Numerical Solutions for Chloride Diffusion Fluctuation in RC Elements from Corrosion Probability Assessments

Abstract

1. Introduction

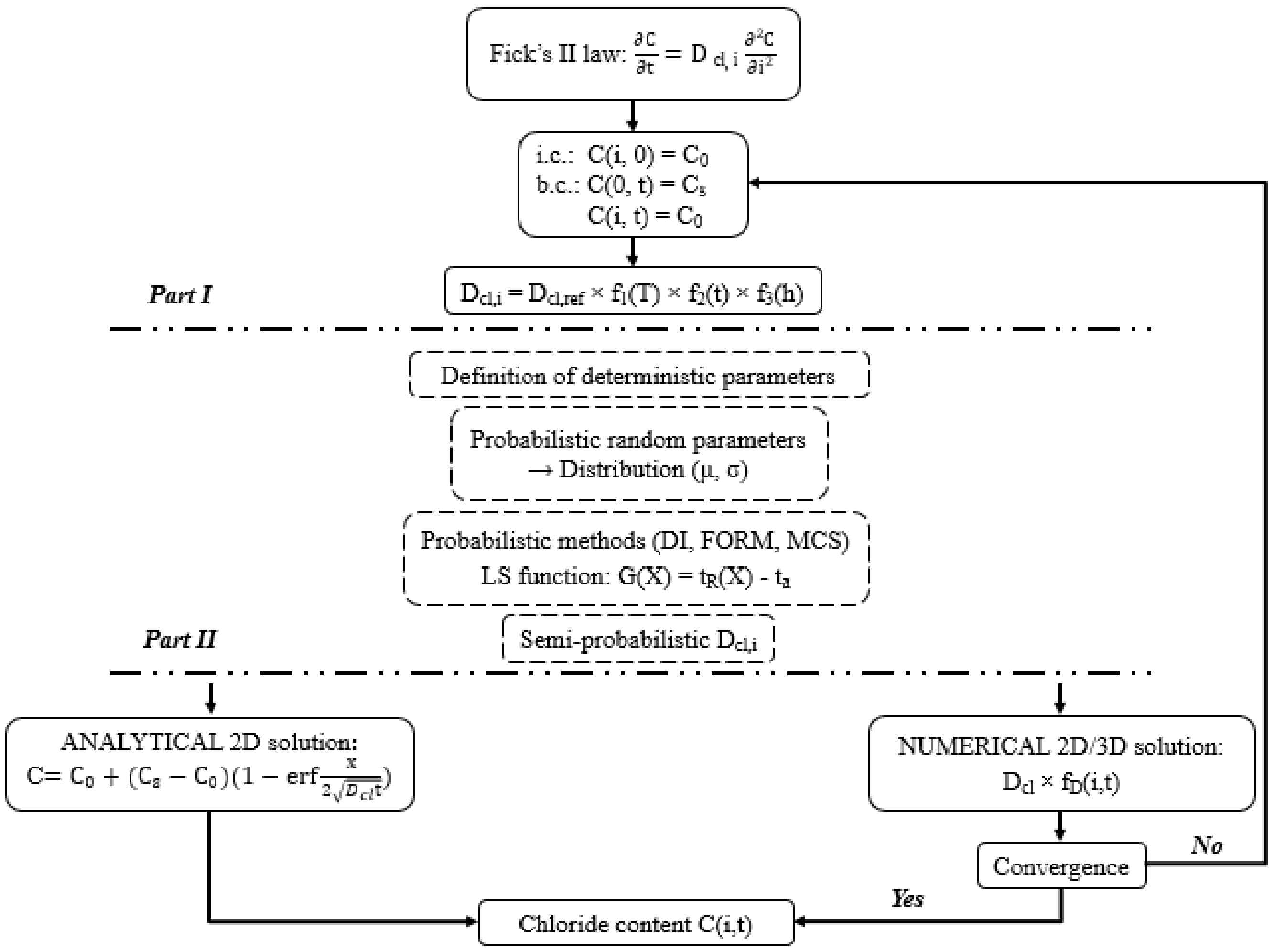

