Abstract

Expansive cement is a unique type of cement that, when mixed with water, produces a paste which expands in volume significantly more than standard Portland cement. This expansion nullifies the deficit of shrinkage that arises during concrete hardening. This paper presents the outcomes of two phases of experimentation. Phase I of the paper provides a summary of the performance of expansive cement concrete mixes prepared with various proportions of expansive cement, which partially supplements the ordinary Portland cement, and which is infused with varying amounts of PVA fibers of 0.5, 1, 1.5, 2, and 2.5%, as a form of reinforcement under compression, tension, and flexure. Concrete strength, curing effect, and PVA fibers are the variables in Phase I of the study. The Phase II findings provide the buckling behavior of the self-stressed concrete columns reinforced with PVA fibers when the optimum concrete mix obtained from the Phase I investigation was poured inside steel tubes of varying thicknesses of 2 mm and 2.5 mm to restrict the expansion of the concrete, thereby making it self-stressed concrete. The D/t ratio, inclusion of expansive cement, and PVA fibers are the variables for Phase II of the study. The self-stressed columns with 2% PVA fibers showed better performance than the other columns.

1. Introduction

For many eons, concrete has been the most popular construction material worldwide. Since it has become an indispensable material in any construction, many studies have been carried out to make concrete more durable and serviceable. As shrinkage of the concrete is the major short-coming that cannot be avoided in any structure, studies were carried out to avoid the shrinkage cracks and to make a high-performance concrete [1]. This study attempts to make concrete more durable by incorporating fibers into the concrete and partially supplementing ordinary Portland cement with sulpho–alumino-type expansive cement. Commercially, there are four types of expansive cement, namely: silicate expansive cement, aluminate expansive cement, sulpho-aluminate expansive cement, and alumino-ferrite expansive cement. The sulpho-aluminate-type cement’s expansivity would most likely be due to negatively charged flocculating grains of ettringite, which possess a high specific surface area formed by a through-solution mechanism; they entice the polar water molecules that encircle the crystals, allowing interparticle (possibly double-layer-type) abhorrence, culminating in overall system expansion. This enables a higher resistance against environmental exposures compared with ordinary concrete in construction. Polyvinyl alcohol (PVA) fiber can be used as a cementitious composite and an alternative reinforcement that prevents cracking and helps concrete to withstand fatigue. The past studies on the usage of magnesium oxide-containing expansive cement showed that they can be used to compensate the shrinkage developed in the concrete and how the hydration process influences the expansion and shrinkage of concrete [2]. In addition, it was observed that the addition of fibers into expansive cement concrete helps to improve the strength and durability of the mix [3].

Several studies have been conducted to explain the mechanism behind the expansion of the cement during hydration, which include that the theory stating that pressure that influences the expansion activity, namely the pressure which is induced by the formation of hydroxide ion crystals and the pressure induced by the swelling of these hydroxide ion crystals during their water absorption. This theory explains that the expansion of the cement is the result of the pressure developed in the cement paste due to the formation of hydroxide ions and their water absorption, which in turn helps in swelling the other particles [2].

Concrete can either be made into shrinkage-renumerating concrete or chemically prestressed concrete, depending on the variety and proportions of expansive agents utilized in the mixture [4]. The most vital aspect that defines the quality of concrete-accommodating expansive cement is its ability to show an ultimate expansion during the hydration process, which is larger in self-stressing concrete. Tetra calcium alumino silicate, calcium sulphate, and lime are the main components of K-type expansive cement, a modified version of Portland cement (calcium oxide). The addition of an expansive agent based on tetra calcium alumino silicate had no effect on the mechanical properties of concrete, but it had a significant impact on its autogenous shrinkage, which was reduced by up to 80% [5]. Studies showed that when the percentage of expansive cement is increased, the hydration process of the cement is greatly affected and the setting time of the concrete mix is increased [6]. When the shrinking ability of the concrete is reduced, nevertheless, by incorporating shrinkage-hindering agents and fibers into the concrete, the concrete mix tends to perform better in aspects of crack development behavior [7].

Because of their utility as a reinforcing material for cementitious compounds, fibers have been used extensively in concrete since the 1980s. The fatigue strength of fiber-intruded concrete was discovered to be greater than that of concrete that lacks fibers, and this strength may very well be related to fiber distribution [8]. When compared to other organic fibers, PVA fibers were known to have a higher tensile strength and Young’s modulus. PVA fiber’s most important properties are its strong connection to the concrete mixture, its higher modulus of elasticity, and its ability to form strong bonds with other PVA fibers. These qualities contribute to enhanced concrete flexibility and tensile strength [9]. The PVA fibers when used as the reinforcement help to improve the strength of the concrete and help to reduce the amount of tensile reinforcement [10]. When employed as reinforcing material, PVA fibers help to improve the strength of concrete while somehow reducing the amount of tensile reinforcement required [4]. As per the investigative outcomes, adding more expansive cement hinders the hydration process of the cement, which increases the time considered necessary for the concrete mix to set [7]. On the contrary, when the shrinkage of the concrete is minimized as a consequence of the inclusion of shrinkage-hindering agents and fibers in the concrete, the concrete mix generally performs more effectively in crack development behavioral aspects [8,11]. Inclusion of shrinkage-hindering agents and fibers is carried out in order to prevent cracks from developing in the concrete [9]. Numerous studies have been carried out in an endeavor to enhance the buckling tolerance of concrete and steel-concrete composite columns by incorporating a wide range of cementitious composites as additives [12,13]. It has been discovered that swapping out expansive cement for ordinary Portland cement (OPC) in the column can enhance the efficiency of plain cement concrete columns [14]. Hence, this paper summarizes the experimental approach of introducing expansive cement into concretes of different grades and varying percentages of PVA fibers under different curing conditions. The variables that are considered for the study were D/t ratio of columns, expansive cement, PVA fibers, and curing conditions. By varying D/t ratio, the amount of self-stress developed in concrete was identified to vary, which is expressed in terms of strain induced in concrete. By varying the proportion of PVA fibers in this self-stressed concrete, the efficacy of fibers was studied. This paper explains these test results in two phases.

2. Phase I: Material Study

The comparison of the chemical composition of expansive cement and ordinary Portland cement is depicted in Table 1. The sulpho–alumino type expansive cement was replaced with the ordinary Portland cement in various percentages of 2.5, 5, 7.5, 10, 12.5, and 15%, whose preliminary tests, such as initial setting time and workability of the concrete, were studied. Based on the findings, it was determined that the amount of expansive cement added to the concrete affects both the setting time and the workability of the concrete. It was found that when the amount of expansive cement which supplements the ordinary Portland cement was increased beyond 10%, the setting time of the mix was increased and the slump value of the concrete mix was reduced. As a result, 10% expansive cement concrete was determined to have tangible importance and to be the best possible percentage for beneficial increase in the volume.

Table 1.

Chemical composition of OPC and sulpho-alumino expansive cement [2].

This experimental study was made with the preparation of expansive cement concrete which contains ordinary Portland cement (OPC) of 53 Grade IS: 12269-2015 [15] and with a specific gravity of 3.172 as the binder material, which is partially replaced by 10% expansive cement (sulpho–alumino type). PVA fibers with an aspect ratio of 50 were mixed with the concrete as reinforcement in various percentages of 0.5%, 1%, 1.5%, 2%, and 2.5% to the total concrete volume. The various expansive cement concrete mix proportions for both the grades M40 and M50 with varying percentages of PVA fibers are summarized in Table 2.

Table 2.

The specifics of expansive cement concrete mixes with PVA fiber reinforcement.

According to IS: 10262-2009 [16], the ratios for M40 and M50 grade concrete were designed to be 1:1.73:2.47:0.45 and 1:1.7:2.35:0.45, respectively. The concrete was mixed using a motor-driven roller mixer with a capacity of 0.4 cubic meters. According to IS 383-2016 specifications, natural river sand and crushed granite blue metal (20 mm) with specific gravities of 2.52 and 2.77 were employed as fine aggregate and coarse aggregate, respectively [17]. For casting and curing, potable water free of oils, acids, salts, and other impurities was used.

3. Discussion on the Mechanical Properties of Fiber-Reinforced Expansive Cement Concrete

Tests were performed on hardened concrete as per IS: 516-1959 [18] at the ages of 7 and 28 days in order to find the mechanical properties of PVA fiber-reinforced expansive cement concrete.

3.1. Effect of Curing

This expansive cement concrete can also be made to be self-stressed by infilling it within the steel tubes, thereby resisting the expansion caused during the hydration of the expansive cement. In these self-stressed concrete specimens, which are confined with steel tubes, direct curing of the specimens is not possible, and hence self- curing is the only option for this issue. Self-curing is the curing process in which the moisture content that was lost during the process of hydration is reused for curing. This self-curing of specimens was achieved by wrapping the concrete specimens within the plastic covers and thereby avoiding the water loss and reusing this trapped water for curing. The self-curing is conducted so that the properties can be compared with behavior of the specimens that will be confined within the steel tubes for restricting the expansion of the concrete with expansive cement, thereby enabling the effect of self-stressing in the concrete. The specimens cast with grades M40 and M50 with varying percentages of PVA fibers, with and without expansive cement, were permitted to cure under self-curing and water-curing conditions. The subsequent sections debate the effectiveness of concrete specimens under various curing conditions.

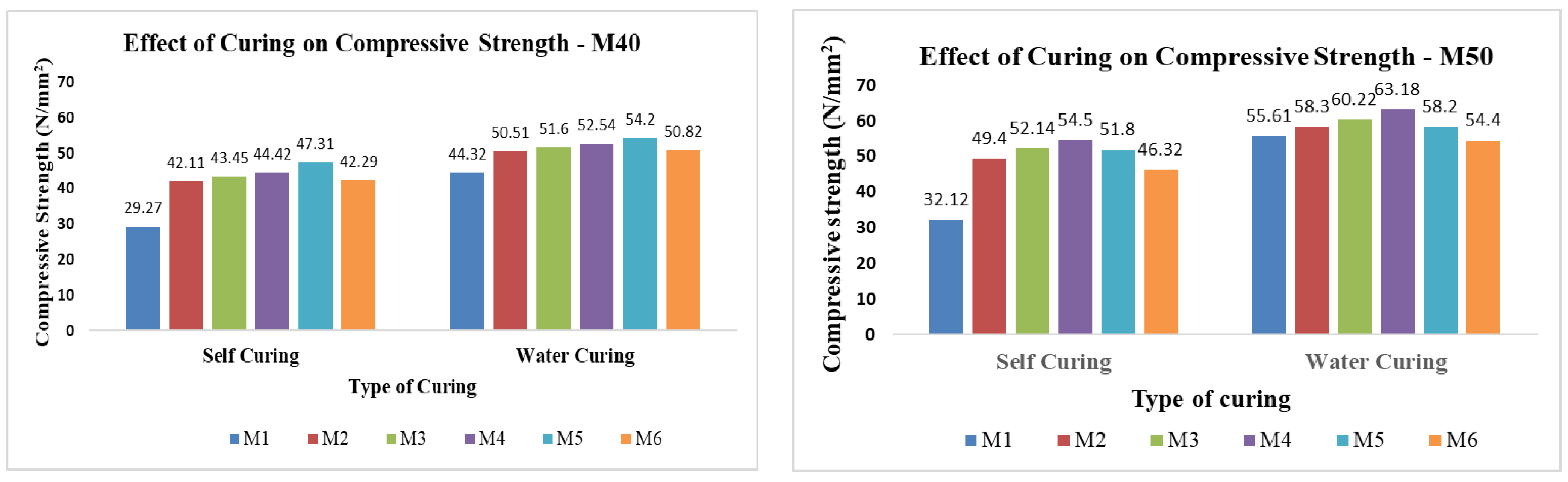

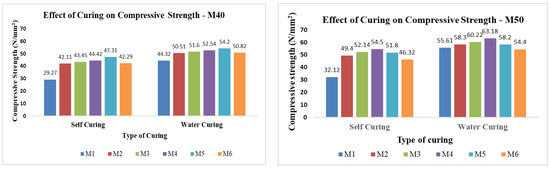

3.1.1. Compressive Strength

The compressive strength of the concrete specimens with and without expansive cement with various percentages of PVA fibers under both water-curing and self-curing conditions were compared in Figure 1. The specimens with labels M2, M3, M4, M5, and M6 under water-curing conditions showed a gradual increase in strength of 43, 48, 52, 62, and 44%, respectively, compared to the compressive strength of M1 of M40 grade concrete, while the specimen labels M2, M3, M4, M5, and M6 showed a gradual increase in strength of 54, 62, 69, 61, and 44%, respectively, compared to the compressive strength of M1 of M50 grade concrete. While the specimens were permitted to cure through self-curing, they showed mild increase in their compressive strength of 14, 16, 18, 22, and 15%, and an increase of 5, 8, 14, and 4% and reduction of 2%, respectively, compared to M1 of M40 and M50 grades, respectively.

