1. Introduction

The building envelope as a barrier between the interior and the exterior must fulfil multiple building physics requirements, such as heat, moisture, airtightness, sound, and light [

1], in order to provide the user with comfortable conditions and low energy demand of the building’s operation. Massive constructions integrate all requirements in one monolithic element, resulting in a high simplicity but at the same time very limited potential to optimize individual functionalities [

1]. Multilayered facades, on the other hand, allow an optimization of individual layers with varying material properties for specific functionalities [

2]. The downside of this approach is that it leads to a very high complexity, along with a high error rate and a low recycling potential. Therefore, efforts are being made to integrate and optimize functions into building elements in a way that does not come with these drawbacks.

Apart from the complexity, the thickness of the wall as well as the material and resource consumption play significant roles in the design of exterior walls with respect to environmental quality. The application of conventional normal-weight concrete to massive walls would result in an unrealistic wall thickness to fulfil the requirements of the U-value. Alternatively, the use of an additional isolation layer would result in a multilayered composite construction, again with increased complexity and decreased recyclability. Lightweight concrete elements can be realized at a smaller width due to lower thermal conductivity. However, the required width for insulation purposes with a monolithic element usually still exceeds the structural needs for standard lightweight concrete mixtures. Thus, there is potential to reduce the material and resource consumption while maintaining or even enhancing the thermal performance. This can be achieved if the wall is not cast as a massive element, but by modifying the inner structure to be similar to hollow bricks instead of solid bricks. Additive manufacturing (AM) is very promising in this context.

AM already revolutionized many industry sectors and is expected to be a key technology for the digitalization of the construction industry [

3]. Amongst other advantages [

4], one key benefit is that AM allows a high-level functionality to be directly embedded into building elements [

5], in particular by functionally graded materials (FGMs) [

6] or by creating complex external and internal geometries [

4]. This approach opens the way to go from complex, multilayered, multi-material building components to mono-material components with multiple integrated and optimized functions, enhancing recyclability, costs, and error rate as well as its performance in terms of building physics. So far, first approaches of multi-functional, mono-material components can be found in the literature using plastic as the feed material for improved thermal insulation [

7], even with an additional integrated movable liquid heat storage [

8]. There is the question of the applicability of this choice of material in large scale construction due to fire safety and especially for load-bearing structures, but it nevertheless shows high potential for integrated and optimized functionalities. For application in the construction industry, concrete extrusion shows a high potential [

9]. Concrete extrusion describes an AM technology where concrete strands are deposited layer by layer in order to build a free-form concrete element. Walls for residential buildings were already extruded with this technology [

10]. By combining this AM technology with lightweight concrete [

11], and optimizing its inner structure, monolithic building elements are possible, optimizing both structural and building physics performance [

12]. As an object is not cast filling the whole space within the formwork, but built of selectively deposited strands only where material is needed, honeycomb and similar inner structures with insulating air-filled cells can be produced, simultaneously increasing thermal performance and reducing resource consumption. However, the effect on thermal conductivity of such structures has not yet been adequately analyzed.

In order to allow an assessment and optimization of integrated thermal functionalities, a detailed thermal evaluation of geometrically complex AM elements is required. Common methods for the evaluation of thermal transmittance, such as the calculation method according to ISO 6946:2017, are not applicable for more complex geometries. Therefore, it is necessary to analyze and evaluate the thermal performance in a different way. A typical approach to assess the thermal performance of such geometries is to rely on physical measurements. Catchpole-Smith et al. [

13] and Tuck et al. [

14] investigated the thermal performance of additively manufactured steel lattice cells by experimental thermal measurements, whereas Piccioni et al. [

7] proposed a digital workflow based on heat transfer simulations, analytical models, and physical measurements to design polymer façade panels with internal cellular structures that are fabricated by fused deposition modeling.

One challenge simulation models face is that both the concrete strands and the voids of an internal structure must be evaluated with regard to heat transfer, considering all heat transfer mechanisms such as conduction, convection, and radiation. In addition, three-dimensionally complex structures can also lead to inhomogeneous thermal properties. Moreover, in such optimized structures, the direction of the heat flux is not only horizontal through the element, but heat can also be diffused vertically or in any other direction within the element. This paper therefore investigates these aspects inspired by the research of Piccioni et al. [

7], adding a differentiated evaluation of 2D and 3D heat flux, a holistic and detailed analytical evaluation, and in situ measurements on an existing prototype. As a result, the present research enables a validated thermal assessment by virtual and physical experiments, thus paving the way for a reliable thermal optimization of an extrusion-based AM lightweight concrete wall element with an internal cellular structure.

2. Materials and Methods

2.1. Extrusion of Lightweight Concrete

Concrete extrusion describes an additive manufacturing technology where concrete strands are deposited layer by layer in order to build a free-form concrete element. In this paper, the focus lies on a lightweight concrete optimized for extrusion. An additively manufactured element made of lightweight concrete with a cellular structure and air-filled voids (for the geometric design see [

15] and

Section 2.2) was produced. The lightweight concrete was composed of expanded glass granulate with a grain size of 0.1–2.0 mm, a Portland limestone cement specially developed for this application [

16], silica fume, and additives. Before pumping, the mixture had a density of approx. 1070 kg/m

3.

For the extrusion process, the material was pumped with a Knauf PFT Swing L FC-400V mortar pump through a 10 m hose and deposited through a round nozzle with a diameter of 22 mm. After deposition, the lightweight concrete had a density of approx. 1460 kg/m3, mostly due to the water absorption of the lightweight aggregates under the pumping pressure. The deposited lightweight concrete strands had a height of 9 mm and a width of approx. 19 mm. As the contour length of the object varied with height due to the opening and closing of the hollow cells and due to the fact that the velocity of the printer was kept constant at approx. 150 mm/s, the layer time varied between 50 s and 1.5 min. The printed element was stored in a hall at 20 ± 5 °C. During hardening, part of the absorbed water was released from the lightweight aggregates and served as an internal curing aid. Thus, the density of the material decreased hyperbolically over time, reaching a density of approx. 1320 kg/m3 at the time of the thermal measurements.

