Abstract

The performance of self-compacting concrete (SCC) is gaining popularity in construction due to its exceptional strength and durability. However, the properties of combined steel and concrete at elevated temperatures lack experimental data from previous research. This study aimed to investigate the behavior of the SCC core with a steel tube at ambient and elevated temperatures varying from 100 °C to 800 °C with 100 °C intervals for each test specimen. Tests were conducted on circular steel tubes filled with SCC for different grades (M25, M30, and M40) under compression at elevated temperatures. Experimental observations revealed that the stress–strain curve increased with increasing the cross-sectional area and grade of concrete. However, increasing the temperature and length-to-diameter ratio reduced the stress–strain curve. At elevated temperatures, confined SCC experienced a smaller decrease in the overall modulus of elasticity when compared to unconfined concrete. Within the compressive elastic region (from 30 °C to 400 °C), there was a significant relationship between lateral strain and longitudinal strain, which was followed by a sudden increase beyond 400 °C. Equations for various design parameters were proposed based on the peak load and confinement factor of confined SCC-filled steel tubes (SCCFSTs) via multiple regression. Moreover, this study developed load–axial shortening curves, identifying significant properties such as the yield strength of confined SCCFSTs, including the load-carrying capacity. The predicted numerical analysis results were well aligned with the experimental results, and the findings contributed valuable insights for designing resilient and durable combined SCC and steel tube infrastructures.

1. Introduction

Self-compacting concrete (SCC) is a revolutionary construction material known for its ability to distribute evenly without the necessity of external vibration. The unique composition and mixing proportions of SCC demand a thorough investigation of its mechanical properties, which differ significantly from those of regular vibrating concrete [1]. Since it has the potential to reduce building costs, improve the workability, and enhance the durability, SCC has gained popularity in various construction projects [2]. However, the full appreciation of SCC’s potential is hindered by the lack of comprehensive research on its mechanical characteristics. Recent studies have demonstrated SCC’s mechanical properties, particularly its compressive and tensile strengths, highlighting the influence of admixtures, aggregates, and curing conditions [3,4]. Despite these advancements, research on SCC’s behavior at elevated temperatures remains scarce. Numerous studies have been done to examine the mechanical properties of SCC. SCC exhibits stronger compressive and tensile properties than normal concrete. The type of admixtures used, the aggregates selected, and the curing procedures all have an impact on the mechanical characteristics of SCC components. Insights into how mix proportions affect SCC’s mechanical properties and strength have also been gained via research on the material’s elastic modulus, stress–strain behavior, and Poisson’s ratio [5,6]. When compared to normal vibrating concrete, SCC has a lower rate of strain at peak stress, a higher strength of compressive load, and a higher elastic modulus. As a result, with the same amount of energy input, overall elasticity is increased. However, due to its smaller aggregate size and lower aggregate concentration, SCC has a lower elastic modulus when compared to high-strength vibrating concrete. Moreover, there are no differences in Poisson’s ratio between SCC and vibrating concrete, showing similar lateral contraction activities under the load [7]. SCC outperforms traditional concrete in many situations, making it more suited for facilities susceptible to high stress and loads. This research work intended to evaluate the elastic modulus, Poisson’s ratio, and stress–strain performance of SCC to deepen understanding of its mechanical behavior [8]. Three distinct mixes with various compressive strengths (25 MPa, 30 MPa, and 40 MPa) were used to cast and test cylindrical SCC specimens in order to determine the stress–strain parameters of each mix. Additionally, an equation was developed to estimate the elastic modulus of SCC within the strength range of 25–40 MPa. With a comprehensive characterization of the SCC’s stress–strain behavior under axial loading, the study aimed to contribute to the development of more resilient and long-lasting structures, particularly under elevated temperature conditions. Civil engineers and construction specialists can significantly benefit from these findings when designing and constructing high-performance structures. SCC has emerged as a game changer in the construction industry due to its exceptional workability, high compressive strength, and durability [8]. Despite recent advancements in understanding its mechanical properties, more research is needed, especially in exploring its behavior under high-temperature conditions. This study’s thorough evaluation of the elastic modulus, Poisson’s ratio, and stress–strain behavior of SCCs intended to close this gap and pave the way for the creation of more durable structures that can endure high temperatures. Its results can have a big impact on how SCC is employed in the construction sector going forward, as there is a rising need for durable and sustainable building materials [9].

In addition to possessing excellent fire resistance and strength, good ductility, and a remarkable capacity for the energy absorption, the concrete-filled steel tubes (CFSTs) and SCC construction have other structural advantages [10,11]. Fire and earthquake hazards can affect these columns. Fires may considerably lower the CFST columns’ capacity to support loads and result in a widespread structural failure. To ensure the fire safety and assess the residual capacity of CFST columns exposed to fire, it is crucial to thoroughly investigate the combined effects of fires and long-term axial loads during such an exposure. Therefore, comprehensive research is necessary to understand the combined impact of elevated temperatures on the structural response. Concrete, with its low heat conductivity and non-combustible nature, can withstand high temperatures quite effectively. However, it still has implications for the strength and stability of structures, making it essential to study its behavior under fire conditions. Owing to its incombustibility and limited thermal conductivity, concrete performs better than most other building materials at high temperatures. However, due to variations in the water/cement ratio and permeability of different concrete grades, the performance of concrete exposed to elevated temperatures varies with the concrete grade [10,12]. Researchers have looked closely at how the mechanical characteristics of concrete (such as the load-carrying capacity, deformation, and stress) change at high temperatures, since these characteristics have an impact on how well concrete performs overall when subjected to monotonic loading [13]. When high-performance concrete is exposed to a temperature of 900 °C, the reduction in the modulus of elasticity, compressive strength, and tensile strength is about 85% to 91% [14,15,16]. In addition to mechanical qualities, fire damage also causes concrete to crack, lose strength, and spall [16]. It was discovered that the vapor pressure mechanism causes spalling to occur at temperatures between 480 °C and 510 °C, and that concrete loses its compressive strength at temperatures between 250 °C and 800 °C [15,17].

2. Research Significance

The current study distinguishes itself from prior research in several key aspects. Firstly, the investigation of the behavior of SCC-filled steel tubes (SCCFSTs) at elevated temperatures ranging from 100 °C to 800 °C represents a unique scope. While previous studies may have delved into similar topics, this specific temperature range has not been commonly explored, setting this research apart and providing valuable insights into extreme temperature conditions often encountered during fires or other critical events. Secondly, the inclusion of various concrete grades (M25, M30, and M40) is a departure from many earlier studies, which often focused on a single concrete grade or a limited range. This diverse range of concrete grades allows for a broader understanding of how the strength of concrete influences the structural response of SCCFSTs under elevated temperatures, contributing to a more comprehensive understanding for the selection of materials under construction scenarios.

Furthermore, the study’s observation regarding the relationship between temperature and the length-to-diameter ratio and its impact on the stress–strain curve is a novel finding. Prior research may not have comprehensively assessed this specific relationship, emphasizing the uniqueness of this study’s approach. Additionally, the emphasis placed on the modulus of elasticity at elevated temperatures distinguishes this research from previous studies that might have concentrated on different material properties or temperature effects. Moreover, the identification of a noticeable relationship between lateral strain and longitudinal strain within the compressive elastic region (from 30 °C to 400 °C) adds to the study’s novelty. This finding offers practical insights into predicting the SCCFSTs’ behavior under specific temperature conditions and loads, a dimension that previous studies may not have examined in such depth. The proposal of equations for design parameters based on the peak load and confinement factor using multiple regression is a distinguishing feature of this research. Previous studies may have lacked comprehensive equation development or focused on different aspects of design parameters, making this work stand out.

Lastly, the creation of a load–axial shortening curve incorporating significant features such as the yield strength and load-carrying capacity or a confined SCCFST is an innovative contribution. This curve provides a comprehensive overview of the material behavior under various loads and temperatures, a perspective that may not have been addressed to the same extent in previous studies. In addition, the strong alignment of predicted numerical analysis results with experimental findings enhances the study’s credibility, making it a reliable resource for practical applications, a characteristic not always achieved in earlier research endeavors.

3. Methodology

When mixing SCC, material selection is critical. In this process, the appropriate cement, water, aggregate, and chemical and mineral admixtures were chosen (Figure 1a). The objective was to make a concrete mix with high strength and good workability. In this study, the primary binder was ordinary Portland cement (OPC) that met IS 12269-1987. Additional cementing ingredients, such as silica fume and Fosroc Conplast SP430, were utilized as binders and to boost the workability and strength of concrete. Table 1 summarizes the chemical and physical properties of these materials. The current study used fine aggregates obtained from Ramanagaram in Karnataka and adhered to the IS code description of zone II grade (IS: 383-1970). The coarse aggregates’ 2.74 specific gravity crushed basalt stones were purchased from neighboring stone crushers. Mineral admixtures, such as silica fume, were employed to enhance the strength and fill any gaps. These components also aided in lowering the water-to-binder (W/B) ratio of the concrete mix. Fosroc Conplast SP430, a viscosity modifying agent, was utilized to increase the workability, lower the W/B ratio, and preserve the proper SCC flow properties. Several trial mix proportions were established by adjusting the cement content, coarse aggregate content, fine aggregate content, and W/B ratio in order to reach the required strength. All mix proportions were thoroughly examined to ensure that they met the criteria for SCC, in line with the standards established by EFNARC. Figure 1b,c displays cutting the steel tubes and curing of the specimens, respectively. Using SCC and filling the steel tubes with round dimensions, Table 2 lists the chemical and physical parameters of the steel tubes based on the source.

