dose of superplasticizer is essential for regulating the workability of UHPC. This ensures that the concrete is sufficiently workable while maintaining the desired properties.

- Use of Fibres. Incorporating fibres serves the purpose of inducing tension and bending tension in the UHPC. This, in turn, increases shear strength and imparts the necessary ductility to the concrete.

- Binder materials;

- Aggregates;

- Fibres;

- Chemical admixtures.

2.1.1. Binder Materials

Portland Cement

Silica Fume

Rice Husk

Fly Ash

Granulated Blast Furnace Slag (GGBFS)

Glass Powder

Metakaolin

2.1.2. Aggregates

- The shape and angularity of coarse aggregates reduce the packing density of the concrete.

- The concentration of stress at the contact points between aggregates has the potential to create vulnerabilities in the concrete matrix.

- The interfacial transition zone (ITZ) between coarse aggregates and the UHPC matrix is weaker compared to the ITZ between sand and the UHPC matrix [25].

2.1.3. Fibres

2.1.4. Chemical Admixtures

2.2. Design Methodology

2.2.1. Dry Particle Packing Method

2.2.2. Wet Particle Packing Method

- Assume the initial W/B.

- Weigh the water and binder materials and mix them.

- Pour the paste into a cylindrical mould and weigh.

- Calculate the solid concentration (Φ) and void ratio (u) form the Equations (2)–(4).

- Achieve the maximum packing density by repetitions of above steps.

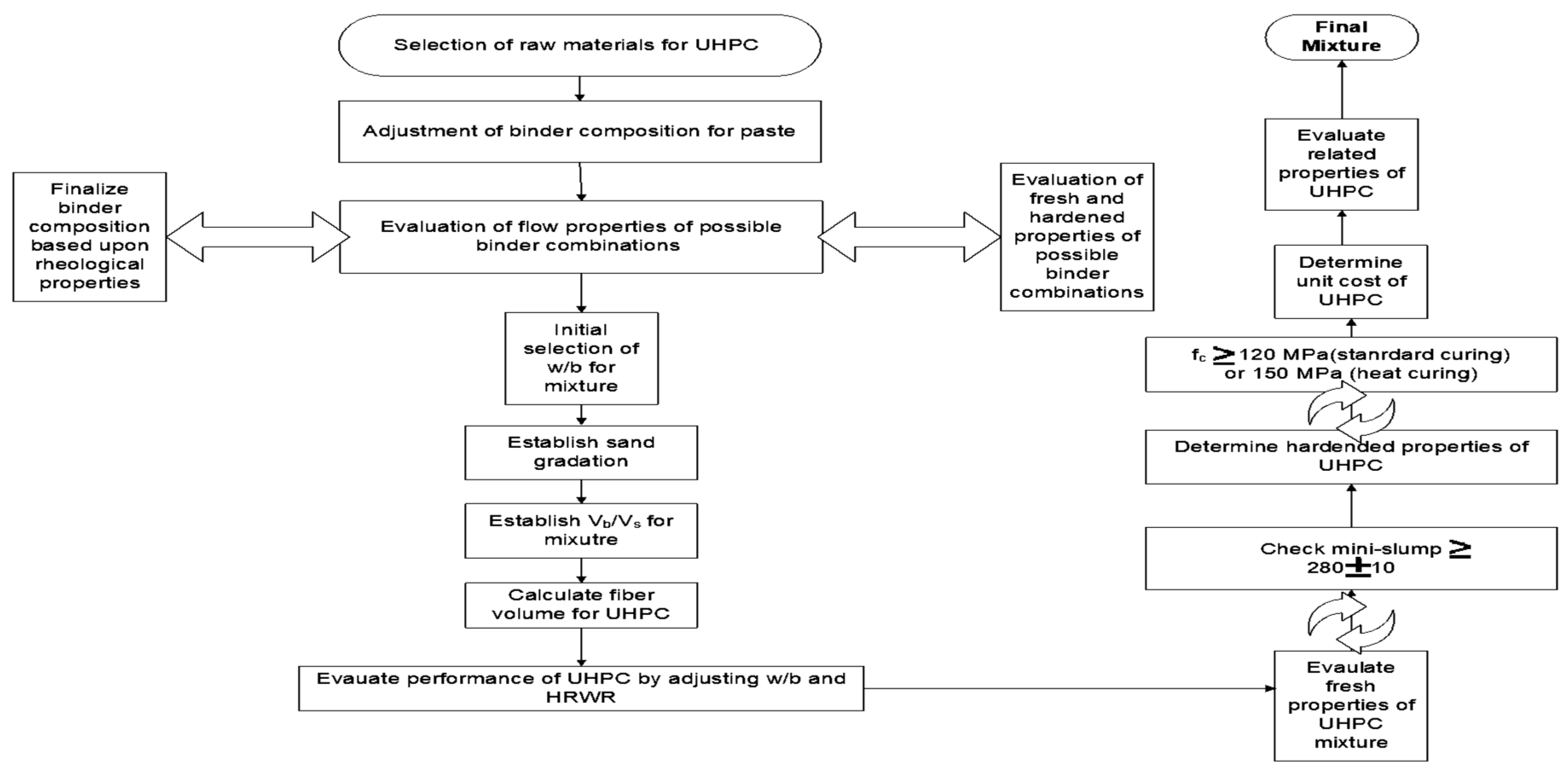

2.2.3. Performance Based Method

- Select binder materials based on the flow properties of the paste.

- Consider material combinations in terms of particle packing, flowability and mechanical properties.

- Evaluate rheological properties, such as plastic viscosity (μp) and yield stress (τ0), to confirm the composition of the mix.

- Determine the workability and compressive strength as key properties to determine the w/b ratio for the mix.

- Use the modified Andreasen and Andersen model to determine the sand gradation, calculate the ratio between the volume of the primary paste and the sand volume of the mortar, and compute the steel fibre content.

- Finalize making UHPC concrete mix as per the given instructions.

3. Production

- Mixing of all dry materials for about 10 min.

- Add water and superplasticizer into dry mixture and mix for approximately 5–10 min.

- Fibres are added if required.

- Finish the mixing when mixture shows enough flowability for good workability and sufficient viscosity.

3.1. Sampling

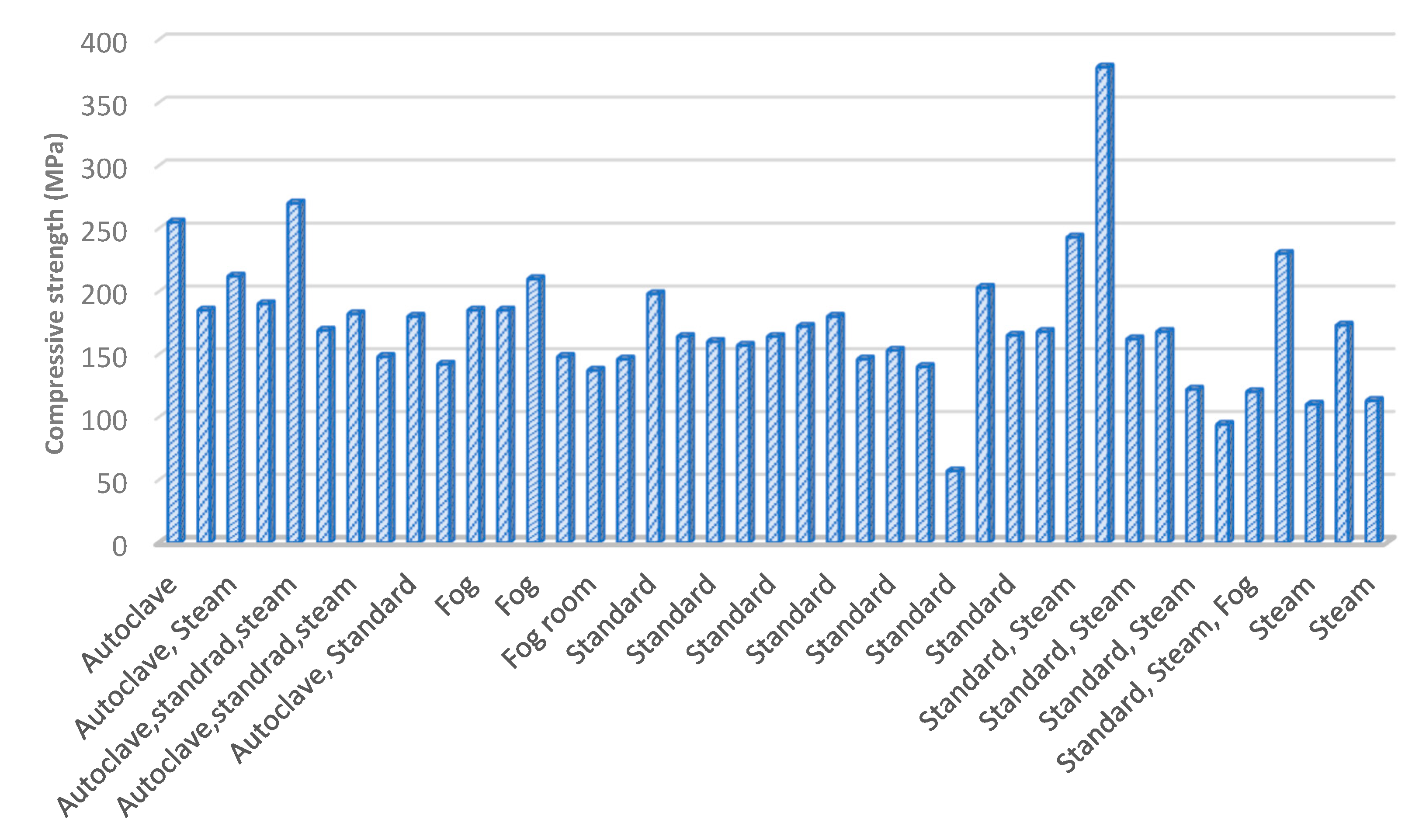

3.2. Curing

- Standard room temperature curing;

- heat curing under atmospheric pressure;

- autoclave curing;

- fog;

- steam.