2.2. Design Tool and Manufactured Demonstrator with Closed-Cell Geometry

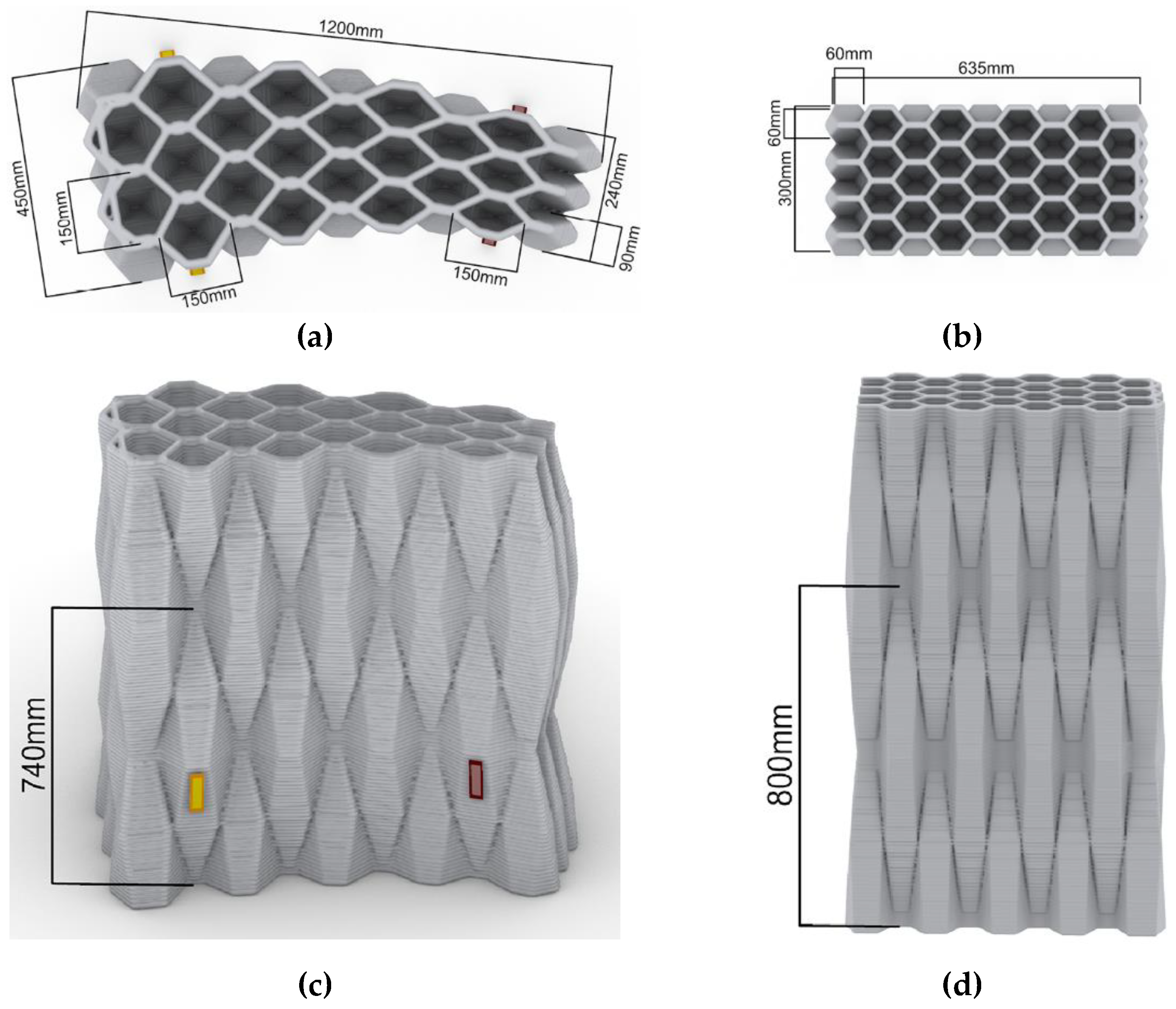

A tool was developed by Jaugstetter [

17] to design complex geometries which fulfill the requirements for a layerwise extrusion process. In order to enhance the thermal performance of extruded lightweight concrete elements, this tool enables an internal cellular structure to be integrated with encapsulated air-filled voids. The parametric modeling is realized within Grasshopper for Rhino [

18] by specially developed Python scripts.

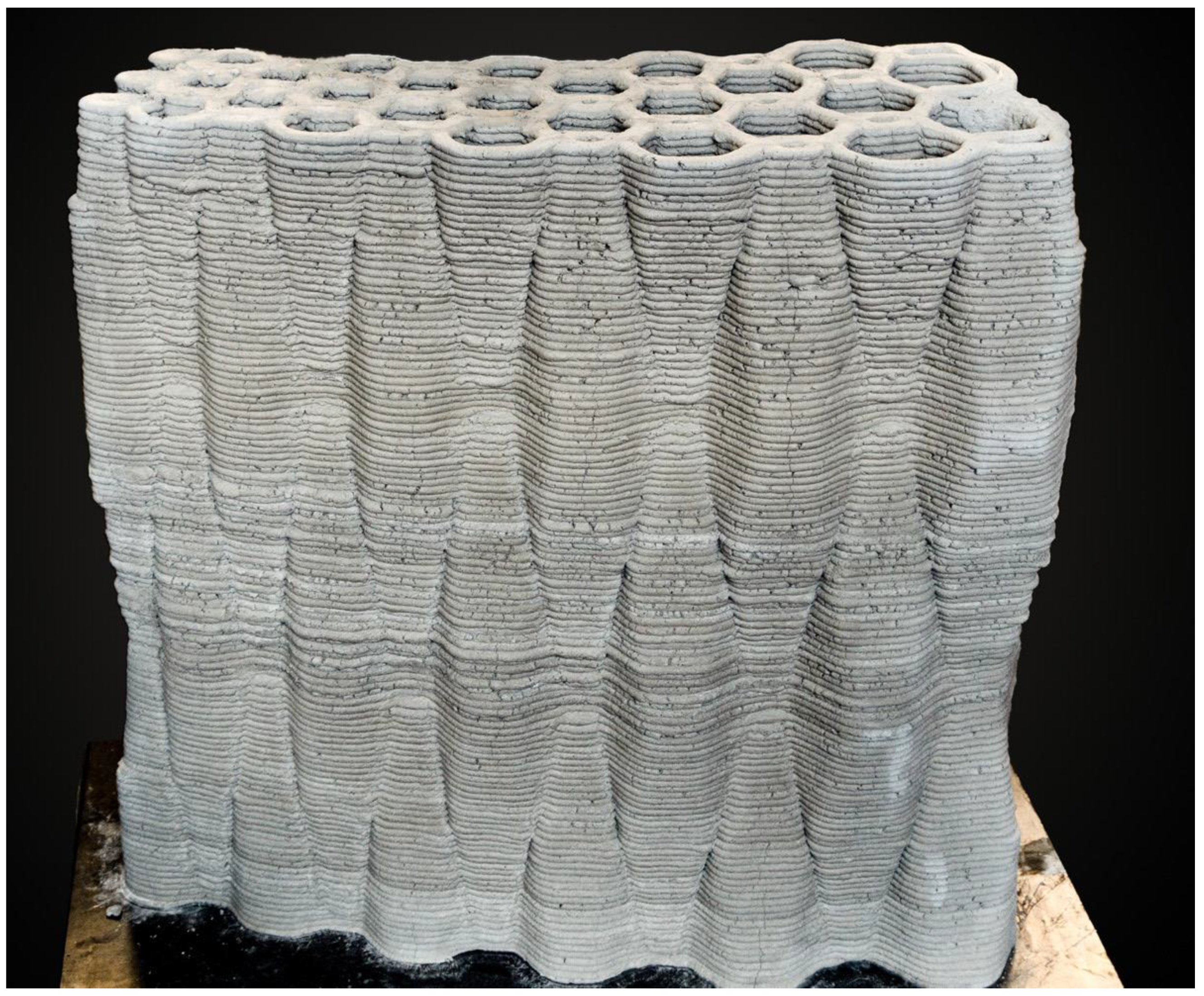

A tetrakaidecahedron, also known as a Kelvin cell [

19], was chosen, aiming for a space filling topology with closed cells and a low ratio of surface area to volume (A/V ratio) for optimized thermal properties. The preceding studies resulted in the manufacturing of a prototype (see

Figure 1), validating the design tool and printability [

15]. This paper refers to that object as the existing prototype and uses it for further investigations, optimizations, and measurements.

2.3. Analytical Description of Heat Transfer in Cellular Solids

The evaluation of heat transfer through cellular solids [

20], such as the cellular wall element, requires the determination of the following parameters, which are represented graphically in

