Abstract

The stability of a steel bracing system is one of the most important indicators by which to measure the stability of the foundation pit. Although a steel bracing system can be monitored using the axial force data, it is subject to the risk of sudden changes due to certain factors and has the characteristics of dynamic discontinuity. Therefore, safety risk management should be applied to the mutability of steel bracing systems to ensure stability. We used the steel bracing system of a foundation pit in Ningbo City, China, as the research object. First, through fault tree analysis (FTA) of the characteristics of the steel bracing system, a safety risk identification of the catastrophe risk was carried out. Second, the safety risk was standardized, and a safety risk evaluation index system was established; the validity and stability of the index system were then verified. Next, a catastrophe theory-based evaluation model was established to determine the safety risk level of the steel bracing system. Finally, a steel bracing risk management process was designed, and a safety risk response was proposed based on the results of the evaluation model. The result was that the membership function value belongs to the general risk area, which accords with the actual state of steel bracing in engineering, and subsequent safety risk response measures can be applied. The proposed method performs well in identifying the risk of sudden changes in steel bracing systems; it also rates the risk and offers response measures to ensure the stability of the steel bracing system. Additionally, this method is of significance due to its applicability in various projects.

1. Introduction

With the development of the global economy and society, the utilization of underground space has increased sharply, and safety accidents related to engineering inevitably occur during the construction process, with deep foundation pit collapses accounting for a large proportion of these accidents. The consequences of the collapse of a foundation pit are self-evident, not only causing casualties and huge economic losses but also affecting social development [1]. While monitoring a foundation pit, observing the enclosure of the foundation pit is important for judging the overall stability of the pit, organizing construction, and ensuring construction safety. The data regarding steel bracing systems are being developed gradually and are characterized by gradual change. However, steel bracing systems are also characterized by abrupt changes because most of the systems are affected by intrinsic, human, and environmental factors, all of which objectively affect the safety of the system [2,3]; these include seismic hazards, surrounding excavations, and the quality of the system [4,5,6]. These abrupt safety risks cannot be monitored or predicted by data but can be identified and evaluated in advance. Therefore, in the safety risk management of a steel bracing system, we should focus on its abrupt variability and develop corresponding safety risk countermeasures. In addition to studying the gradual development of the data, it is also necessary to consider the part of the data that cannot be promptly judged, i.e., sudden changes due to damage, and actually, most systems have such characteristics. Therefore, a safety risk warning for mutability characteristics can effectively manage the safety risk of a system in all respects.

Risk assessment is an important issue in the industry. Many experts and scholars both in China and abroad have used the characteristics of catastrophe theory to solve the safety risk problems in related industries and provide an evaluative basis for the management of safety risks. Catastrophe theory was proposed by a French data scholar, René Thom, in his book, Structural Stability and Morphogenesis. He aimed to be able to predict the behavior of complex, disordered systems. The discontinuous process of change in social and environmental phenomena can be explained by catastrophe theory, which also explains why various phenomena create sudden leaps in form. This is also characteristic of catastrophe theory. In the 1970s, the British mathematician Zeeman E.C. conducted further research into the development and application of catastrophe theory [7]. Vladimir et al. [8] used catastrophe theory to evaluate what mechanization signifies for the construction risk. Kehinde et al. [9] developed a new paradigm for groundwater vulnerability assessment by modifying the standard DRASTIC index (DI) model based on catastrophe theory. Wang et al. [10] implemented the division and evaluation of safety risks for the subway shield construction process using catastrophe theory, compared the method with hierarchical analysis and the entropy power method and analyzed the actual results of field projects to verify the adaptability of the method. Zhang et al. [11] analyzed the buckling stability problem of piles in a slope foundation based on cusp catastrophe theory. Wang et al. [12] used the method to evaluate the safety risk in an embankment project of the Ningxia section of the Yellow River and determined that this method is not only simple and convenient but also deals well with the influential relationship between indicators and has good robustness. Mansour et al. [13] analyzed the geology, population density, and area of the city of Tabriz, Iran, and used the fuzzy characteristics of catastrophe theory to judge the vulnerable of parts of the city in the case of earthquakes and found that it provides an effective basis for future prevention and control.

Given the summary above, catastrophe theory is adaptable to cases of engineering catastrophes. In addition, catastrophe theory may well complement the prediction of steel bracing axial force data, which was the subject of our prior research [14], to enhance the risk management of foundation pit steel bracing systems.

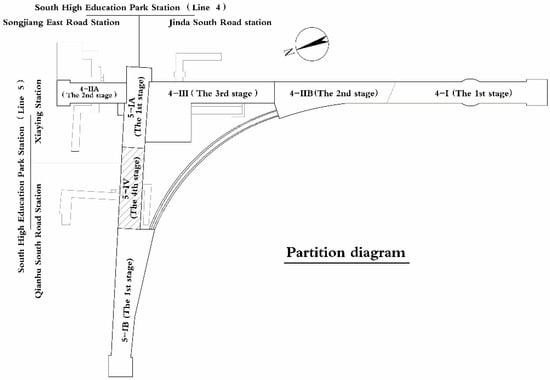

The study area is located in Ningbo, China [14]. Ningbo Rail Transit Line 4 is an important radial line in the rail network from the northwest to southeast, with the starting and ending stations being Cicheng Station and Dongqian Lake Station, respectively. The overall line length is 35.95 km, including 24.45 km of underground line length, and the elevated line and transition section lengths are about 11.2 km and 0.3 km, respectively. The overall line has 25 stations (including six interchange stations), comprising 18 underground stations and seven elevated stations, with an average station spacing of 1.49 km. There is the Cicheng parking lot and the Dongqian Lake vehicle sections. The elevated line of Railway Line 4 is from Cicheng Station (starting point) to Guangxiayiting Station, and the transition interval is from Guangxiayiting Station to Zhuangqiao Station, and the underground line is from Zhuangqiao Station to Dongqianhu Station.

The specific object of this study was South High Education Park Station. It is the 22nd station of Ningbo City Rail Transit Line 4, and the 10th station of Phase I of Line 5 is a T-shape interchange island station of Ningbo City Rail Transit Line 4 and 5, located in Yinzhou District at the intersection of Ningheng Highway and Yinxian Avenue. The station of Line 4 has two floors underground, the structure is a double-column three-span box type, and the station scale is 486.5 × 20.3 m (internal clean). On the southern side of the intersection, the north–south steering wheel is set within the range of Ningheng Highway and the green belt is on the western side, as shown in Figure 1.

