Study on Shear-Lag Effect of Steel–UHPC Ribbed Slab Composite Structures Using Bar Simulation Method

Abstract

1. Introduction

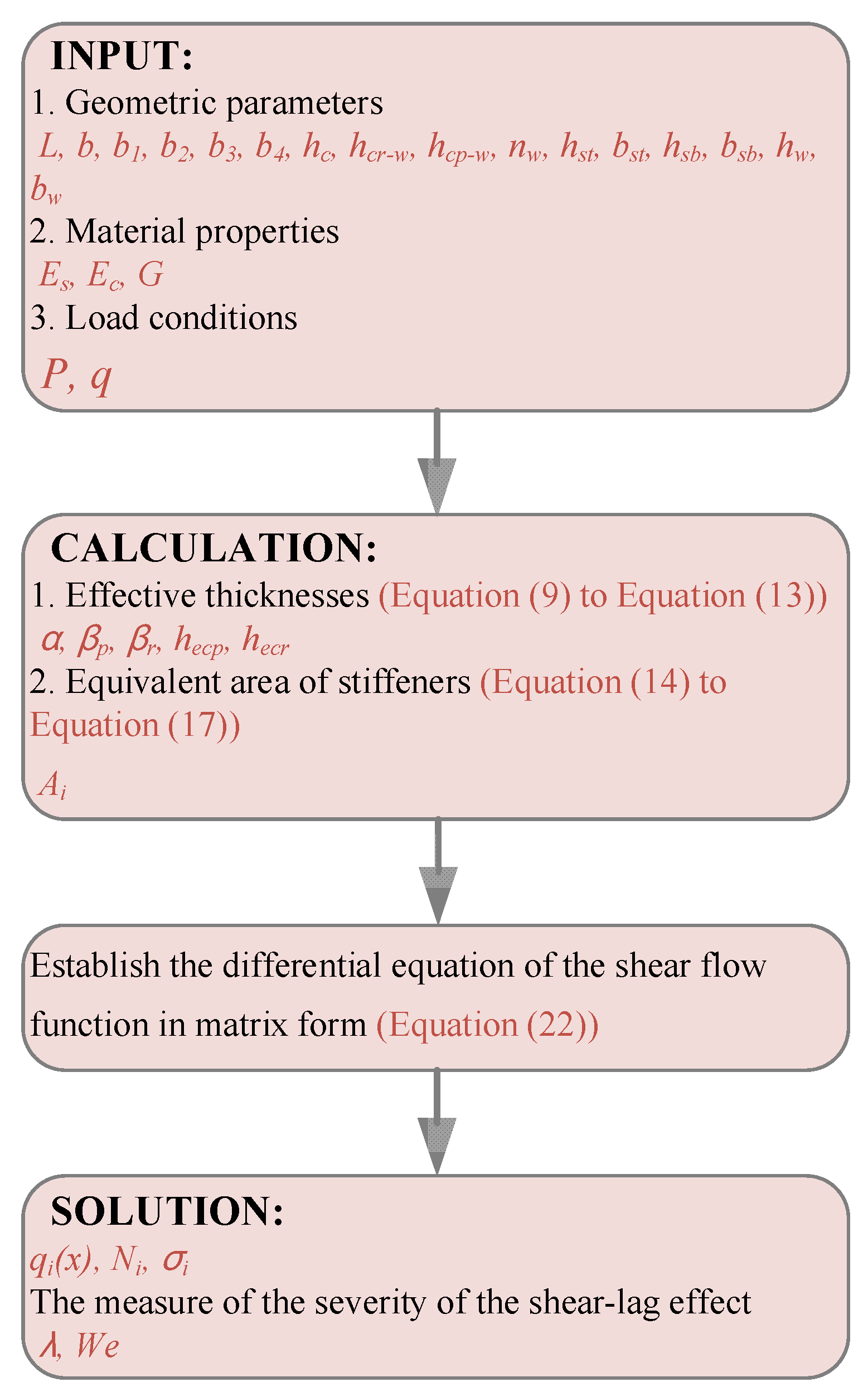