2. Mechanical Model

2.1. Problem Statement

2.2. Analytical Solution

2.3. Numerical Solution

2.4. Chloride Diffusion Coefficient

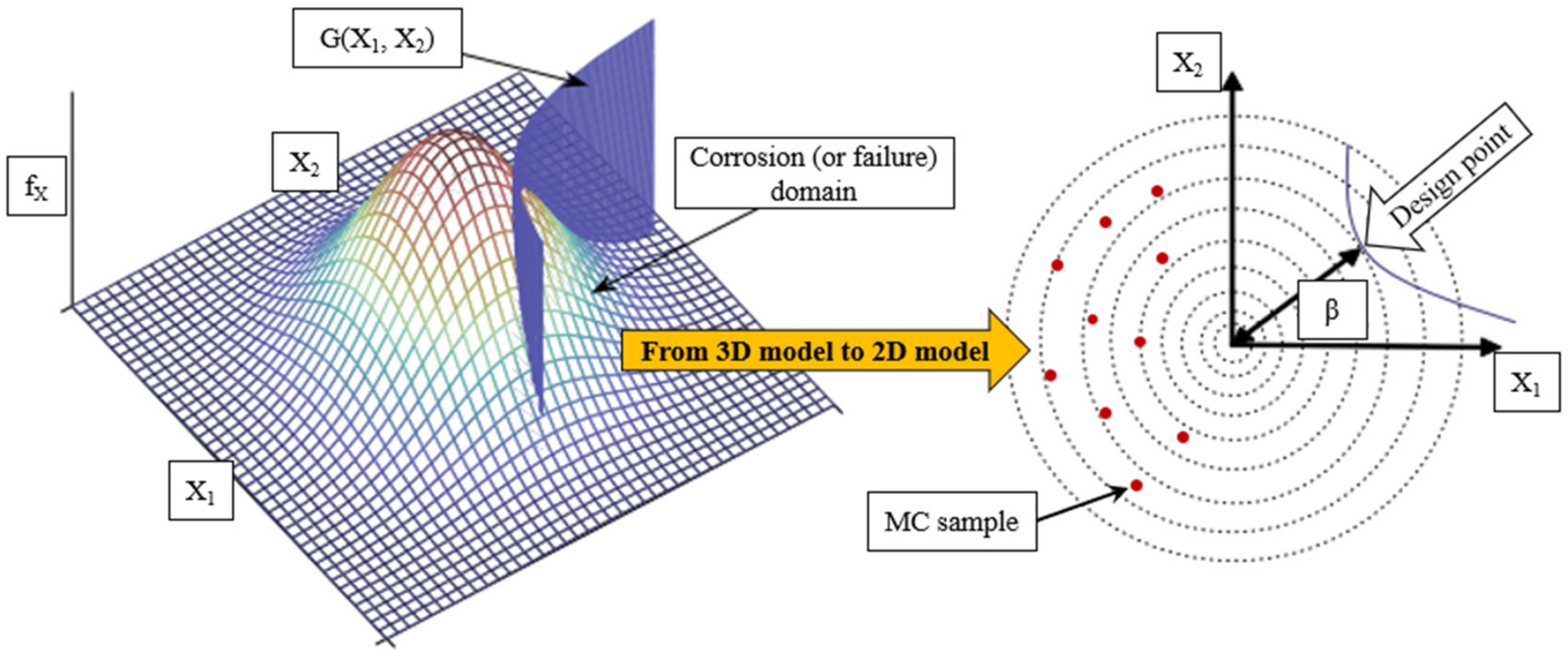

3. Probabilistic Approaches

