Abstract

The interaction of reinforcement bars with concrete determines the structural behavior and bond performance (bond strength) in reinforced cement concrete. Bond strength and its importance in structural applications based on available standards attracted researchers around the globe to evaluate the bond strength in reinforced cement concrete through various test methods and procedures. In this review article, more than 200 globally published studies were collected, and 170 articles were compiled to discuss the importance of bond strength and the factors that affect bond strength in concrete. The various factors/parameters that affect the bond strength, including concrete type and its properties, the reinforcement bar with its geometry and shape, environmental nature of the specimen with its testing methods and standards, and other miscellaneous factors, were comprehensively analyzed. We present a summary of the findings; a surprising fact was that every factor is responsible for developing bond strength in concrete in one way or another.

1. Introduction

Concrete is an extensively used heterogeneous material in every stage of construction and the most influential material responsible for all the infrastructural development of any country. Several advancements in the construction industry have made a highly complex structure look simple for construction. However, despite advances, failure in the structure is unavoidable. Failure in reinforced concrete structures occurs mainly through the weakening of the bond property [1]. Bond strength is the property that builds adhesion between concrete and its adjacent reinforcement bars, making it a key factor in the structural behavior of concrete [2,3]. It is also responsible for transitioning the axial loads safely between structural elements, provided that the composite nature of concrete and strain compatibility is attained [4,5,6]. Bond strength also avoids the discontinuity in transferring the external force [7]. In other words, bonding is nothing but the distribution of uniform shear stress over the reinforcement bars [8,9]. The bonding mechanism has been observed to affect structural members’ ductility, deformation, and energy dissipation levels [10]. It is also responsible for determining the cracking behavior of structural elements [11]. Furthermore, it is believed that an integral bond could terminate local failure risk, confirming the structural element’s sufficient bearing capacity [12]. Insufficient bond strength in reinforced concrete elements often leads to invalid specifications originally designed for elements [13]. To maintain a good bond and strength to resist tensile force, both reinforcing steel and concrete should develop equal strain along their contact surface. To emphasize the importance of bond strength between concrete and steel reinforcement, ACI also suggested codal provisions based on several investigations [14,15,16]. It is known that compressive strength plays a vital role in affecting the bond strength of concrete [17]. Bond strength mainly depends on the compressive strength of concrete, but there are other factors such as geometry, shape, and the orientations of reinforcement bars [18]. Other features that affect the bond strength are concrete cover, confinement and bonding length, external bar coatings, etc. [19,20]. It is also said that even aggregate size and type influence bond strength development [21]. By considering outcomes from various researchers, this review paper is organized with the aim of discussing and analyzing the various factors affecting bond strength between concrete and reinforcement bars.

2. Outline

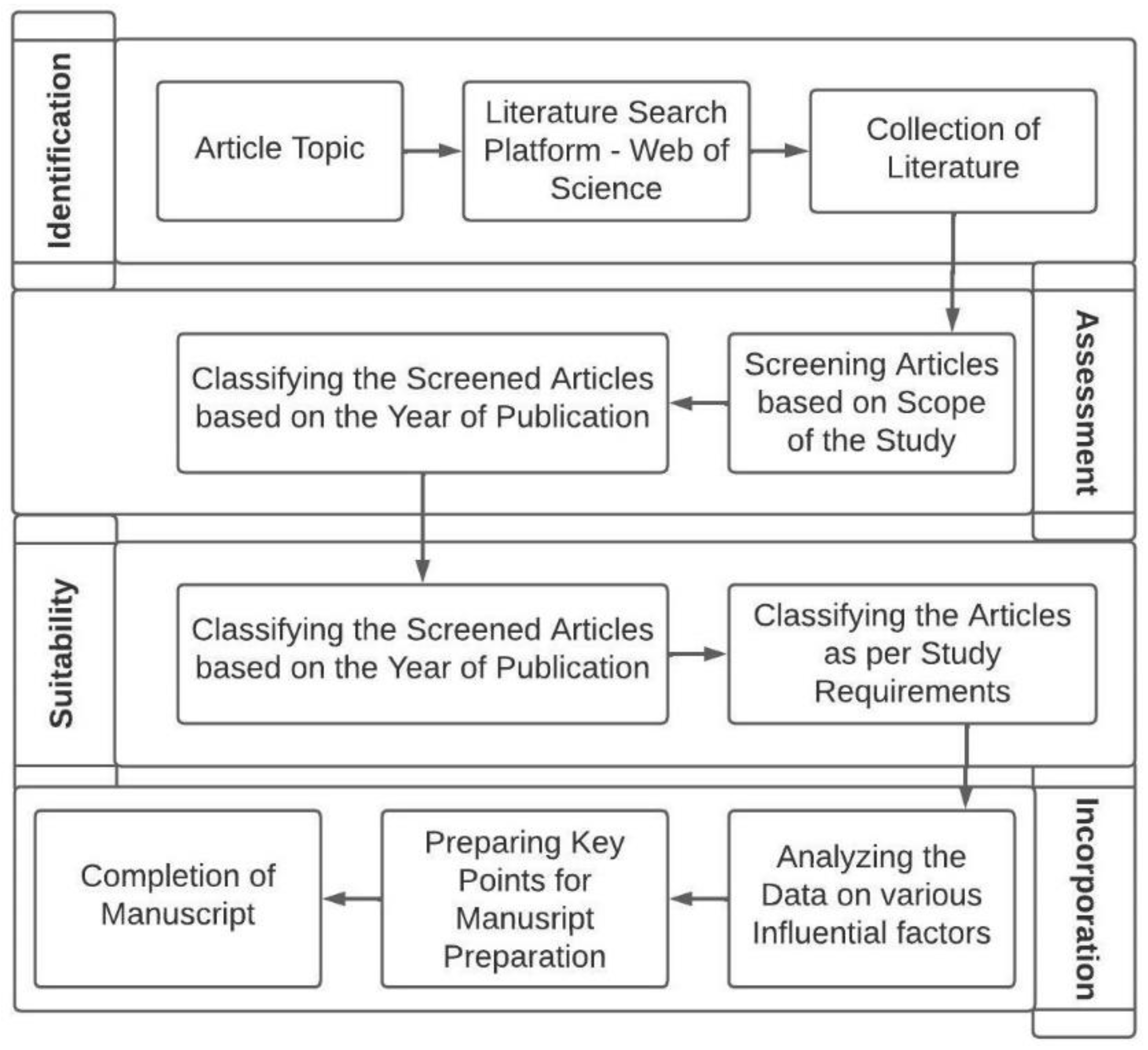

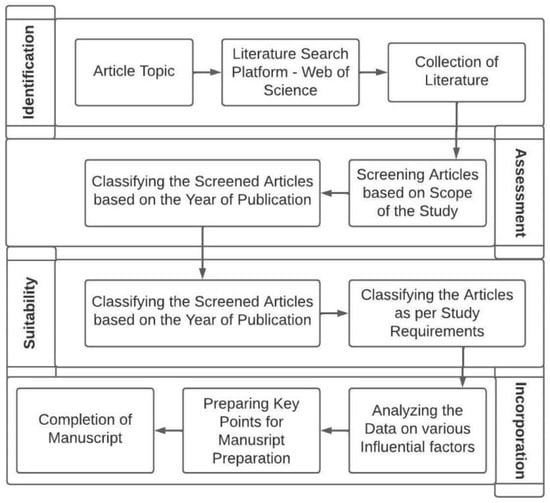

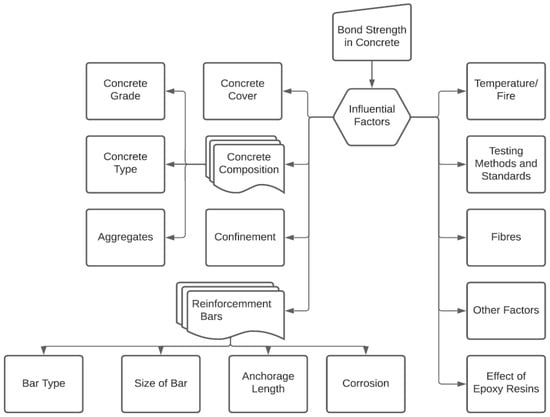

This article focuses mainly on the various parameters affecting or influencing concrete bond strength. A thorough review of about 170 globally published studies from the past five decades has been performed. Literature was categorized based on different factors affecting bond strength in concrete. Factors such as the influence of concrete type and its properties, the reinforcement bar with its geometry and shape, testing methods and standards, and other miscellaneous factors are also included. The research methodology followed in the review article is shown in Figure 1.

Figure 1.

Methodology.