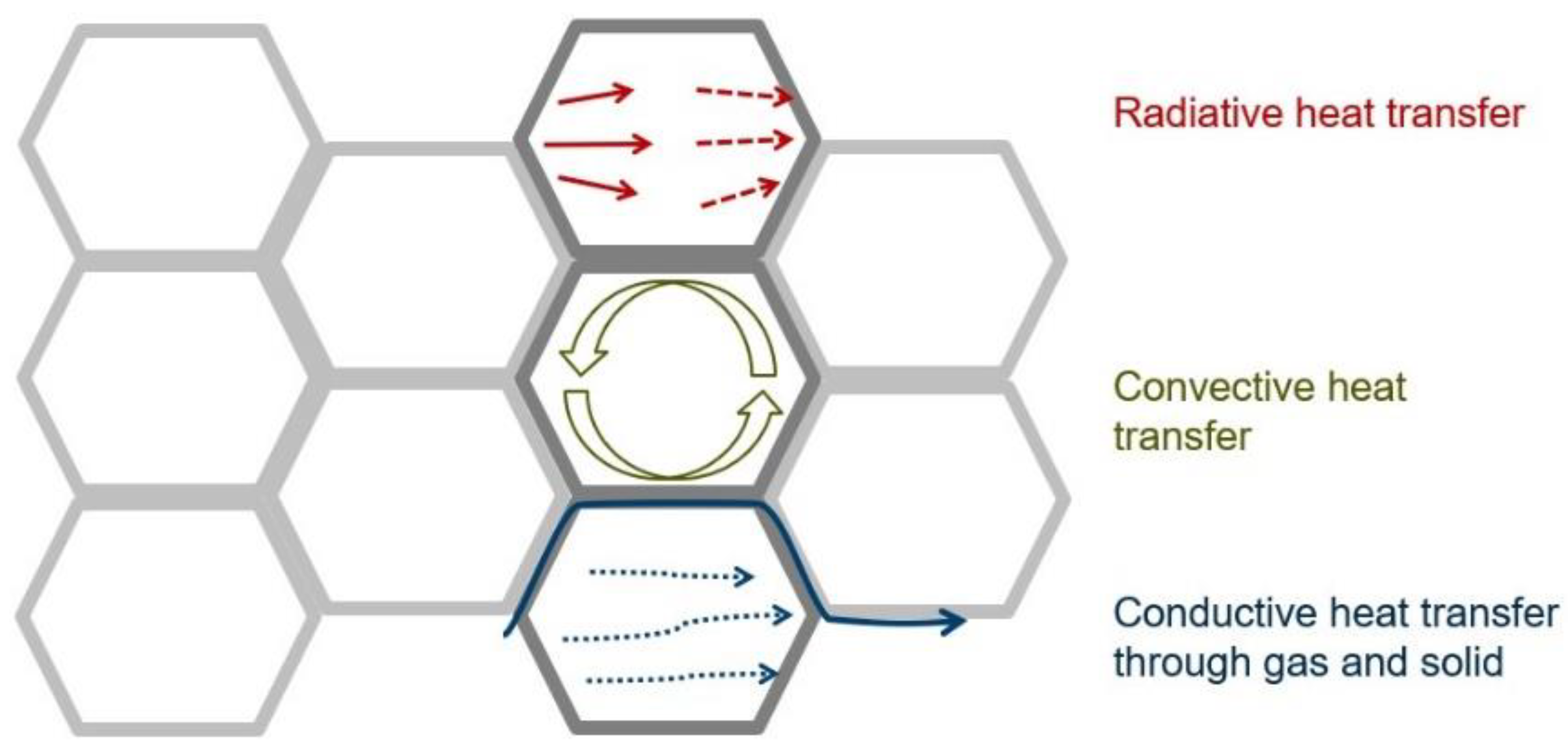

Figure 2:

Solid conductivity ();

Gas conductivity ();

Radiation ();

Natural convection ().

Figure 2.

Heat transfer mechanisms in cellular structures, showing schematically radiative (red) and convective (green) heat transfer within the cells as well as conductive heat transfer (blue) through the gas (dotted line) and solid (continuous line).

Figure 2.

Heat transfer mechanisms in cellular structures, showing schematically radiative (red) and convective (green) heat transfer within the cells as well as conductive heat transfer (blue) through the gas (dotted line) and solid (continuous line).

Relying on analytical expressions found in the existing literature, the total effective thermal conductivity

of a cellular solid consisting of all heat transfer mechanisms mentioned above is expressed in the form of its four constituents [

21,

22,

23,

24,

25]:

with

The optimization of specific geometric attributes reduces the total effective thermal conductivity inside a cell structure [

26]. The thermal conduction through a cellular solid results from the combined conductivities of the gaseous and the solid phases of the structure, hence forming an average property for bulk material in the form of an apparent thermal conduction rather than a true material property [

27]. The direction of heat flow within the cell arrangement influences the amount of apparent thermal conduction [

22]. Hence, the geometric arrangement of the cells, expressed by the ratio of height to diameter and, therefore, the cell elongation, is an essential factor for the reduction of the thermal conductivity, in order to thermally optimize the structure aiming for a higher insulating effect, reduced heat losses, and thus more energy-efficient building operation.

The ratio of the density of a cell structure to the density of the solid forming the cell walls is defined as the relative density

[

20]. By representing the solid share within the cell structure, this ratio

can be used to derive the respective share of the solid and gaseous phase of the total effective thermal conductivity of the cell structure. A reduction of the relative density decreases the mean thermal conductivity of the cellular solid considering the lower thermal conductivity of the gaseous material compared to the solid material.

Through the formation of closed cells with stagnant air, the influence of the convective heat transfer is reduced. The impact of free convection within the cells can be neglected entirely for geometries with a Grashof number (

Gr) below 1000, i.e., with a low ratio of buoyant force to viscous force [

28]. When solving the equation of the Grashof number for a minimum cell size, above which free convection becomes relevant, a critical value of 10 mm is obtained [

28]. Since hollow Kelvin cells with a cell diameter of less than 10 mm cannot be manufactured by lightweight concrete extrusion due to overhangs and track width, the contribution of heat transfer induced by free convection inside the cell structure must be considered. In enclosed spaces, the amount of convective heat transfer across the cell can be quantified using the Nusselt number (Nu), defined as the ratio between the total effective conductivity of the fluid in motion and the thermal conductivity referring to a motionless fluid [

23]. The formula of the Nusselt number, which includes the cell height h (z direction) as well as the cell size b (y direction), allows for the optimization of the cell size with regard to a minimized convective heat transfer. The analytical optimization, conducted through a linear approximation of the respective influence, results in a minimized thermal convection for vertically elongated cells. This is additionally supported by studies of the Nusselt number in dependence of the Rayleigh number for different aspect ratios

h/

b [

29]. Further, the influence of the cell height on the total effective conductivity is found to be smaller than that of the cell diameter.

Measurements on polymer foams at room temperature show that 90% of the transmissivity is above the wavelength that is important for thermal radiation [

25]. Hence, the radiative heat transfer component at room temperature is relatively small. It is therefore simplified in the analytical expression of the total effective thermal conductivity as follows: instead of the complex description of the radiative heat transfer equation in conjunction with the energy conservation equation [

24], the commonly used Rosseland equation is applied, which describes an approximation of the radiative thermal conductivity. This approximation includes the Rosseland extinction coefficient of a cell structure, which is defined as the sum of the absorption coefficient and a weighted scattering coefficient of the foam. The extinction coefficient of a foam is calculated by forming the ratio of the square root of the relative density and the cell size, weighted by a given factor [

25].

The parameters identified in this section that influence the thermal performance are, thus, the ratio of solid material to air, the diameter of the cells, the height of the cells, and the resulting cell elongation. A quantification of the respective influence and an optimization of the parameters will be conducted by means of a sensitivity analysis and a numerical optimization in

Section 3.1 and

Section 3.2.