4. General Methodology

5. Analyses and Results

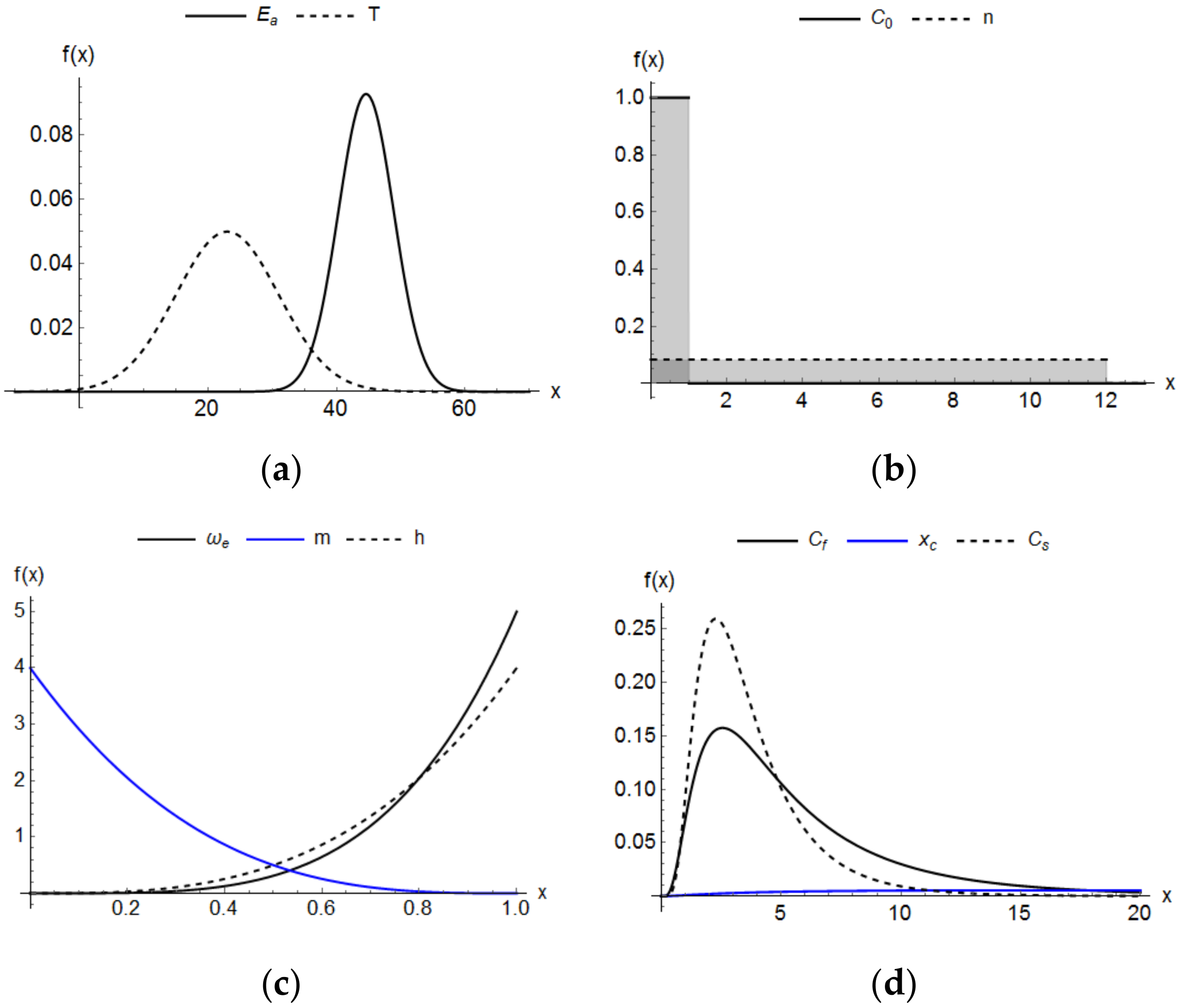

5.1. Probabilistic Results

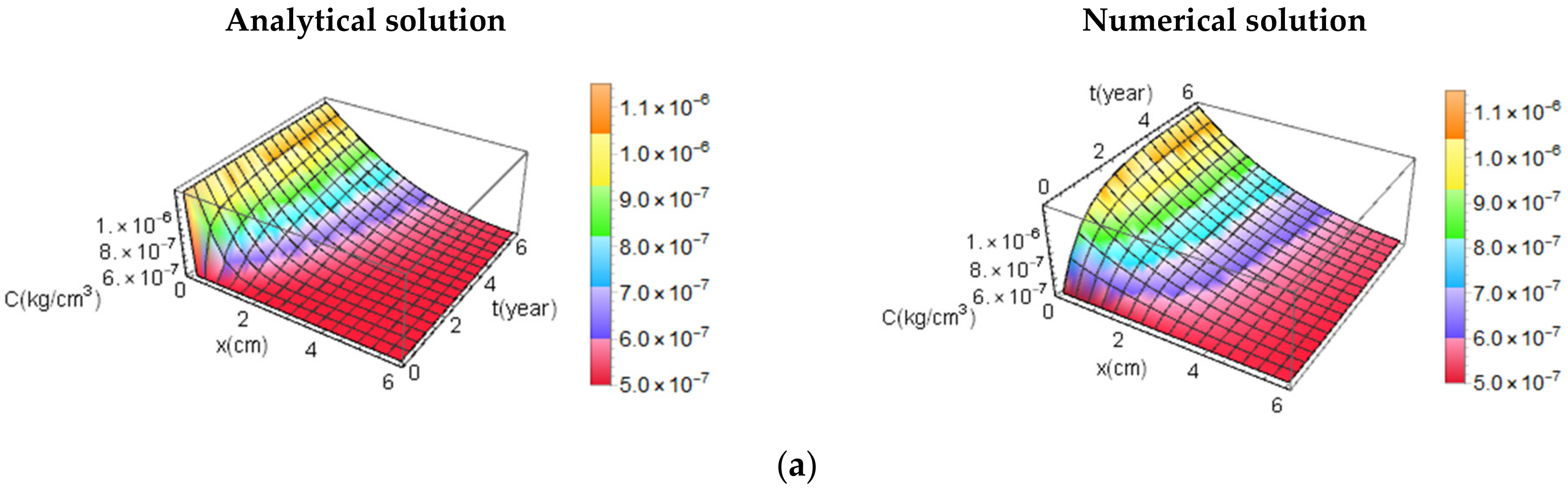

5.2. Numerical Results