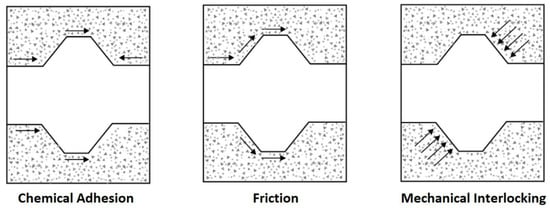

3. Bond Properties of Concrete

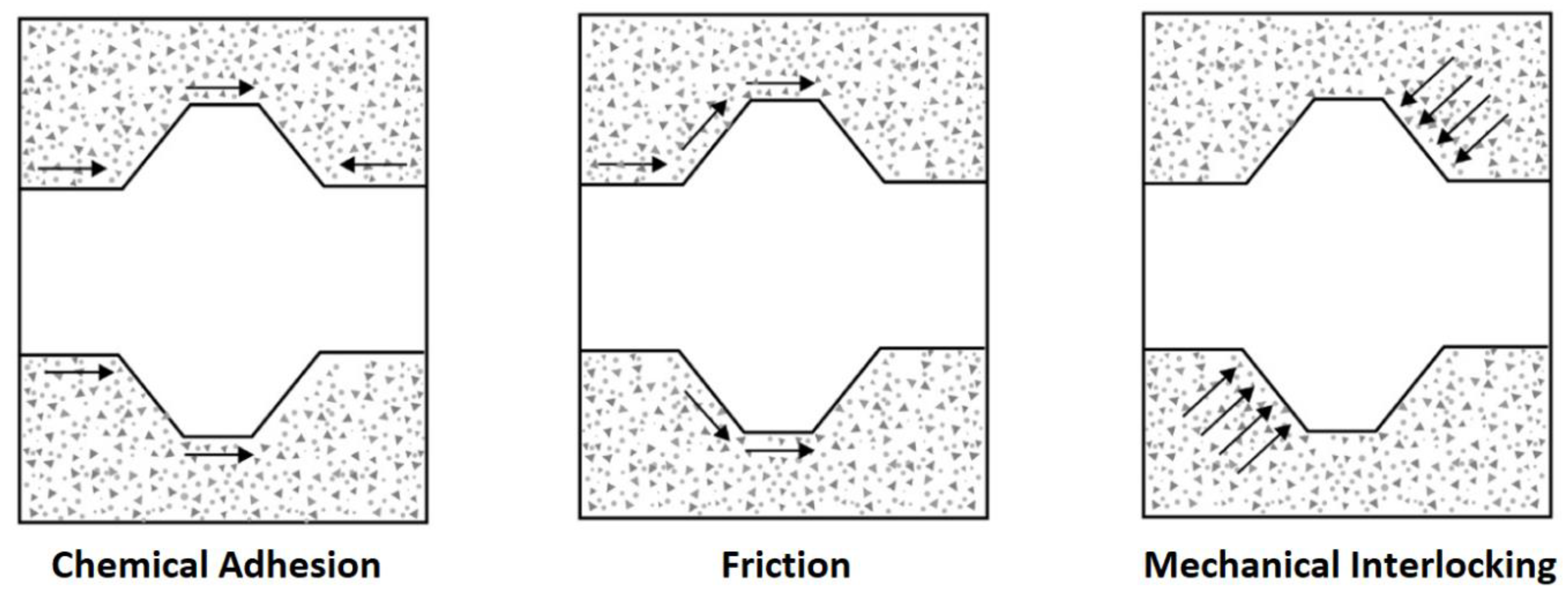

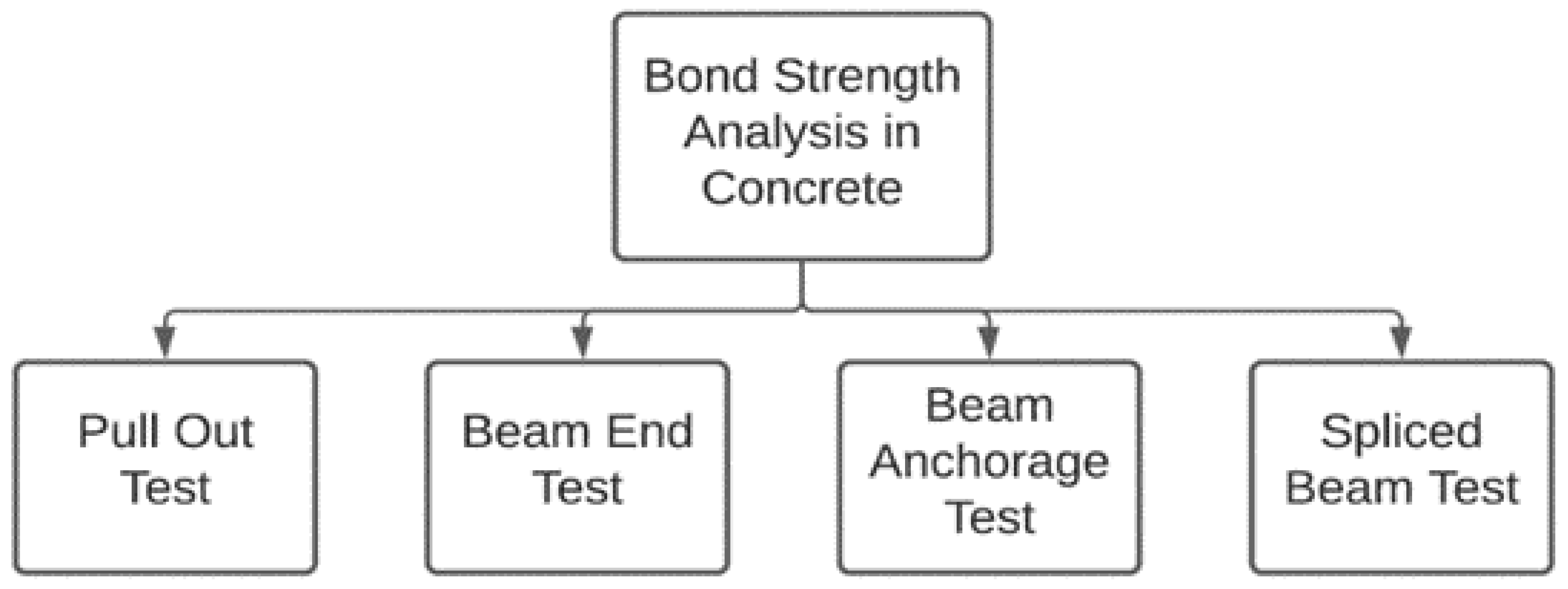

Bond property is the behavior that broadly accepts the performance of reinforced cement concrete (RCC) structures between reinforcing bars and concrete [22]. Earlier, various researchers recognized the bond strength of concrete as a material property. Later, researchers accepted it as a structural property of concrete that includes the behavior of different materials with reinforcing steel bars [16]. Bond strength development occurs in 3 mechanisms: friction, adhesion, and mechanical interlocking, while the bond fails mainly through a lack of friction and adhesion [23]. A graphical representation of the bond mechanism is shown in Figure 2 [24]. Bonding between concrete and reinforcement bars becomes the most critical reason for assessing the mechanical properties and structural behavior of RCC structures [25]. It also acts as a critical factor in the strengthening and soundness of concrete structures [26]. There are five phases of bond behavior: micro-slip, internal cracking, pull-out, descending, and residual stress [27]. Testing bond strength can be traced back 1.5 centuries, as it was performed in the late 1870s by Thaddeus Hyatt [28]. Bond strength in concrete can be evaluated through a typical pull-out test, beam end test, and beam test (beam anchorage and spliced beam test), as shown in Figure 3. The most commonly used method is the direct pull-out test, which can be executed using a Universal Testing Machine (UTM) [29]. The formulae for determining the bond strength in concrete through pull-out and beam tests with codal provisions are listed in Table 1 and Table 2, respectively.

Figure 2.

The bond mechanism between concrete and reinforcement bar [24].

Figure 3.

Various tests for analyzing bond strength in concrete.

Table 1.

Comparison of international codes for determining the bond strength in concrete by pull-out test [6,30,31,32,33,34,35].

Table 2.

Bond strength by spliced beam/beam end test method [16,30,36,37,38].

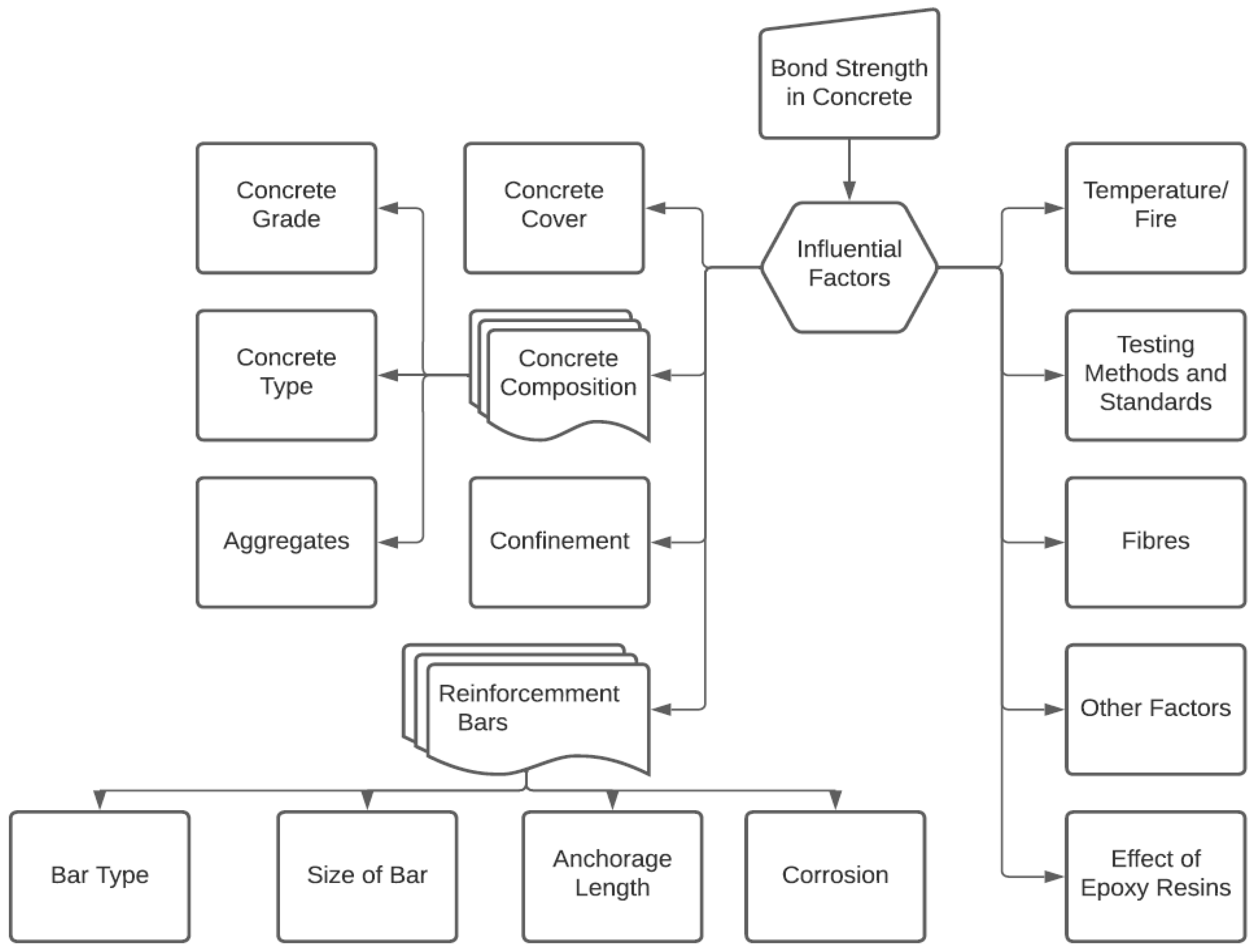

4. Factors Influencing Bond Strength in Concrete

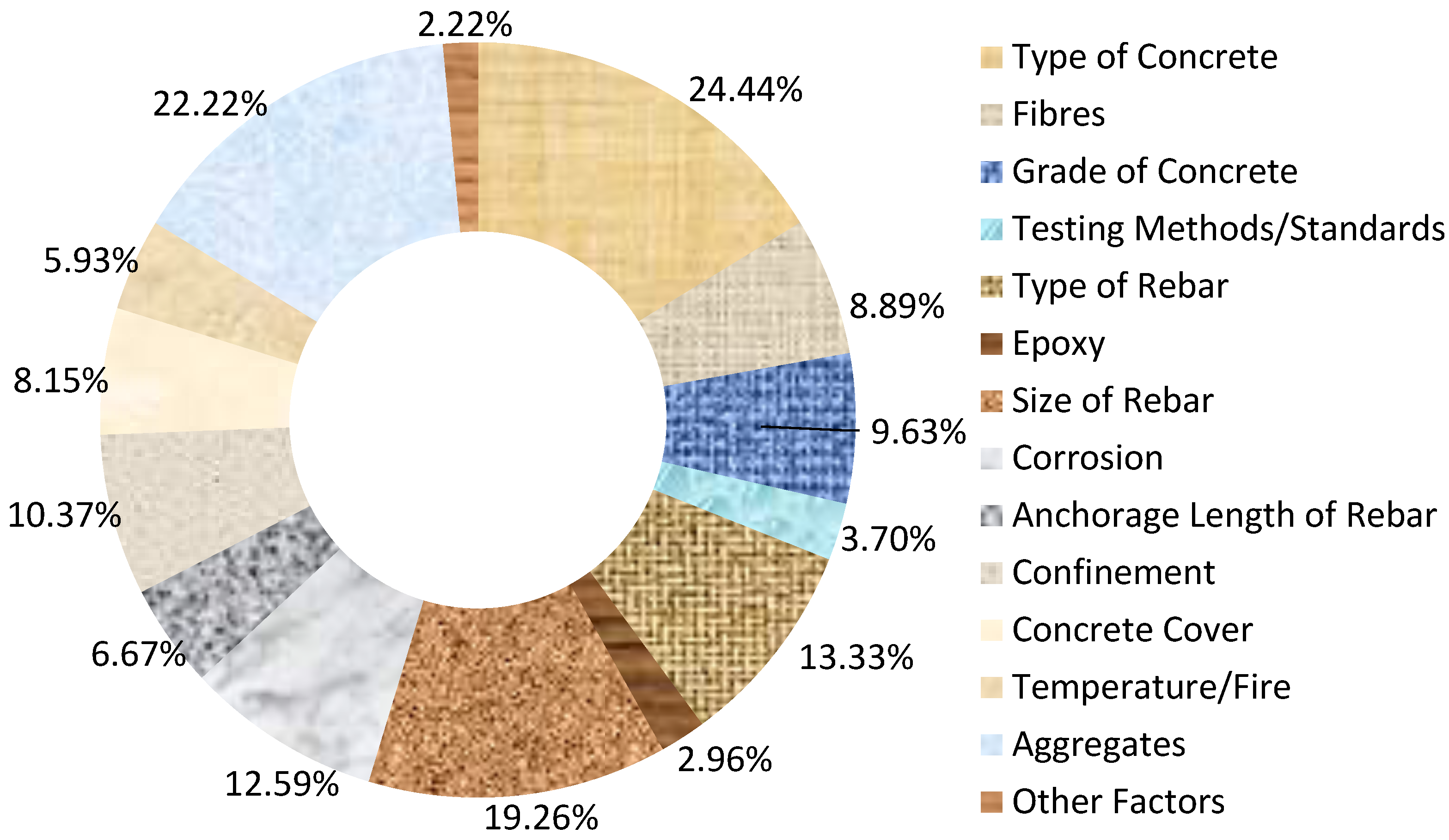

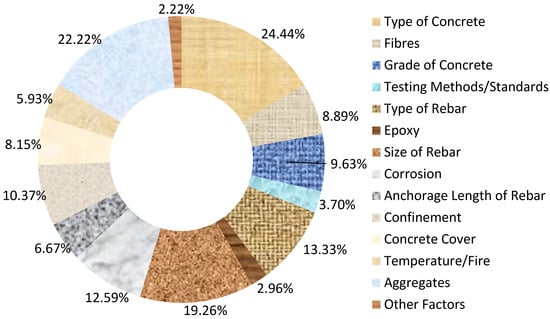

Various studies indicate that several parameters are involved in developing the bond strength in concrete; the most significant are discussed in this article. The various factors that affect the bond strength in concrete are shown in Figure 4. The statistical distribution of the literature contributing to each factor is represented in Figure 5.

Figure 4.

Various factors influencing the bond strength in concrete.

Figure 5.

Contribution of literature on various parameters of bond strength.

4.1. Type of Concrete

It is generally discussed that the concrete type used for evaluation plays a vital role in developing the bond strength in concrete. Bond strength can be influenced by the concrete type based on its workability, performance, usage of recycled materials, industrial wastes, and by-products which are discussed below.

4.1.1. Self-Compacting Concrete (SCC)

Self-compacting concrete (SCC) exhibits better bond strength than conventional concrete (vibrated/compacted concrete) due to high powder content and increased fillers in the concrete mix [30,39,40]. It is observed that the bond property is not influenced by the flowability of concrete [41]. Incorporating by-products such as fly ash, recycled concrete aggregates (RAC), etc., improved the bond strength [42,43]. Regardless of the type and size of bars used, SCC performs much better than conventional vibrated concrete because of the high powder content (sum of cement and filler materials) available in the mix that seals the pores/voids present [30,39,44,45]. Based on the results, it is observed that self-compacting concrete improves the bond strength ranging from 20 to 150% in different concrete mixes [30,39,40,41,42,43,44,45]. The summary of the bond strength comparison between externally compacted concrete and self-compacting concrete with the mix design is given in Table 3. It is observed that the binder content plays an important role in concrete strength, which is responsible for bond strength development.

Table 3.

Comparing bond strength discussed in the literature.

4.1.2. Geopolymer Concrete

Recently, geopolymer concrete has been widely used as a substitute for traditional cement concrete due to its eco-friendly nature and for reducing CO2 emissions [46,47]. Comparing geo-polymer with conventional cement concrete, the former has better bonding ability than the latter because geopolymer concrete exhibits higher splitting tensile strength than traditional Portland cement concrete [48,49]. It also creates strong adhesion between the bars and binder which improves the bond strength [50]. It is observed that geopolymer concrete exhibits a greater bonding nature than conventional cement concrete due to its improved density and mobility. It also creates a homogenous matrix that provides uniform confinement and stiffness to the specimens enhancing bonding strength [47,51]. The denser microstructure of geopolymer concrete is also said to be a factor that improves bond strength [52]. It is observed that roughness determines the bonding capacity of geopolymer concrete, as the higher the roughness the better the bonding strength during the pull-off test [53].

