Shaking Table Test and Parameter Analysis on Vibration Control of a New Damping System (PDAL)

Abstract

:1. Introduction

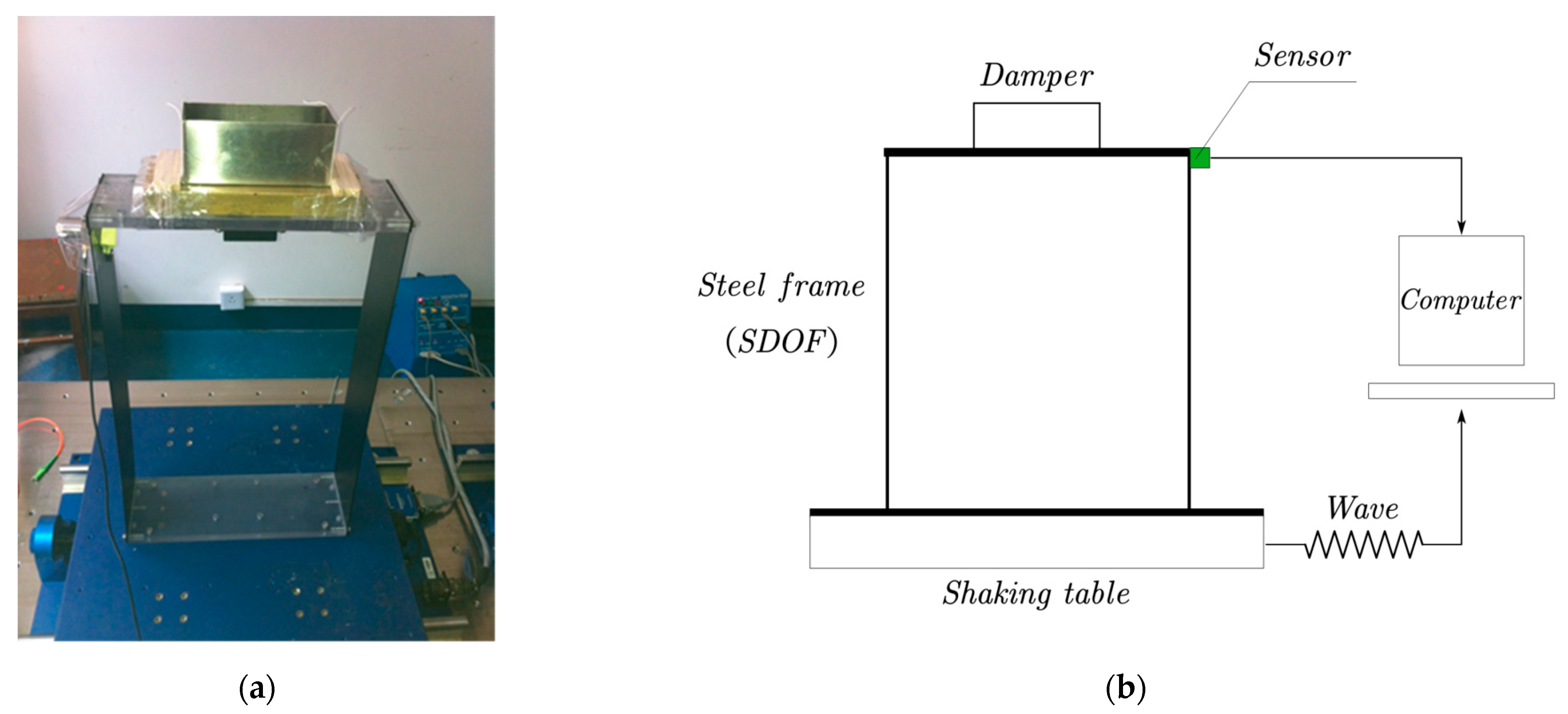

2. Structure of PDAL System and Experimental Setup

2.1. Structure of PDAL System

2.2. Experimental Setup

3. Shaking Table Test Result and Discussion

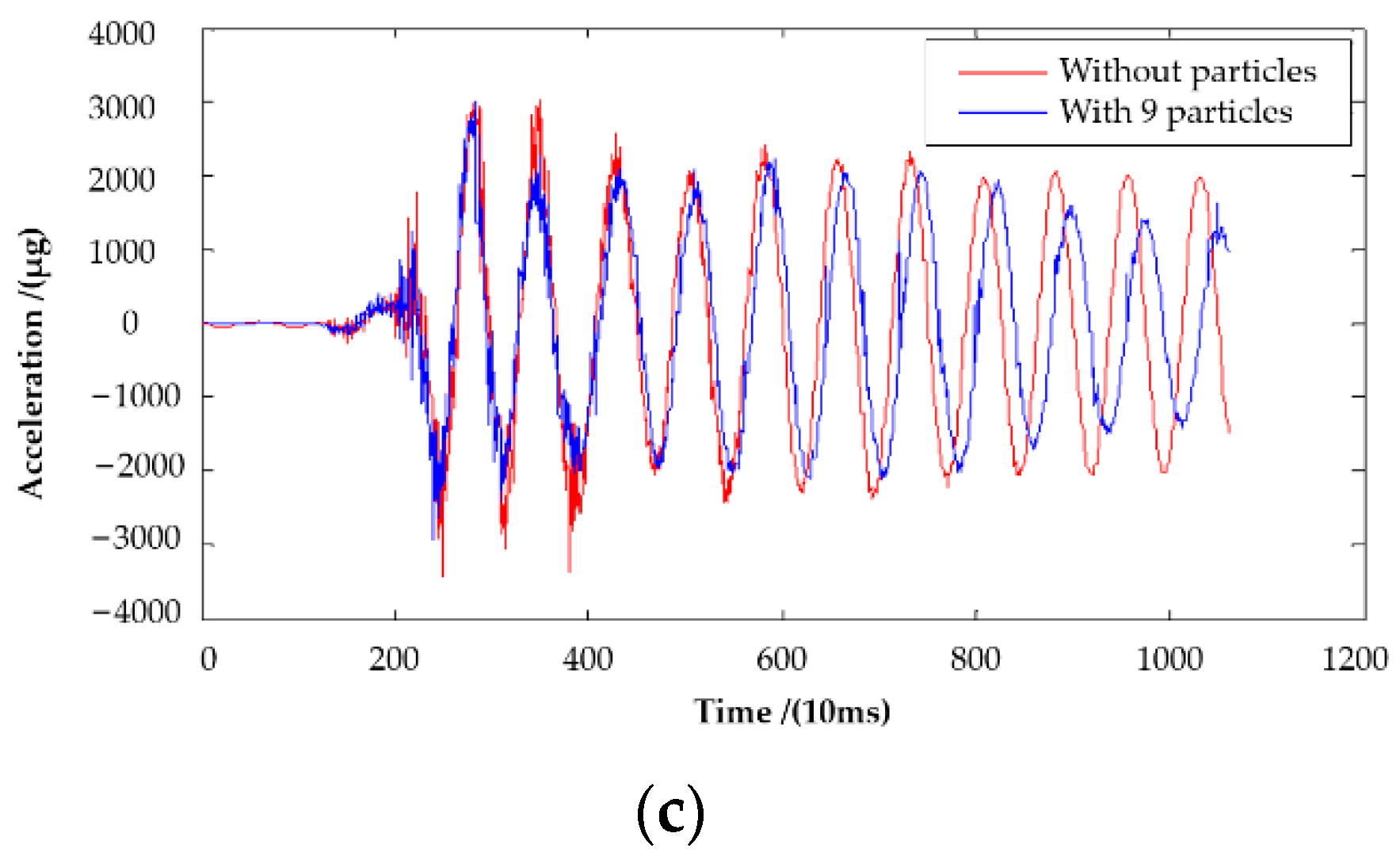

3.1. Validation of PDAL’s Effectiveness

3.2. Parameter Analysis

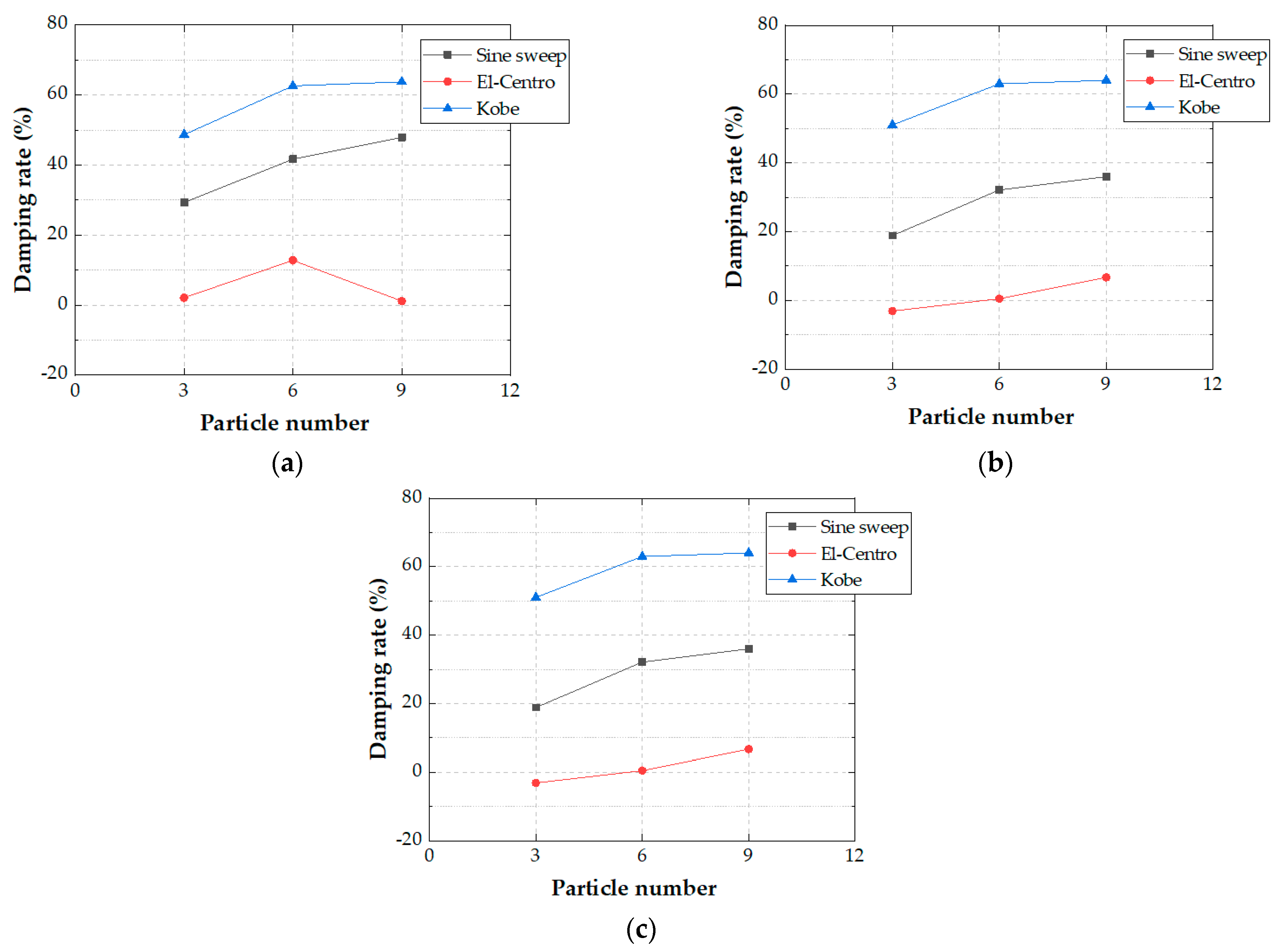

3.2.1. Particle Numbers (Filling Rate of Particles)

3.2.2. Waves

3.2.3. Mass Ratio

4. Conclusions

- (1)

- Compared with traditional PD and TLD systems, the PDAL system’s superiority and reliability when it was installed in a steel frame structure were well demonstrated.

- (2)