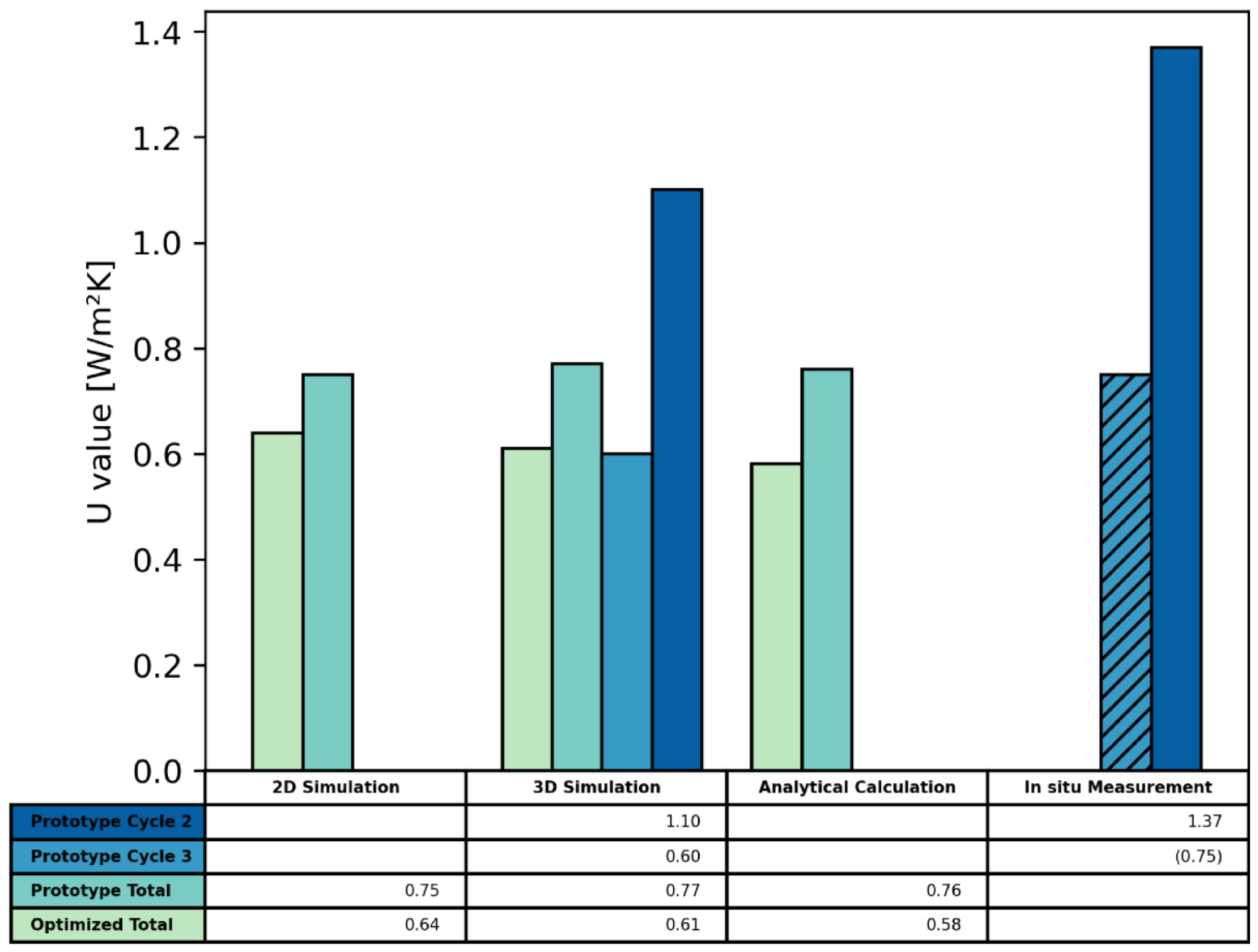

2.4. Numerical 2D Heat Flux Analysis

Based on the theoretical background and analytical description in

Section 2.3, where only a single resultant value

can be calculated with a high geometrical simplification, a more detailed and locally resolved evaluation of thermal performance is enabled by two-dimensional heat transfer simulations. For this purpose, representative layers are selected and with the help of the Ladybug Tool Honeybee [

30], XML files are created and used to simulate the heat flux within the heat-transfer analysis software LBNL THERM [

31]. The algorithm behind THERM (Version 7.6) creates a mesh of discrete elements, defining the cross-sectional geometry, and performs a heat transfer simulation using a finite element solver. The equations used for the analysis are derived from the general energy equation, differentially considering the change in temperature over the change in location as well as internal heat generation inside the geometry [

31]. The 2D simulation includes the heat transfer due to conduction and radiation via the finite element method (FEM) as well as a detailed view-factor-based radiation model [

31]. By contrast, thermal convection is modeled by means of static, temperature-dependent surface heat transfer coefficients, based on natural convection correlations [

32].

These calculations result in a locally boundary conforming mesh of temperatures and heat flux. In this way, THERM enables the calculation of a U-factor as a measure of the heat transfer through the cross section under defined environmental conditions. This is done by integrating the heat flux for a defined boundary segment or a group of segments and dividing that flux by the length of the segments as well as the defined temperature difference [

32].

The boundary conditions include the temperatures on both sides of the studied object, as well as convection and radiation components on all surfaces (outer surfaces of the element or within the element itself). To allow a comparability of the results for the study, customized surface coefficients and boundary conditions regarding the exterior and interior surface of the studied objects were set to either fulfil the requirements defined in ISO 6946:2017-06 or to compare the simulated results with the measured ones by using the measured boundary conditions and surface coefficients.

