Abstract

In this study, the two eco-friendly flame retardants of the polymeric type (PA-PEI) and monomeric type (PA-Arg) phytate amine complexes were prepared via the ionic reaction of polyethylenimine (PEI) or arginine (Arg), respectively, with phytic acid in an aqueous solution. The chemical structure and thermal stability of PA-PEI and PA-Arg were characterized by Fourier-transform infrared spectroscopy (FTIR) and thermogravimetric analysis (TGA). In order to improve the flame retardancy of the polylactic acid (PLA)/polybutylene succinate (PBS) biocomposites (P/15B-based biocomposites), the flame retardants PA-PEI and PA-Arg were embedded into P/15B by thermal blending procedures, respectively, to obtain P/15B/PA-PEI series and P/15B/PA-Arg series biocomposites. The TGA analyses demonstrated that incorporating PA-PEI or PA-Arg into the P/15B polymer enhances the char residues in these P/15B biocomposites. The XRD and SEM analyses of the P/15B/PA-PEI series and P/15B/PA-Arg series suggested the PA-PEI and PA-Arg were embedded into the P/15B polymer matrixes, respectively. The mechanical results showed that P/15B/PA-Arg series exhibited higher values than the P/15B/PA-PEI series biocomposite, which were associated with less roughness of P/15B/PA-Arg than that of the P/15B/PA-PEI series. The flammability results of the P/15B/PA-PEI series and P/15B/PA-Arg series biocomposites exhibited a V-2 level in UL94 vertical test. Further, the fire resistance performance of P/15B-based biocomposites was enhanced by incorporating PA-PEI or PA-Arg into the P/15B matrix through the analyses of the Cone calorimeter test (CCT), as a comparison with neat P/15B. The peak heat release rate (pHRR), the total heat release rate (THR), and char residues of P/15B/15PA-Arg biocomposite were significantly improved to 280.26 kW/m2, 107.89 MJ/m2, and 10.4%, respectively. The enhancement of the P/15B-based composites’ fire resistance is attributed to the interplay effect on the catalytic and condensed effect on the thermal decomposition of PA-PEI or PA-Arg in P/15B biocomposites. The resultant eco-friendly flame-retardant P/15B biocomposites reported in this study can be widely applied in various fields, including construction, electronic appliances, and other fields.

1. Introduction

In the last decades, the global incensement of urbanization has expanded, reaching 54% in 2018, which is beneficial to the infrastructure requirements of the construction industry [1]. Different types of plastics, including high-density polyethylene (HDPE), polyvinyl chloride (PVC), and expanded polystyrene (EPS), are commonly used in the construction industry due to their ease of processing, durability, and relatively low manufacturing cost for various applications. According to a report from Transparency Market Research, the construction industry is also one of the disposable waste contributors; the amount of worldwide construction waste will reach 2.2 billion tons by the year 2025 [2]. With the environmental impact of the exploitation of petroleum and insufficient degradation of petroleum polymers, biodegradable plastic materials, which degrade naturally in a reasonable amount of time, have attracted widespread attention [3,4,5].

Among the major known types of biodegradable plastic materials, poly(lactic acid) (PLA) is regarded as a class of promising biodegradable plastic to replace traditional petroleum-based polymers due to its specific semicrystalline nature, great tensile strength, and ease of processing. Although PLA is a highly versatile biodegradable plastic material, its inherent brittleness and weak heat resistance features are considered major disadvantages. Thus, blending with various ductile polymers has previously been reported as an effective method for improving the toughness of PLA [6,7,8,9]. Among these modified systems, with polybutylene succinate (PBS) being a commercially available bio-based and biodegradable polymer [10,11], much research has been carried out with PLA/PBS blends in the past decades to explore its potential applications in building, transportation, or electrical appliance [12,13,14,15].

Furthermore, the backbone chemical structures of PLA and PBS are constructed by the saturated alkane structure, affecting the flame-retardant properties of the biopolymers [4,14]. Thus, developing effective strategies for improving the fire and flammability performance of PLA/PBS composites is a stimulating challenge. At present, common flame retardants, divided into halogen-based, and non-halogen-based flame retardants, have also been widely studied on the flame retardancy of biopolymer composites [16,17]. While halogen-containing flame retardants can provide excellent flame-retardant effects, they are also associated with harmful risks of smoke and toxic and corrosive gases after combustion in products [18,19,20]. Based on the perspectives of eco-environmental and health considerations, while the development of eco-friendly-based flame retardants has been reported in thermoplastic composites [21,22,23], it provides another way of enhancing the flame retardancy of biopolymer composites [24,25]. Environmental-friendly flame retardants, such as phosphorus-based, nitrogen-based, silicon-based, or inorganic additives, have been brought into biopolymer composites even to this day. Their effects on the results of the mechanical properties and flame-retardant ability are investigated thoroughly [17,26,27,28].

Phytic acid is considered one of the bio-based flame-retardant candidates not only due to its high phosphorus content but also because of its abundance in plant seeds [29]. For instance, Ye et al. reported phytic acid (PA) and furfurylamine (FA)-containing flame retardants (known as PF) for PLA. Their results showed that incorporating PF into the PLA matrix improved the UL-94 flame retardancy and the limiting oxygen index (LOI) values. The calorimeter test results confirmed that PF could suppress the heat release and combustion of PLA in the burning process [30]. Meanwhile, Wu et al. prepared a biobased flame retardant (known as PA-TA) via the ionic reaction of phytic acid (PA) and taurine (TA) and applied it to PLA. They found that adding 5.0 wt% PA-TA could decrease the peak heat release rate (pHRR) and the total heat release rate (THR) of PLA composites [31]. Costes et al. prepared a bio-based flame retardant combined with phytic acid and lignin and mixed it with PLA through a simple melting process. Their studies exhibited the decrement of the peak of the heat release rate (pHRR) during the cone calorimeter test; the V-2 classification in the UL-94 test was evidenced [32]. Liu et al. prepared cotton fabrics with polyethylenimine (PEI)/melamine and PA (known as BL) by a layer-by-layer deposition process. Their reports demonstrated the BL-treated cotton fabrics exhibited self-extinguishing behavior in the vertical burning tests, and the decrement of the pHRR of the BL-treated cotton fabrics in contrast to that of the original cotton [33].

Based on the reports mentioned above, the phytate amine complexes, made by phytic acid and amine group, exhibited effective flame retardancy in bio-polymer composites, as in thermoplastic composites. The fundamental structure of amino acids consisting of the amino and carboxyl groups is considered a potential amine source of the phytate amine complexes. This study selected arginine (Arg) as the amino acid mode target among the amino acid materials. In addition, comparisons of the flame-retardant effect between the polymeric type and monomeric type phytate amine complexes are rarely observed in the literature. Therefore, in this study, polyethylenimine (PEI) and arginine (Arg) were defined as the polymeric and monomeric amine sources, respectively. The structure analysis of two phytate amine complexes (PA-PEI and PA-Arg), prepared via the ionic reaction of amine raw materials with phytic acid in an aqueous solution, has been confirmed by FT-IR and TGA. Furthermore, the influence of two phytate amine flame retardants (PA-PEI and PA-Arg) on the thermal stability, mechanical, and flame-retardant performance of the PLA/PBS blends were investigated systematically.

2. Materials and Methods

2.1. Materials

PLA (4032D, Mw = 158,000 g.mol−1 equiv. PS) and PBS (Bionolle™ 1001, Mw = 260,000 g.mol−1 equiv. PS), provided by NatureWorks LLC and Mitsubishi Chemical Corporation, respectively, were dried in an air flow oven before use. Phytic acid solution (PA, 50% in H2O), polyethylenediamine (PEI), and Arginine (99%) were supplied by Sigma Aldrich and used as received. The diatomite used in the experiments was obtained from the Wurih Brewery, Taiwan Tobacco and Liquor Corporation, Taichung, Taiwan. Due to the diatomite was confirmed not only as a friendly and low-cost flame-retardant additive but also as a compatibilizer in the high-density polyethylene composites through the silane coupling agent modification [22]. Therefore, the silane-coupling agents-treated diatomite (SDE) acted as the interfacial compatibilizer in these P/15B biocomposites, and SDE was prepared according to methods previously developed in the literature [22].

2.2. Sample Preparation

2.2.1. Synthesis of PA-PEI

The synthesis route of PA-PEI was performed by following a slightly modified literature procedure [21]. Briefly, in a two-neck round-bottom flask with a condenser pipe, PEI (1.00 g) was dissolved in 50 mL acetone at 60 °C while stirring for 10 min under an atmosphere. Then, a diluted PA solution, prepared by 1.00 g PA and 20 mL acetone, was dropped slowly into the flask with stirring for 4 h. The mixture was cooled down to room temperature, placed on the stainless-steel mold, and dried at 60 °C in the oven. Finally, the product obtained (PA-PEI) was collected and ground into a fine powder for further use.

2.2.2. Synthesis of PA-Arg

The synthesis route of PA-Arg was performed by following a slightly modified literature procedure [30]. Briefly, in a two-neck round-bottom flask with a condenser pipe, Arg (1.00 g) was dispersed in 50 mL acetone at 60 °C while stirring for 10 min under an atmosphere. Then, a diluted PA solution, prepared by 1.00 g PA and 20 mL acetone, was dropped slowly into the flask with stirring for 4 h. The mixture was cooled down to room temperature, placed on the stainless-steel mold, and dried at 60 °C in the oven. Finally, the product obtained (PA-Arg) was collected and ground into a fine powder for further use.