4. Mechanical Properties of UHPC

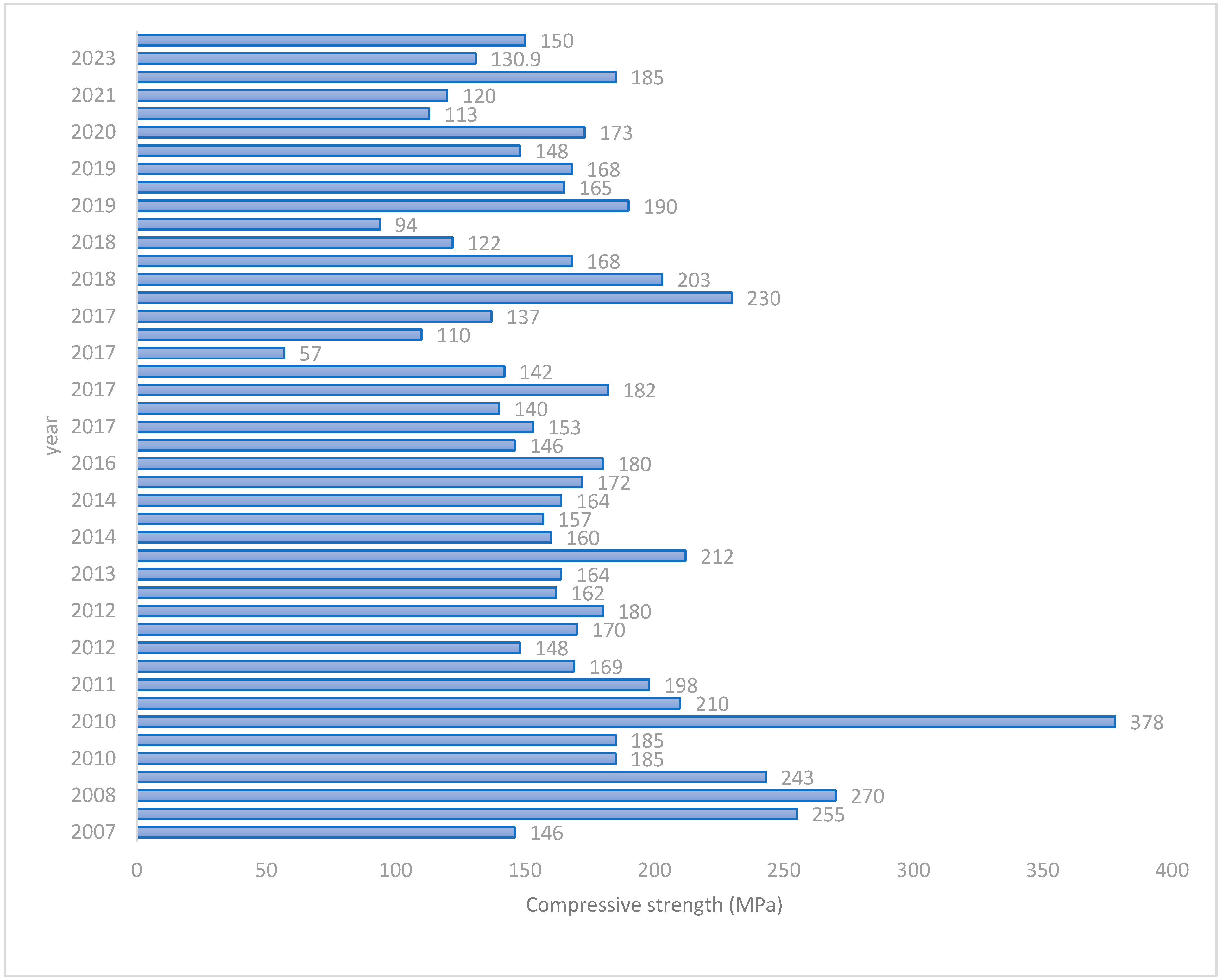

4.1. Compressive Strength

4.2. Flexural Strength

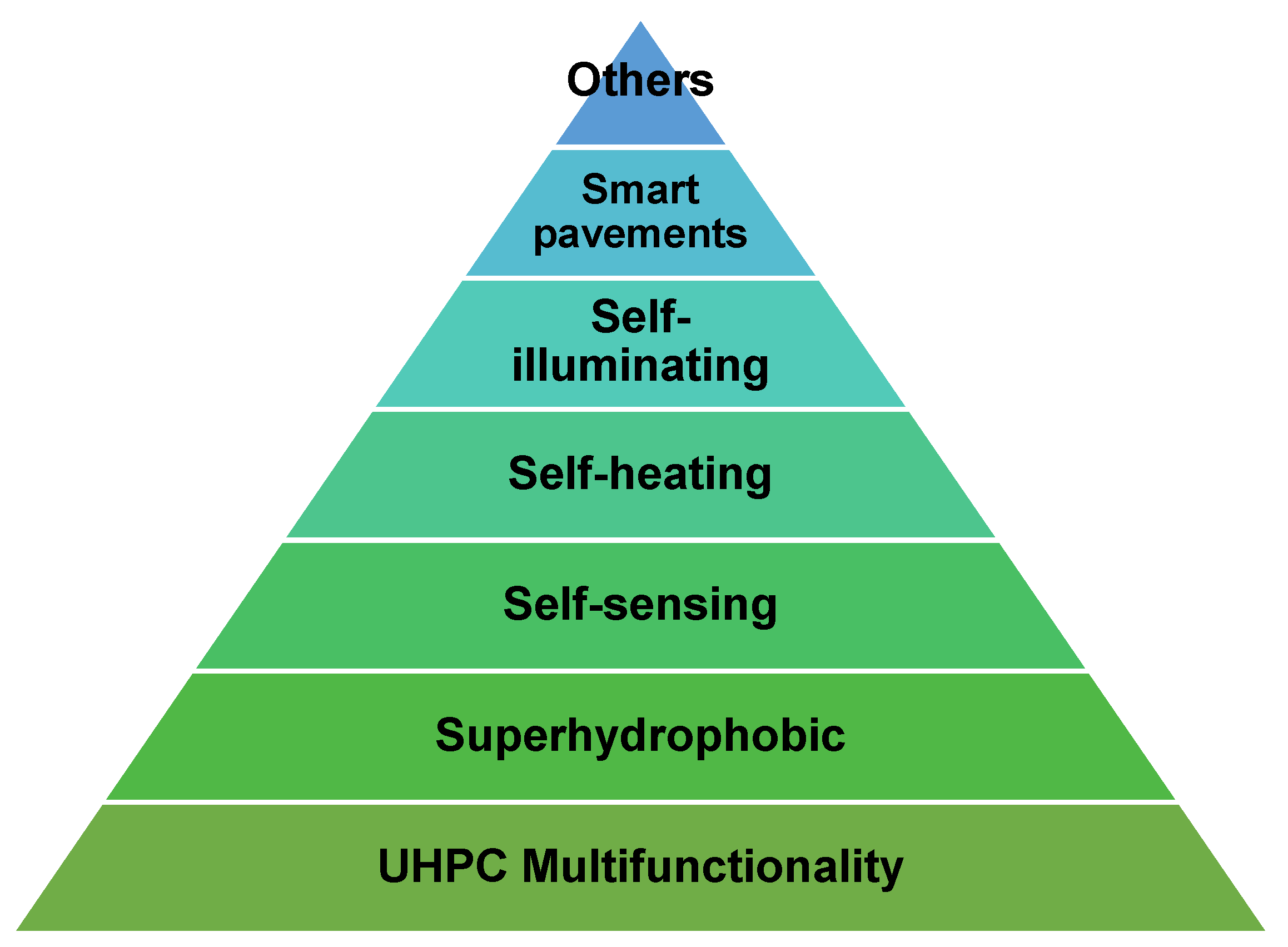

5. Recent Innovations and Research in UHPC

5.1. Superhydrophobic Concrete

5.1.1. Surface Modification Method

5.1.2. Bulk Modification Method

5.2. Self-Sensing UHPC

5.3. Self-Heating UHPC

5.4. Other Concepts

5.5. Multifunctionality

6. Durability of UHPC

6.1. Water Permeability

6.2. Chloride-Ion Permeability

6.3. Corrosion of Steel Reinforcement

6.4. Freeze–Thaw Resistance

6.5. Fire Resistance

6.6. Nanotechnology

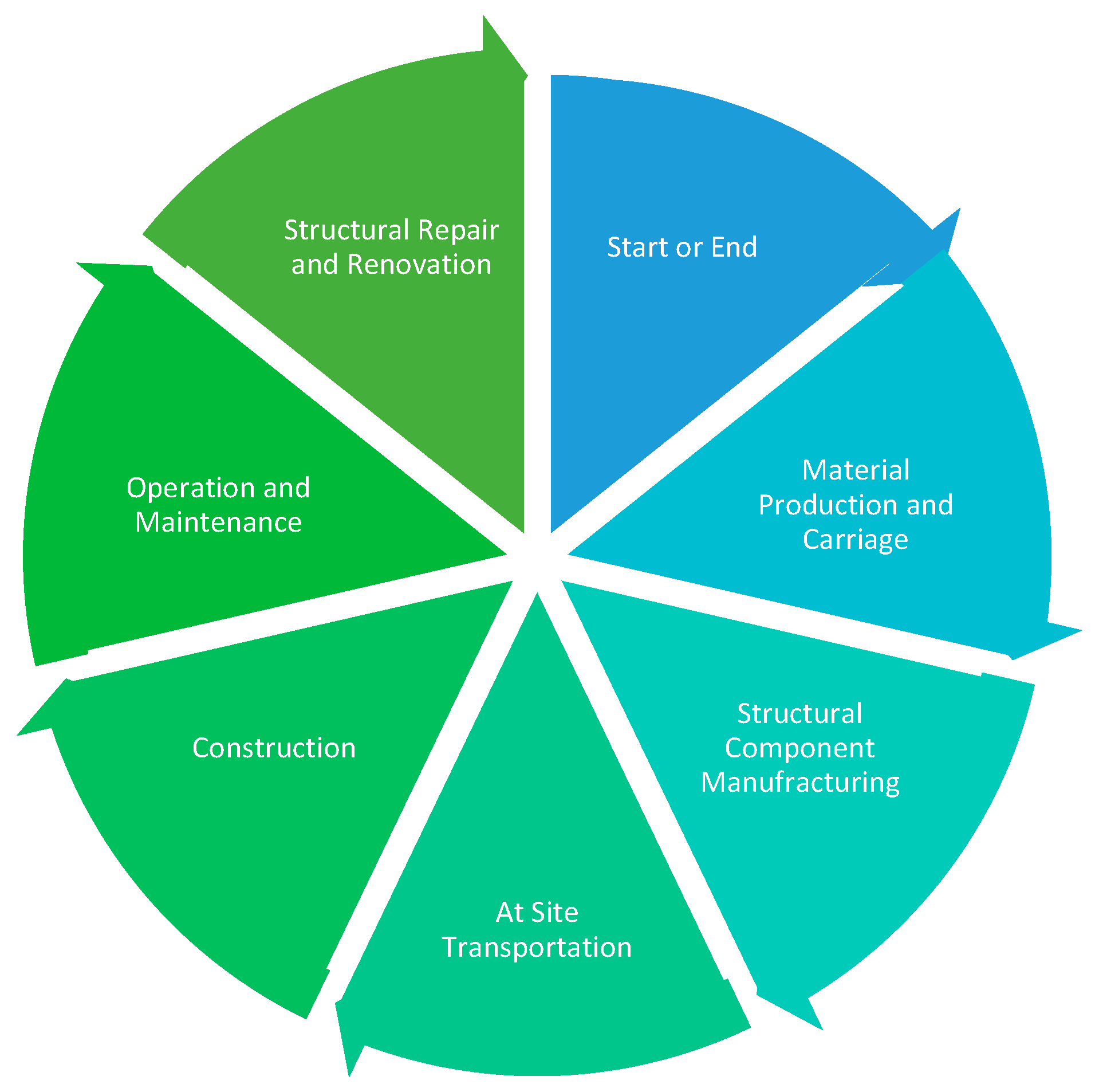

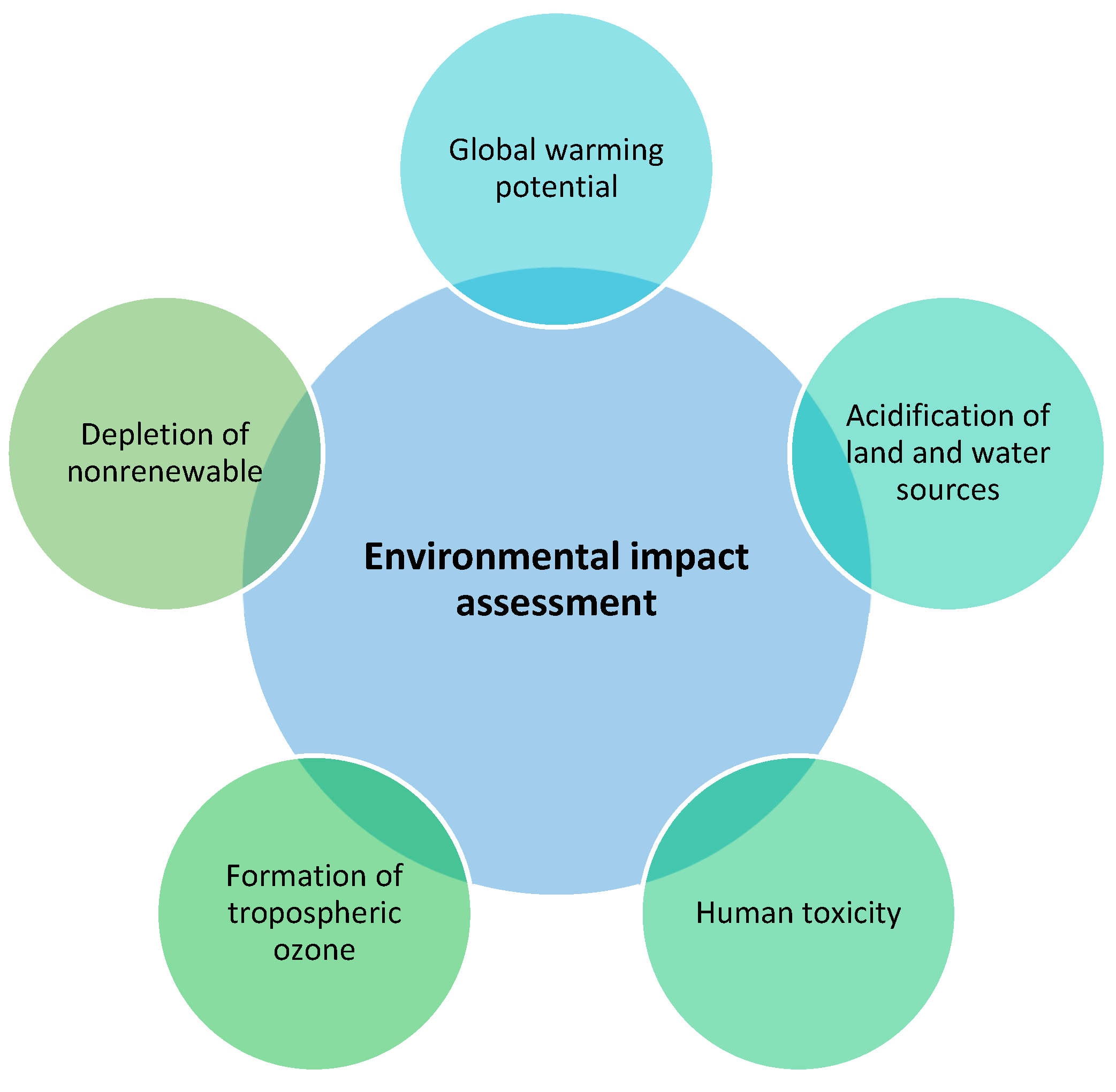

7. Environmental Impact of UHPC: Life-Cycle Assessment and Sustainable Practices

7.1. Environmental Impact Assessment (EIA)

7.2. Life-Cycle Cost Analysis and Equivalent Annual Cost (LCCA)

7.3. Numerical Examples for the Determination of CO2 Emissions

8. Applications of UHPC

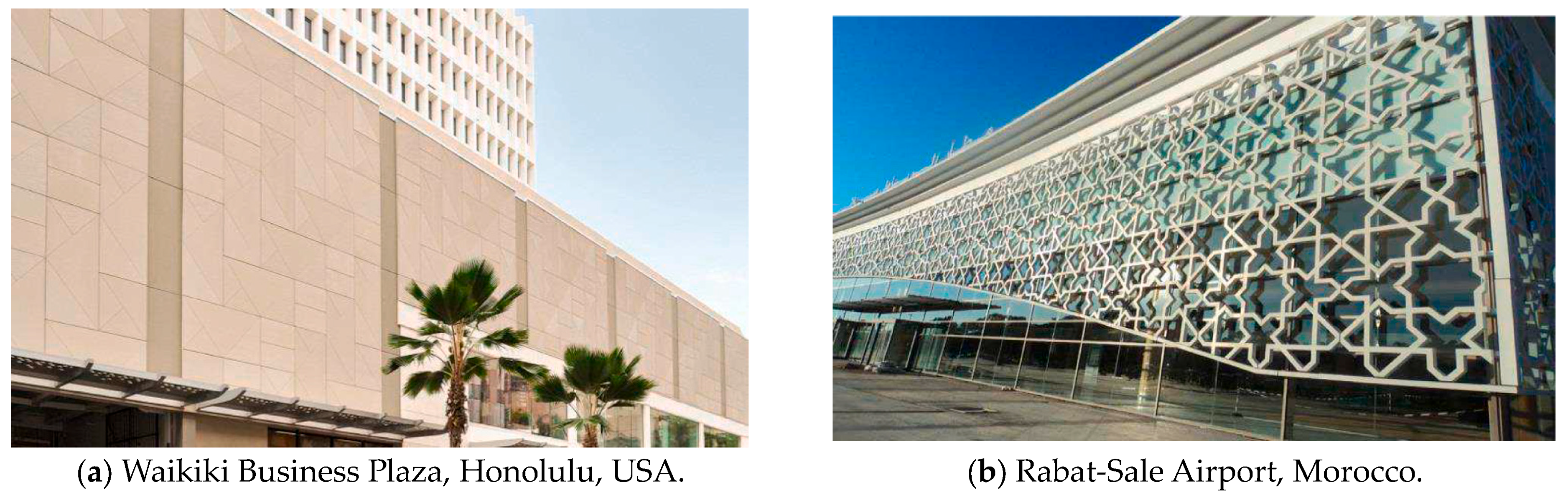

8.1. Buildings

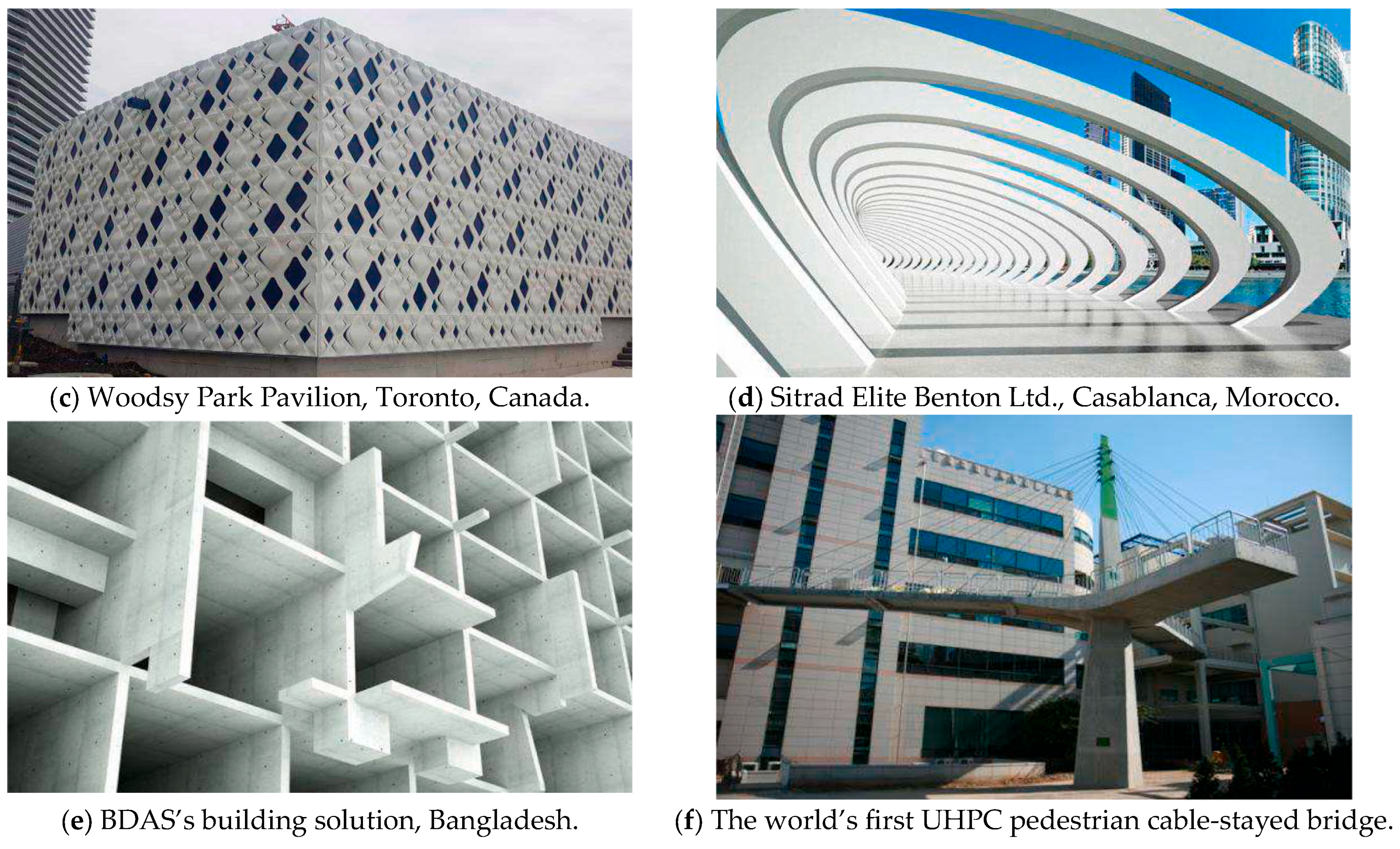

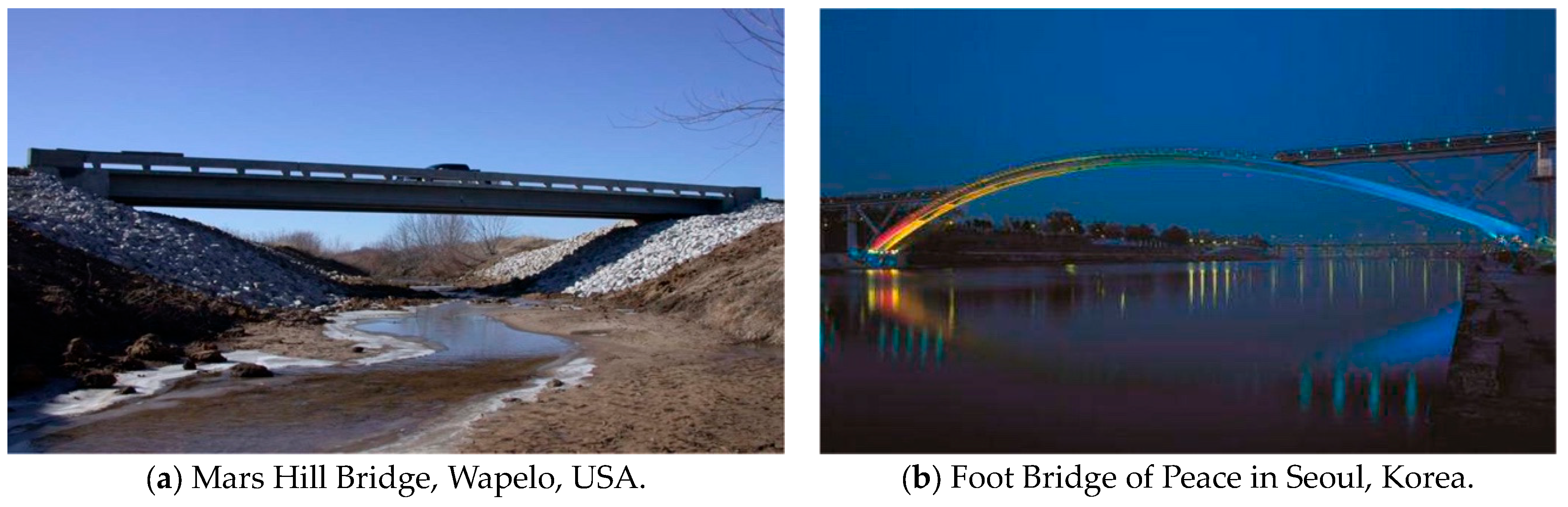

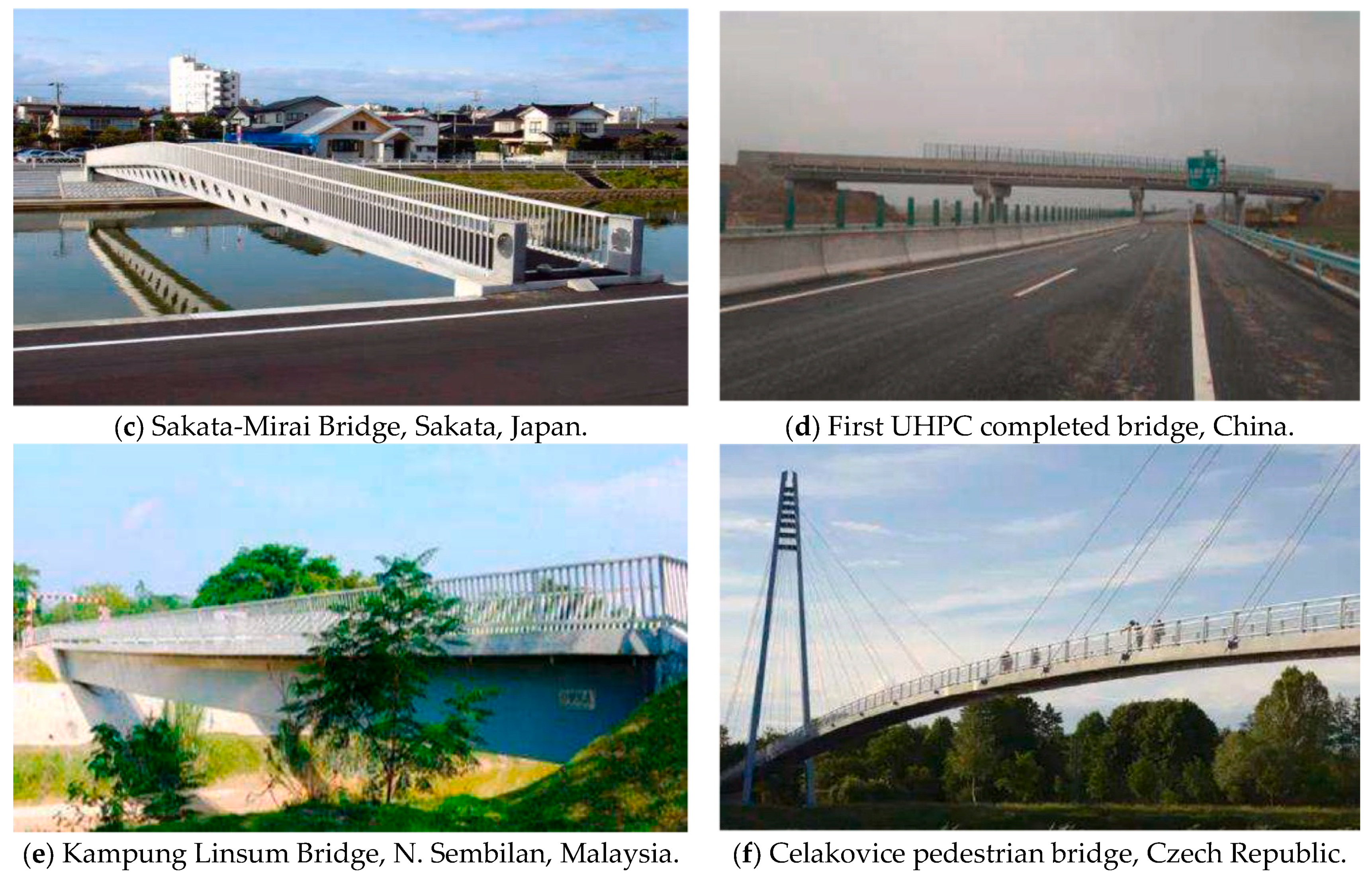

8.2. Bridges

9. Conclusions and Future Perspectives

- It is imperative to minimize the environmental footprint of UHPC production. Exploring sustainable alternatives, recycling methods and environmentally friendly components will improve the overall environmental profile.

- Overcoming the challenges of large-scale production is crucial for the wide acceptance of UHPC. Solving problems related to mixer failures and optimizing production processes can pave the way for wider application in construction projects.

- Developing cost-effective formulations without compromising performance is essential. Exploring alternative materials and production techniques may contribute to reducing the overall cost of UHPC, making it more accessible for various construction projects.

- Further research into the effects of different nanoparticles on the properties of UHPC is warranted. Understanding the interaction mechanisms and optimizing the nanomaterial content can lead to improved mechanical and fresh properties.

- Investigating the use of waste materials from different industries, such as the perfume or geranium industry, can contribute to sustainable and environmentally conscious UHPC practices. This can provide valuable insights into novel waste materials that can improve the performance of UHPC.

- Extending life-cycle assessments (LCAs) to comprehensively evaluate the environmental impact of UHPC throughout its entire life cycle is crucial. Incorporating LCA considerations into material selection and production processes can lead to sustainable practices.

- With a high projected growth rate, the UHPC market is expected to expand globally. Ongoing research, coupled with successful applications in real-world projects, is likely to increase adoption and have a greater impact on the construction industry.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM: West Conshohocken, PA, USA, 2017.

- FHWA. Properties and Behavior of UHPC-Class Materials; FHWA: Georgetown Pike, VA, USA, 2018; pp. 1–153.

- El-Tawil, S.; Tai, Y.-S.; Belcher, J.A., II; Rogers, D. Open-Recipe Ultra-High-Performance Concrete. CI Concr. Int. 2020, 42, 53–57. [Google Scholar]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Su, Y.; Li, J.; Wu, C.; Wu, P.; Li, Z.X. Effects of steel fibres on dynamic strength of UHPC. Constr. Build. Mater. 2016, 114, 708–718. [Google Scholar] [CrossRef]

- Linmei, W.U. Study on dimensional stability of ultra high performance. Ph.D. Thesis, University of Southern Queensland, Darling Heights, QLD, Australia, 2020. [Google Scholar]

- Zhou, M.; Wu, Z.; Ouyang, X.; Hu, X.; Shi, C. Mixture design methods for ultra-high-performance concrete—A review. Cem. Concr. Compos. 2021, 124, 104242. [Google Scholar] [CrossRef]