2. Theoretical Derivations

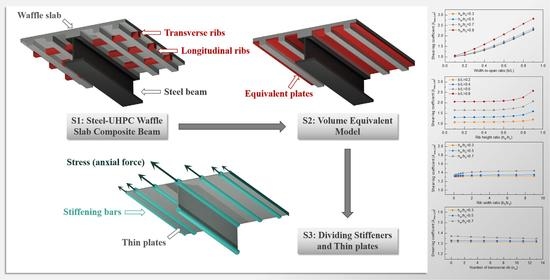

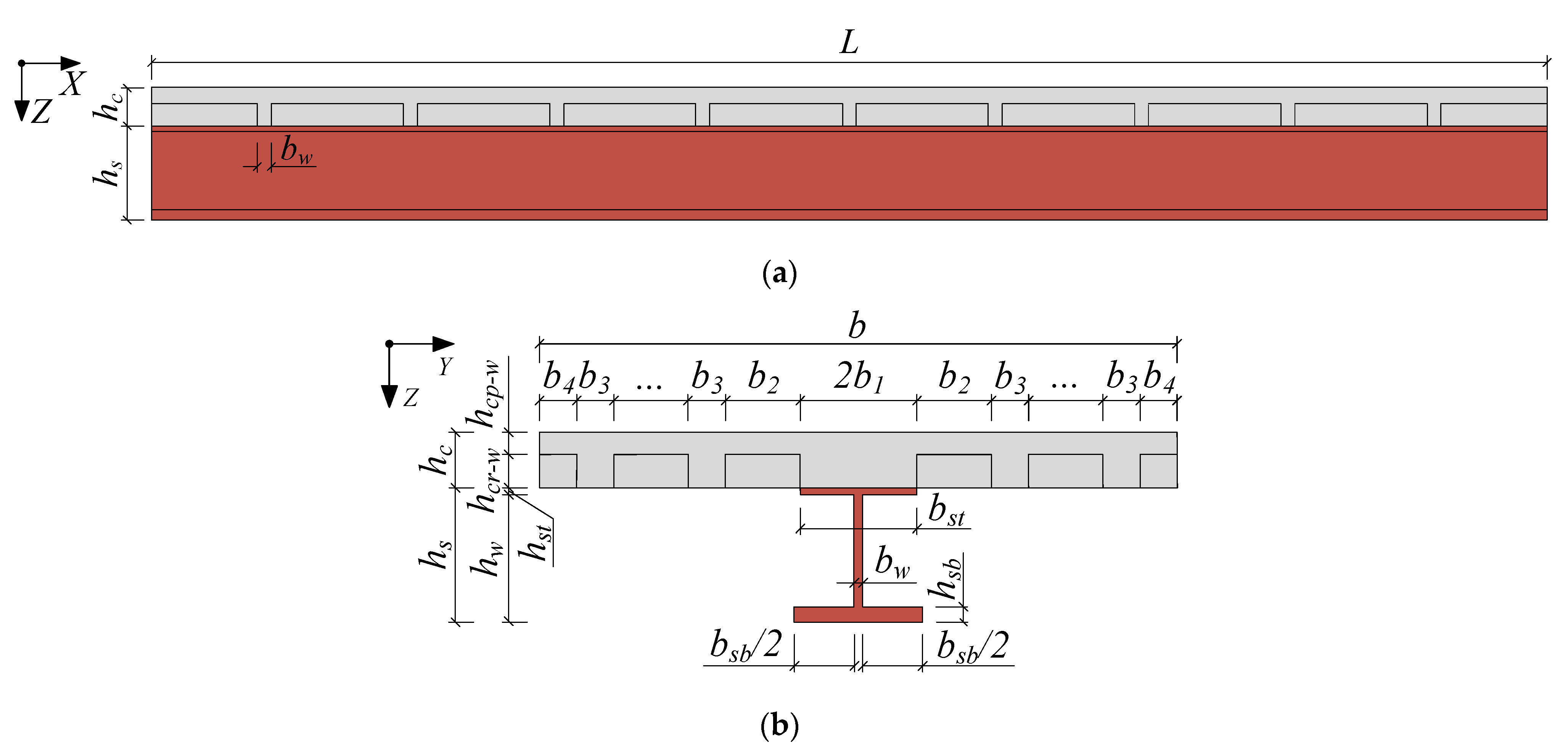

2.1. Description of the SU-RSCS

