The Identification, Development, and Evaluation of BIM-ARDM: A BIM-Based AR Defect Management System for Construction Inspections

Abstract

:1. Introduction

- Identification and categorization of current uses, potentials uses, and barriers for BIM and AR integration within the construction industry.

- An improved AR system for identifying construction defects during an on-site construction inspection.

- A set of novel AR visualisations, and features to improve defect management inspection performance.

- A Revit plugin to autonomously link data recorded during the construction inspection back to the original BIM model.

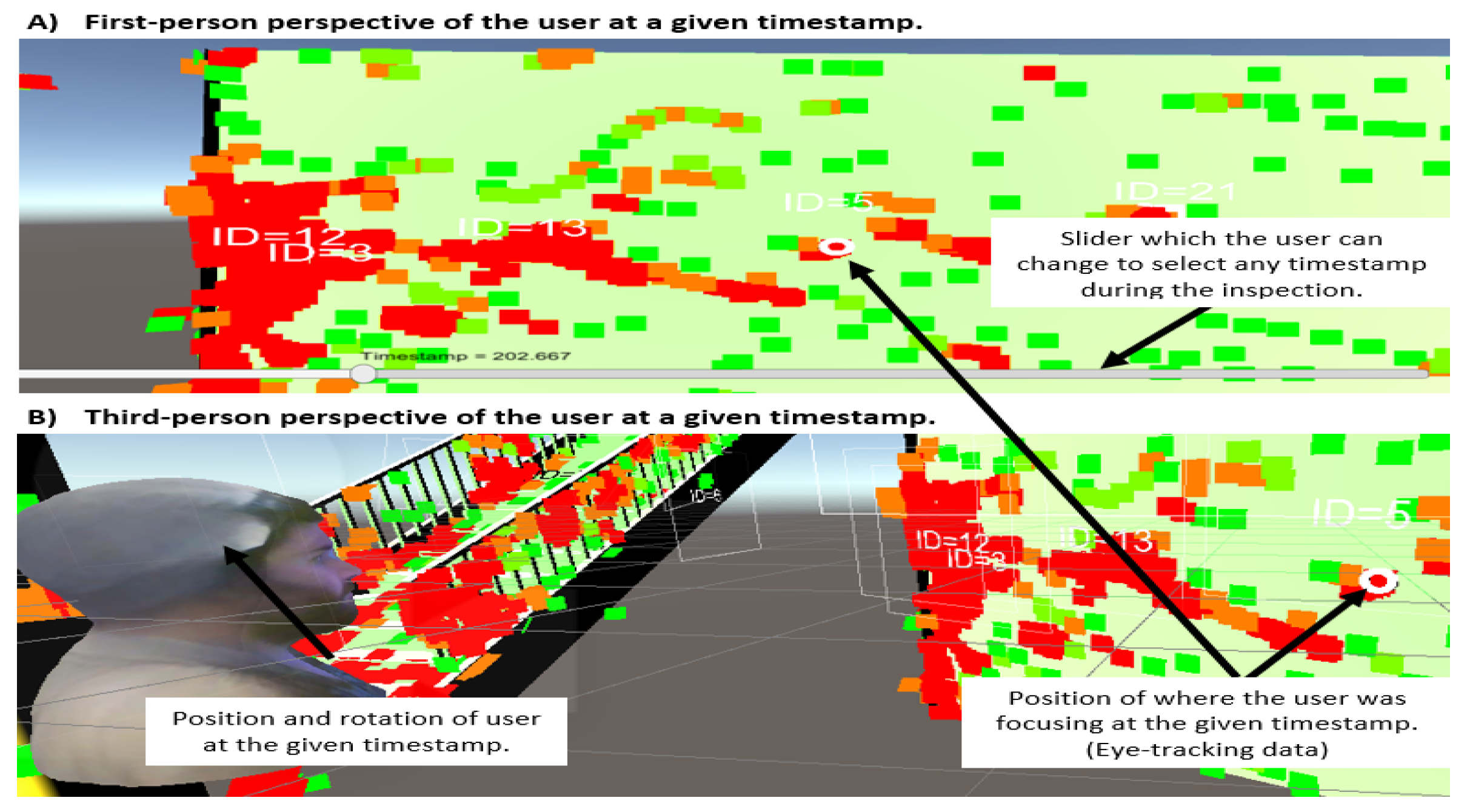

- Data analysis software to evaluate and assess construction inspection performance through eye-tracking, and head-tracking data linked to a four-dimensional visualisation.