- Park, S.; Lee, N.; An, G.-H.; Koh, K.-T.; Ryu, G.-S. Modeling the Effect of Alternative Cementitious Binders in Ultra-High-Performance Concrete. Materials 2021, 14, 7333. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, M.; Fehling, E. Ultra High Performance Concrete: Research, Development and Application in Europe. Am. Concr. Inst. ACI Spec. 2005, 228, 51–77. [Google Scholar]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Song, F.; Li, Q.; Xu, S. A review of self-sensing ultra-high performance concrete: Towards next-generation smart structural materials. Cem. Concr. Compos. 2023, 145, 105350. [Google Scholar] [CrossRef]

- El-Abbasy, A.A. Tensile, flexural, impact strength, and fracture properties of ultra-high-performance fiber-reinforced concrete—A comprehensive review. Constr. Build. Mater. 2023, 408, 133621. [Google Scholar] [CrossRef]

- Huseien, G. A Review on Concrete Composites Modified with Nanoparticles. J. Compos. Sci. 2023, 7, 67. [Google Scholar] [CrossRef]

- Fan, D.; Zhu, J.; Fan, M.; Lu, J.X.; Chu, S.H.; Dong, E.; Yu, R. Intelligent design and manufacturing of ultra-high performance concrete (UHPC)—A review. Constr. Build. Mater. 2023, 385, 131495. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Chen, B.; Su, J.; Xu, G.; Zhang, D.; Zhou, J. Effects of Fibers on the Mechanical Properties of UHPC: A Review. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 363–387. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Majeed, S.S.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part V: Mixture design, preparation, mixing, casting, and curing. Case Stud. Constr. Mater. 2022, 17, e01265. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Shah, H.A.; Yuan, Q.; Photwichai, N. Use of materials to lower the cost of ultra-high-performance concrete—A review. Constr. Build. Mater. 2022, 327, 127045. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Oh, T.; Banthia, N. Nanomaterials in ultra-high-performance concrete (UHPC)—A review. Cem. Concr. Compos. 2022, 134, 104730. [Google Scholar] [CrossRef]

- Wu, Y.; Dong, L.; Shu, X.; Yang, Y.; She, W.; Ran, Q. A review on recent advances in the fabrication and evaluation of superhydrophobic concrete. Compos. B Eng. 2022, 237, 109867. [Google Scholar] [CrossRef]

- Wang, X.; Wu, D.; Zhang, J.; Yu, R.; Hou, D.; Shui, Z. Design of sustainable ultra-high performance concrete: A review. Constr. Build. Mater. 2021, 307, 124643. [Google Scholar] [CrossRef]

- Park, S.; Wu, S.; Liu, Z.; Pyo, S. The role of supplementary cementitious materials (SCMs) in ultra high performance concrete (uhpc): A review. Materials 2021, 14, 1472. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-obeidah, A.; Nassif, H.; Wang, H. New development of ultra-high-performance concrete (UHPC). Compos. B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Larsen, I.L.; Thorstensen, R.T. The influence of steel fibres on compressive and tensile strength of ultra high performance concrete: A review. Constr. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Spasojević, A. Structural Implication of Ultra-High-Performance Fiber Reinforced Concrete in Bridges. Ph.D. Thesis, Swiss Federal Institute of Technology Lausanne, Lausanne, Switzerland, 2008. [Google Scholar]

- Lei, L.; Hirata, T.; Plank, J. 40 years of PCE superplasticizers—History, current state-of-the-art and an outlook. Cem. Concr. Res. 2022, 157, 106826. [Google Scholar] [CrossRef]

- Bache, H.H. Densified cement ultra-fine particle-based materials. In Proceedings of the International Conference on Superplasticizers in Concrete, Ottawa, ON, Canada, 10–12 June 1981. [Google Scholar]

- Richard, P.; Cheyrezy, M. Composition of Reactive Powder Concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Rossi, P.; Arca, A.; Parant, E.; Fakhri, P. Bending and compressive behaviours of a new cement composite. Cem. Concr. Res. 2005, 35, 27–33. [Google Scholar] [CrossRef]

- Soliman, N.A. Development of UHPC Using Waste Glass Materials–Towards Innovative Eco-Friendly Concrete. Ph.D. Thesis, University Sherbrooke, Sherbrooke, QC, Canada, 2016. [Google Scholar]