Figure 1.

(a) Materials for preparing SCCFSTs, (b) cutting steel tubes, and (c) curing (with specimens under water; surface layer appears blurry due to presence of water).

Table 1.

Chemical compositions and various properties of OPC, aggregates, silica fume, and Fosroc Conplast.

Table 2.

Chemical elements and properties of circular steel tubes.

The next step involved preparing mix designs for grades M25, M30, and M40 in accordance with IS 10262-2009 and the Nan Su technique (Table 3). In the table, d and L designate diameter and length of the specimens, respectively. The mechanical properties of SCCFSTs of different length-to-diameter ratios of 8 and 10, as per ASTM, were evaluated after exposure to high temperatures (30–600 °C). OPC 53 grade adhering to IS 12269 (2013) was used. M-sand conforming to IS 2386 (2002) was utilized in the form of fine aggregates and coarse aggregates of size 12 mm, and downsize was employed. Here, potable water was used for mixing concrete, which was made according to the mix design and placed within the steel tubes. Additionally, SCC was placed in a cube mold for testing after 28 days to verify that the desired strength of concrete was reached. The specimen was held for 28 days to cure. After curing, the specimens were exposed to an open environment for a duration of 24 h. The specimen was heated in the Lawrence and Mayo oven (1000 °C capacity) to the desired temperature before being moved to the UTM platform. During this process, the specimens were experiencing axial shortening and uniaxial compressive load. Utilizing the recorded values of the axial shortening and compressive load, the mechanical properties of stress, strain, modulus of elasticity, and Poisson’s ratio for ambient and elevated temperatures were obtained. In Table 4, the designation of the specimens has been described for the common parameters L, d, thickness (t), area of cross-section, and variation in temperature. All 84 experimental tests were conducted from ambient temperatures to elevated temperatures (100 °C, 200 °C, 300 °C, 400 °C, 500 °C, and 600 °C), and out of these tests, three temperatures exhibited major variations, such as ambient temperature having a high strength, at 400 °C a minimum drop in the strength, and at 500 °C a sudden drop in the strength. These behaviors are discussed in the next sections of the article.

Table 3.

SCC mix designs in accordance with IS 10262-2009 and Nan Su technique, selection of dimension, and temperature.

Table 4.

Specimen designation based on common parameters.

3.1. Equations and Procedure

The validation of the experimental data was performed with the following codes and references: Eurocode [18,19], ACI [20], Mandar et al. [21], and Zhao et al. [22].

3.1.1. Load-Carrying Capacity

The load-carrying capacity of CFSTs has a maximum weight or load that these composite columns can support before failing [23]. The benefits of both circular steel and concrete components are combined in CFSTs. The outer steel tube serves as a strong enclosing shell, increasing the structural strength and ductility. The concrete core adds the compressive strength, stiffness, and fire resistance to the structure. The diameter, thickness, and material qualities of steel tube, along with the quality and strength of infilled concrete, all encompass an impact on the load-carrying capacity of CFSTs [24].

To estimate the load-carrying capacity of CFST structures in diverse applications, researchers have employed a variety of analytical methodologies and tests. Eurocode [18,19] provides design recommendations for steel sections that are entirely or partly encased in concrete, with concrete-filled sections with or without reinforcing. The codes take into account the concrete hollow circular steel section confinement [25]. The EC 4 equation (Equation 1) for the load-carrying capacity (P0) of a CFST column is as follows [18]:

where As and Ac are the cross-sectional areas of steel tube and concrete core, respectively. The compressive stress of an unconfined concrete cylinder is given by fc. The equivalent confinement coefficients for the two materials are 1 and 2.25. P0 of the columns was estimated using the identical methods published by the Australian Standards (AS) and American Specifications (ACI), although neither specification takes the confinement on concrete into consideration (Equation (2)):

According to Zhao et al. [22], P0 of concrete is calculated by deducting the amount of friction between the concrete core and steel tube from the axial load of the column, and the concrete compressive strength is derived by dividing the concrete compressive load by the concrete area of the section (Equation (3)):

where fcz is the concrete compressive strength, and σz is the axial strength of steel tube. Equation (3) can be rewritten in the form of Equation (4):

3.1.2. Unconfined and Confined Concrete Stress and Strain

The concrete confinement is insufficient in circular steel tube concrete (CSTC) columns packed with concrete and encompass a higher D/t ratio. This is attributed to the columns’ early demise as a result of localized buckling of steel tubes. Moreover, concrete may be contained very well in CSTC columns that are packed with concrete and have a low D/t ratio. The strength of concrete was extremely enhanced in this D/t ratio, and the confined concrete model can be used as a concrete model [25]. Mander et al. [21] aimed to develop a specific model to represent concrete and compare it with observed results. They created Equations (5) and (6) to construct a concrete model and examined it with compressed concrete behavior lines. These graphs indicated that unconfined concrete is significantly weaker than confined concrete under the same amount of stress. Both had equivalent strain–stress curves calculated at 80% of the compressive strength (0.8fcu). Unconfined strain was found to be approximately 0.003 [21], 0.0035 [26], and 0.0038 [27], while the confined compressive strength (fcc) and related confined strain (εcc) can be calculated using Equations (5) and (6), which were developed by Mander et al. [21]:

where fl denotes the lateral confining pressure that a circular steel tube applies; this is dependent on the D/t ratio, along with the yield strength of the material. Hu et al. [28] developed a formula to calculate the predicted fl for the D/t values ranging from 21.7 to 150. They concluded that tubes with low D/t ratios are significantly influenced by fl, whereas tubes with high ratios are hardly influenced. Equations (5) and (6) can be utilized to calculate the equivalent uniaxial confined concrete compressive strength (fcc) and constrained strain (εcc) with k1 and k2 as 4.1 and 20.5, respectively [29].