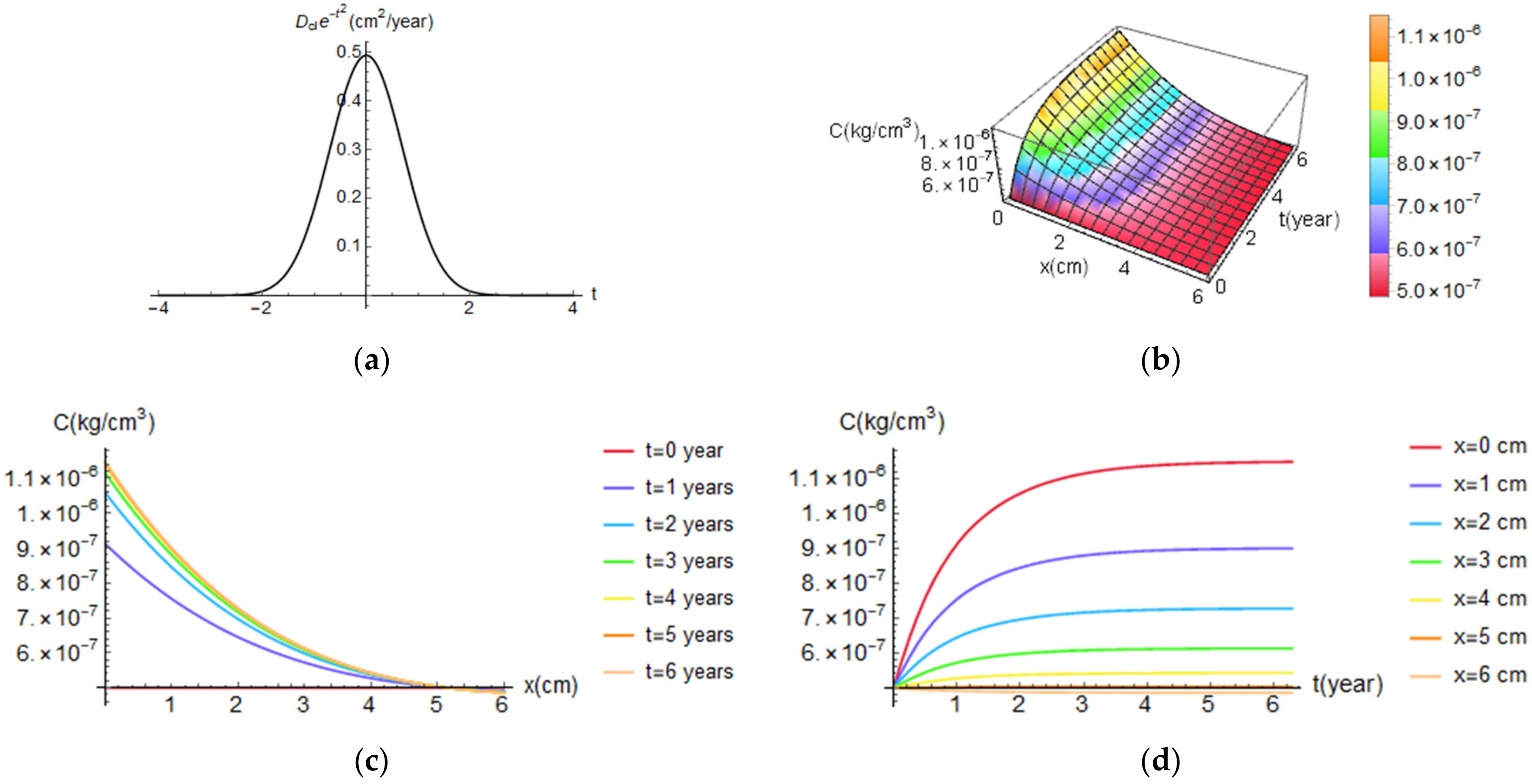

5.2.1. The 2D Chloride Diffusion

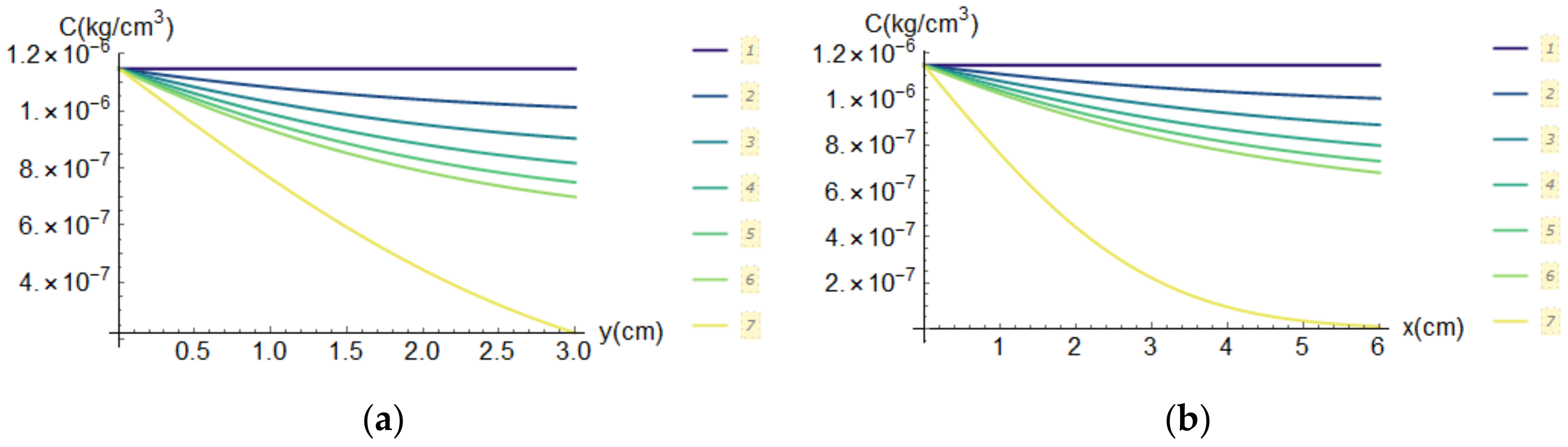

5.2.2. The 3D Chloride Diffusion

6. Conclusions

- (1)