- The damping effect of PDAL is relatively insignificant in the initial time period, but the control effect upon the structural response became obvious after a few seconds. Therefore, the effect of possible input seismic waves on the damping effect needs to be taken into account in the actual design process.

- (3)

- The PDAL system is effective in controlling the structure’s vibration (not only in the steel frame structure used in this paper but also in concrete structures used in already available references [35,36]). In actual engineering applications, various parameters need to be optimized, such as particle number (filling rate of particles), liquid mass ratio, vessel size, and other aspects, in order to achieve the optimal structure control effect. Moreover, PDAL may have a certain effect on the dynamic characteristics of the structure itself. Hence when designing this kind of damping system in actual projects, the dynamic characteristics of each structure given the addition of PDAL should be analyzed in detail in order to obtain the optimal values for the influencing parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rong, K.; Lu, Z. An improved ESM-FEM method for seismic control of particle tuned mass damper in MDOF system. Appl. Acoust. 2021, 172, 107663. [Google Scholar] [CrossRef]

- Hu, Y.W.; Liu, L.F.; Rahimi, S. Seismic Vibration Control of 3D Steel Frames with Irregular Plans Using Eccentrically Placed MR Dampers. Sustainability 2017, 9, 1255. [Google Scholar] [CrossRef] [Green Version]