2.2.3. Preparation of the Flame Retardant P/15B Based Biocomposites

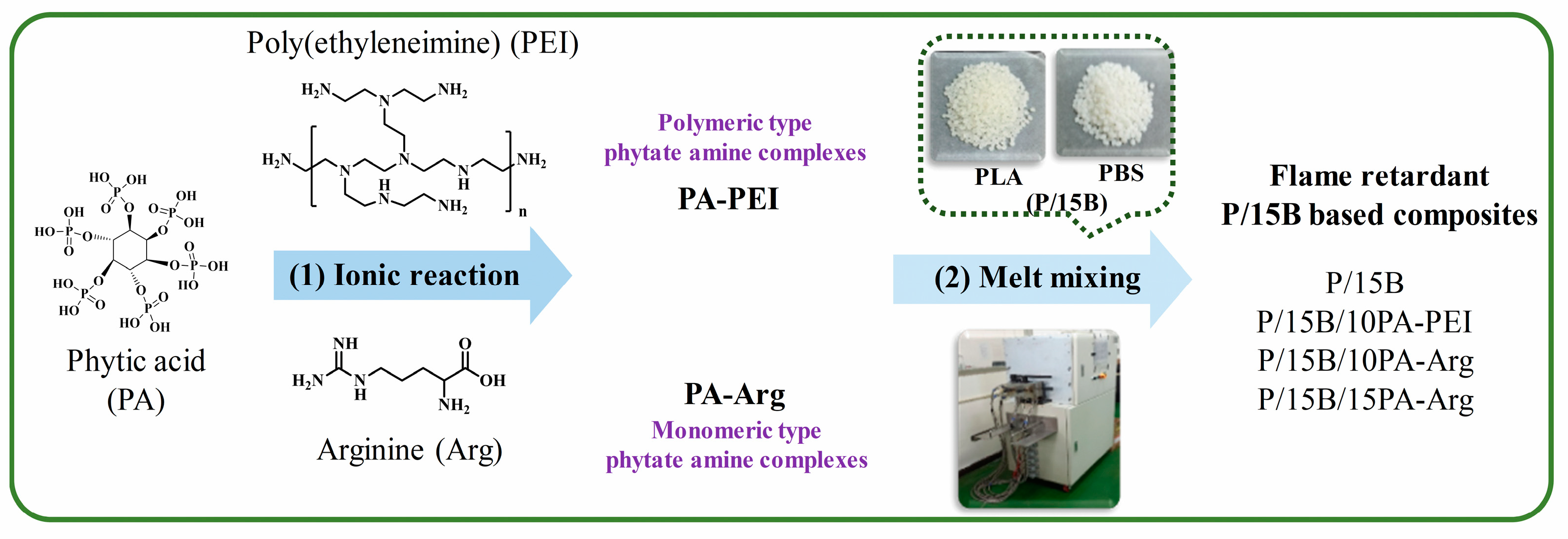

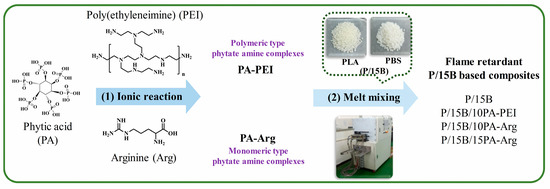

As shown in Figure 1, the general preparation process of the bio-based composites is as follows: First, the PLA, PBS, PA-PEI, PA-Arg, and SDE were dried at 80 °C in a vacuum oven for 12 h. Then, both PLA and PBS pellets were pre-melted in a counter-rotating internal mixer (Brabender PL2000, Duisburg, Germany) at 175 °C with a rotation speed of 50 rpm, followed by adding SDE and flame-retardant additives (PA-PEI or PA-Arg). The mixing chamber (volume: 50 cm3) was filled with 50 g total mass, corresponding to a filling ratio of 80%. After being well blended for 3 min, the composite was granulated. For the purpose of characterization, the test samples of the PLA composite were prepared by compression molding at 170 °C for 5 min (under 1.47 MPa), for 3 min (under 2.94 MPa) for 1 min (under 5.88 MPa), in sequence. The formulation (wt%) of the sample is shown in Table 1.

Figure 1.

The preparation process of the flame-retardant P/15B-based composites.

Table 1.

Formulation of the resulting P/15B-based biocomposites.

2.3. Characterization

2.3.1. Fourier-Transform Infrared Analysis (FTIR)

The Fourier-transform infrared (FTIR) spectroscopy experiments were performed using the Perkin Elmer Paragon 500 (Perkin Elmer, Inc., Waltham, MA, USA). All samples were blended with KBr to obtain pellets and scanned ranging from 4000 cm−1 to 500 cm−1 with a resolution of 4 cm−1 and a scanning number of 32.

2.3.2. X-ray Diffraction (XRD)

XRD analysis of composites was executed to find the crystallinity of biocomposites at an angular incidence of 5° to 40° using a PANalytical X’Pert PRO (Malvern Panalytical Ltd., Almelo, Netherlands) using Cu-K radiation (λ = 0.154 nm) at a scanning rate of 10°/min.

2.3.3. Scanning Electron Microscopy (SEM)

Scanning Electron Microscopy (SEM) (JEOLJSM-6700F, Japan Electron Optics Laboratory Co., Ltd., Tokyo, Japan) was used to observe the surface morphology of P/15B biocomposites with flame retardant additives of PA-PEI or PA-Arg contents.

2.3.4. Thermogravimetric Analysis (TGA)

The thermal behavior was determined by TGA (TGA Q50, TA Instruments, Inc., New Castle, DE, USA). Initially, all samples were placed in an oven at 70 °C to remove water traces and then scanned from 50 to 600 °C at a heating rate of 10 °C/min in the presence of nitrogen flow.

2.3.5. Mechanical Test

The tensile test was carried out according to the ASTM D368 test specification, and the obtained samples were conditioned at 65% RH and 23 °C until equilibrium moisture content was achieved before mechanical testing. The test piece was made into a dumbbell-shaped test piece in the size of 186 mm × 19 mm × 3 mm and tested with a load cell of 20 kN at a strain rate of 50 mm/min at room temperature by an Instron universal tester (HT-9102, Hung Ta Instrument Co., Ltd., Taichung, Taiwan). The impact strength was analyzed according to the ASTM D256 standard test methods for determining the Izod pendulum impact resistance of plastics, using an impact resistance testing machine, Model GT-70045-MDL (Gotech Testing Machines Inc., Taiwan). A total of five specimens of each material were used for testing, and the average values were calculated.

2.3.6. UL-94 Vertical Burning Test

The UL-94 vertical burning test was carried out according to the plastic flammability standard UL-94 issued by Underwriters Laboratories (ASTM D3801 standard). The dimensions of the samples were 130 × 13 × 3 mm3.

2.3.7. Cone Calorimeter Test (CCT)

The cone calorimeter test was carried out in accordance with ISO 5660 via Cone Calorimeter 4 (Toyoseiki, Tokyo, Japan) with a heat flux of 35 kW/m2 and sample size of 100 × 100 × 3 mm3.