Figure 1.

Partition diagram.

2. Catastrophe Theory

Catastrophe theory is based on a variety of approaches and can be used to explain the phenomenon when a system changes rapidly from one stable state to another, and it also applies to discontinuous changes in unknown systems. In a stable state, there is only one extreme value as the only critical value is the state function of the system, but when the selected parameter variables change, the system enters a non-stable state, and the state function of the system will have two or more critical values. Thus, the stability of the system can be fed back by solving for the number of critical values of the state function for which the derivative obtained in the state function is zero. Let the state function be , which contains two parameters and one variable, and find the critical values of this function when given u and the value of v, as in Equation (1):

where, is the state function.

From Equation (1), one or more critical values can be derived, and each time a different u, v value is given, one or more values are obtained, which can be written as Equation (2).

The set of critical values of this function is expressed in three-dimensional space in the form of a surface, when the state of the system is m parameters and n variables, and can be solved by a partial differential equation, as in Equation (3):

where, is the potential function.

The fundamental feature of catastrophe theory is solving the critical value of the potential function. The catastrophe factors appearing in the system are called state variables, and the factors causing the catastrophe in the system are called control variables. The system is controlled by the control variables when it is stable, and the catastrophe occurs when the system is in a specific position.

The state of the system according to catastrophe theory mainly depends on the number of control variables rather than the number of state variables. When the state variables are less than two and the control variables are less than four, the basic catastrophe models can be divided into seven types, and their models and corresponding normalization formulas are shown in Table 1. Because the state variable of the mutation model used in this paper has only one value, and the control variable has two, three, and four separate values, it can be divided into three types, which are spike-point catastrophe, swallow-tail catastrophe, and butterfly catastrophe.

Table 1.

Common catastrophe models and normalization formulas.

The steel bracing system is a complex system with multiple factors, including several structures, all of which are subject to safety risks. In addition to its own risks, the surrounding environment also affects the steel bracing system, and these effects are control variables [15]. Obviously, different projects will generate different working conditions, and the number of state variables and control variables will also vary; consequently, a higher-dimensional catastrophe model of steel bracing system will also be considered and implemented. Various factors affect steel bracing systems and accumulate continuously; thus, at a certain time, there can be a sudden change, which is dynamic and discontinuous, associated with the study of catastrophe theory, which can therefore be used to analyze the catastrophe aspect of steel bracing systems.

3. Steel Bracing System Analysis Based on Catastrophe Theory

For steel bracing systems, there are two states: the first is the slow gradual change state, that is, the normal state of its axial force value data monitoring, and, in this case, effective prediction and appropriate safety risk countermeasures can be taken; the second is the sudden mutation status, where the steel bracing system is affected by certain factors, and encounters sudden damage, including the construction management aspects of the damage and the threat to the steel bracing system caused by the surrounding environment. Therefore, safety risk identification, evaluation, and countermeasures for steel bracing systems need to focus on analyses based on the most unfavorable case, that is, the accidental case. It is necessary to identify and evaluate the safety risks in advance and to develop good countermeasures.

3.1. Applicability of Catastrophe Theory to Steel Bracing Systems

The main objective of catastrophe theory is to study dynamic systems, and its main purpose is to address the causal relationship between the sudden situations that may occur during their development, such as interruptions or abrupt changes, and the factors that lead to these changes. Catastrophe theory mainly uses the conditions of mutual transformation or unilateral transformation between critical points to analyze the characteristics of the system. The essence of this is to take the factors outside the system as control variables, the state generated by the system itself as output content, and the internal conditions of the system as input content, so that the internal conditions of the system and the state generated by the system itself are controlled by the factors outside the system, forming a functional relationship. When the control variables are in the process of continuous change, a function that occurs in a leap change can be considered a sudden change. The safety risks of steel bracing systems are consistent with the characteristics of abrupt change in this respect. The stability and mutability of steel bracing systems are impacted by every step of the construction process, including assembly, positioning welding, hoisting, foundation pit excavation, foundation pit backfilling, and demolition. Steel bracing systems are complex systems that consist of several parts and are closely related to the external environment and personnel behavior. The state outside the system can be considered a control variable, and the state of the steel bracing changes under the influence of multiple factors that may be rapidly accumulated and suddenly changed at a certain moment, with dynamic non-continuous characteristics, which is in line with the problems studied by catastrophe theory.

3.2. Safety Risk Assessment Indicators

3.2.1. Safety Risk Identification

The safety risk identification of steel bracing systems focuses on the analysis of the main factors that affect their stability as the first step in the safety risk evaluation, which is the basis for all the subsequent steps. After summarizing all the possible risk events, more comprehensive knowledge of the risks of the steel bracing system can be obtained. This step focuses on the qualitative aspects of the safety risk factors of steel bracing systems. In terms of quantitative analysis, especially the quantitative analysis of human factors, principal component analysis, the analytic hierarchy process, and the residual trend method can be used [16], which need to be discussed separately. Among several common methods of risk identification, we mainly use fault tree analysis. Relevant expert investigation and analysis reveals that, in addition to the data analysis aspect that can predict the ability of steel bracing systems to produce slow gradual change, there are cases of sudden accidents, which may occur directly or instantaneously and are difficult for humans to predict. These factors should be identified at the outset, and preventive and control measures should be taken in advance.

According to the “Standard for construction safety assessment of metro engineering” and expert investigation and inquiry, the various types of sudden change damage can be summarized as follows [17,18,19]:

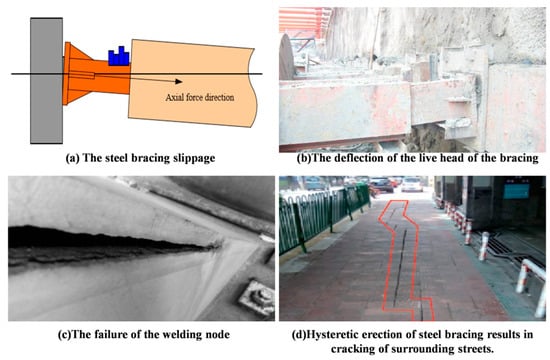

- (1)

- Steel bracing rod eccentric force damage. Due to the knowledge level of construction personnel, technical limitations, welding lack of strength, or non-adherence to the standard application, gaps are most likely to appear in the steel bracing end between the structure and the purl, and, under the influence of eccentric force, the bracing rod is not uniformly stressed. In addition, the bearing plate in the wall under the combined action of eccentric force and horizontal force will increase the possibility of steel bracing slippage, inducing bracing instability collapse.