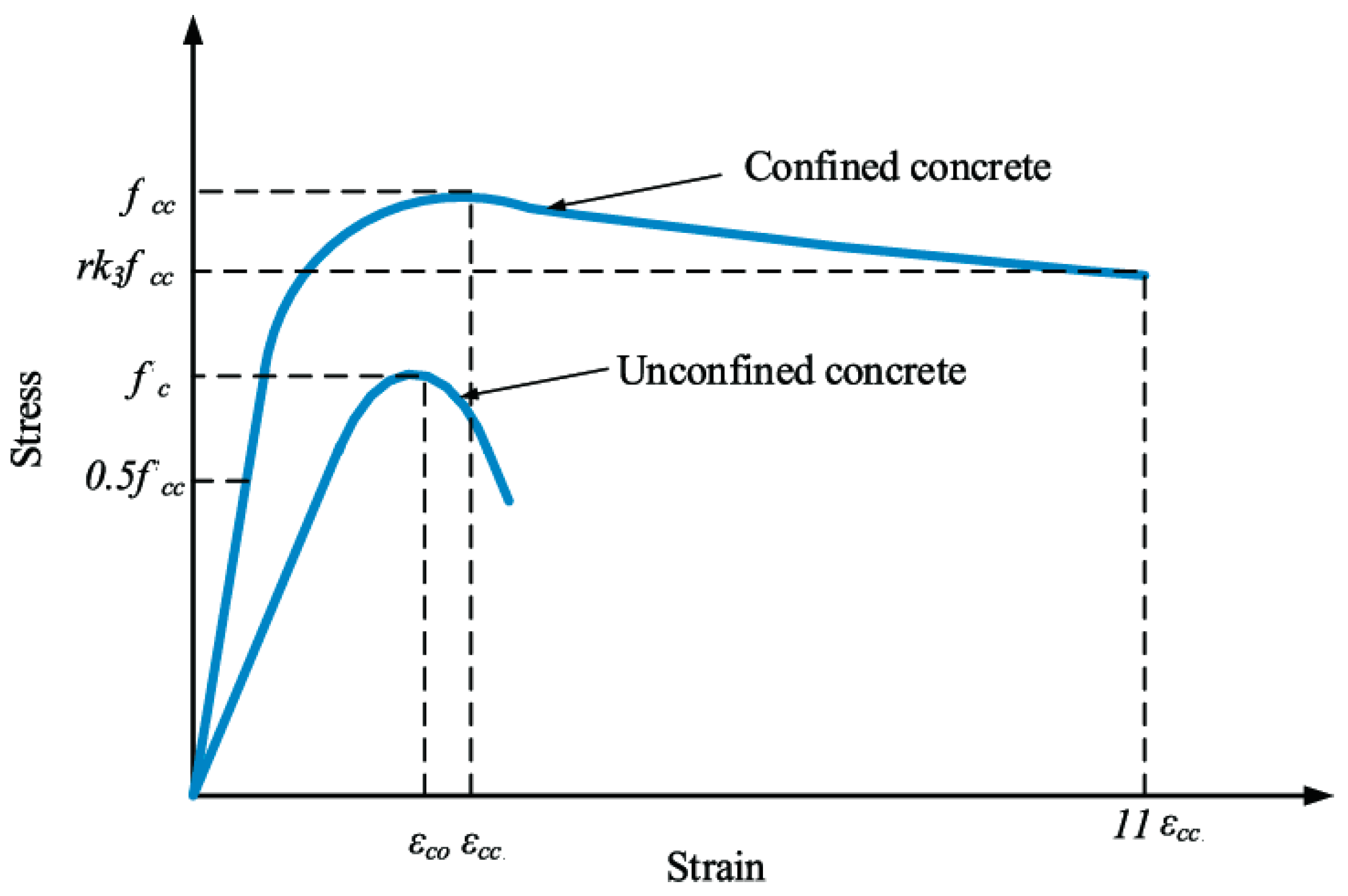

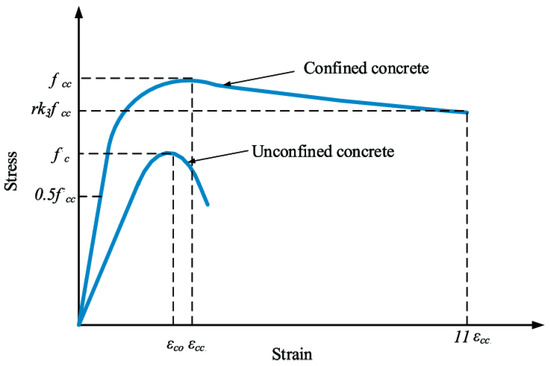

In order to create the complete equivalent uniaxial curve for limited concrete (as depicted in Figure 2), it is important to label and identify three sections that include all the stress and strain data. To begin this process, the elastic range should be checked with a fixed limit that is 0.5 times the structural characteristic compressive strength (fcc). Researchers have reported Poisson’s ratio of confined concrete (νcc) being constant at 0.2, while the modulus of elasticity of confined concrete (Ecc) can be calculated using ACI (Equation (7)) [21]:

Figure 2.

Stress–strain curves for unconfined concrete and confined concrete under a uniaxial load [21].

The portion of the curve referred to as the non-linear section represents the second stage, which is situated at the point of proportional limit stress and concludes just prior to the strength restriction of concrete. A formula created by Saenz [30] was used to constitute this segment of the curve, involving the correlation linking multidimensional stress and strain with the values of uniaxial stress (f) and strain (ε). In determining the stress and strain values that play a definitive role in crafting this reason of the curve, instances of strain (0.5fcc/Ecc) must be ascertained straddling proportional and restricted strains, whereas the stress values can be readily computed using Equation (8), presuming the values of strain:

The calculations that determine the RE and R values are based on Equations (9) and (10), respectively:

As per the study done by Hu and Schnobrich [31], the values of Rσ and Rε were determined to be equal to 4. The third section of the stress–strain diagram for restricted concrete is the area where the curve steadily tapers from the concrete confined compressive strength (fcc) to a subsequent value comparable to rk3fcc at a strain of 11εcc. The deduction factor (k3) determines the D/t ratio and steel tube’s yield strength (fy).

In accordance with [31], the constants Rσ and Rε were set as equal to 4. The third segment of the stress–strain diagram for confined concrete is the section where the curve reduces from fcc to a lower value equivalent to rk3fcc accompanied with a strain of 11εcc. The value for the reduction factor (k3) is reliant on the D/t ratio and steel tube’s yield strength (fy). The k3 value is obtained using empirical equations of Hu et al. [32]. These equations have an effect on D/t ratios and demonstrated a good confinement effect for a range from 21.7 to 150. Also, Hu et al. [32] considered the concrete grade (maximum at a set of 31.2 MPa) to improve the confinement effect. Later, Giakoumelis and Lam [32] mentioned that this value is suitable for cube strengths having a compressive strength lower than 30 MPa. In addition to this, it was found that in the case of the compressive strength higher than 30 MPa for the same values of D/t ratio, the yield stress effectively decreased. Due to this reason, Giakoumelis and Lam [32] designed a factor (r) to make a more precisely confined concrete model based on their experimental results. It is good to calculate the value of r and to start with one for concrete having a compressive strength of 30 MPa. Tomii [33] and Mursi [34] suggested to take a starting of r value equal to 0.5 for concrete having a compressive strength of higher than or equal to 100 MPa. Finally, Giakoumelis and Lam [32] decided to carry out linear interpolations of concrete having a compressive strength between 30 MPa and 100 MPa.

3.2. Multiple Regression

To create a multiple regression line for the different sets of the SCCFST specimens, the following steps were followed: (i) Collect data: Gather a dataset with multiple independent variables (predictors: grades, temperature (T), the areas of concrete core and steel tube (Ac and As), the strength of concrete core (fc), and the yield strength of steel tube (fy), and one dependent variable (outcome: load-carrying capacity (P0))). (ii) Prepare data: Clean the dataset, handle missing values, and normalize variables if necessary. (iii) Choose variables: Select the relevant predictors that may impact the outcome. (iv) Build the model: Use statistical software to fit the data into a multiple linear regression model (y = a + bx + cz + …), where a designates the intersection, b represents the co-efficient of the variable x, c denotes the co-efficient of the variable z, and so on. (v) Evaluate model: Assess the model’s goodness-of-fit, check for multicollinearity, and analyze the significance of variables. (vi) Interpret results: Examine the coefficients and their significance to understand the relationship between the predictors and outcome. (vii) Validate and refine [35,36].

4. Results and Discussion

4.1. Load–Axial Shortening Variation

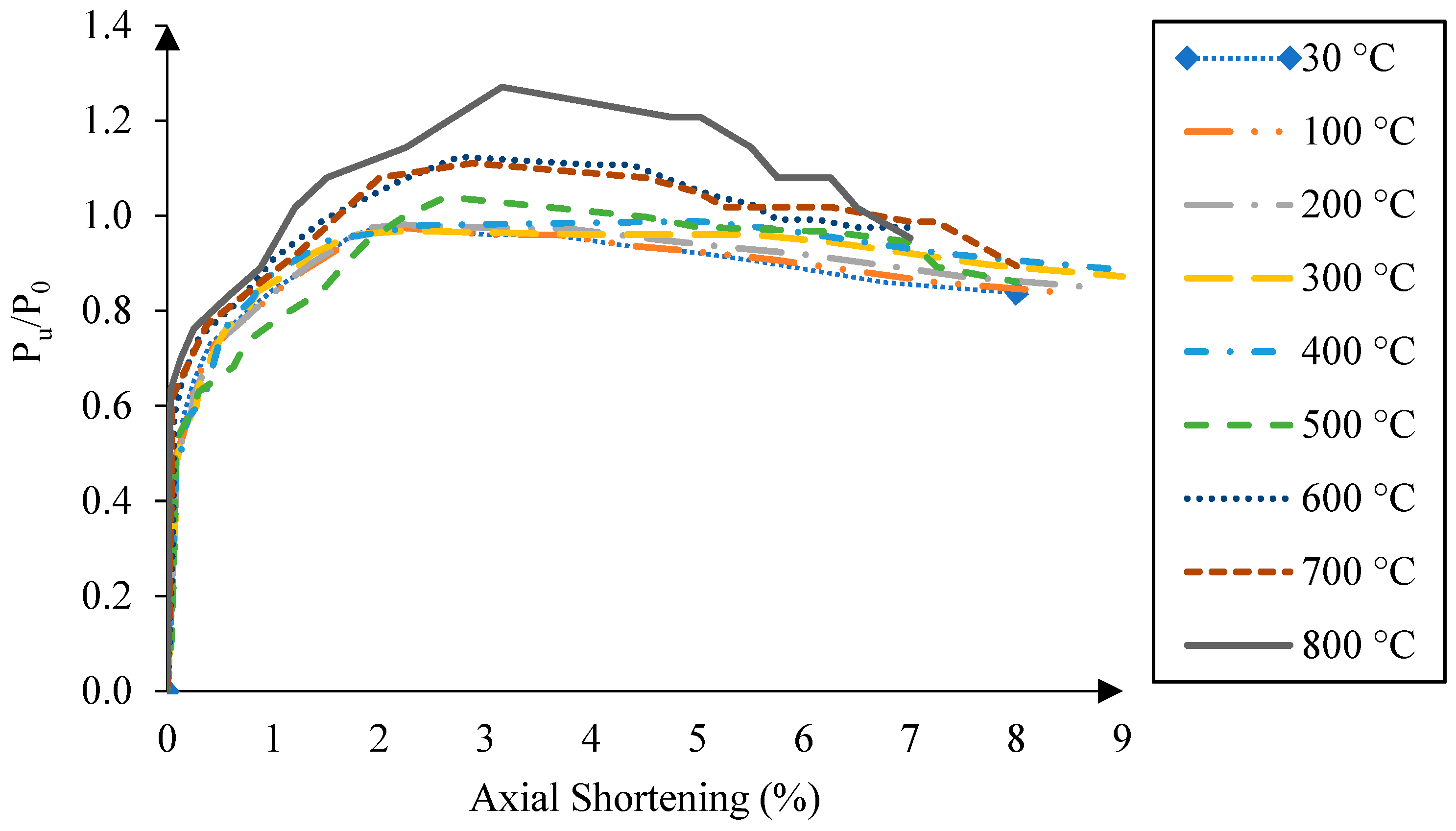

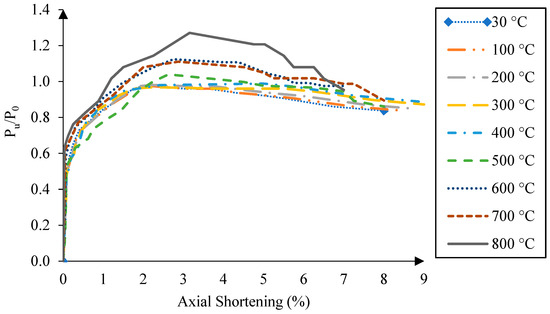

When studying CFST columns under high temperatures or fire exposure situations, the load–axial shortening variation graphs provide valuable information about their behavior. Such graphs initially show a comparable elastic response, but as the temperature increases, the strength of concrete lowers, resulting in earlier cracking and yielding. The slope of the graphs becomes steeper, indicating that they have lost some of their load-carrying capacity. Overall, sufficient deterioration arises when the specimens undergo critical temperatures, and eventually, they fail [37].