- El Ouni, M.H.; Laissy, M.Y.; Ismaeil, M.; Ben Kahla, N. Effect of Shear Walls on the Active Vibration Control of Buildings. Buildings 2018, 8, 164. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Yang, Y.; Sun, Y.; Zhong, Y.; Zhou, L.; Li, S.; Wu, C. Tuned-Mass-Damper-Inerter Performance Evaluation and Optimal Design for Transmission Line under Harmonic Excitation. Buildings 2022, 12, 435. [Google Scholar] [CrossRef]

- Housner, G.W.; Bergman, L.A.; Caughey, T.K.; Chassiakos, A.G.; Claus, R.O.; Masri, S.F.; Skelton, R.E.; Soong, T.T.; Spencer, B.F.; Yao, J.T.P. Structural Control: Past, Present, and Future. J. Eng. Mech. 1997, 123, 897–971. [Google Scholar] [CrossRef]

- Hurlebaus, S.; Gaul, L. Smart structure dynamics. Mech. Syst. Signal Process. 2006, 20, 255–281. [Google Scholar] [CrossRef]

- Reiterer, M.; Schellander, J. A Novel Single Tube Semi-Active Tuned Liquid Gas Damper for Suppressing Horizontal Vibrations of Tower-like Structures. Appl. Sci. 2022, 12, 3301. [Google Scholar] [CrossRef]

- Sadeghian, M.A.; Yang, J.; Wang, F.; Wang, X. Structural Vibration Control Using Novel Adaptive Tuned Mass Inertance Damper (ATMID) with Adjustable Inertance. Appl. Sci. 2022, 12, 4028. [Google Scholar] [CrossRef]

- Shen, Y.J.; Yang, S.P.; Xing, H.J.; Ma, H.X. Design of Single Degree-of-freedom Optimally Passive Vibration Isolation System. J. Vib. Eng. Technol. 2015, 3, 25–36. [Google Scholar]

- Nochebuena-Mora, E.; Mendes, N.; Lourenco, P.B.; Covas, J.A. Vibration control systems: A review of their application to historical unreinforced masonry buildings. J. Build. Eng. 2021, 44, 103333. [Google Scholar] [CrossRef]

- Zhao, B.; Gao, H.; Wang, Z.; Lu, Z. Shaking table test on vibration control effects of a monopile offshore wind turbine with a tuned mass damper. Wind Energy 2018, 21, 1309–1328. [Google Scholar] [CrossRef]

- Lu, Z.; Li, K.; Ouyang, Y.; Shan, J. Performance-based optimal design of tuned impact damper for seismically excited nonlinear building. Eng. Struct. 2018, 160, 314–327. [Google Scholar] [CrossRef]

- Konar, T.; Ghosh, A.D. Flow Damping Devices in Tuned Liquid Damper for Structural Vibration Control: A Review. Arch. Comput. Methods Eng. 2020, 28, 2195–2207. [Google Scholar] [CrossRef]

- Ghaedi, K.; Ibrahim, Z.; Adeli, H.; Javanmardi, A.J. Invited Review: Recent developments in vibration control of building and bridge structures. J. Vibroeng. 2017, 19, 3564–3580. [Google Scholar]

- Bigdeli, Y.; Kim, D. Damping effects of the passive control devices on structural vibration control: TMD, TLC and TLCD for varying total masses. KSCE J. Civ. Eng. 2015, 20, 301–308. [Google Scholar] [CrossRef]

- Lu, Z.; Li, K.; Zhou, Y. Comparative Studies on Structures with a Tuned Mass Damper and a Particle Damper. J. Aerosp. Eng. 2018, 31. [Google Scholar] [CrossRef]

- Shi, W.X.; Wang, L.K.; Lu, Z.; Gao, H. Study on Adaptive-Passive and Semi-Active Eddy Current Tuned Mass Damper with Variable Damping. Sustainability 2018, 10, 99. [Google Scholar] [CrossRef] [Green Version]

- Ocak, A.; Nigdeli, S.M.; Bekdaş, G.; Kim, S.; Geem, Z.W. Adaptive Harmony Search for Tuned Liquid Damper Optimization under Seismic Excitation. Appl. Sci. 2022, 12, 2645. [Google Scholar] [CrossRef]