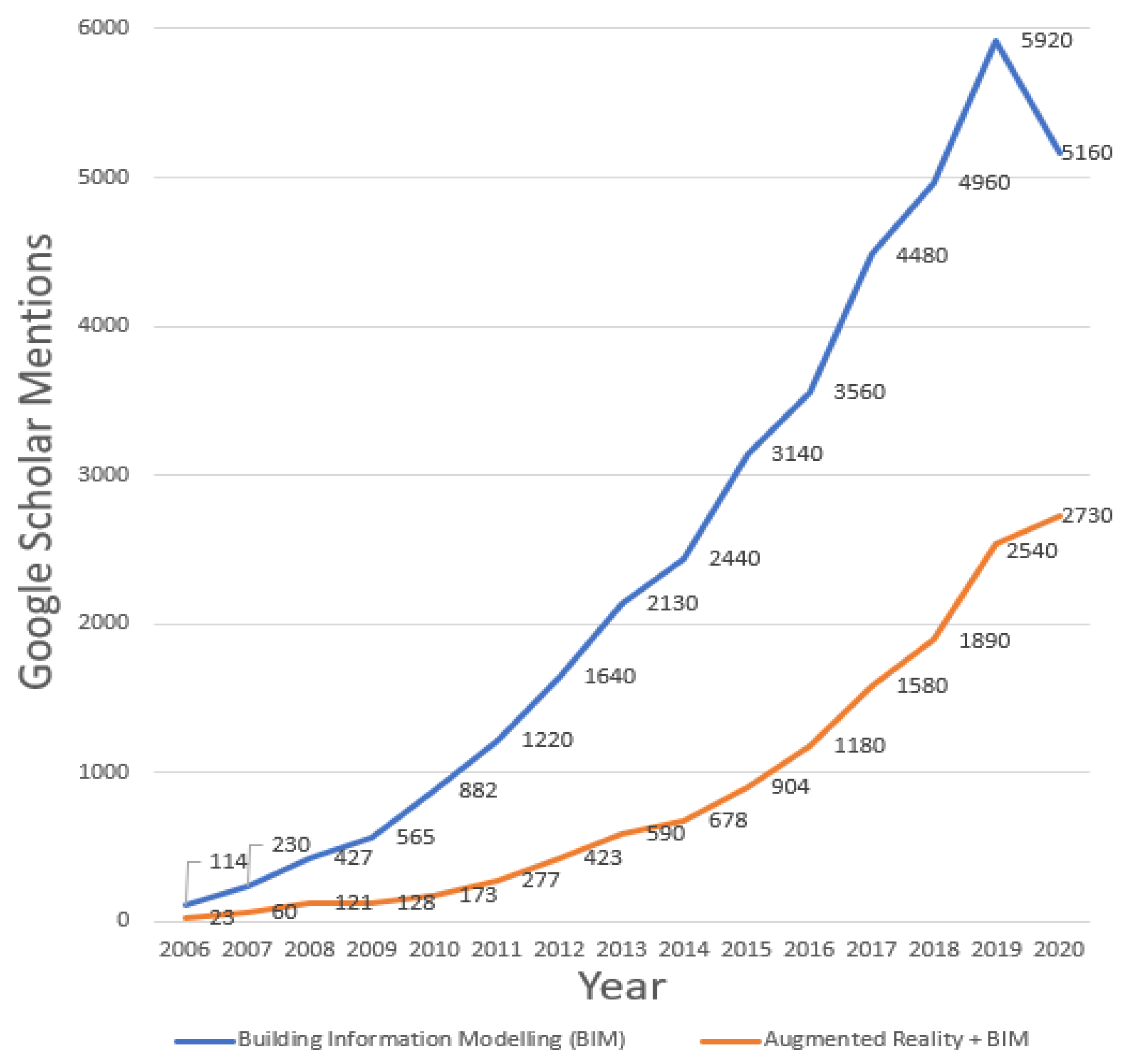

2. Background

2.1. AR Supporting BIM for Construction Inspections

2.2. Current Challenges

2.2.1. Integrating BIM Models from CAD Platforms to Game Engines and SDKs

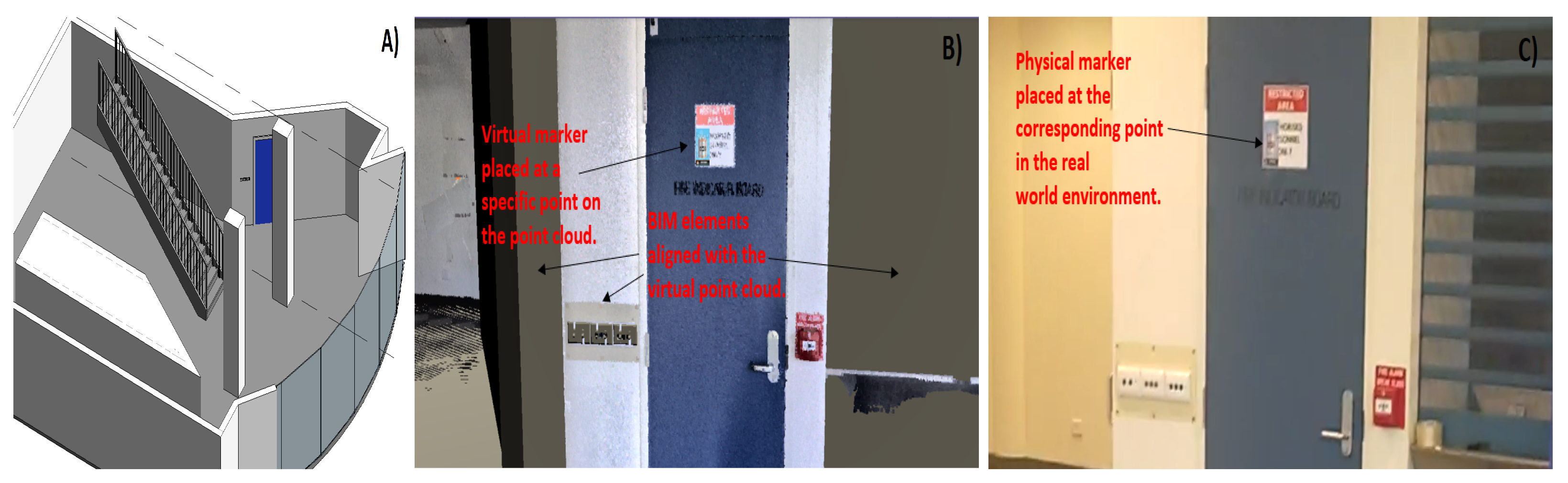

2.2.2. Tracking and Registration

3. Workshop

- What is the current adoption related to the integration of BIM and AR within the construction industry?

- What are the barriers associated with integrating BIM and AR within the construction industry?

- What potential scenarios across the entire construction-project life-cycle could BIM and AR be integrated for?

3.1. Procedure

3.2. Current Uses of BIM and AR

3.3. Current Barriers Surrounding BIM and AR

3.3.1. Maturity and Reliability

3.3.2. Accessibility and Cost

3.3.3. Standards and Data Exchange

3.3.4. Stakeholder Perception and Organisational Culture

3.4. Potential and Future Directions for Using BIM and AR

3.4.1. Quality Assurance and Defect Management Inspections

3.4.2. Safety Inductions and Training

3.4.3. Risk Management

3.4.4. Facilities Management

3.4.5. Building Performance Simulation and Visualisation

3.5. Potential Features

3.5.1. Visualisation and Sequencing

3.5.2. UI Design and User-Friendliness

3.5.3. Accessibility

3.6. Summary

- A1.

- Using AR technologies to conduct on-site quality assurance and defect management inspections on a construction site.

- A2.

- The ability to use AR technologies to visualise BIM models and go through the safety and design review phase and identify which areas on the construction site may have some potential safety concerns.

- A3.

- An AR-based learning/educational/training risk-management application designed to familiarise a person with the safety requirements and hazards associated with the construction site.

- A4.

- A facilities-management-focused AR application that allows facility managers to visualise obstructed or invisible objects within a physical building.

- A5.

- An AR-based building performance simulation and analysis tool that provides the user feedback on whether a room in the building meets specific performance requirements (e.g., acoustics).

- F1.

- Using AR to visualise occluded objects (e.g., wiring, pipes) on a construction site.

- F2.

- Sequencing a BIM model into specific components to insert things, and having a UI providing visual feedback on the insertion process.

- F3.

- Representing data using three-dimensional visualisations as opposed to traditional two-dimensional architectural analogue drawings.

- F4.

- Design the AR application to be highly interactive. Users should have the ability to visualise the building and turn specific components on and off.

- F5.

- Ensuring the general user-friendliness of the AR application and UI is a priority. It needs to be very simple and easy to use for a non-technical user.

- F6.

- Having checklists and other documents required for a construction task to be all accessible within a single device.

- F7.

- An integration of the AR system with existing BIM platforms to improve accessibility.

- F8.

- An improved AR tracking system that is very simple to use and setup.

- F9.

- Linking AR to digital point survey type accuracy for improved tracking.

- F10.

- A system or workflow capable of maintaining BIM data when exchanging BIM data across platforms to avoid loss of data.

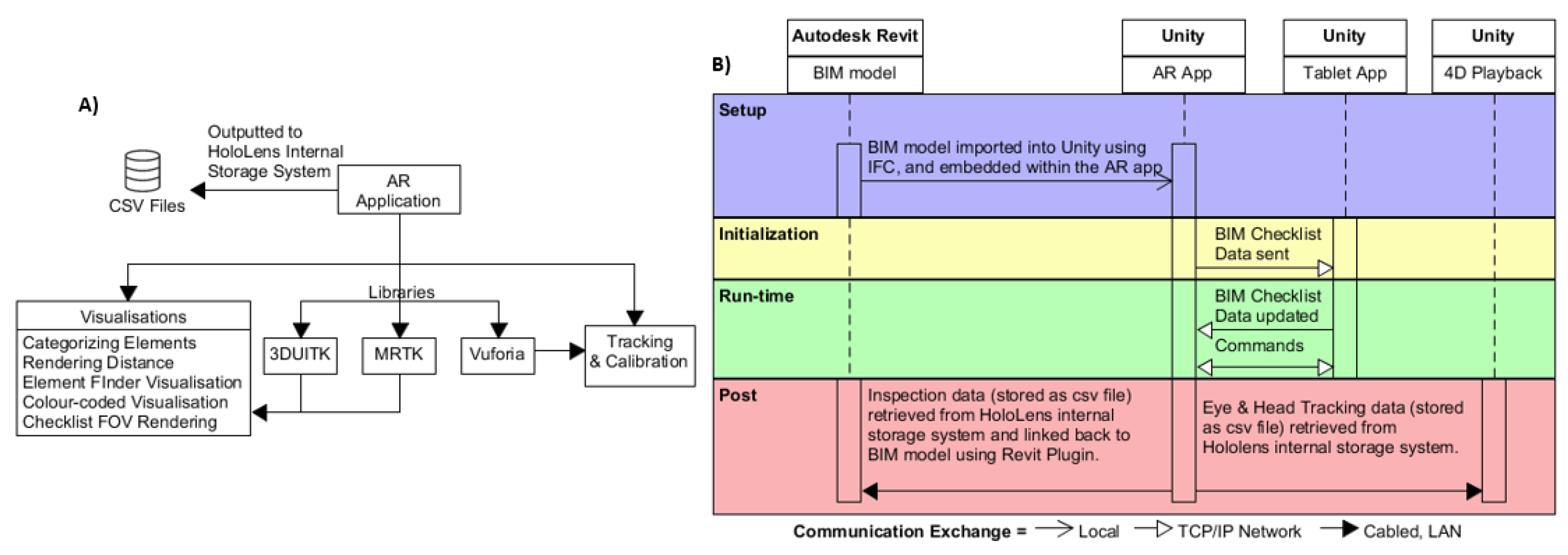

4. BIM-ARDM System Development

- All AR implementations that incorporated HMDs used a holographic interface to input and record data (e.g., checklists). We describe in Section 4.2.1 why we believe this design consideration would not be suitable on a real-world construction site.