4.1.3. Recycled Aggregate Concrete (RAC)

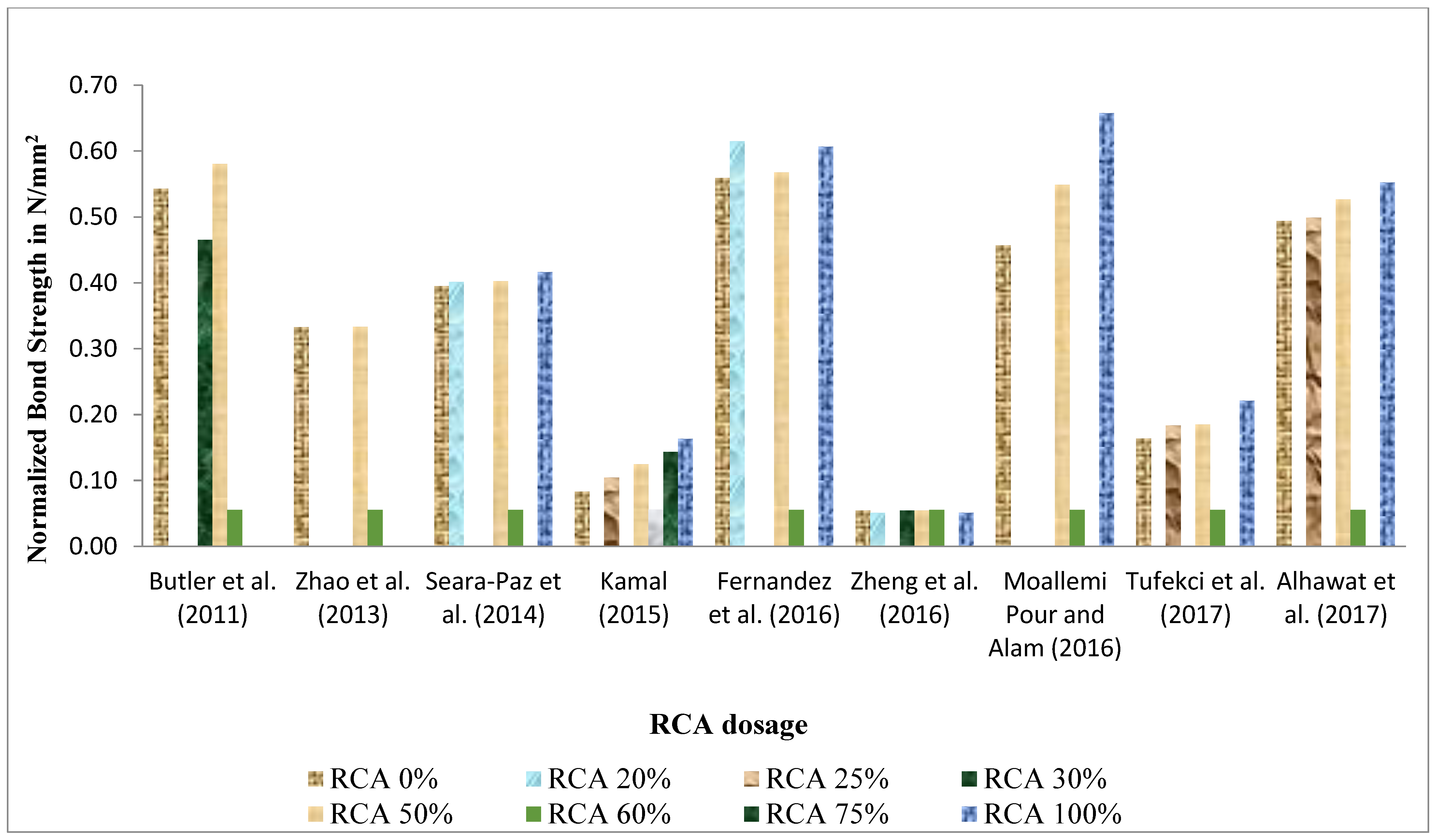

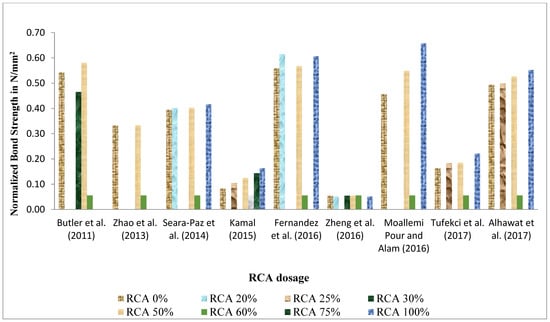

Several researchers found that recycled aggregate concrete (RAC)—a type of concrete with recycled concrete as aggregates (RCA), has both positive and negative influential roles in developing bond strength. RAC has an excellent bond property as it can increase the splitting tensile strength of concrete, improving the bond strength [54,55,56]. In contrast, their bond strength was reduced due to the decreased density of RAC [18,57,58,59,60]. The authors also expressed a different view that RAC did not have any influential role in developing the bond strength in concrete as it neither improved nor degraded the bond strength [13,43,61,62]. It is found that the bond strength in concrete is influenced by the crushing strength of the coarse aggregate (RCA) depending on the fracture energy of the concrete [63]. The normalized bond strength results with various RCA dosages are presented in Figure 6. The results show that incorporating RCA does not affect the bond strength even for higher replacement levels. This shows the compatibility of RCA as an alternate construction material to the industry.

Figure 6.

Bar chart comparing normalized bond strength in terms of dosage of RCA [13,18,43,55,56,57,60,61,62].

4.1.4. Alkali-Activated Concrete (AAC)

Alkali Activated Concrete (AAC) mainly uses fly ash as its binder due to its economic feasibility [64]. Pure ground granulated blast furnace slag (GGBS) concrete (without cement) had no or slight impact on the bond strength, as it was stated that an advanced evaluation of the steel-concrete adhesion was required to validate its effectiveness [65]. GGBS combined with fly ash as a binder shows drastically higher bond performance for fly ash replacements of up to 50% and develops bond strength around 2.5 times higher than nominal fly ash concrete mix. This was due to the denser interfacial transition zone (ITZ) created by the activated slag particles (slag+ NaOH+ Na2SiO3), resulting in a denser microstructure [66]. The bond strength results of AAC reported in the literature are presented in Table 4, which also shows concrete mixture proportions designed along with the type and quantity of alkali activators used in the study. From the table, it was found that slag plays a sizable role in the development of bond strength in AAC as slag content increases the bond strength.

Table 4.

Comparison of bond strength results of AAC.

4.1.5. Other Concrete Types

Incorporating ground granulated blast furnace slag (GGBS) with recycled concrete aggregate (RCA) majorly improves the bond strength unrelated to the dosage introduced in cement concrete due to the tensile strength developed by GGBS. It is shown that GGBS enhances the bond strength of concrete up to 25% more than the standard cement concrete when replaced with up to 60% of the weight of cement with 100% of RCA [56]. Hybrid cement concrete (HCC), a mixture of Portland cement and slag produced by using sodium carbonate as the activator did not attain better bonding properties than OPC concrete due to its low compressive strength and splitting tensile strength [65]. Ultra-high performing concrete proved successful as a repair material in concrete structures due to its high tensile property, which showed better bonding with old concrete substrate [67].

On the other hand, fly ash concrete (FAC) and high-volume fly ash concrete (HVFAC) did not improve the concrete bond strength. The presence of fly ash up to 70% for cement develops only half of the bonding capacity of the concrete without fly ash. The decrease in bond strength was due to the loss in the gripping action of reinforcement bars with concrete, resulting in reduced adhesion because of high volume fly ash [68]. Concrete made with a blend of fly ash and calcium carbide residue (CFRA-70:30 ratio) as a binder did not affect bond strength. In contrast, the above blend with cement (CRFA: cement ratio as 90:10) experienced a slight reduction in bond strength. The conditions mentioned above were due to the compressive strength obtained by the respective concrete mixes as the former showed higher compressive strength whereas the latter showed lower compressive strength [69].

Engineered cementitious composite (ECC) showed better bond strength than conventional concrete due to the confinement generated by fibers [70]. Concrete produced using normal water and seawater for mixing was used to evaluate the bond strength reinforced with sand-coated bars. The results showed a minimal effect on bond strength due to the small adhesion effect of sand coating on the reinforcement bars [71]. It was observed that rubberized concrete with up to 12% crumb rubber replacement for aggregates did not have any reduction in bond strength, above which a reduction of up to 20% can be obtained. The reduction was due to the stiffness caused by the chemical adhesion of crumb rubber, which induced minor cracks in the internal surface of the concrete [72]. Fly ash and silpozz (ash from rice husk) were replaced with cement in dosages of 10% and 0 to 40%, respectively, to find their impacts on bond strength. Results revealed that the combination of 20% silpozz with 10% fly ash exhibited promising bond properties due to the improved tensile strength of silpozz-incorporated concrete. No changes in bond strength were obtained for other mixtures [73].

4.2. Grade of Concrete

The designed concrete grade plays a substantial part in fresh, mechanical, and durability properties. However, the bond strength of concrete is directly dependent on the concrete’s grade (compressive strength). It was found that concrete with higher grades performs better than the lower graded concrete in bond strength due to its high quality, better crack-resisting performance, and better quality of cement paste [74,75]. It was found that an increase in the packing density of concrete improved the bond strength [60,76]. Similar results were also discussed in some of the literature to establish the fact that increasing the grade of concrete improved its bond strength due to the reduction in pores and denser concrete packing. Still, certain linearity in the development was not observed [77].

Several researchers discussed that increasing the grade of concrete developed bond strength two to three times more (greater than 100% improvement) than the bond strength attained by lower grades of concrete [18,30,62,77]. On the other hand, the grade of concrete had a slight (less than 5% improvement) or almost no effect on bond strength [19,78]. It was found that bond strength increased with increased compressive strength during ageing (curing days) [79]. Bond strength development at early stages was satisfactory when compared to aged specimens in normal strength concrete (NSC), and slow development was observed in high strength concrete (HSC). It was inferred that bond strength in concrete improved by increasing the grade up to M35, above which a decline in bond strength was discussed owing to the surface hardness provided by higher grades of concrete [80].

Few studies showed that bond strength increases with higher grades of concrete but inferred that it did not improve the pace at which the compressive strength increases [31,81]. Considering the parameter of concrete grade in other concrete types, such as alkali-activated concrete, recycled aggregate concrete, fly ash concrete, slag concrete, etc., the bond strength improved in ranges of up to 18%, 36%, 56%, and 77%, respectively, [65,82,83,84]. Lachemi et al. (2009) [85] discussed the relationship between concrete grade (compressive strength) and its corresponding bond strength as per the recommendations on ACI 318-05 [86].

To compare the bond strengths obtained by specimens possessing different compressive strengths, the concept of normalized bond strength was used so that the effect of compressive strength variations could be eliminated [87,88,89,90]. The formulae for determining the normalized bond strength are presented in Equation (1).

where

- is the bond strength in N/mm2

- is the cube compressive strength in N/mm2.

4.3. Type of Rebar

Generally, it is noted that the type of rebar used in combination with concrete impacts the bond strength between the rebar and the concrete surface [44]. Some of the commonly used bar types that are responsible for attaining bond strength are discussed below.