Figure 1.

Impact of curing on compressive strength of concrete.

From the results, it was observed that the specimens that were water cured performed better than the specimens that were wrapped with plastic covers. The water that was lost due to heat produced during the hydration process was not sufficient for the curing of the specimen and this resulted in the decrease in strength compared to the specimens that were water cured.

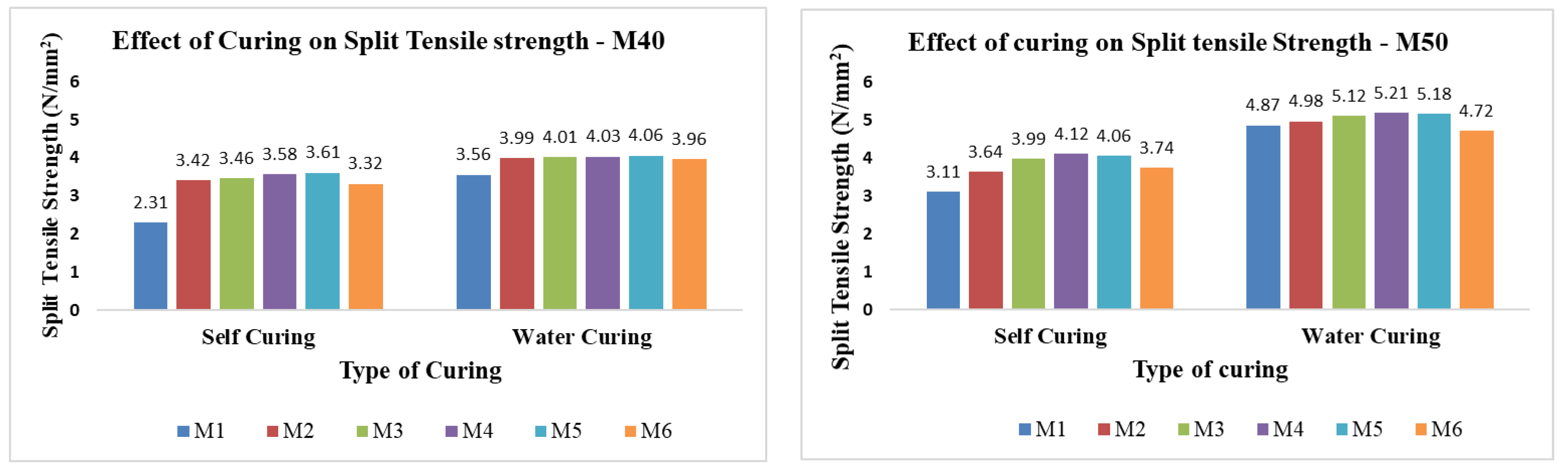

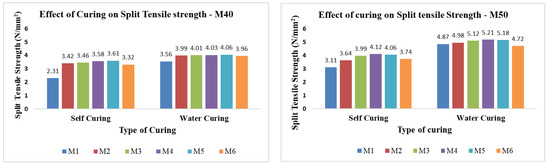

3.1.2. Split Tensile Strength

The split tensile strength of the concrete specimens with and without expansive cement with various percentages of PVA fibers under both self-curing and water-curing conditions are compared in Figure 2.

Figure 2.

Impact of curing on split tensile strength of concrete.

The split tensile strength of specimens with labels M2, M3, M4, M5, and M6 was found to be increased by 48, 49, 54, 56, and 43%, respectively, when the specimens were water-cured, and was found to have increased by 11, 12, 13, 14, and 11%, respectively, when they were self-cured for a 28-day period compared to the split tensile strength of specimen label M1 of M40 grade. For the specimens with M50 grade, the split tensile strength of specimen labels M2, M3, M4, M5, and M6 increased by 54, 62, 70, 61, and 44%, respectively, when the specimens were water-cured, and was found to be increased by 5, 8, 14, and 5% and reduced by 2%, respectively, when they were self-cured for a 28-day period.

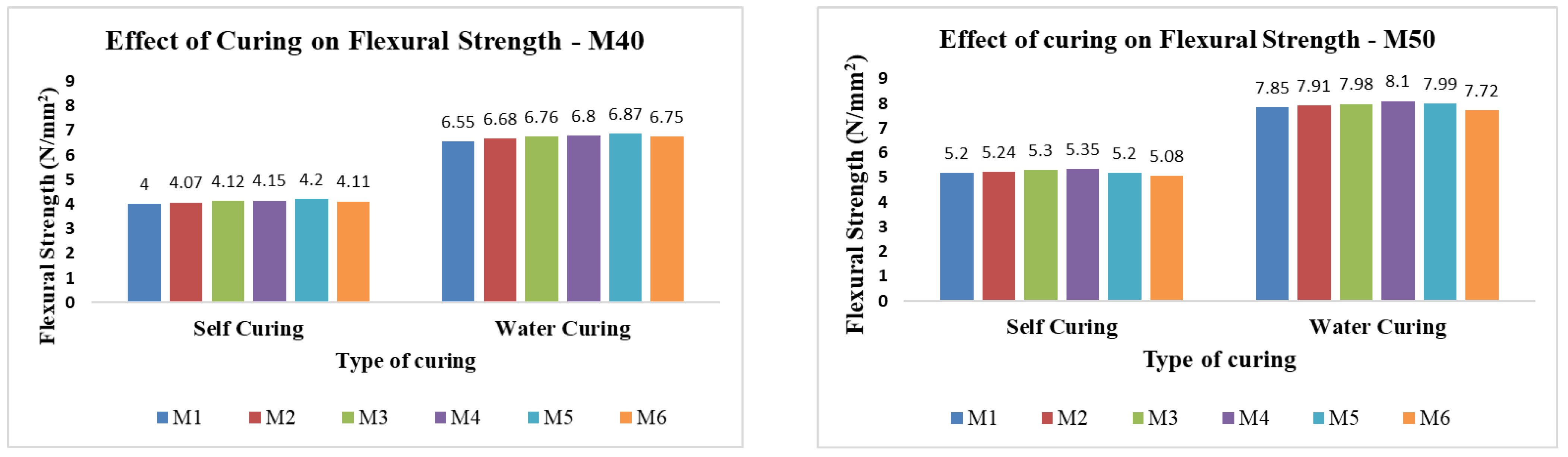

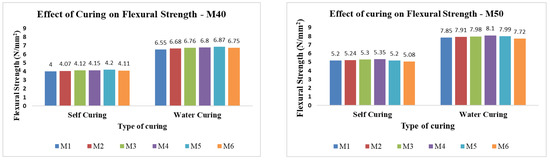

3.1.3. Flexural Strength

The flexural strength of the concrete specimens with and without expansive cement with various percentages of PVA fibers under both self-curing and water-curing conditions are compared in Figure 3.

Figure 3.

Impact of curing on flexural strength of concrete.

The flexural strength of specimen labels M2, M3, M4, M5, and M6 was found to be increased by 1.7, 3, 3.7, 5, and 2.7%, respectively, when the specimens were self-cured, and was found to be increased by 2, 3, 3.8, 4.8, and 3%, respectively, when they were water cured for 28 days compared to the flexural strength of M1 of grade M40. For the specimens with grade M50, the flexural strength was found to have increased by 1, 1.9, 2.9, and 1% and decreased by 2%, respectively, when the specimens were self-cured, and was found to be increased by 1, 1.7, 3, and 1% and decreased by 2%, respectively, when they were water cured for 28 days compared to the flexural strength of the specimen label M1.

It has been discovered that the curing condition has a significant impact on the split tensile strength and the flexural strength of the concrete made with expansive cement and PVA fibers; however, the variation in strength is found to be comparable between the two curing conditions. This change in strength with respect to the type of curing was the result of the fact that the amount of water lost as a result of the heat of hydration was insufficient for the curing of the concrete. This deficiency can be remedied by increasing the water-to-cement ratio of the concrete mix that is being used.

3.2. Effect of PVA Fibers

The specimens cast with grades of M40 and M50 and with different curing conditions (self-curing and water-curing) with varying percentages of PVA fibers of 0, 0.5, 1, 1.5, 2, and 2.5% as reinforcement and their mechanical properties were studied to determine the optimum proportion of PVA fibers for the better performance of the concrete mix. The following section will focus on the discussion of the mechanical characteristics of the concrete specimens that contain varying percentages of PVA fibers.

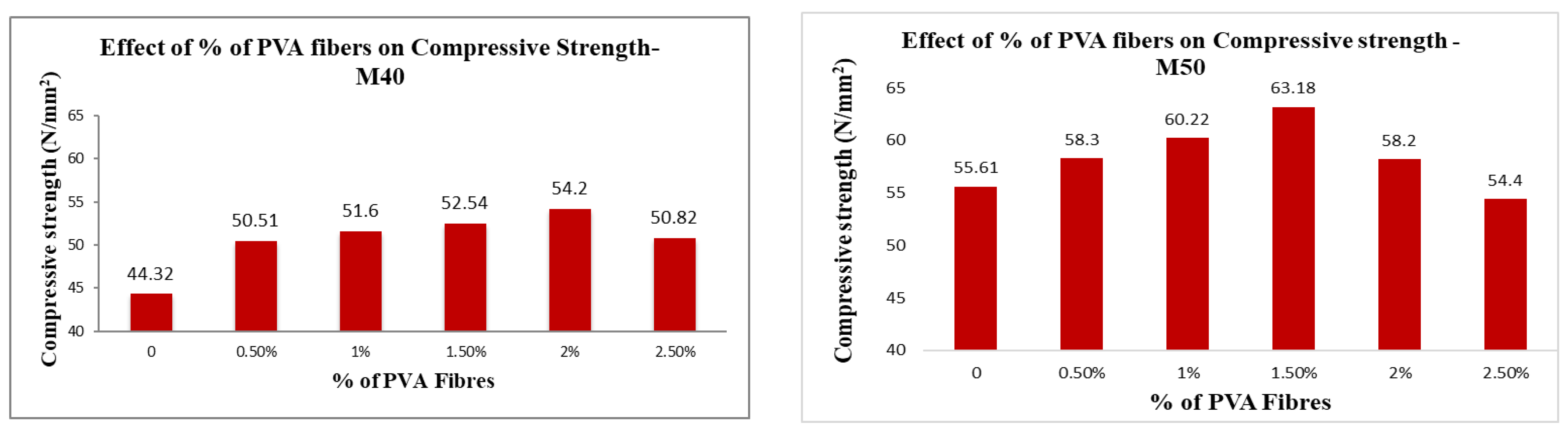

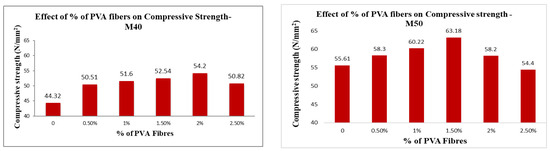

3.2.1. Compressive Strength

The compressive strength of expansive cement concrete specifics with labels M2, M3, M4, M5, and M6 was found to be increased by 13.97, 16.43,18.55, 22.29, and 14.67%, respectively, compared to the compressive strength of M1 of M40 grade and the compressive strength of expansive cement concrete of grade M50 showed an increase of 4.84, 8.29, 13.61, and 4.66% and a decrease of 2.18%, respectively, compared to the compressive strength of the M1 specimen. The comparison of the results of the compressive strength of various mixes is shown in Figure 4.

Figure 4.

Comparison of compression strength of expansive cement concrete specimen.