- No AR systems were proven to perform more effectively than conventional approaches for conducting on-site construction inspections.

- Limited AR features and visualisations were integrated to support the inspector with their on-site inspection performance.

- No AR systems were tested on a real-world construction project.

- No AR systems were capable of storing inspection data back to the original BIM model.

- No systems were capable of quantitatively assessing or evaluating the on-site inspection performance.

4.1. Implementation

4.2. BIM-ARDM System Overview

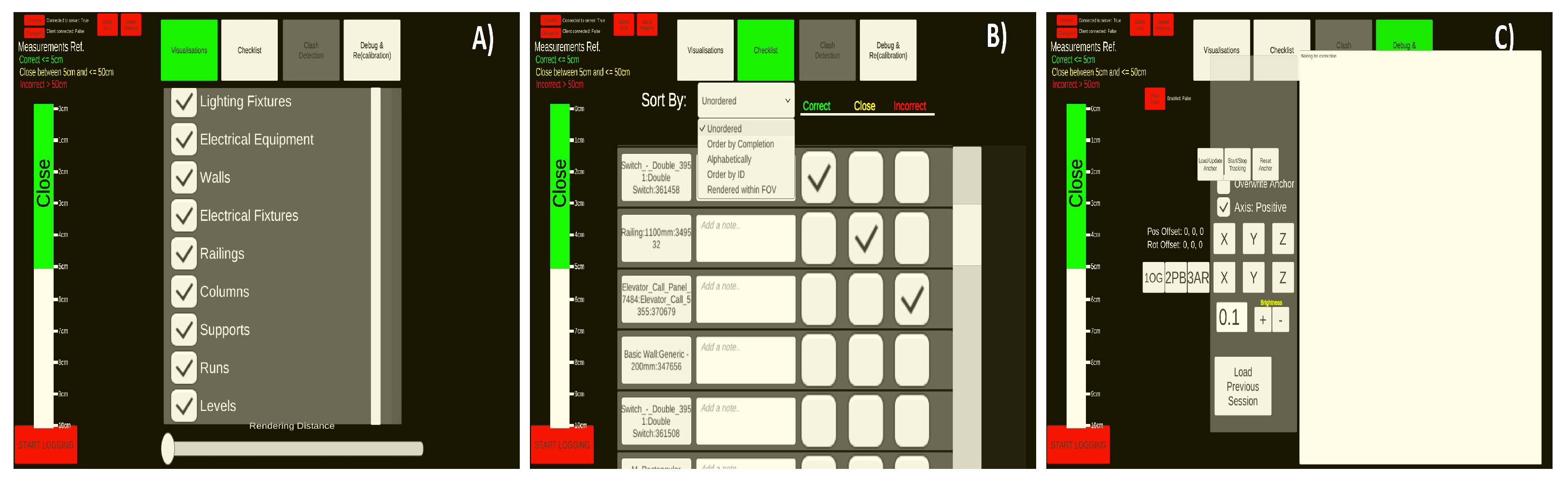

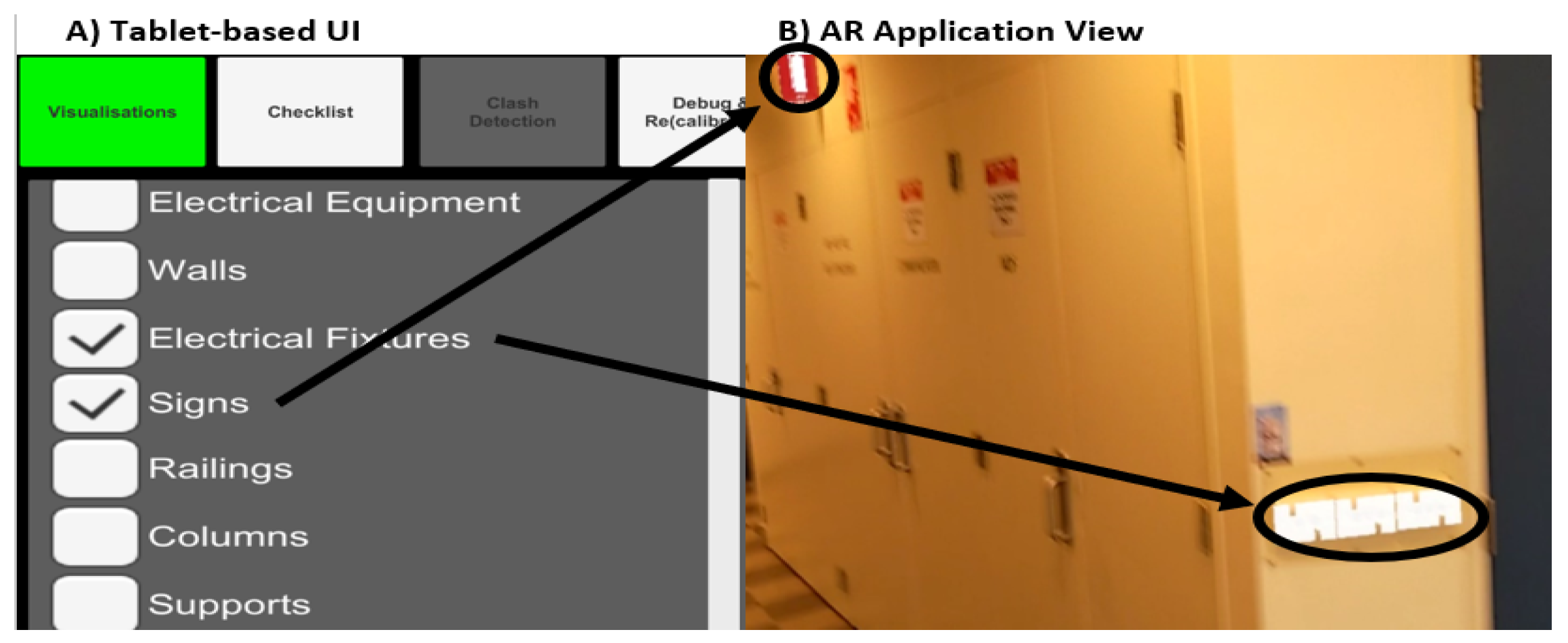

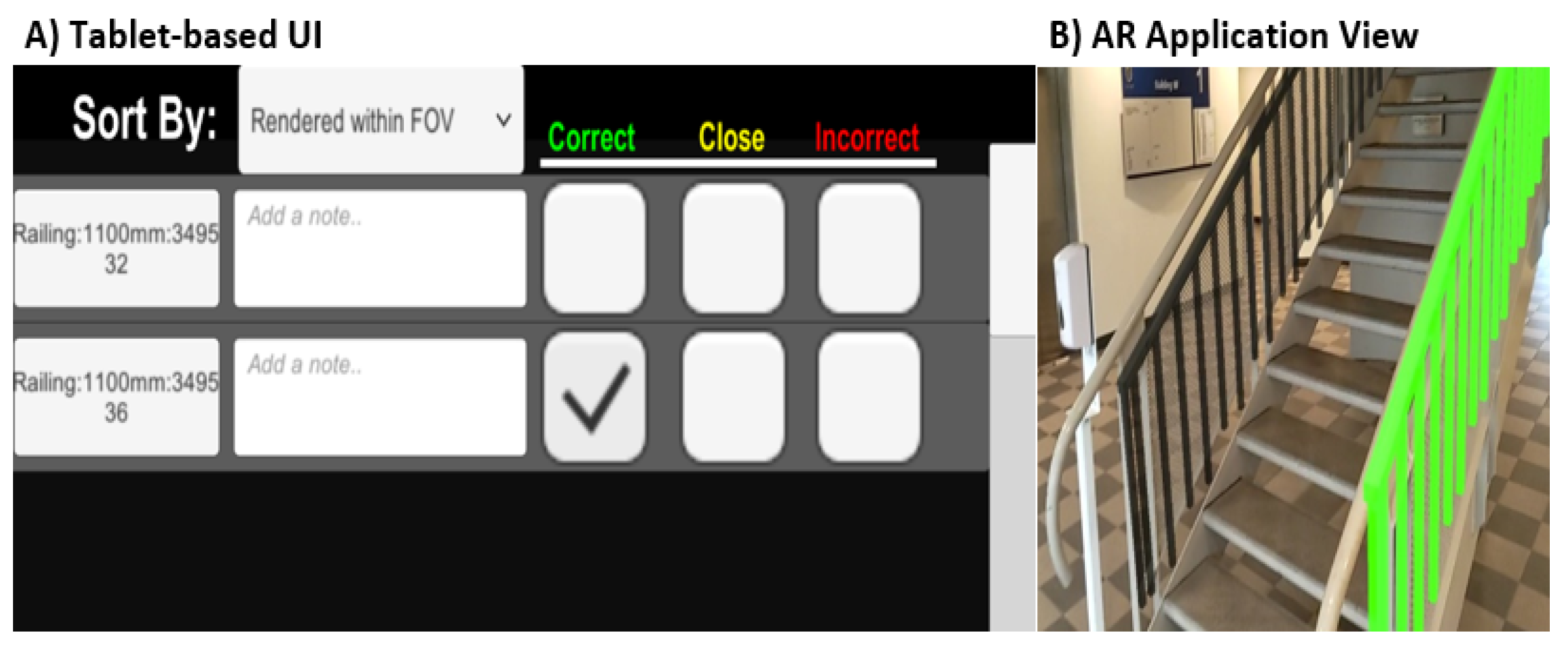

4.2.1. Tablet-Based Application

- Correct (no defect): The construction is correct, contains no defects, and is correctly aligning with the virtual element. In the pilot study, we defined this as a less-than-5 cm drift between the virtual and physical elements.

- Close (minor defect): The construction slightly differs from the virtual element. In the pilot study, we define this as a 5 cm-to-50 cm drift between the virtual and physical elements.

- Incorrect (major defect): The construction significantly differs from the virtual element. In the pilot study, we defined this as a greater-than-or-equal-to-50 cm drift between the virtual and physical elements.

