Full-Scale Prefabrication and Non-Destructive Quality Monitoring of Novel Bridge Substructure for “Pile-Column Integration”

Abstract

:1. Introduction

2. Materials and Methods

2.1. Engineering Description for Prefabricated Pile-Column Integration Application

2.2. Main Materials and Properties of Prefabricated Bridge Substructure

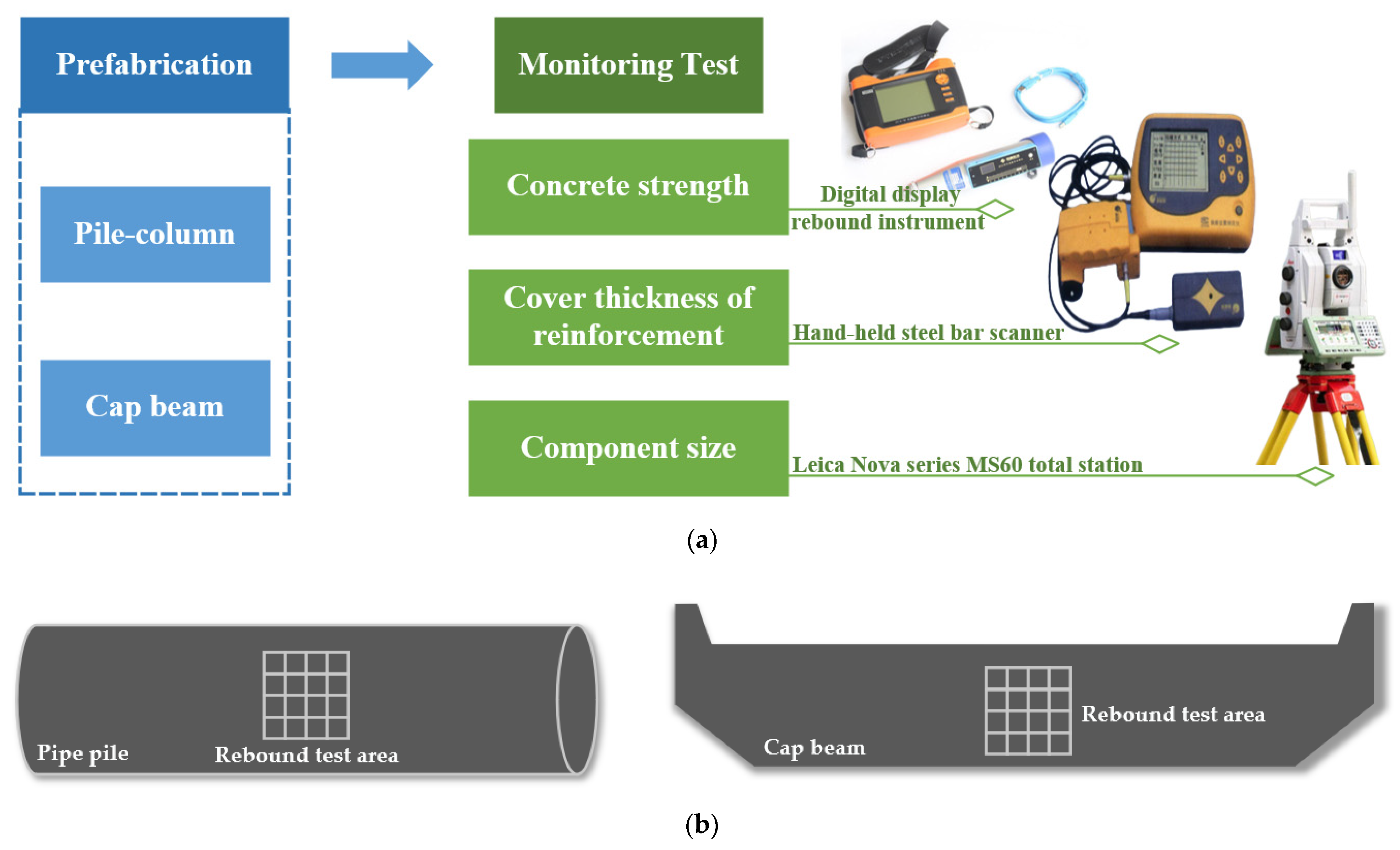

2.3. Non-Destructive Quality Monitoring Methods

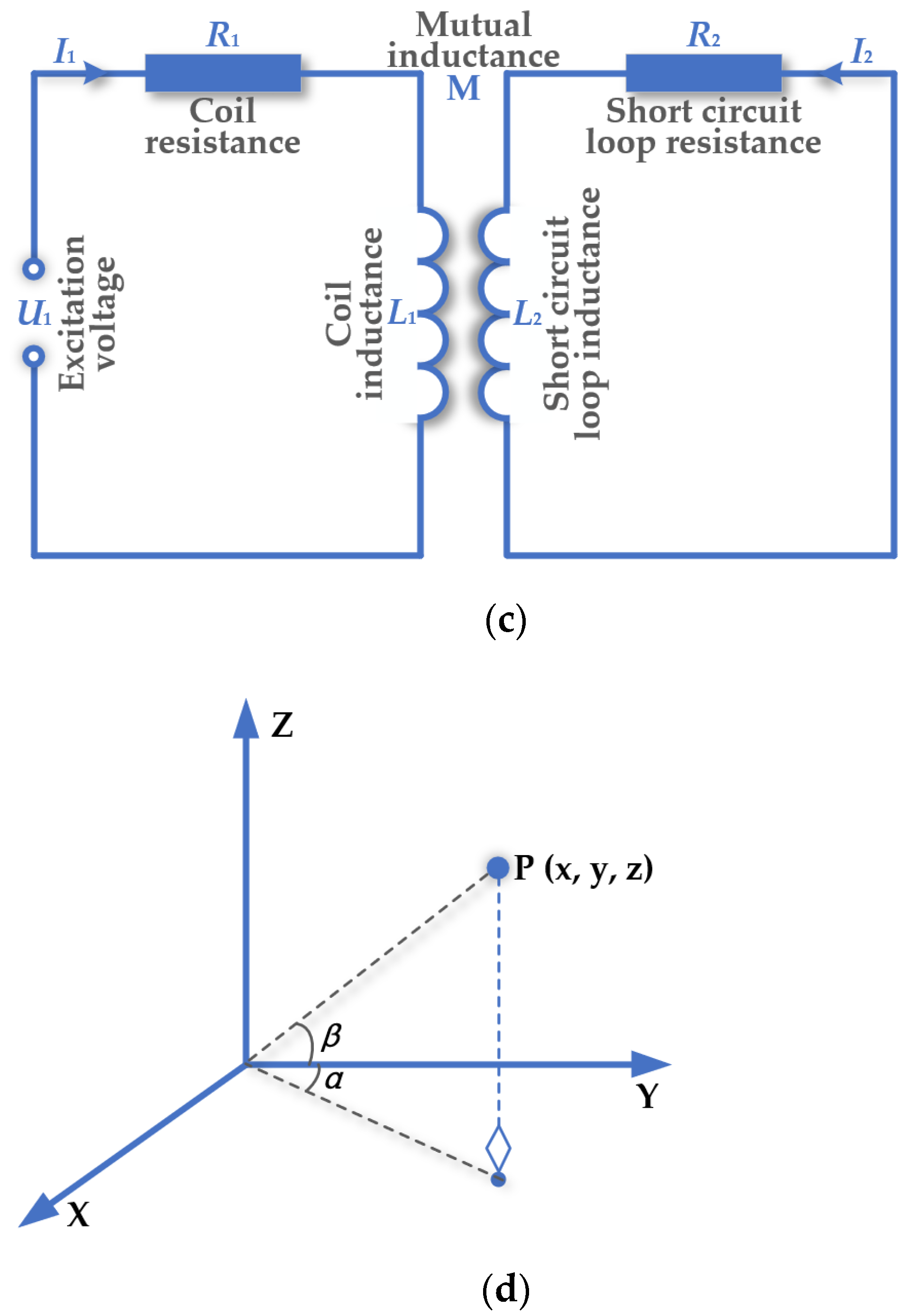

2.3.1. Concrete Strength Monitoring Test Based on Rebound Method

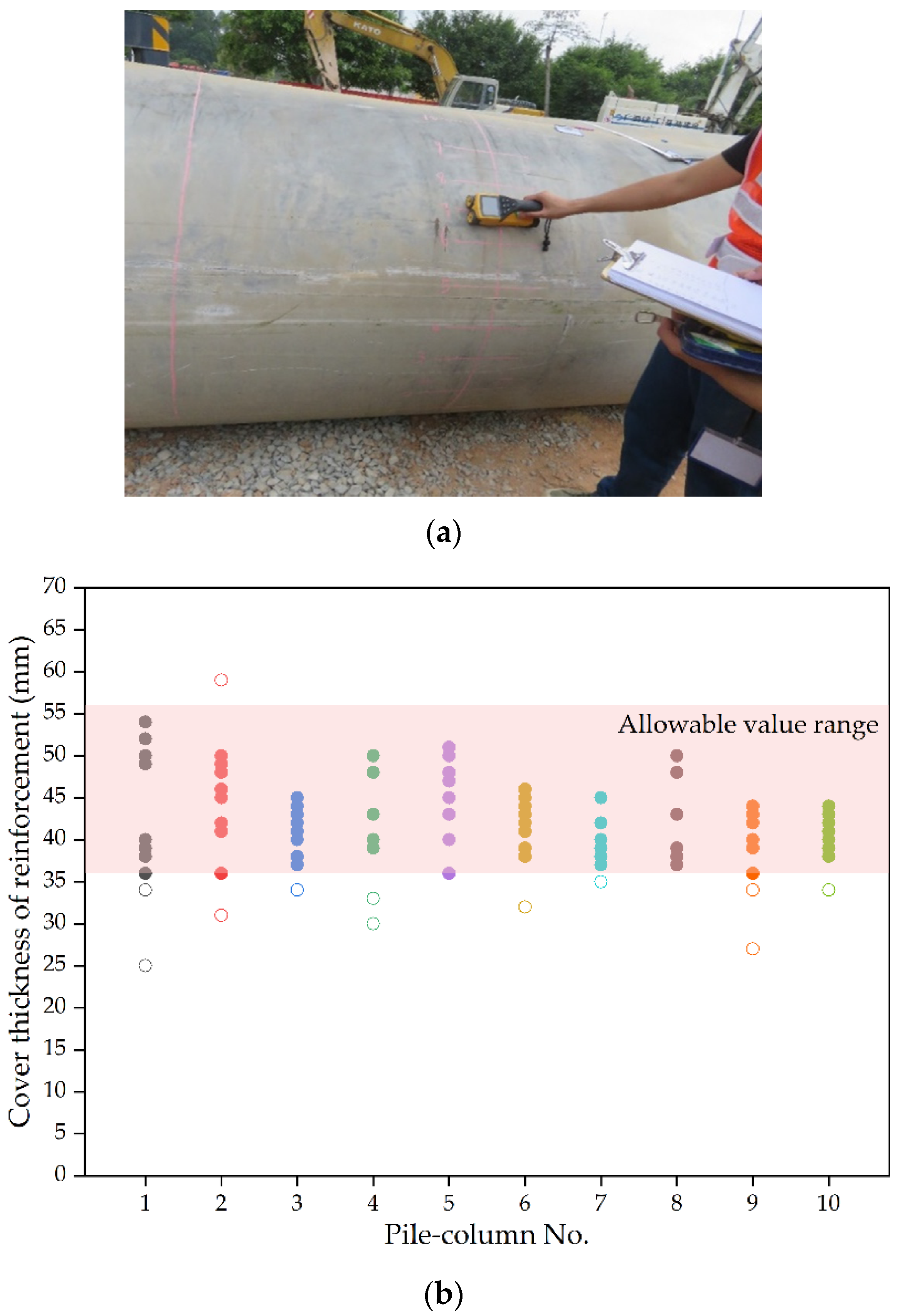

2.3.2. Cover Thickness Monitoring Test of Reinforcement Based on Electromagnetic Induction Method

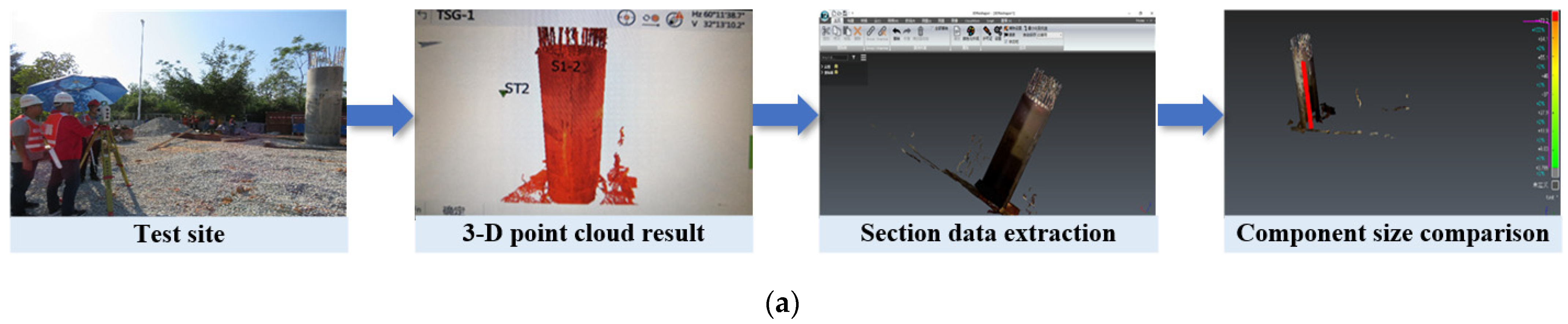

2.3.3. Component Size Monitoring Test Based on 3-D Point Cloud Scanning System