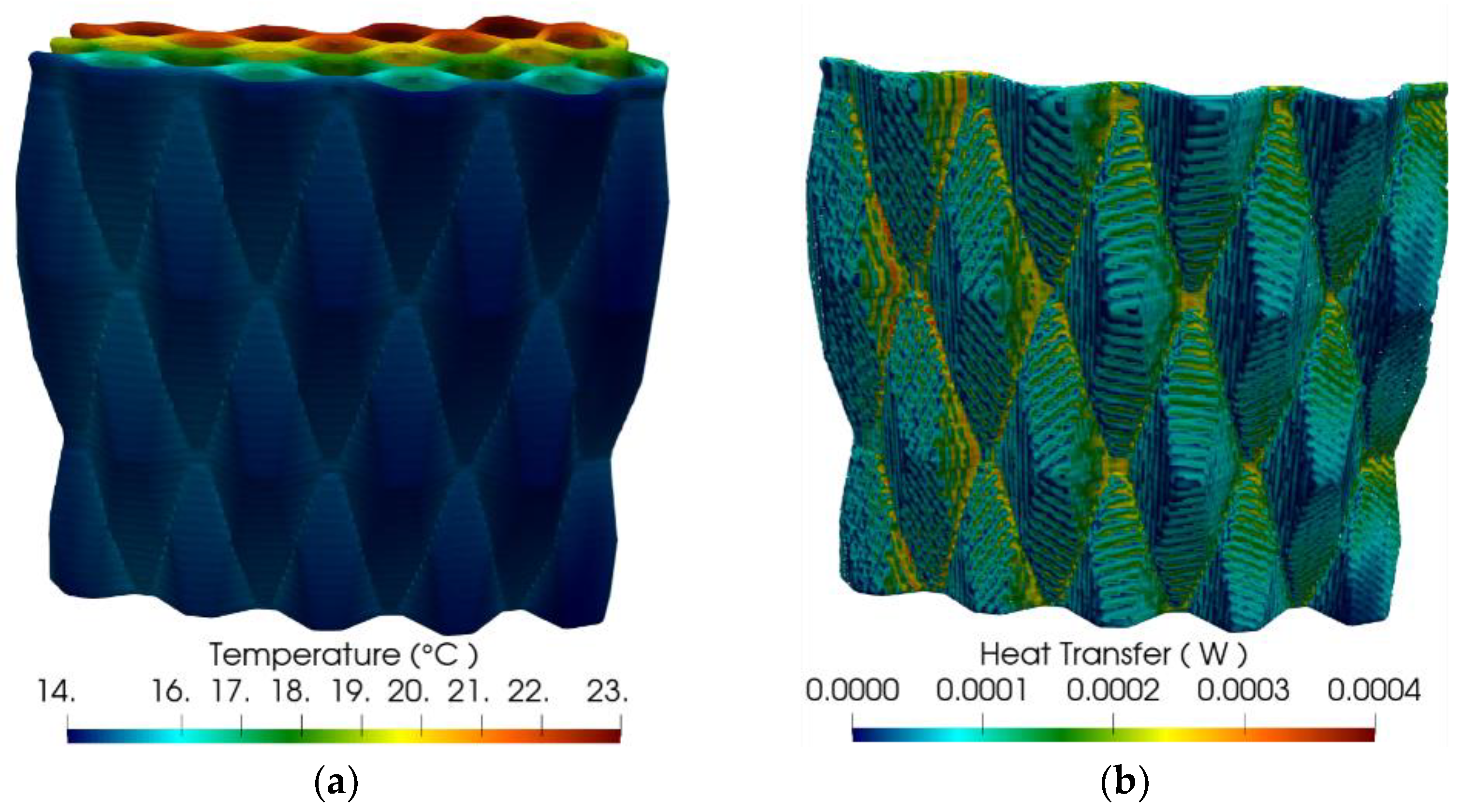

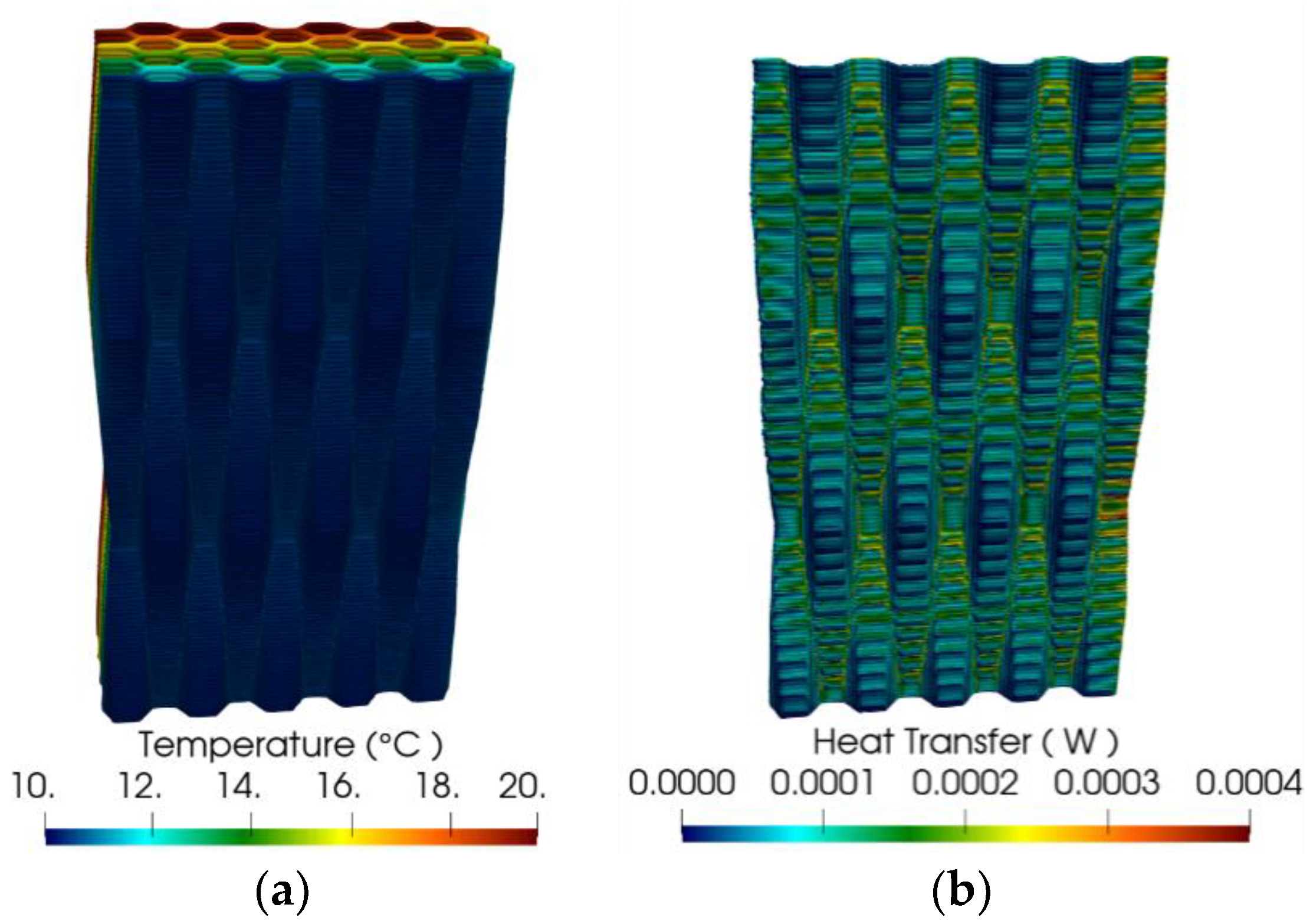

2.5. Numerical 3D Heat Flux Analysis

A supplementary procedure to the 2D numerical analysis with representative layers introduced in

Section 2.4 is a 3D simulation where the whole geometry, as designed, constitutes the computational domain. While this approach requires significantly more computational power, it can provide additional insights that contribute to the validation of the experimental results, as discussed in

Section 3.6.

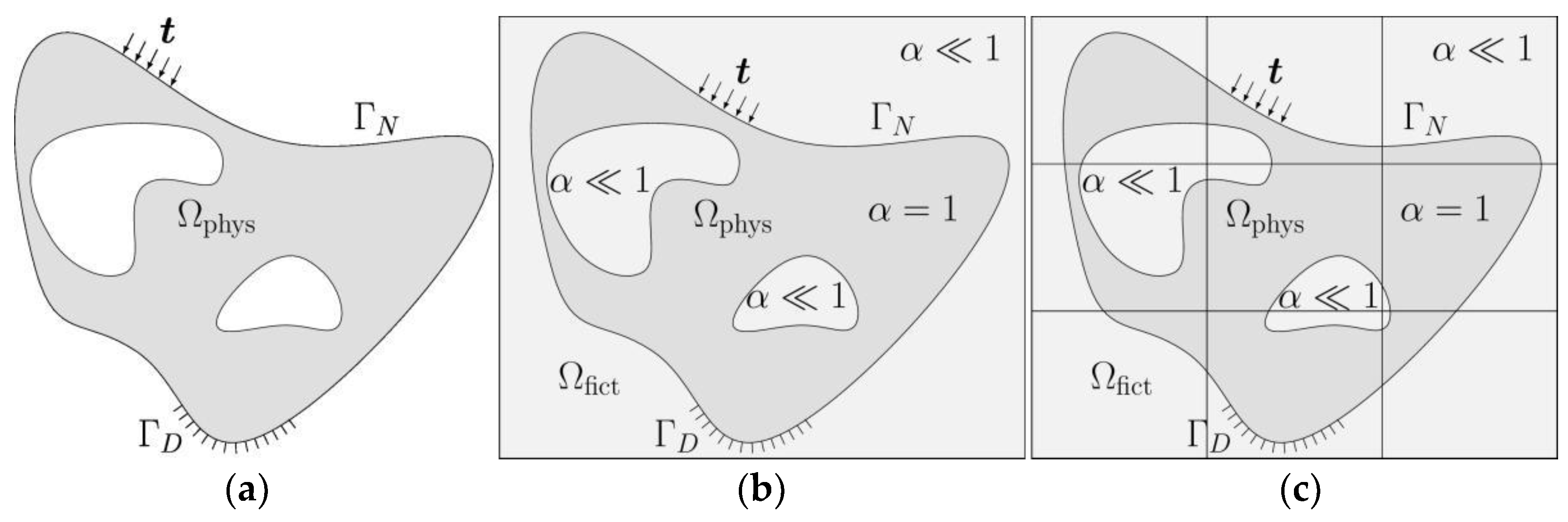

Mesh generation for topologically complex structures in 3D is a challenging task for classical finite elements, especially if as-built geometries need to be accurately represented. An alternative method to the classical finite element method is the finite cell method (FCM) [

33]. It allows for direct computational analysis on boundary representation (B-Rep) models such that the flaws and the imprecision in geometry can be correctly handled [

34]. The finite cell method is an extension of the finite element method and embeds the physical domain

representing the artifact to be analyzed into a fictitious domain

. Their union can then easily be meshed disregarding the boundary of the physical domain. The original geometry of the physical domain is resolved through an indicator function

, which relates a given position

x with the physical or fictitious domain. The accurate resolution of the physical domain is then handled during the numerical integration, a process which is much easier to automatize than the boundary conforming mesh generation required by the finite element method. The FCM workflow is summarized in

Figure 3, where a boundary value problem is defined on

with tractions

t acting on the Neumann boundary

and the Dirichlet boundary condition is defined on

such that

holds. The accuracy of FCM has been extensively studied in a variety of practical problems and was mathematically proven to be equal to the accuracy of the finite element method [

35].

Within the scope of this contribution, the 3D FCM simulation (see

Computer Code S1) computes the heat transfer due to conduction based on the steady-state heat equation, whereas the radiation and convection of air are modeled by static surface coefficients [

14]. More specifically, an effective thermal conductivity coefficient

is assigned to the air domain to model the convective and radiative heat transfer mechanisms.

The adoption of the air model with introduces a modeling error. An interval of U-values can be determined by taking the minimum and maximum plausible values and performing a series of simulations to capture the introduced errors. Defining such an interval is a practical approach to quantify the range of the modeling error introduced by the chosen air model. Thus, the U-values are reported with an associated interval for the sake of completeness.