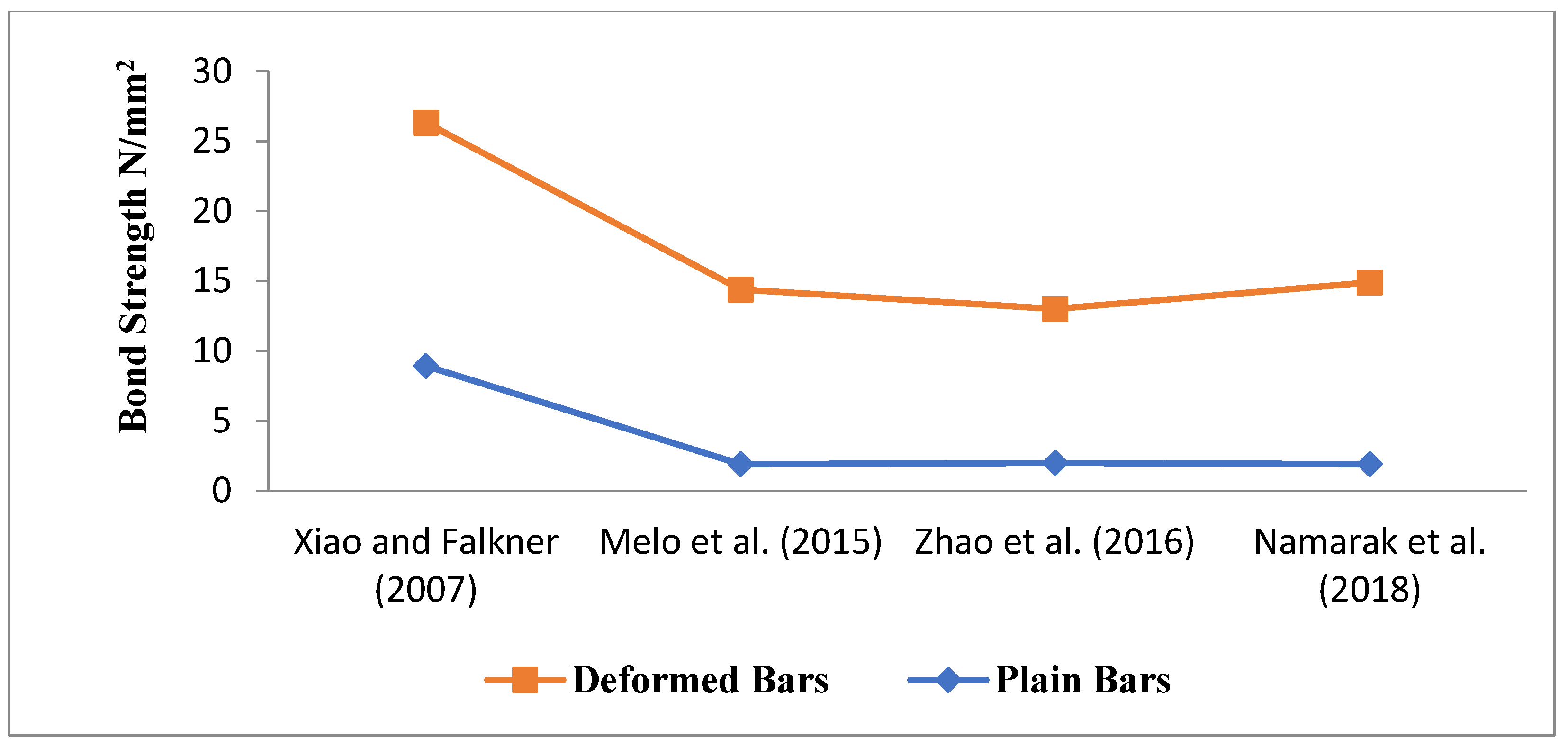

4.3.1. Steel Bars (Deformed vs. Plain/Smooth Bars)

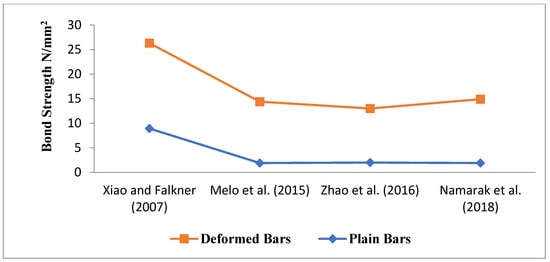

The steel bar cross-section influences bond strength development in concrete as bonding with deformed bars occurs through its rib structure, while chemical adhesion is required for smooth bars [91]. Hence, a comparative analysis of bond strength performance between plain and deformed steel bars was discussed. It is observed that deformed steel bars perform much better than plain/smooth bars as they attain two to ten times more strength than plain bars due to the interlocking mechanism provided by the ribs of steel bars which enhances bond interaction [5,10,68,69,92]. On comparing cold-twisted bars with hot-rolled bars, concrete with cold-twisted bars showed higher bonding than hot-rolled bars due to the better ductile property exhibited by the cold-twisted bars that provided frictional resistance to the bond [93]. It is also due to the mechanical anchorage and friction resistance between the deformed steel bars and concrete [94]. The comparison of bond strength between plain and deformed steel bars is shown in Figure 7. It can be noted that ribbed bars attained bond strength over 15 N/mm2, which is much higher than the plain bars that achieved only around 5 N/mm2 due to the interlocking mechanism created by the ribs of the deformed bar.

Figure 7.

Bond strength of concrete with plain and deformed steel bars [10,68,69,94].

4.3.2. Fiber-Reinforced Polymer Bars (FRP Bars)

Generally, incorporating fibers in concrete enhances the strength and durability of concrete through structural repairs due to their tensile strength and corrosion resistance [25,95,96,97]. Similarly, different FRP bars also influence the bond capacity of concrete. FRP bars made of basalt (BFRP-Basalt Fiber Reinforced Polymer), carbon (CFRP-Carbon Fiber Reinforced Polymer), and glass (GFRP-Glass Fiber Reinforced Polymer) were widely used in concrete as reinforcements [25,42,98]. CFRP bars exhibited a rise in bond strength during initial slips; later, they decreased the bond strength, but CFRP textile reinforcement showed only improvement throughout the test due to the influence of crack width, which seems to be smaller [99]. Concrete with different surfaced CFRP bars (smooth, ribbed, and double wrapped) were evaluated for bond strength and the results revealed that concrete had better bonding with ribbed bars due to the interlocking mechanism created by the ribs [100]. Due to the geometric shape and low elastic modulus, FRP bars (BFRP and GFRP) showed lower bond strength than steel bars [42,101], but a few results interpret that the interlocking mechanism surrounding the concrete made by GFRP bars increased the bond strength [102]. It was found that GFRP bars exhibited good bond strength at the initial stiffness stage due to the chemical adhesion provided by the GFRP bars [103].

Similarly, a minimal or no effect on bond strength was observed during the initial ages of concrete (with GFRP bars), but after 90 days, the bond strength was improved [104]. A drop in the bond strength was observed due to the components used as ribs in GFRP bars [105]. It was observed that environmental exposure to FRP bars influences the property of the bars, which influences the bond strength in concrete [106]. The comparison of bond strength results discussed by various researchers concerning the type of reinforced polymer bars used is given in Table 5. Data from Table 5 reveal that the average loss in bond strength is 33% due to low elastic modulus and components of the rib, while the improvement in bond strength appears to be around 19% due to the chemical adhesion created by the bars that improves stiffness and mechanical interlocking between the bars and surrounding concrete.

Table 5.

Effect of FRP bar type on bond strength.

4.3.3. Alloy Bars

Flat stainless-steel bars were used as reinforcements in place of ribbed steel bars, and the results revealed that flat stainless-steel bars did not improve the bond strength compared to ribbed bars due to the absence of interaction between steel and concrete. There was no satisfactory improvement in the bond strength as the stainless steel bars were replaced with carbon bars [44]. Iron-based shape memory alloy (FeSMA) was used as reinforcement in bars, and the bond strength was evaluated. The results revealed that confined and unconfined structures experienced a loss in bond strength, around 15% and 20%, respectively, compared to standard steel bars. A loss in the bond strength due to the smaller rib area available was observed in the FeSMA bars compared to steel bars [107].

4.3.4. Natural Reinforcement Materials

Bamboo sticks were used as reinforcement with bitumen coating and zeolite powder spraying in concrete to evaluate the bond strength. Results revealed that the bond strength of bamboo was less than that of the mild steel and Thermo-Mechanically Treated bars (TMT bars) [32]. Using bamboo-composite reinforcement with/without water-based epoxy coating and sand coating was analyzed. Results revealed a slight improvement in bond strength owing to the friction produced by the fine sand particles (when the sand coating was used) with the concrete surface [108].

4.4. Size of the Rebar

The size (diameter) of the rebar has a remarkable impact on bond strength of concrete. Several studies identified that the diameter of the bar has both positive and negative impacts on bond strength. Several researchers confirmed that higher the bar diameter the lower the bond property with the concrete surface [6,20,30,31,40,45,62,74,93,105,109,110,111,112]. However, contradictory results were obtained as the increase in bar diameter enhanced the bond strength as it can bear higher forces [48,83,87,113,114,115,116,117].

The increased bond strength in small-sized bars was due to the availability of higher surface area for bonding and low spacing between the ribs of bars [74,93]. A decline in the bond strength was observed to a maximum of 50% due to the increased size of the bar used as larger-sized bars needed lengthier splice area to obtain their maximum efficiency [20,45,62,118]. It was also noticed that the size of the bar used had no significant role in bond strength in concrete [27]. The nominal circular reinforcement bar was replaced with an H-shaped welded steel, and the results showed an outstanding improvement in the bond property of concrete with the replaced H section [119]. The effect of the rebar size on bond strength is furnished in Table 6.

Table 6.

Effect of rebar size on bond strength.

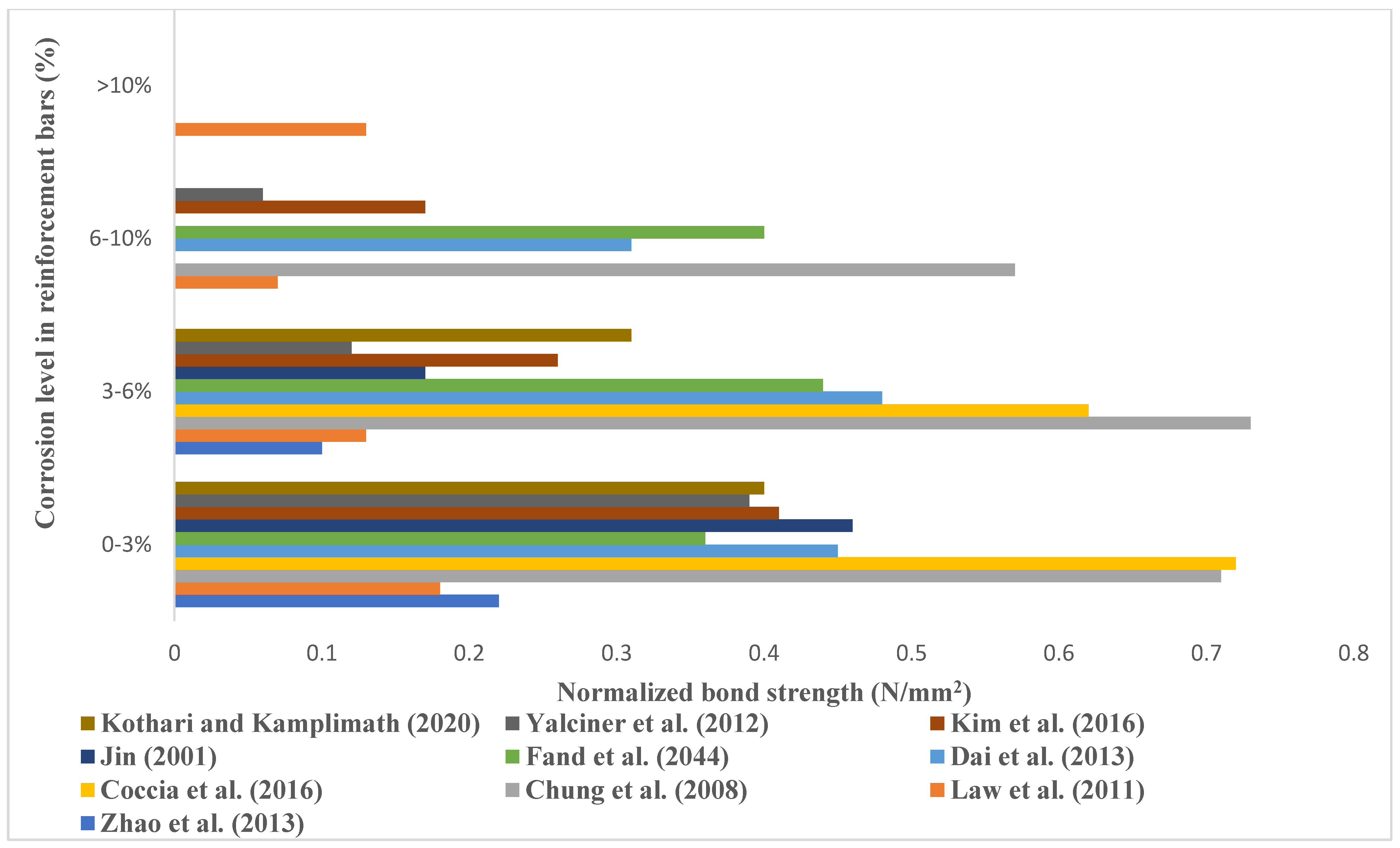

4.5. Effect of Corrosion

Corrosion in steel is one of the most serious problems faced today; it has to be observed in reinforced concrete structures as it greatly deteriorates the structure by its bond strength-reducing property [18]. It also plays a significant part in influencing the bond strength in concrete, as the degree of corrosion plays a crucial role in enhancing/degrading the bond property of concrete and steel rebar [121]. Corrosion is mainly responsible for reducing the adhesion between binder and steel, causing a disturbance in the load transfer system [51]. Almost all the researchers concluded that corrosion in steel bars resulted in both incremental and detrimental effects on bonding between rebar and the surrounding concrete, differing in the degree of corrosion [13,18,109,122,123,124,125,126,127,128,129,130,131,132].

Experimental results from a few studies discussed that low levels or initial degrees of corrosion (<5% corrosion) in the reinforcement bars improved the bonding capacity of concrete as it gained almost 50% more bond strength than corrosion-free specimens. This is due to the initial roughness created through corrosion which helps improve adhesion between steel and concrete, as well as the friction created by the expansion of bars due to corrosion [13,123,125,127,129,133,134]. In contrast, other studies revealed that even under 3% corrosion, a decline in bond strength was observed [124,130,131,132]. It was also noticed that corrosion in bars did not affect the bond strength as it showed neither improvement nor decrement [18,135].

Comparing both smooth and deformed bars under corrosion effects, smooth bars performed better than deformed bars due to the extensive pressure mechanism induced by corrosion and the improved friction in the interface due to the roughness created by corrosion [126]. Cracks were formed in bars above 5% corrosion (up to 10% corrosion) which did not affect bond strength [128] while increasing crack-width in steel bars due to the corrosion effect showed a negative impact on bond strength [109].

A large-scale corrosion effect (0 to 80% corrosion) was studied and the results revealed that around 17% improvement in bond strength was observed on lower levels of corrosion (up to 4% corrosion), followed by drastically reduced strength with up to 8% corrosion and then a gradual decrease in bond strength with up to 45% corrosion above which there was no deficit in bond strength. Improvement in bond strength is due to the pressure created by the expansion mechanism of corrosion products that improved the confinement bonding. Loss of the rib surface upon higher corrosion level leads to steel degradation, making it behave as a plain bar that results in low bond strength [122].

The consequences of corrosion in terms of duration (ageing of corrosion in weeks) were studied where bond strength improvement was observed with up to 5 weeks of corrosion and gradually decreased the strength with an increase in the corrosion period due to the rusting effect caused by corrosion. It was also noticed that despite the decrease in bond strength, the bond strength obtained was higher than the initial strength even after nine weeks of corrosion inhibition [136]. Numerous researchers described bond strength in concrete with altered corrosion levels, and different concrete mixes in combination with bars of the same/different diameters were compared, and the best results are shown in Figure 8. It can be observed that bond strength is higher for corrosion rates of less than 6% when compared to the higher corrosion rates of steel bars.

Figure 8.