- Luo, Z.; Yan, W.; Xu, W.; Zheng, Q.; Wang, B. Experimental research on the multilayer compartmental particle damper and its application methods on long-period bridge structures. Front. Struct. Civ. Eng. 2019, 13, 751–766. [Google Scholar] [CrossRef]

- Vandiver, J.K.; Mitome, S. Effect of liquid storage tank on the dynamic response of offshore platform. Appl. Ocean Res. 1979, 1, 67–74. [Google Scholar] [CrossRef]

- Modi, V.J.; Sun, J.; Shupe, L.S.; Solyomvari, A.S. Suppression of wind-induced instabilities using nutation dampers. Proc. Indian Acad. Sci. Sect. C: Eng. Sci. 1981, 4, 461–470. [Google Scholar] [CrossRef]

- Kareem, A.; Sun, W.J. Stochastic response of structures with fluid-containing appendages—ScienceDirect. J. Sound Vib. 1987, 119, 389–408. [Google Scholar] [CrossRef]

- Fujii, K.; Tamura, Y.; Sato, T.; Wakahara, T. Wind-induced vibration of tower and practical applications of tuned sloshing damper. J. Wind Eng. Ind. Aerodyn. 1990, 33, 263–272. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, J.T.; Jin, F.; Lu, L.Q.; Gui, Y.; Zhou, M.X. Monitoring, H. Real-time hybrid simulation of the size effect of tuned liquid dampers. Struct. Control Health Monit. 2017, 24, e1962. [Google Scholar] [CrossRef]

- Lee, S.K.; Park, E.C.; Min, K.W.; Lee, S.H.; Lan, C.; Park, J.H. Real-time hybrid shaking table testing method for the performance evaluation of a tuned liquid damper controlling seismic response of building structures. J. Sound Vib. 2007, 302, 596–612. [Google Scholar] [CrossRef]

- Ashasi-Sorkhabi, A.; Malekghasemi, H.; Ghaemmaghami, A.; Mercan, O. Experimental investigations of tuned liquid damper-structure interactions in resonance considering multiple parameters. J. Sound Vib. 2016, 388, 141–153. [Google Scholar]

- Lu, Z.; Masri, S.F.; Lu, X. Parametric studies of the performance of particle dampers under harmonic excitation. Struct. Control Health Monit. 2011, 18, 79–98. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, Z.; Masri, S.F.; Lu, X. Particle impact dampers: Past, present, and future. Struct. Control Health Monit. 2018, 18, e2058. [Google Scholar] [CrossRef]

- Lu, Z.; Lu, X.; Masri, S.F. Studies of the performance of particle dampers under dynamic loads. J. Sound Vib. 2010, 329, 5415–5433. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, X.Y.; Zhang, D.C.; Dai, K.S. Experimental and analytical study on the performance of particle tuned mass dampers under seismic excitation. Earthq. Eng. Struct. Dyn. 2017, 46, 697–714. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, D.; Li, P. Comparison Study of Vibration Control Effects between Suspended Tuned Mass Damper and Particle Damper. Shock Vib. 2014, 2014, 903780. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Wang, D.C.; Zhou, Y. Experimental parametric study on wind-induced vibration control of particle tuned mass damper on a benchmark high-rise building. Struct. Des. Tall Spec. Build. 2017, 26, e1359. [Google Scholar] [CrossRef]

- Rakhio, A.; Ido, Y.; Iwamoto, Y.; Toyouchi, A. Experimental and Numerical Analysis of Torque Properties of Rotary Elastomer Particle Damper considering the Effect of Gap and No Gap between Rotor and Body of the Damper. Shock Vib. 2021, 2021, 7724156. [Google Scholar] [CrossRef]

- Soto, M.G.; Adeli, H. Tuned Mass Dampers. Arch. Comput. Methods Eng. 2013, 20, 419–431. [Google Scholar] [CrossRef]