The data displayed in Figure 3 illustrate the relation between normalization of axial load on the y-axis and axial shortening on the x-axis for affected specimens. Through adjusting the axial strength according to the nominal axial load, the results are presented on the ordinate, while axial shortening is calculated from the ratio of strain gauge recorded axial displacement to the column height, then presented on the abscissa. It was easy to recognize the differences in the load–axial shortening curves and their post-peak behavior. Out of all the specimens tested in the graphs depicted in Figure 3, only specimen 1 (30 °C temperature) exhibited a hardening behavior, while the remaining specimens demonstrated softening tendencies. Specimen 6 (500 °C temperature) gave the steepest reduction in the strength following its peak strength and had poor deformability with an axial displacement of 2.62% of the column length. When steel reaches a temperature above 500 °C, it can undergo recrystallization, which causes it to lose its mechanical strength and become more flowable. Its axial strength fell drastically to 24% after reaching its peak strength. This suggests that the elevated temperature of the steel tube is a dominant parameter in determining the peak behavior. Table 5 confirms this point, showing that all the specimens exhibited similar maximum normalized strength values between 0.91 and 1.65. The behavior of circular SCCFSTs was greatly influenced by the surrounding temperature, especially in the case of columns exposed to temperatures of 400 °C and above 500 °C.

Figure 3.

Load–axial shortening curves at various temperatures (30–800 °C).

Table 5.

Summary of specimens’ results at ambient and elevated temperatures.

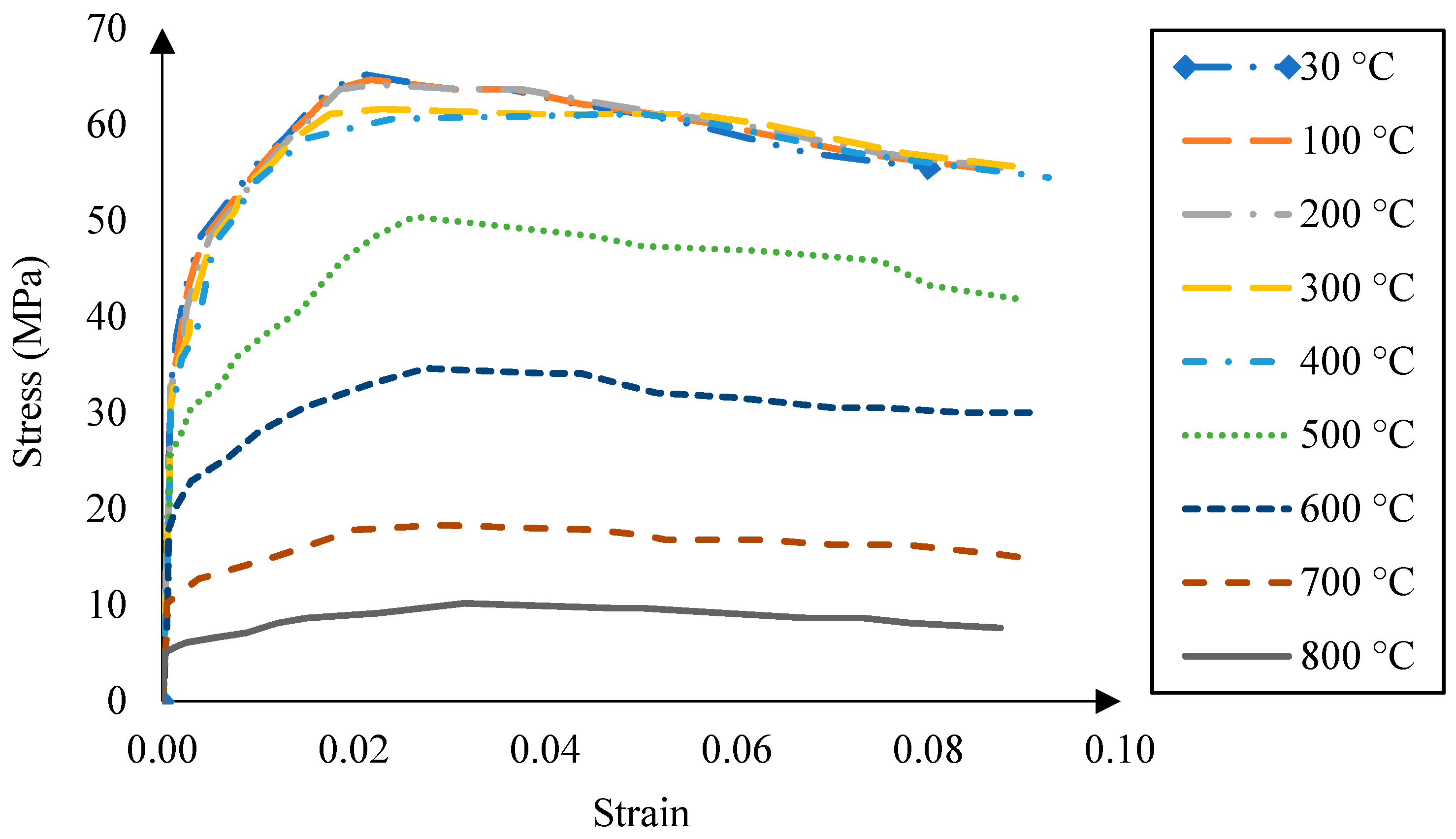

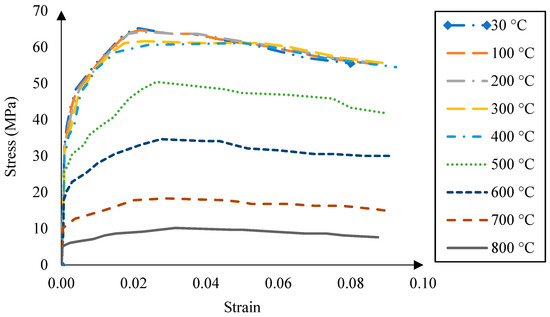

4.2. Compressive Strength at Elevated Temperatures

Under ambient conditions, SCCFSTs exhibited high compressive strength when compared to traditionally reinforced concrete columns. The confinement provided by the steel tube improves the lateral confinement of SCC, resulting in increased compressive strength and ductility [36,38]. Under elevated temperature conditions, the behavior of SCCFSTs can be considerably affected owing to the changes in the material properties of both steel and concrete. At elevated temperatures, concrete experiences thermal degradation, leading to a drop in its mechanical characteristics, such as the compressive strength, modulus of elasticity, and tensile strength [37,39]. In addition, the steel tube’s mechanical properties, including the yield strength and modulus of elasticity, were affected by the temperature.

From Figure 4 and Table 6, the results indicate that the compressive stress–strain curve experienced a sudden drop of 14.77 MPa (22.65%) at 500 °C. Beyond 400 °C up to 800 °C, the mechanical strength of circular SCCFSTs gradually decreased. This behavior was attributed to steel maintaining its strength up to 400 °C, exhibiting only a minimal reduction in the strength compared to under ambient temperature. The steel’s recrystallization temperature was above 400 °C, resulting in decrease in the mechanical strength of the confined SCCFST columns. The reduction in the compressive strength from ambient temperature to 400 °C was minimal, while the most noticeable drop in the reduction ratio was witnessed between 400 °C and 800 °C (Table 7). Further studies were carried out at 30 °C, 400 °C, and 500 °C to reduce the amount of experimental data in the present study.

Figure 4.

Stress–strain behavior of circular SCCFSTs at various temperatures.

Table 6.

Confined compressive strength of specimens at various temperatures.

Table 7.

Reduction ratio for unconfined concrete and confined concrete.