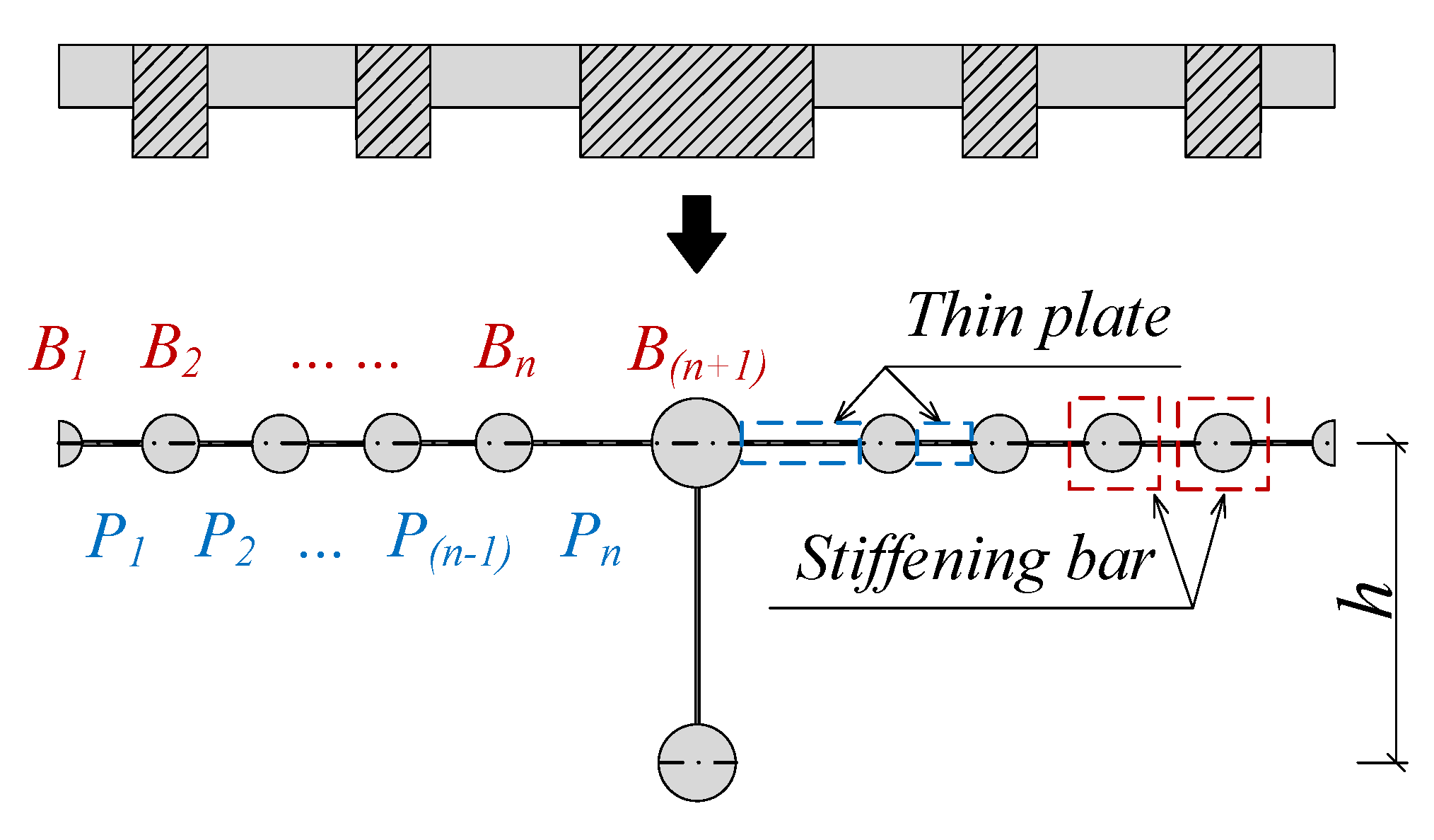

2.2. Calculation of Equivalent Area of Stiffeners

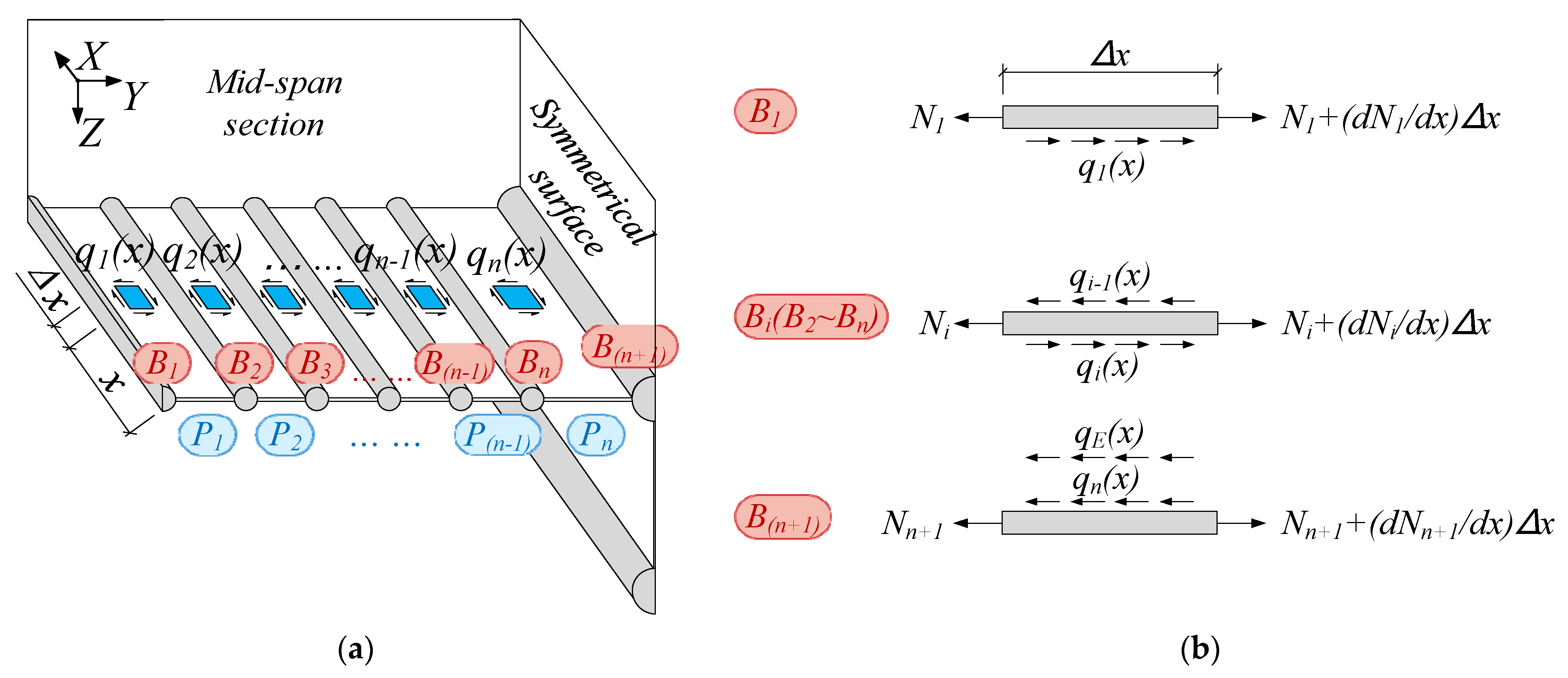