From the test results, it was observed that the compressive strength of the specimens increased gradually with the increase in the volume of polyvinyl alcohol fibers until 2% for M40 grade concrete and 1.5% for M50 grade concrete and on further increase in the proportion of polyvinyl alcohol fibers, there was a reduction in the compressive strength of the concrete. This decrease in strength occurred as a result of the decreased workability of concrete and binding property of cement with fibers.

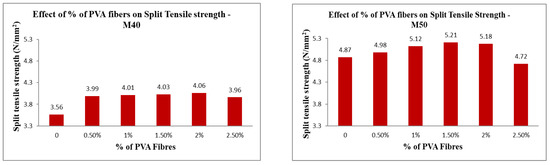

3.2.2. Split Tensile Strength

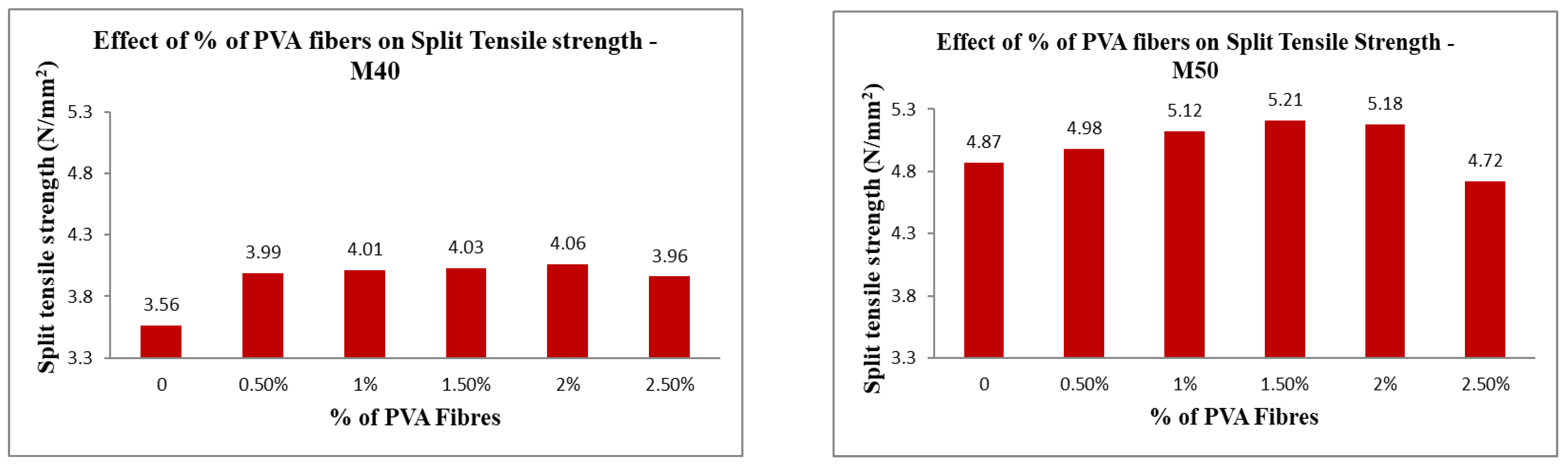

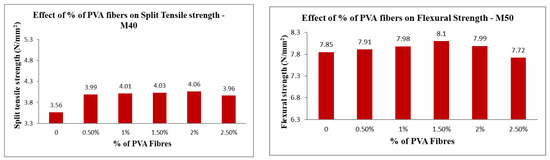

The split tensile strength of specimen labels M2, M3, M4, M5 and M6 was found to be increased by 12.08, 12.64, 13.20, 14.04, and 11.24%, respectively, compared to the split tensile strength of specimen label M1 of grade M40, and it showed an increase of 2.26, 5.13, 6.98, and 6.37% and a decrease of 3.08%, respectively, compared to the split tensile strength of M1 of M50 grade. The comparison of the results on the split tensile strength of various combinations of concrete mixes is shown in Figure 5.

Figure 5.

Comparison of Split tension test results on expansive cement concrete specimen.

From the test results, it is observed that the performance of the specimens under split tensile test improved gradually with the increase in the volume of Polyvinyl Alcohol fibers till 2% for M40 grade concrete and 1.5% for M50 grade concrete and on further increase in the number of polyvinyl alcohol fibers, there was a decrease in the split tensile strength of the concrete, which was the result of reduction in the binding capacity of the concrete when the volume of fibers was increased.

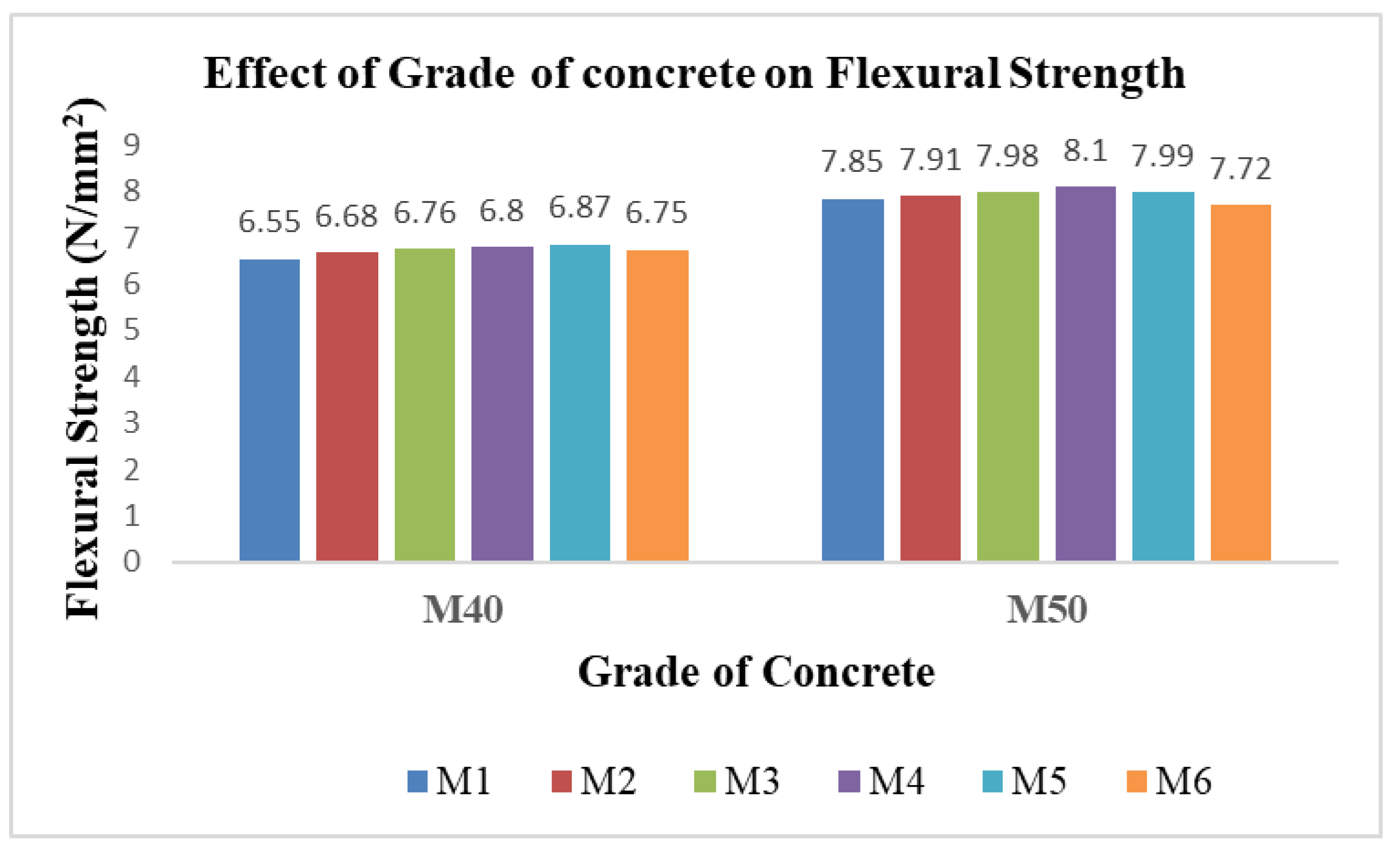

3.2.3. Flexural Strength

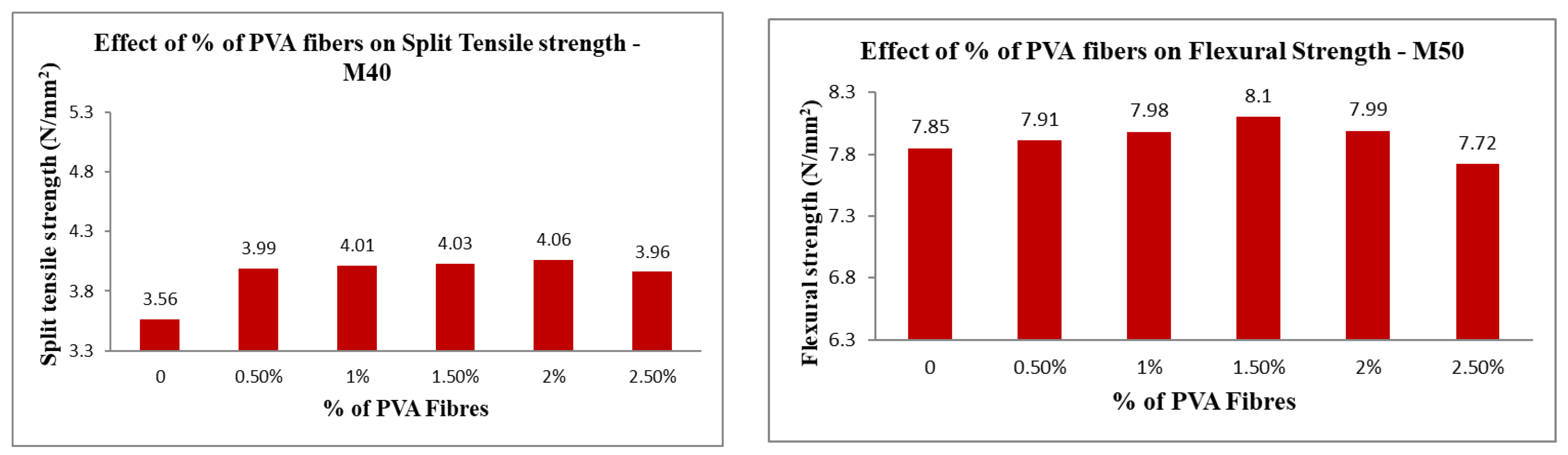

The flexural strength of specimens with labels M2, M3, M4, M5, and M6 was found to have increased by 1.98, 3.21, 3.82, 4.89, and 3.05%, respectively, compared to the flexural strength of the M1 of grade M40, and it showed an increase of 0.76, 1.66, 3.18, and 1.78% and a decrease of 1.66%, respectively, compared to the flexural strength of M1 of grade M50. The comparison of the results of the flexural strength of various mixes is shown in Figure 6.

Figure 6.

Comparison of flexure test results on expansive cement concrete specimen.

The performance of various trial mixes with expansive cement and varying percentages of PVA fibers under flexure test was observed to be similar and there was no considerable enhancement in the performance of concrete under flexure due to PVA fibers. The further increase in the percentage of PVA fibers resulted in a decrease in flexural strength of the concrete.

3.3. Influence of Grade of Concrete

The mechanical properties of specimens cast with varying percentages of PVA fibers, different curing conditions, and varying grades of concrete as M40 and M50 were compared and discussed as follows.