In Figure 5, a notable observation is the shift in failure modes as the temperature increased. Up to 400 °C, SCCFSTs primarily displayed inward buckling failure under compression. This means that tubes either collapsed or deformed inwards when subjected to compressive loads at these lower temperatures. However, as the temperature surpassed 500 °C, a significant change occurred, and outward buckling failure became prevalent. This implies that at higher temperatures, tubes tended to deform outwards when subjected to compression, demonstrating a shift in their structural response. This transition in failure modes highlights the critical influence of temperature on the behavior of SCCFSTs under load, providing valuable insights for the structural design and safety considerations.

Figure 5.

Failure modes of SCCFSTs.

4.3. Modulus of Elasticity at Elevated Temperatures

The modulus of elasticity of confined concrete in a steel tube also shows temperature-dependent behavior. As the temperature rose, the modulus of elasticity decreased due to the reduction in the stiffness of the concrete matrix. However, the steel tube typically maintained its elastic properties under a higher temperature due to its higher recrystallization temperature [40,41,42,43]. These results denote a relatively smaller decrease in the overall modulus of elasticity of confined concrete compared to its unconfined counterpart under elevated temperatures. Table 8 lists the average percentage of reduction in the modulus of elasticity between 5.05% and 12.68%; the modulus of elasticity was calculated using Equation (7).

Table 8.

Variation in modulus of elasticity with respect to affected temperatures.

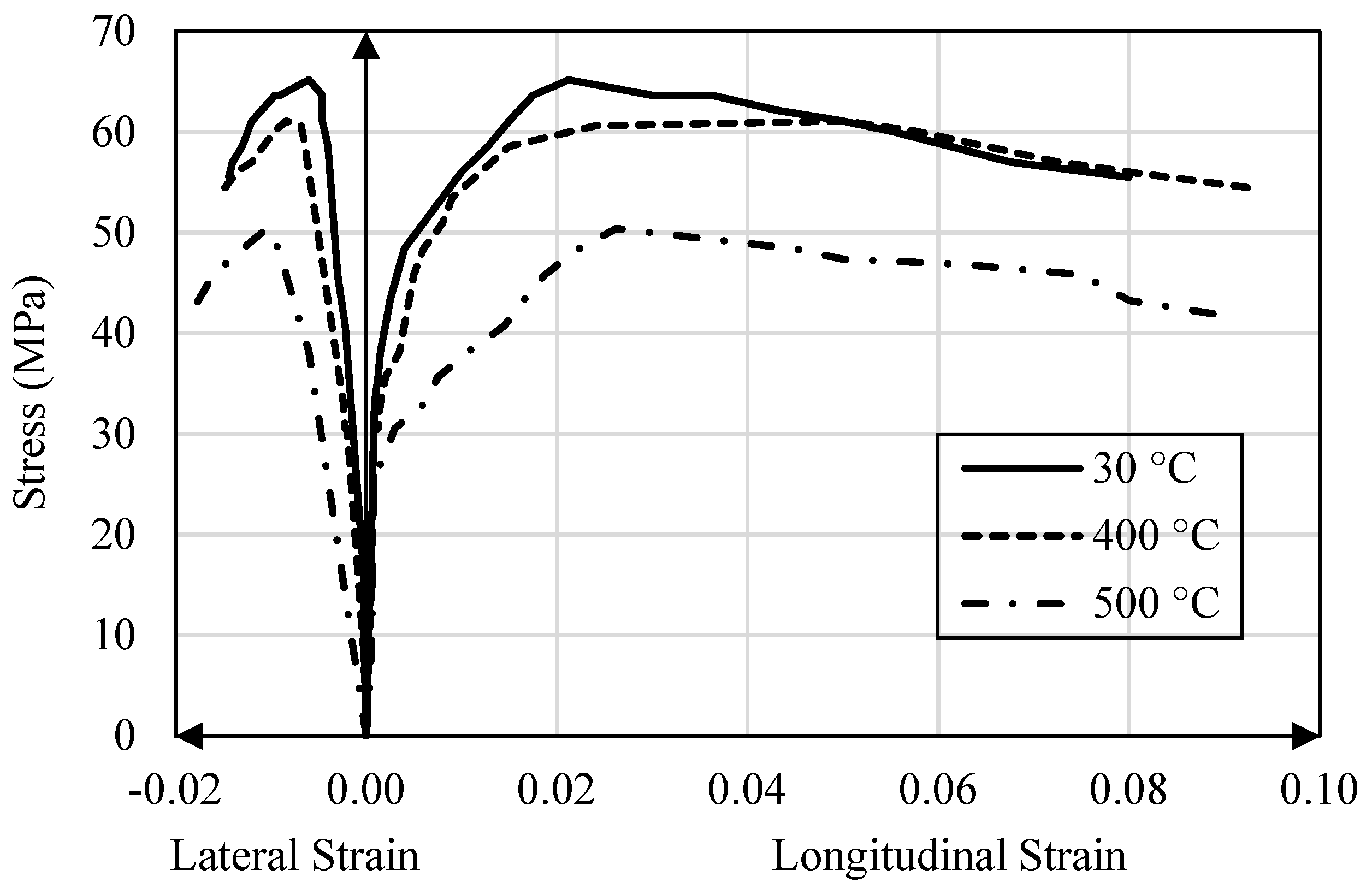

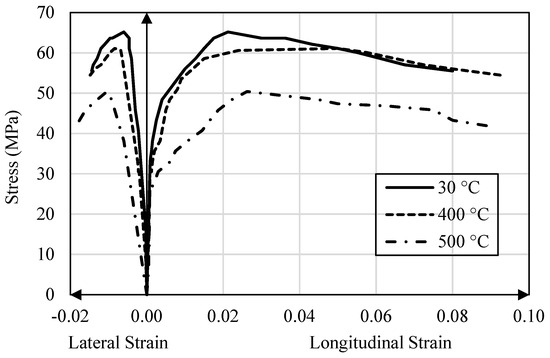

4.4. Effect of Poisson’s Ratio

Figure 6 illustrates the lateral strain and longitudinal strain versus stress curves for the three mixes at elevated temperatures. Additionally, Table 9 provides the corresponding values of Poisson’s ratio. Figure 6 reveals a close relationship between the lateral and longitudinal strains within the elastic regions under compression for temperatures ranging from 30 °C to 400 °C. However, beyond 400 °C, sudden increases in the strain values were observed. Further, Figure 4 highlights that with increasing the strength of concrete, the strain curve tended to become more linear.

Figure 6.

Lateral strain and longitudinal strain versus stress curves of circular SCCFSTs at 30 °C, 400 °C, and 500 °C.

Table 9.

Poisson’s ratio with respect to affected temperatures for tested specimens.

During testing, it was noticed that as the circular SCCFSTs of all three grades were subjected to elevated temperatures under compression until they achieved their ultimate strength, Poisson’s ratio exhibited a rapid increase until failure occurred. Therefore, like the modulus of elasticity, Poisson’s ratio was measured at the peak position of axial stress. This decision was influenced by the significance of this point in the testing process, as it represents a critical stage where the material undergoes plastic deformation and ultimately fails. Consequently, obtaining Poisson’s ratio at this juncture gives valuable insights into the composite material behavior under the extreme loading conditions [40].

