Experimental Assessment and Validation of the Hygrothermal Behaviour of an Innovative Light Steel Frame (LSF) Wall Incorporating a Monitoring System

Abstract

1. Introduction

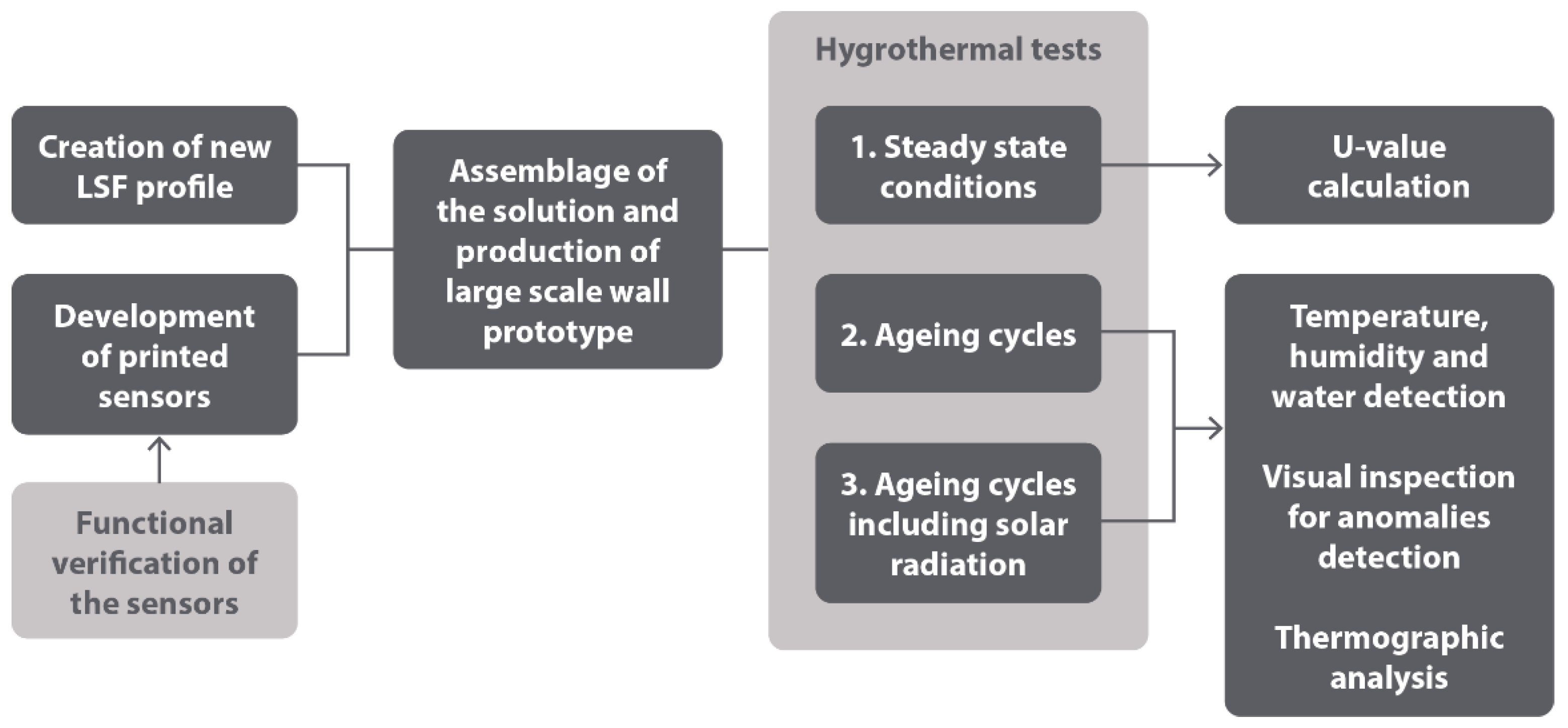

2. Materials and Methods

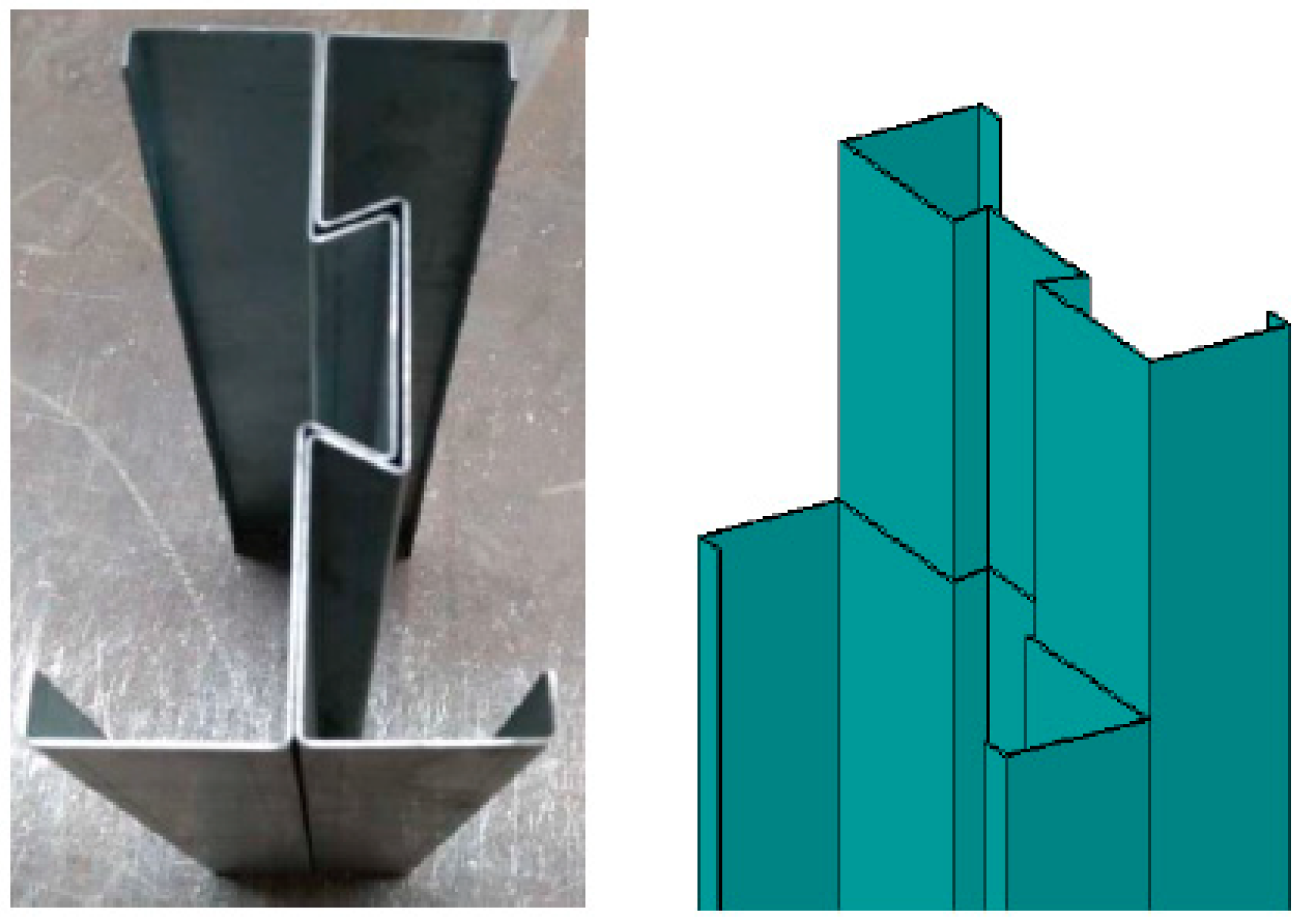

2.1. Description of the LSF Innovative Profile

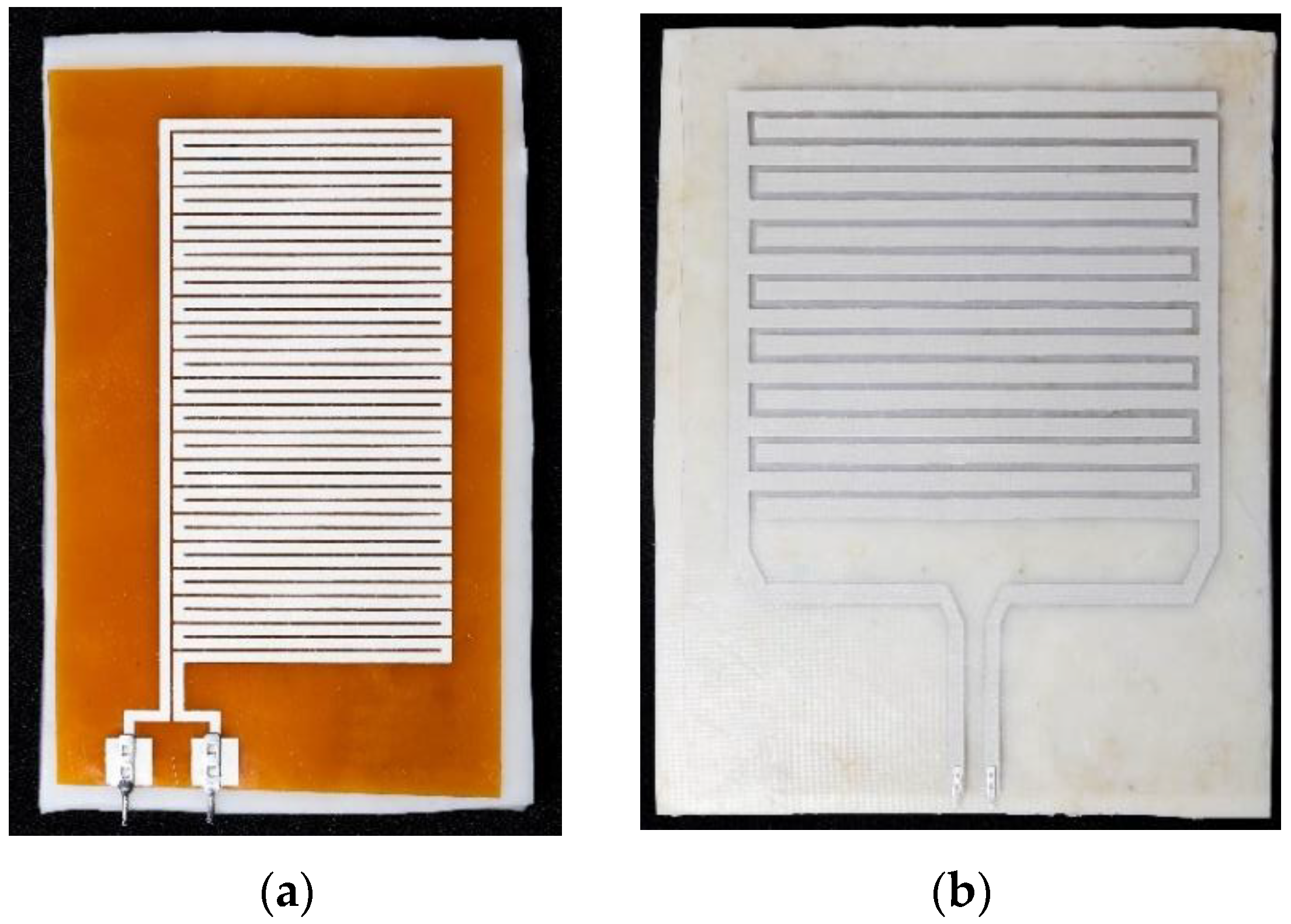

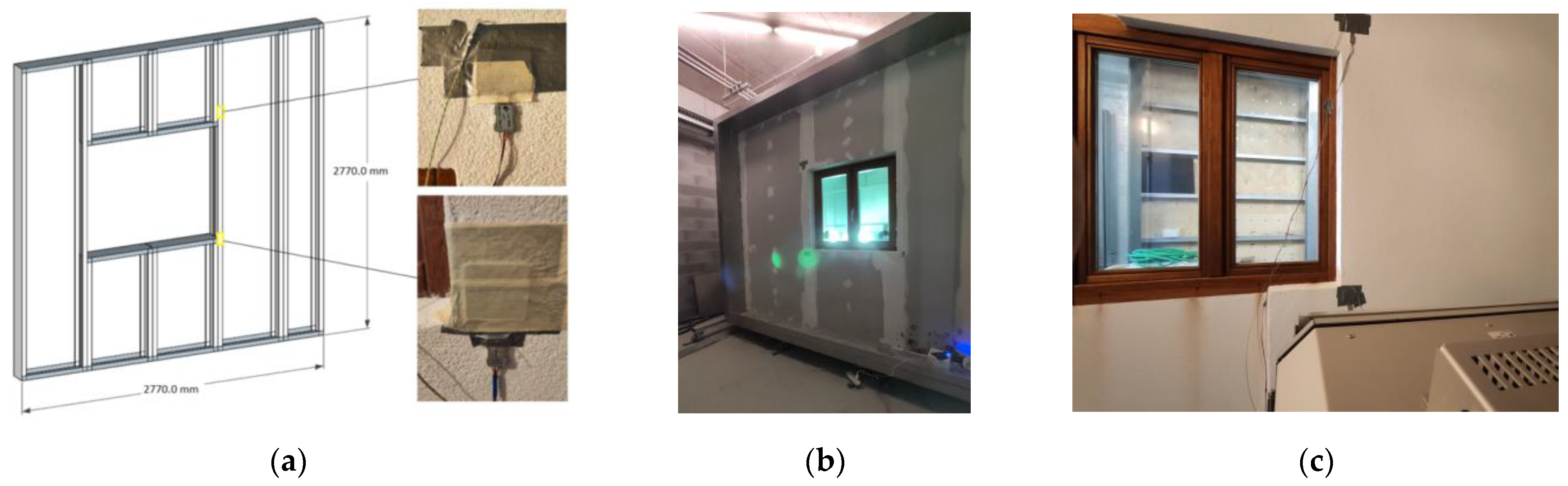

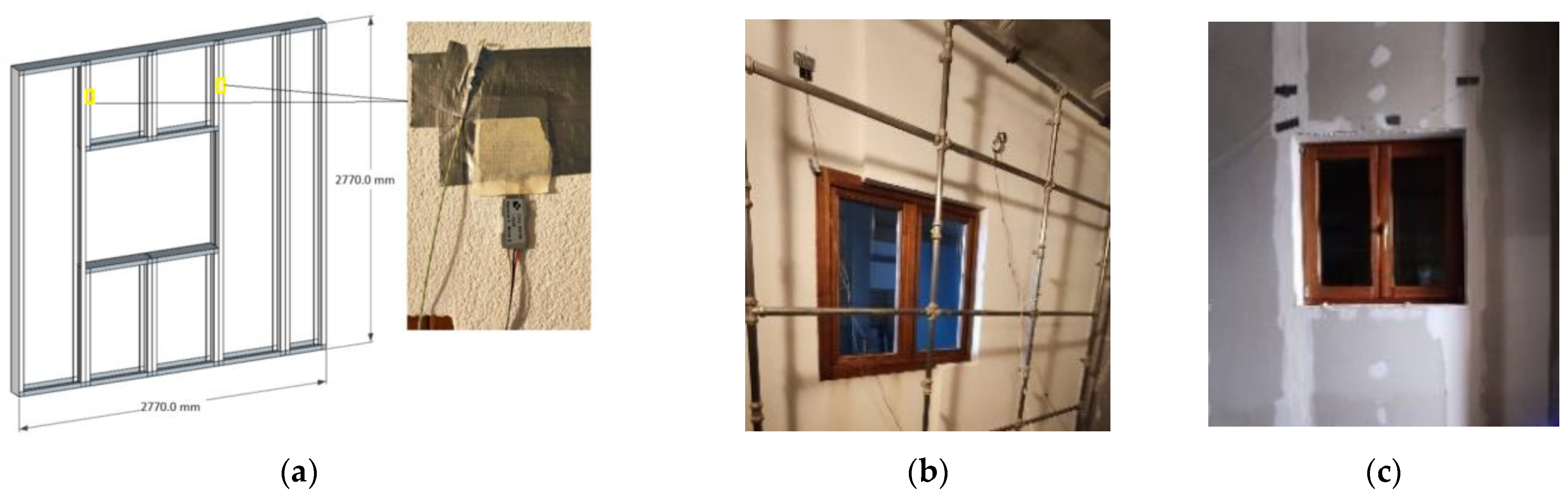

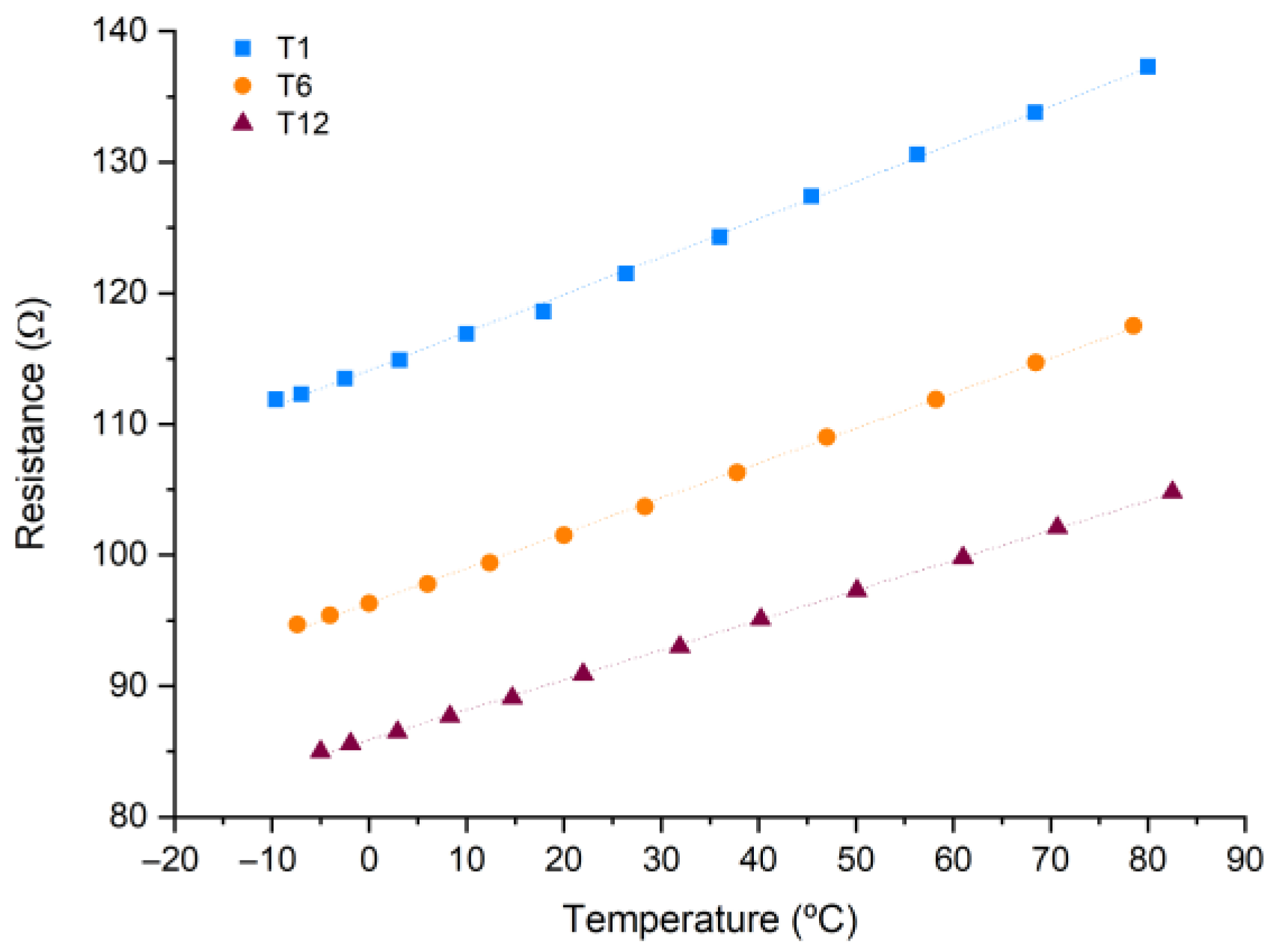