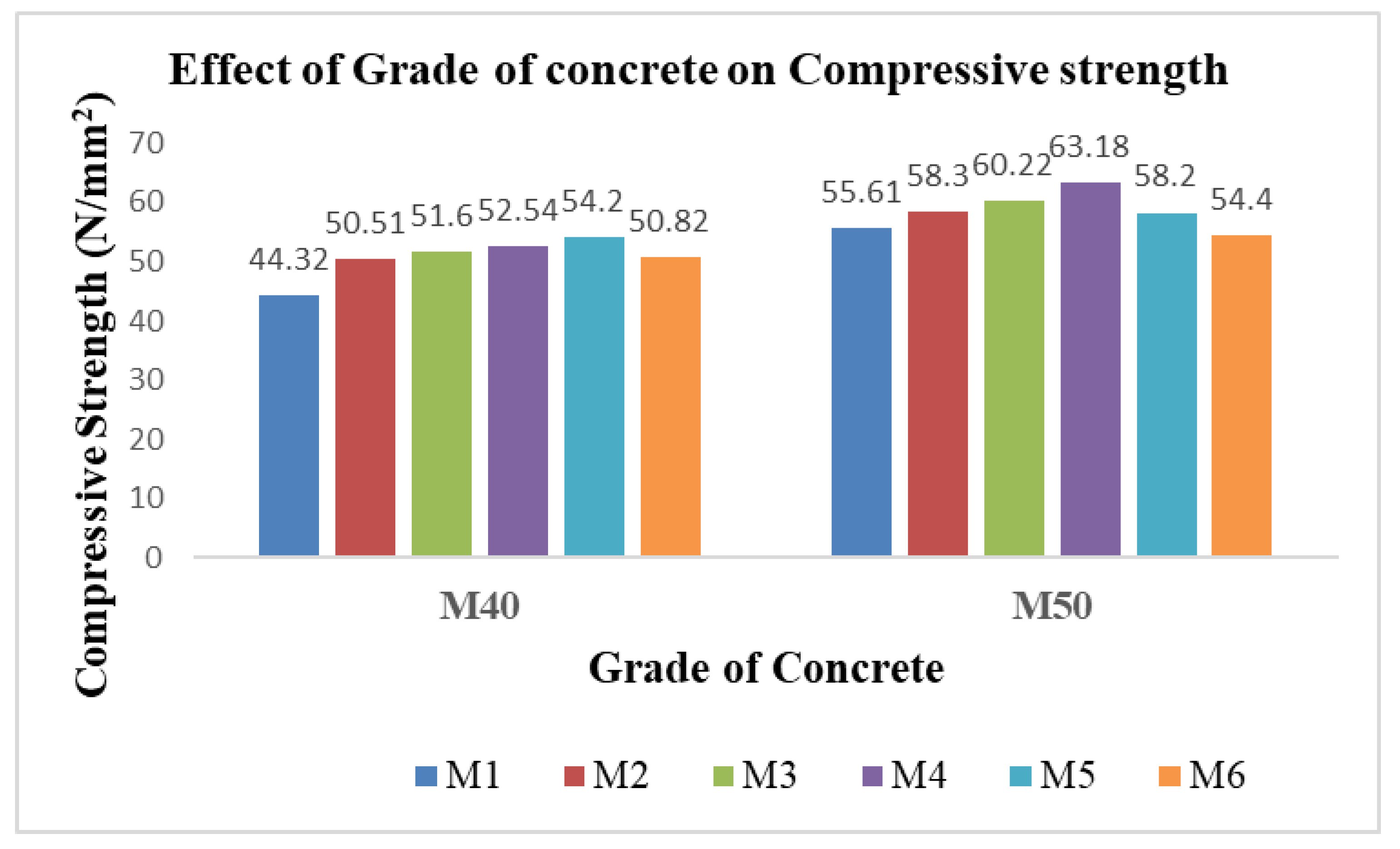

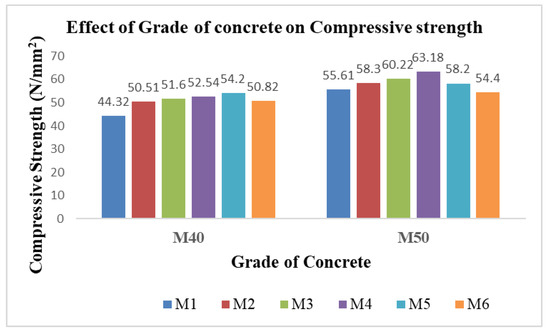

3.3.1. Compressive Strength

The specimens made with grades M40 and M50 with varying curing conditions and varying percentages of PVA fibers were subjected to compressive strength tests; the findings are shown in Figure 7.

Figure 7.

Comparison of the compressive strength of various specimens of different grades.

From the test results, it was observed that the performance of the concrete under compression made with grade M40 varies in a greater proportion with the inclusion of polyvinyl alcohol fibers and expanding cement, while the variation in the performance of M50 grade concrete with the inclusion of polyvinyl alcohol fibers and expanding cement is considerably less under compression. At 380 kN load, the M1 specimen of M40 grade concrete showed its first crack, while the first crack in the M5 specimen of the same grade developed at 460 kN load. It is evident that the accumulation of PVA fibers inhibits the development of cracks and thereby results in a better mix of concrete. Similarly in grade M50, specimen label M1 showed its first crack at 470 kN while the specimen with the label M4 showed its first crack at 540 kN under axial compression. The percentage increase in M40 grade concrete was 21.05%, while M50 grade concrete had an increase of 14.89%, which proves that the performance of the concrete is not greatly affected with the increase in grade of the concrete under compression.

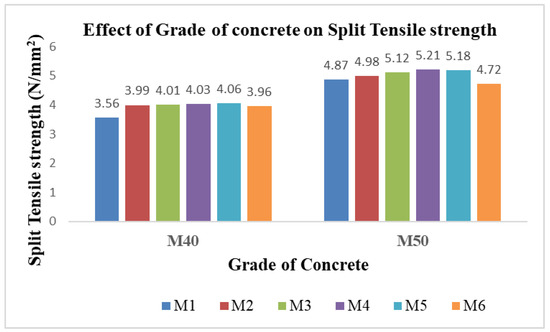

3.3.2. Split Tensile Strength

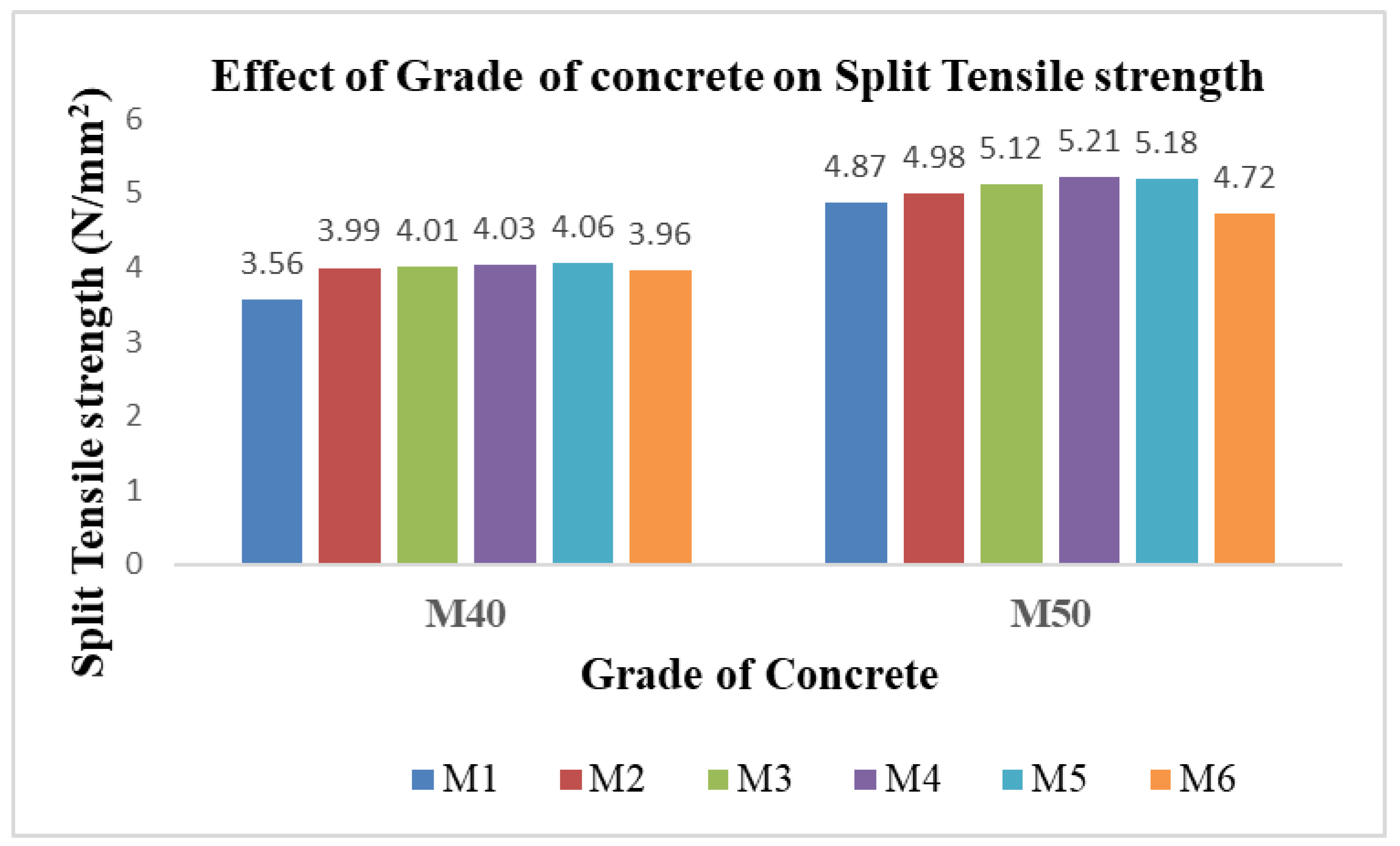

The split tensile strength test was carried out on the specimens made with grades M40 and M50 with varying curing conditions and varying percentages of PVA fibers; the results are compared in Figure 8.

Figure 8.

Comparison of the split tensile strengths of various specimens of different grades.

During the split tensile strength test of the specimens, it was observed that the first crack in the M40 grade concrete with the label M1 developed at 70 kN while the first crack in M5 developed at 88 kN, and the specimen label M1 of grade M50 showed its crack at 93 kN while the specimen label M4 developed its first crack at 116 kN under tension. From the experimental findings, it was observed that the percentage increase in tensile strength in M40 grade concrete was 25.71%, while in M50 grade it was 24.73%, which is quite similar to that of the performance of M40 grade concrete under tension. This proves that the grade of concrete does not heavily affect the behavior of the concrete under tension.

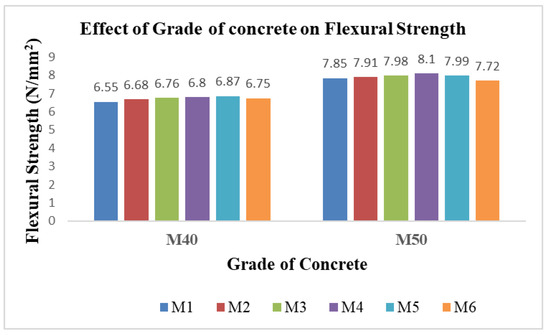

3.3.3. Flexure Strength

The flexural strength test was carried out on the specimens made with grades M40 and M50 with varying curing conditions and varying percentages of PVA fibers; the results are compared in Figure 9.

Figure 9.

Comparison of the flexure strengths of various specimens of different grades.

From the test results, the crack in the specimen of grade M40 with the label M1 started developing when the load reached 20 kN under flexure, while in the specimen M5 it was 25 kN, for specimens of grade M50, the crack first developed at 25 kN in M1, and the load for the first crack in specimen M4 was 31 kN. The substantial improvement in the flexural strength of the specimens of M40 grade was observed to about 25%, while in the specimens with grade M50 it was found to be 24%, which is approximately equal, proving that the concrete of grade M40 behaves similarly to that of the specimens with grade M50 under flexure when the PVA fibers and expansive cement are added to it. This proves that the grade of concrete has no considerable effect in the performance of the concrete under flexure.