Comparison of normalized bond strength at different corrosion levels [13,109,123,124,125,126,127,128,131,135].

4.6. Anchorage Length of Rebar

Embedment length or development length plays a primary role in developing bond strength in RC structures [62]. Several published results discussed that increasing embedment length of specimens decreases the bond between rebar and concrete [36,62,63,74,85,102]. A few researchers observed improvement in bond strength due to increasing bond length [40,137]. The pull-out force increases when the specimen’s anchorage length elongates, negatively impacting bond strength and exhibiting a loss of up to 32% [74,85].

On comparing specimens with 5d and 10d (5 and 10 times the diameter of reinforcement bar used) times anchorage length, the bond strength of 10d specimens was reduced to half the value of 5d specimens since the stress in the member was distributed along the direction of the length. In contrast, specimens with 5d and 10d embedment lengths exhibit better ductility than the higher embedment length specimens that appear to be brittle [62,102].

The effect of embedment length using 5d and 13d in specimens was studied, and the results revealed that higher embedded length leads to lower bond strength since the stresses on the longer anchorage length are distributed in a non-linear manner [138]. An increased embedment length considerably reduced the bond strength in concrete by almost 19%, irrespective of the type of concrete used [36,40,63]. In comparison, the identical specimens improved bond strength by up to 15% when nominal confinement was provided [40]. It was also observed that embedded length enhanced the bond property of concrete during its hardening and softening stages, but a clear relationship between them was not found [137].

4.7. Effect of Confinement

Confinement of stirrups in RC elements plays a sizable part in ductility and bond strength. Generally, providing lateral or transverse confinement in concrete enhances the bond strength of concrete due to the resisting force posed by the stirrups [21,139]. It can also improve up to 1.5 times the bond strength attained by unconfined concrete [40]. Low or poorly confined self-compacting concrete (SCC) exhibited similar bond strength to standard vibrated concrete, whereas well-confined SCC shows better bond strength than vibrated concrete [37]. Specimens with confinement exhibited better bonding than the unconfined ones with no or minimal cracks, as the lateral stirrups provide resistance in vertical and horizontal directions [74,109]. It was observed that all the tested beam specimens (with and without confinement) failed identically through splitting. Due to confinement, the specimens indicated precautionary warnings before failure, which were absent in the unconfined specimens [140].

It was specified that Carbon Fiber Reinforced Polymer (CFRP) wrapping reduced the bond degradation rates in concrete by increasing the transverse resistance and avoiding further crack developments in the specimen [125]. Normal concrete and recycled aggregate concrete specimens without confining stirrups showed a decreased bond strength. In contrast, stirrups in specimens maintained the bond strength of both types of concrete mixes and lowered the difference in strength between the two mixes [13]. Textile reinforced concrete (TRC) confinement improved the ductility of concrete, but the chloride cycles (chloride erosion environment) reduced the bond strength of confined and unconfined concrete samples in combination with deformed bars due to the reduction in tensile properties. TRC and normal concrete with plain reinforcements slightly improved the bond strength in the initial levels of chloride cycles and later declined the bond strength [26].

It was found that specimens confined with iron-based shape memory alloy (FeSMA) bars showed similar bond strength with a slight degradation of under 15% to steel bars while the unconfined specimens had a strength loss of about 20% compared to conventional steel bars. This was due to the ability of FeSMA bars to limit the cracks and restrict them on propagating further [107]. Comparing the effect of confinement in smooth and deformed bars, smooth bars with stirrups exhibited a major increase in bond strength than deformed bars due to the mechanical pressure provided by stirrups that expanded the bars with the surrounding concrete [126]. Results revealed that increasing the confinement ratio (reducing the spacing between stirrups) exhibited better bond strength with an observation of no or minimal crack formation in the concrete specimens due to the tightness provided by the stirrups [55]. The confinement specifications and the bond strength results observed by researchers are tabulated in Table 7. It can be observed from table that providing confinement improves the bond strength in concrete irrespective of the type and diameter of the bars used.

Table 7.

Bond strength comparison with confinement specifications.

4.8. Concrete Cover Thickness

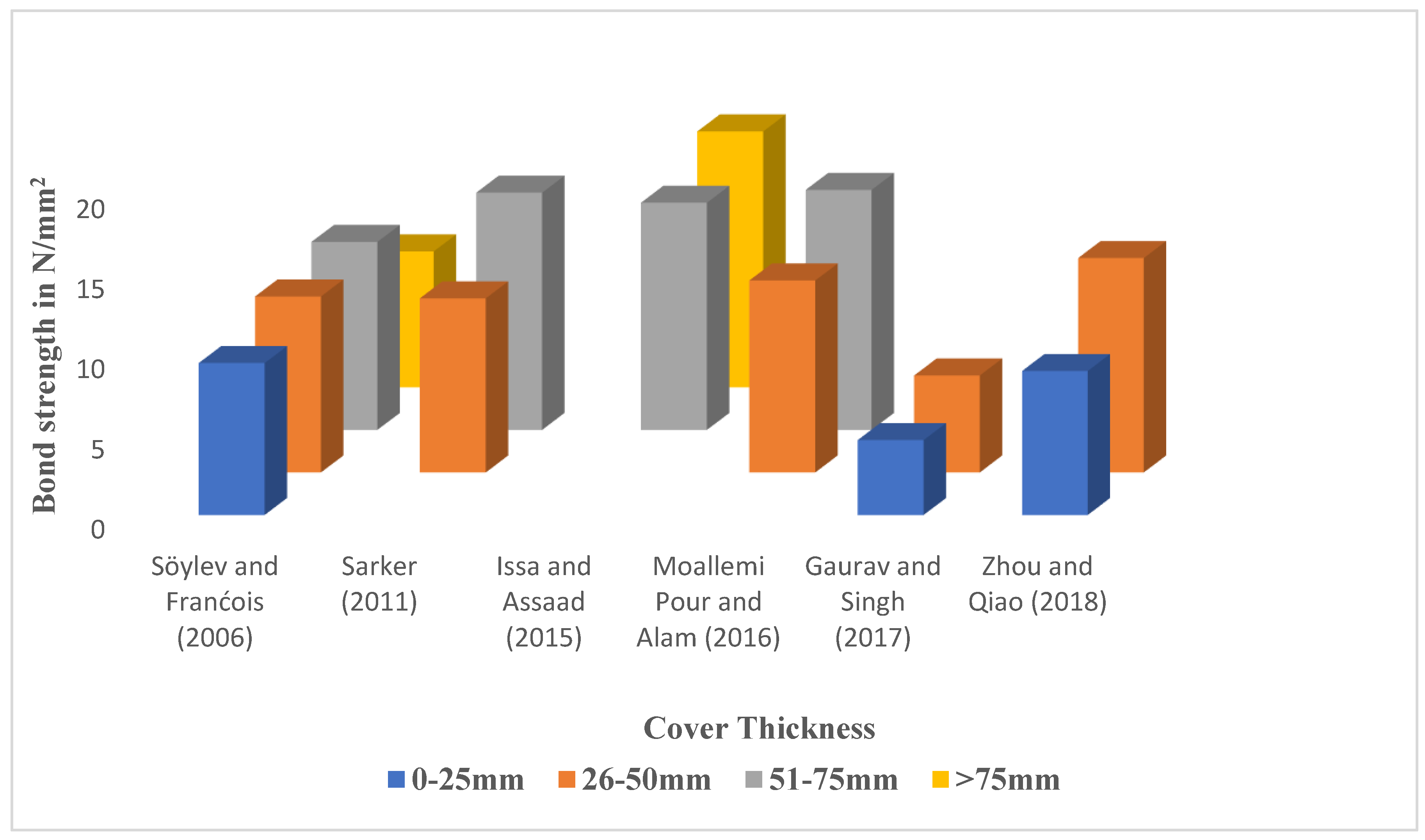

Concrete cover thickness shows an influential role in evaluating the bonding capacity between the concrete surface and reinforcing bars [141,142]. Most researchers expressed a positive note concerning the impact of cover thickness on the bond strength of concrete, as an increase in concrete cover improved the bond strength by up to 50%, irrespective of the type or grade of concrete and the size of the steel bar used. This is because the crack needs more energy to develop when the concrete cover is high for the crack to propagate [21,36,48,62,137]. Increasing the cover thickness improves bonding by eliminating the stresses created by tensile forces acting on concrete surface thereby preventing the crack formation [143].

In contrast, an increase in the cover distance created a negatively improving scenario on bond strength as higher bond strengths were discussed only for specimens with a cover distance ranging from 25 to 40 cm, above which there was a decrease in the bond strength [144]. Considering the washout loss in underwater concrete specimens, increased concrete cover improved its bond property by up to 32% for a specific steel bar size even after a 5.6% washout loss [20]. Improvement in bond strength was observed even on a larger diameter of steel bars due to the thicker concrete cover that increased the time taken for the vertical splitting of concrete [74]. An enhancement in bond strength of around 50% was observed as an increase in the cover thickness created a wrapping action to the H-shaped steel, which is used to stiffen the steel-concrete interface [55]. The bond strength of different concrete mixes concerning the cover thickness are compared, and the best results are shown in Figure 9, which infers that the concrete cover influences the bond strength as an increase in cover thickness improves the bond strength in most cases.

Figure 9.

Chart representing bond strength attained at different cover thickness [20,36,48,62,137,144].

4.9. Effect of Temperature/Fire

Temperature/fire is always considered a destructive threat to the structure as fire/heat damages its integrity [145]. A significant decrease in bond strength was observed between rebar and concrete of up to 54% upon heating due to its loss in elastic modulus when exposed to fire at different heating rates of 43 °C/min, 57 °C/min for 40 min, and 60 min, respectively [119]. Banoth and Agarwal (2020) discussed that rapid heating of specimens (200 °C, 300 °C, 400 °C, and 500 °C) had a substantial reduction in the bond strength due to the formation of numerous cracks resulting in the splitting failure of the specimen, while Sureshbabu and Mathew (2020) discussed that elevated temperature reduces the bond strength due to loss of moisture content (free water, adsorbed water, and chemically bound water) [146,147]. Reducing the temperature (cryogenic levels) shows appreciable development in the bond strength of concrete. An increase in concrete grade simultaneously improves the bond strength at room temperature and up to −80 °C due to the improved ductility attained by the concrete, while below −80 °C, even a higher grade of concrete exhibits lower bond properties between steel and concrete due to the constant or dropping levels of the tensile strength [148].

Bond property in concrete is enhanced by adding recycled concrete aggregates (RCA) regardless of the temperature of concrete specimens due to its high moisture retention ability that improves hydration and thermal expanding properties. Bond strength decreases with a rise in temperature up to 400 °C. It marginally increases above 500 °C due to the thermal expansion and moisture retention abilities of recycled concrete aggregates (RAC) used in the concrete mix [139]. Temperature cycles had a cumulative impact on the bond strength improvement in concrete by up to 8% due to the improvement in compressive strength obtained over the testing period; on the other hand, the wet and dry cycle adversely impacted bond strength as it reduced up to 6% of the initial strength due to the drop in compressive strength of concrete [149]. Increases in temperature automatically damaged the materials in the bonding region, which reduced the bond strength of concrete (due to reduced tensile strength) irrespective of the confinement and coatings in steel bars [145,150]. Epoxy-coated bars showed better bond strength than uncoated specimens for higher temperatures up to 200 °C due to the molten epoxy in the adhesion zone, which led to the strengthening of the bond; above this the bonding reduces as a result of epoxy being burnt by overheating [145].

4.10. Effect of Aggregates

Aggregates are generally of two types, fine and coarse, depending on their particle size. Both fine and coarse have influential roles in acquiring the bond strength in concrete which are discussed below.

4.10.1. Effect of Coarse Aggregates

Recycled concrete aggregates (RCA) were used to replace coarse aggregates in concrete mixes. Researchers expressed diverse opinions about the bond strength of RCA in concrete. The majority of the researchers commented on a positive outcome as RCA attained bond strength up to twice the strength exhibited by conventional aggregates due to the higher friction created by RCA that resists lateral pressure [6,27,54,56,94,113,139,151]; other researchers suggested that bond strength reduced up to 38% due to high water absorption, less stiffness, and internal matrix damages on high compositions of RCA [23,43,60,69,130,152,153]. Very few researchers reported a minimal or no effect on bond strength by RCA replacement [18,36,61,92,117].

Self-compacting concrete incorporated with light weight aggregate (LWA) made of expanded clay was evaluated for bond strength. Results showed that bonding between the steel bars and SCC was better with LWA than conventional aggregates due to the stiffness provided by expanded clay aggregates [154]. Aggregates made of recycled glass, electric arc furnace slag, and limestone were introduced as coarse aggregates in concrete to study their outcomes on bond strength. The experimental demonstrations indicated a decrease in bond strength in the case of glass aggregates due to propagation of smaller cracks, whereas improvement was noted in limestone and slag aggregate-incorporated concrete due to the improved cement matrix that created pronounced bonding in the rib area of the bars [5,84]. Expanded polystyrene (EPS) was used as aggregate in concrete and significantly improved the bond strength of concrete despite its brittle nature [155]. Expanded shale, coconut shell, and blast furnace slag as aggregates in concrete and their bond strength were evaluated. Results indicated a steep fall in the bond strength of up to 38% due to the lightweight property of aggregates [85,114].

4.10.2. Effect of Fine Aggregates

Recycled concrete aggregates (RCA) have also been introduced to replace natural aggregates, and their effects on bond strength were evaluated. The test results revealed that RCA did not majorly affect the bond strength, as there was only a small difference in bond strength for both sources of RCA, even at high volume replacements for conventional fine aggregates [82]. Materials such as weld slag, rubber from waste tires, and glass aggregates were also used as fine aggregates. Test results on bond strength showed that the addition of weld slag exhibited both positive and negative effects as bond strength improved up to 10% slag, above which strength was reduced. However, rubber and glass aggregates improved the bond strength by up to 8%, due to the improvement in frictional co-efficient between cement and rebars [5,72,156].