3. Result and Discussions

3.1. Characterization of PA-PEI and PA-Arg

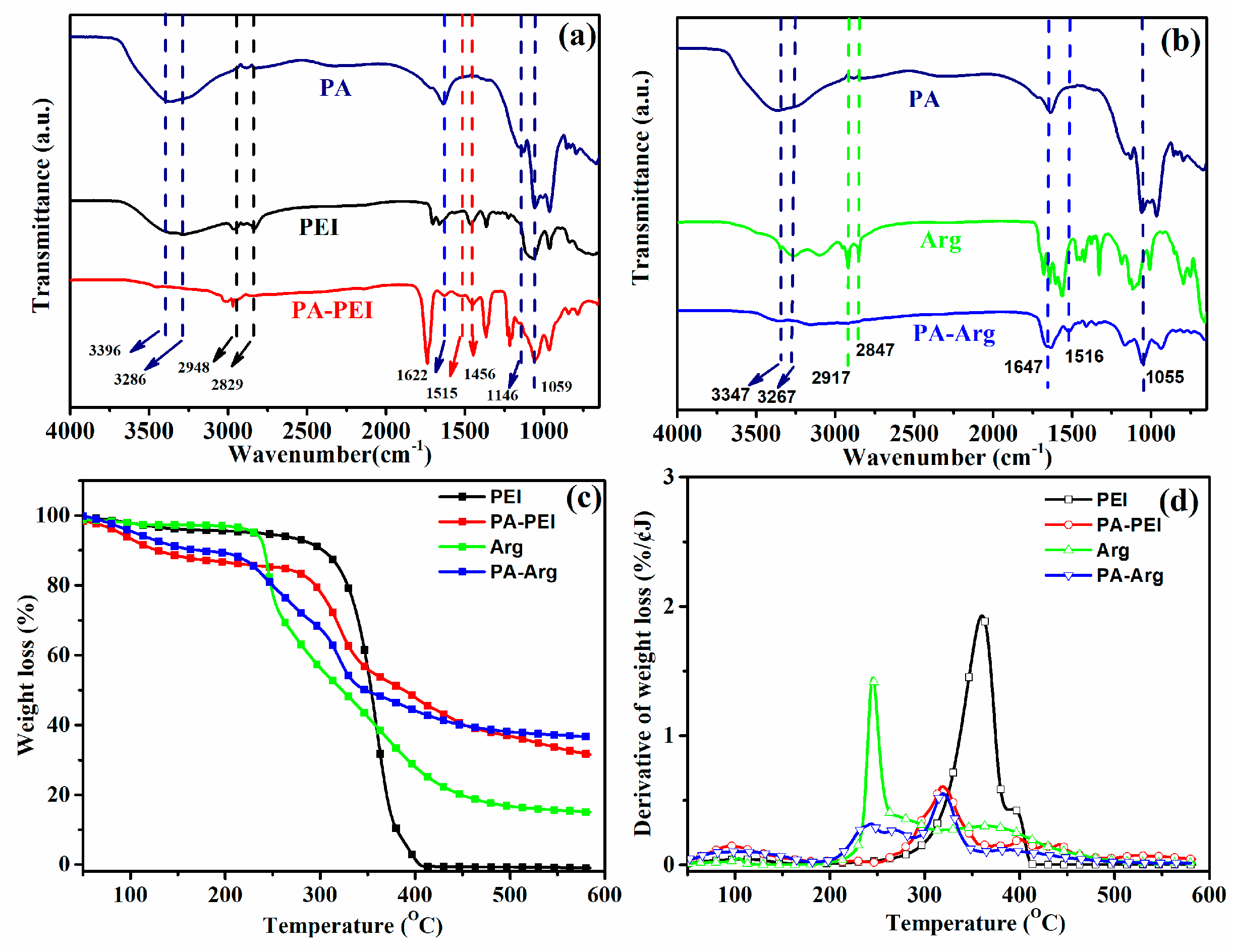

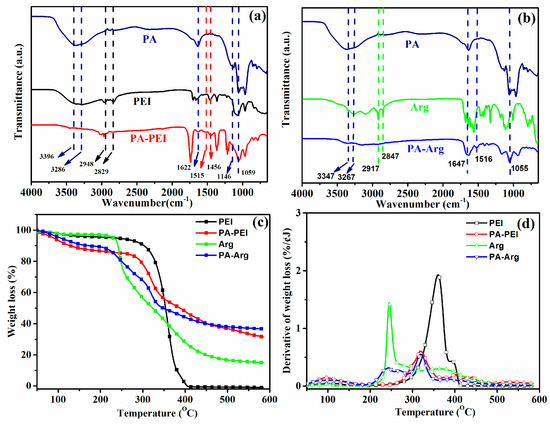

The chemical structure of PA-PEI and PA-Arg was confirmed by FTIR, as shown in Figure 2a. The FTIR analysis (Figure 2a) revealed that the peaks shown at 2852–2958 and 1458 cm−1 were assigned to the C-H and C-N stretching vibrations in the PA-PEI, which are derived from PEI [34]. The peaks at 1622 and 1059 cm−1 in PA-PEI could be ascribed to the stretching vibrations of P = O and P-O structures, respectively, originating from the PA group [35]. The characteristic peak at about 1515 cm−1 in the spectrum of PA-PEI was assigned to the NH3+ vibrational modes [36], resulting from the disappearance of CN stretching vibrations in the 3286 and 3396 cm−1. Figure 2b shows that the absorption peaks at 1647 and 1055 cm−1 resulted from the stretching vibrations of P=O and P-O, respectively [35,37]. The peaks of NH3+ structures in 1516 cm−1 were due to the vanishing of the N-H groups (3347 and 3267 cm−1) in arginine structures [36]. Therefore, the ionic complexation of PA-PEI or PA-Arg materials has been formed successfully according to the results of the FTIR spectrum.

Figure 2.

(a) FTIR spectrum of PA, PEI, PA-PEI (b) FTIR spectrum of PA, Arg, PA-Arg, (c) TGA and (d) DTG curves of PEI, PA-PEI, Arg, and PA-Arg under N2 conditions.

In addition, the thermal stability of PEI, PA-PEI, Arg, and PA-Arg was measured by TGA under the N2 condition, with the results shown in Figure 2c,d and Table 2. As shown in Table 2, the decomposition temperatures for the 10% weight loss (T10wt%) of PA-PEI and PA-Arg were 128.51 and 172.73 °C, respectively, lower than those of PEI (302.97 °C) and Arg (241.16 °C). Moreover, it is also noted that the char yields of PA-PEI and PA-Arg were 31.58% and 37.15%, respectively, higher than those of PEI (0.00%) and Arg (15.61%) due to the formation of a stable and compact char layer. The earlier thermal decomposition effect of these two phytate amine complexes would further promote the formation of a stable and compact char layer.

Table 2.

TGA and DTG data of PEI, PA-PEI, Arg, and PA-Arg materials under N2 atmosphere.