3. Prefabrication of Pile-Column and Cap Beam

3.1. Prefabrication and Quality Monitoring of Pile-Column

3.1.1. Prefabrication of Pile-Column

- The reinforcement was cut reasonably according to the size requirements to avoid waste. Different grades of reinforcement should not be mixed. Before the framework was formed, the main reinforcement was grouped in equal lengths, of which the relative error of length shall not be greater than L/4000. The spiral stirrup Φ 8.0 high strength cold drawn steel wire was used, which was bound and welded with binding wire. Cage reinforcement was divided into inner and outer layers.

- The steel mold was disassembled, the cement slag and other residues were cleaned, and the release agent was sprayed. Cage reinforcement was lifted into the steel mold, and the main reinforcement should be straight and parallel to the edge of the steel mold to prevent the cage reinforcement from loosening.

- The centrifugal forming process could be divided into four stages: low speed—low medium speed—medium speed—high speed. After the pier was centrifuged, the prefabricated samples entered the steam curing pool. The temperature in the pool was set as 30–40 °C, the humidity was ≥95%, and the mold was removed after the total curing time reached 10 h.

- Demolding was carried out after the strength test met the standard, and it was lifted and placed gently to prevent collision and damage. The concrete slag was cleaned and the appearance defects repaired. The exposed reinforcement with cement slurry was then evenly brushed.