- (2)

- Steel bracing failure due to bending deflection and damage to the following forms. For the first form, the bracing is bent by eccentric force, and the support is bent by partial force, resulting in flexure and fracture of joint bolts [20]. For the second form, large settlement differences appear in the excavation process of the foundation pit column bulge, enclosure, and column between the two, leading to bracing deflection damage or shear cracks, or, more seriously, bracing node damage. The third form involves construction of technical means, mechanical equipment that is not in place, and deflection damage caused by bracing installation that lacks sufficient precision.

- (3)

- There are four forms of bracing destabilization damage. In the first form, due to the role of pressurized water, the bottom of the pit rises so that the two sides of the enclosure appear settled. In the second form, the pit cannot be completed within the standard time frame, so the upper bracing force becomes large and destabilized. In the third form, the pit water curtain does not meet the standard construction requirements, so a large amount of water and soil is lost through the enclosure joints, and the pit unilaterally gushing water and sand unloading leads to instability. In the fourth form, the pit excavation depth is too large, and the contact surface pressure between the enclosure and soil is reduced; coupled with the failure to remediate this in a timely manner, it can cause the bracing enclosure wall to detach.

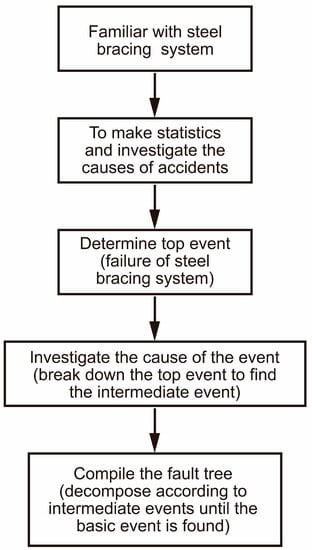

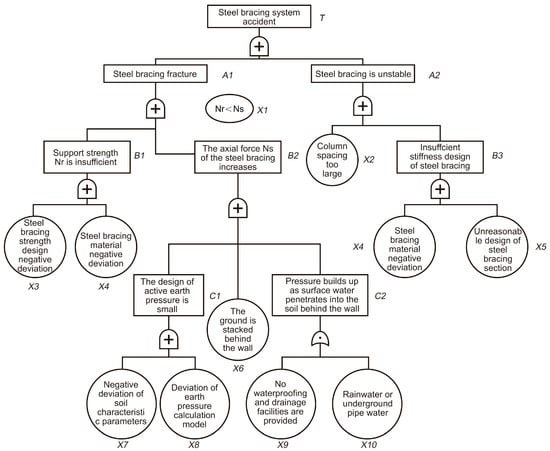

Based on the above summarized points, the accident tree preparation procedure shown in Figure 2, and the accident factors of steel bracing systems, an accident tree of steel bracing systems was established, as shown in Figure 3 (Appendix A Table A1), including several aspects such as eccentricity and instability and the basic events of the risk sources related to the steel bracing system.

Figure 2.

Accident tree preparation procedure.

Figure 3.

Accident tree of steel bracing system.

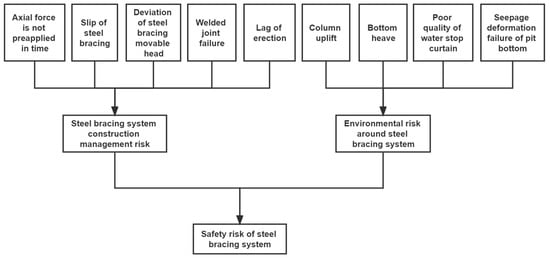

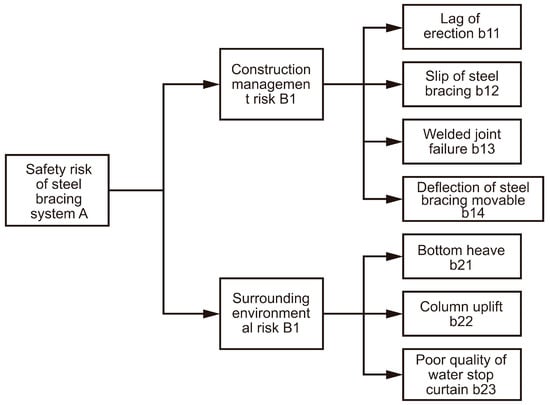

3.2.2. Standardization of Safety Risk

Summarizing the previously mentioned risk sources of the catastrophe damage mode and the accident tree analysis, the safety risks of steel bracing systems under the catastrophe mode are currently divided into two major categories: one for the risks caused by the construction or management of the steel bracing system, and the other for the risks caused by the surrounding environment. After the identification of the safety risk factors of the steel bracing system, the structure and hierarchical distribution of the safety risk factors were re-integrated and summarized, and the safety risk standardization operation was carried out to build the safety risk evaluation index system of the steel bracing system. The relationship between the main risk factors and events is shown in Figure 4.

Figure 4.

Relationship between risk factors and events.

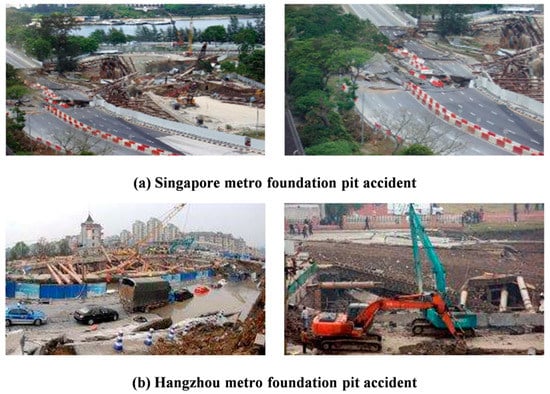

- (1)

- Construction management risks of steel bracing systems [19,21]: The eccentric effect of bracing due to technical problems leads to bracing slippage; the skewed live head of bracing leads to member fracture; the welding node of bracing leads to node failure due to improper technology; the over-excavation of the foundation pit leads to the delayed erection of steel bracing in terms of management; and, in the construction of steel bracing, there is the problem of pre-loading axial force hysteresis, which affects its stability. Therefore, according to the identified safety risks, combined with the structure of the steel bracing system, the construction management risks were determined to include the delayed preloading of axial force, the steel bracing slippage, the deflection of the live head of the bracing, the failure of the welding node, and hysteretic erection (Figure 5) [18]. Examples of these include the Singapore metro foundation pit accident and the Hangzhou metro foundation pit accident, as shown in Figure 6.