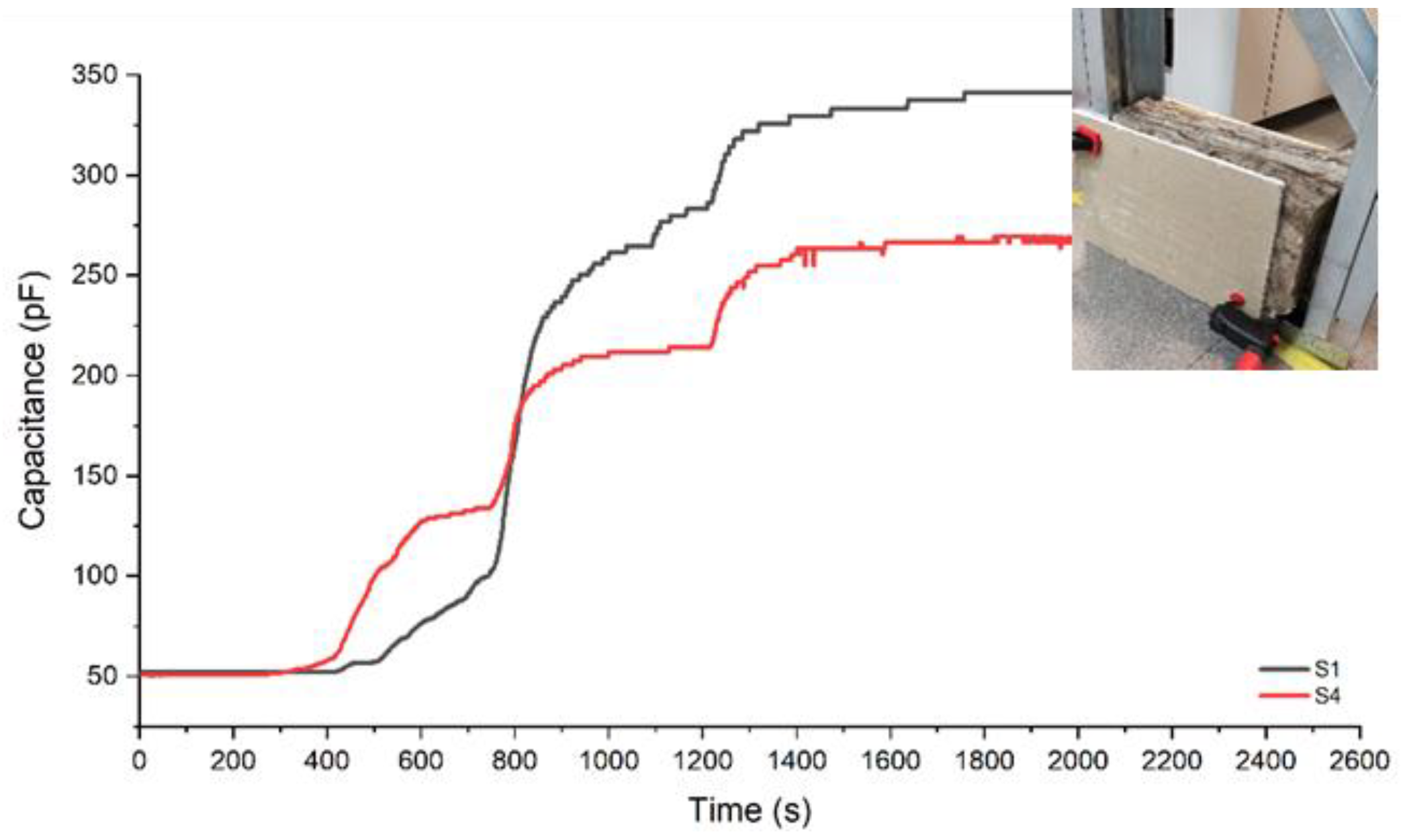

2.2. Development of the Hygrothermal Sensors

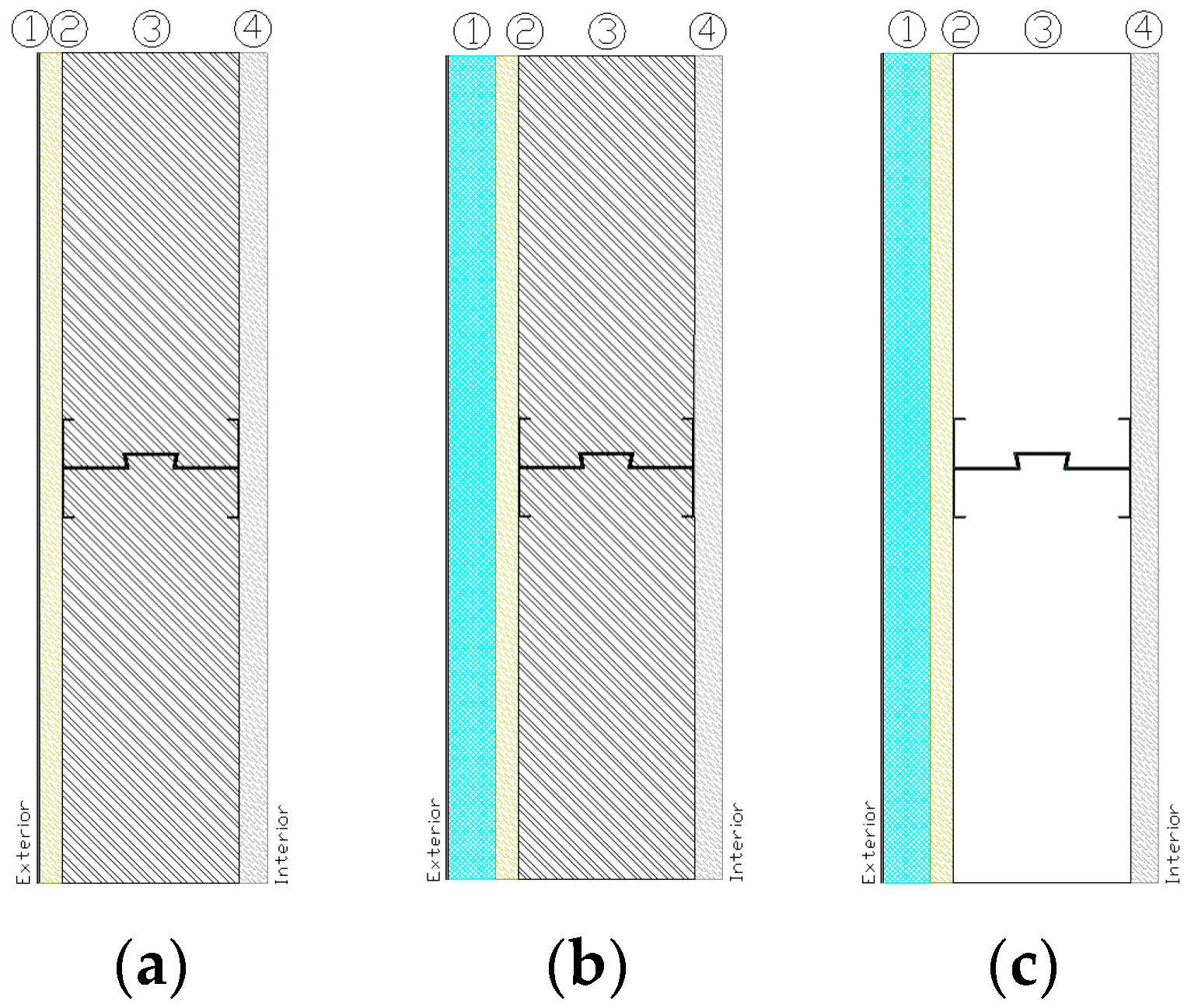

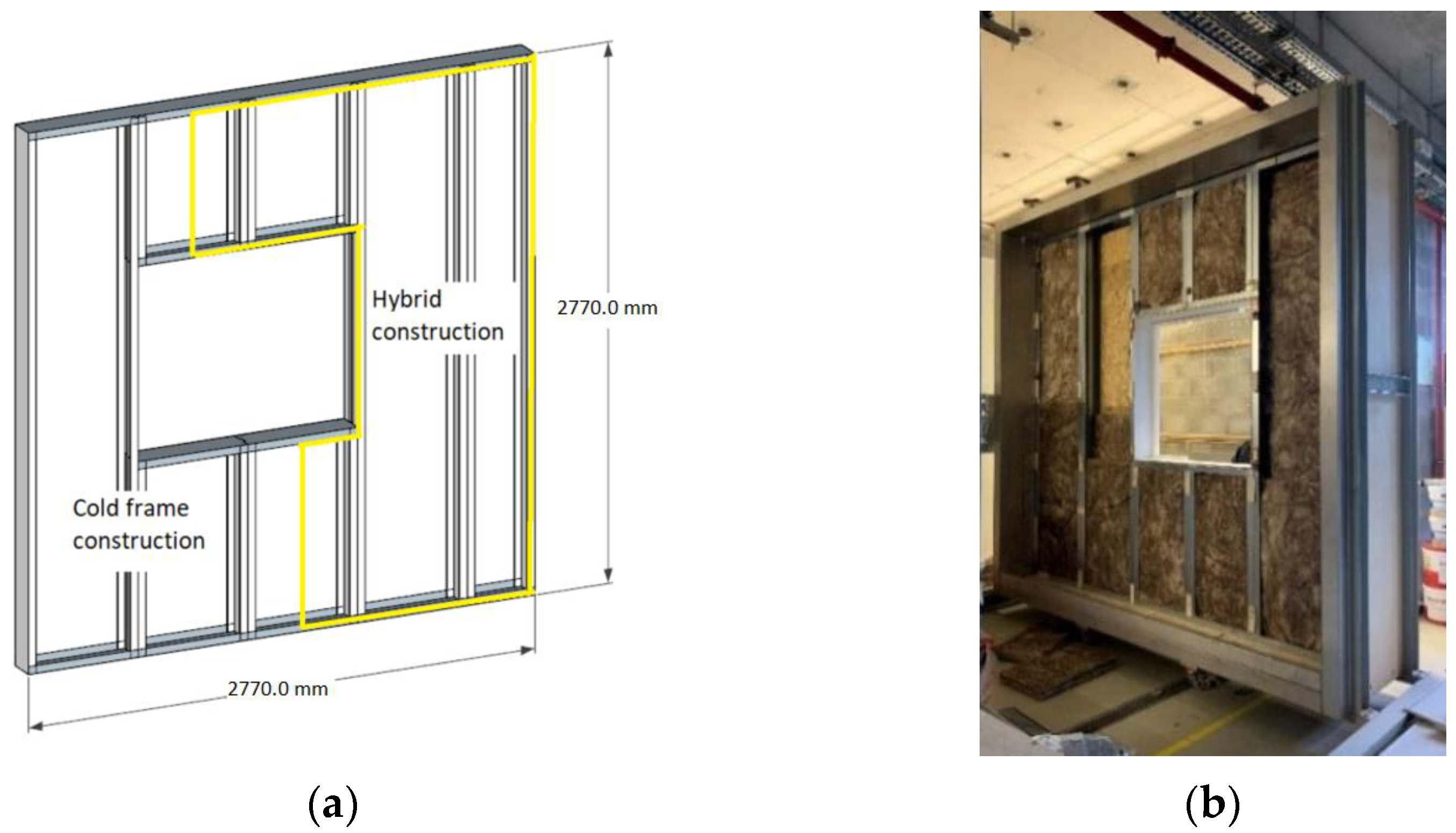

2.3. Description of the Test Specimen

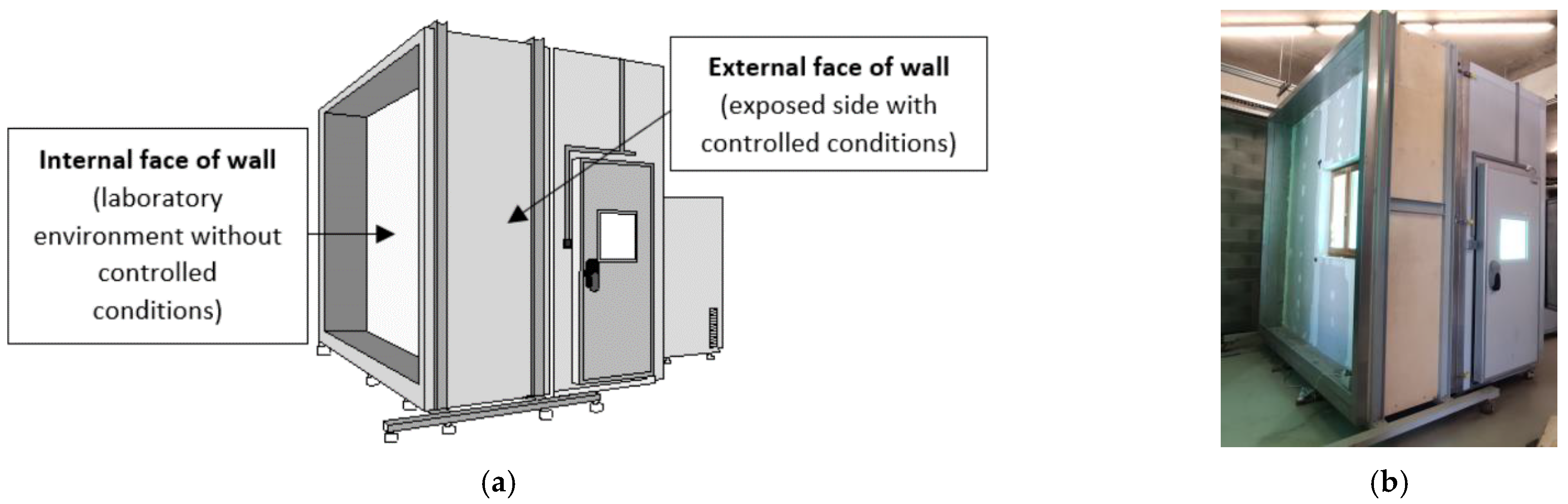

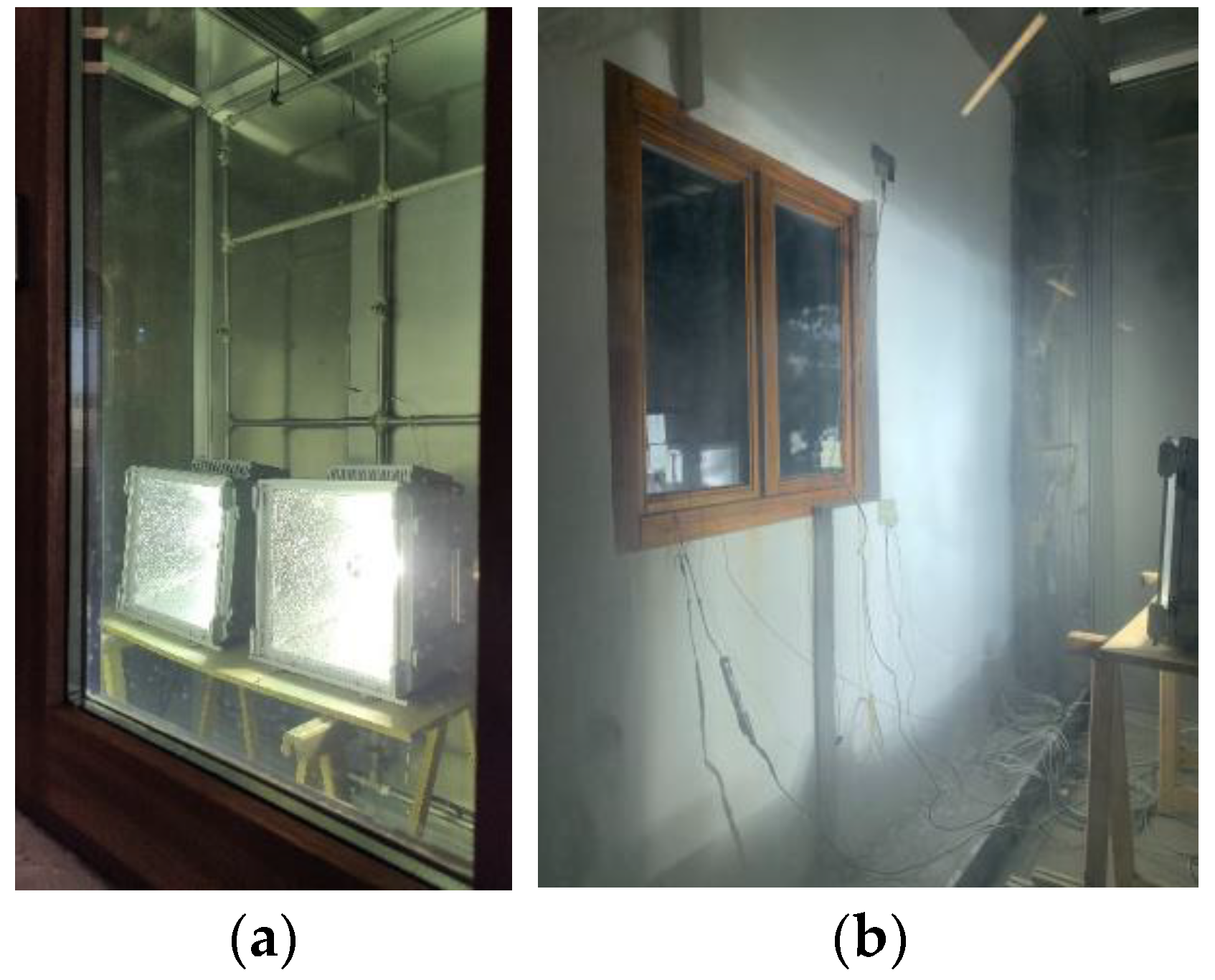

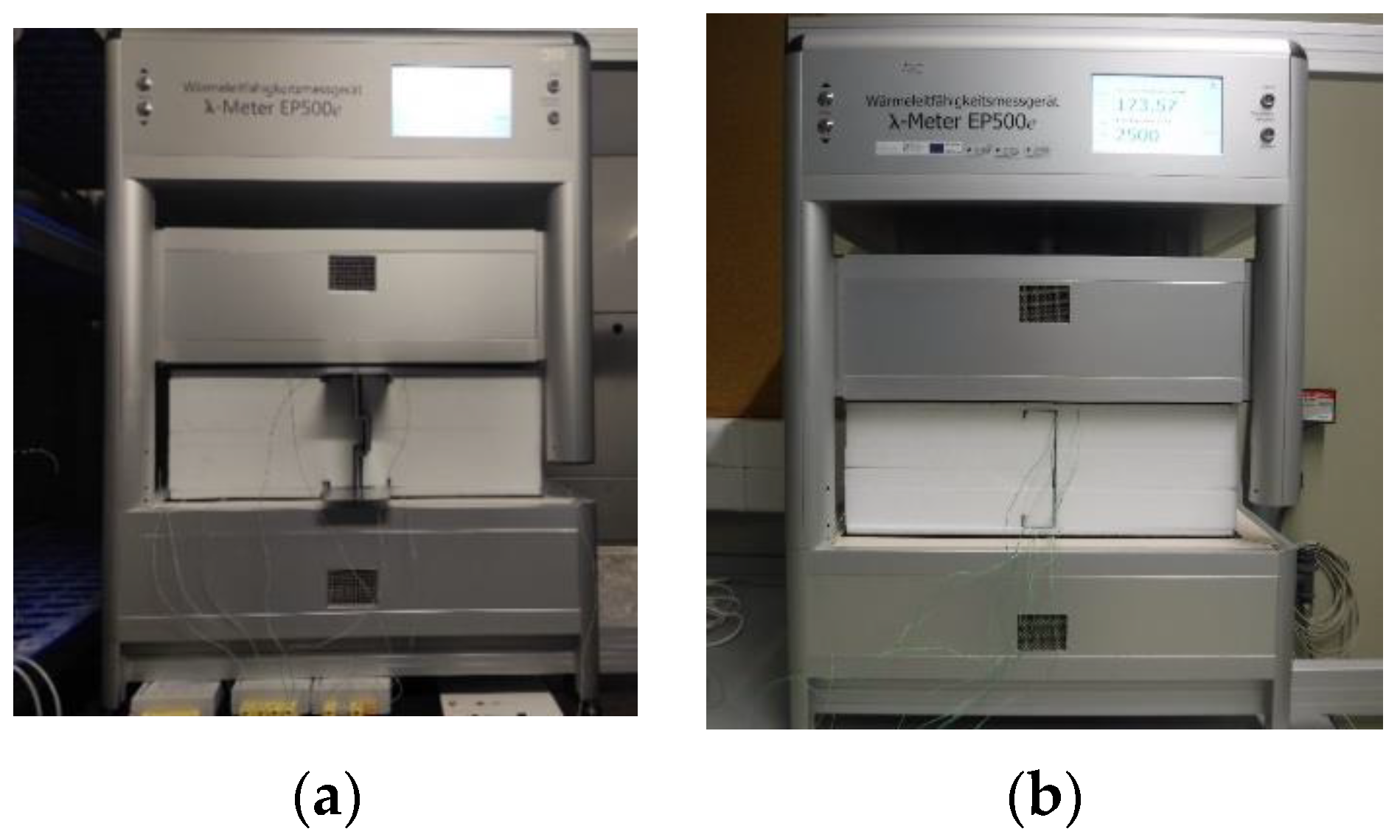

2.4. Description of the Test Apparatus

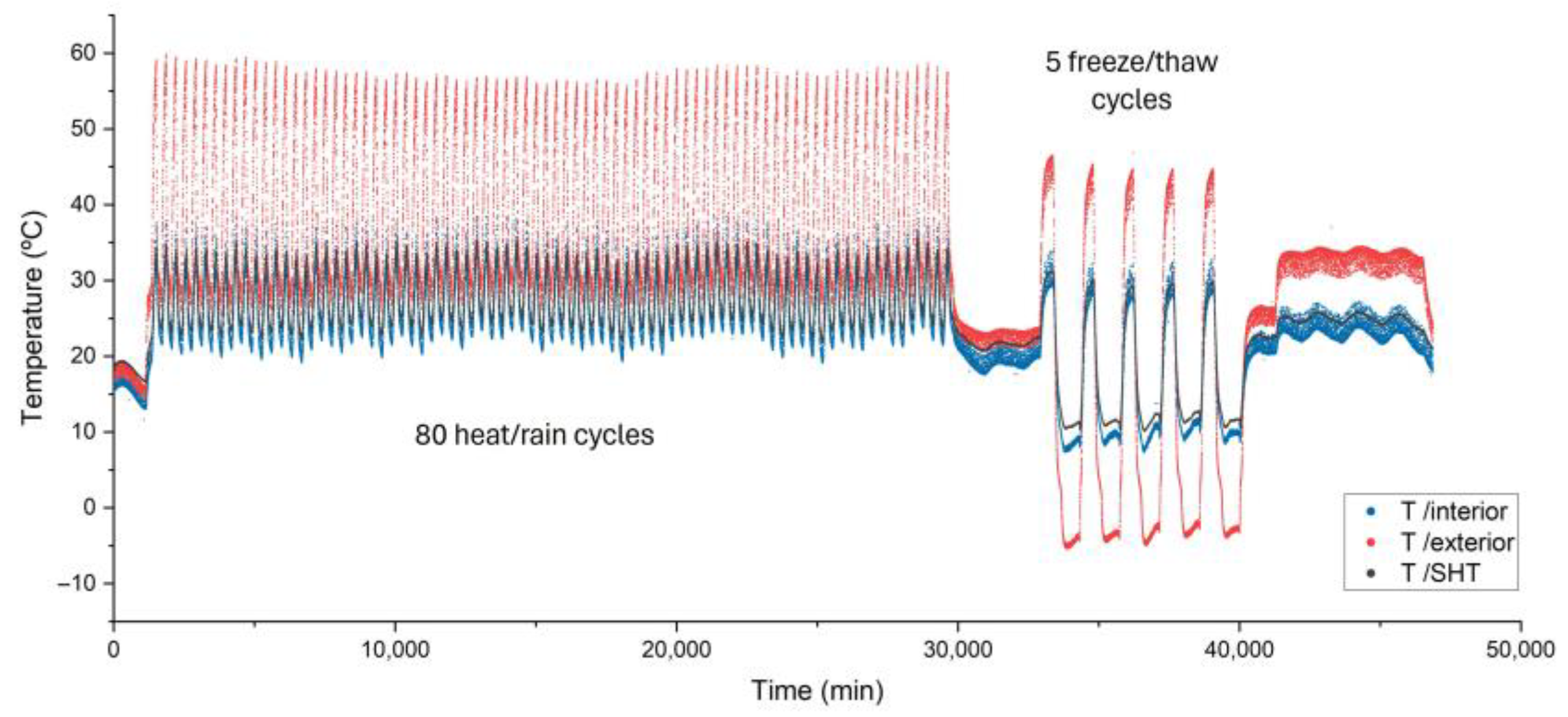

2.5. Description of the Test Procedures

- qi, density of heat flow [W/m2];

- Ti, interior environmental temperature [°C or K];

- Te, exterior environmental temperature [°C or K];

- j, enumerates the individual measurements.

- Heating to 70 °C (for 1 h) and maintaining at (70 ± 5) °C and 10 to 30% RH for 2 h (total of 3 h);

- Spraying for 1 h (water temperature (+15 ± 5) °C, amount of water 1 L/m2 min);

- Leave for 2 h (drainage).

- Exposure to (50 ± 5) °C (increasing for 1 h) and maximum 30% RH for 7 h (total of 8 h);

- Exposure to (−20 ± 5) °C (decreasing for 2 h) for 14 h (total of 16 h).

- Heating to 35 °C (for 1 h) and maintaining the temperature at (35 ± 5) °C and RH at 20–30% for 1 h (total of 2 h);

- Maintaining the temperature at (35 ± 5) °C and turning the solar radiation lamps on at a setpoint of (1100 ± 100) W/m2 for 5 h;

- After turning off the solar radiation lamps, cooling the air chamber within 2 h to a temperature of (−20 ± 5) °C and maintaining it for 15 h (total 17 h).