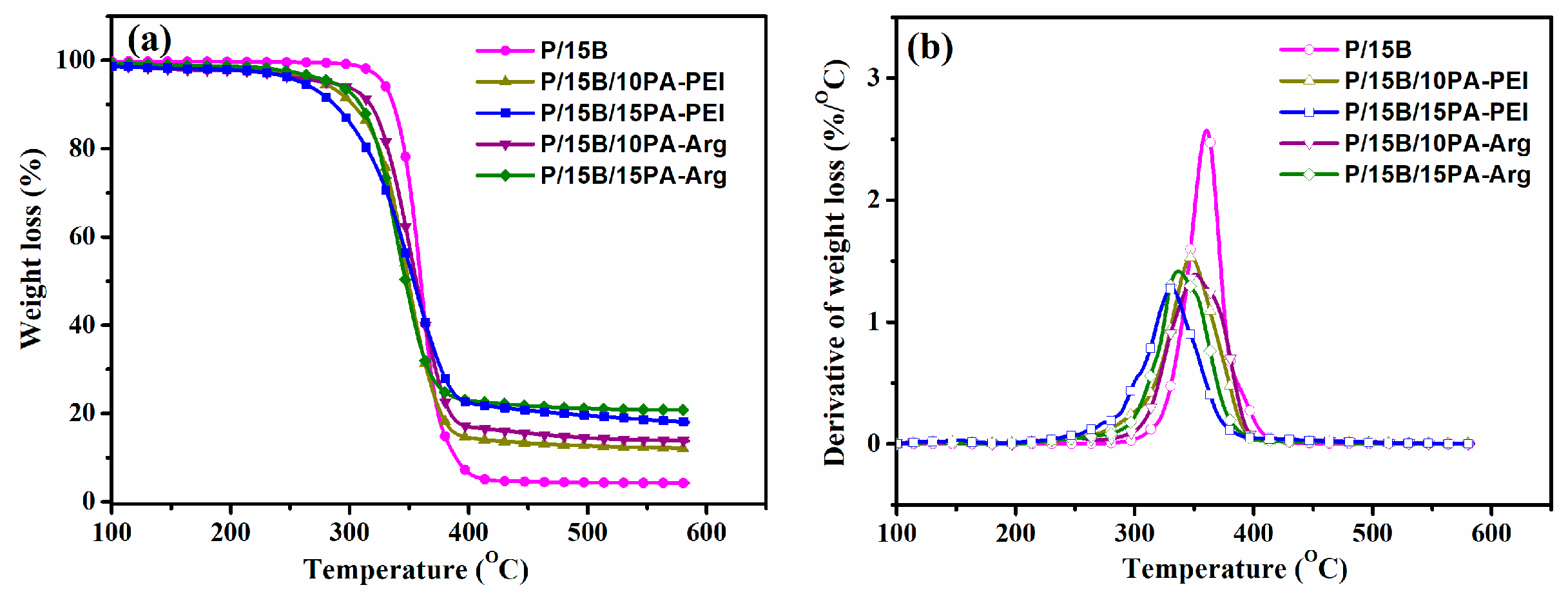

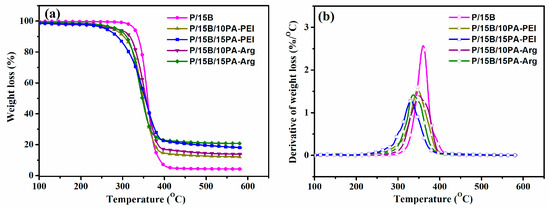

3.2. Thermal Analysis of P/15B Biocomposites

Thermogravimetric analysis (TGA) was carried out to evaluate the thermal stability of the P/15B-based biocomposites. The results are shown in Table 3 and Figure 3. The PA-PEI and PA-Arg containing P/15B biocomposites appear to be a one-stage decomposition process in the TGA curve of Figure 3a. The weight loss process of the P/15B/PA-PEI and P/15B/PA-Arg series biocomposites is similar to that of P/15B, exhibiting in one-step degradation which the main decomposition temperature range is 250–400 °C, indicating that PA-PEI or PA-Arg does not change the thermal decomposition behavior of PLA. For further analysis, it can be noted that the T10wt% of P/15B/10PA-PEI, P/15B/15PA-PEI, P/15B/10PA-Arg, and P/15B/15PA-Arg biocomposites are 302, 287, 317, and 309 °C, respectively, lower than that of the P/15B (336 °C). Meanwhile, the Td1 of P/15B/10PA-PEI, P/15B/15PA-PEI, P/15B/10PA-Arg, and P/15B/15PA-Arg biocomposites are 347, 330, 350, and 338 °C, respectively, lower than that of the P/15B (360 °C). The T10wt% and Td1 of the P/15B/PA-PEI series and P/15B/PA-Arg series composites are both lower than that of P/15B, resulting from the lower initial decomposition temperature of the flame-retardant PA-PEI and PA-Arg with respect to the P/15B [31,38]. The T10wt% of the P/15B/PA-PEI series is lower than those of the P/15B/PA-Arg series, suggesting a higher thermal stability of PA-Arg than PA-PEI, which is also consistent with Table 2. Additionally, the thermal degradation of PA-PEI or PA-Arg promoted intumescent char layer formation, which performed as a condensed phase for the underlying polymer matrix [31,32,33]. Therefore, it can be seen in Table 3 that the residual char yields are ranked in the following order: P/15B (4.24%) < P/15B/10PA-PEI (12.17%) < P/15B/10PA-Arg (13.81%) <P/15B/15PA-PEI (18.61%) < P/15B/15PA-Arg (20.82%). Notably, the char residues (CR550°C) of the PA-PEI or PA-Arg-containing P/15B biocomposites are significantly higher than that of the neat P/15B. This may be due to the faster thermal decomposition of PA-PEI and PA-Arg at relatively lower temperatures, and then phosphorus-containing elements from PA promoted the dehydration and carbonization of P/15B polymer matrix to form stable carbon layers [19], which had a positive effect to enhance the flame retardancy in P/15B biocomposites. Additionally, by increasing the content of PA-PEI or PA-Arg in the P/15B matrix, the CR550°C also exhibited a marked increase associated with the PA-PEI or PA-Arg concentration effect in the P/15B matrix. Therefore, the enhancement in this parameter (CR) may not only be a result of the inherent char formation of PA-PEI or PA-Arg at high temperature, but also the content in the polymer matrix [25,39].

Table 3.

TGA and DTG data of PLA/PBS-based bicomposites under N2 atmosphere.

Figure 3.

(a) TGA and (b) DTG curves of the P/15B-based bicomposites at a heating rate of 10 °C min−1 under N2.

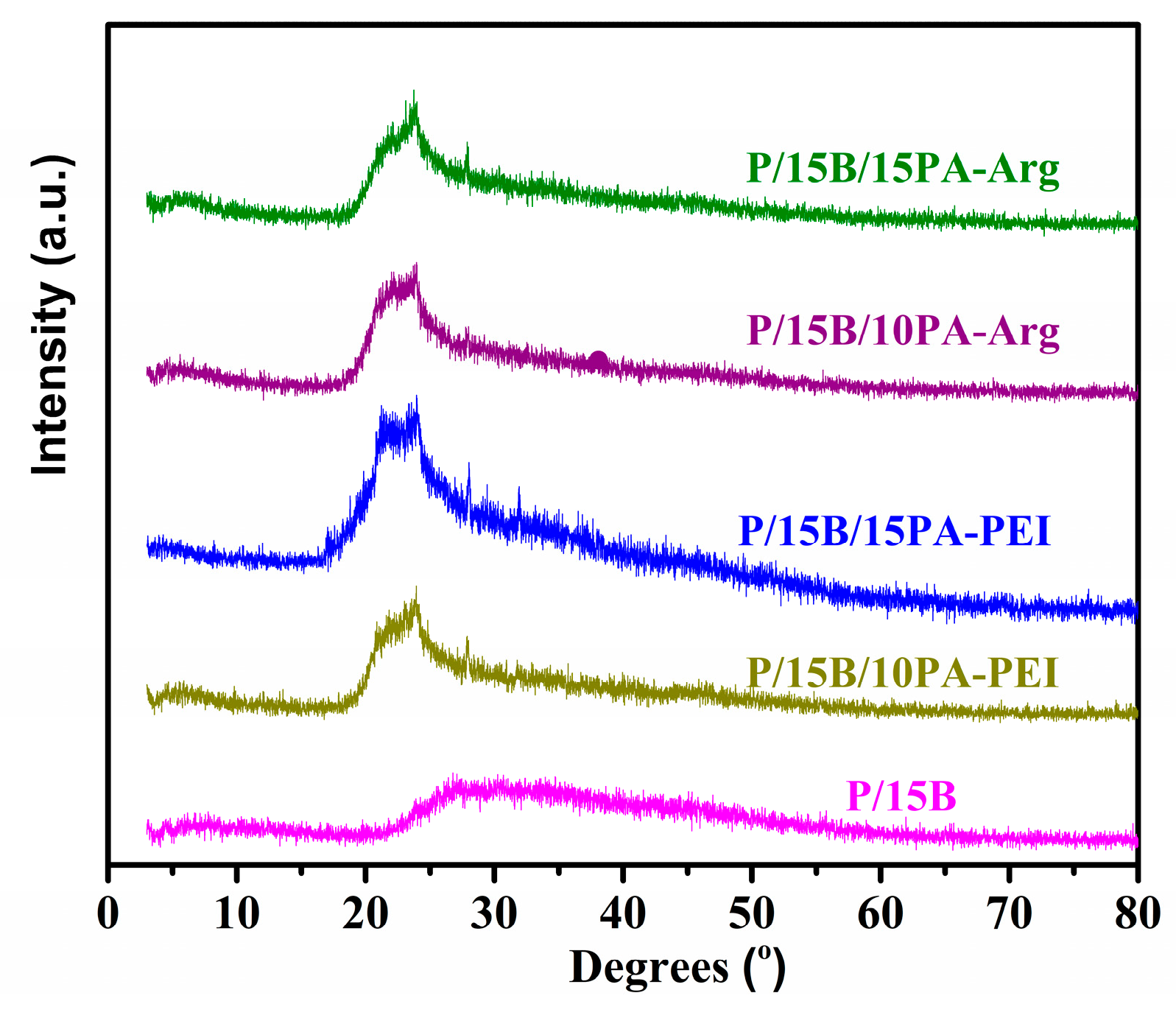

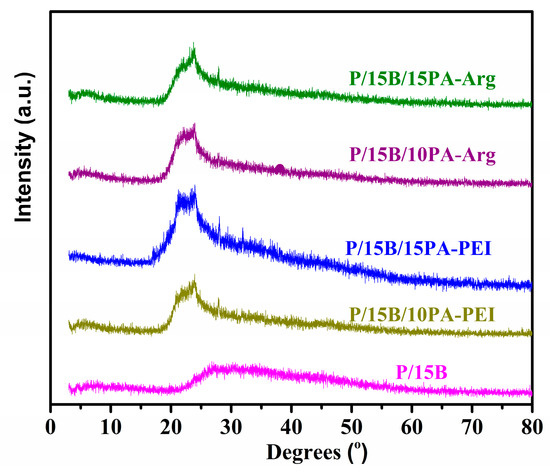

3.3. Surface Analysis of P/15B Biocomposites

Figure 4 illustrates the XRD patterns of the P/15B and the different PA-PEI or PA-Arg containing P/15B composites in the 2ϴ range of 10–70°. The XRD patterns for P/15B blends displayed broad and ambiguous diffraction patterns without the characteristic peaks for PLA (2θ of 16.5° and 19°) or PBS (2θ of 19.5°, 21.5°, 22.5°and 29.4°) [40], indicating that there was negligible co-crystallization in P/15B composite [41]. The patterns for P/15B/10PA-PEI, P/15B/15PA-PEI, P/15B/10PA-Arg, and P/15B/15PA-Arg composites clearly show two peaks at 21.64° and 23.58°, respectively, corresponding to the characteristic diffraction peaks of PBS.

Figure 4.

X-ray diffraction patterns of P/15B-based composites.