- Unordered: Displays elements in their default, randomly generated order.

- Sort by completion: Sorts elements that are currently unassigned before elements that have been assigned.

- Alphabetical order: Sorts elements by alphabetical order.

- Sort by ID: Sorts elements numerically based on their Revit models unique ID.

- Rendered within field of view (FOV): Only displays checklist elements that are actively being rendered within the inspector’s FOV.

4.2.2. AR-Based Application

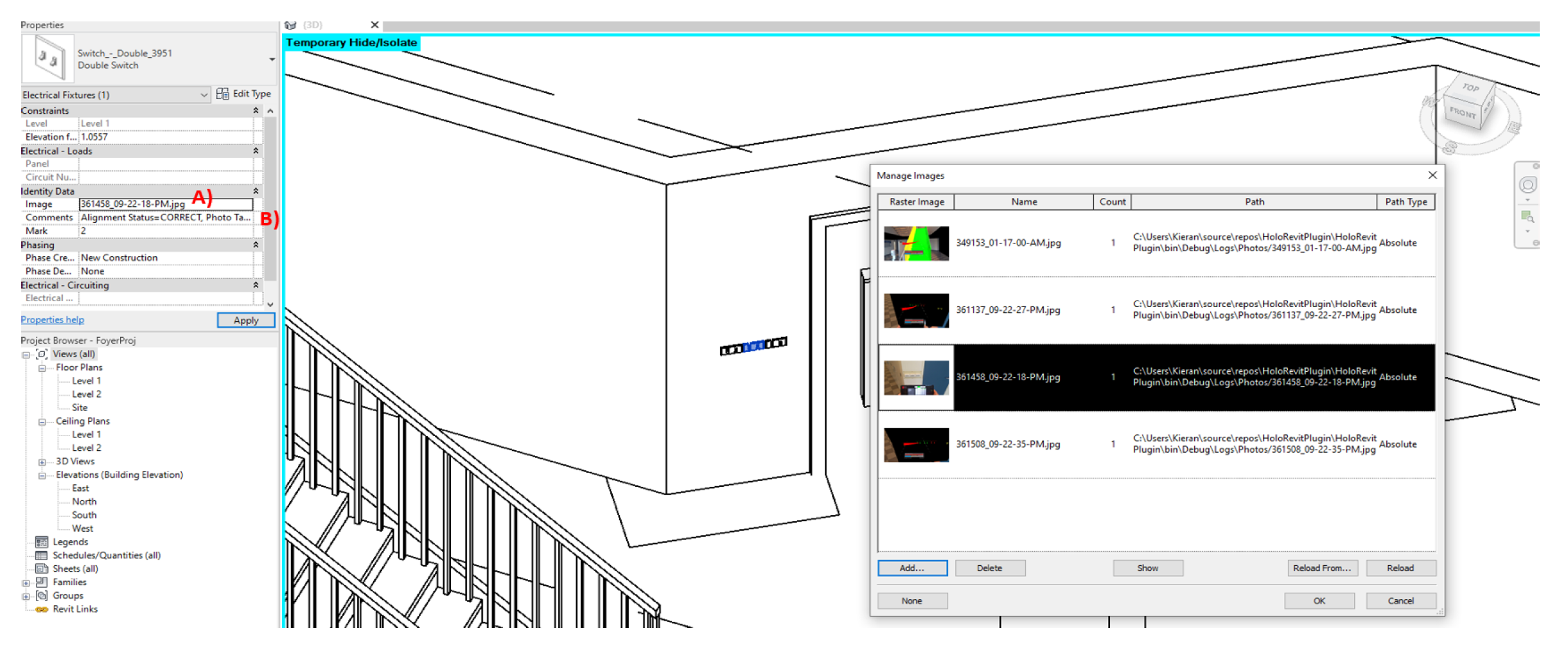

4.2.3. Revit Plugin

- The checklist data, which contain data inputted by the user using the tablet interface. These data include whether the element is correct, close (minor defect), or incorrect (major defect), as well as any other additional comments inputted by the inspector.

- Images captured of on-site elements, which are captured through the built-in HoloLens 2 camera and can be captured by selecting a capture image on the tablet-based interface. Running the Revit plugin links each picture taken during the inspection back to each of the corresponding Revit elements and attaches the images to the elements as a raster image parameter as illustrated in Figure 10.