- Fehling, E.; Schmidt, M.; Walraven, J.; Leutbecher, T.; Froehlich, S. Ultra-High Performance Concrete UHPC: Fundamentals, Design, Examples, 1st ed.; Wilhelm Ernst & Sohn Verlag fur Architektur und Technische Wissenschaften: Berlin, Germany, 2014. [Google Scholar]

- Blais, P.Y.; Couture, M. Precast, Prestressed Pedestrian Bridge World’s First Reactive Powder Concrete Structure. PCI J. 1999, 44, 60–71. [Google Scholar] [CrossRef]

- Zdeb, T. Ultra-high performance concrete-properties and technology. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 183–193. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Kang, S.H.; Jeong, Y.; Tan, K.H.; Moon, J. High-volume use of limestone in ultra-high performance fiber-reinforced concrete for reducing cement content and autogenous shrinkage. Constr. Build. Mater. 2019, 213, 292–305. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Wang, H.; Ye, H. Influence of rice husk ash on strength and permeability of ultra-high performance concrete. Constr. Build. Mater. 2017, 149, 621–628. [Google Scholar] [CrossRef]

- Meng, W.; Valipour, M.; Khayat, K.H. Optimization and performance of cost-effective ultra-high performance concrete. Mater. Struct./Mater. Constr. 2017, 50, 1–16. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; He, B.; He, L. Performance of ultra-high performance concrete (UHPC) with cement partially replaced by ground granite powder (GGP) under different curing conditions. Constr. Build. Mater. 2019, 213, 469–482. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; Zeng, X.; Yang, Z.; Lin, X.; Liang, Y. Mechanical behavior of ultra-high performance concrete (UHPC) using recycled fine aggregate cured under different conditions and the mechanism based on integrated microstructural parameters. Constr. Build. Mater. 2018, 192, 489–507. [Google Scholar] [CrossRef]

- Korpa, A.; Kowald, T.; Trettin, R. Phase development in normal and ultra high performance cementitious systems by quantitative X-ray analysis and thermoanalytical methods. Cem. Concr. Res. 2009, 39, 69–76. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of Ultra-High Performance Concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Ding, M.; Yu, R.; Feng, Y.; Wang, S.; Zhou, F.; Shui, Z.; Gao, X.; He, Y.; Chen, L. Possibility and advantages of producing an ultra-high performance concrete (UHPC) with ultra-low cement content. Constr. Build. Mater. 2021, 273, 122023. [Google Scholar] [CrossRef]

- Fládr, J.; Bílý, P.; Trtík, T. Analysis of the influence of supplementary cementitious materials used in UHPC on modulus of elasticity. IOP Conf. Ser. Mater. Sci. Eng. 2019, 522, 012010. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Gu, C.; Sun, W.; Guo, L.; Wang, Q. Effect of curing conditions on the durability of ultra-high performance concrete under flexural load. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2016, 31, 278–285. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W. Comparative study on flexural properties of ultra-high performance concrete with supplementary cementitious materials under different curing regimes. Constr. Build. Mater. 2017, 136, 307–313. [Google Scholar] [CrossRef]

- Yazici, H.; Yiǧiter, H.; Karabulut, A.Ş.; Baradan, B. Utilization of fly ash and ground granulated blast furnace slag as an alternative silica source in reactive powder concrete. Fuel 2008, 87, 2401–2407. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Peng, Y.; Hu, S.; Ding, Q. Preparation of reactive powder concrete using fly ash and steel slag powder. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 349–354. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K.; Copuroglu, O. Hydration and microstructure of ultra high performance concrete incorporating rice husk ash. Cem. Concr. Res. 2011, 41, 1104–1111. [Google Scholar] [CrossRef]

- Van, V.; Ludwig, H. Proportioning optimization of UHPC containing rice husk ash and ground granulated blast-furnace slag. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012. [Google Scholar]

- ASTM C618-99; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete. ASTM: West Conshohocken, PA, USA, 2021.