- Three different probabilistic techniques (i.e., MCS, FORM, DI) were used to estimate the probability of failure of steel bars by considering the time of corrosion initiation. The probabilistic analyses were carried out using several simulations for each variable. PDF functions were defined, which have a great importance in practical applications since they enable the analyst to know if the probability of failure is acceptable according to the parameters involved (Table 2 and Figure 2). MCS is a technique used to evaluate some functions using several random variables. For each sample, a random variable is assigned as a deterministic value from which several random numbers are generated. The results are treated as a distribution, and they are statistically determined. MCSs directly provide the t-variant failure probability. Results show a strong influence of the T variation. It was also noted that MCS provides high values in favor of safety, i.e., ~6.5 years (Figure 4 and Table 3) with relatively few samples. A very good agreement was achieved with DI and FORM.

- (2)

- Numerical solutions were developed to study the trend of Dcl under different loadings. Fick’s II law expressed by Equation (2) is a highly non-linear equation hard to accurately solve. Considering Dcl as a non-constant value means to assume the problem as non-linear. These disadvantages make this model less attractive in practice. For this reason, analytical solutions are usually used. In particular, a methodology was proposed where four types of functions are used (Table 4). Results show that, due to the oscillations of the generic function (e.g., sinusoidal and general), the chloride content C can assume lower values with respect to C values for constant diffusivity. The 3D analyses, accounting for the random variability and advanced solutions, show that chloride C can be higher than ~1.50 compared to C by traditional approaches.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Ou, G.; Qiu, Q.; Chen, X.; Hong, J.; Xing, F. Chloride transport and microstructure of concrete with/without fly ash under atmospheric chloride condition. Constr. Build. Mater. 2017, 146, 493–501. [Google Scholar] [CrossRef]

- Farahani, A.; Taghaddos, H.; Shekarchizadeh, M. Prediction of long-term chloride diffusion in silica fume concrete in a marine environment. Cem. Concr. Compos. 2015, 59, 10–17. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Chateauneuf, A.; Sánchez-Silva, M.; Bressolette, P.; Schoefs, F. A comprehensive probabilistic model of chloride ingress in unsaturated concrete. Eng. Struct. 2011, 33, 720–730. [Google Scholar] [CrossRef]

- Pellizzer, G.P.; Leonel, E.D.; Nogueira, C.G. Numerical approach about the effect of the corrosion on the mechanical capacity of the reinforced concrete beams considering material nonlinear models. Rev. IBRACON Estruturas Mater. 2018, 11, 26–51. [Google Scholar] [CrossRef][Green Version]

- Zacchei, E.; Bastidas-Arteaga, E. Multifactorial Chloride Ingress Model for Reinforced Concrete Structures Subjected to Unsaturated Conditions. Buildings 2022, 12, 107. [Google Scholar] [CrossRef]

- Meira, G.R.; Andrade, M.C.; Padaratz, I.J.; Alonso, M.C.; Borba, J.C., Jr. Measurements and modelling of marine salt transportation and deposition in a tropical region in Brazil. Atmos. Environ. 2006, 40, 5596–5607. [Google Scholar] [CrossRef]

- El Hassan, J.; Bressolette, P.; Chateauneuf, A.; El Tawil, K. Reliability-based assessment of the effect of climatic conditions on the corrosion of RC structures subject to chloride ingress. Eng. Struct. 2010, 32, 3279–3287. [Google Scholar] [CrossRef]

- Stewart, M.G.; Mullard, J.A. Spatial time-dependent reliability analysis of corrosion damage and the timing of first repair for RC structures. Eng. Struct. 2007, 29, 1457–1464. [Google Scholar] [CrossRef]

- Al-Kutti, W.A.; Rahman, M.K.; Shazali, M.A.; Baluch, M.H. Enhancement in Chloride Diffusivity due to Flexural Damage in Reinforced Concrete Beams. J. Mater. Civ. Eng. 2014, 26, 658–667. [Google Scholar] [CrossRef]

- Xie, Y.; Guan, K.; Zhan, L.; Wang, Q. Mechanical Behavior and Chloride Penetration of Precracked Reinforced Concrete Beams with Externally Bonded CFRP Exposed to Marine Environment. Int. J. Polym. Sci. 2016, 2016, 1790585. [Google Scholar] [CrossRef]

- Zhang, R.; Castel, A.; François, R. Concrete cover cracking with reinforcement corrosion of RC beam during chlo-ride-induced corrosion process. Cem. Concr. Res. 2010, 40, 415–425. [Google Scholar] [CrossRef]

- Nguyen, P.T.; Bastidas-Arteaga, E.; Amiri, O.; El Soueidy, C.-P. An Efficient Chloride Ingress Model for Long-Term Lifetime Assessment of Reinforced Concrete Structures Under Realistic Climate and Exposure Conditions. Int. J. Concr. Struct. Mater. 2017, 11, 199–213. [Google Scholar] [CrossRef]

- Zhang, S.F.; Lu, C.H.; Liu, R.G. Experimental determination of chloride penetration in cracked concrete beams. Procedia Eng. 2011, 24, 380–384. [Google Scholar]