2.3. Calculation of Axial Force of Stiffeners

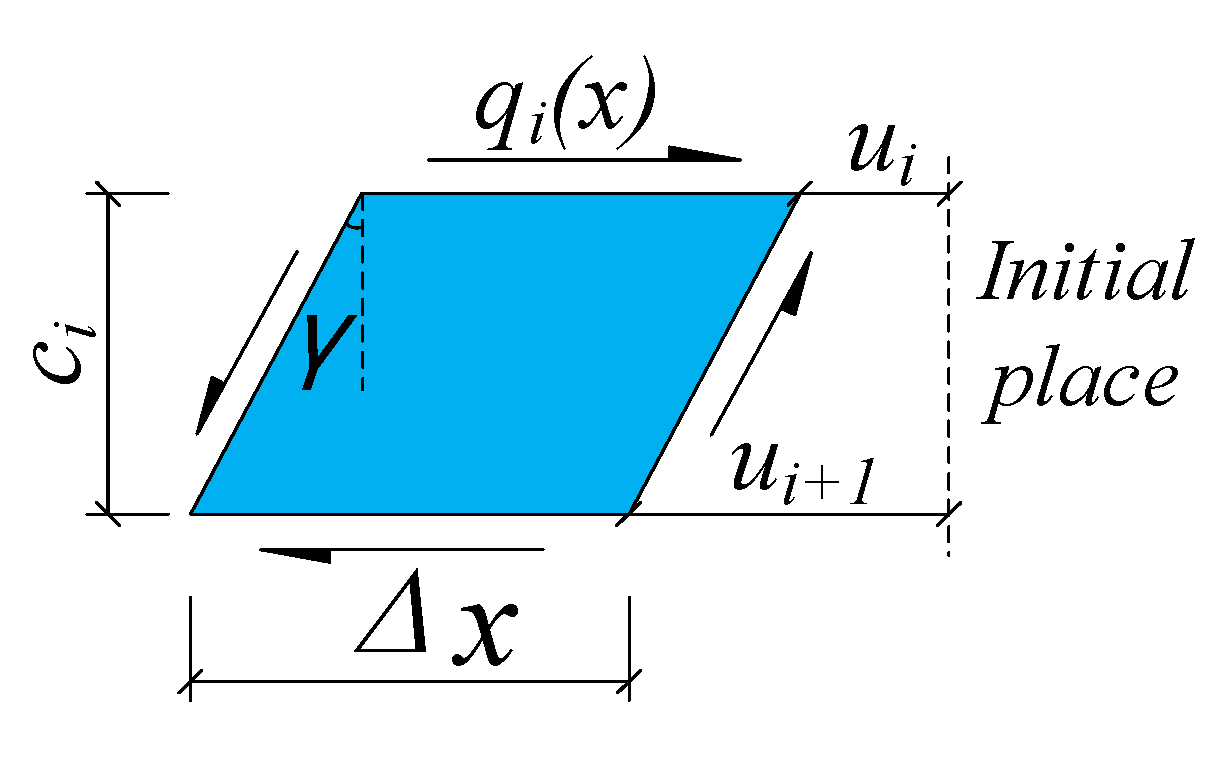

2.3.1. Establishment of Differential Equation

2.3.2. Solution of Differential Equation