- Yazici, H.; Yardimci, M.Y.; Yiǧiter, H.; Aydin, S.; Türkel, S. Mechanical properties of reactive powder concrete containing high volumes of ground granulated blast furnace slag. Cem. Concr. Compos. 2010, 32, 639–648. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Partial substitution of silica fume with fine glass powder in UHPC: Filling the micro gap. Constr. Build. Mater. 2017, 139, 374–384. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Tafraoui, A.; Escadeillas, G.; Lebaili, S.; Vidal, T. Metakaolin in the formulation of UHPC. Constr. Build. Mater. 2009, 23, 669–674. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ferraris, C.F.; Jones, S.Z.; Lootens, D.; Zunino, F. Limestone and silica powder replacements for cement: Early-age performance. Cem. Concr. Compos. 2017, 78, 43–56. [Google Scholar] [CrossRef]

- Fanghui, H.; Qiang, W.; Mutian, L.; Yingjun, M. Early hydration properties of composite binder containing limestone powder with different finenesses. J. Therm. Anal. Calorim. 2016, 123, 1141–1151. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined Clay Limestone Cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Xiao, X.; Fan, D.; Chen, Z.; Cai, J.; Li, X.; He, Y. Feasibility analysis of treating recycled rock dust as an environmentally friendly alternative material in Ultra-High Performance Concrete (UHPC). J. Clean. Prod. 2020, 258, 120673. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E.; Song, W.; Cao, S. Mechanical, flexural and microstructural properties of cement-tailings matrix composites: Effects of fiber type and dosage. Compos. B Eng. 2019, 172, 131–142. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Qu, S.; Kumar, A.; Shao, X. Improvement of flexural and tensile strength of layered-casting UHPC with aligned steel fibers. Constr. Build. Mater. 2020, 251, 118893. [Google Scholar] [CrossRef]

- Hung, C.C.; Lee, H.S.; Chan, S.N. Tension-stiffening effect in steel-reinforced UHPC composites: Constitutive model and effects of steel fibers, loading patterns, and rebar sizes. Compos. B Eng. 2019, 158, 709–721. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef]

- Banthia, N.; Foy, C. Marine Curing of Steel Fiber Composites. J. Mater. Civ. Eng. 1989, 1, 86–96. [Google Scholar] [CrossRef]

- Fan, L.; Meng, W.; Teng, L.; Khayat, K.H. Effect of steel fibers with galvanized coatings on corrosion of steel bars embedded in UHPC. Compos. B Eng. 2019, 177, 107445. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of Hybrid Fibers on Fresh Properties, Mechanical Properties, and Autogenous Shrinkage of Cost-Effective UHPC. J. Mater. Civ. Eng. 2018, 30, 04018030. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Ilg, M.; Plank, J. Non-adsorbing small molecules as auxiliary dispersants for polycarboxylate superplasticizers. Colloids Surf. A Physicochem. Eng. Asp. 2020, 587, 124307. [Google Scholar] [CrossRef]

- Stovall, T.; de Larrard, F.; Buil, M. Linear Packing Density Model of Grain Mixtures. Powder Technol. 1986, 48, 1–12. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Optimization of Ultra-High-Performance Concrete by the Use of a Packing Model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Mixture-Proportioning of High-Performance Concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Fennis, S.A.A.M.; Walraven, J.C.; den Uijl, J.A. Compaction-Interaction Packing Model: Regarding the Effect of Fillers in Concrete Mixture Design. Mater. Struct. 2013, 46, 463–478. [Google Scholar] [CrossRef]

- Fuller, W.B.; Thompson, S.E. The Laws of Proportioning Concrete. Trans. Am. Soc. Civ. Eng. 1907, 59, 67–143. [Google Scholar] [CrossRef]

- Brouwers, H.J.H.; Radix, H.J. Self-Compacting Concrete: Theoretical and Experimental Study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Li, L.G.; Kwan, A.K.H. Packing Density of Concrete Mix under Dry and Wet Conditions. Powder Technol. 2014, 253, 514–521. [Google Scholar] [CrossRef]

- Graybeal, B. Ultra-High Performance Concrete (FHWA-HRT-11-038); Federal Highway Administration: Washington, DC, USA, 2011.

- Teng, L.; Meng, W.; Khayat, K.H. Rheology control of ultra-high-performance concrete made with different fiber contents. Cem. Concr. Res. 2020, 138, 106222. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- He, J.; Chen, W.; Zhang, B.; Yu, J.; Liu, H. The Mechanical Properties and Damage Evolution of UHPC Reinforced with Glass Fibers and High-Performance Polypropylene Fibers. Materials 2021, 14, 2455. [Google Scholar] [CrossRef]

- Chen, H.-J.; Yu, Y.-L.; Tang, C.-W. Mechanical Properties of Ultra-High Performance Concrete before and after Exposure to High Temperatures. Materials 2020, 13, 770. [Google Scholar] [CrossRef]

- Khatib, J.M. Metakaolin Concrete at a Low Water to Binder Ratio. Constr. Build. Mater. 2008, 22, 1691–1700. [Google Scholar] [CrossRef]

- Abdellatief, M.; AL-Tam, S.M.; Elemam, W.E.; Alanazi, H.; Elgendy, G.M.; Tahwia, A.M. Development of Ultra-High-Performance Concrete with Low Environmental Impact Integrated with Metakaolin and Industrial Wastes. Case Stud. Constr. Mater. 2023, 18, e01724. [Google Scholar] [CrossRef]

- Tafraoui, A.; Escadeillas, G.; Vidal, T. Durability of the Ultra High Performances Concrete containing metakaolin. Constr. Build. Mater. 2016, 112, 980–987. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Shui, Z.; Wang, Y.; Rao, S.; Wu, S.; He, Y. Physical and chemical coupling effect of metakaolin induced chloride trapping capacity variation for Ultra High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2019, 223, 765–774. [Google Scholar] [CrossRef]

- Xie, H.; Yang, L.; Li, J.; Chen, Z.; Zhang, F.; Liu, Y.; Sui, Z.; Zhang, Q. Research on Mode-I Fracture Characteristics of Basalt Fiber Reactive Powder Concrete. J. Build. Eng. 2023, 80, 108159. [Google Scholar] [CrossRef]

- Kočí, V.; Vejmelková, E.; Koňáková, D.; Pommer, V.; Grzeszczyk, S.; Matuszek-Chmurowska, A.; Mordak, A.; Černý, R. Basic physical, mechanical, thermal and hygric properties of reactive powder concrete with basalt and polypropylene fibers after high-temperature exposure. Constr. Build. Mater. 2023, 374, 130922. [Google Scholar] [CrossRef]

- AlAteah, A.H. Engineering Characteristics of Ultra-High Performance Basalt Fiber Concrete Incorporating Geranium Plant Waste. Case Stud. Constr. Mater. 2023, 19, e02618. [Google Scholar] [CrossRef]

- Yang, L.; Shi, C.; Liu, J.; Wu, Z. Factors affecting the effectiveness of internal curing: A review. Constr. Build. Mater. 2021, 267, 121017. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Hu, G.; Hui Duan, W.; Shah, S.P. Early-age shrinkage development of ultra-high-performance concrete under heat curing treatment. Constr. Build. Mater. 2017, 131, 767–774. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S.; Liu, Z.; Hansen, W. Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC). Cem. Concr. Compos. 2016, 66, 47–56. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Sifeng, L.; Chujie, J.; Jianzhong, L. Preparation of C200 green reactive powder concrete and its static-dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar] [CrossRef]

- Yang, S.L.; Millard, S.G.; Soutsos, M.N.; Barnett, S.J.; Le, T.T. Influence of aggregate and curing regime on the mechanical properties of ultra-high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2009, 23, 2291–2298. [Google Scholar] [CrossRef]

- Van, V.T.A.; Rößler, C.; Bui, D.D.; Ludwig, H.M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Compos. 2014, 53, 270–278. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Ahmad, S.; Hakeem, I.; Maslehuddin, M. Development of UHPC mixtures utilizing natural and industrial waste materials as partial replacements of silica fume and sand. Sci. World J. 2014, 2014, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Li, Z. Drying shrinkage prediction of paste containing meta-kaolin and ultrafine fly ash for developing ultra-high performance concrete. Mater. Today Commun. 2016, 6, 74–80. [Google Scholar] [CrossRef]

- Kim, H.; Koh, T.; Pyo, S. Enhancing flowability and sustainability of ultra high performance concrete incorporating high replacement levels of industrial slags. Constr. Build. Mater. 2016, 123, 153–160. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K. Effect of rice husk ash on autogenous shrinkage of ultra high performance concrete. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lyngby, Denmark, 15–18 August 2010. [Google Scholar]

- Schießl, P.; Mazanec, O.; Lowke, D. SCC and UHPC-Effect of Mixing Technology on Fresh Concrete Properties; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Yigiter, H.; Aydin, S.; Yazici, H.; Yardimci, M.Y. Mechanical performance of low cement reactive powder concrete (LCRPC). Compos. B Eng. 2012, 43, 2907–2914. [Google Scholar] [CrossRef]

- Lee, N.K.; Koh, K.T.; Park, S.H.; Ryu, G.S. Microstructural investigation of calcium aluminate cement-based ultra-high performance concrete (UHPC) exposed to high temperatures. Cem. Concr. Res. 2017, 102, 109–118. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Mészöly, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.G.; Bansal, P.P. A comprehensive review on effects of mineral admixtures and fibers on engineering properties of ultra-high-performance concrete. J. Build. Eng. 2022, 45, 103314. [Google Scholar] [CrossRef]

- Yalçınkaya, Ç.; Çopuroğlu, O. Hydration heat, strength and microstructure characteristics of UHPC containing blast furnace slag. J. Build. Eng. 2021, 34, 101915. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Sammak, M. Strength and chloride ion penetration resistance of ultra-high-performance fiber reinforced geopolymer concrete. Structures 2021, 32, 1420–1427. [Google Scholar] [CrossRef]

- Alsalman, A.; Dang, C.N.; Martí-Vargas, J.R.; Micah Hale, W. Mixture-proportioning of economical UHPC mixtures. J. Build. Eng. 2020, 27, 100970. [Google Scholar] [CrossRef]

- Ganesh, P.; Murthy, A.R. Tensile behaviour and durability aspects of sustainable ultra-high performance concrete incorporated with GGBS as cementitious material. Constr. Build. Mater. 2019, 197, 667–680. [Google Scholar] [CrossRef]

- Nadiger, A.; Madhavan, M.K. Influence of Mineral Admixtures and Fibers on Workability and Mechanical Properties of Reactive Powder Concrete. J. Mater. Civ. Eng. 2019, 31, 04018394. [Google Scholar] [CrossRef]

- Vigneshwari, M.; Arunachalam, K.; Angayarkanni, A. Replacement of silica fume with thermally treated rice husk ash in Reactive Powder Concrete. J. Clean. Prod. 2018, 188, 264–277. [Google Scholar] [CrossRef]

- Bahedh, M.A.; Jaafar, M.S. Ultra high-performance concrete utilizing fly ash as cement replacement under autoclaving technique. Case Stud. Constr. Mater. 2018, 9, e00202. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y.; Li, H. Experimental Investigation and Prediction of Compressive Strength of Ultra-High Performance Concrete Containing Supplementary Cementitious Materials. Adv. Mater. Sci. Eng. 2017, 2017, 1–8. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Ferdosian, I.; Camões, A.; Ribeiro, M. High-Volume Fly Ash Paste for Developing Ultra-High Performance Concrete (UHPC). Ciênc. Tecnol. Mater. 2017, 29, 157–161. [Google Scholar] [CrossRef]

- Azreen, N.M.; Rashid, R.S.M.; Mugahed Amran, Y.H.; Voo, Y.L.; Haniza, M.; Hairie, M.; Alyousef, R.; Alabduljabbar, H. Simulation of ultra-high-performance concrete mixed with hematite and barite aggregates using Monte Carlo for dry cask storage. Constr. Build. Mater. 2020, 263, 120161. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, L.; Yuan, Z.; Zhang, C.; Bangi, T. Mechanical properties, durability and application of ultra-high-performance concrete containing coarse aggregate (UHPC-CA): A review. Constr. Build. Mater. 2022, 334, 127360. [Google Scholar] [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2023.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2023.