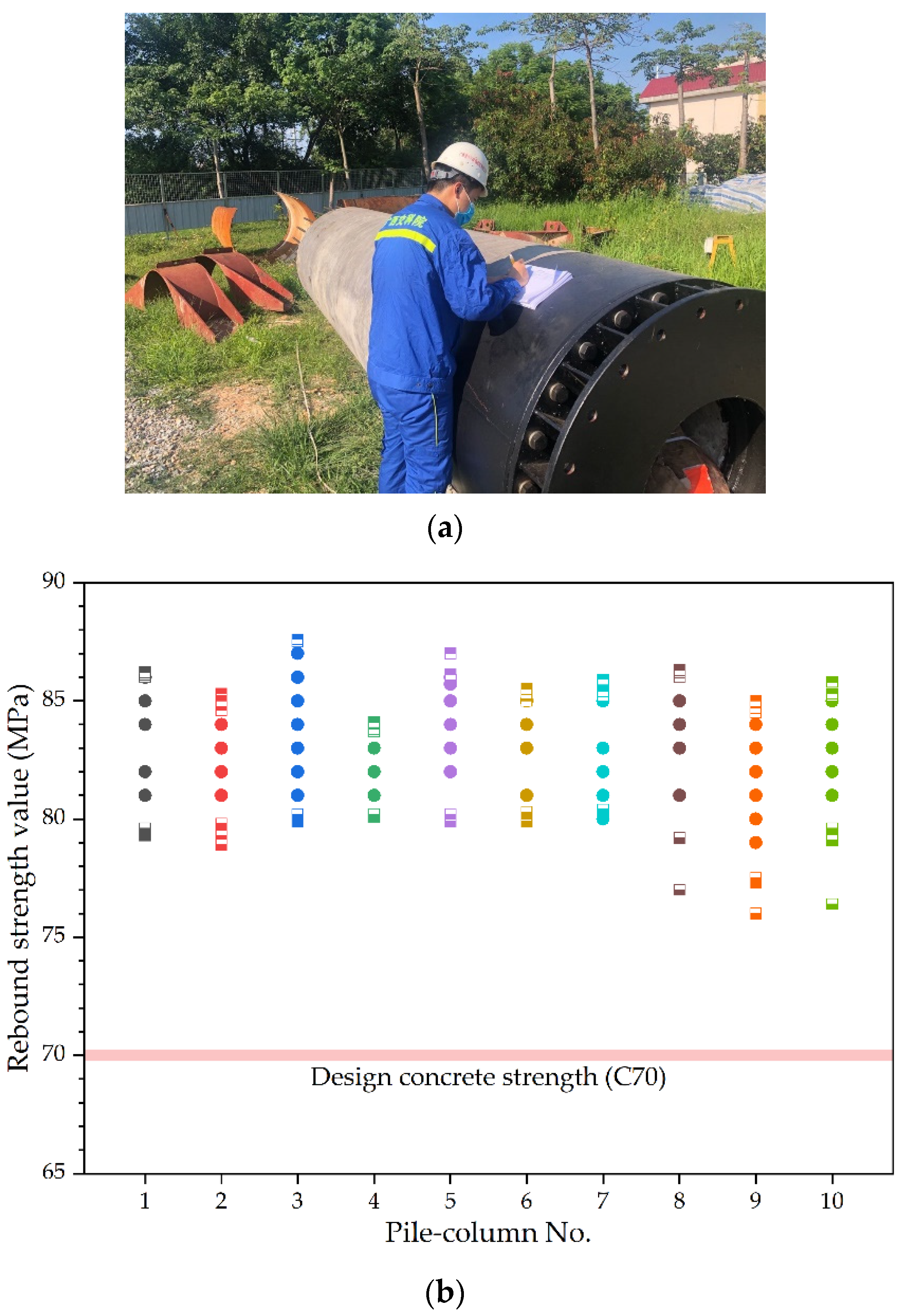

3.1.2. Quality Monitoring of Pile-Column

- Concrete strength of prefabricated pile-column

- Cover thickness of reinforcement of prefabricated pile-column

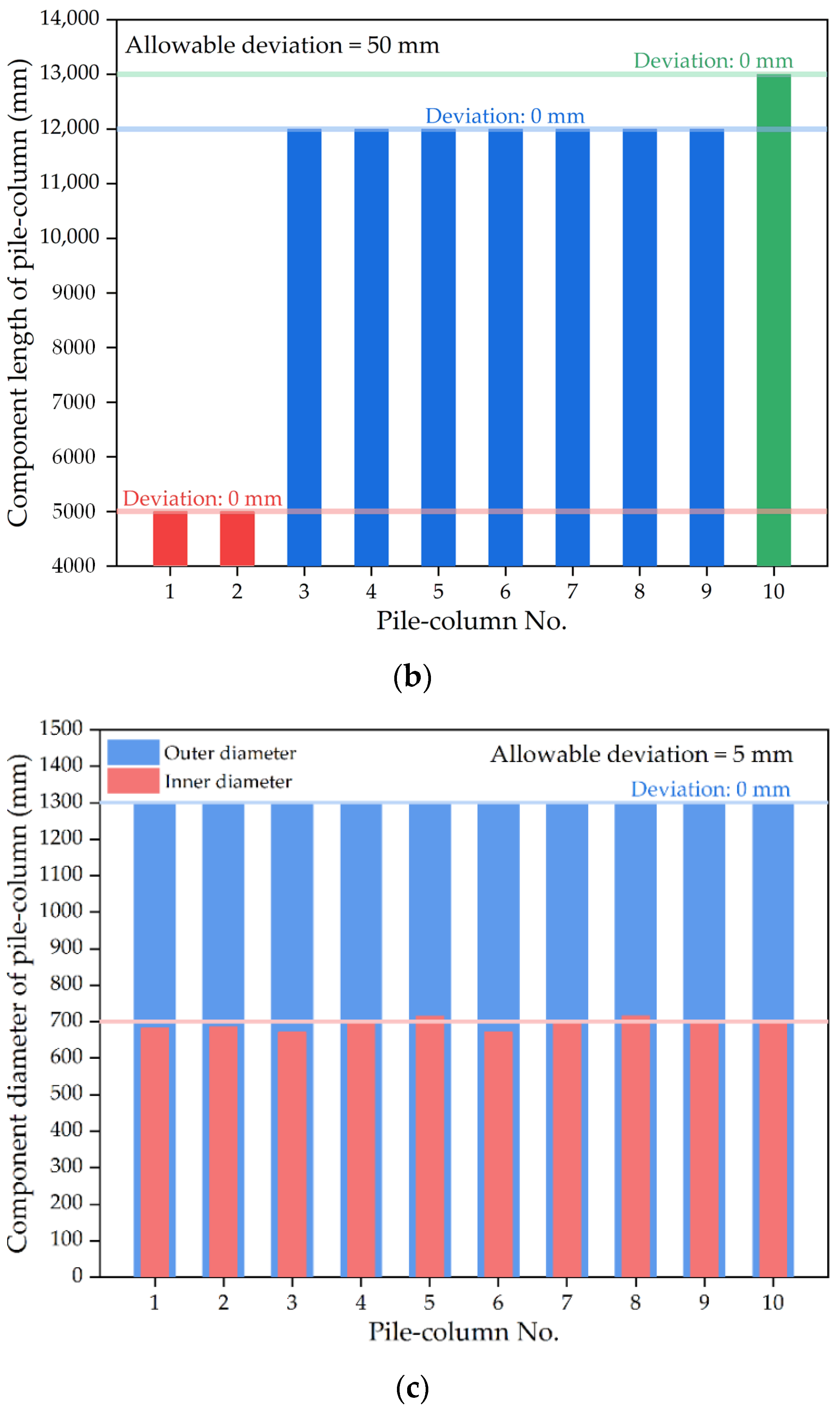

- Component size of prefabricated pile-column

3.2. Prefabrication and Quality Monitoring of Cap Beam

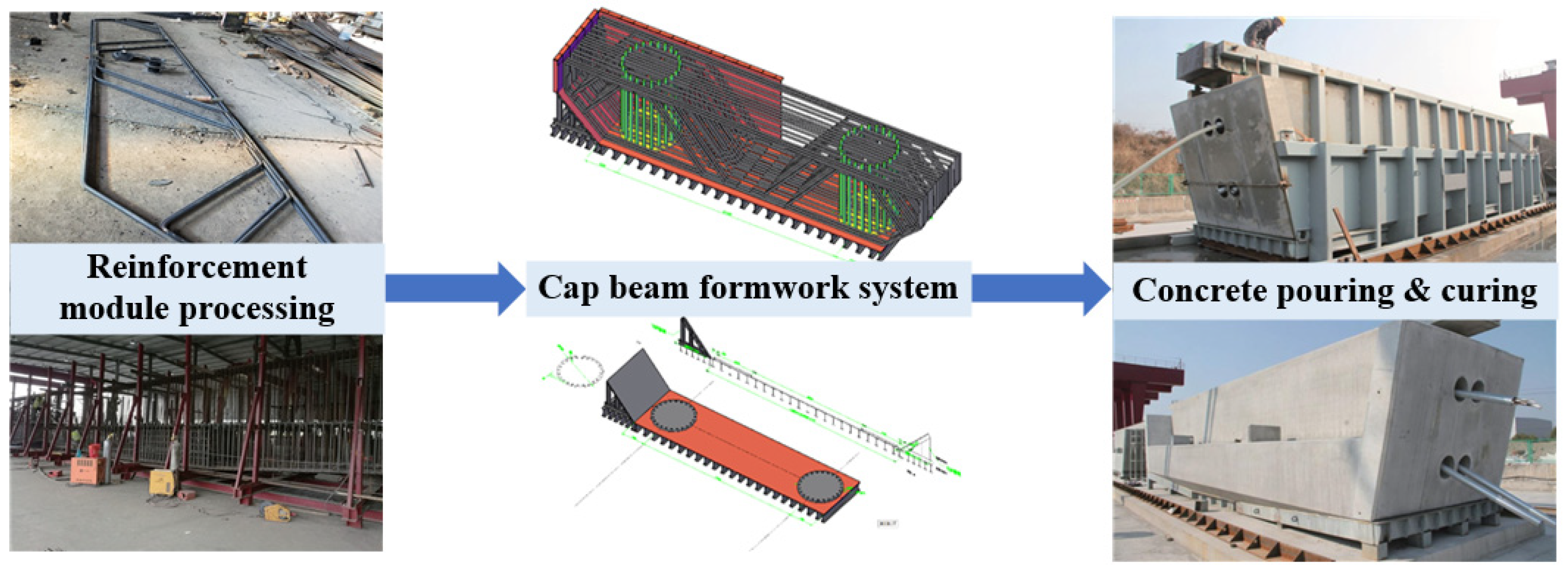

3.2.1. Prefabrication of Cap Beam

- The reinforcement cage processing of the cap beam adopted the concept of modular finishing of reinforcement. The Machine Elettroniche Piegatrici (MEP) reinforcement numerical control bending and shearing center is used to cut, bend and straighten the reinforcement.

- The steel formwork used for prefabricated cap beams requires high processing accuracy, convenient disassembly and assembly of formwork, and reasonable combination. The thickness of the steel plate should not be less than 10 mm, and the finish rolled deformed bar was adopted. Sandblasting and spray painting treatment was carried out in the steel formwork.

- Concrete of grade C40 was used for the pouring of cap beam, polycarboxylic acid water reducer was used, and the water-cement ratio was controlled within 0.28. Water pipes were used for direct spray curing to ensure the spray curing every 2 h. In high-temperature conditions, geotechnical wetting and covering measures were taken to ensure spray curing at least once every 1 h.