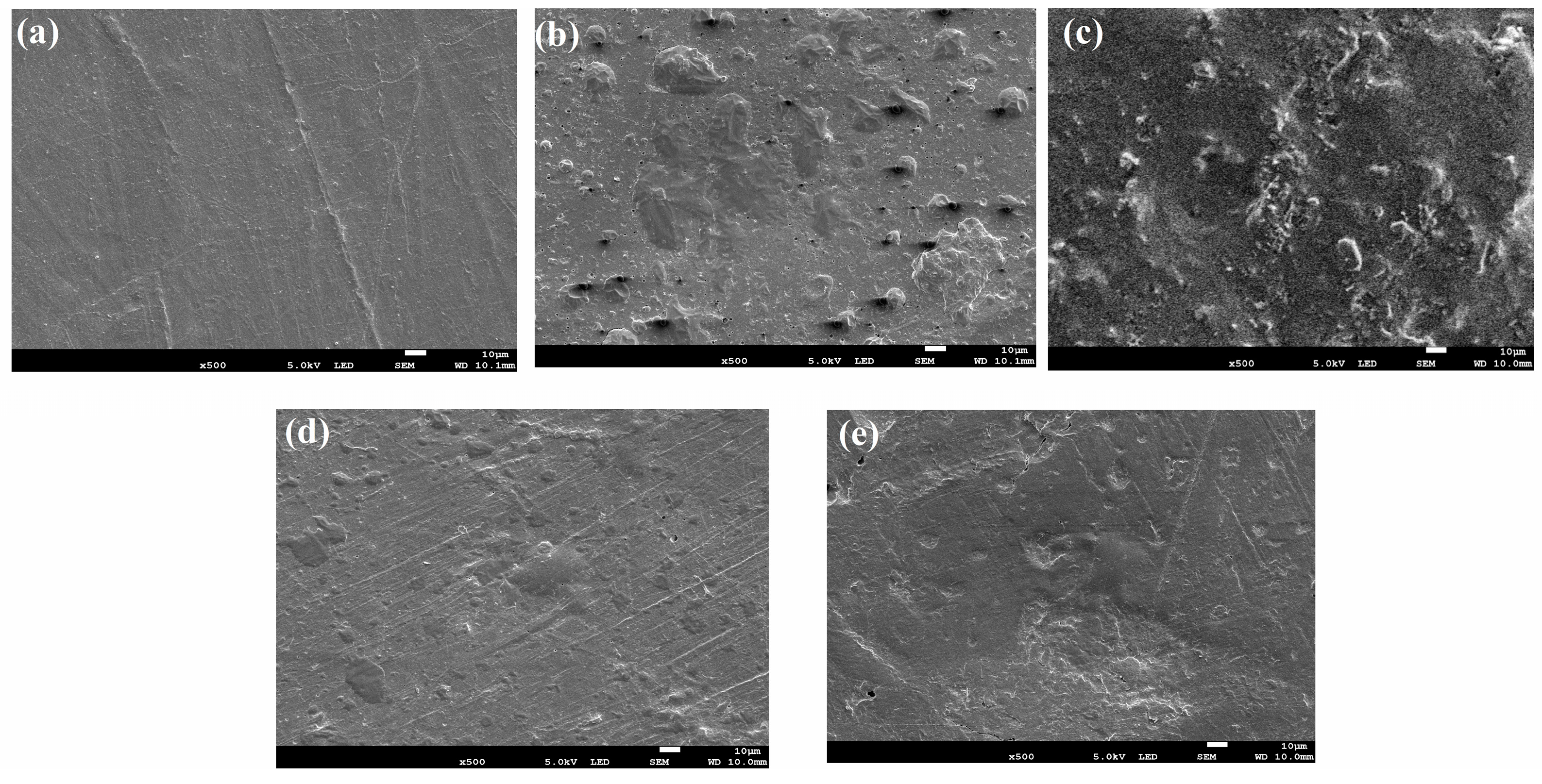

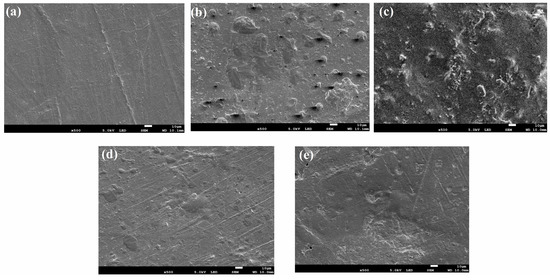

The surface morphology of P/15B and the different PA-PEI or PA-Arg containing P/15B composites is further characterized by the SEM technique, as shown in Figure 5. In particular, Figure 5a shows that P/15B blends demonstrated a smoother surface, resulting from the compatibility of the PLA-PBS blends [42]. Although it seems that the flame-retardant additives of PA-PEI or PA-Arg were fully embedded into the P/15B matrix, as shown in Figure 5b–e. It was found that the presence of P/15B/15PA-PEI exhibited higher agglomeration than P/15B/10PA-PEI as shown in Figure 5b,c, respectively, this appearance also can be found in P/15B/PA-Arg series biocomposites (Figure 5d,e). In general, the incorporation of higher content of flame retardants into a polymer matrix can cause an agglomeration phenomenon [43]. Meanwhile, the surface topography of P/15B/PA-Arg series biocomposites demonstrates less agglomeration as compared with P/15B/PA-PEI series biocomposites. This phenome indicates that the P/15B/PA-Arg series biocomposites show well dispersion than P/15B/PA-PEI series biocomposites, attributing the molecular weight of the PA-Arg lower than that of PA-PEI. As a result, the agglomeration phenome of PA-PEI or PA-Arg containing P/15B composites may negatively affect the mechanical properties of the P/15B matrix, which has also been reported in previous works [39,43].

Figure 5.

SEM images of surface morphology obtained by (a) P/15B, (b) P/15B/10PA-PEI, (c) P/15B/15PA-PEI, (d) P/15B/10PA-Arg and (e) P/15B/15PA-Arg.

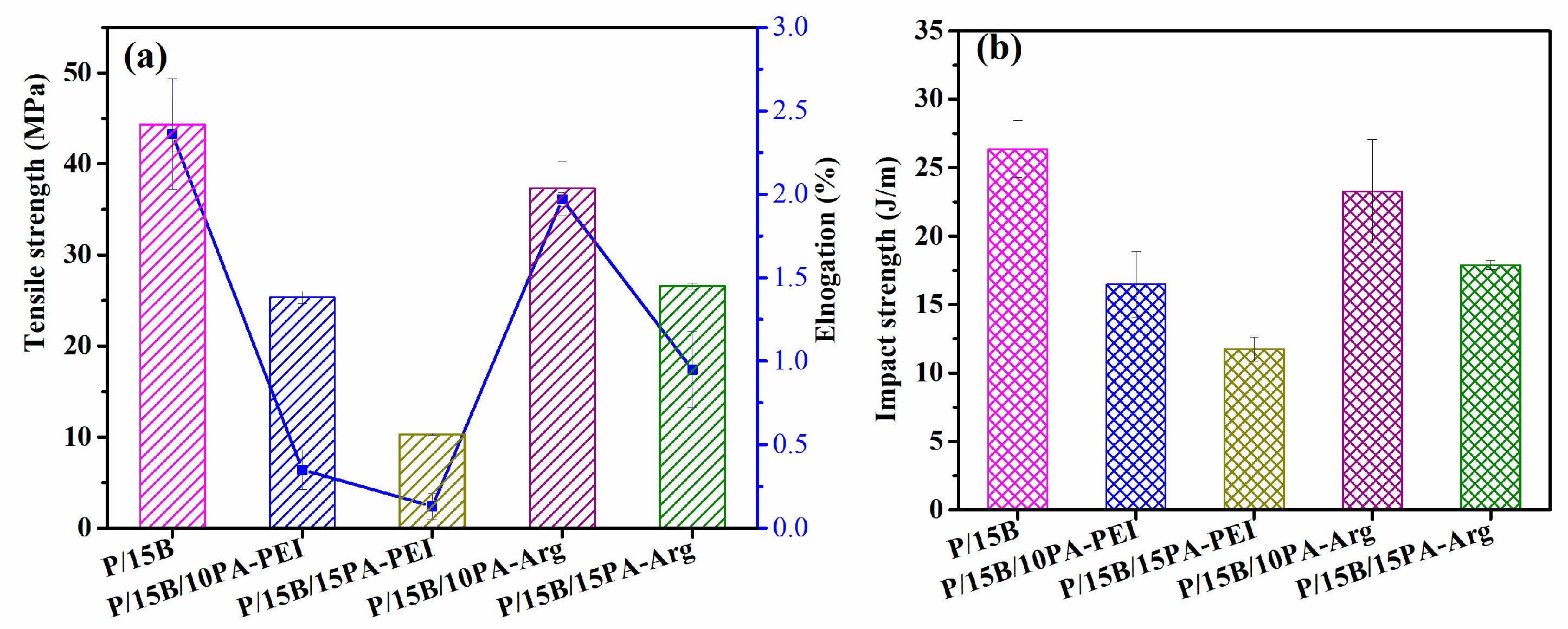

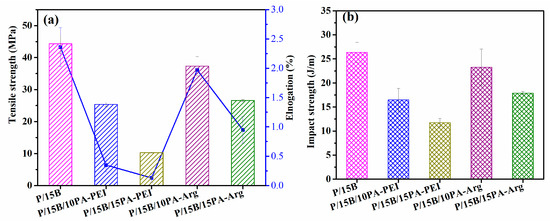

3.4. Mechanical Analysis of P/15B Biocomposites

The mechanical properties of the P/15B-based composites are shown in Figure 6, and the relevant data are depicted in Table 4. As shown in Figure 6, the tensile strength, elongation at break, and impact strengths of P/15B/PA-PEI series and P/15B/PA-Arg series biocomposites exhibited a slight decline as compared to those of P/15B. Meanwhile, the P/15B/15PA-Arg exhibited fewer mechanical properties as compared with P/15B/10PA-Arg, while this phenome also can be found in P/15B/PA-PEI series biocomposites. The addition of PA-PEI or PA-Arg into the P/15B matrix induced a negative impact on the mechanical properties of these obtained biocomposites due to the catalyzing decomposition effect of PA-PEI or PA-Arg, which has also been found in other previous research [44,45,46,47]. Notably, the mechanical properties (such as tensile strength, elongation, and impact strength) of the P/15B/PA-Arg series biocomposites are slightly higher than those of the P/15B/PA-PEI series biocomposite, as shown in Figure 6 and Table 4. This may be because the P/15B/PA-PEI series biocomposites exhibited uneven dispersion than P/15B/PA-Arg series biocomposites as shown in Figure 5b–e, respectively. Thus, this behavior may indicate that the monomeric-based phytic acid complex (PA-Arg) exhibited less deterioration in the mechanical performance than the polymeric-based phytic acid complex (PA-PEI). Therefore, not only does it meet the proper mechanic properties, but it also demonstrates better flame-retardant efficiency via introducing the monomeric-based phytic acid complex into the biodegradable composites (such as PLA and PBS) for construction fields.