- Chan, Y.W.; Chu, S.H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Ding, L.; Jiang, K.; Liu, X.; Liu, J.; Wu, Z. Spalling resistance and mechanical properties of ultra-high performance concrete reinforced with multi-scale basalt fibers and hybrid fibers under elevated temperature. J. Build. Eng. 2023, 77, 107435. [Google Scholar] [CrossRef]

- Bărbos, G.A. What Makes Ultra-High Performance Concrete (Uhpc) a Special Material? In Lucrările Conferinţei de Cercetare în Construcţii, Economia Construcţiilor, Urbanism şi Amenajarea Teritoriului; INCD URBAN-INCERC: București, Romania, 2023; pp. 77–84. [Google Scholar]

- Alkadhim, H.A.; Amin, M.N.; Ahmad, W.; Khan, K.; Umbreen-us-Sahar; Al-Hashem, M.N.; Mohamed, A. An overview of progressive advancement in ultra-high performance concrete with steel fibers. Front. Mater. 2022, 9, 1091867. [Google Scholar] [CrossRef]

- Bede Odorčić, N.; Kravanja, G. Combined Effects of Metakaolin and Hybrid Fibers on Self-Compacting Concrete. Materials 2022, 15, 5588. [Google Scholar] [CrossRef]

- Rizwan Mumtaz, A.; Bede Odorčić, N.; Garro, N.; Lubej, S.; Ivanič, A.; Comite, A.; Pagliero, M.; Kravanja, G. Novel Ultra-High-Performance Concrete (UHPC) Enhanced by Superhydrophobic and Self-Luminescent Features. Sustainability 2024, 16, 1068. [Google Scholar] [CrossRef]

- Zhong, X.; Hu, H.; Yang, L.; Sheng, J.; Fu, H. Robust Hyperbranched Polyester-Based Anti-Smudge Coatings for Self-Cleaning, Anti-Graffiti, and Chemical Shielding. ACS Appl. Mater. Interfaces 2019, 11, 14305–14312. [Google Scholar] [CrossRef]

- Azreen, N.M.; Rashid, R.S.M.; Haniza, M.; Voo, Y.L.; Mugahed Amran, Y.H. Radiation shielding of ultra-high-performance concrete with silica sand, amang and lead glass. Constr. Build. Mater. 2018, 172, 370–377. [Google Scholar] [CrossRef]

- Zelić, J.; Rušić, D.; Veža, D.; Krstulović, R. Role of silica fume in the kinetics and mechanisms during the early stage of cement hydration. Cem. Concr. Res. 2000, 30, 1655–1662. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.; Wu, X.; Xu, G. Quantitative analysis of steel fibers on UHPFRC uniaxial tensile behavior using X-CT and UTT. Constr. Build. Mater. 2023, 368, 130349. [Google Scholar] [CrossRef]

- Wang, W.; Sha, A.; Lu, Z.; Jia, M.; Jiang, W.; Liu, Z.; Yuan, D. Self-luminescent cement-based composite materials: Properties and mechanisms. Constr. Build. Mater. 2021, 269, 121267. [Google Scholar] [CrossRef]

- Ribbing, C. Environmentally Friendly Use of Non-Coal Ashes in Sweden. Waste Manag. 2007, 27, 1428–1435. [Google Scholar] [CrossRef] [PubMed]

- El-Tawil, S.; Tai, Y.S.; Meng, B.; Hansen, W.; Liu, Z. Commercial Production of Non-Proprietary Ultra High Performance Concrete (No. RC-1670); Michigan Department of Transportation: Lansing, MI, USA, 2018.

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Denarié, E.; Brühwiler, E. Strain-Hardening Ultra-High Performance Fibre Reinforced Concrete: Deformability versus Strength Optimization. Restor. Build. Monuments 2011, 17, 397–410. [Google Scholar] [CrossRef]

- Muhd Norhasri, M.S.; Hamidah, M.S.; Mohd Fadzil, A.; Megawati, O. Inclusion of nano metakaolin as additive in ultra high performance concrete (UHPC). Constr. Build. Mater. 2016, 127, 167–175. [Google Scholar] [CrossRef]

- Al-Rousan, E.T.; Khalid, H.R.; Rahman, M.K. Fresh, mechanical, and durability properties of basalt fiber-reinforced concrete (BFRC): A review. Dev. Built Environ. 2023, 14, 100155. [Google Scholar] [CrossRef]

- Larissa, L.C.; Marcos, M.A.; Maria, M.V.; de Souza, N.S.L.; de Farias, E.C. Effect of high temperatures on self-compacting concrete with high levels of sugarcane bagasse ash and metakaolin. Constr. Build. Mater. 2020, 248, 118715. [Google Scholar]

- Özkan, Ş.; Demir, F. The hybrid effects of PVA fiber and basalt fiber on mechanical performance of cost effective hybrid cementitious composites. Constr. Build. Mater. 2020, 263, 120564. [Google Scholar] [CrossRef]

- Xu, X.; Cui, S.; Cao, Z.; Zhang, S.; Woody Ju, J.W.; Liu, P.; Wang, X. Study on the interfacial bonding performance of basalt ultra-high performance concrete repair and reinforcement materials under severe service environment. Constr. Build. Mater. 2023, 400, 132624. [Google Scholar] [CrossRef]

- Xie, H.; Wei, P.; Liu, N.; Gao, J.; Yang, L.; Li, J.; Chen, S. Study on failure characteristics of basalt fiber reactive powder concrete under uniaxial loading. Constr. Build. Mater. 2023, 404, 133246. [Google Scholar] [CrossRef]

- Ziada, M.; Erdem, S.; Tammam, Y.; Kara, S.; Lezcano, R.A.G. The effect of basalt fiber on mechanical, microstructural, and high-temperature properties of fly ash-based and basalt powder waste-filled sustainable geopolymer mortar. Sustainability 2021, 13, 12610. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Jinping, O. Smart and Multifunctional Concrete toward Sustainable Infrastructures; Springer: Singapore, 2018. [Google Scholar]

- Elnaggar, E.M.; Elsokkary, T.M.; Shohide, M.A.; El-Sabbagh, B.A.; Abdel-Gawwad, H.A. Surface protection of concrete by new protective coating. Constr. Build. Mater. 2019, 220, 245–252. [Google Scholar] [CrossRef]

- Guo, T.; Weng, X. Evaluation of the freeze-thaw durability of surface-treated airport pavement concrete under adverse conditions. Constr. Build. Mater. 2019, 206, 519–530. [Google Scholar] [CrossRef]

- Habibnejad Korayem, A.; Ghoddousi, P.; Shirzadi Javid, A.A.; Oraie, M.A.; Ashegh, H. Graphene oxide for surface treatment of concrete: A novel method to protect concrete. Constr. Build. Mater. 2020, 243, 118229. [Google Scholar] [CrossRef]

- Zheng, W.; Chen, W.G.; Feng, T.; Li, W.Q.; Liu, X.T.; Dong, L.L.; Fu, Y.Q. Enhancing chloride ion penetration resistance into concrete by using graphene oxide reinforced waterborne epoxy coating. Prog. Org. Coat. 2020, 138, 105389. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Assessing drying shrinkage and water permeability of reactive powder concrete produced in Hong Kong. Constr. Build. Mater. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.C.; Li, N. A review on concrete surface treatment Part I: Types and mechanisms. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Tittarelli, F.; Moriconi, G. Comparison between surface and bulk hydrophobic treatment against corrosion of galvanized reinforcing steel in concrete. Cem. Concr. Res. 2011, 41, 609–614. [Google Scholar] [CrossRef]

- Basheer, P.A.M.; Basheer, L.; Cleland, D.J.; Long, A.E. Surface Treatments for Concrete: Assessmentmethods and Reported Performance. Constr. Build. Mater. 1997, 11, 413–429. [Google Scholar] [CrossRef]

- De Vries, I.J.; Polder, R.B. Hydrophobic Treatment of Concrete. Constr. Build. Mater. 1997, 11, 259–265. [Google Scholar] [CrossRef]

- Tittarelli, F. Oxygen diffusion through hydrophobic cement-based materials. Cem. Concr. Res. 2009, 39, 924–928. [Google Scholar] [CrossRef]

- Gao, Y.; Qu, L.; He, B.; Dai, K.; Fang, Z.; Zhu, R. Study on effectiveness of anti-icing and deicing performance of super-hydrophobic asphalt concrete. Constr. Build. Mater. 2018, 191, 270–280. [Google Scholar] [CrossRef]

- Lv, L.; Zhao, W.; Zhong, X.; Fu, H. Fabrication of Magnetically Inorganic/Organic Superhydrophobic Fabrics and Their Applications. ACS Appl. Mater. Interfaces 2020, 12, 45296–45305. [Google Scholar] [CrossRef]

- Sakr, M.R.; Bassuoni, M.T. Silane and methyl-methacrylate based nanocomposites as coatings for concrete exposed to salt solutions and cyclic environments. Cem. Concr. Compos. 2021, 115, 103841. [Google Scholar] [CrossRef]

- Wei, Q.; Liu, X.; Zhang, X. Facile preparation of mechanically robust superhydrophobic concrete with self-cleaning property. Mater. Res. Express 2019, 6, 015001. [Google Scholar] [CrossRef]

- Ong, J.; Zhao, D.; Han, Z.; Xu, W.; Lu, Y.; Liu, X.; Liu, B.; Carmalt, C.J.; Deng, X.; Parkin, I.P. Super-Robust Superhydrophobic Concrete. J. Mater. Chem. A 2017, 5, 14542–14550. [Google Scholar]

- Kravanja, G.; Godec, R.F.; Rozman, M.; Rudolf, R.; Ivanič, A. Biomimetic Superhydrophobic Concrete with Enhanced Anticorrosive, Freeze Thaw, and Deicing Resistance. Adv. Eng. Mater. 2022, 24, 2101445. [Google Scholar] [CrossRef]

- Chen, P.-W.; Chung, D.D.L. Carbon Fiber Reinforced Concrete for Smart Structures Capable of Non-Destructive Flaw Detection. Smart Mater. Struct. 1993, 2, 22–30. [Google Scholar] [CrossRef]

- Guo, Y.; Li, W.; Dong, W.; Wang, K.; He, X.; Vessalas, K.; Sheng, D. Self-sensing cement-based sensors with superhydrophobic and self-cleaning capacities after silane-based surficial treatments. Case Stud. Constr. Mater. 2022, 17, e01311. [Google Scholar] [CrossRef]

- Ding, S.; Dong, S.; Wang, X.; Ding, S.; Han, B.; Ou, J. Self-heating ultra-high performance concrete with stainless steel wires for active deicing and snow-melting of transportation infrastructures. Cem. Concr. Compos. 2023, 138, 105005. [Google Scholar] [CrossRef]

- Peña-García, A. The impact of lighting on drivers well-being and safety in very long underground roads: New challenges for new infrastructures. Tunn. Undergr. Space Technol. 2018, 80, 38–43. [Google Scholar] [CrossRef]