3.2.2. Quality Monitoring of Cap Beam

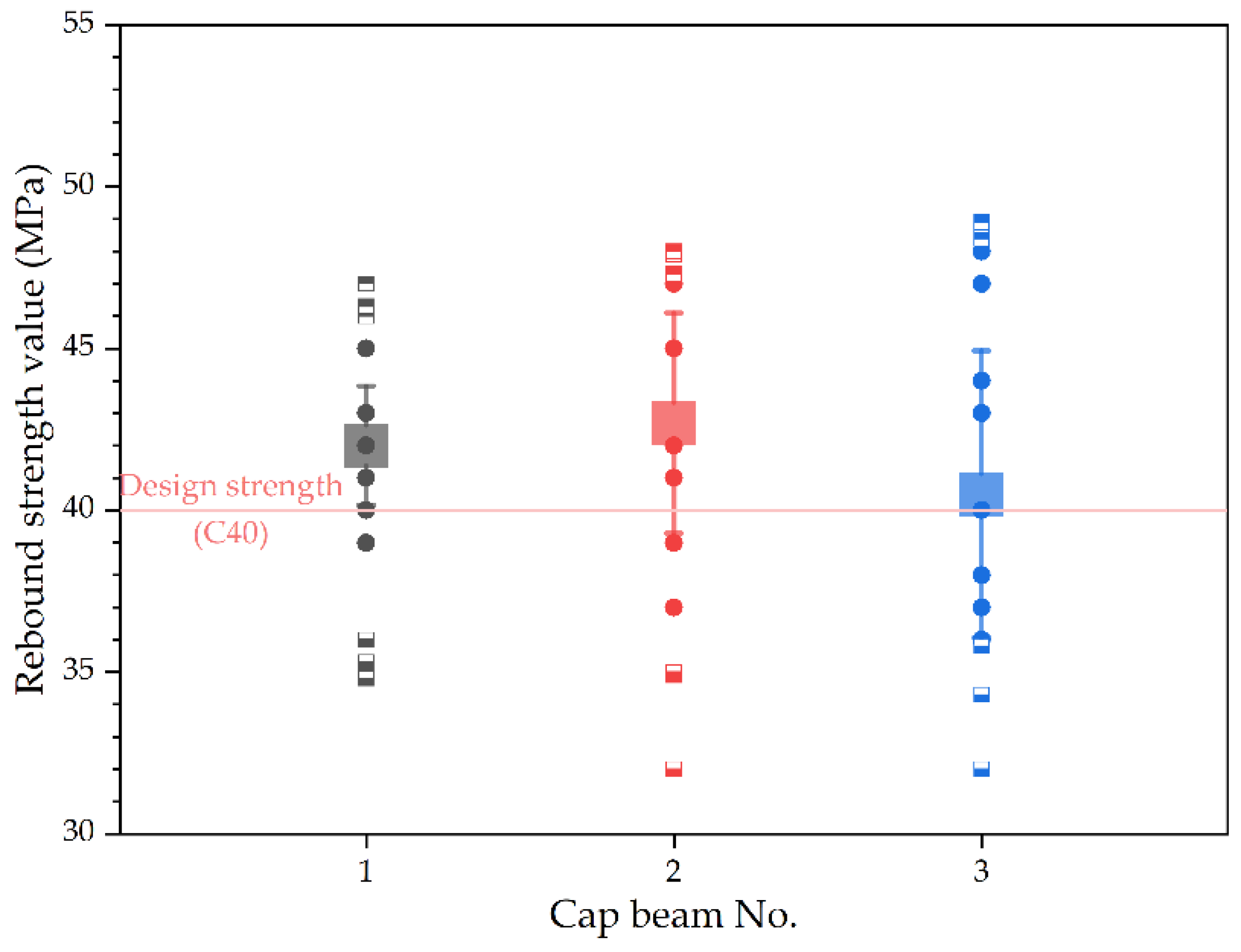

- Concrete strength of prefabricated cap beam.

- Cover thickness of reinforcement of prefabricated cap beam.

- Component size of prefabricated cap beam.

4. Conclusions

- (1)

- The concrete strength monitoring results of prefabricated components by the rebound method are relatively stable. The concrete strength of the prefabricated components was higher than the design concrete strength and their qualified rate was 100%, indicating that the prefabricated components could meet the design requirements.

- (2)

- According to the monitoring of cover thickness of reinforcement, the cover thickness values of reinforcement in prefabricated components by electromagnetic induction method were relatively stable, the cover thickness of reinforcement basically fell within the allowable range, and their qualified rates were around 90%.

- (3)

- The component size of the prefabricated components could be tested by a 3-D point cloud scanning system. When the component size was relatively larger, the monitoring results of component size of prefabricated components by the 3-D point cloud scanning system were relatively stable, but the monitoring effect of the 3-D point cloud scanning system still needs to be improved.