4.11. Effect of Fibers

Generally, bond strength in fiber-reinforced concrete (FRC) is better than conventional concrete regardless of the type of fiber used due to its ability to bridge between the cracks and avoid the rapid propagation of cracks and also due to its corrosion-resisting property [3,157,158,159]. Metallic fibers improved the bond strength, while carbon fibers failed to enhance the bond property. A hybrid of these two fibers could not improve the bond strength [160]. The incorporation of steel fibers improved the bond property of concrete and steel, as the steel fibers enhanced the bond strength by 5 to 60%. It shows that the addition of 1 to 2% fibers in concrete almost attains 1.5 times the bond strength achieved by conventional concrete due to the bridging effect on the internal cracks produced by the steel fibers that blocked the further development of cracks [3,141,161,162].

On the other hand, other reports on steel fibers showed a degrading effect on bond strength. They reduced up to 30% of the strength exhibited by conventional concrete due to the disturbance in the matrix caused by the rebar between concrete and concrete [31]. Incorporating chopped basalt fibers in concrete did not improve the bond strength up to the C50 grade of concrete. However, it improved the ductility of concrete. When the fibers are incorporated in C60 grade concrete, they improve the bond strength for almost all dosages of fibers [19]. Assessing the effect of fibers in normal strength concrete (NSC) and high strength concrete (HSC), fibers had more positive impacts on HSC than NSC in combination with bars of higher diameter as it created a confinement that bridged the development of radial cracks [31,81]. Polyethylene fibers used with sea sand concrete and GFRP bars improved the bonding capacity due to their ability to retard crack formation in concrete [158,163].

Steel fibers also enhanced the bond property of geopolymer concrete. Different steel fibers enhanced the bond strength by up to 66% due to the crack-resisting nature created by the fibers on the surrounding concrete surface [164]. The incorporation of polypropylene fibers resulted in minimal or no impact on the bond property of concrete since the fibers tend to improve only the tensile strength of concrete, which was not experienced during the pull-out test [165]. The bond strength obtained when several fibers were used in concrete is summarized in Table 8. It can be observed that incorporating hooked end steel fibers and polypropylene fibers mostly improved the bond strength due to their ability to bridge between the cracks thereby restricting the crack propagation.

Table 8.

Comparison of bond strength results with various fibers in concrete.

4.12. Testing Methods and Standards

It is witnessed that the testing methods used in evaluation of bond strength in concrete influence the bond property. Ultra-high performance concrete (UHPC) showed good bonding with the concrete substrate under debonding test evaluation with a coefficient of variation from 1.4% to 3.4%, which was the least when compared to other investigating procedures such as pull-off (28% to 67%), modified pull-off (22.5%), and indirect tensile test (2.1%) [67]. The failure mode of both specimens determines the bonding behavior of the concrete: the pull-out test shows better bonding since it involves the pull-out failure of the specimen compared to the spliced beam test which exhibited splitting failure of the specimen [113]. When comparing the results of the pull-out test and beam test, it can be observed that the beam test shows higher bond strength values when compared to the pull-out test due to the presence of confinement (stirrups) in the beam specimen. The relationship between the concrete mixes in bond strength is not very affected [13]. Bond strength results obtained through the flexural pull-out test (beam end test) are higher than the direct pull-out test [31]. No significant changes were observed when comparing the bond strength results of the pull-out test with the beam and spliced beam test, which shows the accuracy of both test procedures in finding the bond strength [30,83].

The direction of lateral tension influences the failure modes of concrete specimens, which affects the bond strength [166]. The impact of lateral pressure on bond strength is limited as lateral loading only induces cracks of smaller widths, increasing the frictional resistance of the steel-concrete interface. The effect of the loading rate in the bond slip can be reduced by reducing the diameter of bars [167]. The acoustic emission (AE) technique can also be used to determine the bond performance in concrete. Bond strength can be related to the AE count observed in the specimens. There was a rise and fall pattern in the AE count ratio as it went up, then fell to 20,000 counts, rose again to a maximum of 80,000 counts and finally ended the process at 5000 counts due to a decline in the bond force of the concrete [168]. Ultrasonic signals were sent to measure the time-of-flight variation (TOFV) created by the pull-out action of the steel bars. It is suggested that this NDT type of structural health monitoring can be used in full-time applications, and more effective results can be achieved in combination with the AE technique [153]. Differential displacement with a frequency of 2 Hz and 5 Hz was induced to the rebar before setting up the embedded rebar to study its effect on the bond property with concrete. It is understood that the bond strength reduces when the displacement frequency is higher, and the specimens mostly experienced pull-out failure [169]. Bond strength can be evaluated through any of the testing methods (pull-out test, beam end test, beam anchorage test, and spliced beam test) prescribed by various codal provisions such as ASTM International, American Concrete Institute (ACI), Eurocode (EN), RILEM, and the Bureau of Indian Standards (IS). However, researchers most commonly suggested the pull-out test for evaluating the bond strength because of its nature of evaluating a particular factor [170]. It is also suggested for its accuracy, simple procedure, and calculations.

4.13. Effect of Epoxy

Epoxy grouting and ultra-high-performance concrete (UHPC) mixes exhibited the best bond strength; it was suggested to use epoxy grout, and UHPC mixes with a reduced bond length in concrete [169]. Bond strength was evaluated by applying epoxy coatings on steel bars with two coating thicknesses of 200 µm and 600 µm. The results revealed that epoxy coatings affected the bond strength as the coating decreased the bond strength of concrete; epoxy coated bars exhibited bond strength up to 32% lower than the uncoated bars [171,172]. Epoxy coating in steel bars improved the bond strength upon temperature effect as the melted epoxy created chemical adhesion between bar and concrete [145].

4.14. Other Factors

In addition to the major/main factors discussed so far, a few other factors affecting the steel-concrete bond are also elaborated in this section. Incorporating latex in concrete improved the bond strength irrespective of the type of latex polymers used since it increases the adhesive nature in the elastic stage. Specifically, PVA (Polyvinyl Acetate)-incorporated concrete specimens showed better bonding with concrete than SBR (Styrene Butadiene Rubber) latex [120]. Waste steel shavings were introduced as an additive in concrete, and the results indicated that 1% of steel shavings exhibited lower bond strength than control concrete. In comparison, higher quantities showed similar or higher bond strength than control concrete [110]. Chloride attack on concrete specimens with chloride wet/dry cycles reduced the bond strength when combined with deformed bars regardless of the textile-reinforced concrete (TRC) confinement [26].

5. Concluding Remarks

An extensive and exhaustive study of varied internationally published literature on the different parameters involved in the development of bond strength in concrete was performed, and the following important points are stipulated:

- Based on the comparison of different types of concrete, it was found that bond strength did not vary considerably regarding the type of concrete used;

- The grade of concrete is linearly proportional () to the bond strength as the higher-grade concrete exhibits better crack resistance and good packing structure, which improves the bond property;

- Smaller-sized (diameter less than 16 mm) deformed or ribbed steel bars created better bonding (gripping) between the reinforcement and the concrete surface surrounding the rebar;

- Concrete with reinforcement bars at a bonding length of less than 5d (embedded length = 5 times the diameter of the bar used) exhibits good bond behavior;

- The thicker the concrete cover distance, the higher the bond strength in concrete will be, and incorporating lateral confinement improves the bond property by preventing splitting failure in concrete;

- The temperature rise decreased the bond strength in concrete (inversely proportional). At the same time, the same trend was also followed in terms of cryogenic temperatures (below 0 °C);

- The aggregate type has positive and negative effects on bond strength depending upon the physical properties and source of the aggregates. It is also observed that a recycled concrete aggregate (RCA) provides some hope for bond strength enhancement;

- Fibers play a prominent role in developing bond strength, as steel and glass fibers drastically improve the bond strength in concrete;

- Determination of bond strength in concrete can also be executed using non-destructive testing (NDT) methods such as ultrasonic signals and acoustic emission techniques;

- Incorporating epoxy grouting, ultra-high-performance concrete (UHPC), and latex polymers (polyvinyl acetate-PVA) enhanced the bonding ability of concrete with the reinforced bars.

In summary, it is exciting that the compressive strength and the tensile strength of the concrete obtained through the addition of various materials/admixtures was the frequently highlighted factor that influenced the bond strength in concrete.

Author Contributions

Conceptualization, P.R.S.V. and A.K.A.; methodology, P.R.S.V. and A.K.A.; validation, P.R.S.V. and A.K.A.; formal analysis, P.R.S.V. and A.K.A.; investigation, P.R.S.V.; resources, P.R.S.V. and A.K.A.; data curation, P.R.S.V. and A.K.A. writing—original draft preparation, P.R.S.V.; writing—review and editing, P.R.S.V. and A.K.A.; visualization, P.R.S.V. and A.K.A. supervision, P.R.S.V. and A.K.A.; project administration, A.K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to express their gratitude towards Vellore Institute of Technology, Chennai, Tamil Nadu, India for providing the resources. The APC was funded by Vellore Institute of Technology, Chennai, Tamil Nadu, India.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jathar, R. Study of Bond Strength of Fibre Reinforced Concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 2371–2380. [Google Scholar] [CrossRef]

- Mousavi, S.S.; Mousavi Ajarostaghi, S.S.; Bhojaraju, C. A Critical Review of the Effect of Concrete Composition on Rebar–Concrete Interface (RCI) Bond Strength: A Case Study of Nanoparticles. SN Appl. Sci. 2020, 2, 1–23. [Google Scholar] [CrossRef]

- Mo, K.H.; Goh, S.H.; Alengaram, U.J.; Visintin, P.; Jumaat, M.Z. Mechanical, Toughness, Bond and Durability-Related Properties of Lightweight Concrete Reinforced with Steel Fibres. Mater. Struct. Constr. 2017, 50, 46. [Google Scholar] [CrossRef]

- Ganesan, N.; Indira, P.V.; Sabeena, M.V. Bond Stress Slip Response of Bars Embedded in Hybrid Fibre Reinforced High Performance Concrete. Constr. Build. Mater. 2014, 50, 108–115. [Google Scholar] [CrossRef]

- Wang, F.; Wu, X.; Guo, C.; Song, W. Experimental Study on Bond Strength of Deformed Steel Bars in Recycled Glass Aggregate Concrete. KSCE J. Civ. Eng. 2018, 22, 3409–3418. [Google Scholar] [CrossRef]

- John Robert Prince, M.; Singh, B. Bond Behaviour of Deformed Steel Bars Embedded in Recycled Aggregate Concrete. Constr. Build. Mater. 2013, 49, 852–862. [Google Scholar] [CrossRef]

- Everard, J.L.; Tanner, K.E. Reinforced Concrete Design; Mcgraw-Hill Inc.: New York, NY, USA, 1983; ISBN 0070495041. [Google Scholar]

- Dahou, Z.; Castel, A.; Noushini, A. Prediction of the Steel-Concrete Bond Strength from the Compressive Strength of Portland Cement and Geopolymer Concretes. Constr. Build. Mater. 2016, 119, 329–342. [Google Scholar] [CrossRef]

- Yazici, Ş.; Arel, H.Ş. The Effect of Steel Fiber on the Bond between Concrete and Deformed Steel Bar in SFRCs. Constr. Build. Mater. 2013, 40, 299–305. [Google Scholar] [CrossRef]

- Melo, J.; Rossetto, T.; Varum, H. Experimental Study of Bond–Slip in RC Structural Elements with Plain Bars. Mater. Struct. Constr. 2015, 48, 2367–2381. [Google Scholar] [CrossRef]

- Gudonis, E.; Kacianauskas, R.; Gribniak, V.; Weber, A.; Jakubovskis, R.; Kaklauskas, G. Mechanical Properties of the Bond Between GFRP Reinforcing Bars and Concrete. Mech. Compos. Mater. 2014, 50, 457–466. [Google Scholar] [CrossRef]

- Lutz, L.A.; Gergely, P. Mechanics of Bond and Slip of Deformed Bars in Concrete. ACI Int. Concr. Abstr. Portal J. Proc. 1967, 64, 711–721. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, H.; Wu, K.; Jin, W. Bond Behaviour of Normal/Recycled Concrete and Corroded Steel Bars. Constr. Build. Mater. 2013, 48, 348–359. [Google Scholar] [CrossRef]

- ACI Committee 408. Opportunities in Bond Research; American Concrete Institute: Farmington Hills, MI, USA, 1970; Volume 67. [Google Scholar] [CrossRef]

- ACI 408.2R-92; Bond under Cyclic Loads. American Concrete Institute: Farmington Hills, MI, USA, 1999; Volume 92, pp. 1–5.

- ACI 408R-03; Bond and Development of Straight Reinforcing Bars in Tension. American Concrete Institute: Farmington Hills, MI, USA, 2003; pp. 1–49.