- Voravanicha, K.; Leelachao, S.; Sahasithiwat, S.; Kumnorkaew, P.; Dangtungee, R. Natural Rubber Filled with Phosphorescent Materials for Pavement. Mater. Today 2019, 17, 1971–1976. [Google Scholar] [CrossRef]

- Zhu, C.; Lv, J.; Chen, L.; Lin, W.; Zhang, J.; Yang, J.; Feng, J. Dark, heat-reflective, anti-ice rain and superhydrophobic cement concrete surfaces. Constr. Build. Mater. 2019, 220, 21–28. [Google Scholar] [CrossRef]

- Konarzewska, B. Smart Materials in Architecture: Useful Tools with Practical Applications or Fascinating Inventions for Experimental Design? IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 052098. [Google Scholar] [CrossRef]

- Sha, A.; Liu, Z.; Jiang, W.; Qi, L.; Hu, L.; Jiao, W.; Barbieri, D.M. Advances and development trends in eco-friendly pavements. J. Road Eng. 2021, 1, 1–42. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Voo, Y.L. Mechanical and permeability properties of the interface between normal concrete substrate and ultra high performance fiber concrete overlay. Constr. Build. Mater. 2012, 36, 538–548. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. The effect of nanosilica addition on flowability, strength and transport properties of ultra high performance concrete. Mater. Des. 2014, 59, 1–9. [Google Scholar] [CrossRef]

- Chuang, M.L.; Huang, W.H. Durability Analysis Testing on Reactive Powder Concrete. Adv. Mat. Res. 2013, 811, 244–248. [Google Scholar] [CrossRef]

- Liu, J.; Song, S.; Wang, L. Durability and micro-structure of reactive powder concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2009, 24, 506–509. [Google Scholar] [CrossRef]

- Roux, N.; Andrade, C.; Sanjuan, M.A. Experimental Study of Durability of Reactive Powder Concretes. J. Mater. Civ. Eng. 1996, 8, 1–6. [Google Scholar] [CrossRef]

- Ghafari, E.; Arezoumandi, M.; Costa, H.; Júlio, E. Influence of nano-silica addition in the durability of UHPC. Constr. Build. Mater. 2015, 94, 181–188. [Google Scholar] [CrossRef]

- Bondar, D.; Lynsdale, C.J.; Milestone, N.B.; Hassani, N. Sulfate Resistance of Alkali Activated Pozzolans. Int. J. Concr. Struct. Mater. 2015, 9, 145–158. [Google Scholar] [CrossRef]

- Mu, R.; Miao, C.; Luo, X.; Sun, W. Interaction between Loading, Freeze–Thaw Cycles, and Chloride Salt Attack of Concrete with and without Steel Fiber Reinforcement. Cem. Concr. Res. 2002, 32, 1061–1066. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, J.; Liu, J.; Ke, J.; Wang, F. Properties and microstructure of reactive powder concrete having a high content of phosphorous slag powder and silica fume. Constr. Build. Mater. 2015, 101, 482–487. [Google Scholar] [CrossRef]

- Dils, J.; Boel, V.; De Schutter, G. Influence of cement type and mixing pressure on air content, rheology and mechanical properties of UHPC. Constr. Build. Mater. 2013, 41, 455–463. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Material design and characterization of high performance pervious concrete. Constr. Build. Mater. 2015, 98, 51–60. [Google Scholar] [CrossRef]

- Sanchayan, S.; Foster, S.J. High temperature behaviour of hybrid steel–PVA fibre reinforced reactive powder concrete. Mater. Struct./Mater. Constr. 2016, 49, 769–782. [Google Scholar] [CrossRef]

- Feylessoufi, A.; Crespin, M.; Dion, P.; Bergaya, F.; Van Damme, H.; Richard, P. Controlled Rate Thermal Treatment of Reactive Powder Concretes. Adv. Cem. Based Mater. 1997, 6, 21–27. [Google Scholar] [CrossRef]

- Rajak, M.A.A.; Majid, Z.A.; Ismail, M. Morphological Characteristics of Hardened Cement Pastes Incorporating Nano-palm Oil Fuel Ash. Procedia Manuf. 2015, 2, 512–518. [Google Scholar] [CrossRef]

- Alhassan, M.; Alkhawaldeh, A.; Betoush, N.; Alkhawaldeh, M.; Huseien, G.F.; Amaireh, L.; Elrefae, A. Life Cycle Assessment of the Sustainability of Alkali-Activated Binders. Biomimetics 2023, 8, 58. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Zhi, T.; Liu, X.; Yin, K.; Pan, H.; Feng, H.; Song, Y.; Su, Y. Effects of different nanomaterials on the early performance of ultra-high performance concrete (UHPC): C–S–H seeds and nano-silica. Cem. Concr. Compos. 2023, 142, 105211. [Google Scholar] [CrossRef]

- Zhang, A.; Yang, W.; Ge, Y.; Du, Y.; Liu, P. Effects of nano-SiO2 and nano-Al2O3 on mechanical and durability properties of cement-based materials: A comparative study. J. Build. Eng. 2021, 34, 101936. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C.; Tutikian, B.F.; Chen, Q. Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3. Cem. Concr. Compos. 2021, 119, 103992. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Chung, S.Y.; Sikora, P.; Rucinska, T.; Stephan, D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials 2019, 12, 3078. [Google Scholar] [CrossRef]

- Beigi, M.H.; Berenjian, J.; Lotfi Omran, O.; Sadeghi Nik, A.; Nikbin, I.M. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 2013, 50, 1019–1029. [Google Scholar] [CrossRef]

- Behzadian, R.; Shahrajabian, H. Experimental Study of the Effect of Nano-silica on the Mechanical Properties of Concrete/PET Composites. KSCE J. Civ. Eng. 2019, 23, 3660–3668. [Google Scholar] [CrossRef]

- Hosan, A.; Shaikh, F.U.A. Influence of nano silica on compressive strength, durability, and microstructure of high-volume slag and high-volume slag–fly ash blended concretes. Struct. Concr. 2021, 22, E474–E487. [Google Scholar] [CrossRef]

- Potapov, V.; Efimenko, Y.; Fediuk, R.; Gorev, D. Effect of hydrothermal nanosilica on the performances of cement concrete. Constr. Build. Mater. 2021, 269, 121307. [Google Scholar] [CrossRef]

- Madandoust, R.; Mohseni, E.; Mousavi, S.Y.; Namnevis, M. An experimental investigation on the durability of self-compacting mortar containing nano-SiO2, nano-Fe2O3 and nano-CuO. Constr. Build. Mater. 2015, 86, 44–50. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, D.; Zhang, S.; Cui, H.; Li, D. Effect of nano-SiO2 on the hydration and microstructure of Portland cement. Nanomaterials 2016, 6, 241. [Google Scholar] [CrossRef] [PubMed]

- Saleh, N.J.; Ibrahim, R.I.; Salman, A.D. Characterization of nano-silica prepared from local silica sand and its application in cement mortar using optimization technique. Adv. Powder Technol. 2015, 26, 1123–1133. [Google Scholar] [CrossRef]

- Kontoleontos, F.; Tsakiridis, P.E.; Marinos, A.; Kaloidas, V.; Katsioti, M. Influence of colloidal nanosilica on ultrafine cement hydration: Physicochemical and microstructural characterization. Constr. Build. Mater. 2012, 35, 347–360. [Google Scholar] [CrossRef]

- Adak, D.; Sarkar, M.; Mandal, S. Structural performance of nano-silica modified fly-ash based geopolymer concrete. Constr. Build. Mater. 2017, 135, 430–439. [Google Scholar] [CrossRef]

- Deb, P.S.; Sarker, P.K.; Barbhuiya, S. Sorptivity and acid resistance of ambient-cured geopolymer mortars containing nano-silica. Cem. Concr. Compos. 2016, 72, 235–245. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Chindaprasirt, P.; Sata, V.; Hanjitsuwan, S.; Hatanaka, S. The effect of adding nano-SiO2 and nano-Al2O3 on properties of high calcium fly ash geopolymer cured at ambient temperature. Mater. Des. 2014, 55, 58–65. [Google Scholar] [CrossRef]

- Revathy, J.; Gajalakshmi, P.; Aseem Ahmed, M. Flowable Nano SiO2 Based Cementitious Mortar for Ferrocement Jacketed Column. Mater. Today 2020, 22, 836–842. [Google Scholar] [CrossRef]

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High strength sustainable concrete using silica nanoparticles. Constr. Build. Mater. 2017, 138, 285–295. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J. Use of nano-silica to reduce setting time and increase early strength of concretes with high volumes of fly ash or slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Najafi Kani, E.; Rafiean, A.H.; Alishah, A.; Hojjati Astani, S.; Ghaffar, S.H. The effects of Nano-Fe2O3 on the mechanical, physical and microstructure of cementitious composites. Constr. Build. Mater. 2021, 266, 121137. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Mohd Sam, A.R.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Ma, B.; Li, H.; Mei, J.; Li, X.; Chen, F. Effects of nano-TiO2 on the toughness and durability of cement-based material. Adv. Mater. Sci. Eng. 2015, 2015, 583106. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Luo, W.; Zhou, W. Effects of adding nano-TiO2 on compressive strength, drying shrinkage, carbonation and microstructure of fluidized bed fly ash based geopolymer paste. Constr. Build. Mater. 2016, 106, 115–125. [Google Scholar] [CrossRef]

- Idrees, M.; Saeed, F.; Amin, A.; Hussain, T. Improvement in compressive strength of Styrene-Butadiene-Rubber (SBR) modified mortars by using powder form and nanoparticles. J. Build. Eng. 2021, 44, 102651. [Google Scholar] [CrossRef]

- Mirgozar Langaroudi, M.A.; Mohammadi, Y. Effect of nano-clay on workability, mechanical, and durability properties of self-consolidating concrete containing mineral admixtures. Constr. Build. Mater. 2018, 191, 619–634. [Google Scholar] [CrossRef]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. Polypropylene fiber reinforced cement mortars containing rice husk ash and nano-alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Praveenkumar, T.R.; Vijayalakshmi, M.M.; Meddah, M.S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Abbasi, S.M.; Ahmadi, H.; Khalaj, G.; Ghasemi, B. Microstructure and mechanical properties of a metakaolinite-based geopolymer nanocomposite reinforced with carbon nanotubes. Ceram. Int. 2016, 42, 15171–15176. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Gao, Y. Effect of TiO2 nanoparticles on physical and mechanical properties of cement at low temperatures. Adv. Mater. Sci. Eng. 2018, 2018, 8934689. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Improvement compressive strength of concrete in different curing media by Al2O3 nanoparticles. Mater. Sci. Eng. A 2011, 528, 1183–1191. [Google Scholar] [CrossRef]

- Zhang, M.H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Shekari, A.H.; Razzaghi, M.S. Influence of nano particles on durability and mechanical properties of high performance concrete. Procedia Eng. 2011, 14, 3036–3041. [Google Scholar] [CrossRef]

- Kishore, K.; Pandey, A.; Wagri, N.K.; Saxena, A.; Patel, J.; Al-Fakih, A. Technological challenges in nanoparticle-modified geopolymer concrete: A comprehensive review on nanomaterial dispersion, characterization techniques and its mechanical properties. Case Stud. Constr. Mater. 2023, 19, e02265. [Google Scholar] [CrossRef]

- Dong, Y. Performance assessment and design of ultra-high performance concrete (UHPC) structures incorporating life-cycle cost and environmental impacts. Constr. Build. Mater. 2018, 167, 414–425. [Google Scholar] [CrossRef]

- Steinberg, E. Structural Reliability of Prestressed UHPC Flexure Models for Bridge Girders. ASCE 2009, 15, 65–72. [Google Scholar] [CrossRef]

- Kim, S.; Frangopol, D.M. Probabilistic bicriterion optimum inspection/monitoring planning: Applications to naval ships and bridges under fatigue. Struct. Infrastruct. Eng. 2012, 8, 912–927. [Google Scholar]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Bouhaya, L.; Le Roy, R.; Feraille-Fresnet, A. Simplified environmental study on innovative bridge structure. Environ. Sci. Technol. 2009, 43, 2066–2071. [Google Scholar] [CrossRef] [PubMed]