4.2.4. 4D Playback Analysis Tool

4.3. System Limitations

4.3.1. Tracking Accuracy

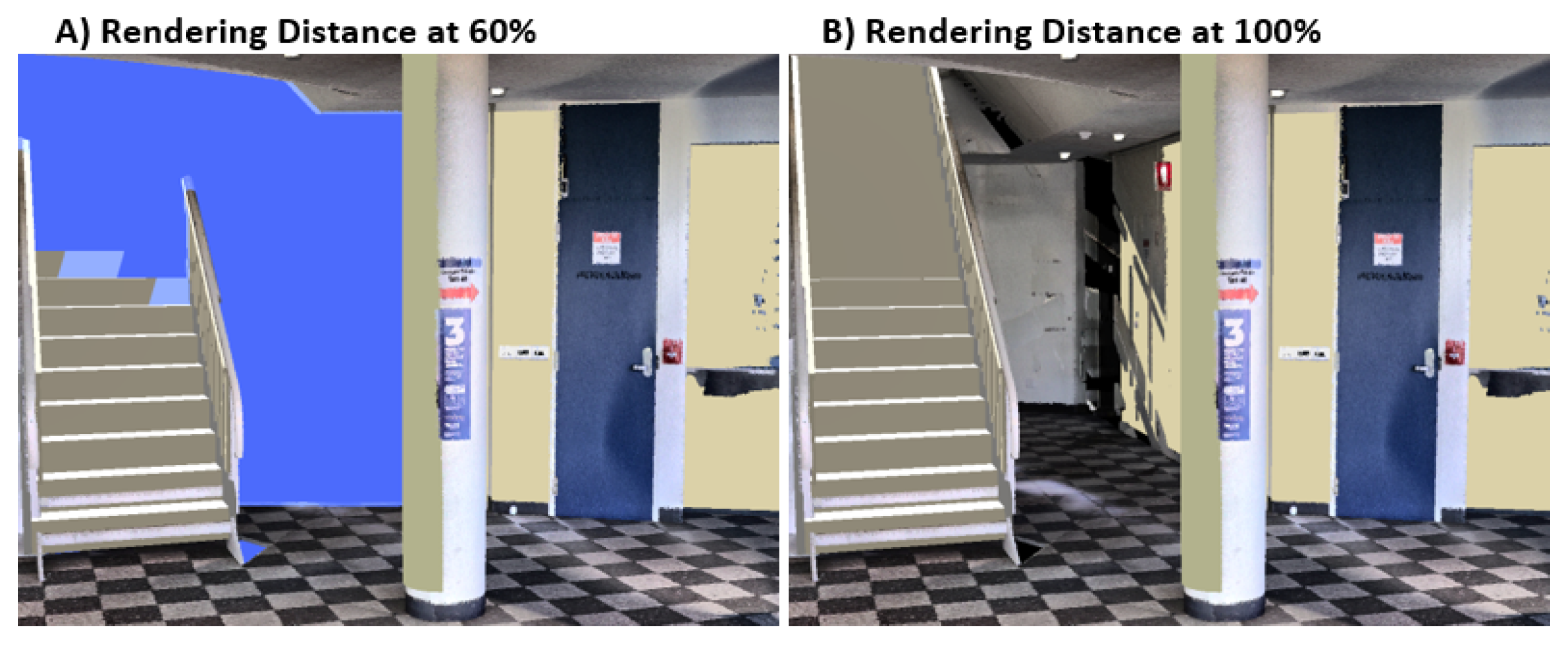

4.3.2. Performance

5. User Study

5.1. Experimental Design

5.2. Results

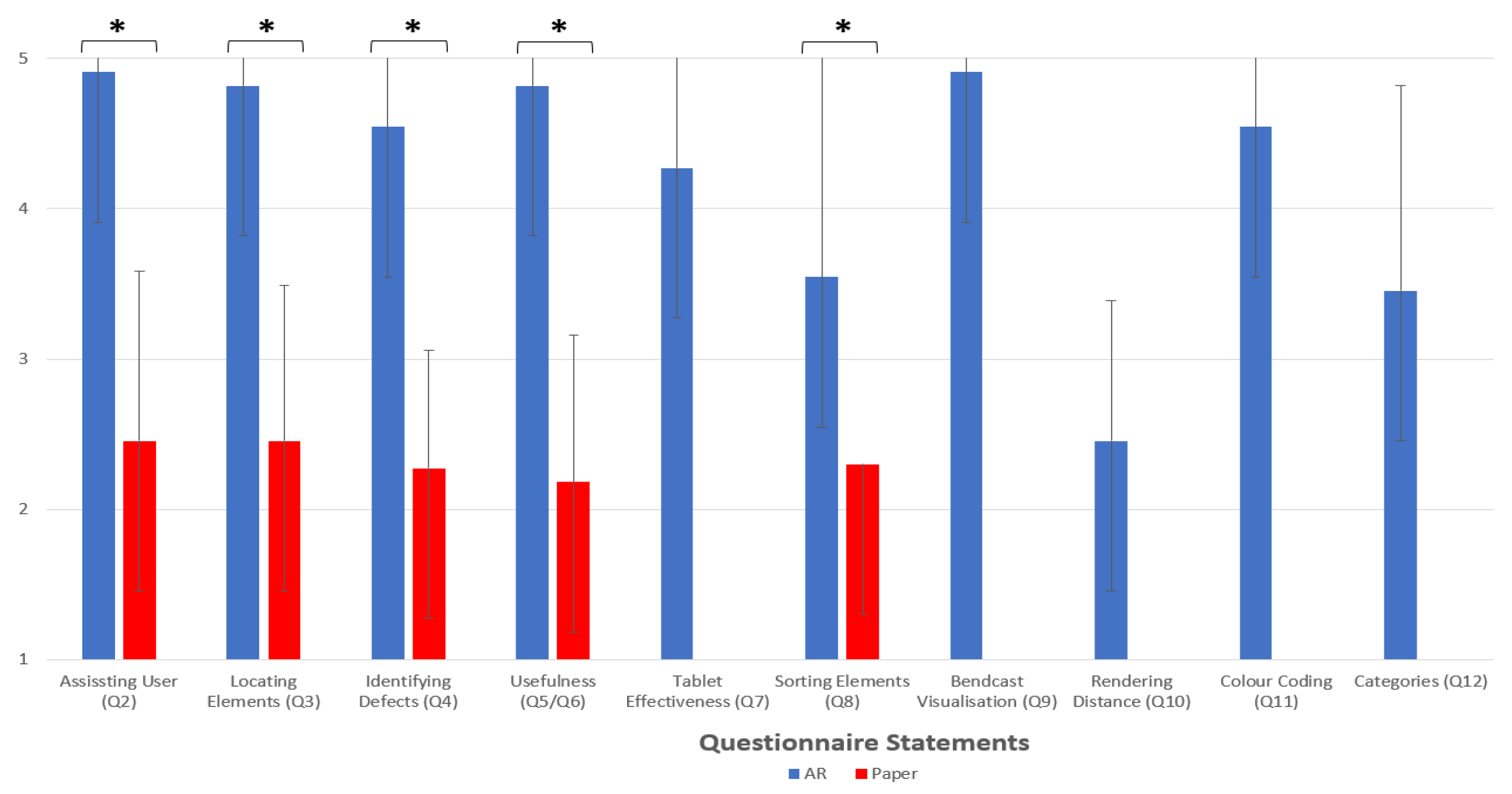

5.2.1. Usability

5.2.2. Features and Visualisations

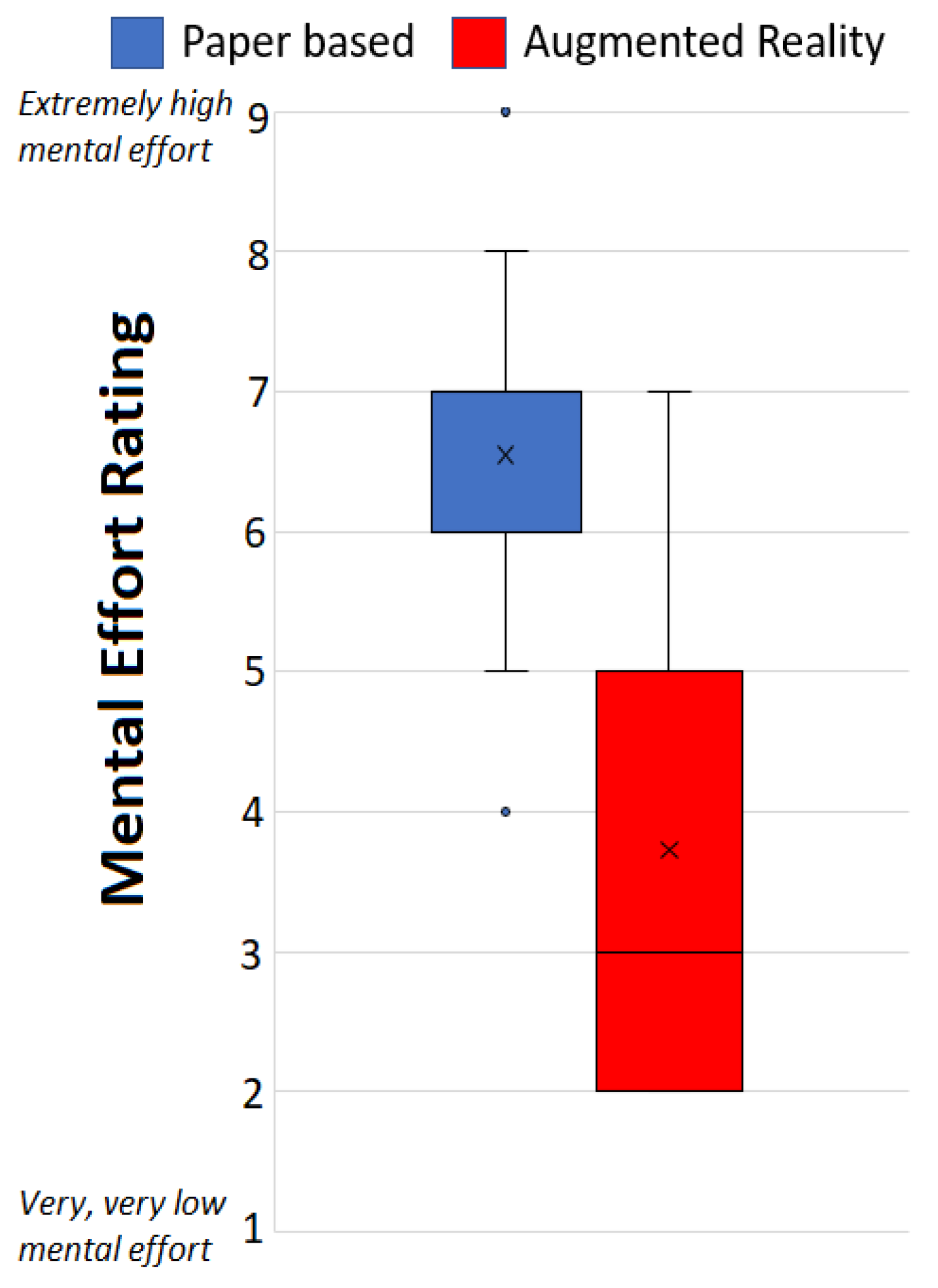

5.2.3. Cognitive Load Scale

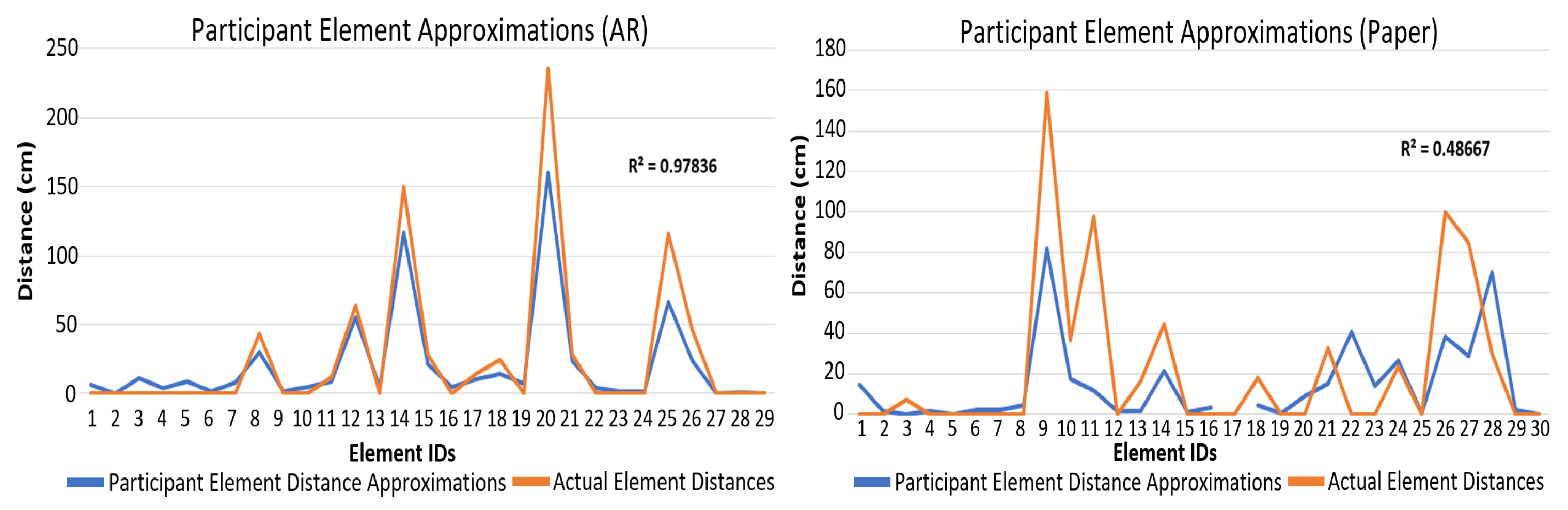

5.2.4. Participant Performance

5.2.5. Feedback

5.3. Discussion

6. Conclusions

- Identification and categorization of current uses, potentials uses, and barriers for BIM and AR integration within the construction industry.

- An improved AR system for identifying construction defects during an on-site construction inspection.

- A set of novel AR visualisations, and features to improve defect management inspection performance.

- A Revit plugin to autonomously link data recorded during the construction inspection back to the original BIM model.

- Data analysis software to evaluate and assess construction inspection performance through eye-tracking, and head-tracking data linked to a four-dimensional visualisation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eiris, R.; Gheisari, M.; Esmaeili, B. PARS: Using augmented 360-degree panoramas of reality for construction safety training. Int. J. Environ. Res. Public Health 2018, 15, 2452. [Google Scholar] [CrossRef] [Green Version]

- Park, C.S.; Kim, H.J. A framework for construction safety management and visualization system. Autom. Constr. 2013, 33, 95–103. [Google Scholar] [CrossRef]

- Albert, A.; Hallowell, M.R.; Kleiner, B.; Chen, A.; Golparvar-Fard, M. Enhancing construction hazard recognition with high-fidelity augmented virtuality. J. Constr. Eng. Manag. 2014, 140, 04014024. [Google Scholar] [CrossRef]