3. Results

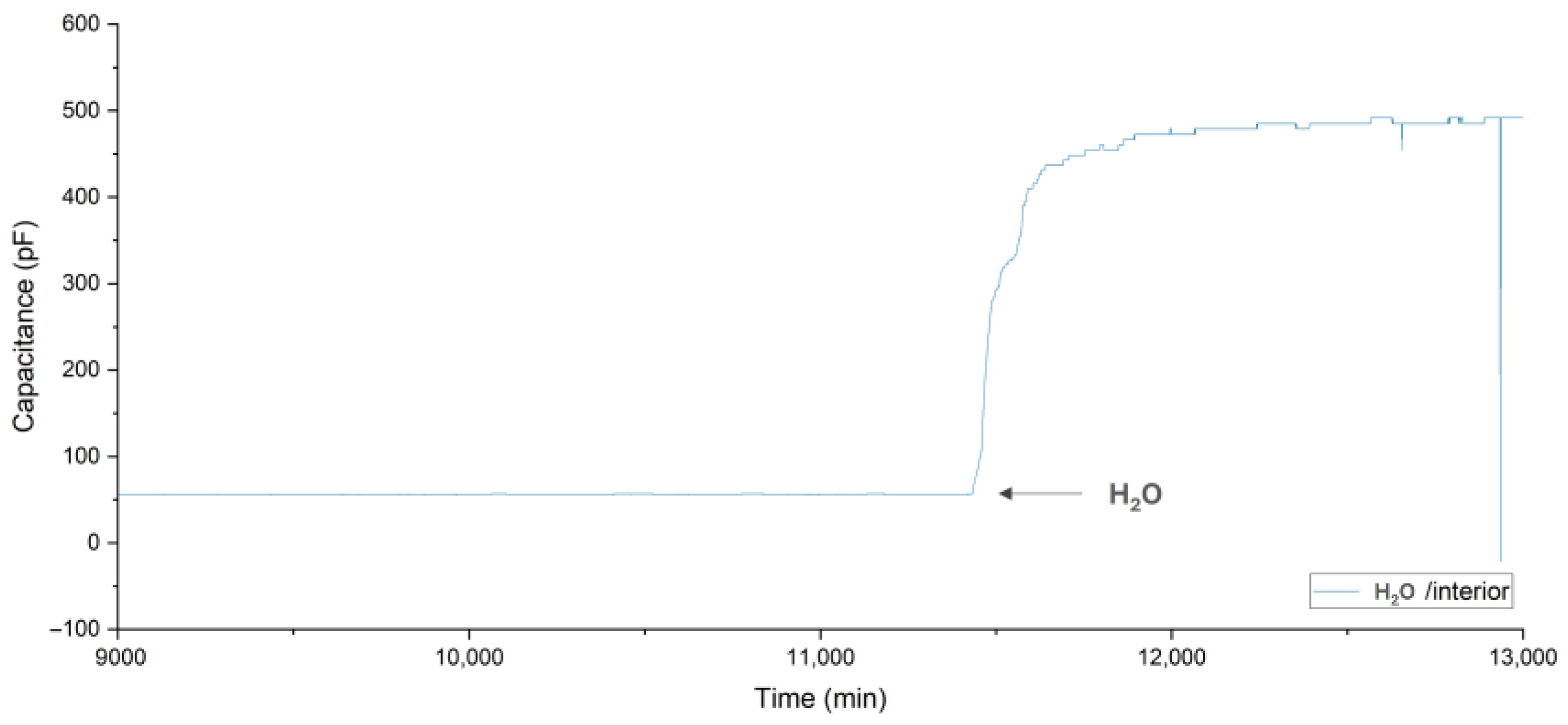

3.1. Initial Verification of the Developed Sensors

3.2. Hygrothermal Cycles of the Innovative LSF Profile

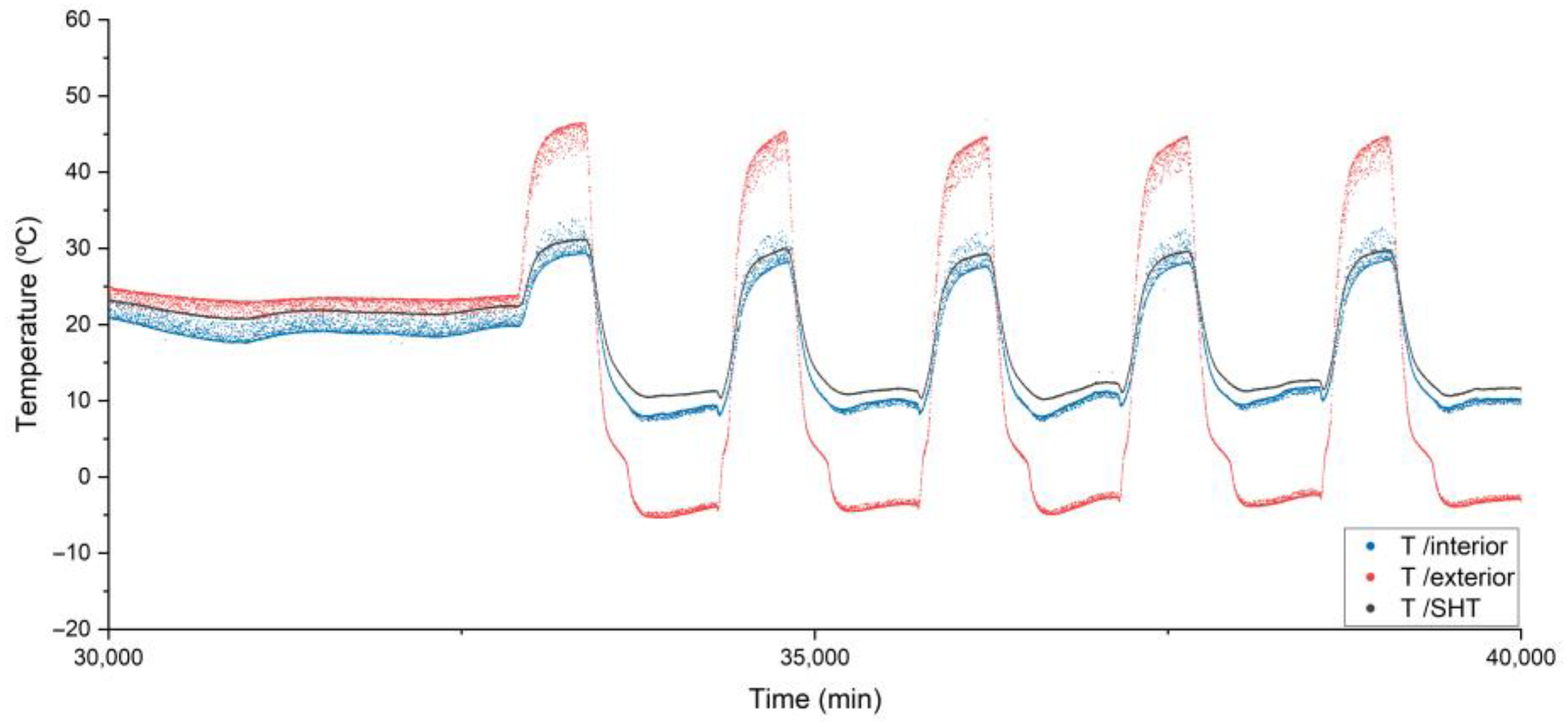

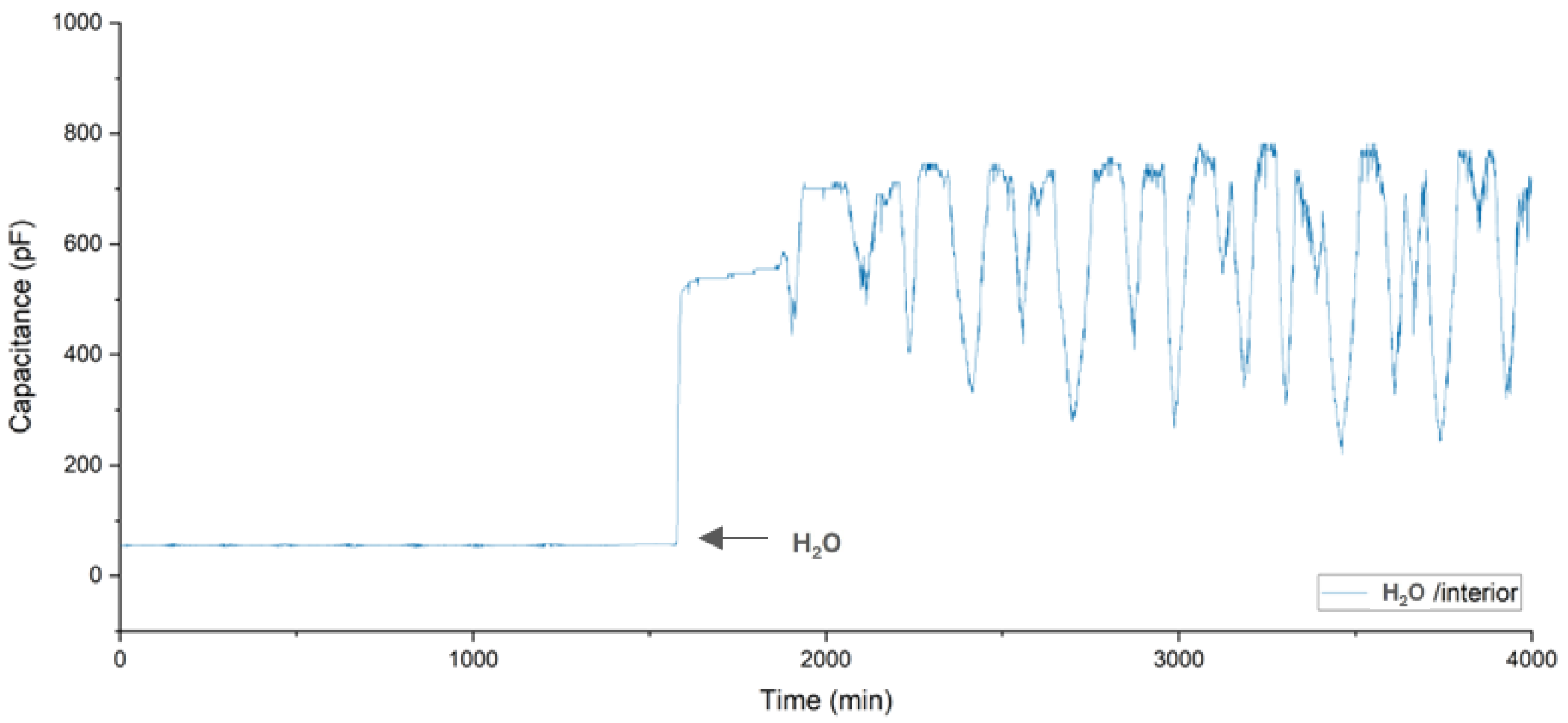

3.2.1. Temperature and Water Detection Measurements during Hygrothermal Cycles

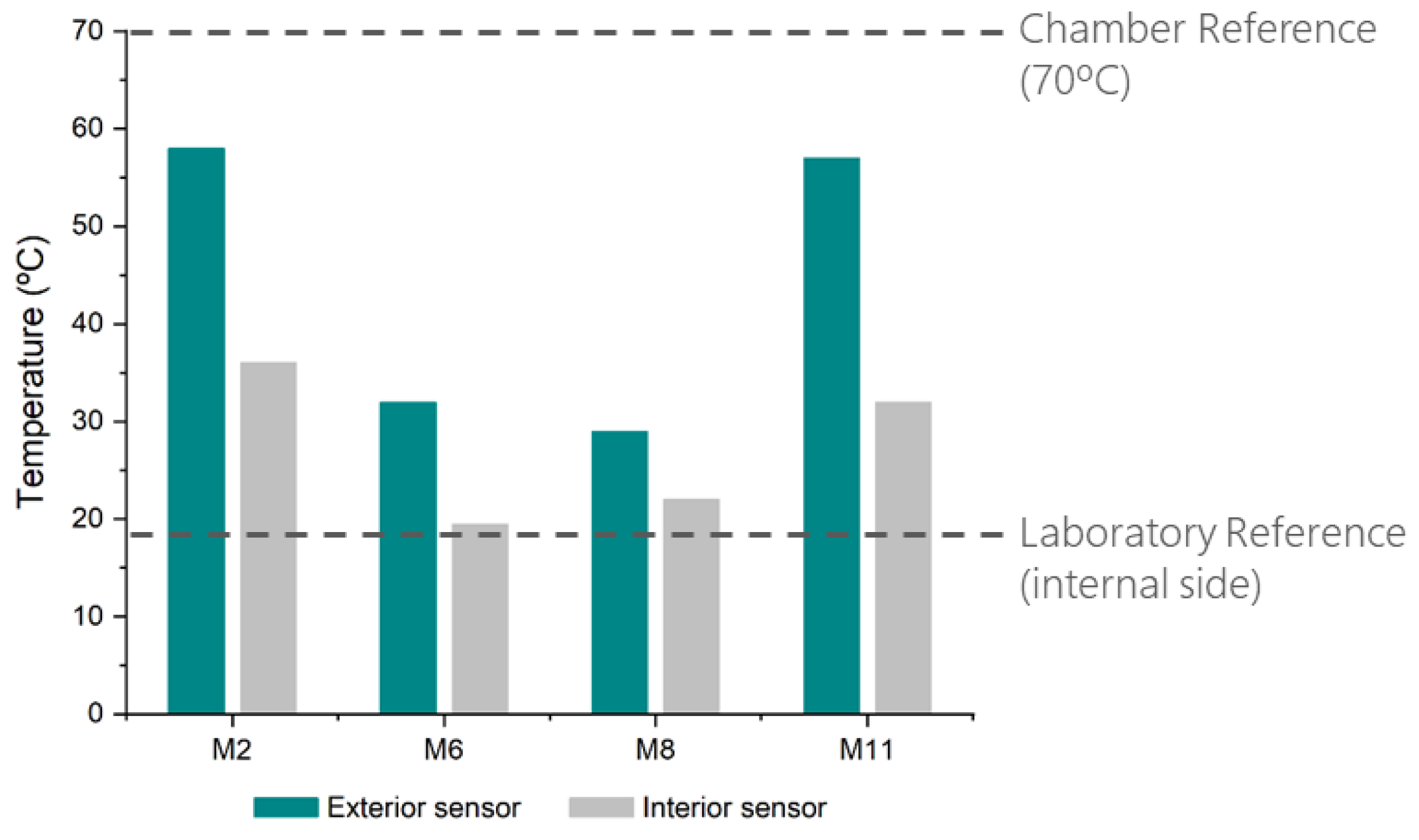

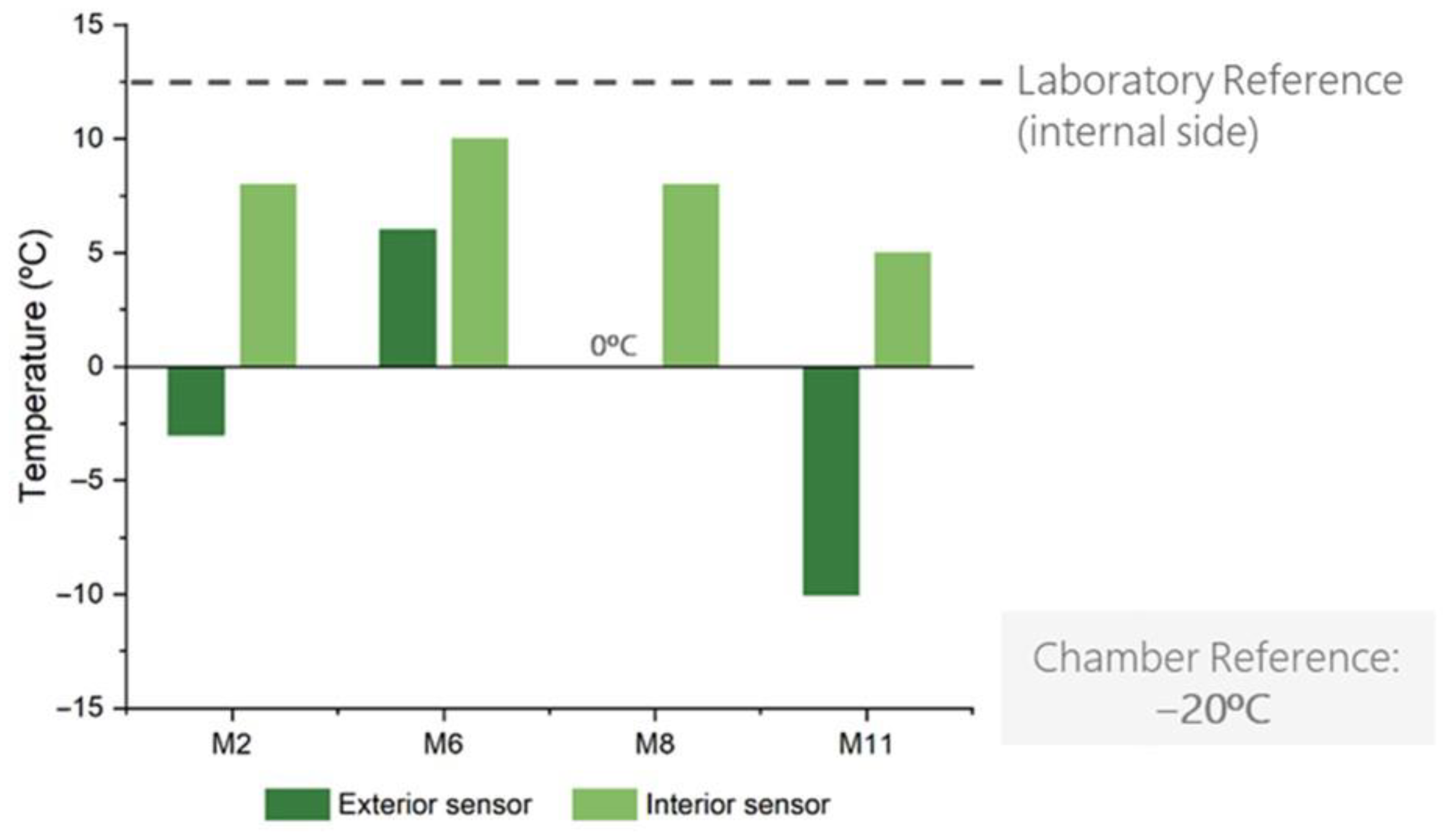

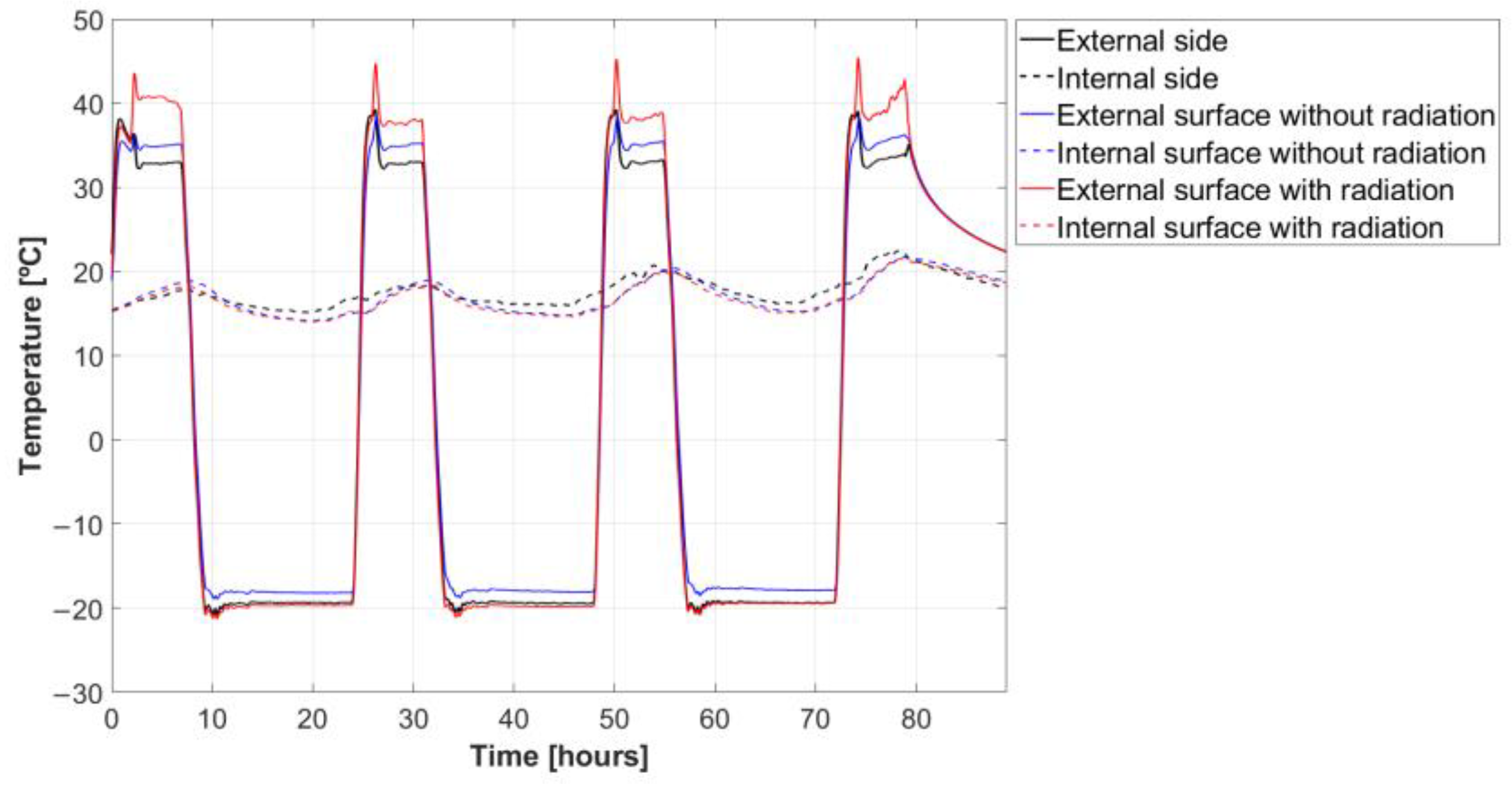

3.2.2. Temperature Measurements during Solar Radiation Cycles

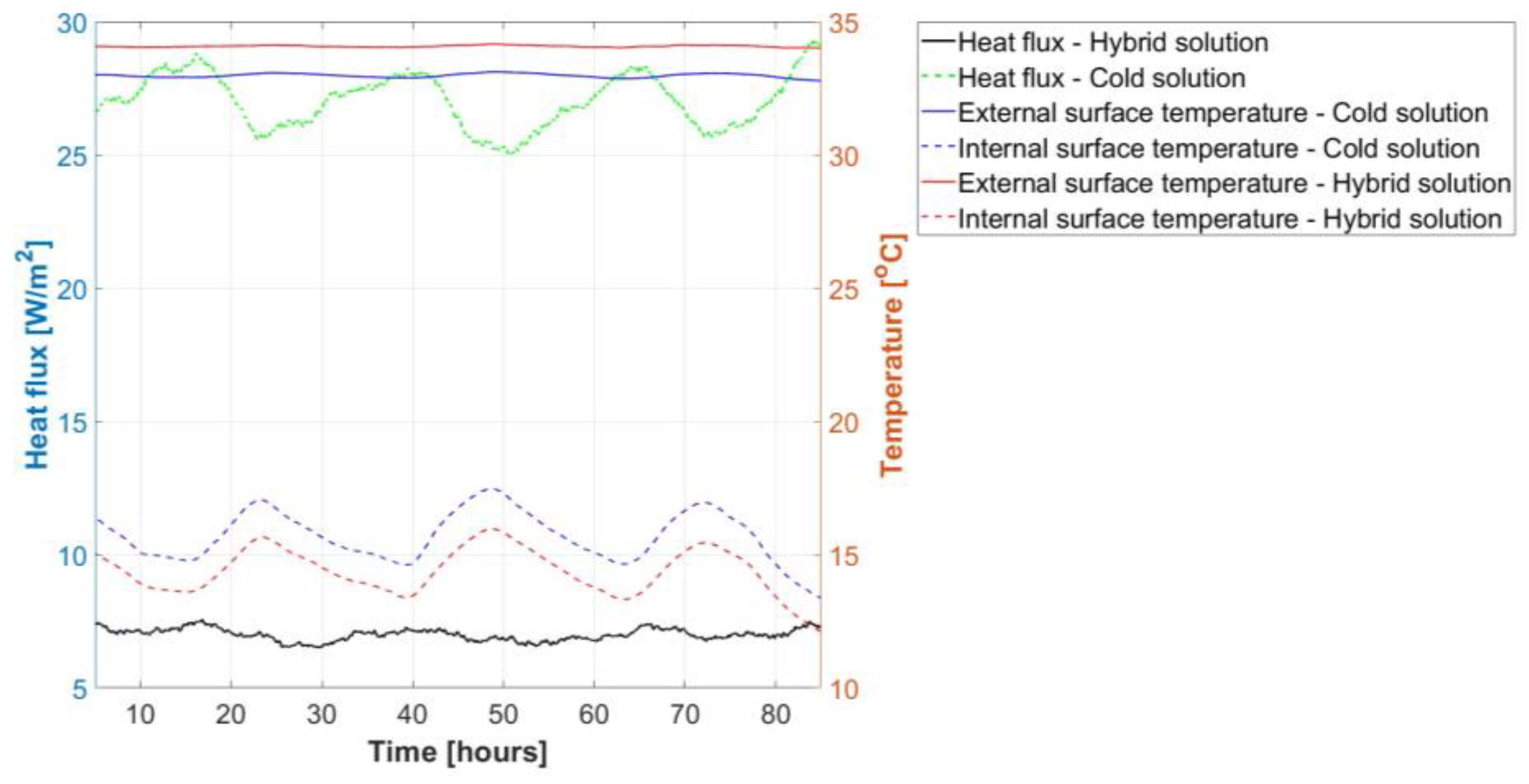

3.2.3. Determination of the Thermal Transmission Coefficient, U-Value

3.2.4. Visual Inspection

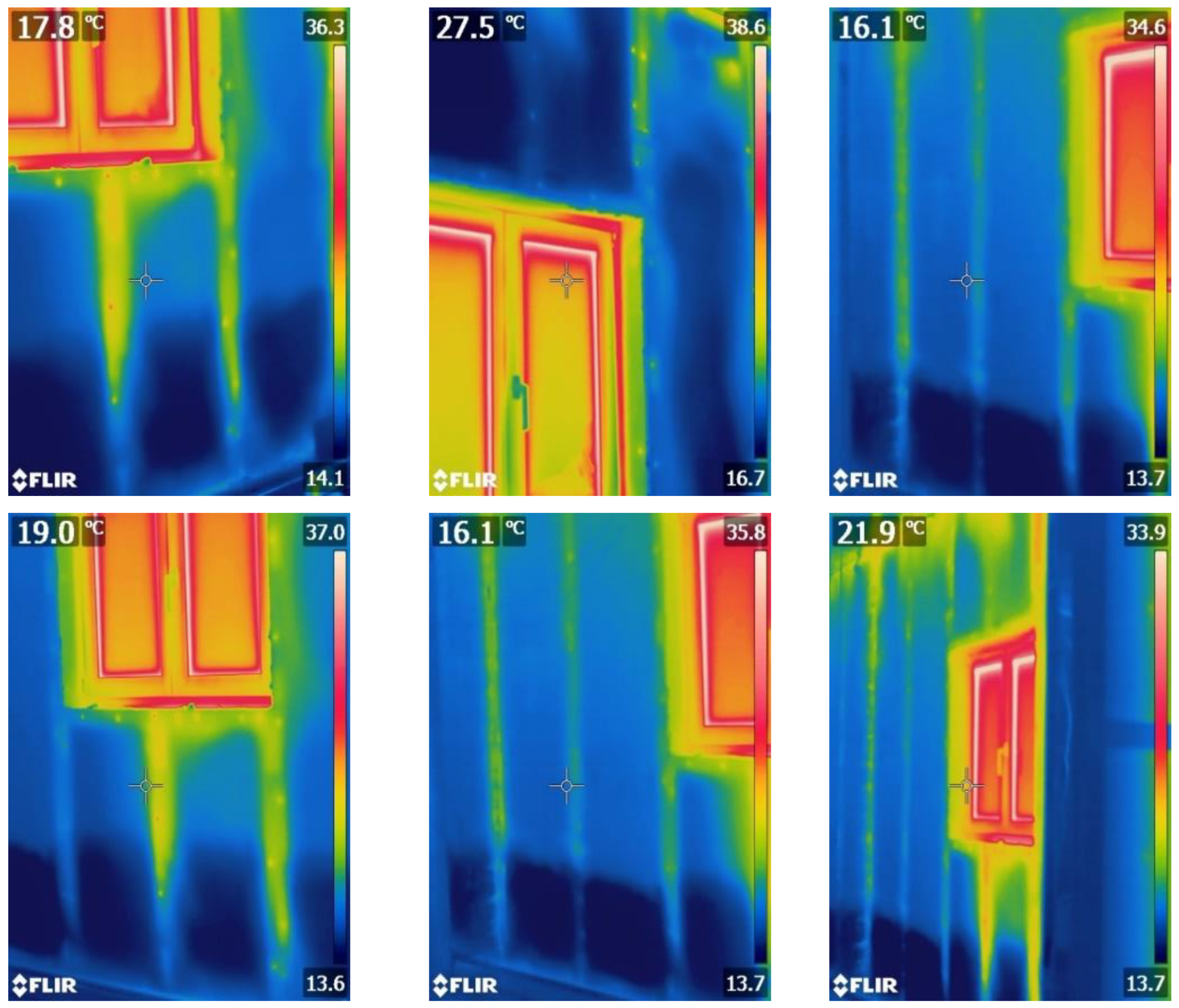

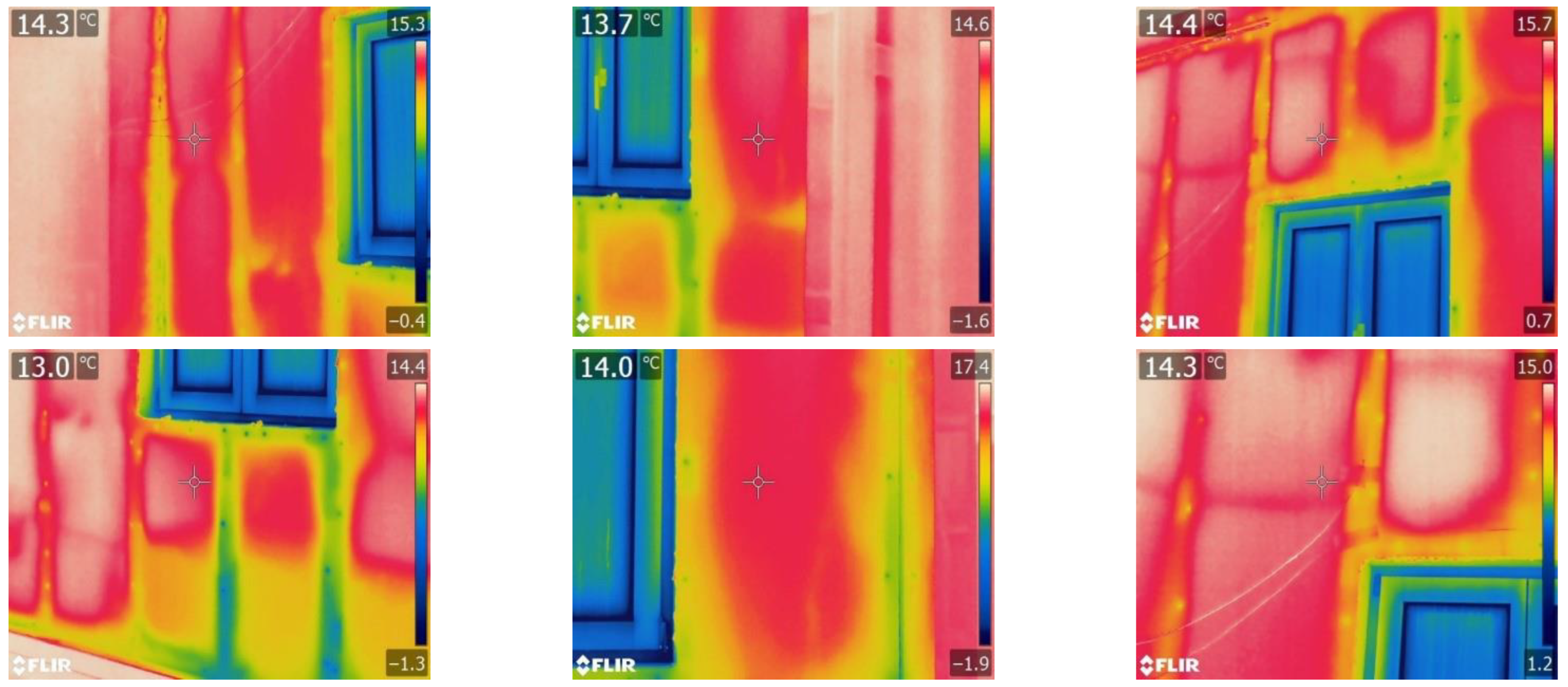

3.2.5. Thermographic Analysis

4. Discussion

4.1. Main Findings

4.2. Limitations and Advantages

5. Conclusions

- The sensors used in the integrated monitoring system proved to be efficient. The results show that the measurements with the printed sensors followed the expected variation of each test cycle; they were also consistent with the pattern of the reference sensors (SHT). Furthermore, the monitoring system was capable of evaluating the thermal gradients and the presence of water infiltration that occurred during the tests.

- The innovative profile developed proved to be stable during the hygrothermal cycles. No failures or defects such as deformations, warping, or distortions that could compromise the hygrothermal behavior of the system occurred. Thus, the stability of the innovative profiles is considered validated from the point of view of hygrothermal behavior. Wind resistance tests were performed for a maximum pressure of 3000 Pa, as well as impact tests of 10 J (not presented in this paper), and the wall kept its structural integrity.

- The hybrid LSF constructive solution using an external thermal insulation composite system applied to the OSB layer leads to more stable temperatures on the inner surface. On the other hand, this constructive solution resulted in a higher external surface temperature than the solution without ETICS, leading to higher levels of stress for the rendering system.