Figure 5. Construction management risks of steel bracing systems.

Figure 5. Construction management risks of steel bracing systems. Figure 6. Metro foundation pit accident.

Figure 6. Metro foundation pit accident.

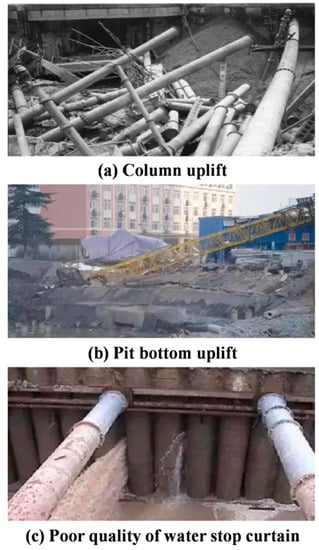

- (2)

- Environmental risks affecting steel bracing systems [22,23,24,25]: The continuous excavation of the pit soil can easily lead to column uplift and pit bottom uplift, which can lead to cracking of the bracing nodes and destabilization fracture of the steel bracing, respectively; in the case of a poor-quality water stop curtain, soil erosion can occur, and when this does occur, it can also lead to destabilization of the steel bracing system; additionally, the seepage deformation and failure of the pit bottom can cause the displacement and subsidence of soil outside the pit. According to the characteristics of the steel bracing system, combined with the analysis of common safety accidents of steel bracing system damage in China, and combined with expert opinions, it was determined that the environmental risks include column uplift, pit bottom uplift, seepage deformation failure of the pit bottom, and poor-quality water stop curtains leading to soil erosion (Figure 7).

Figure 7. Environmental risks affecting steel bracing systems.

Figure 7. Environmental risks affecting steel bracing systems.

In summary, according to the results of the expert investigation method and accident tree analysis, we can better understand the safety risk of steel bracing systems, analyze their hierarchical structures, and establish safety risk standardization. The safety risks of steel bracing systems under the catastrophe mode were divided into two categories: construction management risks and surrounding environment risks. The safety risk evaluation index of steel bracing systems was constructed based on catastrophe theory and can be used to provide a relevant theoretical basis for the safety risk evaluation of steel bracing systems.

3.2.3. Inspection of Safety Risk Assessment Indicators

According to the above, two aspects of safety risk factors and relationship schema were built, and according to the qualitative analysis, we obtained a list of safety risk factors of steel bracing systems, as presented in Table 2.

Table 2.

List of safety risks of steel bracing systems.

It is necessary to establish that the aforementioned indices adhere to the fundamental guidelines established for the creation of the index system and to evaluate the accuracy and dependability of the constructed indices. Index selection is crucial for assessing the safety risk of steel bracing systems. The following principles must be considered when constructing a safety risk assessment index system for bracing support:

- (1)

- Principle of generality. To simplify the transversal comparison of steel bracing systems across several projects to determine their common law, when selecting the evaluation index, the index with the highest frequency of usage and the greatest degree of universality should be selected. Avoid non-essential or low-impact indices.

- (2)

- The principle of representativeness. In the evaluation of steel bracing systems, multiple connected indices may be selected. In this instance, the principle of representativeness must be adhered to, and some indices with evident importance and significant influence on the assessment findings of the steel bracing system must be selected for study to improve the efficacy of the evaluation results.

- (3)

- The principle of comprehensiveness. The principle of comprehensiveness dictates that the selected index system should be exhaustive and capable of reflecting all the features of the steel bracing system.

- (4)

- The principle of testability. The index’s concept should be explicit; the data required to calculate it should be simple to obtain; and the computation procedure should be straightforward and intuitive.

- (5)

- The principle of systematism. The index system should be able to reflect the comprehensive state of the steel bracing system, and the indices should follow a logical progression.

In addition, the validity and reliability of safety risk assessment indicators should be tested:

- (1)

- The validity of safety risk assessment indicators. In the evaluation process, when the expert group uses the same index to evaluate the same target, but the data obtained from the evaluation vary significantly, this indicates that the evaluation index does not accurately reflect the situation and should be eliminated. Using the validity coefficient method, this issue is resolved. Suppose that the evaluation index system is , the number of experts is S, the scoring set of experts j for the evaluation target is , and the validity coefficient of index is :where is the average of the scores of the evaluation index ; is the centralized scoring optimal value of index , taking the mode.

The validity coefficient of evaluation index system is defined as :

The smaller the absolute number of (close to 0.1), the more effective the evaluation index system.

- (2)

- The reliability of safety risk assessment indicators. Suppose there is a set of evaluation data that accurately reflects the evaluation of the objective’s nature. If the evaluation data obtained by the designed index system are closer to the target group of data, the evaluation data obtained by the evaluation index system can be considered to be closer to the essence of the evaluation target, and the evaluation index system’s stability will be higher. Consequently, the correlation coefficient can be used as the stability coefficient of the evaluation index system to reflect the evaluation index system’s stability. Assume that the average data group for the panel score is .

The stability coefficient is :

Among them:

The formula takes the mean value of evaluation results of evaluation indicator as the ideal value and calculates the degree of difference between evaluation data and their mean value to reflect the difference of the evaluation data. If is larger (close to 1.0), it indicates that the difference of the evaluation data is small, and the stability of the indicator system is high.

3.2.4. Establishment of Safety Risk Assessment Indicator System

There is a correlation between the initial factors analyzed in the accident tree, and changes in some factors can affect others, thereby increasing the repeatability between indicators. Therefore, it is necessary to reduce the number of initial factors, which is convenient for constructing risk evaluation indicators using the mutation theory. In this study, rough set theory was applied to reduce the number of factors to improve the accuracy of the risk mutation evaluation:

- (1)

- The above indicators were scored by 10 experienced experts on site for the project, with 1 point for the lightest impact, 2 points for medium impact, and 3 points for the most serious impact, as shown in Table 3. According to the validity and stability analysis, the validity coefficient of the scores shown in Table 3 was , and the reliability coefficient was . The data show that the proposed safety risk indicators have relatively acceptable effectiveness and stability.