- Rahimi, A.; Gehlen, C. Semi-probabilistic approach to the service life design of reinforced concrete structures under chloride attack. Beton-Und Stahlbetonbau 2018, 113, 13–21. [Google Scholar] [CrossRef]

- Pang, L.; Li, Q. Service life prediction of RC structures in marine environment using long term chloride ingress data: Comparison between exposure trials and real structure surveys. Constr. Build. Mater. 2016, 113, 979–987. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, W.; Guo, L.; Gu, C.; Zong, J. Modeling Chloride Diffusion Coefficient of Steel Fiber Reinforced Concrete under Bending Load. Adv. Civ. Eng. 2018, 2018, 3789214. [Google Scholar] [CrossRef]

- Ortega, N.F.; Robles, S.I. Assessment of Residual Life of concrete structures affected by reinforcement corrosion. HBRC J. 2016, 12, 114–122. [Google Scholar] [CrossRef][Green Version]

- Lizarazo-Marriaga, J.; Claisse, P. Modelling chloride penetration in concrete using electrical voltage and current ap-proaches. Mater. Res. 2011, 14, 31–38. [Google Scholar] [CrossRef][Green Version]

- Malheiro, R.; Meira, G.; Lima, M.; Perazzo, N. Influence of mortar rendering on chloride penetration into concrete structures. Cem. Concr. Compos. 2010, 33, 233–239. [Google Scholar] [CrossRef][Green Version]

- Bastidas-Arteaga, E.; Schoefs, F.; Stewart, M.G.; Wang, X. Influence of global warning on durability of corroding RC structures: A probabilistic approach. Eng. Struct. 2013, 51, 259–266. [Google Scholar] [CrossRef]

- Zacchei, E.; Nogueira, C.G. 2D/3D numerical analysis of corrosion initiation in RC structures accounting fluctuation of chloride ions by external actions. KSCE J. Civ. Eng. 2021, 25, 2105–2120. [Google Scholar] [CrossRef]

- Frier, C.; Sorensen, J.D. Stochastic analysis of the multi-dimensional effect of chloride ingress into reinforced concrete. In Proceedings of the 10th International Conference, ICASP10, Applications of Statistics and Probability in Civil Engineering, Tokyo, Japan, 31 July–3 August 2007. [Google Scholar]

- Zacchei, E.; Nogueira, C.G. Calibration of boundary conditions correlated to the diffusivity of chloride ions: An accurate study for random diffusivity. Cem. Concr. Compos. 2021, 126, 104346. [Google Scholar] [CrossRef]

- Andrade, C.; Díez, J.M.; Alonso, C. Mathematical Modeling of a Concrete Surface “Skin Effect” on Diffusion in Chloride Contaminated Media. Adv. Cem. Based Mater. 1997, 6, 39–44. [Google Scholar] [CrossRef]

- Saetta, A.V.; Schrefler, B.A.; Vitaliani, R.V. 2-D model for carbonation and moisture/hear flow in porous materials. Cem. Concr. Res. 1995, 25, 1703–1712. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Wang, Y.; Ju, X.; Li, Q. Modelling of two-dimensional chloride diffusion concentrations considering the heterogeneity of concrete materials. Constr. Build. Mater. 2020, 243, 118213. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Lu, Z. Probabilistic assessment of reinforcing steel depassivation in concrete under aggressive chloride environments based on natural exposure data. J. Wuhan Univ. Technol. Sci. Ed. 2011, 26, 126–131. [Google Scholar] [CrossRef]

- Yuan, C.; Li, Y.; Chen, X.; Wang, W. Effect of Reinforced Concrete Cracking on Chloride Ion Penetration. MATEC Web Conf. 2015, 22, 04026. [Google Scholar] [CrossRef]

- Saassouh, B.; Lounis, Z. Probabilistic modelling of chloride-induced corrosion in concrete structures using first- and sec-ond-order reliability methods. Cem. Concr. Compos. 2012, 34, 1082–1093. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Evaluating effect of chloride attack and concrete cover on the probability of corrosion. Front. Struct. Civ. Eng. 2013, 7, 379–390. [Google Scholar] [CrossRef]

- Pang, R.; Xu, B.; Zhou, Y.; Song, L. Seismic time-history response ad system reliability analysis of slopes considering un-certainty of multi-parameters and earthquake excitations. Comput. Geotech. 2021, 136, 104245. [Google Scholar] [CrossRef]

- Pang, R.; Xu, B.; Zhou, Y.; Zhang, X.; Wang, X. Fragility analysis of high CFRDs subjected to mainshock-aftershock se-quences based on plastic failure. Eng. Struct. 2020, 206, 110152. [Google Scholar] [CrossRef]

- United Nations (UN). Transforming Our World: The 2030 Agenda for Sustainable Development; Technical Report A/RES/70/1; United Nations (UN): New York, NY, USA, 2015; p. 35. Available online: https://sdgs.un.org/2030agenda (accessed on 1 January 2022).

