1. Introduction

In addition to various advantages, large-span spatial structures also have characteristics such as a frequency density, complex vibration modes, and significant spatial effects in terms of earthquake action [

1]. The seismic response of large-span spatial structures is complex, and seismic damage events are often reported [

2]. The shaking table test is an important means of seismic research [

3,

4,

5,

6]. The size of the shaking table is limited, but the span of the spatial structure is often large. A scale model for large-span spatial structures for dynamic studies has to be made. In addition, the similarity of the length for large-span spatial structures is very small. The similarity relationship between the prototype structure and the dynamic scale model is a key parameter of the shaking table test.

The shaking table test can be separated into a scientific-research-oriented test and an engineering-oriented test according to its purpose. The differences between the two in terms of the scale model design requirements and the limiting conditions are obvious.

In terms of scientific research, the shaking table test is used for validating the research results of engineering seismic theory. Ye et al. [

7] conducted a shaking table test to study the strong earthquake collapse of single-layer spherical-shell structures. Three dynamic scale models with a geometric similarity ratio of 1/10 were designed. The three models were made of oxygen-blown steel pipes and welded hollow steel balls. However, significant residual deformation during the welding made the welding quality poor. Wang et al. [

8] conducted a shaking table test to study the dynamic collapse mechanism of grid shell structures. They designed a dynamic scale model with a geometric similarity ratio of 1/10. The components were made of structural steel. Li et al. [

9] conducted a shaking table test to study the seismic response of a single-layer cylindrical-lattice shell with friction pendulum isolation under multiple seismic inputs, and they designed a dynamic scale model with a geometric similarity ratio of 1/10. The model was made of structural steel.

For the shaking table test for scientific research, the geometric similarity of the dynamic scale model can be determined with a suitable value of about 1/10. Then, based on the geometric similarity relationship, the geometric dimensions and cross-sectional dimensions of the prototype structure can be inferred. With a suitable geometric similarity, the cross-sectional dimension of the scale model will be suitable, and the materials of the scale model and the prototype structure can be consistent. Overall, the design of dynamic scale models for scientific research has low complexity.

In terms of practical engineering, the purpose of the shaking table test is to verify the reliability of engineering structures under earthquake conditions. Zhang et al. [

10,

11] conducted a shaking table test on a 93-meter-span dome structure. A dynamic scale model with a geometric similarity ratio of 1/10 was manufactured, and structural steel was used for both the scale model and the prototype structure. It was found that it was difficult to obtain structural-steel pipes that met the similarity relationship. Zhang et al. [

12] conducted a shaking table test on the large-span roof structure of the Beijing Daxing International Airport Terminal and designed a dynamic scale model with a geometric similarity ratio of 1/60. Since the geometric similarity was very small, yellow bronze was used for the dynamic scale model. It was also difficult to obtain yellow bronze pipes that met the similarity relationship. However, the elastic modulus and yield strength between the structural steel and the yellow bronze were different; it affected the accuracy of the shaking table test results.

Since the geometric dimensions, component cross-sections, and material categories of actual engineering structures cannot be changed, the geometric similarity ratio of dynamic scale models is constrained by the size of the shaking table. The small geometric dimensions and cross-sections bring various difficulties when making dynamic scale models. In an actual large-span spatial roof structure, there are dense components and various cross-sections. When a small geometric similarity ratio is used, the dense structural components, various small cross-sections and super-thin-walled members make it difficult to obtain small-cross-section thin-walled components that fully meet the similarity relationship using the same materials as the prototype structure. When it is necessary to design a dynamic scale model using alternative materials, the differences in the elastic modulus and yield strength between the alternative materials and the prototype materials make the similarity relationship more complex. Overall, the design of dynamic scale models for large-span spatial structures facing practical engineering has more limitations and greater difficulty.