2.4. Validation with Experimental Data

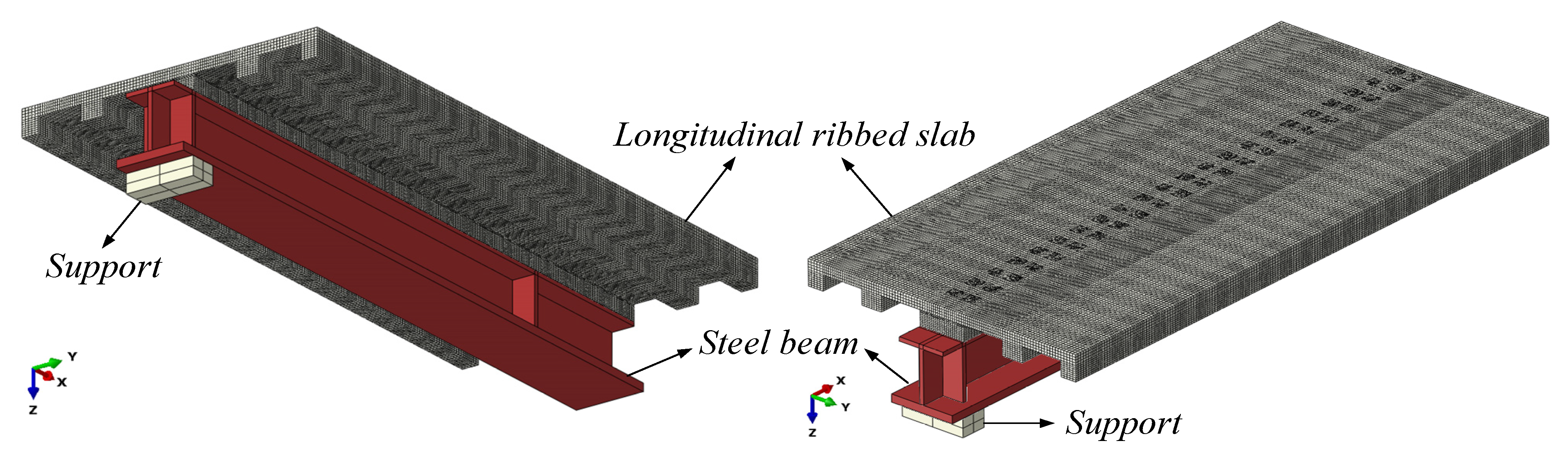

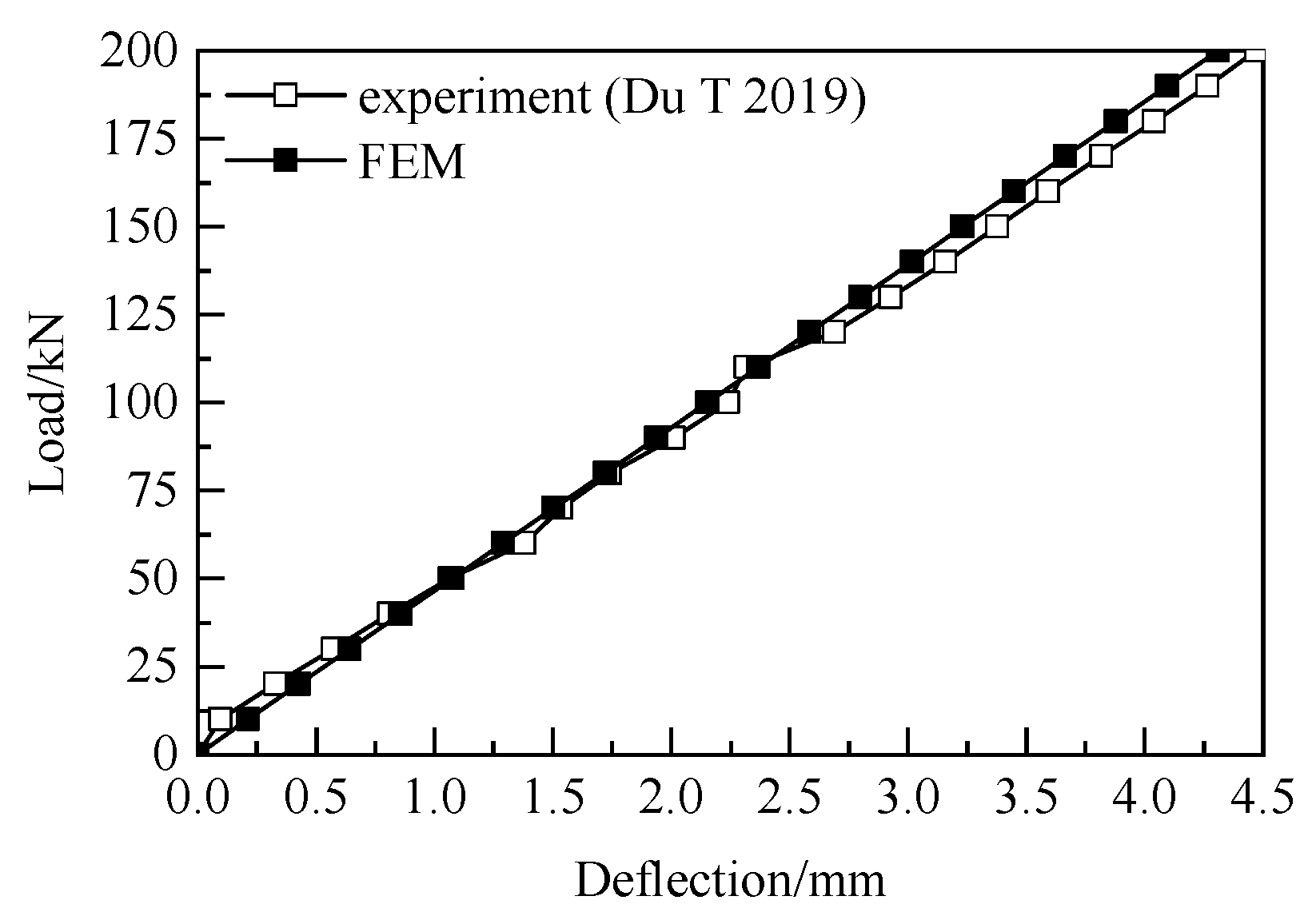

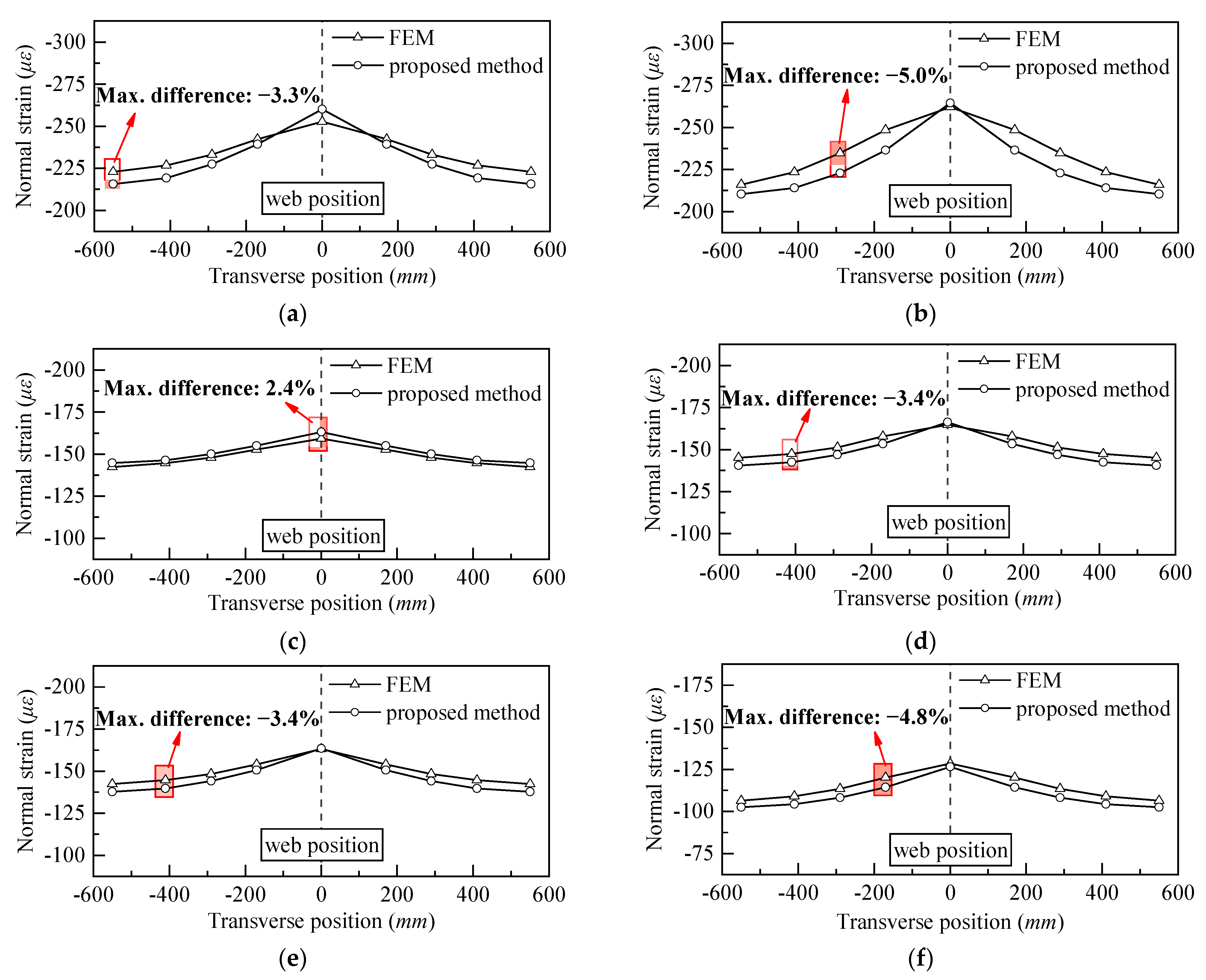