- Carrara, P.; De Lorenzis, L.; Bentz, D.P. Chloride diffusivity in hardened cement paste from microscale analyses and accounting for binding effects. Model. Simul. Mater. Sci. Eng. 2016, 24, 065009. [Google Scholar] [CrossRef] [PubMed]

- Andrade, C. Concepts on the chloride diffusion coefficient. In Proceedings of the Third RILEM Workshop on Testing and Modelling the Chloride Ingress into Concrete, Madrid, Spain, 9–10 September 2002. [Google Scholar]

- Sun, Y.-M.; Liang, M.-T.; Chang, T.-P. Time/depth dependent diffusion and chemical reaction model of chloride transportation in concrete. Appl. Math. Model. 2012, 36, 1114–1122. [Google Scholar] [CrossRef]

- Fu, C.; Jin, X.; Jin, N. Modeling of chloride ions diffusion in cracked concrete. In Proceedings of the Earth and Space 2010: Engineering, Science, Construction, and Operations in Challenging Environments, Honolulu, HI, USA, 14–17 March 2010; pp. 3579–3589. [Google Scholar]

- Fan, W.-J.; Wang, X.-Y. Prediction of Chloride Penetration into Hardening Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 616980. [Google Scholar] [CrossRef]

- Halamickova, P.; Detwiler, R.J.; Bentz, D.; Garboczi, E.J. Water permeability and chloride ion diffusion in Portland cement mortars: Relationship to sand content and critical pore diameter. Cem. Concr. Res. 1995, 25, 790–802. [Google Scholar] [CrossRef]

- Kong, J.S.; Ababneh, A.; Frangopol, D.; Xi, Y. Reliability analysis of chloride penetration in saturated concrete. Probabilistic Eng. Mech. 2002, 17, 305–315. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, J.; Zhang, J. A variable-order time-fractional derivative model for chloride ions sub-diffusion in concrete structures. Fract. Calc. Appl. Anal. 2012, 16, 76–92. [Google Scholar] [CrossRef]

- Wolfram Mathematica; Version 11, Student ed.; Wolfram Research: Champaign, IL, USA, 2017; Available online: https://www.wolfram.com/mathematica/ (accessed on 14 April 2022).

- Fu, C.; Jin, X.; Ye, H.; Jin, N. Theoretical and Experimental Investigation of Loading Effects on Chloride Diffusion in Saturated Concrete. J. Adv. Concr. Technol. 2015, 13, 30–43. [Google Scholar] [CrossRef]

- Zacchei, E.; Nogueira, C.G. Chloride diffusion assessment in RC structures considering the stress-strain sate effects and crack width influences. Constr. Build. Mater. 2019, 201, 100–109. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, L.; Wang, Y.; Liu, C.; Li, Q. Effects of coarse aggregates on chloride diffusion coefficients of concrete and interfacial transition zone under experimental drying-wetting cycles. Constr. Build. Mater. 2018, 185, 230–245. [Google Scholar] [CrossRef]

- Damrongwiriyanupap, N.; Limkatanyu, S.; Xi, Y. A Thermo-Hygro-Coupled Model for Chloride Penetration in Concrete Structures. Adv. Mater. Sci. Eng. 2015, 2015, 682940. [Google Scholar] [CrossRef]

- Zofia, S.; Adam, Z. Theoretical model and experimental tests on chloride diffusion and migration processes in concrete. Procedia Eng. 2013, 57, 1121–1130. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Lee, B.-J.; Kwon, S.-J. Evaluation Technique of Chloride Penetration Using Apparent Diffusion Coefficient and Neural Network Algorithm. Adv. Mater. Sci. Eng. 2014, 2014, 647243. [Google Scholar] [CrossRef]

- Van Mien, T.; Stitmannaithum, B.; Nawa, T. Simulation of chloride penetration into concrete structures subjected to both cyclic flexural loads and tidal effects. Comput. Concr. 2009, 6, 421–435. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Najjar, L.J. Nonlinear water diffusion in nonsaturated concrete. Mater. Struct. 1972, 5, 3–20. [Google Scholar] [CrossRef]

- Ishida, T.; Iqbal, P.O.; Anh, H.T.L. Modeling of chloride diffusivity coupled with non-linear binding capacity in sound and cracked concrete. Cem. Concr. Res. 2009, 39, 913–923. [Google Scholar] [CrossRef]

- Nogueira, C.G.; Leonel, E.D.; Coda, H.B. Probabilistic failure modelling of reinforced concrete structures subjected to chloride penetration. Int. J. Adv. Struct. Eng. 2012, 4, 10. [Google Scholar] [CrossRef]

- Michel, A.; Solgaard, A.; Pease, B.J.; Geiker, M.R.; Stang, H.; Olesen, J.F. Experimental investigation of the relation between damage at the concrete-steel interface and initiation of reinforcement corrosion in plain and fibre reinforced concrete. Corros. Sci. 2013, 77, 308–321. [Google Scholar] [CrossRef]

- Rosenblatt, M. Remarks on a Multivariate Transformation. Ann. Math. Stat. 1952, 23, 470–472. [Google Scholar] [CrossRef]