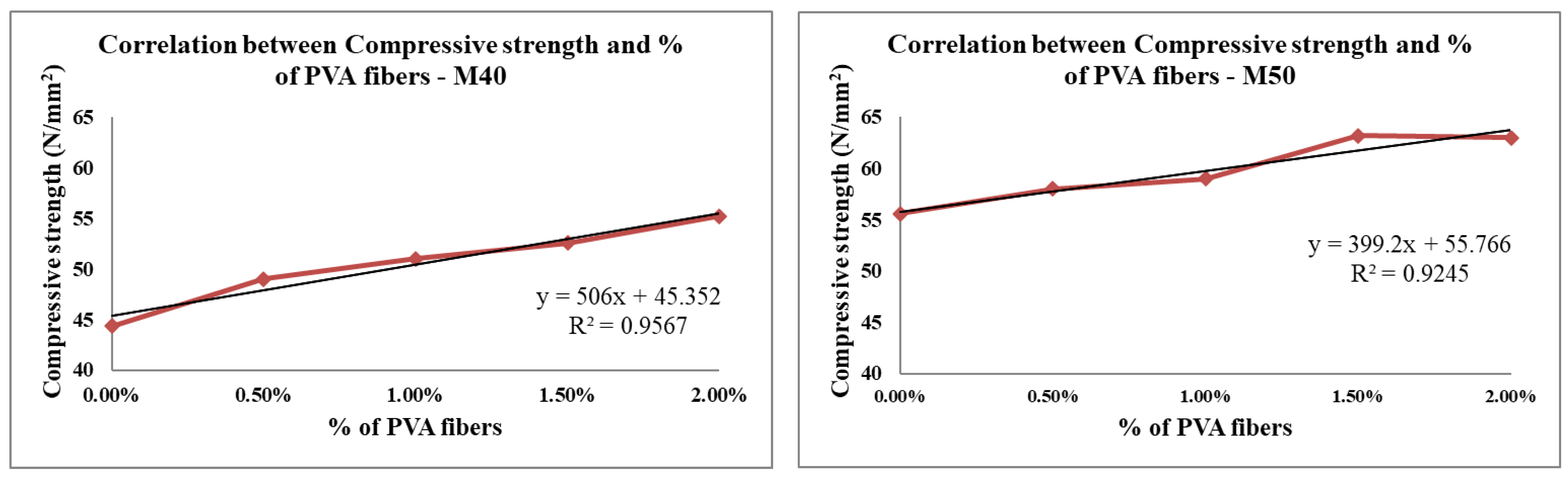

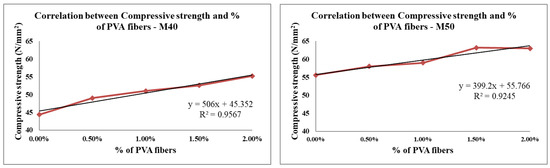

3.4. Correlation Evaluation of Results

Figure 10 depicts a developed correlation expression between the compressive strength of the test samples and the proportion of addition of PVA fibers. The value of regression coefficient (R2) and the corresponding linear equation are also expressed in the figure. The value of the R2 coefficient is found to be 0.9567 for concrete of grade M40 and 0.9245 for the concrete of grade M50, which is greater than 0.85, which exhibits the remarkable correlation between the parameters chosen.

Figure 10.

Graph showing correlation between the strength of concrete and the proportion of PVA fibers.

4. Phase II: Self-Stressed Concrete Columns

The optimum concrete mix obtained from the above mechanical properties was poured inside the steel tubes, which acted as the confinement for the expanding nature of the expansive cement during hydration process and eventually induced the intrinsic stress in the concrete, making it self-stressed. The following discussion explains the experimental and analytical study of these self-stressed concrete columns under axial compression.

4.1. Experimental Study on Self-Stressed Columns

The concrete of grade M40 made with 10% expansive cement with the optimum percentage of PVA fibers of 2% which was found to be the optimum percentage from the mechanical properties tests was poured inside the steel tubes of internal diameter 140 mm and varying thicknesses of 2 mm and 2.5 mm and length of 600 mm. The details of the specimens are listed in Table 3. The fibers must be distributed evenly to achieve the desired strength of concrete. For this even distribution, the addition of fibers is carried out before adding water to the concrete. This proper distribution of fibers is accomplished by introducing the fibers through a wire basket into the mixer [18].

Table 3.

The specifics of the fiber-reinforced self-stressed concrete columns.

The concrete containing 10% expansive cement when mixed with water tends to expand its volume, and when this expansion is restricted externally with steel confinement, the stress is indirectly induced in the concrete, making it intrinsically prestress or in other words, self-stressed. These columns were tested under axial compression to illustrate their buckling nature [19]. The columns, cast and are ready for testing, are exhibited in Figure 11.

Figure 11.

Self-stressed columns.

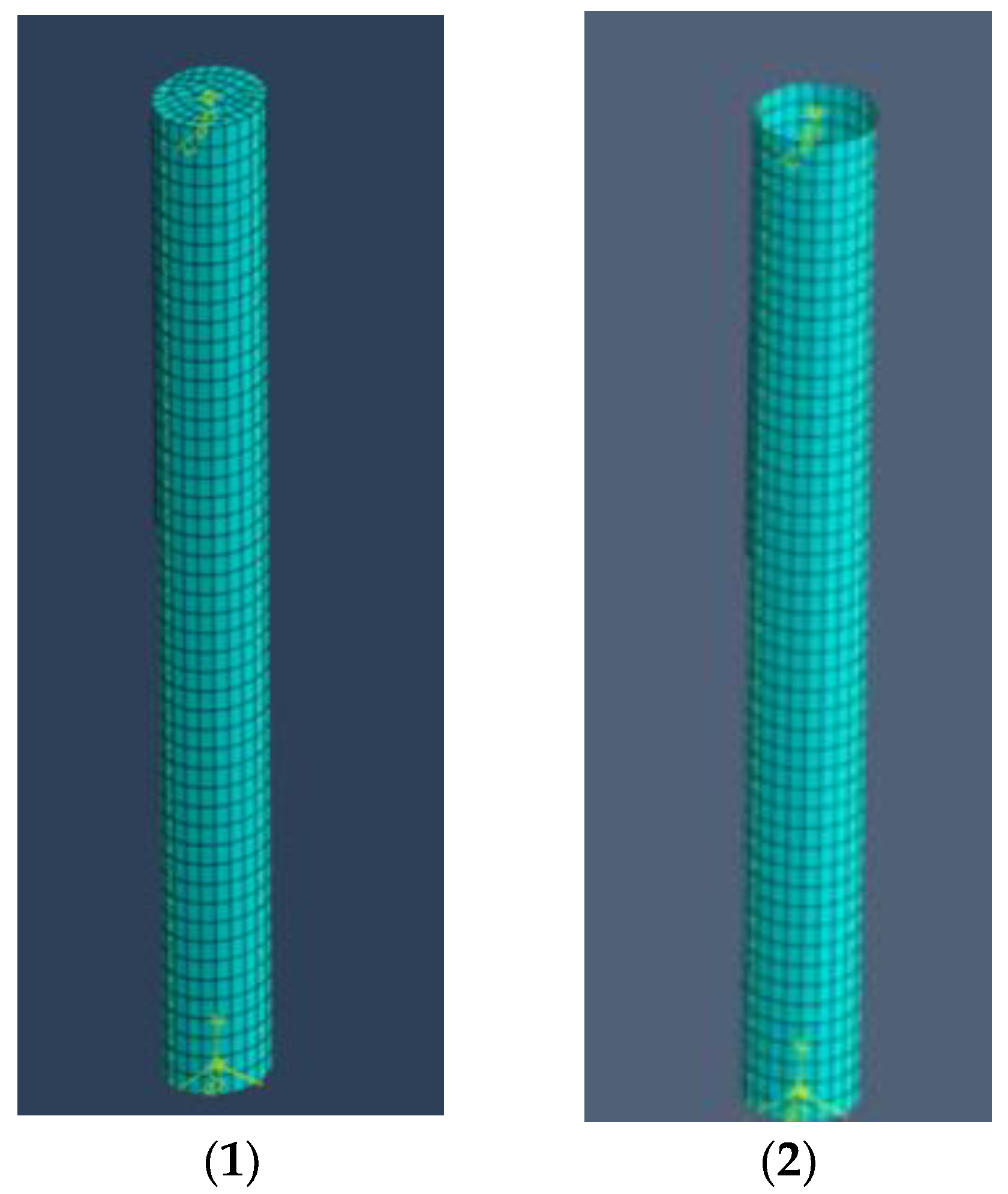

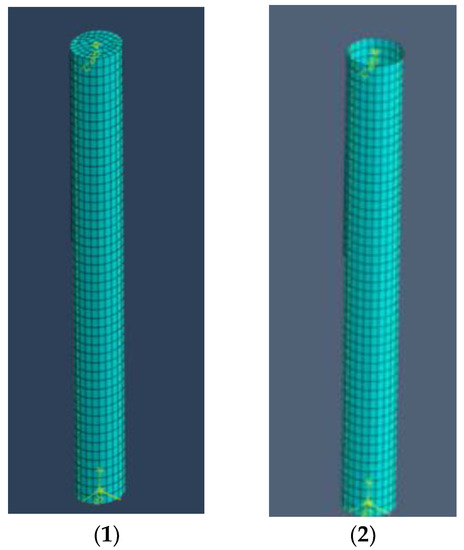

4.2. Analytical Study

The specimens were analyzed using finite element software to substantiate the experimental evaluation on the buckling behavior of self-stressed concrete columns reinforced with PVA fibers (ABAQUS). In ABAQUS, the steel tube is simulated as the shell part, and the concrete core is patterned as the solid part. These two parts are modelled separately as separate parts and assembled together in ABAQUS using the interference option. The mesh model of the samples generated by the finite element software is shown in Figure 12, the Concrete core is shown in (1) and Steel tube is shown in (2).

Figure 12.

Meshing of concrete infilled steel columns. (1) Concrete core, (2) steel tube.

Both steel tubes and concrete were provided with finer mesh, through which more precise and satisfactory outcomes can be accomplished. ABAQUS 6.13 offers four dimensional tetrahedrons (C3D4), six-noded triangular prisms (C3D8), and eight-noded bricks (C3D8). The concrete core is meshed with (C3D8R) eight-noded brick elements with equality and inequality constraints, while the steel tube is meshed with (S4R) four-node doubly curved thin or thick shell elements with respect to the parameters. Steel tubes were modelled in ABAQUS to have a modulus of elasticity of 200 GPa and a Poisson’s ratio of 0.3. A yield stress of 290 MPa was used to model the steel tube. The post-yielding properties of the steel were recorded as 430 MPa. The coefficient of friction was assumed to be 0.2, and the experimental analysis-yielded values were taken for modulus of elasticity and Poisson’s ratio for concrete as 43.86 GPa and 0.15, respectively. Using the interaction pair option, the target surface was chosen as the top and bottom lines of the tube, while the contact surface was chosen as the composite tube, with the target presumed as rigid and the contact body kept flexible. The tube’s top line was made as a rigid target which was constrained across all degrees of freedom, while the bottom line was constrained throughout all degrees of freedom apart from the y-direction.