4.5. Multiple Regression Fit

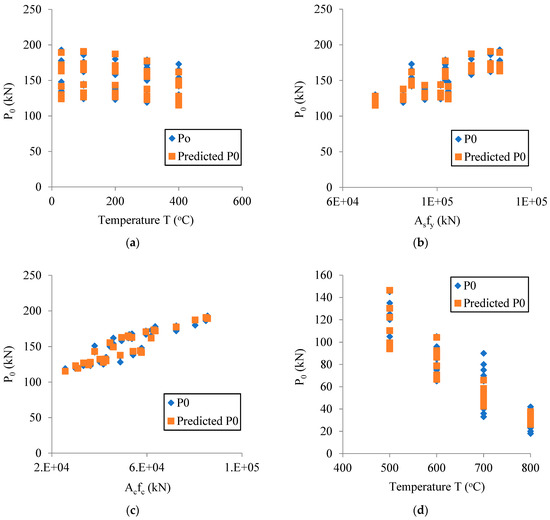

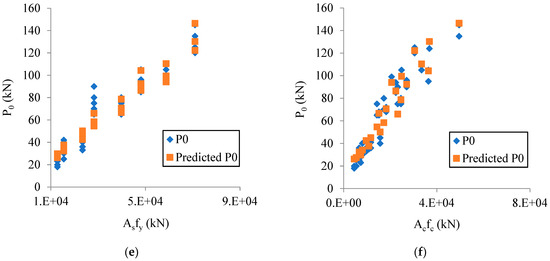

4.5.1. Peak Load of Confined SCCFSTs

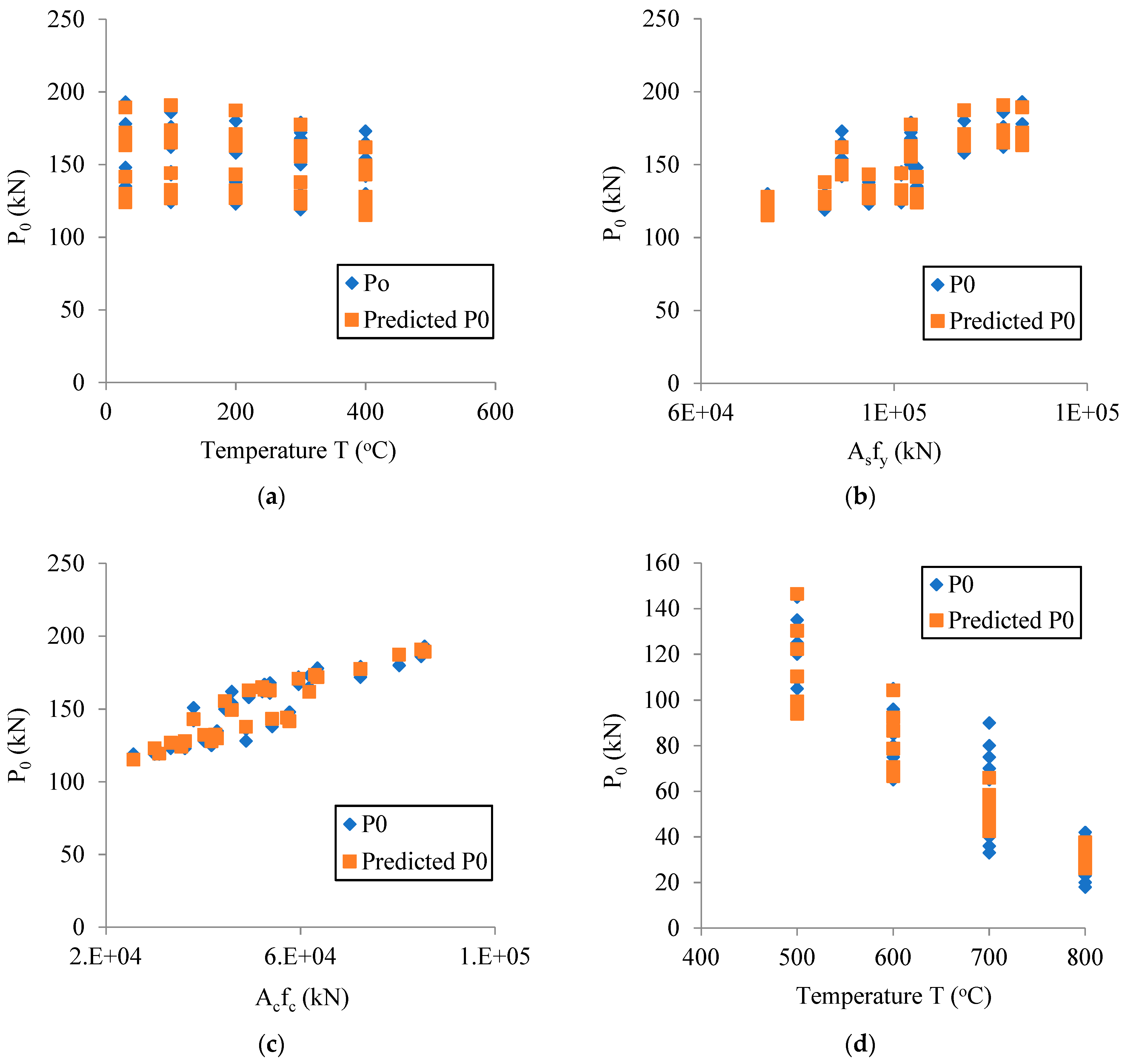

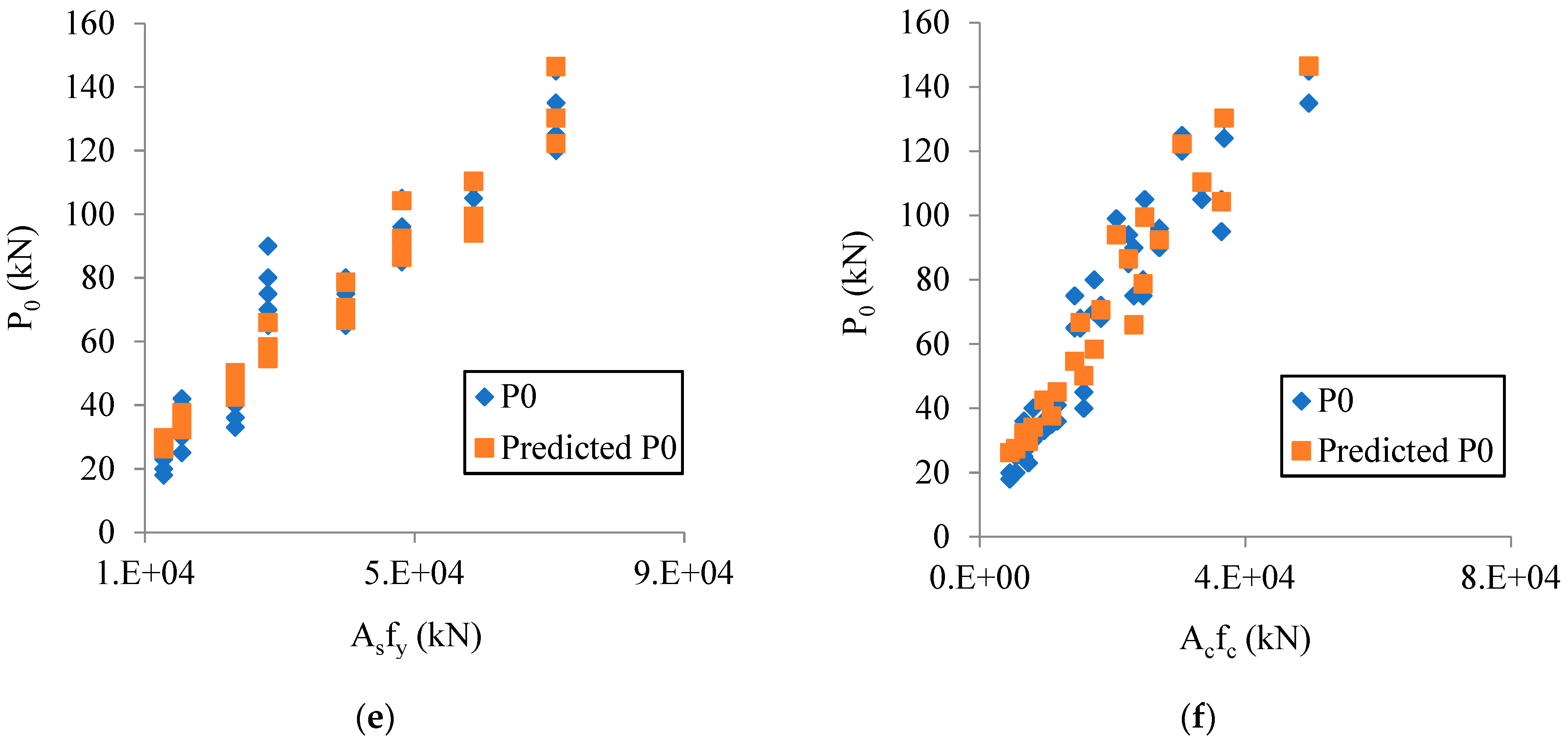

Temperature effect (from 30 °C to 400 °C): The peak load (P0) of confined SCCFSTs in the temperature range from 30 °C to 400 °C can be approximated using Equation (11). The peak load is influenced by the temperature (T), with a positive coefficient of 0.0957. As the temperature increased within this range, the peak load tended to decrease, as depicted in Figure 7a. Furthermore, the peak load was affected by the area of steel tube (As) and the yield strength of steel tube (fy), with a coefficient of 0.0011, as illustrated in Figure 7b. Additionally, the peak load was influenced by the area of concrete (Ac) and the compressive strength of concrete (fc), with a coefficient of 0.00078, as displayed in Figure 7c. These factors collectively contributed to the peak load behavior within this temperature range. Temperature effect (from 500 °C to 800 °C): For elevated temperatures between 500 °C and 800 °C, the peak load of confined SCCFSTs can be estimated using Equation (12). The temperature (T) still plays a role in determining the peak load, but its influence is reduced compared to the previous temperature range. The temperature coefficient for this range was 0.0376, as demonstrated in Figure 7d, indicating a smaller impact on the peak load. Moreover, the area of steel tube (As) and the yield strength of steel tube (fy) combined with the area of concrete (Ac) and the compressive strength of concrete (fc) affected the peak load, with a coefficient of 0.0012, as shown in Figure 7e,f.

Figure 7.

Predicted values of P0: (a) Temperature line fit plot from 30 °C to 400 °C, (b) Asfy line fit plot from 30 °C to 400 °C, (c) Acfc line fit plot from 30 °C to 400 °C, (d) Temperature line fit plot from 500 °C to 800 °C, (e) Asfy line fit plot from 500 °C to 800 °C, and (f) Acfc line fit plot from 500 °C to 800 °C.

The multiple linear regression model provides a reasonable fit to the peak load of confined SCCFSTs under distinctly elevated temperatures. It indicates how the temperature and properties of the steel tube and concrete noticeably influence the peak load response in specific temperature ranges. These findings can be valuable for understanding and predicting the behavior of confined SCCFSTs under varying temperature conditions, aiding in the design and assessment of structures subjected to extreme thermal environments.