- Kim, K.; Kim, H.; Kim, H. Image-based construction hazard avoidance system using augmented reality in wearable device. Autom. Constr. 2017, 83, 390–403. [Google Scholar] [CrossRef]

- Carrasco, M.D.O.; Chen, P.H. Application of mixed reality for improving architectural design comprehension effectiveness. Autom. Constr. 2021, 126, 103677. [Google Scholar] [CrossRef]

- Ahn, K.; Ko, D.S.; Gim, S.H. A study on the architecture of mixed reality application for architectural design collaboration. In Proceedings of the International Conference on Applied Computing and Information Technology; Springer: Berlin/Heidelberg, Germany, 2018; pp. 48–61. [Google Scholar] [CrossRef]

- Walsh, J.A.; Baumeister, J.; Thomas, B.H. Spatial Augmented Reality Visibility and Line-of-Sight Cues for Building Design. In Proceedings of the 27th ACM Symposium on Virtual Reality Software and Technology, Osaka, Japan, 8–10 December 2021; Association for Computing Machinery: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- El Ammari, K.; Hammad, A. Remote interactive collaboration in facilities management using BIM-based mixed reality. Autom. Constr. 2019, 107, 102940. [Google Scholar] [CrossRef]

- Ammari, K.E.; Hammad, A. Collaborative BIM-based markerless mixed reality framework for facilities maintenance. In Proceedings of the 2014 International Conference on Computing in Civil and Buidling Engineering, Orlando, FL, USA, 23–25 June 2014; pp. 657–664. [Google Scholar] [CrossRef] [Green Version]

- Messadi, T.; Newman, W.E.; Braham, A.; Nutter, D. Immersive learning for sustainable building design and construction practices. J. Civ. Eng. Archit. 2017, 11, 841–852. [Google Scholar] [CrossRef] [Green Version]