- The results during the accelerated ageing cycles under solar radiation simulation show that the incidence of solar radiation may lead to surface temperatures 5 °C higher compared to the surface without the incidence of direct solar radiation, even using a light color.

- The thermographic study and the in situ determination of the U-value reveal that the use of an ETICS system is essential to minimize the effect of thermal bridges caused by LSF profiles. The U-value of the hybrid constructive solution is, as expected, lower than the cold constructive solution. Moreover, the thermograms showed higher heat transfer rates in the profile zone of the cold constructive solution than the profile zone of the hybrid constructive solution.

- Additionally, the thermographic study confirmed the presence of water in the bottom of the test specimen. This indicates that the wall became wet due to capillary action, as indicated by the readings from the printed sensors installed in this area of the test specimen. Consequently, the evidence obtained from the thermographic study supports and validates the results obtained from the sensors developed.

- One of the weaknesses of the wall is the singularities associated with the window installation. The thermograms clearly show the thermal bridges created in the wall-window junctions. The window in the LSF was installed normally, with no difficulties arising in its execution. No water penetration was registered. However, it is highly recommended to cover the window frame with insulation or to fit the window with the plane of the wall insulation in order to minimize the installation thermal bridges.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Atsonios, I.A.; Mandilaras, I.D.; Kontogeorgos, D.A.; Founti, M.A. Two new methods for the in-situ measurement of the overall thermal transmittance of cold frame lightweight steel-framed walls. Energy Build. 2018, 170, 183–194. [Google Scholar] [CrossRef]