- (4)

- The quality monitoring of full-scale bridge substructures for “pile-column integration” proved the rationality of prefabrication and the feasibility of non-destructive testing technologies, providing references for the application of “pile-column integration”.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Serra, M.; Festa, G.; Vassallo, M.; Zollo, A.; Quattrone, A.; Ceravolo, R. Damage detection in elastic properties of masonry bridges using coda wave interferometry. Struct. Control Health Monit. 2017, 24, e1976. [Google Scholar] [CrossRef]

- Liu, H.B.; Wang, H.; Tan, G.J.; Wang, W.S.; Liu, Z.Y. Effect of temperature and spring-mass systems on modal properties of timoshenko concrete beam. Struct. Eng. Mech. 2018, 65, 389–400. [Google Scholar]

- Jiang, G.F.; Liang, Q.X.; Wang, H.; Ju, Y.C.; Wang, H.H.; Wang, X.R.; Wang, L.L.; Wang, W.S. Study on evaluation theory of bridge damage state and methodology on early-warning of danger. Adv. Mater. Sci. Eng. 2021, 2021, 6636959. [Google Scholar] [CrossRef]

- Yi, T.Y.; Wang, H.; Xie, J.T.; Wang, W.S. Flexural strength and acoustic damage characteristics of steel bar reactive powder concrete. Appl. Sci. 2021, 11, 7017. [Google Scholar] [CrossRef]

- Wang, X.R.; Wang, L.L.; Wang, H.; Ning, Y.H.; Huang, K.N.; Wang, W.S. Performance evaluation of a long-span cable-stayed bridge using non-destructive field loading tests. Appl. Sci. 2022, 12, 2367. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.L.; Zhuo, X.L.; Huang, K.N.; Wang, X.R.; Wang, W.S. Study on the precise displacement controlling method for a suspended deck in the hanger replacement process of an arch bridge. Appl. Sci. 2021, 11, 9607. [Google Scholar] [CrossRef]

- Saleem, M.A.; Zafar, M.N.; Saleem, M.M.; Xia, J. Recent developments in the prefabricated bridge deck systems. Case Stud. Constr. Mater. 2021, 15, e00750. [Google Scholar] [CrossRef]

- Xia, L.L.; Hu, Z.J.; Shah, Y.I. Longitudinal load distribution of a weakly connected prefabricated bridge abutment. Arch. Appl. Mech. 2021, 91, 4121–4140. [Google Scholar] [CrossRef]

- Shim, C.S.; Dang, S.N.; Park, S. Three-dimensional information delivery for design and construction of prefabricated bridge piers. Struct. Eng. Int. 2018, 28, 6–12. [Google Scholar] [CrossRef]

- Ryu, H.K.; Kim, Y.J.; Chang, S.P. Crack control of a continuous composite two-girder bridge with prefabricated slabs under static and fatigue loads. Eng. Struct. 2007, 29, 851–864. [Google Scholar] [CrossRef]

- Haider, M.A.; Batikha, M.; Elhag, T. Precast versus cast in-situ concrete in the construction of post-tensioned box-girder bridges: Span effect. Struct. Concr. 2020, 21, 56–64. [Google Scholar] [CrossRef]

- Moyo, P.; Sibanda, B.; Beushausen, H. Modelling and integrity assessment of shear connectors in precast cast-in-situ concrete bridges. Struct. Eng. Mech. 2012, 42, 55–72. [Google Scholar] [CrossRef]

- Kurylowicz-Cudowska, A. Determination of thermophysical parameters involved in the numerical model to predict the temperature field of cast-in-place concrete bridge deck. Materials 2019, 12, 3089. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jensen, T.W.; Poulsen, P.N.; Hoang, L.C. Limit analysis of reinforced concrete slabs with construction joints. Eng. Struct. 2020, 205, 110062. [Google Scholar] [CrossRef]

- Fasching, S.; Huber, T.; Rath, M.; Kollegger, J. Semi-precast segmental bridges: Development of a new construction method using thin-walled prefabricated concrete elements. Struct. Concr. 2021, 22, 1561–1573. [Google Scholar] [CrossRef]

- Suffner, A.; Schulze, T. Green bridges from prefabricated arch-segments. Bautechnik 2016, 93, 98–101. [Google Scholar] [CrossRef]

- Koem, C.; Shim, C.S.; Park, S.J. Seismic performance of prefabricated bridge columns with combination of continuous mild reinforcements and partially unbonded tendons. Smart Struct. Syst. 2016, 17, 541–557. [Google Scholar] [CrossRef]

- Billington, S.L.; Barnes, R.W.; Breen, J.E. A precast segmental substructure system for standard bridges. PCI J 1999, 44, 56–73. [Google Scholar] [CrossRef]

- Zhuo, W.D.; Tong, T.; Liu, Z. Analytical pushover method and hysteretic modeling of precast segmental bridge piers with high-strength bars based on cyclic loading test. J. Struct. Eng. 2019, 145, 04019050. [Google Scholar] [CrossRef]

- ElGawady, M.A.; Dawood, H.M. Analysis of segmental piers consisted of concrete filled frp tubes. Eng. Struct. 2012, 38, 142–152. [Google Scholar] [CrossRef]

- Peeters, B.; Couvreur, G.; Razinkov, O.; Kundig, C.; Van der Auweraer, H.; De Roeck, G. Continuous monitoring of the oresund bridge: System and data analysis. Struct. Infrastruct. Eng. 2009, 5, 395–405. [Google Scholar] [CrossRef]

- Park, J.; Choi, J.; Jang, Y.; Park, S.K.; Hong, S. An experimental and analytical study on the deflection behavior of precast concrete beams with joints. Appl. Sci. 2017, 7, 1198. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.K.; Shen, G.Q.P.; Li, Z.D.; Zhang, B.Y.; Zhang, W.Q. Barriers to promoting prefabricated construction in china: A cost-benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.F.; Li, L.; Gao, Y.L. Constraints on the promotion of prefabricated construction in china. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef] [Green Version]