Table 3. Expert scoring of safety risk factors of a steel bracing system.

Table 3. Expert scoring of safety risk factors of a steel bracing system. - (2)

- For a given knowledge base , let be an equivalence relation and . If , then is also an equivalence relation, denoted as , which is also an indiscernable relation of . If , can be omitted in ; otherwise, it cannot. According to the rules of rough intensive subtraction:make , then conform to

After rough and intensive reduction, the impact of and among the original factor indicators was small and could be ignored and removed. The risk indicators were redefined and numbered according to the impact degree to obtain a new indicator evaluation system, as shown in Figure 8.

Figure 8.

Safety risk evaluation index system for a steel bracing system of a foundation pit.

From the above scoring, it can be seen that:

- (1)

- Construction management risk factors have the greatest impact, and the impact of lagging erection is the greatest among these because it directly leads to cracking of the enclosure structure and a greater risk of the foundation pit collapsing; the next most important impact is steel bracing slippage, as the eccentric force of steel bracing leads to the bearing plate being subjected to the horizontal force of the wall, causing the bracing to be unstable and fall down; finally, there is the problem of failure of the welding node and deflection of the bracing live head.

- (2)

- The impact of the surrounding environment risk is the most severe, and the impact of the pit bottom uplift is the greatest among the lower indicators. The condition of pit bottom uplift appears when the soil at the bottom of the pit is subjected to the action of bearing water, and the settlement of the enclosure on both sides causes the destabilization and destruction of the bracing. This is followed by the uplift of the column, which continuously threatens the stability of the steel bracing system. The least impact is created by the erosion factor caused by the poor quality of the water stop curtain.

3.3. Catastrophe Theory Assessment Model

The safety risk evaluation indices obtained from the above qualitative analysis were evaluated using catastrophe theory. They were first scored by experts and project managers, then the scoring data were normalized. A score of 9 represents the smallest negative impact, and a score of 1 represents the largest negative impact. The data given by the experts and the data after the experts’ normalization are shown in Table 4.

Table 4.

Expert scoring of safety risk evaluation indicators for steel bracing.

According to the stability and validity analysis, the validity coefficient of the above scores was , and the reliability coefficient was . The judgment of importance prior to the reduction in the rough set was not entirely consistent, so the stability and validity scores were not particularly accurate. However, after the rough set reduction, the repeatability and insignificant factors were eliminated, and the safety risk evaluation indicators had perfect validity and stability. Because, in catastrophe theory, the underlying indicators represent different aspects of the characteristics and their characteristic values have different units of variables in the system, there will be deviations in their scales and value ranges, which can lead to the problem of not being able to compare the data. Therefore, the original data should be normalized by maximum normalization, and the formula for processing them is Equation (12):

where, Cm is the average score of Cij given by the expert group.

Based on the model in Table 1, we can proceed to the next step. There are four underlying indicators of construction management factors, so the normalized formula for butterfly-type catastrophes was used.

As there is an obvious correlation between construction management factors, all of which cause eccentric force damage to the steel bracing system, the indicators need to comply with the principle of “complementarity”, and then was obtained.

There are three underlying indicators for the surrounding environmental factors, so the normalization formula of the dovetail catastrophe was used to calculate the following:

As there is no obvious correlation between the surrounding environment factors, the indicators need to comply with the “non-complementary” principle, and then was obtained.

For the intermediate layer, there are two indicators, so the normalization formula for cusp catastrophes was used.

As there is a correlation between the construction management risk and the surrounding environment risk, the indicators need to comply with the “complementary” principle, and then was obtained.

According to Li and Fan’s [26] method of safety risk rating, the risk levels were classified as shown in Table 5. Due to the aggregation characteristics of the normalization formula of the mutation evaluation method, the final comprehensive evaluation value was generally high (close to 1), and the gap between the evaluation values was small. Although the order of the comprehensive evaluation value can be used to determine the “good” and “bad” aspects of the evaluation object, it is not as intuitive as the evaluation value obtained using the general comprehensive evaluation method [27]. We can choose the evaluation index reasonably and adjust the method of calculating the initial comprehensive value to distinguish the grade and size of the evaluation value more intuitively. Additionally, in this study, the method was modified using the score transformation [28] to correspond with the base function value of the underlying index to the final affiliation function value A. The results are shown in Table 6.

Table 5.

Risk level classification.

Table 6.

X–A correspondence.

According to the X–A correspondence, it is known that is in the interval of heavy metal and the steel bracing system of the pit is in the general risk state. Furthermore, a small number of steel bracings in the project caused alarm, but they were properly handled, and no large risk occurred, which proved that the score was in line with the actual situation of the project, and the corresponding risk countermeasures could be formulated accordingly in the follow-up.

4. Safety Risk Countermeasures for Steel Bracing Systems

Due to the constraints of human cognition, there are limitations in the depth and breadth of people’s understanding of problems, which limits analysis and processing, and this is also true in engineering projects. When the target object has cognitive uncertainty or the number of samples is very small, it is difficult, using the mathematical statistics method based on probability theory, to obtain the distribution function of random variables. Some studies have shown that, even if there is a very small deviation between the distribution parameters and actual values, reliability analysis may show a large deviation [29], thus being unable to produce an accurate description of practical problems. Therefore, people’s cognition of engineering projects cannot completely avoid the problem of information acquisition deficiencies; thus, in engineering project construction, this causes people’s objective cognition to be defective and means a lack of consistent prediction of the engineering system compared to the reality, which is the key factor that causes safety risks. This feature means that it is necessary to individually customize risk management strategy solutions for each project according to their differences, even for different parts of the project. In other words, it is important to tailor the risk management strategy to the time and place and to analyze the project environment before developing the risk management strategy.