- Soliman, A.; Hafeez, G.; Erkmen, E.; Ganesan, R.; Ouf, M.; Hammad, A.; Eicker, U.; Moselhi, O. Innovative construction material technologies for sustainable and resilient civil infrastructure. Mater. Today Proc. 2022, 60, 365–372. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Ren, D. Quantitative study on external benefits of prefabricated buildings: From perspectives of economy, environment, and society. Sustain. Cities Soc. 2022, 86, 104132. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Gao, W.; Kuroki, S. Life cycle environmental and cost performance of prefabricated buildings. Sustainability 2020, 12, 2609. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, D.; Tian, Z.; Guo, Q. Factors influencing construction time performance of prefabricated house building: A multi-case study. Habitat Int. 2023, 131, 102731. [Google Scholar] [CrossRef]

- Navaratnam, S.; Satheeskumar, A.; Zhang, G.; Nguyen, K.; Venkatesan, S.; Poologanathan, K. The challenges confronting the growth of sustainable prefabricated building construction in Australia: Construction industry views. J. Build. Eng. 2022, 48, 103935. [Google Scholar] [CrossRef]

- Tavares, V.; Gregory, J.; Kirchain, R.; Freire, F. What is the potential for prefabricated buildings to decrease costs and contribute to meeting EU environmental targets? Build. Environ. 2021, 206, 108382. [Google Scholar] [CrossRef]

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Pan, W.; Zhang, Z. Benchmarking the sustainability of concrete and steel modular construction for buildings in urban development. Sustain. Cities Soc. 2023, 90, 104400. [Google Scholar] [CrossRef]

- Lim, Y.W.; Ling, P.C.H.; Tan, C.S.; Chong, H.Y.; Thurairajah, A. Planning and coordination of modular construction. Autom. Constr. 2022, 141, 104455. [Google Scholar] [CrossRef]