Figure 6.

(a) Tensile strength and elongation strength at break, (b) impact strength of P/15B-based biocomposites.

Table 4.

Mechanical properties of P/15B-based bicomposites.

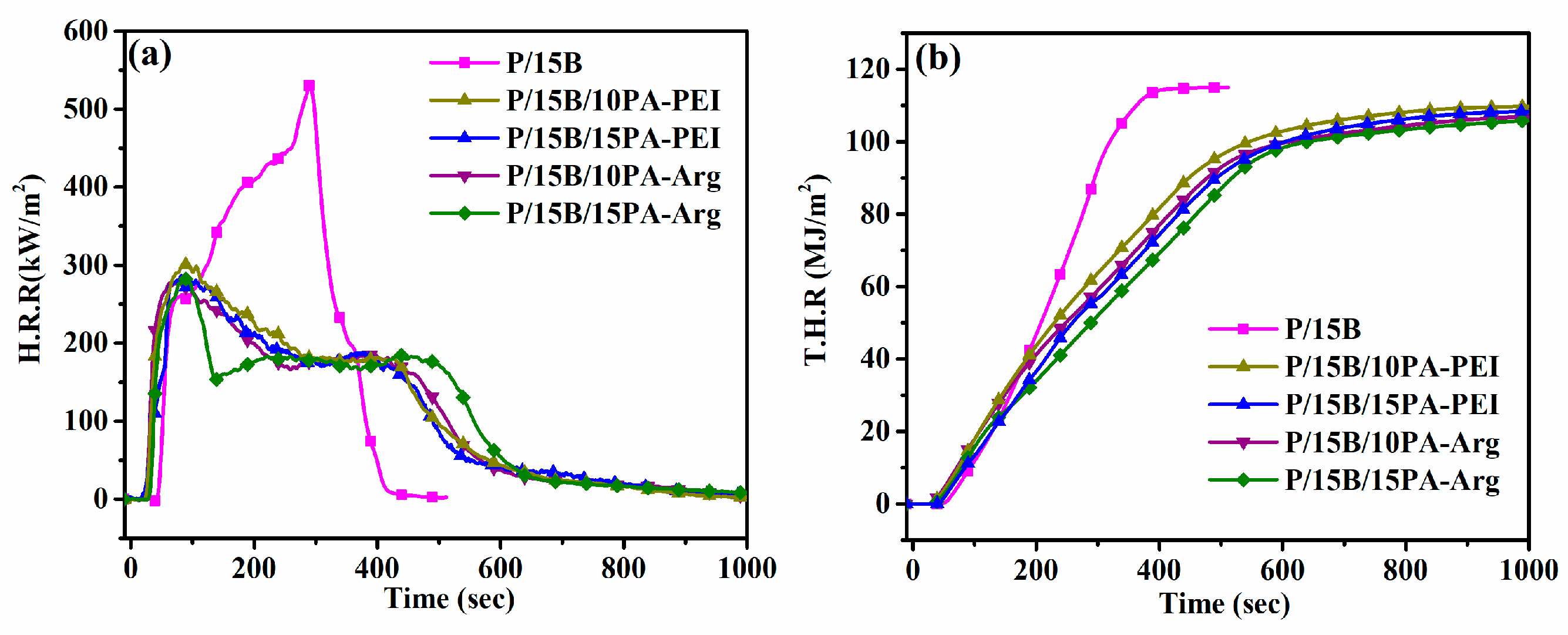

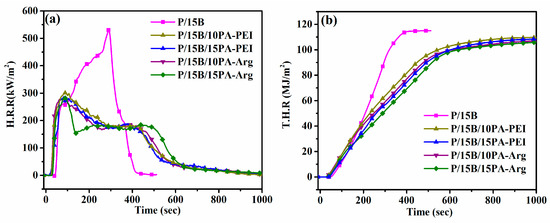

3.5. Flame Retardancy Properties of P/15B Biocomposites

The flammability of the flame-retardant additives of PA-PEI or PA-Arg was thoroughly investigated through UL-94 and cone calorimetry tests to investigate their influence on the combustion performance of the P/15B biocomposites. Figure 7 displays the heat release rate (HRR) and total heat release (THR) curves of the flame-retardant P/15B biocomposites. On the other hand, the important parameters of five P/15B biocomposites are depicted in Table 5. As shown in Table 5, the time to ignition (TTI) of the neat P/15B is recorded as 44 ± 3 s, while the TTI values of P/15B/10PA-PEI, P/15B/15PA-PEI, P/15B/10PA-Arg, and P/15B/15PA-Arg biocomposites are reduced significantly to 28 ± 2, 25 ± 3, 22 ± 2 and 21 ± 2 s, respectively. It is observed that the flame-retardant additive of PA-PEI or PA-Arg decreases the TTI of P/15B, owing to the catalytic effect on the thermal decomposition of PA-PEI or PA-Arg in P/15B biocomposites [31], which is consistent with the TGA results. Meanwhile, the P/15B/PA-Arg series exhibited shorter TTI values than that of the P/15B/PA-PEI series, due to the lower thermal decomposition temperature (as shown in Table 2). The peak of the heat release rate (pHRR), THR, and residual char of the neat P/15B biocomposite is 532.35 kW/m2, 113.67 MJ/m2, and 0.05%, respectively. Among these P/15B biocomposites, the P/15B/15PA-Arg biocomposite demonstrates the lowest value of pHRR (280.26 kW/m2) and THR (107.89 MJ/m2), with the highest char residues (10.4%). Additionally, it can be seen in Table 4 that the pHRR values (or THR values) are ranked in the following order: P/15B > P/15B/PA-PEI > P/15B/PA-Arg series. After incorporating flame-retardant additive (PA-PEI or PA-Arg) into the P/15B matrix, the pHRR and THR values exhibited decrement trends compared with the neat P/15B biocomposite, indicating that the PA-PEI or PA-Arg is beneficial for forming physical barriers to protect the P/15B matrix effectively [30,32]. Meanwhile, the pHRR and THR values of P/15B/10PA-Arg are lower than that of the P/15B/10PA-PEI, indicating that the flame-retardancy of monomeric-based phytic acid complex (PA-Arg) is more efficient than the polymeric-based phytic acid complex (PA-PEI). Such phenomes have been ascribed to the fact that the thermal decomposition temperature of PA-Arg is lower than PA-PEI, as consistent with the TGA and DTG results (Table 3). Additionally, the pHRR and THR values of P/15B/15PA-Arg are slightly lower than those of P/15B/10PA-Arg, as well as shown in the P/15B/PA-PEI series. This phenome indicates the flame retardancy properties of P/15B composites exhibited a slight improvement via increasing the concentration of PA-PEI or PA-Arg in P/15B biocomposites owing to increasing the concentration amount decreased the burning amount. Therefore, the improvement in the combustion performance of P/15B biocomposites can be ascribed to not only the inherent lower thermal decomposition temperature of PA-PEI or PA-Arg which help the char formation at high temperature but also the concentration content of PA-PEI or PA-Arg in the P/15B polymer matrix.

Figure 7.

(a) HRR and (b) THR curves of P/15B-based biocomposites.

Table 5.

The combustion data of P/15B-based bicomposites.