- Oliveira, H.L.; Chateauneuf, A.; Leonel, E.D. Probabilistic mechanical modelling of concrete creep based on the boundary element method. Adv. Struct. Eng. 2018, 22, 337–348. [Google Scholar] [CrossRef]

- Apostolopoulos, C.; Papadakis, V. Consequences of steel corrosion on the ductility properties of reinforcement bar. Constr. Build. Mater. 2007, 22, 2316–2324. [Google Scholar] [CrossRef]

- Suo, Q.; Stewart, M.G. Corrosion cracking prediction updating of deteriorating RC structures using inspection information. Reliab. Eng. Syst. Saf. 2009, 94, 1340–1348. [Google Scholar] [CrossRef]

- Dattoli, G. Generalized polynomials, operational identities and their applications. J. Comput. Appl. Math. 2000, 118, 111–123. [Google Scholar] [CrossRef]

- Martin-Perez, B.; Pantazopoulou, S.; Thomas, M. Numerical solution of mass transport equations in concrete structures. Comput. Struct. 2001, 79, 1251–1264. [Google Scholar] [CrossRef]

- Homan, L.; Ababneh, A.; Xi, Y. The effect of moisture transport on chloride penetration in concrete. Constr. Build. Mater. 2016, 125, 1189–1195. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Tang, L.; Memon, S.A.; Ma, G.; Xing, F.; Sun, H. Corrosion induced stress field and cracking time of reinforced concrete with initial defects: Analytical modeling and experimental investigation. Corros. Sci. 2017, 120, 158–170. [Google Scholar] [CrossRef]

| α [44] | β [44] | Dcl,ref [29] | w/c * | T0 [40] |

| 11.80 | 4.0 | 0.40 cm2/year | 0.50 a | 23.0 °C (296.0 K) |

| R [40] | tref [43] | T * | tr [43] | hDcl [50] |

| 8.134 J/mol K | 28 days (0.076 years) | 25.0 years | 30.0 years | 0.75 |

| Parameter | PDF Distribution | μ | ±σ a | CV (%) |

|---|---|---|---|---|

| Ea (kJ/mol) | Normal | 44.60 [40] b | 4.30 | 10.0 |

| T (°C) | Normal | 23.0 *c | 8.0 | 35.0 |

| Cf (kg/m3) | Log-normal | 1.50 [44] | 0.75 | 50.0 |

| ωe | Beta (5, 1) | 0.83 * | 0.1408 | 17.0 |

| m | Beta (1, 4) | 0.20 [48] | 0.1632 | 82.0 |

| h | Beta (4, 1) | 0.80 * | 0.1632 | 20.0 |

| n | Uniform (0, 12) | 6.0 [50] | 3.4641 | 58.0 |

| xc (cm) | Log-normal | 5.0 *d | 1.50 | 30.0 |

| C0 (kg/m3) | Uniform (0, 1) | 0.50 * | 0.2886 | 58.0 |

| Cs (kg/m3) | Log-normal | 1.15 [7] e | 0.575 | 50.0 |

| Scenario I a Dcl = 0.423 cm2/Year Cb = 3.31 × 10−6 kg/cm3 | Scenario II Dcl = 0.256 cm2/Year Cb = 3.31 × 10−6 kg/cm3 | Scenario III Dcl = 0.256 cm2/Year Cb = 4.51 × 10−6 kg/cm3 | ||||

|---|---|---|---|---|---|---|

| μtR (Year) | σtR (Year) | μtR (Year) | σtR (Year) | μtR (Year) | σtR (Year) | |

| MCS | 21.44 (14.11) b | 14.95 (4.68) | 35.41 (23.39) | 24.96 (8.01) | 35.03 (23.31) | 24.58 (7.98) |

| FORM | 14.82 | 4.21 | 24.36 | 6.92 | 24.36 | 6.36 |

| DI | 14.87 | 5.20 | 24.41 | 8.54 | 24.41 | 8.54 |

| Type | Dcl × fD(x,t) | Possible Applications |

|---|---|---|

| Constant | Dcl × constant |

|

| Sinusoidal | Dcl × Sin(t) |

|

| Gaussian |

| |

| General | a |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zacchei, E.; Nogueira, C.G. Numerical Solutions for Chloride Diffusion Fluctuation in RC Elements from Corrosion Probability Assessments. Buildings 2022, 12, 1211. https://doi.org/10.3390/buildings12081211

Zacchei E, Nogueira CG. Numerical Solutions for Chloride Diffusion Fluctuation in RC Elements from Corrosion Probability Assessments. Buildings. 2022; 12(8):1211. https://doi.org/10.3390/buildings12081211

Chicago/Turabian StyleZacchei, Enrico, and Caio Gorla Nogueira. 2022. "Numerical Solutions for Chloride Diffusion Fluctuation in RC Elements from Corrosion Probability Assessments" Buildings 12, no. 8: 1211. https://doi.org/10.3390/buildings12081211

APA StyleZacchei, E., & Nogueira, C. G. (2022). Numerical Solutions for Chloride Diffusion Fluctuation in RC Elements from Corrosion Probability Assessments. Buildings, 12(8), 1211. https://doi.org/10.3390/buildings12081211