- Osello, A.; Del Giudice, M.; Guinea, A.M.; Rapetti, N.; Ronzino, A.; Ugliotti, F.; Migliarino, L. Augmented Reality and gamification approach within the DIMMER Project. In Proceedings of the INTED2015 9th International Technology, Education and Development Conference, Madrid, Spain, 2–4 March 2015; pp. 2707–2714. [Google Scholar]

- Fukuda, T.; Yokoi, K.; Yabuki, N.; Motamedi, A. An indoor thermal environment design system for renovation using augmented reality. J. Comput. Des. Eng. 2019, 6, 179–188. [Google Scholar] [CrossRef]

- May, K.W.; Walsh, J.; Smith, R.T.; Gu, N.; Thomas, B.H. VRGlare: A Virtual Reality Lighting Performance Simulator for real-time Three-Dimensional Glare Simulation and Analysis. In Proceedings of the International Symposium on Automation and Robotics in Construction ISARC, Kitakyushu, Japan, 26–30 October 2020; Volume 37, pp. 32–39. [Google Scholar] [CrossRef]

- Ma, Z.; Cai, S.; Mao, N.; Yang, Q.; Feng, J.; Wang, P. Construction quality management based on a collaborative system using BIM and indoor positioning. Autom. Constr. 2018, 92, 35–45. [Google Scholar] [CrossRef]

- Shin, D.H.; Dunston, P.S. Identification of application areas for Augmented Reality in industrial construction based on technology suitability. Autom. Constr. 2008, 17, 882–894. [Google Scholar] [CrossRef]

- Shin, D.H.; Dunston, P.S. Evaluation of Augmented Reality in steel column inspection. Autom. Constr. 2009, 18, 118–129. [Google Scholar] [CrossRef]

- Hart, S.G.; Staveland, L.E. Development of NASA-TLX (Task Load Index): Results of Empirical and Theoretical Research. In Human Mental Workload; Hancock, P.A., Meshkati, N., Eds.; Advances in Psychology; Elsevier: Amsterdam, The Netherlands, 1988; Volume 52, pp. 139–183. [Google Scholar] [CrossRef]

- Portalés, C.; Casas, S.; Gimeno, J.; Fernández, M.; Poza, M. From the paper to the tablet: On the design of an AR-based tool for the inspection of pre-fab buildings. Preliminary results of the SIRAE project. Sensors 2018, 18, 1262. [Google Scholar] [CrossRef] [Green Version]

- García-Pereira, I.; Portalés, C.; Gimeno, J.; Casas, S. A collaborative augmented reality annotation tool for the inspection of prefabricated buildings. Multimed. Tools Appl. 2019, 79, 6483–6501. [Google Scholar] [CrossRef]

- Brooke, J. “SUS-A Quick and Dirty Usability Scale”. Usability Evaluation in Industry; CRC Press: Boca Raton, FL, USA, 1996; ISBN 9780748404605. [Google Scholar]

- FENG, C.W.; CHEN, C.W. Using BIM and MR to Improve the Process of Job Site Construction and Inspection. Wit Trans. Built Environ. 2019, 192, 21–32. [Google Scholar] [CrossRef]

- Park, C.S.; Lee, D.Y.; Kwon, O.S.; Wang, X. A framework for proactive construction defect management using BIM, augmented reality and ontology-based data collection template. Autom. Constr. 2013, 33, 61–71. [Google Scholar] [CrossRef]

- Kwon, O.S.; Park, C.S.; Lim, C.R. A defect management system for reinforced concrete work utilizing BIM, image-matching and augmented reality. Autom. Constr. 2014, 46, 74–81. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, H.; Yang, Y. Implementation of augmented reality for segment displacement inspection during tunneling construction. Autom. Constr. 2017, 82, 112–121. [Google Scholar] [CrossRef]

- Hernández, J.L.; Martín Lerones, P.; Bonsma, P.; Van Delft, A.; Deighton, R.; Braun, J.D. An IFC interoperability framework for self-inspection process in buildings. Buildings 2018, 8, 32. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://technical.buildingsmart.org/standards/ifc/ (accessed on 20 December 2021).

- Available online: https://www.tridify.com/ (accessed on 20 December 2021).

- Available online: https://github.com/helpsterTee/Unity-IFCEngine (accessed on 20 December 2021).

- Available online: https://www.pixyz-software.com/ (accessed on 20 December 2021).

- Marchand, E.; Uchiyama, H.; Spindler, F. Pose estimation for augmented reality: A hands-on survey. IEEE Trans. Vis. Comput. Graph. 2015, 22, 2633–2651. [Google Scholar] [CrossRef] [Green Version]

- Wagner, D.; Langlotz, T.; Schmalstieg, D. Robust and unobtrusive marker tracking on mobile phones. In Proceedings of the 2008 7th IEEE/ACM International Symposium on Mixed and Augmented Reality, Washington, DC, USA, 15–18 September 2008; pp. 121–124. [Google Scholar] [CrossRef]

- Comport, A.I.; Marchand, E.; Pressigout, M.; Chaumette, F. Real-time markerless tracking for augmented reality: The virtual visual servoing framework. IEEE Trans. Vis. Comput. Graph. 2006, 12, 615–628. [Google Scholar] [CrossRef] [Green Version]

- Simon, G.; Fitzgibbon, A.W.; Zisserman, A. Markerless tracking using planar structures in the scene. In Proceedings of theIEEE and ACM International Symposium on Augmented Reality (ISAR 2000), Munich, Germany, 5–6 October 2000; pp. 120–128. [Google Scholar] [CrossRef] [Green Version]

- Xiao, C.; Lifeng, Z. Implementation of mobile augmented reality based on Vuforia and Rawajali. In Proceedings of the 2014 IEEE 5th International Conference on Software Engineering and Service Science, Beijing, China, 27–29 June 2014; pp. 912–915. [Google Scholar] [CrossRef]

- Kato, H.; Billinghurst, M. Marker tracking and hmd calibration for a video-based augmented reality conferencing system. In Proceedings of the 2nd IEEE and ACM International Workshop on Augmented Reality (IWAR’99), San Francisco, CA, USA, 20–21 October 1999; pp. 85–94. [Google Scholar] [CrossRef] [Green Version]

- Kopsida, M.; Brilakis, I. BIM Registration Methods for Mobile Augmented Reality-Based Inspection. In Proceedings of the 11th European Conference on Product and Process Modelling eWork and eBusiness in Architecture, Engineering and Construction, (ECPPM 2016), Limassol, Cyprus, 7–9 September 2016; Christodoulou, S., Scherer, R., Eds.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Hübner, P.; Clintworth, K.; Liu, Q.; Weinmann, M.; Wursthorn, S. Evaluation of HoloLens Tracking and Depth Sensing for Indoor Mapping Applications. Sensors 2020, 20, 1021. [Google Scholar] [CrossRef] [Green Version]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology, 2nd ed.; Sage Publications: Thousand Oaks, CA, USA, 2004. [Google Scholar]

- Rankohi, S.; Waugh, L. Review and analysis of augmented reality literature for construction industry. Vis. Eng. 2013, 1, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, S. A review on using opportunities of augmented reality and virtual reality in construction project management. Organ. Technol. Manag. Constr. Int. J. 2018, 10, 1839–1852. [Google Scholar] [CrossRef] [Green Version]

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. From BIM to extended reality in AEC industry. Autom. Constr. 2020, 116, 103254. [Google Scholar] [CrossRef]

- Hakkarainen, M.; Woodward, C.; Rainio, K. Software architecture for mobile mixed reality and 4D BIM interaction. In Proceedings of the CIB-W78 25th International Conference on Information Technology in Construction, Santiago, Chile, 15–17 July 2008; Rischmoller, L., Ed.; Universidad de Talca: Talca, Chile, 2009; pp. 1–8. [Google Scholar]