2.4.1. Validation on SU-LRSCS

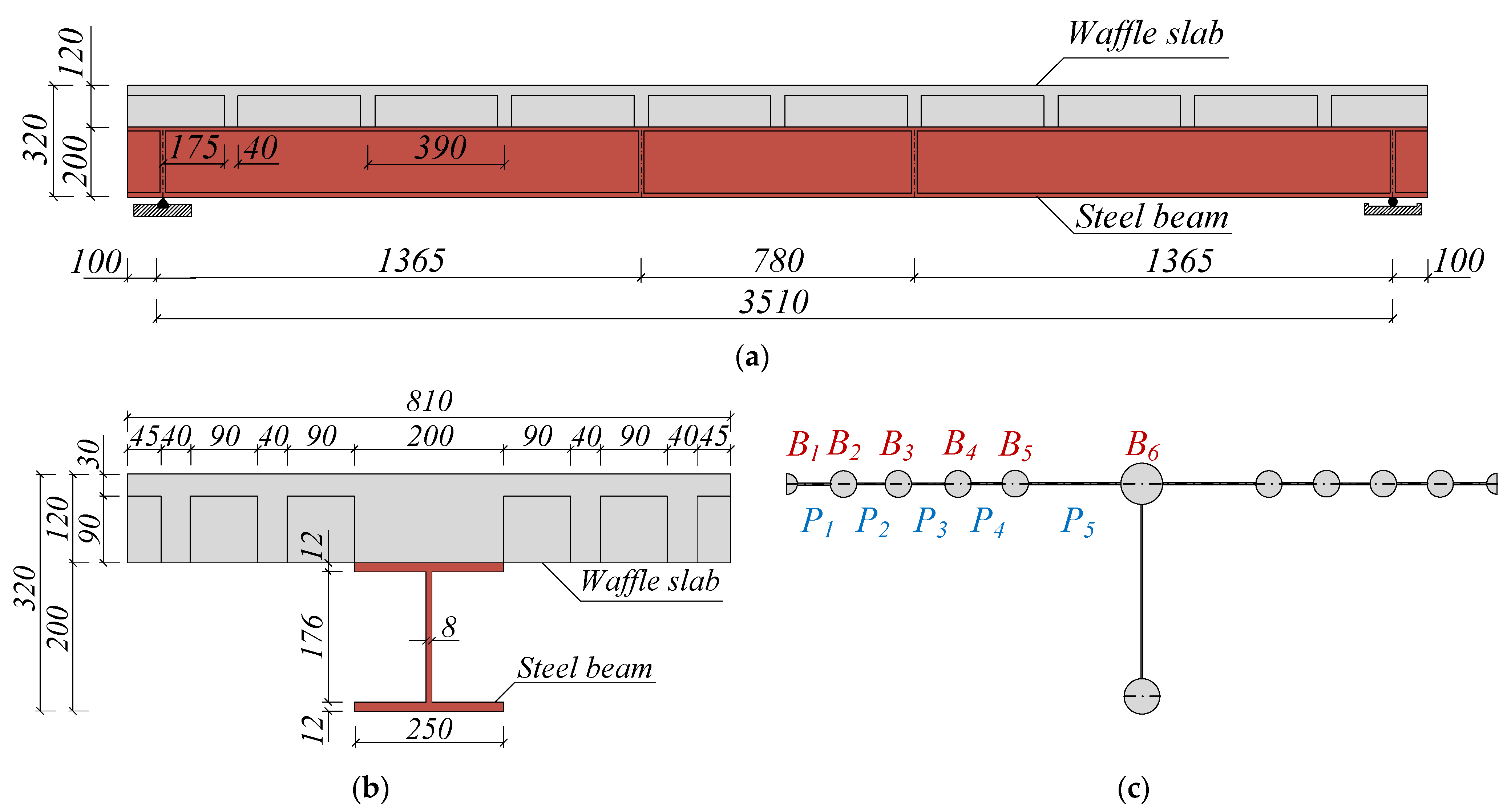

2.4.2. Validation on SU-WSCS

3. Orthogonal Analysis (OA)

3.1. Introduction of OA