Stainless steels have attracted extensive interest due to their distinguished mechanical properties [

13]. It has been recognized that one of the most important microstructural properties that allows an optimum balance between strength and ductility in these steels is the presence of metastable austenite [

14]. It was found that austenitic 304 stainless steel is commonly used to process small-cross-section, thin-walled, hollow pipes and solid rods. There are many types of standard section specifications available, and hot extrusion molding technology [

15,

16] can also be used to process non-standard hollow pipe sections. In summary, using austenitic 304 stainless steel to design dynamic scale model components for engineering-oriented large-span spatial structures makes it easy to obtain component sections that meet geometric similarity ratios. In addition, austenitic 304 stainless steel plates can be used for welding hollow ball joints or other commonly used solid joints. Gas-shielded welding can effectively achieve the high-quality welding of austenitic 304 stainless steel rods and nodes [

17]. In summary, the difficulty in manufacturing austenitic 304-stainless-steel dynamic scale models with a small geometric similarity is not significant.

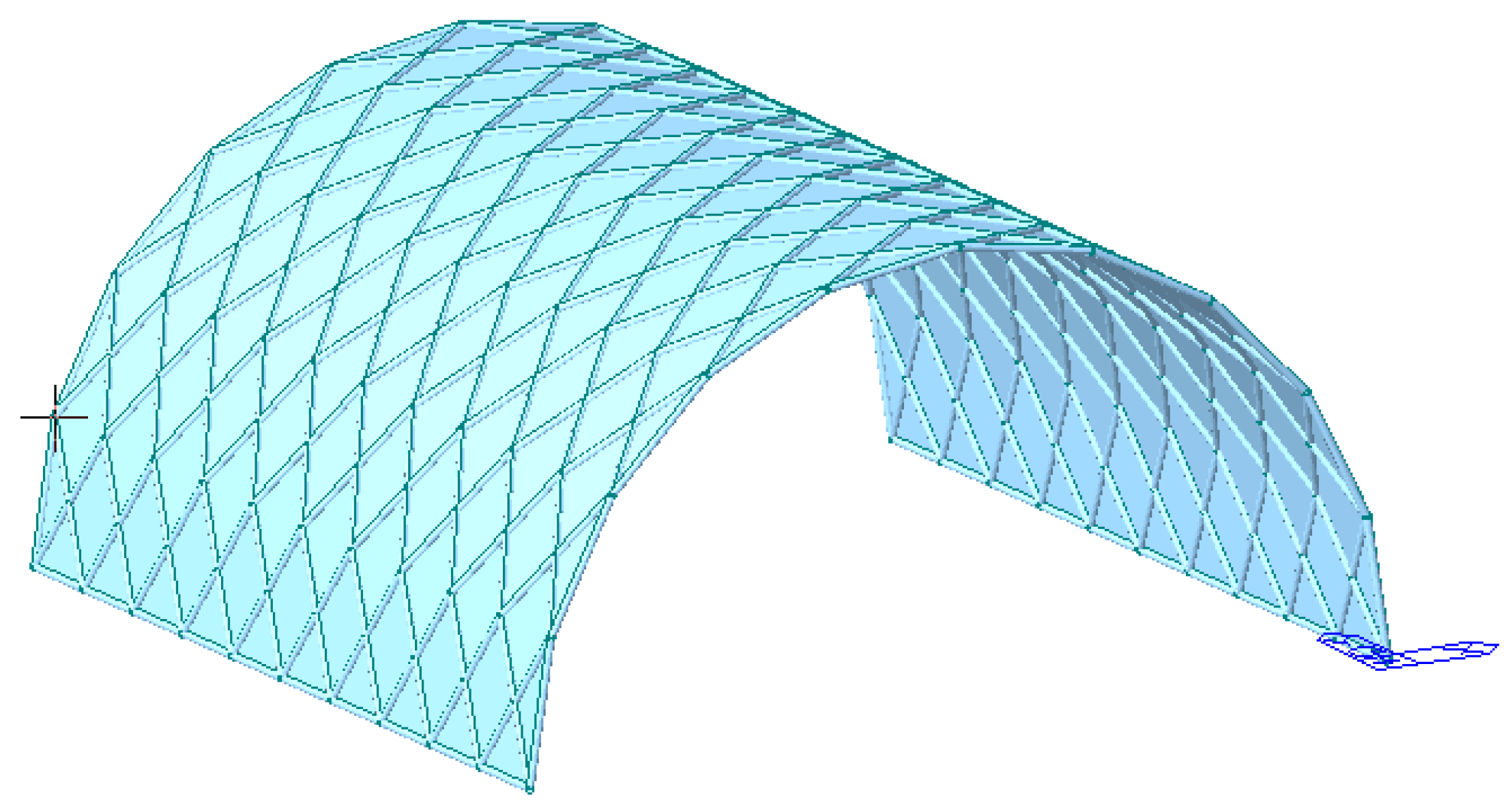

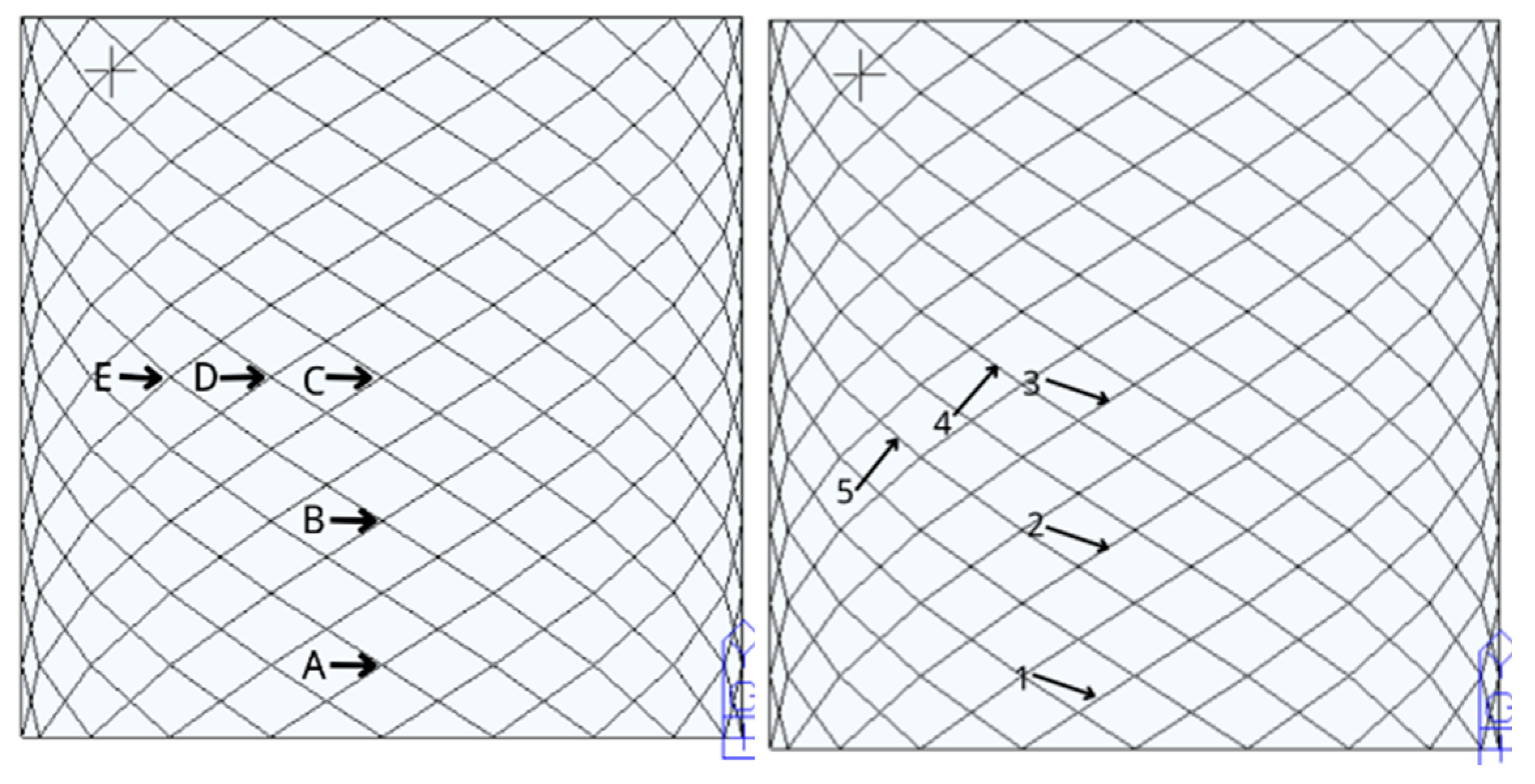

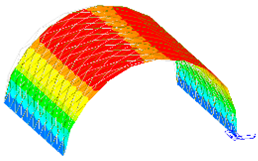

Hence, in this paper, austenitic 304 stainless steel is proposed for designing a dynamic scale model for engineering-oriented large-span spatial structures. The similarity between the 304-stainless-steel dynamic scale model and the structural-steel prototype structure was the key parameter for designing the dynamic scale model in this study. In this paper, a uniaxial tensile test was conducted to determine the elastic modulus similarity and the stress similarity between the 304 stainless steel and three typical structural steels. Then, the similarity of other variables was derived by the dimensional analysis method. Furthermore, taking a finite element model of a single-layer cylindrical reticulated shell as an example, the static similarity and the dynamic similarity of the dynamic scale model and the prototype structure were verified.

4. Discussion

This article provides a design method for a dynamic model of a large-span spatial structure with a small geometric similarity using 304 stainless steel. The similarity relationship between the 304 stainless steel and three typical structural steels, including Q235, Q355 and Q420, was studied. There are several limitations with this paper.

Firstly, the research in this article verified that the proposed similarity relationship was applicable to the elastic stage. The similarity in the inelastic stage requires further study. Secondly, only three typical structural steels were studied in this paper. Other structural steels require investigation. In addition, some references mentioned the use of bronze tubes to design engineering-oriented dynamic scale models, and further research is needed to determine the similarity relationship between bronze and structural steels.

5. Conclusions

Due to the size limitation of shaking tables, dynamic scale models of large-span-space structures for engineering have small cross-sections and super-thin-wall components. It is difficult to use structural steels in prototypes to make dynamic scale models. It was proposed in this paper to use 304 stainless steel to make a scale model, and the similarity relationship between the structural-steel prototype and the 304-stainless-steel dynamic scale model was studied.