- Gheisari, M.; Goodman, S.; Schmidt, J.; Williams, G.; Irizarry, J. Exploring BIM and mobile augmented reality use in facilities management. In Proceedings of the 2014 Construction Research Congress: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; Castro-Lacouture, D., Irizarry, J., Ashuri, B., Eds.; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 1941–1950. [Google Scholar] [CrossRef]

- May, K.; Hanan, I.; Cunningham, A.; Thomas, B. 3DUITK: An Opensource Toolkit for Thirty Years of Three-Dimensional Interaction Research. In Proceedings of the 2019 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct), Beijing, China, 10–18 October 2019; pp. 175–180. [Google Scholar] [CrossRef]

- Riege, K.; Holtkamper, T.; Wesche, G.; Frohlich, B. The bent pick ray: An extended pointing technique for multi-user interaction. In Proceedings of the IEEE Symposium on 3D User Interfaces (3DUI), Alexandria, VA, USA, 25–26 March 2006; pp. 62–65. [Google Scholar] [CrossRef] [Green Version]

- Paas, F. Training Strategies for Attaining Transfer of Problem-Solving Skill in Statistics: A Cognitive-Load Approach. J. Educ. Psychol. 1992, 84, 429–434. [Google Scholar] [CrossRef]

| Participant | Role | Construction-Industry Experience |

|---|---|---|

| (1) | General Builder and Director | 33 Years |

| (2) | BIM Manager | 33 Years |

| (3) | BIM Manager | 10 Years |

| (4) | Project Administrator | 4 Years |

| AR Headset | Year | Price (USD) |

|---|---|---|

| Meta 1 † | 2014 | 750 |

| Meta 2 † | 2016 | 494 |

| HoloLens 1 † | 2016 | 3000 |

| Magic Leap 1 † | 2018 | 2295 |

| HoloLens 2 | 2019 | 3500 |

| Magic Leap 2 ‡ | 2021 | 2295 |

| Apple AR Headset § | 2022 | 3000 |

| # | Statements | Cond | Mean | SD | p | |

|---|---|---|---|---|---|---|

| Q1 | Based on the mental effort scale, please rank the cognitive-load of the task. |  | Paper AR | 6.545 3.727 | 1.368 1.793 | 0.003 |

| Shared-Condition Statements | ||||||

| Q2 | I found this system was useful in assisting me to complete the inspection task. |  | Paper AR | 2.454 4.909 | 1.128 0.301 | 0.003 |

| Q3 | I found this system was useful for locating building elements in the building. |  | Paper AR | 2.454 4.818 | 1.035 0.404 | 0.003 |

| Q4 | I found this system was useful to identify construction defects. |  | Paper AR | 2.272 4.545 | 0.786 0.522 | 0.003 |

| Condition-Specific Statements | ||||||

| Q5 Q6 | I found the paper-based architectural plans were useful in assisting me to complete the task. I found the visualisations were useful in assisting me to complete the task. |  | Paper AR | 2.181 4.818 | 0.981 0.404 | 0.003 |

| Q7 | I found the tablet user-interface effective for inputting data into a checklist and controlling the visualisations. |  | AR | 4.272 | 1.009 | nil |

| Visualisations and Features Questions | ||||||

| Q8 | Sorting elements in the checklist. |  | Paper AR | 2.3 3.545 | 1.337 1.572 | 0.01 |

| Q9 | Bendray visualisation. |  | AR | 4.909 | 0.301 | nil |

| Q10 | Rendering-distance visualisation. |  | AR | 2.454 | 0.934 | nil |

| Q11 | Colour-coding visualisation. |  | AR | 4.545 | 0.934 | nil |

| Q12 | Visualising elements based on categories. |  | AR | 3.454 | 1.368 | nil |

| Post-Questions | ||||||

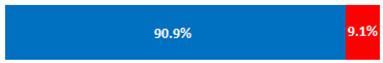

| Q13 | Please tick the condition you found MOST effective for completing the inspection task. |  |  | |||

| Q14 | Please tick the condition that was your personal preference. |  |  | |||

| Q15 | Please tick the condition you felt you were less likely to make mistakes/errors with. |  |  | |||

| Cond | Correct | Minor | Major | |||

|---|---|---|---|---|---|---|

| Mean Error Rate | Mean Error Dist | Mean Error Rate | Mean Error Dist | Mean Error Rate | Mean Error Dist | |

| AR | 2.33 | 3.86 cm | 1.75 | 22.5 cm | 0.5 | 41.8 cm |

| Paper | 2 | 5.47 cm | 7.75 | 40 cm | 6.75 | 70.3 cm |

| p-val | 0.49 Paired T-Test | 0.53 Wilcoxon Signed Rank Test | <0.001 Paired T-Test | 0.02 Wilcoxon Signed Rank Test | 0.1 Wilcoxon Signed Rank Test | 0.23 Paired T-Test |

| Augmented Reality | |||

|---|---|---|---|

| Element ID: Name | Incorrect Percentage | Participant Answers | Correct Answer |

| 1: basic wall | 6 (54.5%) | major (1 m) × 2, major (30 cm), major (10 cm, correct, major (rot 45) | minor defect (rot) |

| 4:stair springer | 5 (45.4%) | minor 15cm × 2, minor (bit to the left), minor 20 cm, incorrect 60 cm | correct (0 cm) |

| 20: light 37782 | 5 (45.4%) | minor 5 cm, minor 30 cm, minor 10c m, minor 15 cm, minor 7 cm | correct (0 cm) |

| 23:light 377731 | 4 (36.3%) | minor 5 cm × 2, minor 10 cm × 2 | correct (0 cm) |

| 8:railing | 4 (36.3%) | minor 7 cm, minor 10 cm, major 60 cm | correct (0 cm) |

| paper-based | |||

| 3: switch 361548 | 10 (90.9%) | correct × 10 | minor (7.5 cm) |

| 14: basic wall | 9 (81.8%) | correct × 5, major × 4 | minor (44.3 cm) |

| 27: exit sign 2 | 9 (81.8%) | correct × 4, minor (30 cm) × 2, minor (20 cm) | major (85 cm) |

| 28: fire sign | 8 (72.7%) | major 2 m, major 1m × 2, major 3 m, correct × 3 | minor (30 cm) |

| 18: light sign | 8 (72.7%) | correct × 8 | minor (18.2 cm) |

| 13: switch 361508 | 8 (72.7%) | correct × 8 | minor (16.4 cm) |

| Statements | Summary of Comments (AR) | Summary of Comments (Paper) |

|---|---|---|

| What do you like and/or dis-like about the... (AR Cond) tablet-based user-interface? (Paper Cond) paper-based architectural plans? | Dislikes

| Dislikes

|

| What did you like about this system? |

|

|

| What did you NOT like about this system? |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

May, K.W.; KC, C.; Ochoa, J.J.; Gu, N.; Walsh, J.; Smith, R.T.; Thomas, B.H. The Identification, Development, and Evaluation of BIM-ARDM: A BIM-Based AR Defect Management System for Construction Inspections. Buildings 2022, 12, 140. https://doi.org/10.3390/buildings12020140

May KW, KC C, Ochoa JJ, Gu N, Walsh J, Smith RT, Thomas BH. The Identification, Development, and Evaluation of BIM-ARDM: A BIM-Based AR Defect Management System for Construction Inspections. Buildings. 2022; 12(2):140. https://doi.org/10.3390/buildings12020140

Chicago/Turabian StyleMay, Kieran W., Chandani KC, Jose Jorge Ochoa, Ning Gu, James Walsh, Ross T. Smith, and Bruce H. Thomas. 2022. "The Identification, Development, and Evaluation of BIM-ARDM: A BIM-Based AR Defect Management System for Construction Inspections" Buildings 12, no. 2: 140. https://doi.org/10.3390/buildings12020140

APA StyleMay, K. W., KC, C., Ochoa, J. J., Gu, N., Walsh, J., Smith, R. T., & Thomas, B. H. (2022). The Identification, Development, and Evaluation of BIM-ARDM: A BIM-Based AR Defect Management System for Construction Inspections. Buildings, 12(2), 140. https://doi.org/10.3390/buildings12020140