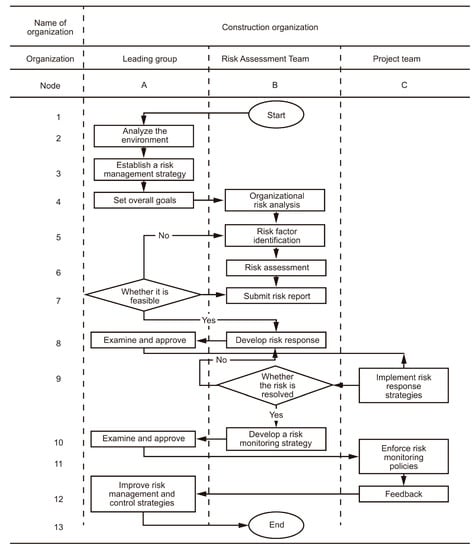

The risk analysis of steel bracing systems based on catastrophe theory in this project was carried out as described above. A risk analysis project for steel bracing systems could also be the responsibility of a risk assessment team. Finally, this team needs to provide a risk report that can be used to help with the steel bracing part of the project and identify and evaluate the possible risk factors in each phase. If the risk analysis is feasible, the risk response can be implemented; if not, the risk analysis will be repeated until it is feasible. After identifying and evaluating the safety risks of steel bracing systems, a safety risk management flowchart for steel bracing systems was designed and the corresponding safety risk countermeasures were proposed. The flow chart is shown in Figure 9.

Figure 9.

Risk management process for steel bracing projects.

This risk control process can be applied to steel bracing systems. As mentioned above, the risk control process should be customized to each project and location. This study suggests that the risk control process method can be universal, but it needs to be considered by an expert group for the individual needs of different projects and different locations. For example, it can be used to monitor settlement, displacement, strain, and so on.

4.1. Safety Risk Countermeasures

Safety risk response measures are based on risk identification and risk evaluation, followed by the stage of developing corresponding measures to eliminate risk, mitigate risk, or control risk.

The risk of a steel bracing system according to catastrophe theory, because such events are not usually clearly reflected in the data, is the sudden occurrence of safety risks. One possible response to this is developing and implementing countermeasures in three respects before the exposure of the source of danger based on the different levels of risk events.

- (1)

- Risk avoidance: This is mainly for the original implementation plan; it requires the means to cancel or modify and reduce the possibility of risk occurrence and loss to an acceptable range. This approach is mainly for safety risks that are more serious and could cause larger losses.

- (2)

- Risk transfer: This is achieved through certain means, such as signing a contract with a third party, that allow the risk to be transferred to others. This method is applicable when the occurrence of safety risks is less likely but could cause greater losses.

- (3)

- Risk acceptance: In cases where there is a probability of the occurrence of small risks and lower losses, risk acceptance can be adopted, i.e., one assumes the risk, and, under certain conditions, such risks can also be effectively mitigated by certain management approaches.

The abovementioned risk response measures are generally aimed at acceptable risks. As the main body of management, we must not reduce the supervision of the target simply because we have risk response measures, but we must instead strengthen management to avoid or reduce the occurrence of risks.

4.2. Safety Risk Response Based on Catastrophe Theory

According to the results of the safety risk evaluation of steel bracing systems described above, the primary indicators are construction management risks and surrounding environment risks, in descending order. The first four corresponding secondary indicators are hysteresis erection, steel bracing slippage, pit bottom bulge, and welding node failure.

The following risk avoidance measures can be taken for lagging erection:

- (1)

- First, strengthen monitoring and improve the monitoring frequency, which can be changed from once a day to twice a day, to judge the state of steel bracing axial force in a timely manner.

- (2)

- Speed up the construction progress, follow the principle of “bracing with excavation”, strictly prohibit over-excavation, ensure the timely erection of steel bracing, and reduce the exposure time without bracing.

Risk avoidance measures for steel bracing slippage:

- (1)

- Local reinforcement of the slippage part and a separate set of steel braces added outside the existing steel bracing system that play a reinforcing role.

- (2)

- Determine the soil quality before construction. When the soil at the bottom of the pit is soft or the foundation soil is softened, it can cause the wall to slip, resulting in the slippage of the steel bracing.

- (3)

- According to site construction, concrete columns are poured at the edge of the foundation pit’s enclosure pile to play a temporary protective role.

- (4)

- After the steel bracing system is erected, it needs to be installed in time to prevent falling measures, and, in steel bracing systems with larger spans, clamps should be installed on the steel balance beam.

Risk avoidance measures for pit bottom uplift:

- (1)

- The pit bottom uplift is generally the upward displacement of soil, mainly due to the plastic flow of soil caused by the unloading rebound of deep soil and excavation pressure differences; the plastic flow effect of the soil and the surrounding geotechnical extrusion together, resulting in the accumulation of plastic deformation around the boundary of the steel bracing system thereby producing uplift, which can be reinforced by a passive area to improve the soil resistance and reduce the deformation of the pit bottom.

- (2)

- Pit bottom uplift can also be modified to a reasonable earth excavation program for risk mitigation, the main principle of which is horizontal layering, using the longitudinal segmentation method of construction. Horizontal stratification can facilitate the erection of the bracing system, while longitudinal segmentation can make the earth excavation and the main construction form an interdependent relationship to ensure the safety of excavation.

- (3)

- Risks can be mitigated to a certain extent by accelerating the construction and reporting to the design and risk control unit in time.

Risk avoidance measures for welding node failure:

- (1)

- Such problems, once they occur, require excavation to immediately stop, and, according to the needs of the site and the supervisory party requirements, re-welding is necessary.

- (2)

- Improper handling of nodes, such as only using spot welding, can cause overall deformation damage due to local instability. More nodes in the steel bracing system make it unconducive to controlling the quality of installation, so full welding is recommended to ensure the node welding strength.

- (3)

- Improve the quality of operations of practitioners. They must receive strict safety training after being licensed to work to ensure that the steel bracing welding nodes are welded solid.

For the above problems, one can also adopt similar risk transfer measures. For the other three problems, due to the low-risk degree, in addition to risk avoidance and risk transfer measures, risk acceptance measures can also be adopted when risks are less likely to occur or when they are likely to cause less impact.

When the above risks are found in the operation of a steel bracing system, the frequency of monitoring should be increased, and contingency plans should be made in advance to provide more comprehensive information for risk avoidance and rescue:

- (1)

- Special monitoring managers need to be dispatched on duty at the site.

- (2)

- Establish a safety risk assessment team if available and deploy the team according to the flow chart for the safety risk management of steel bracing systems. It is also necessary to have more than two groups of monitoring management personnel according to the site conditions if the conditions are limited.