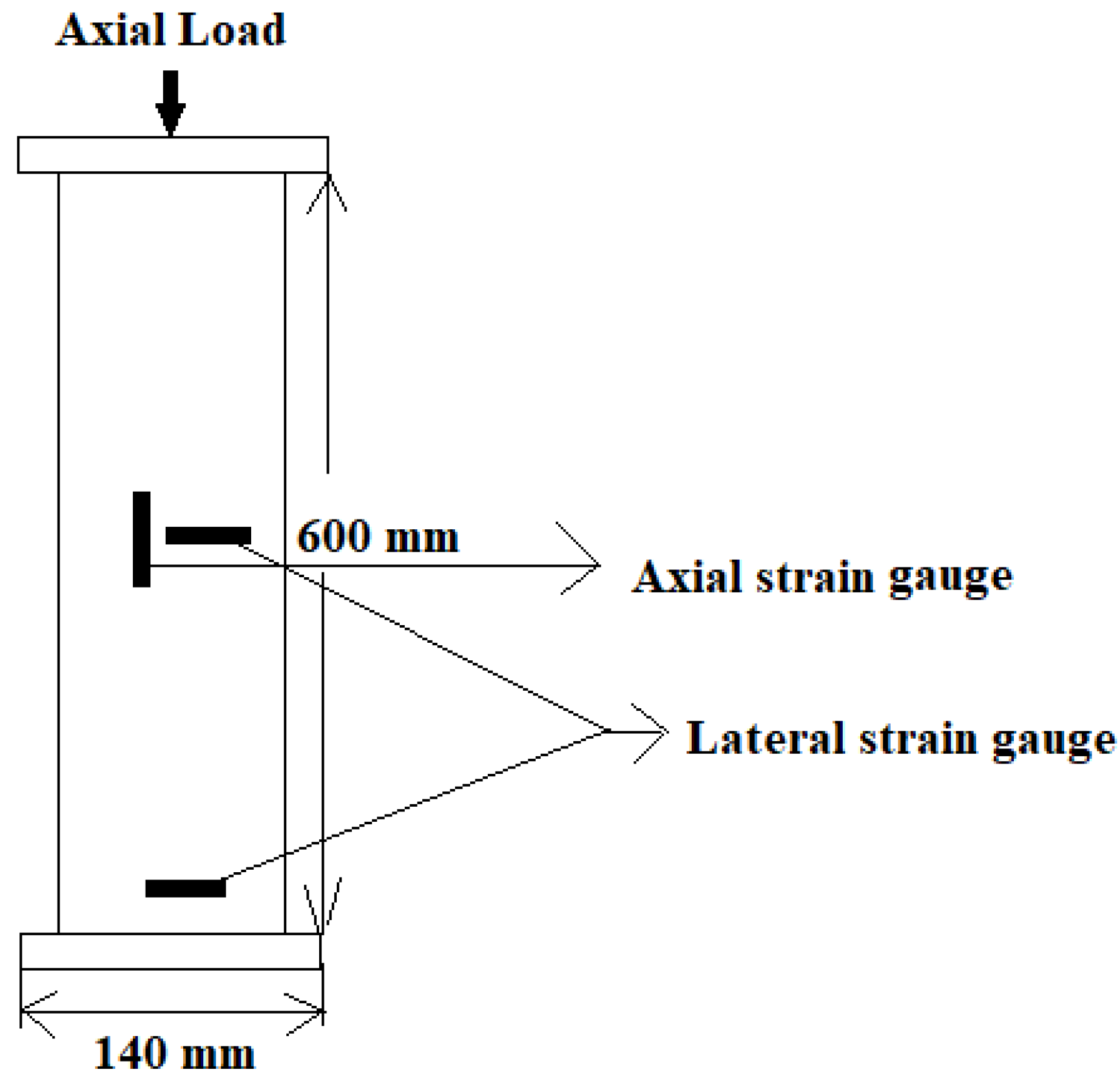

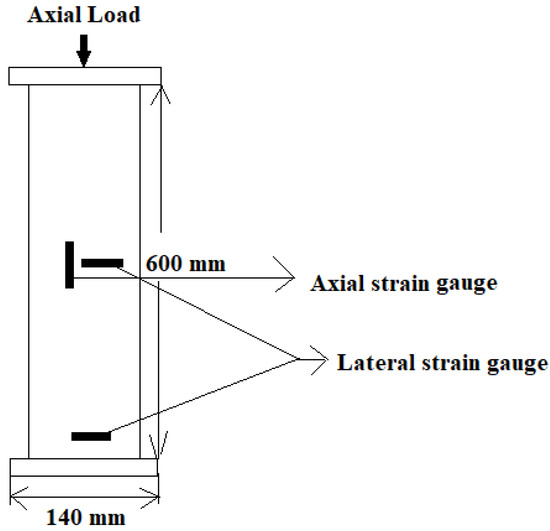

4.3. Testing of Self-Stressed Columns under Axial Compression

The buckling behavior of the PVA fiber-reinforced self-stressed concrete specimens of grade M40 was compared with the columns cast without expanding cement and without polyvinyl alcohol fibers with a varying D/t ratio of 70 and 56 when they were subjected to axial compressive loads. The load versus axial deformation of all the columns were studied for the comparison. The line sketch of the experimental setup is shown in Figure 13. The specimens were tested under axial compression during their expansion phase of hydration. It was found that the expansion in the concrete was very high in the initial stage of hydration, and this expansion rate dropped and almost stopped in the later stage. However, this expansion of the concrete which had taken place in the earlier stage of hardening compensated for the shrinkage that developed in the lateral stage of hardening.

Figure 13.

Arrangement of test specimen.

This increased expansion of the expansive cement concrete will also result in the development of self-stress when the expansion is being restricted by the external confinement provided by steel tubes. This development of self-stress is expressed in terms of strain developed on the internal walls of steel tube.

This hoop strain (ε) developed on the walls of steel tube can be calculated from the following equation as,

where σ stands for the circumferential stress developed by the external loads and (D/t) ratio is the diameter to thickness ratio of the steel tube.

The circumferential stress can be calculated from the equation,

where E and are the Young’s modulus and Poisson’s ratio of the steel, respectively, and εc and εz are the circumferential and longitudinal strains recorded using strain gauges during the compression loading tests of the specimens [20].

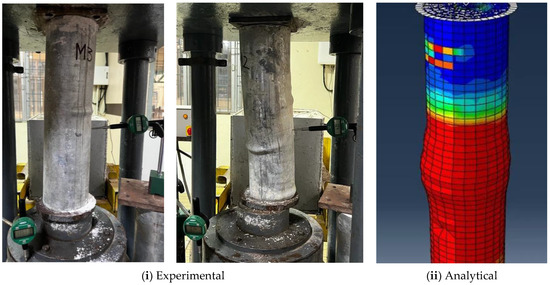

4.3.1. Failure Patterns of Columns

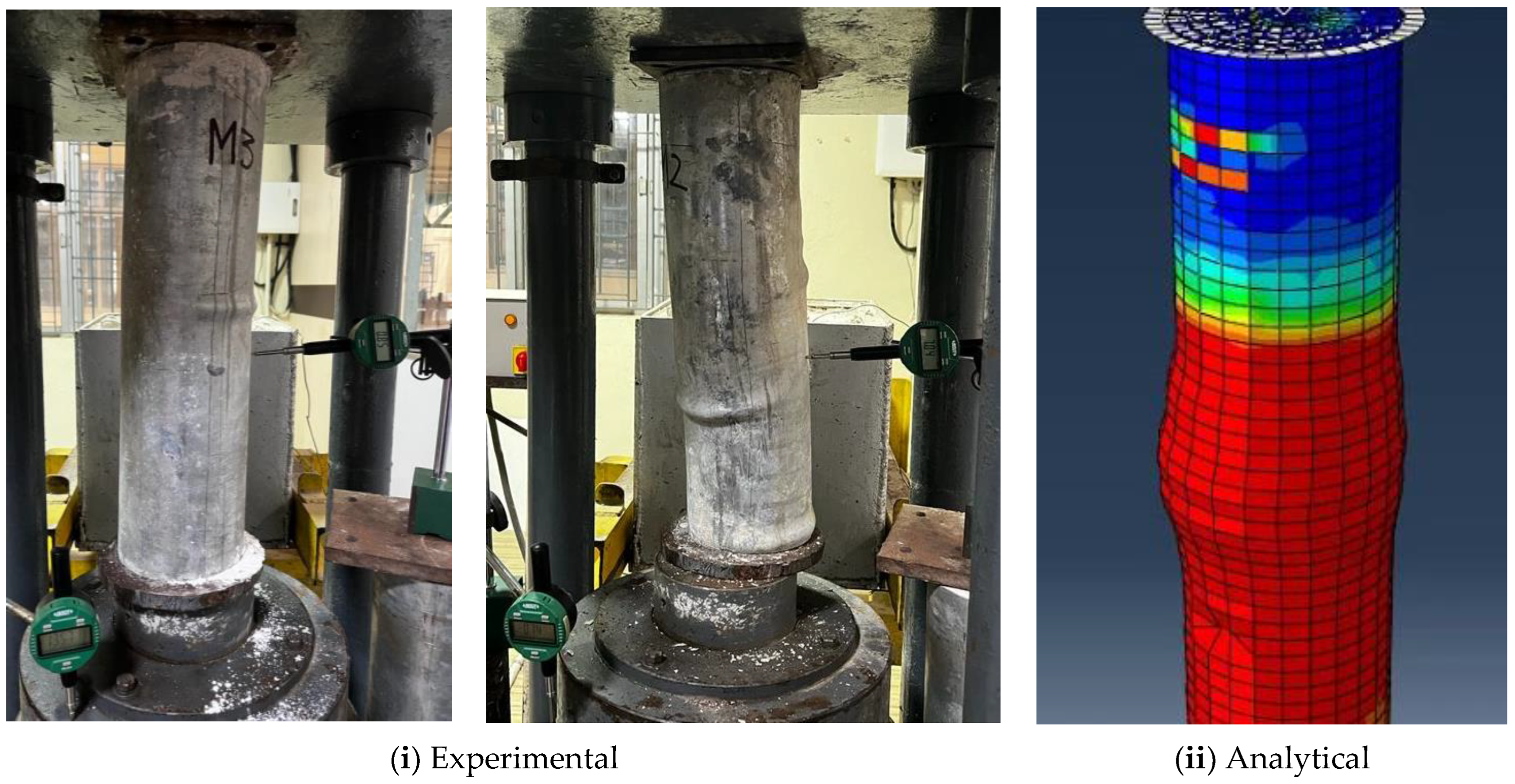

The failure patterns of the columns were found to be similar in both the experimental and analytical study, in which the buckling was initiated at the center of the columns longitudinally. The ductility of the columns was found to be increased with the inclusion of expanding cement and Polyvinyl Alcohol fibers. The failure modes of the columns in both experimental and analytical tests are depicted in Figure 14.

Figure 14.

Failure modes of PVA fiber-reinforced self-stressed concrete columns.

The columns were tested for axial compression in a compression testing machine with a capacity of 3000 kN by applying progressively increasing compressive loads in the axial direction with strain gauges of impedance 120 ohms assembled at the center and at the bottom in both longitudinal and transitional directions to indicate the axial deformation that occurred. The initial deformation was developed at the bottom of the column, which resembled the elephant foot shape. On further increase in the loads, the column failed due to buckling at the center of the column longitudinally. These results were in agreement with the findings of M. A. Reda et al. [13]. The load carrying capacity of the columns improved with respect to the decrement in the D/t ratio and with the inclusion of expansive cement and PVA fibers. The findings from the experimental testing of the columns were validated by the numerical study conducted by the finite element software where the ultimate failure happened due to the buckling of steel tubes.