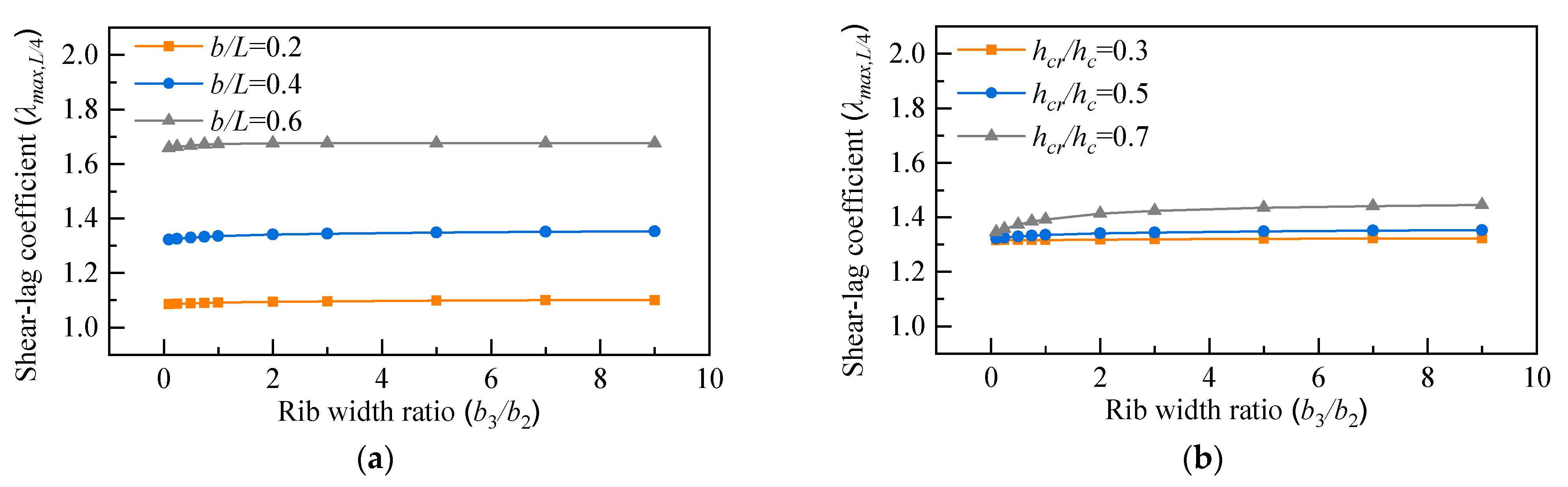

3.2. Test Design and Calculation

3.3. Analysis of Variance (ANOVA)

4. Parametric Study