The basic assumptions and simplifications adopted in 3D analysis closely follow the approaches employed in 2D analysis (see

Section 2.4). The consistency between the two numerical approaches is further ensured with the definition of boundary conditions. The 3D simulation imposes the boundary conditions as laid out in

Section 2.4 on the corresponding surfaces. This is analogous to the imposed boundary conditions on the lines in 2D simulation. Hence, requirements defined in ISO 6946:2017-06 are likewise fulfilled.

Similar to the 2D analysis, the main objective of the numerical study in 3D is to estimate the U-value of the whole wall element. To this end, the total heat flux on a specified surface area is calculated by integrating the local heat flux contributions and dividing by the area of the surface to find the heat flux density on the surface. The U-value is then calculated using the temperature difference and the heat flux density, as specified in ISO 15099:2003. The flexibility to choose a designated surface for the calculation of the U-value is especially convenient as the surface can be selected to match areas of interest, for instance where the heat flux is measured in the experimental setting (see

Section 2.7). This allows for a local U-value calculation on a selected surface and results in a very accurate representation of the physical situation within the numerical analysis.

2.6. Experimental Thermal Conductivity Assessment

The thermal conductivity of the used lightweight concrete material is required as an input parameter for the solid conductivity

in the analytical approach (see

Section 2.3) and as an initial value for the simulations. In parallel to the production of the element described in

Section 2.1 and

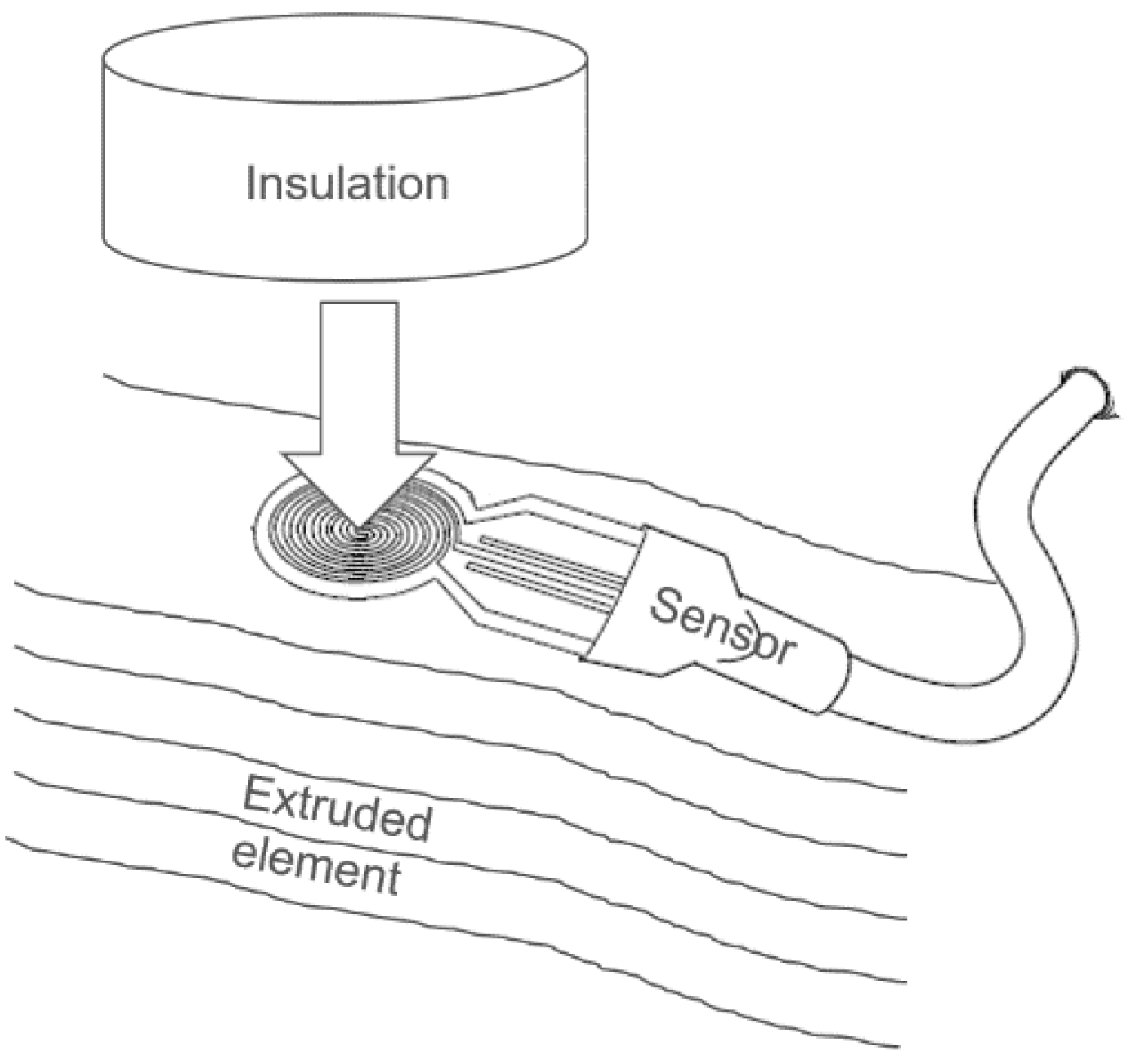

Section 2.2, lightweight concrete prisms were prepared. The thermal conductivity was determined using a dynamic measuring method. The hot disc method is specified in ISO 22007-2:2015-12 and is applicable for materials which have a thermal conductivity between 0.01 and 500 W/mK. The standard focuses on polymers, but the method can also be applied to other types of material.

In order to determine the thermal conductivity of the lightweight concrete, the Kapton sensor of the Hot Disk TPS 1500 was placed between two plane-parallel sawn halves of the specimen and heat was applied with 50 mW over 80 s. The thermal conductivity can be calculated via the recorded heat dissipation

, where

is the initial power,

is the radius of the sensor,

is the dimensionless specific time function, and

is the temperature increase on the specimen surface (see ISO 22007-2:2015-12). Since drying processes lead to deviations in the thermal conductivity of the material over time (0.44 W/mK after 14 days vs. 0.40 W/mK after 6 months), the thermal conductivity was additionally determined on the printed element itself at a comparable material age as the heat flux measurements (see

Section 2.7) in order to be able to compare the numerical results with the experimental results. The same device (Hot Disk TPS 1500) was used for this measurement. As the sensor can only be placed on one side of the printed element, a highly heat-insulating material was applied and fixed on the opposite side of the sensor and a one-sided analysis was performed (

Figure 4).

To compensate for the influence of an air gap or uneven surface, the material of the additively manufactured element was ground flat on an area slightly larger than the sensor. The measurements were conducted at an ambient temperature of 19 ± 2 °C. Thermal conductivity was measured three times each: perpendicular to the layers on the right side and on the left side of the element and parallel to the layers at the top of the last 3D-printed layer. The mean value was calculated in each case. As the hot disc method is an absolute measuring technology, no calibration of the system was necessary.