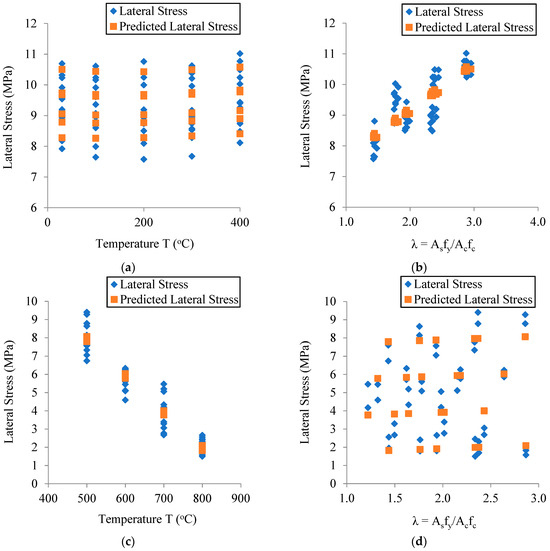

4.5.2. Confinement Factor of Confined SCCFSTs

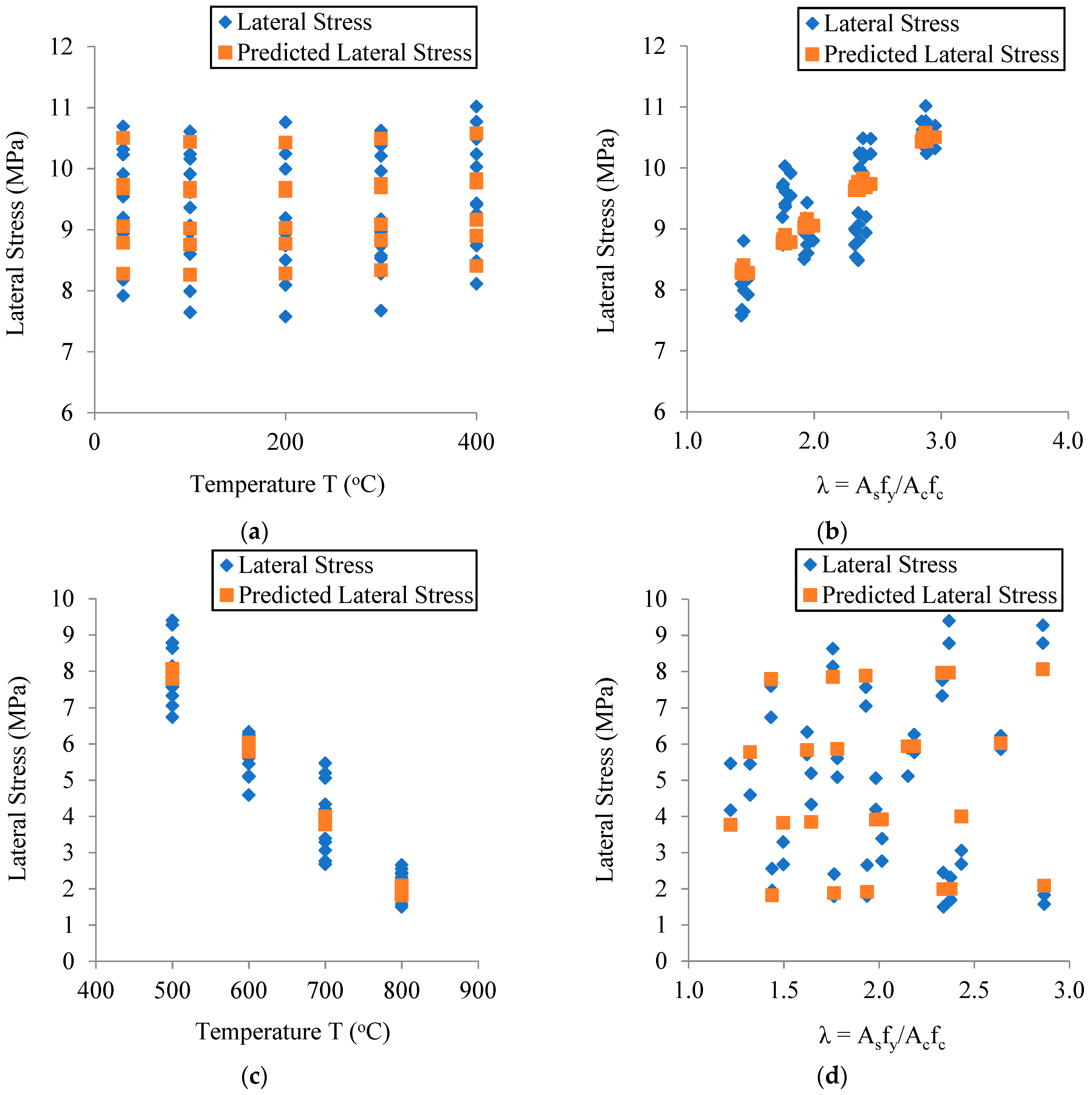

The enhanced compressive strength of CFST columns is attributed to the steel tube confinement on infilled concrete. The confinement effect is commonly measured using the confinement factor, λ, which is typically stated as λ = , where As and Ac designate the cross-sectional areas of steel tube and concrete core, respectively, and fy and fc represent the yield strength of steel tube and the strength of concrete core, respectively [43]. The graph of the multiple linear regression fit for λ of confined SCCFSTs demonstrates two Equations (13) and (14). The relationship between λ and T was described utilizing these equations for two distinct temperature ranges. For the temperature ranging from 30 °C to 400 °C, Equation (13) was used. On the other hand, for temperatures between 500 °C and 800 °C, Equation (14) was employed.

Figure 8a,c displays how lateral confining stress (fl) was influenced by different temperature conditions. From Figure 8b,d, it can be observed that the relationship between λ and fl was linear for both temperature ranges. As the temperature increased within the specified ranges, the behavior of λ became apparent in the variations of fl. The coefficients of λ in Equations (13) and (14) gave insights into how changes in λ affected the response (fl) for each temperature range.

Figure 8.

Predicted values of lateral stress in steel with respect to confinement factor and temperature: (a) Temperature line fit plot from 30 °C to 400 °C, (b) λ = Asfy/Acfc fit plot from 30 °C to 400 °C, (c) Temperature line fit plot from 500 °C to 800 °C, and (d) λ = Asfy/Acfc line fit plot from 500 °C to 800 °C.

5. Conclusions

This study focused on the stress–strain behavior, modulus of elasticity, and Poisson’s ratio in SCC cores within the steel tubes at ambient and high temperatures (from 100 °C to 800 °C). Three specimens per combination were examined, yielding full-confined SCCFST stress–strain curves. The experimental investigation provided the following results:

- The tested specimens had varying behaviors under elevated temperatures; at 30 °C one specimen showed hardening, while the others exhibited softening tendencies, and at 500 °C, one specimen presented the steepest strength reduction, indicating that elevated temperature played a dominant role in determining the peak behavior.

- The circular SCCFST specimens revealed comparable maximum normalized strength values ranging from 0.91 to 1.65, with remarkable effects from the surrounding temperatures, particularly when exposed to temperatures of 400 °C and above 500 °C.

- The compressive stress–strain curve of the circular SCCFSTs experienced a sudden drop of 14.77 MPa (22.65%) at 500 °C, followed by a gradual decrease in the mechanical strength beyond 400 °C up to 800 °C, which was attributed to the steel tube maintaining its strength up to 400 °C with only minimal reduction. But recrystallization above 400 °C resulted in a significant reduction in the mechanical strength of the confined SCCFSTs, and the most substantial drop in the reduction ratio occurred between 400 °C and 800 °C.

- The confined concrete displayed a relatively smaller reduction in the overall modulus of elasticity compared to its unconfined counterpart under elevated temperatures, with an average percentage of reduction ranging between 5.05% and 12.68%.

- A close relationship was found between the lateral strain and longitudinal strain within elastic limits under compression for temperatures ranging from 30 °C to 400 °C, but a sudden increase in strain was seen beyond 400 °C.

- The validation of the experimental data was conducted using EC4 [18,19], ACI [20], Mandar et al. [21], and Zhao et al. [22], and confirmed the accuracy and reliability of the results obtained through the analysis.

- The multiple regression analysis demonstrated a close alignment between the predicted and experimental P0 values at elevated temperatures. The temperature was set between 30 °C and 400 °C, and the average variation was 2.23%, while above 400 °C, the average variation increased to 11.88%.