4.3.2. Influence of D/t Ratio

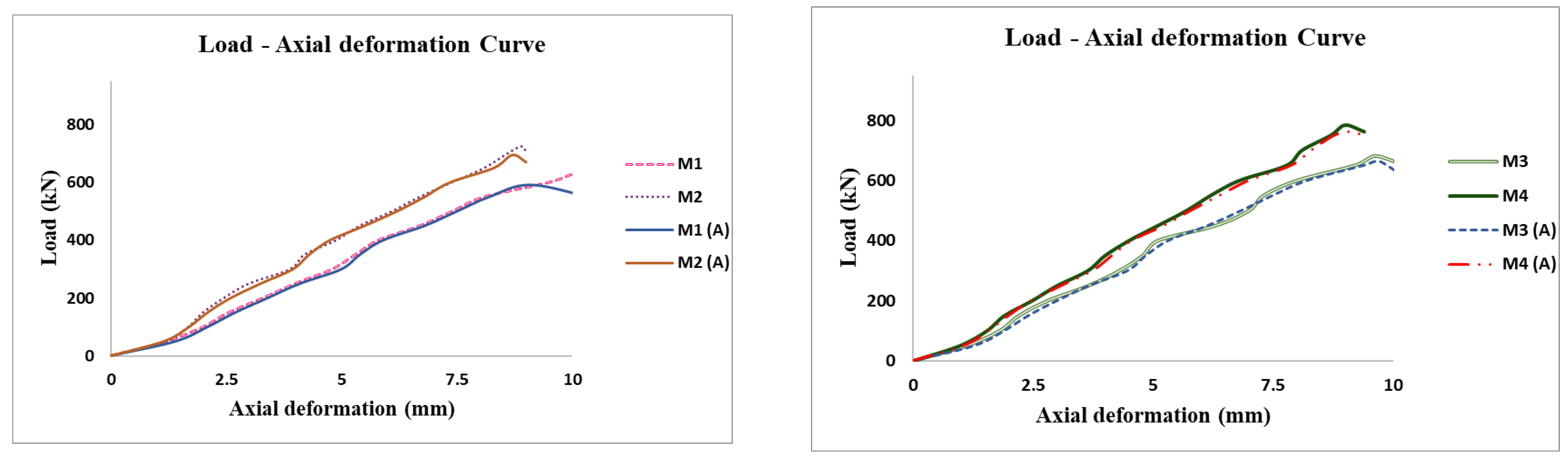

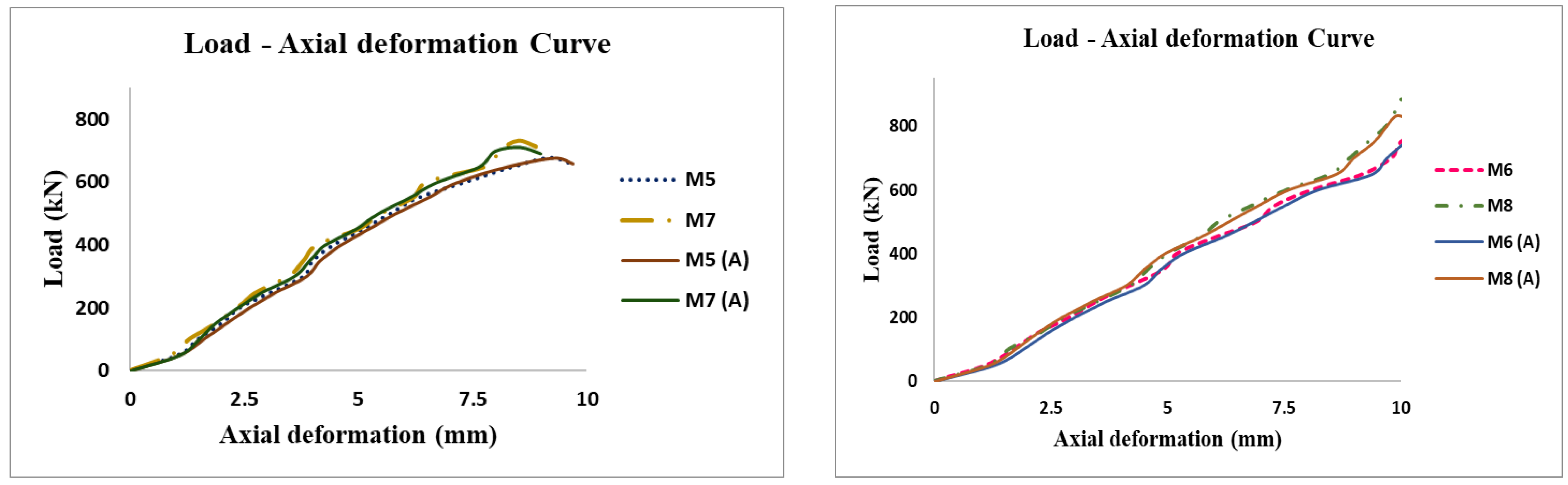

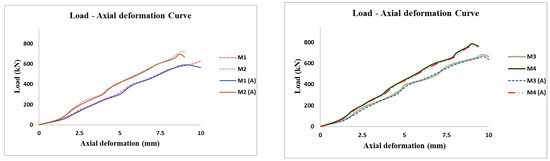

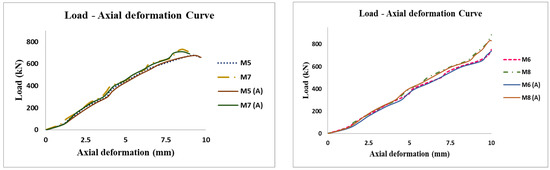

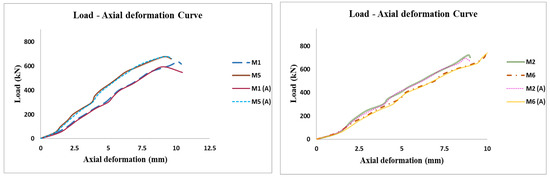

The fiber-reinforced self-stressed columns of grade M40 were made with varying D/t ratios of 70 and 56 and with an inner diameter of the column of 140 mm and steel tube thicknesses of 2 mm and 2.5 mm. The columns were tested for their buckling behavior under axial compression and were compared with the numerical analysis made with ABAQUS. The test results are graphically depicted in Figure 15.

Figure 15.

Load vs. axial deformation curves of self-stressed columns for the impact of D/t ratio.

From the test results, it is clear that when D/t ratio is decreased, the load carrying capacity of the columns was improved and the lateral deformation was also reduced. This is due to the increase in the thickness of steel tubes, which increases the confinement of the expansion of the concrete mix, thereby increasing the stress induced internally in the concrete. The results of the analytical study clearly agree with the result obtained from the experiments.

4.3.3. Influence of Expansive Cement

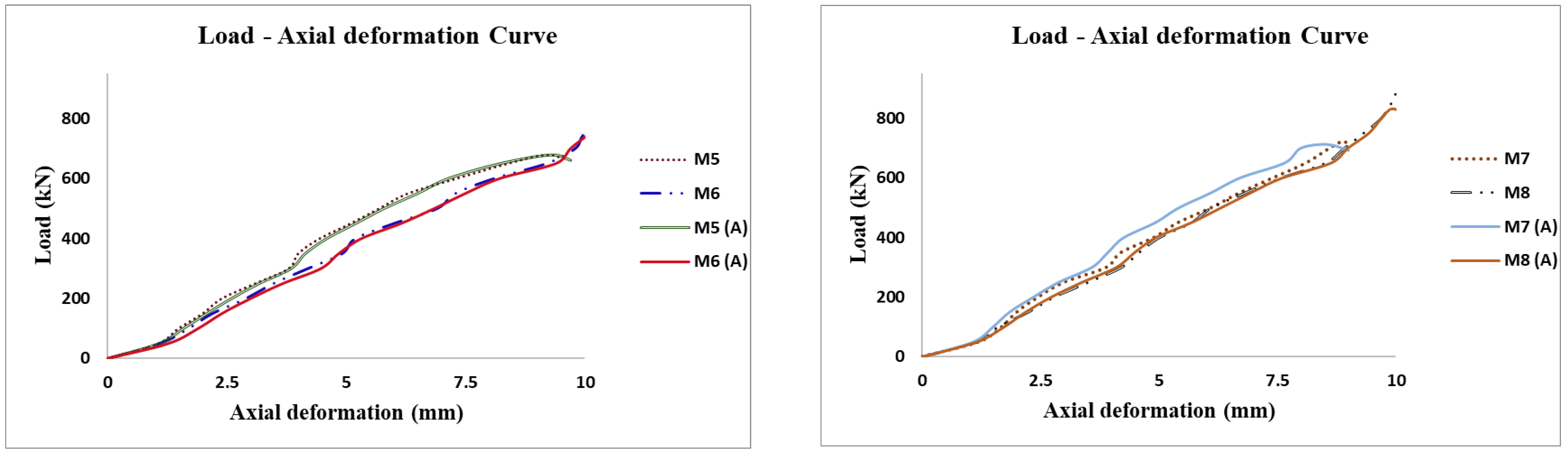

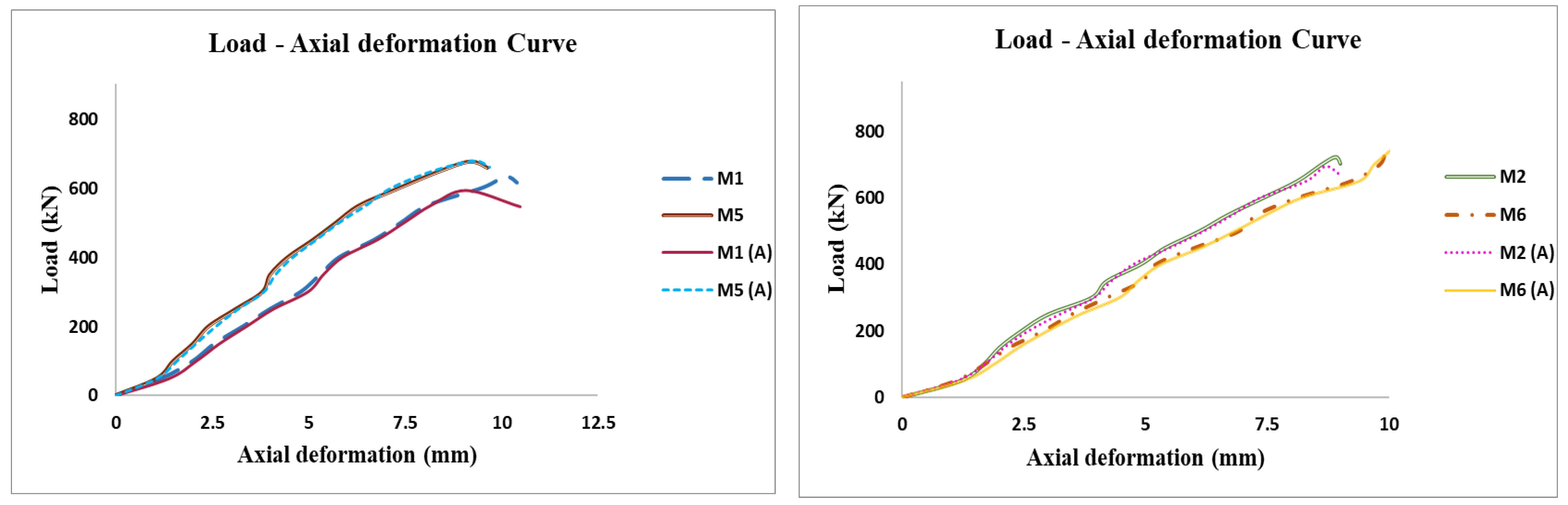

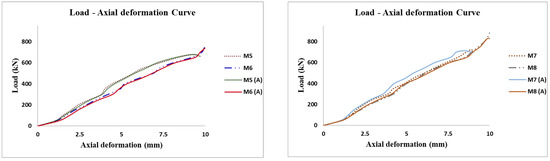

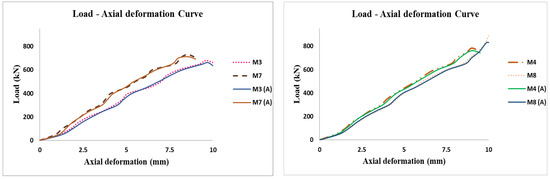

The juxtaposition and altercation that follows will concentrate on the effectiveness of columns fabricated with expanding cement and polyvinyl alcohol fibers on grade 40 concrete when 10% of ordinary Portland cement is supplanted with expanding cement and the effectiveness of these specimens was examined. The load versus corresponding axial deformation were plotted, and these plots were evaluated by comparing and addressed. The influence of expanding cement on the load-axial behavior of experimental and analytical studies of self-stressed columns is illustrated in Figure 16.

Figure 16.

Load vs. axial deformation curves of self-stressed columns for the impact of expanding cement.

The load-bearing efficiency of the columns was improved by supplanting 10% of OPC with expanding cement. It was discovered that when this expansive cement was partially replaced with OPC in concrete of grade M40 in the columns of thickness 2 mm, the load carrying capacity enhanced by 22.78% and in steel tubes of thickness 2.5 mm, the load carrying capacity was enhanced by 27.98%. Therefore, the partial substitution of OPC with expanding cement in concrete tends to increase load bearing efficiency with diminished deformation.