- Lu, Z.; Liao, Y.; Zhou, Y. Experimental and numerical study on vibration control effects of a compound mass damper. Struct. Des. Tall Spéc. Build. 2018, 27, e1511. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, X.L.; He, R.F.; Yu, C.H.; Cheng, J. Experimental Study on Shaking Table Test of a Combined Mass Damper. In Proceedings of the 3rd International Conference on Power and Energy Systems (PES 2016), Bangkok, Thailand, 30–31 December 2016; pp. 43–46. [Google Scholar]

| Weight/kg | Self-Vibration Frequency/Hz | Lateral Stiffness/(N/m) |

|---|---|---|

| 1.60 | 2.50 | 500 |

| Waves | Particle Number | Acceleration Value (m/s2) | |||

|---|---|---|---|---|---|

| Amplitude | Root Mean Square | Amplitude | Root Mean Square | ||

| Sine sweep | 0 | 3.916 | 1.266 | / | / |

| 3 | 3.051 | 0.965 | 20.10669 | 29.32568 | |

| 6 | 3.373 | 0.796 | 11.65684 | 41.69899 | |

| 9 | 2.740 | 0.712 | 28.23888 | 47.90181 | |

| El-Centro | 0 | 3.360 | 1.237 | / | / |

| 3 | 3.410 | 1.189 | −4.75579 | 2.093733 | |

| 6 | 4.024 | 1.059 | −23.6312 | 12.79345 | |

| 9 | 3.007 | 1.201 | 7.612519 | 1.130037 | |

| Kobe | 0 | 6.035 | 2.315 | / | / |

| 3 | 5.787 | 1.344 | 29.17841 | 48.67777 | |

| 6 | 5.337 | 0.979 | 34.67891 | 62.61422 | |

| 9 | 5.047 | 0.950 | 38.23357 | 63.74366 | |

| Waves | Particle Number | Acceleration Value (m/s2) | |||

|---|---|---|---|---|---|

| Amplitude | Root Mean Square | Amplitude | Root Mean Square | ||

| Sine sweep | 0 | 3.912 | 1.317 | / | / |

| 3 | 3.416 | 1.108 | 10.5517 | 18.8453 | |

| 6 | 2.920 | 0.927 | 23.52005 | 32.11324 | |

| 9 | 3.041 | 0.874 | 20.37093 | 35.98722 | |

| El-Centro | 0 | 3.262 | 1.221 | / | / |

| 3 | 3.270 | 1.253 | −0.46486 | −3.1095 | |

| 6 | 3.136 | 1.209 | 3.652485 | 0.473184 | |

| 9 | 3.046 | 1.134 | 6.403217 | 6.681852 | |

| Kobe | 0 | 5.864 | 2.045 | / | / |

| 3 | 5.706 | 1.283 | 30.16902 | 51.01045 | |

| 6 | 5.065 | 0.969 | 38.01302 | 63.00508 | |

| 9 | 4.920 | 0.942 | 39.78374 | 64.03637 | |

| Waves | Particle Number | Acceleration Value (m/s2) | |||

|---|---|---|---|---|---|

| Amplitude | Root Mean Square | Amplitude | Root Mean Square | ||

| Sine sweep | 0 | 3.839 | 1.273 | / | / |

| 3 | 3.142 | 1.149 | 17.71598 | 15.90227 | |

| 6 | 3.531 | 1.006 | 7.531956 | 26.33654 | |

| 9 | 3.202 | 0.897 | 16.15124 | 34.31194 | |

| El-Centro | 0 | 3.427 | 1.133 | / | / |

| 3 | 3.964 | 1.382 | −21.7966 | −13.7392 | |

| 6 | 3.575 | 1.384 | −9.84401 | −13.8886 | |

| 9 | 2.995 | 1.193 | 7.993192 | 1.754671 | |

| Kobe | 0 | 5.551 | 1.918 | / | / |

| 3 | 5.458 | 1.176 | 33.2045 | 55.10495 | |

| 6 | 5.363 | 1.038 | 34.35703 | 60.35266 | |

| 9 | 4.925 | 0.979 | 39.72487 | 62.62295 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, H.; Fan, Q.; Lu, Z. Shaking Table Test and Parameter Analysis on Vibration Control of a New Damping System (PDAL). Buildings 2022, 12, 896. https://doi.org/10.3390/buildings12070896

Ren H, Fan Q, Lu Z. Shaking Table Test and Parameter Analysis on Vibration Control of a New Damping System (PDAL). Buildings. 2022; 12(7):896. https://doi.org/10.3390/buildings12070896

Chicago/Turabian StyleRen, Hongmei, Qiaoqiao Fan, and Zheng Lu. 2022. "Shaking Table Test and Parameter Analysis on Vibration Control of a New Damping System (PDAL)" Buildings 12, no. 7: 896. https://doi.org/10.3390/buildings12070896

APA StyleRen, H., Fan, Q., & Lu, Z. (2022). Shaking Table Test and Parameter Analysis on Vibration Control of a New Damping System (PDAL). Buildings, 12(7), 896. https://doi.org/10.3390/buildings12070896