- de Larrard, F.; Schaller, I.; Fuchs, J. Effect of bar diameter on the bond strength of passive reinforcement in high-performance concrete. ACI Mater. J. 1993, 90, 333–339. [Google Scholar]

- Fernandez, I.; Etxeberria, M.; Marí, A.R. Ultimate Bond Strength Assessment of Uncorroded and Corroded Reinforced Recycled Aggregate Concretes. Constr. Build. Mater. 2016, 111, 543–555. [Google Scholar] [CrossRef]

- Meng, W.; Liu, H.; Liu, G.; Kong, X.; Wang, X. Bond-Slip Constitutive Relation between BFRP Bar and Basalt Fiber Recycled-Aggregate Concrete. KSCE J. Civ. Eng. 2016, 20, 1996–2006. [Google Scholar] [CrossRef]

- Issa, C.A.; Assaad, J.J. Bond of Tension Bars in Underwater Concrete: Effect of Bar Diameter and Cover. Mater. Struct. Constr. 2015, 48, 3457–3471. [Google Scholar] [CrossRef]

- Bandelt, M.J.; Billington, S.L. Bond Behavior of Steel Reinforcement in High-Performance Fiber-Reinforced Cementitious Composite Flexural Members. Mater. Struct. Constr. 2016, 49, 71–86. [Google Scholar] [CrossRef]

- Huang, L.; Chi, Y.; Xu, L.; Chen, P.; Zhang, A. Local Bond Performance of Rebar Embedded in Steel-Polypropylene Hybrid Fiber Reinforced Concrete under Monotonic and Cyclic Loading. Constr. Build. Mater. 2016, 103, 77–92. [Google Scholar] [CrossRef]

- Pandurangan, K.; Dayanithy, A.; Om Prakash, S. Influence of Treatment Methods on the Bond Strength of Recycled Aggregate Concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Krishnaveni; Rajendran A State of the Art on Characterization and Application of Artificial Neural Networks on Bond Strength between Steel Rebar and Concrete. Constr. Build. Mater. 2022, 354, 129124. [CrossRef]

- Liu, X.; Wang, X.; Xie, K.; Wu, Z.; Li, F. Bond Behavior of Basalt Fiber-Reinforced Polymer Bars Embedded in Concrete Under Mono-Tensile and Cyclic Loads. Int. J. Concr. Struct. Mater. 2020, 14, 19. [Google Scholar] [CrossRef]

- Jing, L.; Yin, S.; Lv, H. Bonding Behavior of Textile Reinforced Concrete (TRC)-Confined Concrete and Reinforcement under Chloride Erosion Environment. KSCE J. Civ. Eng. 2020, 24, 826–834. [Google Scholar] [CrossRef]

- Prince, M.J.R.; Singh, B. Bond Strength of Deformed Steel Bars in High-Strength Recycled Aggregate Concrete. Mater. Struct. Constr. 2015, 48, 3913–3928. [Google Scholar] [CrossRef]

- Abrams, D.A. Test of Bond Between Concrete and Steel. Eng. Exp. Stn. 1913, XI, 117. [Google Scholar]

- Lundgren, K.; Robuschi, S.; Zandi, K. Methodology for Testing Rebar-Concrete Bond in Specimens from Decommissioned Structures. Int. J. Concr. Struct. Mater. 2019, 13, 38. [Google Scholar] [CrossRef]

- De Almeida Filho, F.M.; El Debs, M.K.; El Debs, A.L.H.C. Bond-Slip Behavior of Self-Compacting Concrete and Vibrated Concrete Using Pull-out and Beam Tests. Mater. Struct. Constr. 2008, 41, 1073–1089. [Google Scholar] [CrossRef]

- Dancygier, A.N.; Katz, A.; Wexler, U. Bond between Deformed Reinforcement and Normal and High-Strength Concrete with and without Fibers. Mater. Struct. Constr. 2010, 43, 839–856. [Google Scholar] [CrossRef]

- Kute, S.Y.; Wakchaure, M.R. Performance Evaluation for Enhancement of Some of the Engineering Properties of Bamboo as Reinforcement in Concrete. J. Inst. Eng. Ser. A 2013, 94, 235–242. [Google Scholar] [CrossRef]

- Is 2770; Methodes of Testing Bond in Reinforced Concrete. Bureau of Indian Standards: New Delhi, India, 1967.

- European Standard PrEN 10080; Steel for the Reinforcement of Concrete-Weldable Reinforcing Steel-General. British Standards Institution: London, UK, 2005.

- Wight, J.K.; Barth, F.G.; Becker, R.J.; Bondy, K.B.; Breen, J.E.; Cagley, J.R.; Collins, M.P.; Corley, W.G.; Dolan, C.W.; Fiorato, A.E.; et al. ACI Committee 318, “Building Code Requirements for Structural Concrete (ACI 318-05) and Commentary (ACI 318r-05)”; American Concrete Institute: Farmington Hills, MI, USA, 2005; Volume 2003, p. 430. [Google Scholar]

- Gaurav, G.; Singh, B. Bond Strength Prediction of Tension Lap Splice for Deformed Steel Bars in Recycled Aggregate Concrete. Mater. Struct. Constr. 2017, 50, 230. [Google Scholar] [CrossRef]

- Pandurangan, K.; Kothandaraman, S.; Sreedaran, D. A Study on the Bond Strength of Tension Lap Splices in Self Compacting Concrete. Mater. Struct. Constr. 2010, 43, 1113–1121. [Google Scholar] [CrossRef]

- Rilem. RILEM Technical Recommendations for the Testing and Use of Construction Materials; CRC Press: Boca Raton, FL, USA, 1994; ISBN 9781482271362. [Google Scholar]

- Desnerck, P.; De Schutter, G.; Taerwe, L. Bond Behaviour of Reinforcing Bars in Self-Compacting Concrete: Experimental Determination by Using Beam Tests. Mater. Struct. Constr. 2010, 43, 53–62. [Google Scholar] [CrossRef]

- Sabău, M.; Pop, I.; Oneţ, T. Experimental Study on Local Bond Stress-Slip Relationship in Self-Compacting Concrete. Mater. Struct. Constr. 2016, 49, 3693–3711. [Google Scholar] [CrossRef]

- Harkouss, R.H.; Hamad, B.S. Performance of High Strength Self-Compacting Concrete Beams under Different Modes of Failure. Int. J. Concr. Struct. Mater. 2015, 9, 69–88. [Google Scholar] [CrossRef]

- Zhou, L.; Zheng, Y.; Li, H.; Song, G. Identification of Bond Behavior between FRP/Steel Bars and Self-Compacting Concrete Using Piezoceramic Transducers Based on Wavelet Energy Analysis. Arch. Civ. Mech. Eng. 2020, 20, 1–16. [Google Scholar] [CrossRef]

- Kamal, M.M.; Etman, Z.A.; Afify, M.R.; Salem, M.M. Bond Strength of Concrete Containing. Concr. Res. 2015, 6, 93–111. [Google Scholar]

- Ertzibengoa, D.; Matthys, S.; Taerwe, L. Bond Behaviour of Flat Stainless Steel Rebars in Concrete. Mater. Struct. Constr. 2012, 45, 1639–1653. [Google Scholar] [CrossRef]

- Zhu, W.; Sonebi, M.; Bartos, P.J.M. Bond and Interfacial Properties of Reinforcement in Self-Compacting Concrete. Mater. Struct. Constr. 2004, 37, 442–448. [Google Scholar] [CrossRef]

- Al-Azzawi, M.; Yu, T.; Hadi, M.N.S. Factors Affecting the Bond Strength Between the Fly Ash-Based Geopolymer Concrete and Steel Reinforcement. Structures 2018, 14, 262–272. [Google Scholar] [CrossRef]

- Laskar, S.M.; Talukdar, S. Preparation and Tests for Workability, Compressive and Bond Strength of Ultra-Fine Slag Based Geopolymer as Concrete Repairing Agent. Constr. Build. Mater. 2017, 154, 176–190. [Google Scholar] [CrossRef]

- Sarker, P.K. Bond Strength of Reinforcing Steel Embedded in Fly Ash-Based Geopolymer Concrete. Mater. Struct. Constr. 2011, 44, 1021–1030. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond Strength between Blended Slag and Class F Fly Ash Geopolymer Concrete with Steel Reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Cui, Y.; Qu, S.; Bao, J.; Zhang, P. Bond Performance of Steel Bar and Fly Ash-Based Geopolymer Concrete in Beam End Tests. Polymers 2022, 14, 2012. [Google Scholar] [CrossRef] [PubMed]

- Kusbiantoro, A.; Nuruddin, M.F.; Shafiq, N.; Qazi, S.A. The Effect of Microwave Incinerated Rice Husk Ash on the Compressive and Bond Strength of Fly Ash Based Geopolymer Concrete. Constr. Build. Mater. 2012, 36, 695–703. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Cao, R.; Ding, J.; Chen, X. Feasibility of Using Geopolymers to Investigate the Bond Behavior of FRP Bars in Seawater Sea-Sand Concrete. Constr. Build. Mater. 2021, 282, 122636. [Google Scholar] [CrossRef]

- Asayesh, S.; Shirzadi Javid, A.A.; Ziari, H.; Mehri, B. Evaluating Fresh State, Hardened State, Thermal Expansion and Bond Properties of Geopolymers for the Repairing of Concrete Pavements under Restrained Conditions. Constr. Build. Mater. 2021, 292, 123398. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D.; Park, W.S.; Jang, Y. Il Bond Strength Prediction for Deformed Steel Rebar Embedded in Recycled Coarse Aggregate Concrete. Mater. Des. 2015, 83, 257–269. [Google Scholar] [CrossRef]

- Zheng, H.; Chen, Z.; Xu, J. Bond Behavior of H-Shaped Steel Embedded in Recycled Aggregate Concrete under Push-out Loads. Int. J. Steel Struct. 2016, 16, 347–360. [Google Scholar] [CrossRef]

- Tüfekçi, M.M.; Çakır, Ö. An Investigation on Mechanical and Physical Properties of Recycled Coarse Aggregate (RCA) Concrete with GGBFS. Int. J. Civ. Eng. 2017, 15, 549–563. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A. Bond Strength between Corroded Steel Reinforcement and Recycled Aggregate Concrete. Structures 2019, 19, 369–385. [Google Scholar] [CrossRef]

- Gao, D.; Yan, H.; Fang, D.; Yang, L. Bond Strength and Prediction Model for Deformed Bar Embedded in Hybrid Fiber Reinforced Recycled Aggregate Concrete. Constr. Build. Mater. 2020, 265, 120337. [Google Scholar] [CrossRef]

- Rockson, C.; Tamanna, K.; Shahria Alam, M.; Rteil, A. Effect of Rebar Embedment Length on the Bond Behavior of Commercially Produced Recycled Concrete Using Beam-End Specimens. Constr. Build. Mater. 2021, 286, 122957. [Google Scholar] [CrossRef]

- Seara-Paz, S.; González-Fonteboa, B.; Eiras-López, J.; Herrador, M.F. Bond Behavior between Steel Reinforcement and Recycled Concrete. Mater. Struct. Constr. 2014, 47, 323–334. [Google Scholar] [CrossRef]

- Breccolotti, M.; Materazzi, A.L. Structural Reliability of Bonding between Steel Rebars and Recycled Aggregate Concrete. Constr. Build. Mater. 2013, 47, 927–934. [Google Scholar] [CrossRef]

- Moallemi Pour, S.; Alam, M.S. Investigation of Compressive Bond Behavior of Steel Rebar Embedded in Concrete With Partial Recycled Aggregate Replacement. Structures 2016, 7, 153–164. [Google Scholar] [CrossRef]

- Butler, L.; West, J.S.; Tighe, S.L. The Effect of Recycled Concrete Aggregate Properties on the Bond Strength between RCA Concrete and Steel Reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Gomaa, E.; Gheni, A.A.; Kashosi, C.; ElGawady, M.A. Bond Strength of Eco-Friendly Class C Fly Ash-Based Thermally Cured Alkali-Activated Concrete to Portland Cement Concrete. J. Clean. Prod. 2019, 235, 404–416. [Google Scholar] [CrossRef]

- Bilek, V.; Bonczková, S.; Hurta, J.; Pytlík, D.; Mrovec, M. Bond Strength between Reinforcing Steel and Different Types of Concrete. Procedia Eng. 2017, 190, 243–247. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Chauhan, D.; Gupta, S.; Kar, A.; Adak, D. Evaluation of Structural Performance of Concrete with Ambient-Cured Alkali-Activated Binders BT-Proceedings of SECON’19; Dasgupta, K., Sajith, A.S., Unni Kartha, G., Joseph, A., Kavitha, P.E., Praseeda, K.I., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–10. [Google Scholar]

- Valipour, M.; Khayat, K.H. Debonding Test Method to Evaluate Bond Strength between UHPC and Concrete Substrate. Mater. Struct. Constr. 2020, 53, 1–10. [Google Scholar] [CrossRef]

- Zhao, J.; Cai, G.; Yang, J. Bond-Slip Behavior and Embedment Length of Reinforcement in High Volume Fly Ash Concrete. Mater. Struct. Constr. 2016, 49, 2065–2082. [Google Scholar] [CrossRef]

- Namarak, C.; Tangchirapat, W.; Jaturapitakkul, C. Bar-Concrete Bond in Mixes Containing Calcium Carbide Residue, Fly Ash and Recycled Concrete Aggregate. Cem. Concr. Compos. 2018, 89, 31–40. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Bond Strength of GFRP Bars Embedded in Engineered Cementitious Composite Using RILEM Beam Testing. Int. J. Concr. Struct. Mater. 2018, 12, 6. [Google Scholar] [CrossRef]

- Parvizi, M.; Noël, M.; Vasquez, J.; Rios, A.; González, M. Assessing the Bond Strength of Glass Fiber Reinforced Polymer (GFRP) Bars in Portland Cement Concrete Fabricated with Seawater through Pullout Tests. Constr. Build. Mater. 2020, 263, 120952. [Google Scholar] [CrossRef]

- Romanazzi, V.; Leone, M.; Tondolo, F.; Fantilli, A.P.; Aiello, M.A. Bond Strength of Rubberized Concrete with Deformed Steel Bar. Constr. Build. Mater. 2021, 272, 121730. [Google Scholar] [CrossRef]

- Jena, T.; Panda, K.C.; Behera, J.R. Usage of Fly Ash and Silpozz on Strength and Sorptivity of Marine Concrete. Int. J. Appl. Eng. Res. 2017, 12, 5768–5780. [Google Scholar]