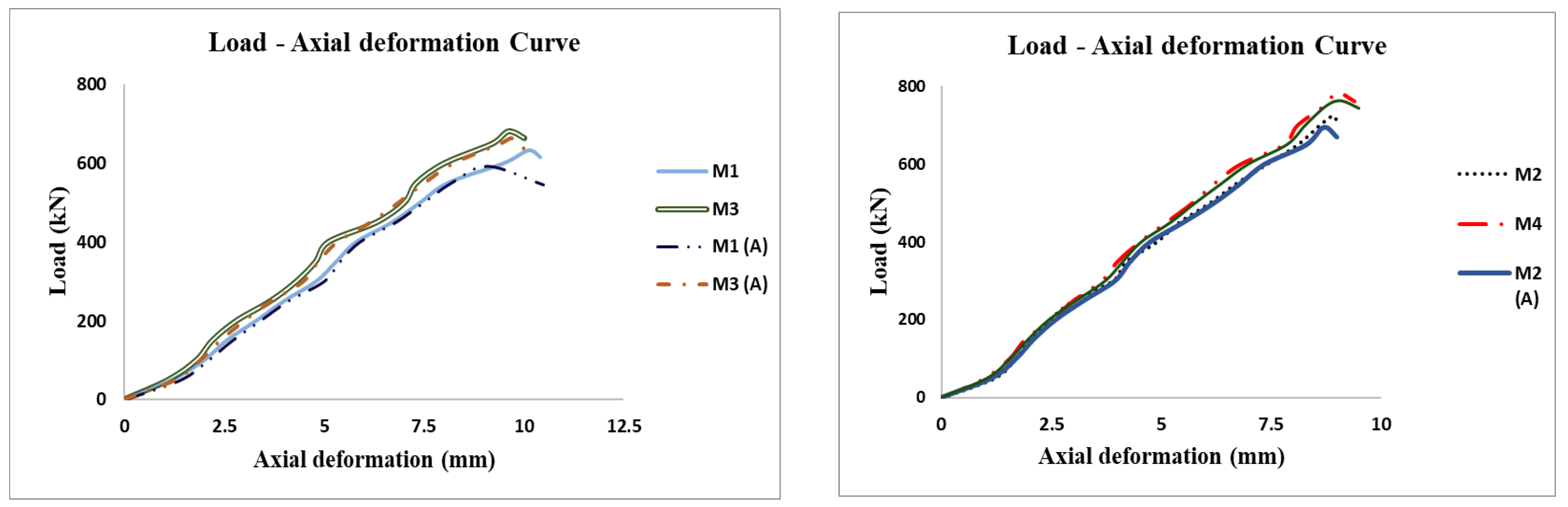

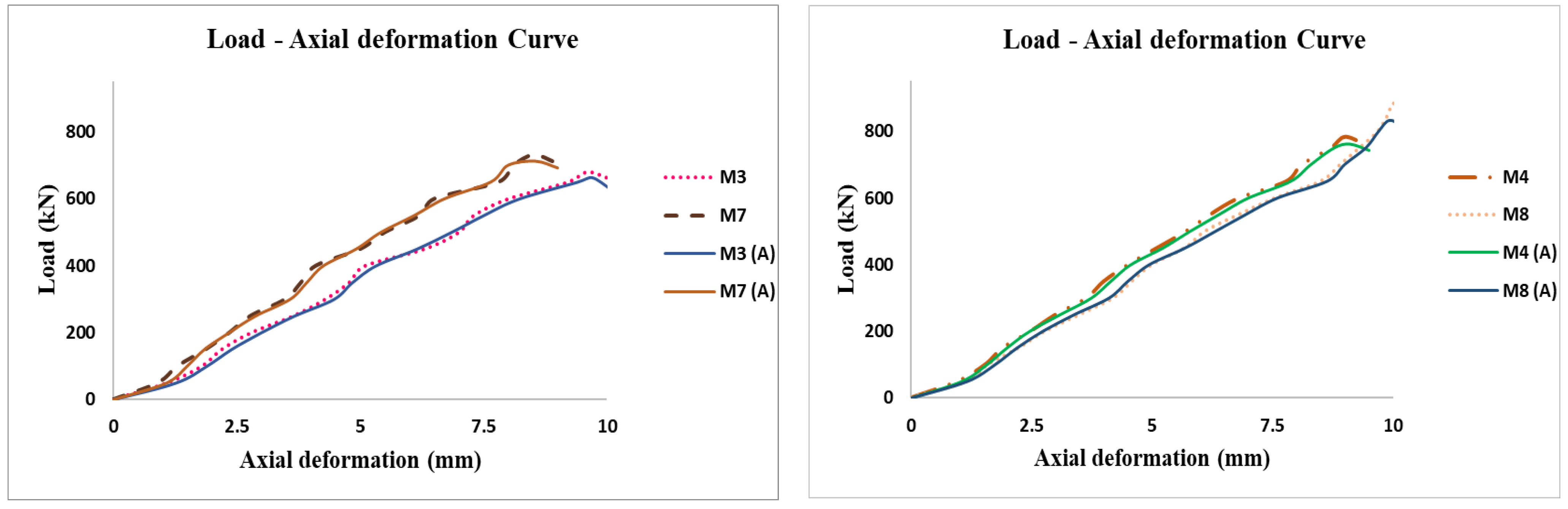

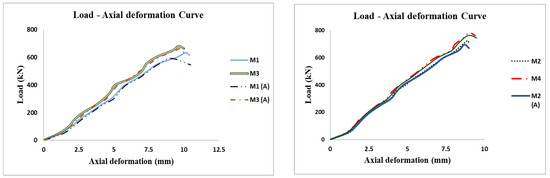

4.3.4. Influence of PVA Fibers

The efficacy of self-stressed columns of grade M40 was investigated by appending 2% PVA fibers to them and plotting the load–axial deformation curves to assess the impact of the PVA fibers in them. Figure 17 depicts the load values which were plotted against the axial deformation assessed by the dial gauge attached at the base of the column.

Figure 17.

Load vs. axial deformation curves of self-stressed columns for the impact of PVA fibers.

These findings are consistent with those of K.M.A. Hossain et al., who encountered that axial load capacity is decreased with increasing slenderness and increased with translational and hoop reinforcement. In terms of axial load capacity and ductility, circular columns outperformed their rectangular and square counterparts [21].

5. Conclusions

This paper presents the two-phase experimental survey on the mechanical properties of PVA fiber-reinforced expansive cement concrete and the behavior of the columns made with the most suitable mix as determined from the initial phase. Examined parameters include concrete grade, expansive cement, PVA fiber concentration, and various curing conditions. The outcomes that were drawn from the experimental findings are as follows:

The optimum percentage of expansive cement required for effective self-stressing that can replace the ordinary Portland cement was found from various properties of cement and concrete as 10%.

The specimens were found to have expanded in volume more than the conventional concrete specimens, but this expansion was restricted by providing steel tubes as confinement around the specimens, which creates chemical pre-stressing intrinsically.

The specimens that were water cured performed better than the specimens that were wrapped with plastic covers. The reason behind this decrease in performance was that the water lost during the hydration of cement was insufficient for the curing of the specimen, hence the water–cement ratio may be increased to enable sufficient water for curing, and this should be achieved without compromising the performance of the concrete while increasing the water–cement ratio of the mix.

The performance of the concrete under compression made with grade M40 was found to vary to a greater extent with the inclusion of polyvinyl alcohol fibers and expanding cement, while the increase in the performance of grade M50 with the inclusion of polyvinyl alcohol fibers and expanding cement is considerably less under compression.

The performance of the concrete specimens made with grade M40 under split tension and flexure was similar to the performance of grade M50 with the inclusion of polyvinyl alcohol fibers and expanding cement. This proves that the grade of concrete does not affect the performance of the concrete under tension and flexure.

The mechanical properties increase with increase in polyvinyl alcohol fibers until 2% addition for M40 grade concrete and 1.5% addition for M50 grade concrete, and it gradually decreases with the further increase of fibers. This reduction in the strength was due to the decrease in the workability of concrete and reduced bonding strength between fibers and concrete. Hence, it is concluded that 2% and 1.5% of fibers were the optimum proportion of polyvinyl alcohol fibers for M40 and M50 grade concrete mixes, respectively, with a 10% replacement of ordinary Portland concrete by expansive cement.

The PVA fiber-reinforced self-stressed columns showed a better performance which was 1.3 times more than the strength of the columns with the D/t ratio of 70 and 1.2 times the strength of the columns of D/t ratio 56 which were made without expansive cement and PVA fibers. These fiber-reinforced self-stressed columns showed much less deformation than the concrete infilled steel columns of grade 40 without expanding cement and polyvinyl alcohol fibers.

The failure modes of the columns were bulging, buckling at the center, and formation of elephant foot either at the top or bottom.

Author Contributions

Conceptualization, P.K. and P.G.; methodology, P.K.; validation, P.K., P.G. and J.R.; formal analysis, P.K.; investigation, P.G.; resources, P.K.; data curation, P.K.; writing—original draft preparation, P.K.; writing—review and editing, P.K., P.G. and J.R.; visualization, P.K.; supervision, P.G.; project administration, P.K. and P.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, F.; Xu, K.; Ding, W.; Qiao, Y.; Wang, L. Microstructural characteristics and their impact on mechanical properties of steel-PVA fiber reinforced concrete. Cem. Concr. Compos. 2021, 123, 104196. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M.; Al-Tabbaa, A. MgO expansive cement and concrete in China: Past, present and future. Cem. Concr. Res. 2014, 57, 1–12. [Google Scholar] [CrossRef]

- Yu, H.; Wu, L.; Liu, W.V.; Pourrahimian, Y. Effects of fibres on expansive shotcrete mixtures consisting of calcium sulfoaluminate cement, ordinary Portland cement, and calcium sulfate. J. Rock Mech. Geotech. Eng. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Geng, G.; Lin, A.; Biolzi, L.; Ostertag, C.P.; Monteiro, P.J.M. The influence of expansive cement on the mechanical, physical, and microstructural properties of hybrid-fiber-reinforced concrete. Cem. Concr. Compos. 2021, 96, 21–32. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Nonat, A. Hydration of cementitious materials, present and future. Cem. Concr. Res. 2019, 41, 651–665. [Google Scholar] [CrossRef]

- Zheng, L.; Xuehua, C.; Mingshu, T. Hydration and setting time of MgO-type expansive cement. Cem. Concr. Res. 1992, 22, 1–5. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Wang, A. Effects of MgO-based expansive additive on compensating the shrinkage of cement paste under non-wet curing conditions. Cem. Concr. Compos. 2012, 34, 377–383. [Google Scholar] [CrossRef]

- Passuello, A.; Moriconi, G.; Shah, S.P. Cracking behavior of concrete with shrinkage reducing admixtures and PVA fibers. Cem. Concr. Compos. 2012, 31, 699–704. [Google Scholar] [CrossRef]

- Yurtseven, A.E.; Yaman, I.O.; Tokyay, M. Mechanical properties of hybrid fiber reinforced concrete. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Dordrecht, The Netherlands, 2012; pp. 207–214. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M.; Sammour, M.; Sonebi, M. Influence of Polyvinyl Alcohol, Steel, and Hybrid Fibers on Fresh and Rheological Properties of Self-Consolidating Concrete. J. Mater. Civ. Eng. 2012, 24, 1211–1220. [Google Scholar] [CrossRef]

- Nuruddin, M.F.; Khan, S.U.; Shafiq, N.; Ayub, T. The strength development of high-strength ductile concrete incorporating metakaolin and PVA fibers. Sci. World J. 2014, 2014, 387259. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Li, N.; Li, S. Behavior of FRP-confined concrete-filled steel tube columns. Polymers 2014, 6, 1333–1349. [Google Scholar] [CrossRef]

- Reda, M.A.; Ebid, A.M.; Ibrahim, S.M.; El-Aghoury, M.A. Strength of composite columns consists of welded double CF sigma-sections filled with concrete—An experimental study. Designs 2022, 6, 82. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M. Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem. Concr. Res. 2010, 40, 437–446. [Google Scholar] [CrossRef]

- IS: 12269-2015; Specifications of 53 Grade Ordinary Portland Cement. Bureau of Indian Standards: New Delhi, India, 2015.

- IS: 10262-2009; Recommended Guidelines for Concrete Mix Design. Bureau of Indian Standards: New Delhi, India, 2009.

- IS: 383-2016; Specification for Coarse and Fine Aggregates from Natural Sources for Concrete. Bureau of Indian Standards: New Delhi, India, 2016.

- Shetty, M.S. Concrete Technology Theory and Practice; S Chand & Co.: New Delhi, India, 2006. [Google Scholar]

- IS: 516-1959; Methods of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 1959.

- Xu, C.; Chengkui, H.; Decheng, J.; Yuancheng, S. Push-out test of pre-stressing concrete filled circular steel tube columns by means of expansive cement. Constr. Build. Mater. 2009, 23, 491–497. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Chu, K.; Anwar, M.S. Axial load behavior of ultrahigh strength concrete-filled steel tube columns of various geometric and reinforcement configurations. Infrastructures 2021, 6, 66. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).