- Wu, Q.H.; Qiu, Z.Z.; Niu, Z. Study on the factory prefabrication technology of large-span bridges pier. Appl. Mech. Mater. 2014, 501–504, 1413–1417. [Google Scholar] [CrossRef]

- Li, F.Y.; Shen, Y. Full-scale test of the hydration heat and the curing method of the wet joints of a precast segmental pier of a bridge. Eur. J. Environ. Civ. Eng. 2017, 21, 348–370. [Google Scholar] [CrossRef]

- Chen, R.F.; Tan, Y.; Zhang, B.L.; Shen, W.G.; Liu, G.L.; Wang, Z.W. Installation of integral prefabricated bridge abutment and pier with flexible water stop curtain. J. Constr. Eng. Manag. 2018, 144, 04018087. [Google Scholar] [CrossRef]

- Wu, D.J.; Xiong, W.; Guo, J.M. Establishment and repetition survey of primary gnss control network of hong kong-zhuhai-macao bridge. J. Surv. Eng. 2022, 148, 05021006. [Google Scholar] [CrossRef]

- Yan, X.Z.; Zhang, H.; Zhang, W.Y. Intelligent monitoring and evaluation for the prefabricated construction schedule. Comput. Civ. Infrastruct. Eng. 2022. [Google Scholar] [CrossRef]

- Worley, R.; Dewoolkar, M.M.; Xia, T.; Farrell, R.; Orfeo, D.; Burns, D.; Huston, D.R. Acoustic emission sensing for crack monitoring in prefabricated and prestressed reinforced concrete bridge girders. J. Bridg. Eng. 2019, 24, 04019018. [Google Scholar] [CrossRef] [Green Version]

- Tsangouri, E.; Remy, O.; Boulpaep, F.; Verbruggen, S.; Livitsanos, G.; Aggelis, D.G. Structural health assessment of prefabricated concrete elements using acoustic emission: Towards an optimized damage sensing tool. Constr. Build. Mater. 2019, 206, 261–269. [Google Scholar] [CrossRef]

- Fan, J.J.; Feng, D.C.; Wu, G.; Hou, S.T.; Lu, Y. Experimental study of prefabricated rc column-foundation assemblies with two different connection methods and using large-diameter reinforcing bars. Eng. Struct. 2020, 205, 110075. [Google Scholar] [CrossRef]

- Xu, T.Z.; Li, J. Assessing the spatial variability of the concrete by the rebound hammer test and compression test of drilled cores. Constr. Build. Mater. 2018, 188, 820–832. [Google Scholar] [CrossRef]

- Kobaka, J.; Katzer, J.; Ponikiewski, T. A combined electromagnetic induction and radar-based test for quality control of steel fibre reinforced concrete. Materials 2019, 12, 3507. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Li, Q.Q.; Yang, B.; Xiao, W.; Chen, C.; Dong, Z. Automatic 3-d reconstruction of indoor environment with mobile laser scanning point clouds. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2019, 12, 3117–3130. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Elastic Modulus (MPa) | Bulk Density (kN/m3) | Axial Compression Strength Design fcd (MPa) | Axial Tension Strength Design ftd (MPa) | Poisson’s Ratio | Linear Expansion Coefficient (°C) |

|---|---|---|---|---|---|---|

| C70 | 3.75 × 104 | 26 | 30.5 | 2.10 | 0.2 | 1.0 × 10−5 |

| C50 | 3.45 × 104 | 26 | 22.4 | 1.83 | 0.2 | 1.0 × 10−5 |

| C40 | 3.25 × 104 | 26 | 18.4 | 1.65 | 0.2 | 1.0 × 10−5 |

| C30 | 3.00 × 104 | 26 | 13.8 | 1.39 | 0.2 | 1.0 × 10−5 |

| Parameters | Elastic Modulus Es (MPa) | Tensile Design Strength fsd (MPa) | Standard Strength fsk (MPa) |

|---|---|---|---|

| HPB300 | 2.1 × 105 | 195 | 300 |

| HPB400 | 2.0 × 105 | 280 | 400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Wang, H.; Yang, K.; Xie, S.; Wei, G.; Li, R.; Wang, W. Full-Scale Prefabrication and Non-Destructive Quality Monitoring of Novel Bridge Substructure for “Pile-Column Integration”. Buildings 2022, 12, 715. https://doi.org/10.3390/buildings12060715

Wang L, Wang H, Yang K, Xie S, Wei G, Li R, Wang W. Full-Scale Prefabrication and Non-Destructive Quality Monitoring of Novel Bridge Substructure for “Pile-Column Integration”. Buildings. 2022; 12(6):715. https://doi.org/10.3390/buildings12060715

Chicago/Turabian StyleWang, Longlin, Hua Wang, Kailv Yang, Shuzhi Xie, Gangrong Wei, Ruijiao Li, and Wensheng Wang. 2022. "Full-Scale Prefabrication and Non-Destructive Quality Monitoring of Novel Bridge Substructure for “Pile-Column Integration”" Buildings 12, no. 6: 715. https://doi.org/10.3390/buildings12060715

APA StyleWang, L., Wang, H., Yang, K., Xie, S., Wei, G., Li, R., & Wang, W. (2022). Full-Scale Prefabrication and Non-Destructive Quality Monitoring of Novel Bridge Substructure for “Pile-Column Integration”. Buildings, 12(6), 715. https://doi.org/10.3390/buildings12060715