- Li, H.; Deeks, A.J.; Su, X.; Huang, D. Tensile Bond Anchorage Properties of Australian 500N Steel Bars in Concrete. J. Cent. South Univ. 2012, 19, 2718–2725. [Google Scholar] [CrossRef]

- İpek, S.; Ayodele, O.A.; Mermerdaş, K. Influence of Artificial Aggregate on Mechanical Properties, Fracture Parameters and Bond Strength of Concretes. Constr. Build. Mater. 2020, 238, 1177556. [Google Scholar] [CrossRef]

- Sreehari, A.; Kavitha, P.E. Effect of Acid Environment on Bond Durability of Basalt Fiber Reinforced Polymer Bars and Steel Bars Embedded in Concrete BT-Proceedings of SECON’19; Dasgupta, K., Sajith, A.S., Unni Kartha, G., Joseph, A., Kavitha, P.E., Praseeda, K.I., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 881–891. [Google Scholar]

- Zhang, Y.; Lu, Z. Bond Property Test of Reinforced Concrete with All Soaking and Impressed Current Method Corrosion. Trans. Tianjin Univ. 2013, 19, 366–371. [Google Scholar] [CrossRef]

- Zhang, J.; Tao, X.; Li, X.; Zhang, Y.; Liu, Y. Analytical and Experimental Investigation of the Bond Behavior of Confined High-Strength Recycled Aggregate Concrete. Constr. Build. Mater. 2022, 315, 125636. [Google Scholar] [CrossRef]

- Chowdhury, S.H. Early Age Bond Strength of Reinforcing Bars in High Strength Concrete. In Proceedings of the 4th International Conference on Structural Engineering and Construction Management 2013, Kandy, Sri Lanka, 13–15 December 2013; pp. 78–89. [Google Scholar]

- Basaran, B.; Kalkan, I. Investigation on Variables Affecting Bond Strength between FRP Reinforcing Bar and Concrete by Modified Hinged Beam Tests. Compos. Struct. 2020, 242, 112185. [Google Scholar] [CrossRef]

- Dancygier, A.N.; Katz, A. Bond over Direct Support of Deformed Rebars in Normal and High Strength Concrete with and without Fibers. Mater. Struct. Constr. 2012, 45, 265–275. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H. Do Evaluation of the Bond Behavior of Steel Reinforcing Bars in Recycled Fine Aggregate Concrete. Cem. Concr. Compos. 2014, 46, 8–18. [Google Scholar] [CrossRef]

- Looney, T.J.; Arezoumandi, M.; Volz, J.S.; Myers, J.J. An Experimental Study on Bond Strength of Reinforcing Steel in Self-Consolidating Concrete. Int. J. Concr. Struct. Mater. 2012, 6, 187–197. [Google Scholar] [CrossRef]

- Faleschini, F.; Santamaria, A.; Zanini, M.A.; San José, J.T.; Pellegrino, C. Bond between Steel Reinforcement Bars and Electric Arc Furnace Slag Concrete. Mater. Struct. Constr. 2017, 50, 170. [Google Scholar] [CrossRef]

- Lachemi, M.; Bae, S.; Hossain, K.M.A.; Sahmaran, M. Steel-Concrete Bond Strength of Lightweight Self-Consolidating Concrete. Mater. Struct. Constr. 2009, 42, 1015–1023. [Google Scholar] [CrossRef]

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008; Volume 2007, ISBN 9780870312649. [Google Scholar]

- Majain, N.; Ahmad, A.B.; Adnan, A.; Mohamed, R.N. Bond Behaviour of Deformed Steel Bars in Steel Fibre High-Strength Self-Compacting Concrete. Constr. Build. Mater. 2022, 318, 125906. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. Bridge Design Specifications AASHTO-2010; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1998. [Google Scholar]

- Japan Society of Civil Engineers. Guidelines for Concrete: Standard Specifications for Concrete Structures; Japan Society of Civil Engineers: Tokyo, Japan, 2007. [Google Scholar]

- CAN3-A23-CSA; Design of Concrete Standards for Buildings. Canadian Standards Association: Toronto, ON, Canada, 2004.

- Leibovich, O.; Dancygier, A.N.; Yankelevsky, D.Z. An Innovative Experimental Procedure to Study Local Rebar-Concrete Bond by Direct Observations and Measurements. Exp. Mech. 2016, 56, 673–682. [Google Scholar] [CrossRef]

- Xiao, J. Bond–Slip Between Recycled Aggregate Concrete and Rebar. Recycl. Aggreg. Concr. Struct. 2018, 299–319. [Google Scholar] [CrossRef]

- Rafi, M.M. Study of Bond Properties of Steel Rebars with Recycled Aggregate Concrete. Experimental Testing. Strength Mater. 2018, 50, 937–950. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. Bond Behaviour between Recycled Aggregate Concrete and Steel Rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Zou, X.; Sneed, L.H. Bond Behavior Between Steel Fiber Reinforced Polymer (SRP) and Concrete. Int. J. Concr. Struct. Mater. 2020, 14, 1–17. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, Y.; Pang, Y.; Gao, D.; Xu, Q.; Zhang, S.; Ahmed Sheikh, S. Experimental Study on the Interfacial Bond Behavior of FRP Plate-High-Strength Concrete under Seawater Immersion. Constr. Build. Mater. 2020, 259, 119799. [Google Scholar] [CrossRef]

- Saleh, N.; Ashour, A.; Lam, D.; Sheehan, T. Experimental Investigation of Bond Behaviour of Two Common GFRP Bar Types in High–Strength Concrete. Constr. Build. Mater. 2019, 201, 610–622. [Google Scholar] [CrossRef]

- Godat, A.; Aldaweela, S.; Aljaberi, H.; Al Tamimi, N.; Alghafri, E. Bond Strength of FRP Bars in Recycled-Aggregate Concrete. Constr. Build. Mater. 2021, 267, 120919. [Google Scholar] [CrossRef]

- El Ghadioui, R.; Proske, T.; Tran, N.L.; Graubner, C.A. Structural Behaviour of CFRP Reinforced Concrete Members under Bending and Shear Loads. Mater. Struct. Constr. 2020, 53, 63. [Google Scholar] [CrossRef]

- Gao, J.; Xu, P.; Fan, L.; Terrasi, G. Pietro Study on Bond-Slip Behavior between Seawater Sea-Sand Concrete and Carbon Fiber-Reinforced Polymer (CFRP) Bars with Different Surface Shapes. Polymers 2022, 14, 2689. [Google Scholar] [CrossRef]

- Albidah, A.; Altheeb, A.; Alrshoudi, F.; Abadel, A.; Abbas, H.; Al-Salloum, Y. Bond Performance of GFRP and Steel Rebars Embedded in Metakaolin Based Geopolymer Concrete. Structures 2020, 27, 1582–1593. [Google Scholar] [CrossRef]

- Oh, H.; Sim, J.; Kang, T.; Kwon, H. An Experimental Study on the Flexural Bonding Characteristic of a Concrete Beam Reinforced with a GFRP Rebar. KSCE J. Civ. Eng. 2011, 15, 1245–1251. [Google Scholar] [CrossRef]

- Saleh, N.; Ashour, A.; Sheehan, T. Bond between Glass Fibre Reinforced Polymer Bars and High-Strength Concrete. Structures 2019, 22, 139–153. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Chen, S. Effect of Different Environments on Bond Strength of Glass Fiber-Reinforced Polymer and Steel Reinforcing Bars. KSCE J. Civ. Eng. 2012, 16, 994–1002. [Google Scholar] [CrossRef]

- Hao, Q.D.; Wang, Y.L.; Zhang, Z.C.; Ou, J.P. Bond Strength Improvement of GFRP Rebars with Different Rib Geometries. J. Zhejiang Univ. Sci. A 2007, 8, 1356–1365. [Google Scholar] [CrossRef]

- Li, J.; Gravina, R.J.; Smith, S.T.; Visintin, P. Bond Strength and Bond Stress-Slip Analysis of FRP Bar to Concrete Incorporating Environmental Durability. Constr. Build. Mater. 2020, 261, 119860. [Google Scholar] [CrossRef]

- Fawaz, G.; Murcia-Delso, J. Bond Behavior of Iron-Based Shape Memory Alloy Reinforcing Bars Embedded in Concrete. Mater. Struct. Constr. 2020, 53, 114. [Google Scholar] [CrossRef]

- Javadian, A.; Wielopolski, M.; Smith, I.F.C.; Hebel, D.E. Bond-Behavior Study of Newly Developed Bamboo-Composite Reinforcement in Concrete. Constr. Build. Mater. 2016, 122, 110–117. [Google Scholar] [CrossRef]

- Law, D.W.; Tang, D.; Molyneaux, T.K.C.; Gravina, R. Impact of Crack Width on Bond: Confined and Unconfined Rebar. Mater. Struct. Constr. 2011, 44, 1287–1296. [Google Scholar] [CrossRef]

- Osifala, K.B.; Salau, M.A.; Obiyomi, T.H. Effect of Waste Steel Shavings on Bond Strength between Concrete and Steel Reinforcement. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012080. [Google Scholar] [CrossRef]

- Pop, I.; De Schutter, G.; Desnerck, P.; Szilagy, H. Influence of Self-Compacting Concrete Fresh Properties on Bond to Reinforcement. Mater. Struct. Constr. 2015, 48, 1875–1886. [Google Scholar] [CrossRef]

- Trabacchin, G.; Sebastian, W.; Zhang, M. Experimental and Analytical Study of Bond between Basalt FRP Bars and Geopolymer Concrete. Constr. Build. Mater. 2022, 315, 125461. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Steele, A.R.; Volz, J.S. Evaluation of the Bond Strengths Between Concrete and Reinforcement as a Function of Recycled Concrete Aggregate Replacement Level. Structures 2018, 16, 73–81. [Google Scholar] [CrossRef]

- Nadir, Y.; Sujatha, A. Bond Strength Determination between Coconut Shell Aggregate Concrete and Steel Reinforcement by Pull-out Test. Asian J. Civ. Eng. 2018, 19, 713–723. [Google Scholar] [CrossRef]

- Khaksefidi, S.; Ghalehnovi, M.; de Brito, J. Bond Behaviour of High-Strength Steel Rebars in Normal (NSC) and Ultra-High Performance Concrete (UHPC). J. Build. Eng. 2021, 33, 101592. [Google Scholar] [CrossRef]

- Qi, J.; Cheng, Z.; John Ma, Z.; Wang, J.; Liu, J. Bond Strength of Reinforcing Bars in Ultra-High Performance Concrete: Experimental Study and Fiber–Matrix Discrete Model. Eng. Struct. 2021, 248, 113290. [Google Scholar] [CrossRef]

- Prince, M.J.R.; Singh, B. Bond Behaviour between Recycled Aggregate Concrete and Deformed Steel Bars. Mater. Struct. Constr. 2014, 47, 503–516. [Google Scholar] [CrossRef]

- Eltantawi, I.; Alnahhal, W.; El Refai, A.; Younis, A.; Alnuaimi, N.; Kahraman, R. Bond Performance of Tensile Lap-Spliced Basalt-FRP Reinforcement in High-Strength Concrete Beams. Compos. Struct. 2022, 281, 114987. [Google Scholar] [CrossRef]

- Wang, W.H.; Han, L.H.; Tan, Q.H.; Tao, Z. Tests on the Steel–Concrete Bond Strength in Steel Reinforced Concrete (SRC) Columns After Fire Exposure. Fire Technol. 2017, 53, 917–945. [Google Scholar] [CrossRef]

- Issa, C.A.; Assaad, J.J. Stability and Bond Properties of Polymer-Modified Self-Consolidating Concrete for Repair Applications. Mater. Struct. Constr. 2017, 50, 28. [Google Scholar] [CrossRef]

- Fu, B.; Chen, S.Z.; Liu, X.R.; Feng, D.C. A Probabilistic Bond Strength Model for Corroded Reinforced Concrete Based on Weighted Averaging of Non-Fine-Tuned Machine Learning Models. Constr. Build. Mater. 2022, 318, 125767. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Al-Gahtani, A.S.; Aziz, A.R. Rasheeduzzafar Effect of Reinforcement Corrosion on Bond Strength. Constr. Build. Mater. 1996, 10, 123–129. [Google Scholar] [CrossRef]

- Chung, L.; Jay Kim, J.H.; Yi, S.T. Bond Strength Prediction for Reinforced Concrete Members with Highly Corroded Reinforcing Bars. Cem. Concr. Compos. 2008, 30, 603–611. [Google Scholar] [CrossRef]

- Coccia, S.; Imperatore, S.; Rinaldi, Z. Influence of Corrosion on the Bond Strength of Steel Rebars in Concrete. Mater. Struct. Constr. 2016, 49, 537–551. [Google Scholar] [CrossRef]

- Dai, X.D.; Wang, X.H.; Kou, X.J. Bond Behavior of Corroded Reinforcement in Concrete Wrapped with Carbon Fiber Reinforced Polymer under Cyclic Loading. J. Shanghai Jiaotong Univ. 2013, 18, 271–277. [Google Scholar] [CrossRef]

- Fang, C.; Lundgren, K.; Chen, L.; Zhu, C. Corrosion Influence on Bond in Reinforced Concrete. Cem. Concr. Res. 2004, 34, 2159–2167. [Google Scholar] [CrossRef]

- JIN, W. Effect of Corrosion on Bond Behavior and Bending Strength of Reinforced Concrete Beams. J. Zhejiang Univ. Sci. 2001, 2, 298. [Google Scholar] [CrossRef]

- Kim, H.R.; Choi, W.C.; Yoon, S.C.; Noguchi, T. Evaluation of Bond Properties of Reinforced Concrete with Corroded Reinforcement by Uniaxial Tension Testing. Int. J. Concr. Struct. Mater. 2016, 10, 43–52. [Google Scholar] [CrossRef]