- Mohammed Safi, H.S.R.K.; George, R. Development of the Swedish bridge management system by upgrading and expanding the use of LCC. Struct. Infrastruct. Eng. 2013, 9, 1240–1250. [Google Scholar] [CrossRef]

- Jones, T.W.; Smith, D. An Historical Perspective of Net Present Value and Equivalent Annual Cost. Account. Hist. J. 1982, 9, 103–110. [Google Scholar] [CrossRef]

- Kauffmann, P.; Howard, E.; Yao, J.; Harbinson, D.; Brooks, N.; Williams, R.; Gurganus, C. Criteria for fleet management. Transp. Res. Rec. 2012, 2292, 171–178. [Google Scholar] [CrossRef]

- Chu, H.; Wang, F.; Wang, L.; Feng, T.; Wang, D. Mechanical properties and environmental evaluation of ultra-high-performance concrete with aeolian sand. Materials 2020, 13, 3148. [Google Scholar] [CrossRef]

- Kien, T.T. Comparison of energy consumption, CO2 emissions between normal concrete and UHPC in rural bridge application. J. Sci. Technol. Civ. Eng. 2023, 17, 168–179. [Google Scholar] [CrossRef]

- Mazzacane, P.; Ricciotti, R.; Teply, F.; Tollini, E.; Corvez, D. Mucem: The Builder’s Perspective. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fibre-Reinforced Concrete, Marseille, France, 1–3 October 2013. [Google Scholar]

- Aubry, S.; Bompas, P.; Vaudeville, B.; Corvez, D.; Lagrange, T.; Mazzacane, P.; Brizou, A. A UHPFRC Cladding Challenge: The Fondation Louis Vuitton Pour La Création. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fibre-Reinforced Concrete, Marseille, France, 1–3 October 2013. [Google Scholar]

- Muttoni, A.; Brauen, U.; Jaquier, J.L.; Moullet, D. A New Roof for the Olympic Museum At. In Proceedings of the International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, Marseille, France, 1–3 October 2013. [Google Scholar]

- Russell, H.G.; Graybeal, B.A.; Russell, H.G. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community (No. FHWA-HRT-13-060); Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2013.

- Akhnoukh, A.K.; Buckhalter, C. Ultra-high-performance concrete: Constituents, mechanical properties, applications and current challenges. Case Stud. Constr. Mater. 2021, 15, e00559. [Google Scholar] [CrossRef]

- Prabhu, S.; Prakash, K.B.; Shashishankar, A.; Mahdi, S.N.; Mohiyuddin, C.S. Green approach on ternary blended pre stressed cement concrete railway sleepers. Clean. Mater. 2022, 4, 100079. [Google Scholar] [CrossRef]

| Reviews Content | Year | References |

|---|---|---|

| Historical development of UHPC composition, Design methodology, Production, Manufacturing, Mechanical Properties, Innovation and research, Superhydrophobicity, Self-Sensing, Multifunctionality, Durability, Nanotechnology, Life cycle assessment, Numerical examples and Applications | 2024 | This review |

| Production, Manufacturing, Mechanical Properties, Self-sensing and Applications | 2023 | [12] |

| Design methodology, Production Manufacturing, and Mechanical Properties | 2023 | [13] |

| Mechanical Properties, Innovation and research, Superhydrophobicity, Durability and Nanotechnology | 2023 | [14] |

| Design methodology, Production, Manufacturing, Mechanical Properties, Innovation and research, and 3-D printing | 2023 | [15] |

| Design methodology, Mechanical Properties and Durability | 2022 | [16] |

| Historical development of UHP composition and Mechanical Properties | 2022 | [17] |

| Design methodology, Production and Manufacturing | 2022 | [18] |

| Historical development of UHPC composition, Mechanical Properties, Durability, Life-cycle assessment and Applications | 2022 | [19] |

| Mechanical Properties and Durability | 2022 | [20] |

| Historical development of UHPC composition, Mechanical Properties, Self-sensing, Durability and Nanotechnology | 2022 | [21] |

| Superhydrophobicity and Durability | 2022 | [22] |

| Design methodology and Production | 2021 | [7] |

| Design methodology and Mechanical Properties | 2021 | [23] |

| Mechanical Properties and Life-Cycle Assessment | 2021 | [24] |

| Historical development of UHPC composition, Design methodology, Production, Mechanical Properties, Durability and Applications | 2021 | [25] |

| Design methodology and Mechanical Properties | 2020 | [26] |

| Historical development of UHPC composition, Design methodology, Production and Applications | 2018 | [11] |

| Historical development of UHPC composition, Design methodology, Production, Manufacturing and Nanotechnology | 2015 | [10] |

| Composition | Sequence | Type of Fibre | Length and Diameter | Amount of Fibres Vol. % or kg/m3 | Cement kg/m3 | Ref. |

|---|---|---|---|---|---|---|

| PC + SF + Q | Steel Fibre | 13 mm × 0.16 mm ∅ 6 mm × 0.16 mm ∅ | 2–2.5 | 788 | [16] | |

| PC + FA + SF | Steel Fibre | 13 mm × 0.20 mm ∅ | 1–3 | 642–662 | [80] | |

| PC + FS+ SF | Steel Fibre | 0–2 | 712 | [16] | ||

| PC + SF + FA | Steel Fibre | 20 mm × 0.20 mm ∅ 25 mm × 0.30 mm ∅ | 1 | 360–900 | [16] | |

| PC + FA + GGBS | Steel Fibre | 0 | 582.1–896.3 | [81] | ||

| PC + SF + QP | Glass Fibre | 6 mm × 0.015 mm ∅ | 12 * | 750 | [82] | |

| PC + SF + UFSP | Polypropylene | 12 mm × 0.050 mm ∅ | 0–78 | 737–1005 | [83] | |

| PC + MK + NMK | 720–800 | [16] | ||||

| PC + MK+ FA | 482 | [84] | ||||

| PC + MK + LS | 608 | [84] | ||||

| PC + GGBS + QP + FS | GGBS 30% | Steel Fibre | 13 mm × 0.20 mm ∅ | 2 | 630 | [85] |

| PC + GGBS + QP + FS | GGBS 40% | Steel Fibre | 2 | 540 | [85] | |

| PC + GGBS + QP + FS | GGBS 50% | Steel Fibre | 2 | 450 | [85] | |

| PC + FA + QP + SF | FA 20% | Steel Fibre | 2 | 720 | [85] | |

| PC + FA + QP + SF | FA 25% | Steel Fibre | 2 | 675 | [85] | |

| PC + FA + QP + SF | FA 50% | Steel Fibre | 2 | 630 | [85] | |

| PC + MK + SF | MK 15% | Steel Fibre | 2 | 765 | [85] | |

| PC + MK + SF | MK 20% | Steel Fibre | 2 | 720 | [85] | |

| PC + MK + SF | MK 25% | Steel Fibre | 2 | 675 | [85] | |

| PC + SF | Metal fibre | 13 mm × 160 μm ∅ | 138 * | 691 | [86] | |

| PC + MK | Metal fibre | 138 * | 691 | [86] | ||

| PC + FA + SF | Straight steel fibre | 13 mm × 0.20 mm ∅ | 156 * | 754 | [87] | |

| PC + FA + SF + MK | 156 * | 754 | [87] | |||

| PC + FA + MK | 156 * | 754 | [87] | |||

| PC + SF + QS | Basalt Fibre | 12 mm × 15 μm ∅ | 0, 0.5, 1.0, 2.5 | 706 | [88] | |

| PC + SF + QP + QS | Basalt Fibre | 12 mm × 18 μm ∅ | 6 * | 876 | [89] | |

| PC + GP + SF + WG | Basalt Fibre | 24 mm × 16 + 0.2 μm ∅ | 8.1 * | 720–400 | [90] |

| Property | Ordinary Concrete (OC) | High-Performance Concrete (HPC) | Ultra-High-Performance Concrete (UHPC) |

|---|---|---|---|

| [27] | [125] | [126] | |

| Compressive Strength (MPa) | <50 | 60–100 | >120 |

| Flexural Strength (MPa) | <5.4 | 8.94 | >12 |

| Cement (kg/m3) | <400 | 425–500 | 746 |

| Water-Cement Ratio | >0.35 | 0.4 | 0.24 |

| Coarse and Fine Aggregates Ratio | 1:0.70 | 1:0.54 | 0:1 |

| Admixtures Used | - | Superplasticizer | Superplasticizer |

| Curing Method | 28 days water curing | 28 days water curing | 28 days water curing |

| Special Ingredients | - | Metakaolin and steel fibres | Metakaolin/Micro Silica and basalt fibres |

| Application/Use Cases | Construction and Infrastructures | Construction and Infrastructures | Construction, Infrastructures, high elevated temperature zone, harsh marine environment and high security zone construction |

| W/B | Silica Fume % | Metakaolin % | Steel Fibre kg/m3 | Curing Methods | Compressive Strength | Flexural Strength | |

|---|---|---|---|---|---|---|---|

| Method | Hours/Days | MPa | MPa | ||||

| 0.22 | 25 | T @ 90 °C | 70/5 | 133 | 5 | ||

| T @ 150 °C | 70/5 | 141 | 11 | ||||

| 25 | 164 | T @ 90 °C | 70/5 | 126 | 6 | ||

| T @ 150 °C | 70/5 | 140 | 14 | ||||

| 25 | 165 | T @ 90 °C | 70/5 | 204 | 34 | ||

| T @ 150 °C | 70/5 | 234 | 34 | ||||

| Material | Reference [216] | Reference [224] | Reference [225] | |||

|---|---|---|---|---|---|---|

| Weight | Unit CO2 Emission | Weight | Unit CO2 Emission | Weight | Unit CO2 Emission | |

| (kg) | (kg-CO2/kg) | (kg) | (kg-CO2/kg) | (kg) | (kg-CO2/kg) | |

| Cement | 800 | 0.865 | 646 | 0.8324 | 1025 | 0.8650 |

| Fly ash | - | - | 323 | 0.0090 | 175 | 0.1965 |

| Silica fume | 250 | 0 | 108 | 0 | 330 | 0.0070 |

| Silica powder | - | - | - | - | 300 | 0.0018 |

| Silica sand | - | - | - | - | 650 | 0.0009 |

| Aeolian sand | - | - | 862 | 0.0010 | - | - |

| Aggregate | 750 | 0.0013 | - | - | - | - |

| Steel fibre | 195 | 0.94 | 195 | 1.4965 | 235 | 0.9299 |

| Water | 200 | - | 215 | 0.0003 | 246 | - |

| Superplasticizer | 40 | 0.0184 | 22 | 0.7200 | 31 | 0.092 |

| Expensive agent | - | - | 32 | 0.0810 | - | - |

| CO2 emissions/m3 | 877 kg-CO2/m3 | 852 kg-CO2/m3 | 1146 kg-CO2/m3 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kravanja, G.; Mumtaz, A.R.; Kravanja, S. A Comprehensive Review of the Advances, Manufacturing, Properties, Innovations, Environmental Impact and Applications of Ultra-High-Performance Concrete (UHPC). Buildings 2024, 14, 382. https://doi.org/10.3390/buildings14020382

Kravanja G, Mumtaz AR, Kravanja S. A Comprehensive Review of the Advances, Manufacturing, Properties, Innovations, Environmental Impact and Applications of Ultra-High-Performance Concrete (UHPC). Buildings. 2024; 14(2):382. https://doi.org/10.3390/buildings14020382

Chicago/Turabian StyleKravanja, Gregor, Ahmad Rizwan Mumtaz, and Stojan Kravanja. 2024. "A Comprehensive Review of the Advances, Manufacturing, Properties, Innovations, Environmental Impact and Applications of Ultra-High-Performance Concrete (UHPC)" Buildings 14, no. 2: 382. https://doi.org/10.3390/buildings14020382

APA StyleKravanja, G., Mumtaz, A. R., & Kravanja, S. (2024). A Comprehensive Review of the Advances, Manufacturing, Properties, Innovations, Environmental Impact and Applications of Ultra-High-Performance Concrete (UHPC). Buildings, 14(2), 382. https://doi.org/10.3390/buildings14020382