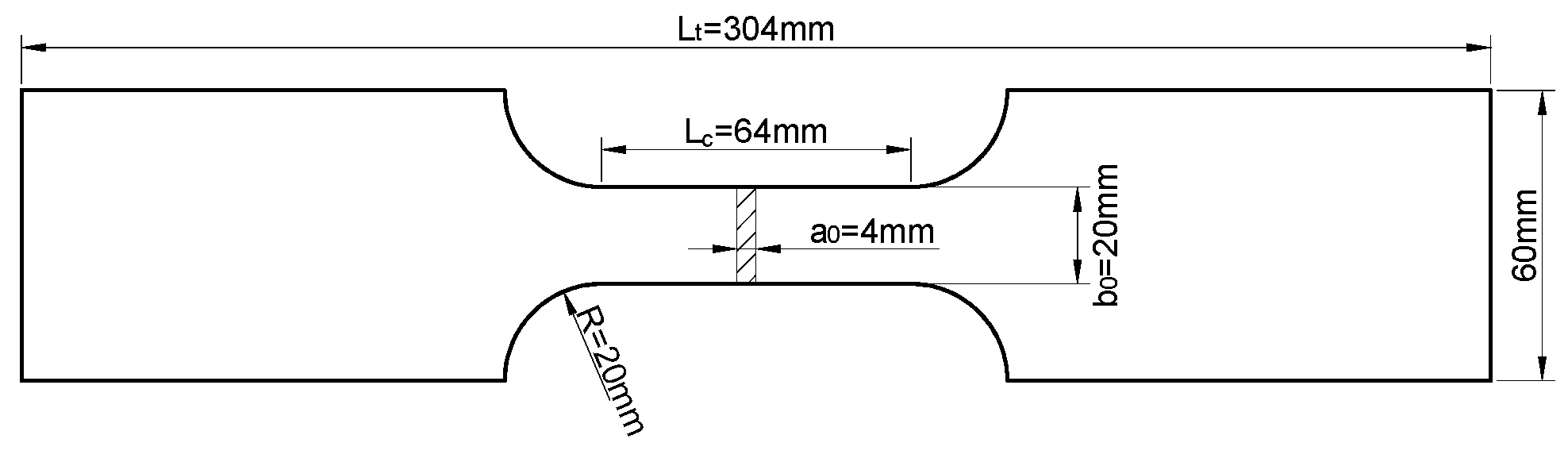

A uniaxial tensile test was performed to determine the elastic modulus similarity and the yield stress similarity. The results of the uniaxial tensile test show that the elastic modulus similarity ratio was taken as 1:1, and the stress similarity ratios of the 304 stainless steel and the Q235, Q355 and Q420 steels were taken as 1:1, 1:1.5 and 1:1.8, respectively.

The similarity relationship of other main physical parameters was studied using the dimensional analysis method. The mass density, length and time were defined as the three basic physical parameters. The length similarity ratio, yield stress similarity ratio and acceleration similarity ratio were selected as the control constants of the similarity relationship.

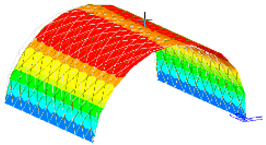

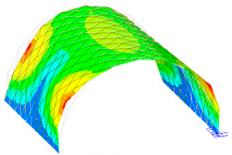

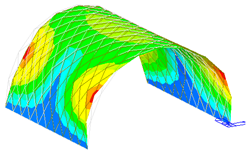

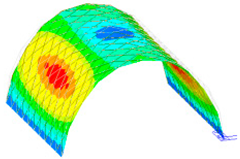

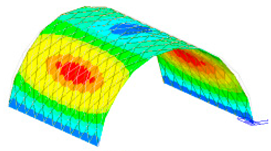

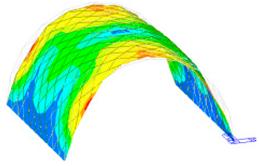

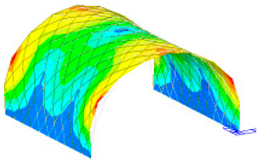

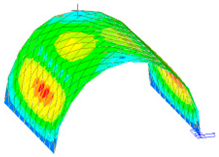

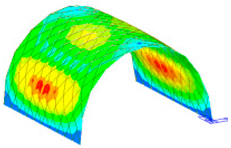

For verifying the similarity, a single-layer spherical reticulated shell and a dynamic scale model with a length similarity ratio of 1:20 were established, and the static analysis and natural vibration characteristics were analyzed. The analysis results verified the similarity between the low-alloy, high-strength structural steel prototype and the 304 stainless steel dynamic scale model.

In future research, static loading experiments on prototype structures and scaled models will be conducted. The similarity between the two in terms of the structural stiffness and ultimate bearing capacity will be studied, and the differences in the failure characteristics between the two will be discussed to verify that the proposed similarity relationship is applicable in the inelastic stage.