2.7. Experimental Heat Flux Measurements

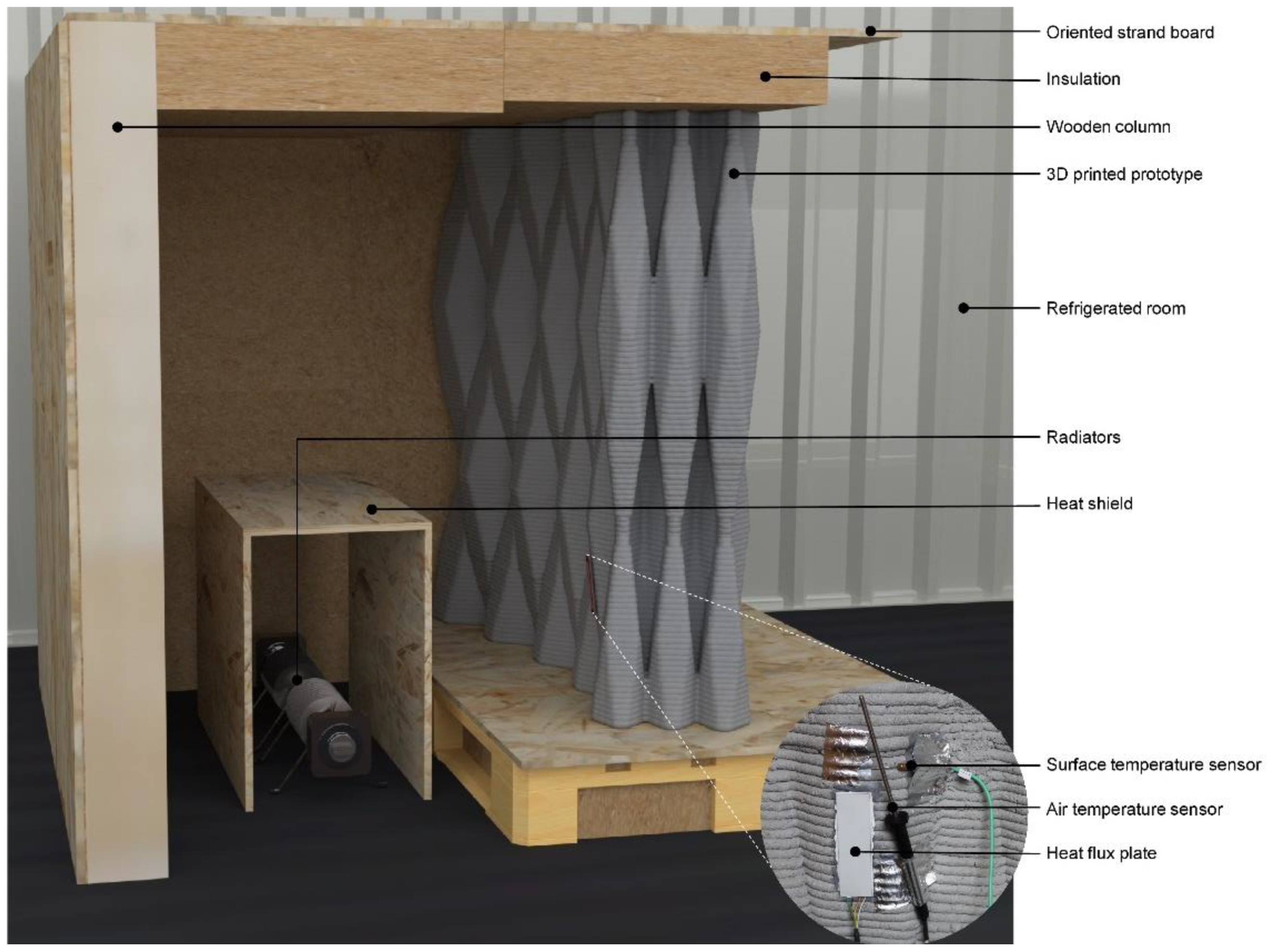

To validate the analytical and numerical approaches (as designed) and investigate the actual thermal performance (as built), the thermal transmittance of the element (U-value) was measured, which is defined in the ISO 7345 as the “Heat flow rate in the steady state divided by area and by the temperature difference between the surroundings on each side of a system”. The approach mainly follows the “Heat flow meter method” described in ISO 9869-1:2014, assuming a good estimate of the steady-state by averaging in situ measurements using a heat flow meter over a sufficiently long period. Since the tested object was transportable and not an immovable building component, the experimental setup was complemented with ideas of the “Calibrated and guarded hot box” in ISO 8990:1994.

The core requirements for the measurements and their implementation are summarized in

Table 1. In order to achieve controlled boundary conditions, the test setup was located inside a refrigerated 20’ shipping container to provide stable boundary conditions over the course of the measurement. In order to create a temperature differential as a driver for the heat flux through the tested element, an insulated and heated enclosure was constructed, consisting of four sides around the prototype (12.5 mm oriented strand boards, construction lumber, and 120 mm wood fiber boards with

). The construction is visualized in

Figure 5.

The boundary conditions were controlled to remain in a set temperature range to achieve nearly steady-state conditions. The outside air temperature (

) is defined as the air temperature of the refrigerated container, which was kept at 13 °C to 16 °C. The inner enclosure was equipped with two radiators (2 × 250 W) that were attached to a proportional-integral-derivative (PID) controller to regulate the indoor air temperature (

) within 23 °C to 25 °C. An additional housing (12.5 mm oriented strand boards), which was left open on two sides, was built around the radiators to guarantee an even distribution of the heat and to avoid direct radiation to the measurement set up (see heat shield in

Figure 5).

For the measurement setup itself, a calibrated digital heat flow plate (Ahlborn FQAD117T; calibration accuracy of 5% at nominal temperature of 23 °C) measured the heat flow density , with an integrated NTC (Negative Temperature Coefficient Thermistor) temperature sensor (±0.5 K at 0 °C to +80 °C) for automatic correction of the temperature coefficient. The heat flow plate was mounted on the inner surface of the wall element using a heat-conducting paste with a thermal conductivity of to compensate for the unevenness of the surface between the extruded filaments.

Air temperature and surface temperature were measured inside () next to the heat flow plate and at the corresponding location on the outer wall surface () using ice-bath calibrated temperature sensors (Ahlborn PT 100; 4-wire; ZA 9030-FS1; accuracy within ±0.05 K or 0.05% of measured value at −200 °C to +850 °C). Additional thermal cameras monitored the measurement qualitatively from the inside and outside.