- Roque, E.; Vicente, R.; Almeida, R.M.S.F.; Ferreira, V.M. Energy consumption in intermittently heated residential buildings: Light Steel Framing vs hollow brick masonry constructive system. J. Build. Eng. 2021, 43, 103024. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Soares, N.; Santos, P.; Gervásio, H.; Costa, J.J.; Simões da Silva, L. Energy efficiency and thermal performance of lightweight steel-framed (LSF) construction: A review. Renew. Sustain. Energy Rev. 2017, 78, 194–209. [Google Scholar] [CrossRef]

- Roque, E.; Santos, P. The effectiveness of thermal insulation in lightweight steel-framedwalls with respect to its position. Buildings 2017, 7, 13. [Google Scholar] [CrossRef]

- Perera, D.; Poologanathan, K.; Gillie, M.; Gatheeshgar, P.; Sherlock, P.; Nanayakkara, S.M.A.; Konthesingha, K.M.C. Fire performance of cold, warm and hybrid LSF wall panels using numerical studies. Thin-Walled Struct. 2020, 157, 107109. [Google Scholar] [CrossRef]

- Zhan, Q.; Xiao, Y.; Musso, F.; Zhang, L. Assessing the hygrothermal performance of typical lightweight steel-framed wall assemblies in hot-humid climate regions by monitoring and numerical analysis. Build. Environ. 2021, 188, 107512. [Google Scholar] [CrossRef]

- Zhan, Q.; Pungercar, V.; Musso, F.; Ni, H.; Xiao, Y. Hygrothermal investigation of lightweight steel-framed wall assemblies in hot-humid climates: Measurement and simulation validation. J. Build. Eng. 2021, 42, 103044. [Google Scholar] [CrossRef]

- Santos, P.; Mateus, D. Experimental assessment of thermal break strips performance in load-bearing and non-load-bearing LSF walls. J. Build. Eng. 2020, 32, 101693. [Google Scholar] [CrossRef]

- De Angelis, E.; Serra, E. Light steel-frame walls: Thermal insulation performances and thermal bridges. Energy Procedia 2014, 45, 362–371. [Google Scholar] [CrossRef]

- Perera, D.; Upasiri, I.R.; Poologanathan, K.; Gatheeshgar, P.; Sherlock, P.; Hewavitharana, T.; Suntharalingam, T. Energy performance of fire rated LSF walls under UK climate conditions. J. Build. Eng. 2021, 44, 103293. [Google Scholar] [CrossRef]

- Brambilla, A.; Sangiorgio, A. Mould growth in energy efficient buildings: Causes, health implications and strategies to mitigate the risk. Renew. Sustain. Energy Rev. 2020, 132, 110093. [Google Scholar] [CrossRef]

- Gradeci, K.; Labonnote, N.; Time, B.; Köhler, J. Mould growth criteria and design avoidance approaches in wood-based materials—A systematic review. Constr. Build. Mater. 2017, 150, 77–88. [Google Scholar] [CrossRef]

- Orlik-Kozdoń, B. Microclimate conditions in rooms: Their impact on mold development in buildings. Energies 2020, 13, 4492. [Google Scholar] [CrossRef]

- Hancock, G.J. Cold-formed steel structures. J. Constr. Steel Res. 2003, 59, 473–487. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Parker, S.; Askew, K.; Poologanathan, K.; Navaratnam, S.; McIntosh, A.; Widdowfield Small, D. Flexural behaviour and design of modular construction optimised beams. Structures 2021, 32, 1048–1068. [Google Scholar] [CrossRef]

- Hadjipantelis, N.; Gardner, L.; Wadee, M.A. Prestressed cold-formed steel beams: Concept and mechanical behaviour. Eng. Struct. 2018, 172, 1057–1072. [Google Scholar] [CrossRef]

- Hadjipantelis, N.; Gardner, L.; Wadee, M.A. Finite-Element Modeling of Prestressed Cold-Formed Steel Beams. J. Struct. Eng. 2019, 145, 04019100. [Google Scholar] [CrossRef]

- Ye, J.; Hajirasouliha, I.; Becque, J.; Pilakoutas, K. Development of more efficient cold-formed steel channel sections in bending. Thin-Walled Struct. 2016, 101, 1–13. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Poologanathan, K.; Gunalan, S.; Nagaratnam, B.; Tsavdaridis, K.D.; Ye, J. Structural behaviour of optimized cold-formed steel beams. Steel Constr. 2020, 13, 294–304. [Google Scholar] [CrossRef]

- Keerthan, P.; Mahendran, M. Improved shear design rules of cold-formed steel beams. Eng. Struct. 2015, 99, 603–615. [Google Scholar] [CrossRef]

- Keerthan, P.; Mahendran, M.; Hughes, D. Numerical studies and design of hollow flange channel beams subject to combined bending and shear actions. Eng. Struct. 2014, 75, 197–212. [Google Scholar] [CrossRef][Green Version]

- Perera, N.; Mahendran, M. Finite element analysis and design for section moment capacities of hollow flange steel plate girders. Thin-Walled Struct. 2019, 135, 356–375. [Google Scholar] [CrossRef]

- Poologanathan, K.; Mahen, M. Numerical Modeling of LiteSteel Beams Subject to Shear. J. Struct. Eng. 2011, 137, 1428–1439. [Google Scholar] [CrossRef]

- Anapayan, T.; Mahendran, M.; Mahaarachchi, D. Section moment capacity tests of LiteSteel beams. Thin-Walled Struct. 2011, 49, 502–512. [Google Scholar] [CrossRef]

- Siahaan, R.; Keerthan, P.; Mahendran, M. Finite element modeling of rivet fastened rectangular hollow flange channel beams subject to local buckling. Eng. Struct. 2016, 126, 311–327. [Google Scholar] [CrossRef]

- Steau, E.; Mahendran, M.; Keerthan, P. Web crippling tests of Rivet Fastened Rectangular Hollow Flange Channel Beams under Two Flange Load Cases. Thin-Walled Struct. 2015, 95, 262–275. [Google Scholar] [CrossRef]

- Roy, K.; Ting, T.C.H.; Lau, H.H.; Lim, J.B.P. Nonlinear behaviour of back-to-back gapped built-up cold-formed steel channel sections under compression. J. Constr. Steel Res. 2018, 147, 257–276. [Google Scholar] [CrossRef]

- Roy, K.; Lau, H.H.; Ting, T.C.H.; Chen, B.; Lim, J.B.P. Flexural capacity of gapped built-up cold-formed steel channel sections including web stiffeners. J. Constr. Steel Res. 2020, 172, 106154. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Zayed, T. A study of literature in modular integrated construction—Critical review and future directions. J. Clean. Prod. 2020, 277, 124044. [Google Scholar] [CrossRef]

- Zhan, Q.; Xiao, Y.; Zhang, L.; Lin, Z.; Zou, Y.; Liao, W. Hygrothermal performance optimization of lightweight steel-framed wall assemblies in hot–humid regions using orthogonal experimental design and a validated simulation model. Build. Environ. 2023, 236, 110262. [Google Scholar] [CrossRef]

- Martins, J.A.; Gomes, C.M.; Fontanini, P.; Dornelles, K. Comparative analysis on thermal performance of MgO and fiber cement boards applied to light steel frame building systems. J. Build. Eng. 2019, 21, 312–316. [Google Scholar] [CrossRef]

- Friis, N.K.; Møller, E.B.; Lading, T. Hygrothermal assessment of external walls in Arctic climates: Field measurements and simulations of a test facility. Build. Environ. 2023, 238, 110347. [Google Scholar] [CrossRef]

- Santos, P.; Gonçalves, M.; Martins, C.; Soares, N.; Costa, J.J. Thermal transmittance of lightweight steel framed walls: Experimental versus numerical and analytical approaches. J. Build. Eng. 2019, 25, 100776. [Google Scholar] [CrossRef]

- EOTA External Thermal Insulation Composite Systems (Etics) with Renderings. 2019. Available online: https://www.eota.eu/download?file=/2014/14-04-0083/for%20ojeu/ead%20040083-00-0404_ojeu2020.pdf (accessed on 2 September 2022).

- (DIN) DIN 75220; Ageing of Automotive Components in Solar Simulation Units. Deutsches Institut fur Normung E.V.: Berlin, Germany, 1992.

- ISO 9869-1:2014; Thermal Insulation—Building Elements—Insitu Measurement of Thermal Resistance and Thermal Transmittance. Part 1: Heat Flow Meter Method. ISO: Geneva, Switzerland, 2014.

| Cold Frame Construction | Hybrid Construction | ||

|---|---|---|---|

| Component | Thickness [mm] | Component | Thickness [mm] |

| Gypsum board | 12.5 | Gypsum board | 12.5 |

| Mineral wool | 150 | Mineral wool | 150 |

| OSB | 12 | OSB | 12 |

| Rendering system | 2 | ETICS system with 40 mm of EPS | 45 |

| Item (Model) | Description | Output | Illustration |

|---|---|---|---|

| Climatic chamber (FitoClima 1000 EC 50) | Climatic chamber with 14.5 m3 of conditioned volume. Temperature range capacity of −20 to 150 °C (±5 °C) and humidity of 10–98% (±10%); Includes a water spraying system with 1 ± 0.1 L/(min·m2). This chamber is annually calibrated to accomplish the test procedure requirements. | Temperature control, relative humidity control and water spraying. |  |

| Thermocouples (Type T thermocouples) | Thermocouple with temperature range between −270 to 370 °C and accuracy ± 1.0 °C or 0.75% | Temperature |  |

| Heat flux sensor (FHF02SC-02) | Heat flux sensor with a measurement range (−10 to +10) × 103 W/m2, a sensitivity of 5.5 × 10−6 V/(W/m2) and an uncertainty of calibration of 5% | Heat flux (W/m2) and temperature (°C) |  |

| Data logger (Keysight 34970A) | Data acquisition unit | Data files |  |

| Infrared camera (FLIR T630sc) | Infrared camera with accuracy: ±1 °C or ±1% at 25 °C; object temperature range: −40 °C to 150 °C; and resolution: 640 × 480 pixels | Infrared thermograms |  |

| Solar radiation simulation system (BF SUN 2500 W) | BF SUN 2500 W with a Osram HMI 2500 W lamp, and an Electronic Power Supply Unit | Solar radiation: UV-C, UV-B, UV-A, visible and infrared radiation |  |

| Test Specimen | λ23 °C [W/(m·°C)] | R23 °C [m2·°C/W] |

|---|---|---|

| Innovative LSF profile + EPS | 0.16684 | 1.271 |

| Current LSF profile + EPS | 0.11487 | 1.511 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jerónimo, R.; Gonçalves, M.; Furtado, C.; Rodrigues, K.; Ferreira, C.; Simões, N. Experimental Assessment and Validation of the Hygrothermal Behaviour of an Innovative Light Steel Frame (LSF) Wall Incorporating a Monitoring System. Buildings 2023, 13, 2509. https://doi.org/10.3390/buildings13102509

Jerónimo R, Gonçalves M, Furtado C, Rodrigues K, Ferreira C, Simões N. Experimental Assessment and Validation of the Hygrothermal Behaviour of an Innovative Light Steel Frame (LSF) Wall Incorporating a Monitoring System. Buildings. 2023; 13(10):2509. https://doi.org/10.3390/buildings13102509

Chicago/Turabian StyleJerónimo, Rui, Márcio Gonçalves, Cristina Furtado, Kevin Rodrigues, César Ferreira, and Nuno Simões. 2023. "Experimental Assessment and Validation of the Hygrothermal Behaviour of an Innovative Light Steel Frame (LSF) Wall Incorporating a Monitoring System" Buildings 13, no. 10: 2509. https://doi.org/10.3390/buildings13102509

APA StyleJerónimo, R., Gonçalves, M., Furtado, C., Rodrigues, K., Ferreira, C., & Simões, N. (2023). Experimental Assessment and Validation of the Hygrothermal Behaviour of an Innovative Light Steel Frame (LSF) Wall Incorporating a Monitoring System. Buildings, 13(10), 2509. https://doi.org/10.3390/buildings13102509