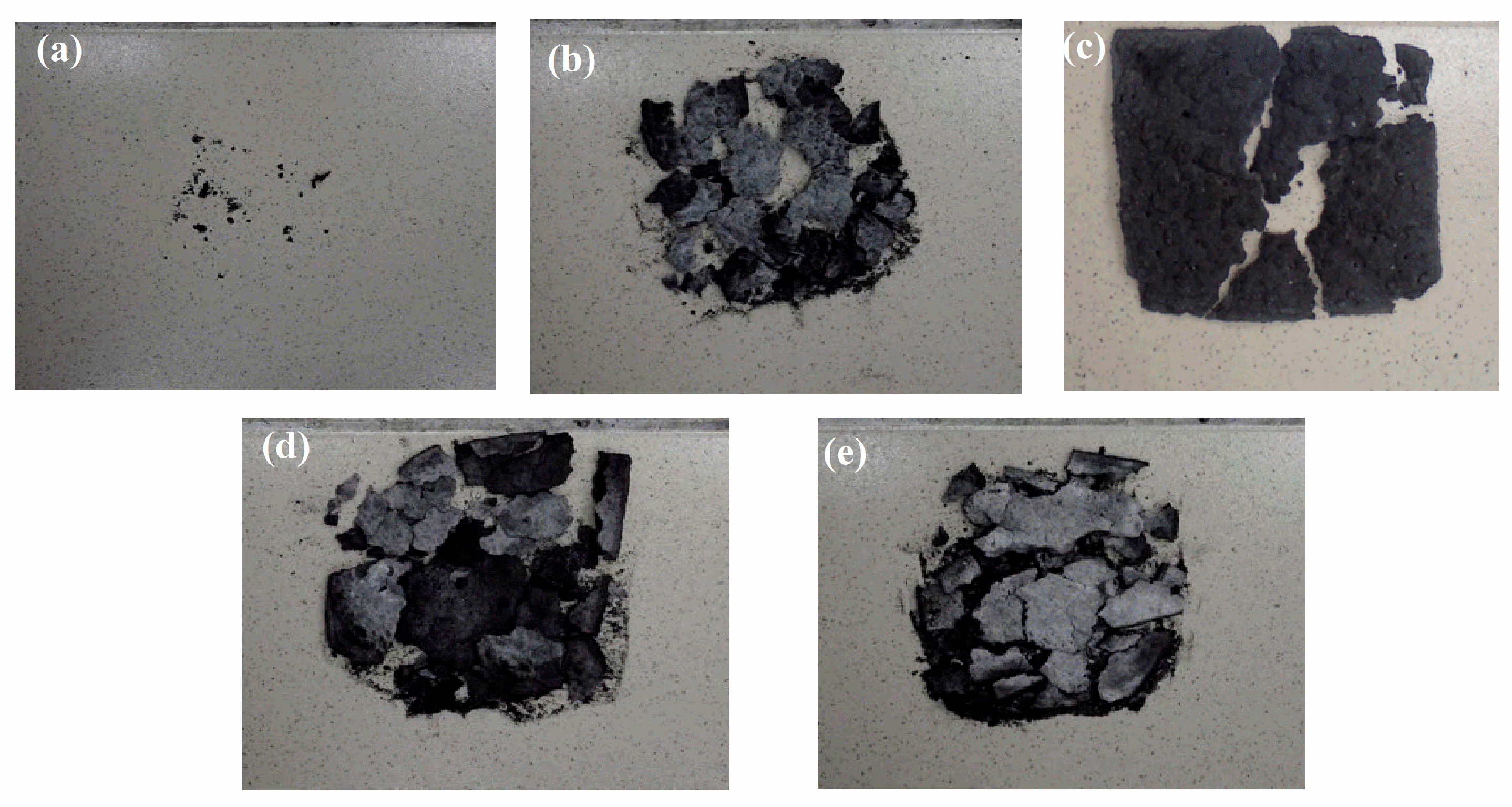

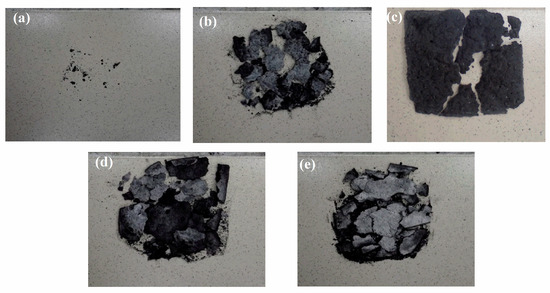

The digital photos of the char residues of P/15B biocomposites after the cone calorimeter test are shown in Figure 8. The neat P/15B biocomposites exhibited non-char residues, as shown in Figure 8a. Meanwhile, the P/15B/10PA-PEI, P/15B/15PA-PEI, P/15B/10PA-Arg, and P/15B/15PA-Arg biocomposites (Figure 8b–e) exhibited char residues resulting from the presence of PA-PEI or PA-Arg and leading to the formation of a cohesive and compact char layers, which is consistent with the cone calorimeter test results. Furthermore, Table 5 indicates that incorporating PA-PEI or PA-Arg increases the amount of residual char compared with the neat P/15B, owing to the formation of a protective char layer, resulting in higher char residues. Noteworthily, the good dispersion state of PA-PEI or PA-Arg in the P/15B matrix is also associated with the higher char residues, ascribed to the existence of multi-active sites in the P/15B matrix. In Table 5, the neat P/15B biocomposite exhibited a serious dripping phenomenon during combustion. Additionally, the UL-94 vertical burning test results of the P/15B/PA-PEI series and P/15B/PA-Arg series biocomposites reach the V-2 level. Overall, the above flame retardancy test results demonstrate that the flame retardancy of P/15B biocomposites can be effectively increased by embedding the flame-retardant PA-PEI or PA-Arg.

Figure 8.

Digital images of the residues for (a) P/15B, (b) P/15B/10PA-PEI, (c) P/15B/15PA-PEI, (d) P/15B/10PA-Arg and (e) P/15B/15PA-Arg after CCT.

4. Conclusions

In this study, two eco-friendly flame retardants (PA-PEI and PA-Arg) were successfully prepared by a green method in water. Subsequently, they were applied in the melt-mixing process of fire-resistance polylactic acid/polybutylene succinate biocomposites (P/15B). In contrast with the neat P/15B, the char residues of P/15B/PA-PEI series and P/15B/PA-Arg series biocomposites are moderately improved with the incorporation of PA-PEI and PA-Arg according to the TGA results. However, the mechanical performance exhibited a slight decrement trend in P/15B/PA-PEI or P/15B/PA-Arg biocomposites, resulting from the catalyzing decomposition effect of PA-PEI or PA-Arg, with respect to that of the neat P/15B. Notably, the monomeric type phytate amine complexes (PA-Arg) exhibited higher mechanical features than the polymeric type (PA-PEI) due to the good dispersion state in the P/15B matrix. After the combustion process, the flame retardancy of P/15B biocomposites is significantly improved with the incorporation of PA-PEI or PA-Arg, resulting from the formation of cohesive and compact char layers in P/15B biocomposites. Among all P/15B biocomposites, the P/15B/15PA-Arg exhibited a noticeable improvement in the pHRR (280.26 kW/m2) by a reduction of 47.35% and THR (107.89 MJ/m2) by a reduction of 5.08% as compared to that of the neat P/15B. Furthermore, our research demonstrates that the monomeric type phytate amine complexes (PA-Arg) exhibited higher flame resistance properties than the polymeric type (PA-PEI) and suitable mechanical properties with proper loads.

Author Contributions

Conceptualization, Y.-F.S.; methodology and validation, C.-W.L. and Y.-L.C.; data curation, C.-W.L., Y.-L.C. and Y.-H.C.; writing—original draft preparation, Y.-H.C.; writing—review and editing, Y.-H.C., K.J. and Y.-F.S.; supervision, Y.-F.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the Ministry of Science and Technology, Taiwan, grant number MOST 110-2813-C-324-021-E.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations, World Urbanization Prospects: The 2018 Revision. Available online: https://www.un.org/development/desa/pd/content/world-urbanization-prospects-2018-revision (accessed on 30 June 2022).

- Dadsetan, S.; Siad, H.; Lachemi, M.; Sahmaran, M. Construction and demolition waste in geopolymer concrete technology: A review. Mag. Concr. Res. 2019, 71, 1232–1252. [Google Scholar] [CrossRef]

- Pozo Morales, A.; Güemes, A.; Fernandez-Lopez, A.; Carcelen Valero, V.; De La Rosa Llano, S. Bamboo–Polylactic Acid (PLA) Composite Material for Structural Applications. Materials 2017, 10, 1286. [Google Scholar] [CrossRef] [PubMed]

- Bourbigot, S.; Fontaine, G. Flame retardancy of polylactide: An overview. Polym. Chem. 2010, 1, 1413–1422. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Wang, L.; Ma, W.; Gross, R.A.; McCarthy, S.P. Reactive compatibilization of biodegradable blends of poly(lactic acid) and poly(ε-caprolactone). Polym. Degrad. Stab. 1998, 59, 161–168. [Google Scholar] [CrossRef]

- Sheth, M.; Kumar, R.A.; Davé, V.; Gross, R.A.; McCarthy, S.P. Biodegradable polymer blends of poly(lactic acid) and poly(ethylene glycol). J. Appl. Polym. Sci. 1997, 66, 1495–1505. [Google Scholar] [CrossRef]

- Chen, G.X.; Kim, H.S.; Kim, E.S.; Yoon, J.S. Compatibilization-like effect of reactive organoclay on the poly(l-lactide)/poly(butylene succinate) blends. Polymer 2005, 46, 11829–11836. [Google Scholar] [CrossRef]

- Chiu, H.T.; Huang, S.Y.; Chen, Y.F.; Kuo, M.T.; Chiang, T.Y.; Chang, C.Y.; Wang, Y.H. Heat Treatment Effects on the Mechanical Properties and Morphologies of Poly (Lactic Acid)/Poly (Butylene Adipate-co-terephthalate) Blends. Int. J. Polym. Sci. 2013, 2013, 951696. [Google Scholar] [CrossRef]

- Yokohara, T.; Yamaguchi, M. Structure and properties for biomass-based polyester blends of PLA and PBS. Eur. Polym. J. 2008, 44, 677–685. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly(butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly(lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef]

- Wang, D.Y.; Song, Y.P.; Lin, L.; Wang, X.L.; Wang, Y.Z. A novel phosphorus-containing poly(lactic acid) toward its flame retardation. Polymer 2011, 52, 233–238. [Google Scholar] [CrossRef]

- Pattanashetti, N.A.; Heggannavar, G.B.; Kariduraganavar, M.Y. Smart Biopolymers and their Biomedical Applications. Procedia Manuf. 2017, 12, 263–279. [Google Scholar] [CrossRef]