- (3)

- Ensure that the monitoring equipment on site meets the monitoring conditions and ensure the maintenance of monitoring equipment for the smooth implementation of monitoring works.

- (4)

- Organize a good risk emergency management team in advance and carry out rescue operations at any time when encountering sudden changes that damage the steel bracing system.

- (5)

- Establish effective transmission and reporting of information and timely monitoring and analysis of steel bracing system measurement data.

4.3. Safety Risk Tracking and Monitoring Plan

Risk monitoring is essentially designed to monitor and control the operation process of steel bracing systems, to identify and track the possible risk factors inside and outside the system, and to develop effective safety risk countermeasures to ensure safety based on grasping the dynamic risk level changes. As a dynamic cycle process, risk monitoring must track all the stages of a steel bracing system, from erection and installation to dismantling. A detailed description is provided below:

- (1)

- Develop a risk monitoring plan: before risk management is implemented, a reasonable safety risk monitoring plan needs to be developed to implement a general plan for the overall safety risk monitoring task as a guiding program for risk-monitoring activities, which should cover the objectives of risk monitoring, system, and management system establishment, etc.

- (2)

- Tracking and monitoring: track and monitor the progress of each risk factor and the risks in the steel bracing system, which is conducive to being aware of its state.

- (3)

- Evaluation of risk status: this process includes several steps to evaluate the risks and handle the screening of all the risk factors that may be collected, thereby enabling managers to better understand the risk information, grasp the status of risks, and amend risk response measures in a timely manner.

- (4)

- Sending risk warning signals: when a risk event has a tendency to develop in a negative direction, or when the data values obtained from the forecast may exceed the warning values, the safety risk managers should be notified in time to check the steel bracing system.

- (5)

- Develop specific strategies for risk elimination: managers, based on the early warning information obtained, should use the safety risk response measures that have been developed or discuss the corresponding program to deal with various types of risks in a targeted and timely manner.

When monitoring a steel bracing system, the monitoring of the surrounding environment should also include the following aspects:

- (1)

- Column settlement monitoring.

- (2)

- Monitoring of deep horizontal displacement of buildings and building settlement at the periphery of the pit.

- (3)

- Seam monitoring of the enclosure wall.

- (4)

- Monitoring of the groundwater level.

- (5)

- Monitoring of horizontal displacement, vertical displacement, and deep horizontal displacement of the wall at the top of the enclosure wall.

During the operation of a steel bracing system, certain measures were taken to track the parameters corresponding to the safety risk events, and the risk tracking and monitoring requirements (see Table 7) were compiled according to the characteristics of the steel bracing system of the foundation pit. These were strictly implemented according to the monitoring requirements to determine the status of the safety risk events in a timely manner.

Table 7.

Monitoring requirements for steel bracing systems.

5. Conclusions

In this study, we took the steel bracing system of a foundation pit in Ningbo, China, as an engineering case study, carried out risk identification and evaluation based on catastrophe theory, designed a safety risk management flow chart for steel bracing systems, and formulated safety risk response measures. The main conclusions of the paper are as follows:

- We used FTA to carry out the safety risk identification of the steel bracing system of a foundation pit in Ningbo, China. We carried out a standardized operation of safety risks, established a safety risk index system, and verified the validity and stability of the index system. The risk identification thereof was approved by the project experts and was determined to be feasible.

- Based on the safety risk evaluation index system already established for steel bracing systems, an evaluation model was established using catastrophe theory. The model showed that the steel bracing system was within the general risk range. In the actual project, a small part of the steel bracing caused alarm, but it was properly handled and did not create a high risk, which proved that the rating was in line with the actual situation of the project. This also showed that catastrophe theory is applicable in the analysis of steel bracing systems.

- Based on catastrophe theory, we designed a risk control process, carried out a safety risk response, formulated a safety risk tracking and monitoring plan, and explained specific risk management measures to ensure that the risk management of the steel bracing system was in place. This risk management process can be extended; however, for individual sites and projects, more risks need to be identified by experts. Finally, different projects may apply a higher-dimensional catastrophe model.

Author Contributions

H.C.: validation, investigation, visualization, writing—original draft, writing—review and editing. K.Z. (Ke Zhang): supervision, methodology, conceptualization. K.Z. (Kun Zhou): resources, project administration. T.F.: methodology, conceptualization, writing—review and editing. X.S.: validation, investigation. X.K.: methodology, visualization. Y.L.: validation, investigation. Z.W.: supervision, methodology. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors are grateful to the Jiangsu Water Conservancy Science and Technology project (2019054).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

A detailed description of the accident tree.

Table A1.

A detailed description of the accident tree.

| Symbols | Description | Symbols | Description |

|---|---|---|---|

| T | Steel bracing system accident | X2 | Column spacing too large |

| A1 | Steel bracing fracture | X3 | Steel bracing strength design negative deviation |

| A2 | Steel bracing is unstable | X4 | Steel bracing material negative deviation |

| B1 | Support strength Nr is insufficient | X5 | Unreasonable design of steel bracing section |

| B2 | The axial force Ns of the steel bracing increases | X6 | The ground is stacked behind the wall |

| B3 | Insufficient stiffness design of steel bracing | X7 | Negative deviation of soil characteristic parameters |

| C1 | The design of active earth pressure is small | X8 | Deviation of earth pressure calculation model |

| C2 | Pressure builds up as surface water penetrates into the soil behind the wall | X9 | No waterproofing and drainage facilities are provided |

| X1 | Nr < Ns | X10 | Rainwater or underground pipe water |

References

- Wang, C.T.; Wang, H.; Qin, W.M.; Zhong, G.Q.; Chen, W. Evaluation of collapse possibility of deep foundation pits in metro stations based on multi-state fuzzy Bayesian networks. Rock Soil Mech. 2020, 41, 1670–1679. [Google Scholar] [CrossRef]

- Sun, X.F.; Shao, H.Y.; Xiang, X.Y.; Yuan, L.G.; Zhou, Y.Z.; Xian, W. A Coupling Method for Eco-Geological Environmental Safety Assessment in Mining Areas Using PCA and Catastrophe Theory. Nat. Resour. Res. 2020, 29, 4133–4148. [Google Scholar] [CrossRef]

- Dolsek, M. Incremental dynamic analysis with consideration of modeling uncertainties. Earthq. Eng. Struct. Dyn. 2009, 38, 805–825. [Google Scholar] [CrossRef]