Author Contributions

A.U.K.: conceptualization; methodology; investigation; validation; writing—original draft. N.S.K.: conceptualization; methodology; investigation; validation; writing—original draft. A.B.: conceptualization; methodology; investigation; validation; formal analysis; resources; writing—original draft; writing—review and editing. Y.O.Ö.: conceptualization; methodology; investigation; validation; writing—original draft; writing—review and editing. M.I.: investigation; formal analysis. E.A.: conceptualization; methodology. S.I.: investigation; validation. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

Data will be made available on request.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Abha, Saudi Arabia for providing financial support to this research work through Large Groups Research Project under grant number RGP2/563/44.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gowripalan, N.; Shakor, P.; Rocker, P. Pressure exerted on formwork by self-compacting concrete at early ages: A review. Case Stud. Constr. Mater. 2021, 15, e00642. [Google Scholar] [CrossRef]

- Kumar, M.A.; Balaji, S.; Selvapraveen, S.; Kulanthaivel, P. Laboratory study on mechanical properties of self compacting concrete using marble waste and polypropylene fiber. Clean. Mater. 2022, 6, 100156. [Google Scholar] [CrossRef]

- Alshahrani, A.; Kulasegaram, S.; Kundu, A. Elastic modulus of self-compacting fibre reinforced concrete: Experimental approach and multi-scale simulation. Case Stud. Constr. Mater. 2023, 18, e01723. [Google Scholar] [CrossRef]

- Hassan, A.A.; Ismail, M.K.; Mayo, J. Mechanical properties of self-consolidating concrete containing lightweight recycled aggregate in different mixture compositions. J. Build. Eng. 2015, 4, 113–126. [Google Scholar] [CrossRef]

- Ganapathy, G.P.; Keshav, L.; Ravindiran, G.; Razack, N.A. Strength prediction of self-consolidating concrete containing steel fibre with different fibre aspect ratio. J. Nanomater. 2022, 2022, 7604383. [Google Scholar] [CrossRef]

- Tejaswini, G.L.S.; Rao, A.V. A detailed report on various behavioral aspects of self-compacting concrete. Mater. Today Proc. 2020, 33, 839–844. [Google Scholar] [CrossRef]

- Mousavi Alizadeh, S.M.; Rezaeian, A.; Rasoolan, I.; Tahmouresi, B. Compressive stress-strain model and residual strength of self-compacting concrete containing recycled ceramic aggregate after exposure to fire. J. Build. Eng. 2021, 38, 102206. [Google Scholar] [CrossRef]

- Lu, X.; Hsu, C.-T.T. Tangent Poisson’s ratio of high-strength concrete in triaxial compression. Mag. Concr. Res. 2007, 59, 69–77. [Google Scholar] [CrossRef]

- Boğa, A.R.; Karakurt, C.; Şenol, A.F. The effect of elevated temperature on the properties of SCC’s produced with different types of fibers. Constr. Build. Mater. 2022, 340, 127803. [Google Scholar] [CrossRef]

- Yang, Y.F.; Han, L.H. Concrete filled steel tube (CFST) columns subjected to concentrically partial compression. Thin-Walled Struct. 2012, 50, 147–156. [Google Scholar] [CrossRef]

- Wei, X.; Yang, Y.; Liu, J.; Yang, W.; Chen, Y.F.; Zhang, H. Experimental and numerical study of fire performance of L-shaped concrete-filled steel tubular columns under eccentric compression. J. Build. Eng. 2022, 50, 104149. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Zhao, X.-Y. Residual mechanical properties of compound concrete containing demolished concrete lumps after exposure to high temperatures. Fire Saf. J. 2019, 105, 62–78. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, W.; Wang, R.; Yan, L.; He, M. Deformation characteristics of cement mortar under triaxial cyclic loading: An experimental investigation. Int. J. Fatigue 2021, 150, 106305. [Google Scholar] [CrossRef]

- Tu, W.; Zhang, M. Behaviour of alkali-activated concrete at elevated temperatures: A critical review. Cem. Concr. Compos. 2023, 138, 104961. [Google Scholar] [CrossRef]

- Chan, Y.; Peng, G.; Anson, M. Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures. Cem. Concr. Compos. 1999, 21, 23–27. [Google Scholar] [CrossRef]

- Ning, X.; Li, J.; Li, Y. An explorative study into the influence of different fibers on the spalling resistance and mechanical properties of self-compacting concrete after exposure to elevated temperatures. Appl. Sci. 2022, 12, 12779. [Google Scholar] [CrossRef]

- Chan, S.; Peng, G.F.; Anson, M. Fire behavior of high-performance concrete made with silica fume at various moisture contents. Materials 1999, 96, 405–409. [Google Scholar]

- DD ENV 1994-1-1.2004; Eurocode 4: Design of Composite Steel and Concrete Structures—Part 1-1: General Rules and Rules for Buildings [Authority: The European Union Per Regulation 305/2011, Directive 98/34/EC, Directive 2004/18/EC]. British Standards Institution: London, UK, 1994.

- DD ENV 1994-1-2.2005; Eurocode 4: Design of Composite Steel and Concrete Structures—Part 1-2: General Rules—Structural Fire Design [Authority: The European Union Per Regulation 05/2011, Directive 98/34/EC, Directive 2004/18/EC]. British Standards Institution: London, UK, 1994.

- ACI 318-99; ACI Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Detroit, MI, USA, 1999.

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Zhao, Y.-G.; Lin, S.; Lu, Z.-H.; Saito, T.; He, L. Loading paths of confined concrete in circular concrete loaded CFT stub columns subjected to axial compression. Eng. Struct. 2018, 156, 21–31. [Google Scholar] [CrossRef]

- Wu, C.; Li, J.; Su, Y. Ultra-high performance concrete-filled steel tubular columns. In Development of Ultra-High Performance Concrete against Blasts; Elsevier: Duxford, UK, 2018; pp. 283–395. [Google Scholar] [CrossRef]

- Geiker, M.; Jacobsen, S. Self-compacting concrete (SCC). In Developments in the Formulation and Reinforcement of Concrete; Elsevier: Duxford, UK, 2019; pp. 229–256. [Google Scholar] [CrossRef]

- Ellobody, E.; Young, B.; Lam, D. Behaviour of normal and high strength concrete-filled compact steel tube circular stub columns. J. Constr. Steel Res. 2006, 62, 706–715. [Google Scholar] [CrossRef]

- CSA Standard A23.3-04; Concrete Design Handbook. Cement Association of Canada: Ottawa, ON, Canada, 2004.

- Park, R.; Paulay, T. Reinforced Concrete Structures; John Wiley & Sons: New York, NY, USA, 1975. [Google Scholar]

- Hu, H.T.; Huang, C.S.; Wu, M.H.; Wu, Y.M. Nonlinear analysis of axially loaded concrete-filled tube columns with confinement effect. J. Struct. Eng. 2003, 129, 1322–1329. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandzaeg, A.; Brown, R.L. A Study of the Failure of Concrete under Combined Compressive Stresses; Bulletin No. 185; University of Illinois Engineering Experimental Station: Champaign, IL, USA, 1928. [Google Scholar]

- Saenz, L.P. Discussion of ‘Equation for the stress–strain curve of concrete’ by P. Desayi, and S. Krishnan. J. Am. Concr. Inst. 1964, 61, 1229–1235. [Google Scholar]

- Hu, H.T.; Schnobrich, W.C. Constitutive modeling of concrete by using nonassociated plasticity. J. Mater. Civ. Eng. 1989, 1, 199–216. [Google Scholar] [CrossRef]

- Giakoumelis, G.; Lam, D. Axial capacity of circular concrete-filled tube columns. J. Constr. Steel Res. 2004, 60, 1049–1068. [Google Scholar] [CrossRef]

- Tomii, M. Ductile and strong columns composed of steel tube, infilled concrete and longitudinal steel bars. In Proceedings of the 3rd International Conference on Steel-Concrete Composite Structures, Fukuoka, Japan, 18 February 1991. [Google Scholar]

- Mursi, M.; Uy, B. Strength of concrete filled steel box columns incorporating interaction buckling. J. Struct. Eng. 2003, 129, 626–639. [Google Scholar] [CrossRef]

- Petchko, K. Data and Methodology. In How to Write About Economics and Public Policy; Academic Press: Cambridge, MA, USA, 2018; pp. 241–270. [Google Scholar] [CrossRef]

- Petchko, K. Results, Discussion, and Conclusion. In How to Write about Economics and Public Policy; Academic Press: Cambridge, MA, USA, 2018; pp. 271–300. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Gholampour, A. Pre- and post-heating behavior of concrete-filled steel tube stub columns containing steel fiber and tire rubber. Structures 2020, 27, 2346–2364. [Google Scholar] [CrossRef]

- Ho, J.; Ou, X.; Li, C.; Song, W.; Wang, Q.; Lai, M. Uni-axial behaviour of expansive CFST and DSCFST stub columns. Eng. Struct. 2021, 237, 112193. [Google Scholar] [CrossRef]

- Agra, R.R.; Serafini, R.; de Figueiredo, A.D. Effect of high temperature on the mechanical properties of concrete reinforced with different fiber contents. Constr. Build. Mater. 2021, 301, 124242. [Google Scholar] [CrossRef]

- Singh, R. Heat Treatment of Steels. In Applied Welding Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 111–124. [Google Scholar] [CrossRef]

- López, B. Recrystallisation and grain growth in hot working of steels. In Microstructure Evolution in Metal Forming Processes; Elsevier: Amsterdam, The Netherlands, 2012; pp. 67–113. [Google Scholar] [CrossRef]

- Mellor, M. A Review of Basic Snow Mechanics; US Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1974. [Google Scholar]

- Lee, H.-J.; Park, H.-G.; Choi, I.-R. Compression loading test for concrete-filled tubular columns with high-strength steel slender section. J. Constr. Steel Res. 2019, 159, 507–520. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).