- Xiao, F.; Fontaine, G.; Bourbigot, S. Recent developments in fire retardancy of polybutylene succinate. Polym. Degrad. Stab. 2021, 183, 109466. [Google Scholar] [CrossRef]

- Tawiah, B.; Yu, B.; Fei, B. Advances in Flame Retardant Poly(Lactic Acid). Polymers 2018, 10, 876. [Google Scholar] [CrossRef]

- Venier, M.; Salamova, A.; Hites, R.A. Halogenated Flame Retardants in the Great Lakes Environment. Acc. Chem. Res. 2015, 48, 1853–1861. [Google Scholar] [CrossRef]

- Jans, U. Emerging Brominated Flame Retardants in Sediments and Soils: A Review. Curr. Pollut. Rep. 2016, 2, 213–223. [Google Scholar] [CrossRef]

- Charbonnet, J.A.; Weber, R.; Blum, A. Flammability standards for furniture, building insulation and electronics: Benefit and risk. Emerg. Contam. 2020, 6, 432–441. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, H.; Shen, L.; Fang, Z.; Zhang, X.; Wang, J.; Zhang, B. A phosphorus-, nitrogen- and carbon-containing polyelectrolyte complex: Preparation, characterization and its flame retardant performance on polypropylene. RSC Adv. 2014, 4, 48285–48292. [Google Scholar] [CrossRef]

- Shih, Y.; Chen, Y.; Lai, S.; Chen, Y.; Wang, S.; Zhang, S.P. The effect of thermal, flammability, and mechanical properties of wood plastic composites made from recycled food-packaging LDPE and eco-friendly phytic acid. Int. J. Appl. Eng. Res. 2021, 18, 2021266. [Google Scholar] [CrossRef]

- Kabir, I.I.; Sorrell, C.C.; Mofarah, S.S.; Yang, W.; Yuen, A.C.Y.; Nazir, M.T.; Yeoh, G.H. Alginate/Polymer-Based Materials for Fire Retardancy: Synthesis, Structure, Properties, and Applications. Polym. Rev. 2021, 61, 357–414. [Google Scholar] [CrossRef]

- Hobbs, C.E. Recent Advances in Bio-Based Flame Retardant Additives for Synthetic Polymeric Materials. Polymers 2019, 11, 224. [Google Scholar] [CrossRef] [PubMed]

- Laoutid, F.; Vahabi, H.; Shabanian, M.; Aryanasab, F.; Zarrintaj, P.; Saeb, M.R. A new direction in design of bio-based flame retardants for poly(lactic acid). Fire Mater. 2018, 42, 914–924. [Google Scholar] [CrossRef]

- Hörold, S. Chapter 6—Phosphorus-based and Intumescent Flame Retardants. In Polymer Green Flame Retardants; Papaspyrides, C.D., Kiliaris, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 221–254. [Google Scholar] [CrossRef]

- Mishra, N.; Vasava, D. Recent developments in s-triazine holding phosphorus and nitrogen flame-retardant materials. J. Fire Sci. 2020, 38, 552–573. [Google Scholar] [CrossRef]

- Hamdani, S.; Longuet, C.; Perrin, D.; Lopez-cuesta, J.-M.; Ganachaud, F. Flame retardancy of silicone-based materials. Polym. Degrad. Stab. 2009, 94, 465–495. [Google Scholar] [CrossRef]

- Perera, I.; Seneweera, S.; Hirotsu, N. Manipulating the Phytic Acid Content of Rice Grain Toward Improving Micronutrient Bioavailability. Rice 2018, 11, 4. [Google Scholar] [CrossRef]

- Ye, G.; Huo, S.; Wang, C.; Shi, Q.; Liu, Z.; Wang, H. One-step and green synthesis of a bio-based high-efficiency flame retardant for poly (lactic acid). Polym. Degrad. Stab. 2021, 192, 109696. [Google Scholar] [CrossRef]

- Wu, F.; Xu, J.; Qiu, X.; Lin, S.; Zhang, M.; Ma, M.; Shi, Y.; He, H.; Chen, S.; Wang, X. Super-Low-Addition Biobased Flame Retardant Dedicated to Polylactic Acid through Ionic Reaction between Phytic Acid and Taurine. ACS Appl. Polym. Mater. 2021, 3, 4579–4586. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Delvosalle, C.; Dubois, P. Phytic acid–lignin combination: A simple and efficient route for enhancing thermal and flame retardant properties of polylactide. Eur. Polym. J. 2017, 94, 270–285. [Google Scholar] [CrossRef]

- Liu, L.; Huang, Z.; Pan, Y.; Wang, X.; Song, L.; Hu, Y. Finishing of cotton fabrics by multi-layered coatings to improve their flame retardancy and water repellency. Cellulose 2018, 25, 4791–4803. [Google Scholar] [CrossRef]

- Dong, H.; Ding, L.; Yan, F.; Ji, H.; Ju, H. The use of polyethylenimine-grafted graphene nanoribbon for cellular delivery of locked nucleic acid modified molecular beacon for recognition of microRNA. Biomaterials 2011, 32, 3875–3882. [Google Scholar] [CrossRef]

- Zhu, Z.M.; Shang, K.; Wang, L.X.; Wang, J.S. Synthesis of an effective bio-based flame-retardant curing agent and its application in epoxy resin: Curing behavior, thermal stability and flame retardancy. Polym. Degrad. Stab. 2019, 167, 179–188. [Google Scholar] [CrossRef]

- Gao, Y.Y.; Deng, C.; Du, Y.Y.; Huang, S.C.; Wang, Y.Z. A novel bio-based flame retardant for polypropylene from phytic acid. Polym. Degrad. Stab. 2019, 161, 298–308. [Google Scholar] [CrossRef]

- Huo, S.; Yang, S.; Wang, J.; Cheng, J.; Zhang, Q.; Hu, Y.; Ding, G.; Zhang, Q.; Song, P. A liquid phosphorus-containing imidazole derivative as flame-retardant curing agent for epoxy resin with enhanced thermal latency, mechanical, and flame-retardant performances. J. Hazard. Mater. 2020, 386, 121984. [Google Scholar] [CrossRef]

- Liang, B.; Hong, X.; Zhu, M.; Gao, C.; Wang, C.; Tsubaki, N. Synthesis of novel intumescent flame retardant containing phosphorus, nitrogen and boron and its application in polyethylene. Polym. Bull. 2015, 72, 2967–2978. [Google Scholar] [CrossRef]

- Yang, Y.X.; Haurie, L.; Zhang, J.; Zhang, X.Q.; Wang, R.; Wang, D.Y. Effect of bio-based phytate (PA-THAM) on the flame retardant and mechanical properties of polylactide (PLA). Express Polym. Lett. 2020, 14, 705–716. [Google Scholar] [CrossRef]

- Park, J.W.; Im, S.S. Phase behavior and morphology in blends of poly(L-lactic acid) and poly(butylene succinate). J. Appl. Polym. Sci. 2002, 86, 647–655. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Pimpan, V.; Chuayjuljit, S.; Leejarkpai, T. Biodegradable Plastics Prepared from Poly(lactic acid), Poly(butylene succinate) and Microcrystalline Cellulose Extracted from Waste-Cotton Fabric with a Chain Extender. J. Polym. Environ. 2015, 23, 114–125. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Parveez, B.; Hussain Bhat, A.; Alamery, S. Morphology, Structural, Thermal, and Tensile Properties of Bamboo Microcrystalline Cellulose/Poly(Lactic Acid)/Poly(Butylene Succinate) Composites. Polymers 2021, 13, 465. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, J.; Liu, T.; Xi, L.; Sai, T.; Ran, S.; Fang, Z.; Huo, S.; Song, P. A molecularly engineered bioderived polyphosphate for enhanced flame retardant, UV-blocking and mechanical properties of poly(lactic acid). Chem. Eng. J. 2021, 411, 128493. [Google Scholar] [CrossRef]

- Liao, F.; Ju, Y.; Dai, X.; Cao, Y.; Li, J.; Wang, X. A novel efficient polymeric flame retardant for poly (lactic acid) (PLA): Synthesis and its effects on flame retardancy and crystallization of PLA. Polym. Degrad. Stab. 2015, 120, 251–261. [Google Scholar] [CrossRef]

- Jin, X.; Gu, X.; Chen, C.; Tang, W.; Li, H.; Liu, X.; Bourbigot, S.; Zhang, Z.; Sun, J.; Zhang, S. The fire performance of polylactic acid containing a novel intumescent flame retardant and intercalated layered double hydroxides. J. Mater. Sci. 2017, 52, 12235–12250. [Google Scholar] [CrossRef]

- Sun, L.; Xie, Y.; Wu, J.; Wang, H.; Wang, S.; Li, W.; Zhang, J.; Zhang, Z.; Zhu, P.; Lu, Z.; et al. A novel P/N-based flame retardant synthesized by one-step method toward cotton materials and its flame-retardant mechanism. Cellulose 2021, 28, 3249–3264. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, L.; Wu, X.; Xu, B. The influence of nano ZnO coated by phosphazene/triazine bi-group molecular on the flame retardant property and mechanical property of intumescent flame retardant poly (lactic acid) composites. Thermochim. Acta 2019, 679, 178336. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).