- Castaldo, P.; Calvello, M.; Palazzo, B. Probabilistic analysis of excavation-induced damages to existing structures. Comput. Geotech. 2013, 53, 17–30. [Google Scholar] [CrossRef]

- Ordaz, M.; Salgado-Gálvez, M.A.; Pérez-Rocha, L.E.; Cardona, O.D.; Mena-Hernández, U. Optimum earthquake design coefficients based on probabilistic seismic hazard analyses: Theory and applications. Earthq. Spectra 2017, 33, 1455–1474. [Google Scholar] [CrossRef]

- Dall’Asta, A.; Dabiri, H.; Tondi, E.; Morci, M. Influence of time-dependent seismic hazard on structural design. Bull. Earthq. Eng. 2021, 19, 2505–2529. [Google Scholar] [CrossRef]

- Wildgen, W. Catastrophe Theoretic Semantics: An Elaboration and Application of René Thom’s Theory; John Benjamins Publishing Company: Amsterdam, The Netherlands, 1982; ISBN 9789027225252. [Google Scholar]

- Zorin, V.; Baurova, N. Assessment of means of mechanization of construction risks using catastrophe theory. MATEC Web Conf. 2018, 251, 03008. [Google Scholar] [CrossRef]

- Mogaji, K.A.; Lim, H.S. Development of a GIS-based catastrophe theory model (modified DRASTIC model) for groundwater vulnerability assessment. Earth Sci. Inform. 2017, 10, 339–356. [Google Scholar] [CrossRef]

- Wang, Y.X.; Wu, T.; Li, L.; Huang, Y.; Geng, D.X. Safety risk assessment of subway shield construction based on catastrophe progression method. Saf. Environ. Eng. 2021, 28, 95–102. [Google Scholar] [CrossRef]

- Zhang, R.; Li, C.X.; Jin, D.D. Buckling Stability Analysis for Piles in the Slope Foundation Based on Cusp Catastrophe Theory. Math. Probl. Eng. 2021, 11, 5560790. [Google Scholar] [CrossRef]

- Wang, X.J.; Sun, Y.; Yuan, X.M.; Chen, X.T. Catastrophe Theory and BP neural network-jointed comprehensive evaluation on levee safety. Water Resour. Hydropower Eng. 2018, 49, 167–173. [Google Scholar] [CrossRef]

- Arouq, M.K.; Esmaeilpour, M.; Sarvar, H. Vulnerability assessment of cities to earthquake based on the catastrophe theory: A case study of Tabriz city, Iran. Environ. Earth Sci. 2020, 79, 14. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, K.; Jiang, Y.B.; Shi, Z. Prediction and forewarning of axial force of steel bracing in foundation pit based on verhulst model. PLoS ONE 2022, 17, e0265845. [Google Scholar] [CrossRef]

- Li, S.; Zhang, D.L.; Shao, Y.D. Research on spatio-temporal law of deep excavation deformation under complicated environment in Beijing Subway Station. J. Beijing Jiaotong Univ. 2019, 43, 29–36. [Google Scholar]

- Yan, L.; Wang, J.Z.; Zhang, X.D.; Chen, K.; Li, Y.; Zhang, K.R.; Yan, Z.Q.; Li, M.; Wu, H.D.; Kang, E.Z.; et al. Methods for quantitatively assess the impacts of natural and anthropogenic factors on vegetation changes of grassland ecosystem. Acta Ecol. Sin. 2022, 42, 1098–1107. [Google Scholar]

- Chen, Z.P.; Zhang, J.C. The Key to Deep Foundation Pit Excavation for Metro—Station. Shanghai Geol. 2004, 4, 26–28. [Google Scholar] [CrossRef]

- Ma, W.J. Study of Steel Support Axial Force Based on Artificial Neural Network for Deep Excavation. Master’s Thesis, Ocean University of China, Qingdao, China, 2012. [Google Scholar] [CrossRef]

- SZ-08-2000; Specification for Excavation in Shanghai Metro Construction. Shanghai Municipal Engineering Administration Bureau: Shanghai, China, 2000.

- Cao, X.Y.; Feng, D.C.; Wang, Z.; Wu, G. Parametric investigation of the assembled bolt-connected buckling-restrained brace and performance evaluation of its application into structural retrofit. J. Build. Eng. 2022, 48, 103988. [Google Scholar] [CrossRef]

- Xiong, D.D.; Yang, Z.; Liao, Z.G. Analysis on Pre Axial Force of Steel Support in Deep Foundation Pit of Subway. Chin. J. Undergr. Space Eng. 2018, 14, 1049–1055. [Google Scholar]

- Song, E.X.; Fu, H.; Li, Y.J. Improvement of calculation method for safety factor of basal heave stability of deep excavation. China Civ. Eng. J. 2021, 54, 109–118. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.Y.; Liu, T. Simplified Method for Estimating the Inner Support and Internal Force through Stand Column Uplift of Foundation Pit in Soft Soil. Appl. Mech. Mater. 2014, 580–583, 474–480. [Google Scholar] [CrossRef]

- Feng, H.; Liu, Y.H.; Xu, C.L. Effect of column uplift on the stability of steel supporting system in metro deep excavation. China Sci. 2014, 9, 1301–1305. [Google Scholar] [CrossRef]

- Ji, Y.J.; Liu, J.J.; Xue, Q. Numerical simulation of seepage-stress interaction during foundation ditch excavation. Rock Soil Mech. 2007, 28, 630–634. [Google Scholar] [CrossRef]

- Li, Y.Z.; Fan, M. Research on risk level assessment of engineering projects based on cross-influence method. Mod. Manag. Sci. 2010, 12, 90–92. [Google Scholar] [CrossRef]

- Tang, M.; Shao, D.G.; Yao, C.L.; Huang, X.F. Improved catastrophe theory based evaluation method and its application to drought disaster risk evaluation. J. Hydraul. Eng. 2009, 40, 858–862+869. [Google Scholar]

- Feng, P.; Li, S.F.; Li, J.Z. Catastrophe theory-based risk evaluation of Groundwater environmental. J. Nat. Disasters 2008, 2, 13–18. [Google Scholar] [CrossRef]

- Ben-Haim, Y.; Elishakoff, I. Convex Models of Uncertainty in Applied Mechanics; Elsevier: Amsterdam, The Netherlands, 1990; ISBN 9781483290973. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).