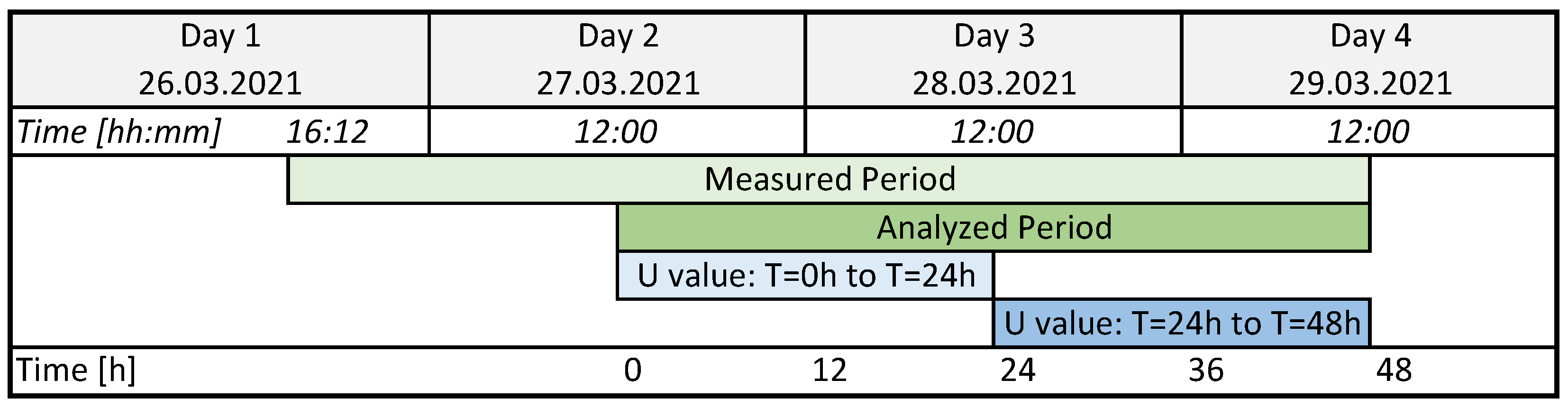

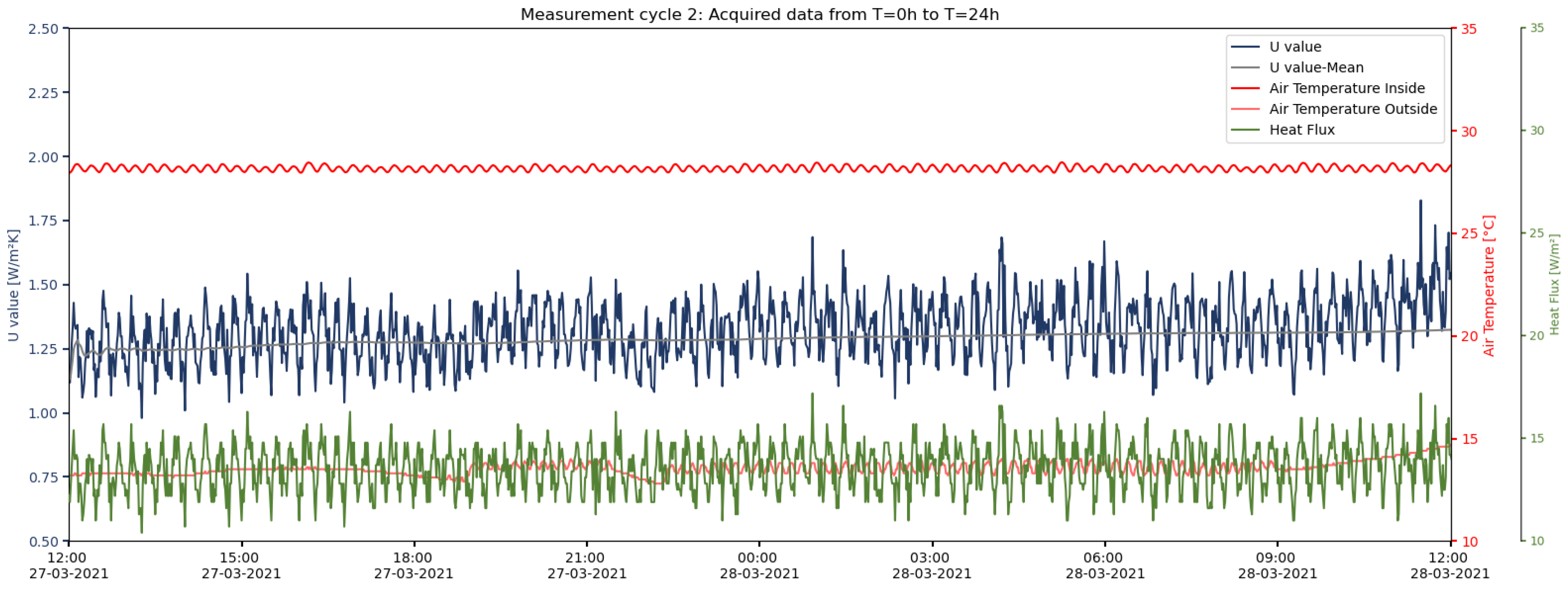

Following the average method (ISO 9869-1:2014), the acquired data over the total measured period were analyzed over time periods with integer multiples of 24 h (see

Figure 6). All data sets were tested with respect to the conditions regarding the thermal resistance (R-value; see Equations (10) and (11)) defined in the standard to determine the applicability of the results for further evaluations:

The R-value obtained at the end of the test does not deviate by more than ±5% from the value obtained 24 h before;

The R-value obtained by analyzing the data from the first time period does not deviate by more than ±5% from the values obtained from the data of the last time period of the same duration.

Figure 6.

Schematic timeline for the data evaluation of the heat flux measurements (measurement cycle 2) according to the average method (ISO 9869-1:2014); showing the measured period (light green), the analyzed period (dark green), and the respective subdivided time periods (blue).

Figure 6.

Schematic timeline for the data evaluation of the heat flux measurements (measurement cycle 2) according to the average method (ISO 9869-1:2014); showing the measured period (light green), the analyzed period (dark green), and the respective subdivided time periods (blue).

Generally speaking, the thermal transmittance (U-value) of a building component describes the amount of heat flowing through a surface area of 1 m

2 within one second, with a deviation of steady-state air temperatures on both sides of 1 K [

36]. The corresponding total thermal resistance R sums up all thermal resistances of individual material layers and the thermal resistances on both surfaces of the component (see Equation (9)). Since this theoretical assumption is only valid for equilibrium state, its application for the experimental evaluation is limited [

36]. As a result, the U-value calculation was based on a cyclic acquisition of the mean temperature values and the mean values of the heat flux density (see Equation (11)) [

36,

37]:

4. Discussion

The idea and the potential of combining additive manufacturing with lightweight concrete and thereby creating extruded mono-material, multi-functional wall elements are underlined and supported by this study. Using the advantages of the automated AM process of lightweight concrete extrusion, the geometry of a wall element can be optimized, reducing the material use by creating a complex cellular solid with an optimized insulating functionality without the necessity of multiple layers and using only one material, enhancing recyclability. Since simple methods to evaluate the thermal performance of building elements—such as ISO 6946:2017—are not applicable to such complex geometries, this paper demonstrates several alternative, more detailed evaluation methods: an analytical approach, layerwise 2D simulations, 3D simulations, and heat flux measurements.

Using an existing AM prototype, these approaches were applied to evaluate its thermal properties and to further optimize its geometry. The comparison of the results showed a high correspondence of all three theoretical approaches among each other (2D and 3D simulation, analytical approach) with 3 to 10% deviation, indicating their appropriate application. Looking more closely into the methods themselves revealed individual strengths and limitations as well as specifically suitable use cases. The analytical approach, which can be seen as the most simplified one due to its geometrical simplification, is particularly suitable for mathematical optimization techniques due to its negligible calculation effort; however, it enables only a single resultant value. In contrast to this solely analytical description, the 2D simulation additionally allows for visualization of the heat flux within a finite element mesh and thus also enables local interpretation of thermal properties. This is essential for highly complex geometries, such as the one presented in this study. Furthermore, this method is directly embedded in the design workflow, facilitating a highly automated and fast feedback loop within the design process. On the downside, the limiting factors are that only one representative layer can be evaluated at once, the cell height is not taken into account, and the influence of convection within the air voids is not calculated explicitly. The approach of 3D computations adds the missing vertical dimension to the evaluation, allowing an overall view of the thermal performance of the whole wall element. At the same time, this enables a local assessment of designated areas of interest, for instance, in the sense of a “hot spot analysis” for moisture problems or complex three-dimensional thermal bridges in general [

41,

42]. Even though the convective heat transfer is not yet implemented and the thermal conductivity of air in the cells is simplified, the results already show a very promising validity.

The initial assumption, that the actual measured performance (as built) is lower than the theoretically assessed properties (as designed) due to inaccuracies of the extruded concrete strands (cracks and cavities), was verified. In general, the experimental U-value evaluation using heat flux measurements and its comparison to the simulated results showed the validity and applicability of the theoretical approaches. The deviation of 25% can be traced back to several potential error sources. Inaccuracies of the printed object, especially regarding the layer thickness, layer height, and the print paths themselves, lead to geometrical deviations between as built and as designed. Moreover, the cracks caused by the drying process of the lightweight concrete and imperfections in general due to irregularities during the extrusion process are assumed to influence the local thermal properties. Furthermore, the complex geometry and uneven surface of the printed object are challenging for the measurement process. In combination with demanding and sensitive boundary conditions as well as required long measurement periods, this leads to the limitation that only one out of three measurement cycles can be evaluated without or with little reservations. Further improvements of the measurement setup and a larger number of measurements over a longer period on several locations would be needed for an even more reliable validation of theoretical and experimental results. Additionally, further studies on the discrepancies between as designed and as built could be realized using laser scanner and point clouds.

In general, the cellular solid geometry of the existing prototype was further optimized using the approaches mentioned above. The optimization resulted in a reduction of the U-values by about 20%, accounting for approximately 0.6 W/m2 K at a comparable total wall thickness of 30 cm. The printability of the optimized geometry will be subject to future research as well as the validation of its target performance by improved measurements.

5. Outlook

In combination with the possibility of grading the material properties (e.g., with respect to their thermal conductivity and load-bearing capacity), components could be designed completely freely and the locally required material properties could be determined via simulations in order to achieve a consistent U-value along the whole element. Similarly, complex connection situations (e.g., wall/floor or inner/outer wall) could be improved by using material grading and an optimized internal cellular solid structure. In general, the approach of optimizing the internal structure with regard to thermal performance can be combined with common topology optimization for its structural behavior.

Furthermore, the presented study can pave the way for bringing AM in construction to the next level by integrating additional active functions within AM wall elements. Active functions could be added by directly integrating ducting or channeling for heating, cooling, and/or ventilation purposes. For this objective, the presented approaches for performance evaluation by modeling and measurements as well as geometric optimization are essential.