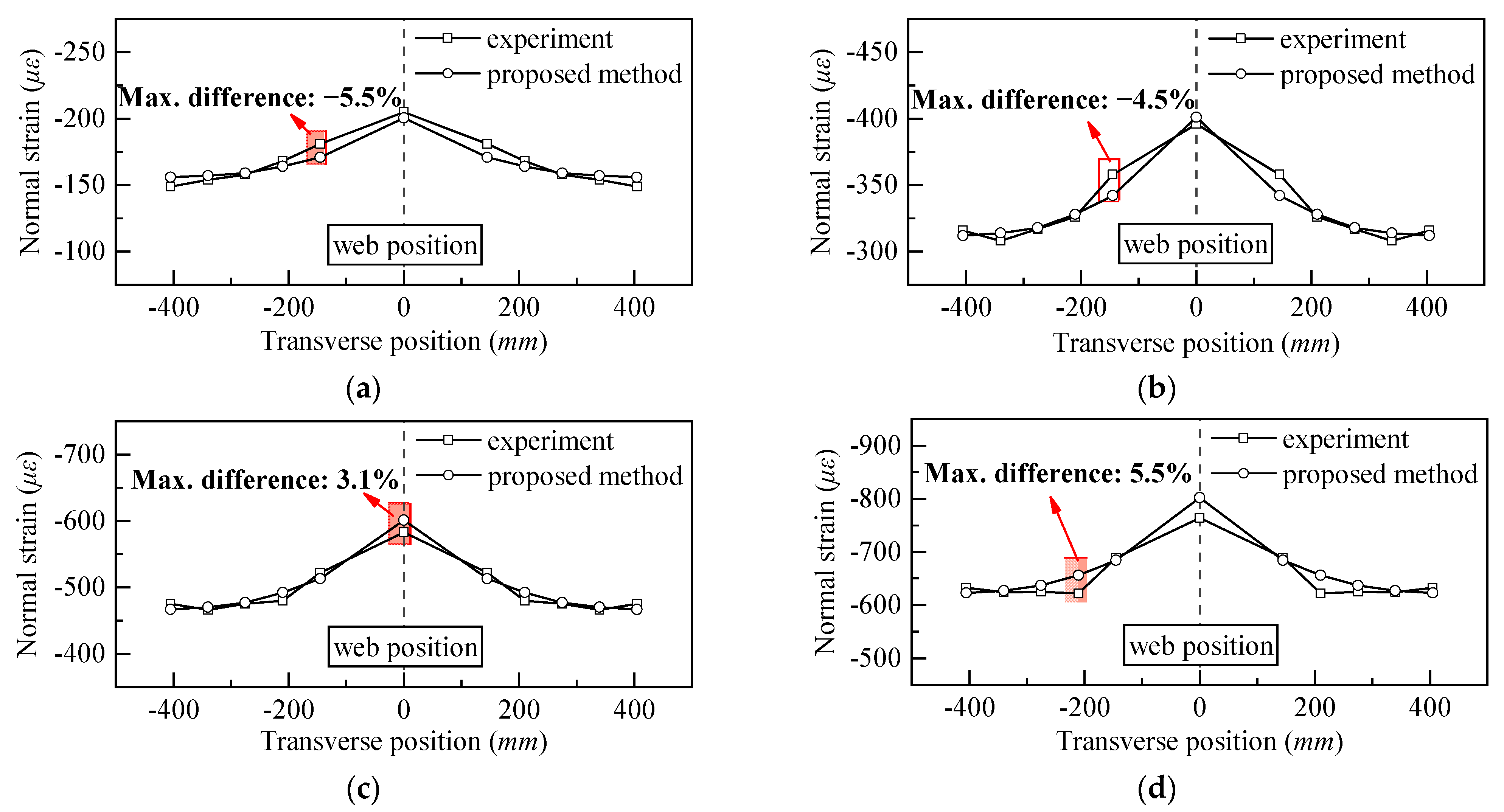

4.1. Effect of the Width-to-Span Ratio (b/L)

4.2. Effect of Rib–Height Ratio (hcr/hc)

4.3. Effect of Rib Width Ratio (b3/b2)

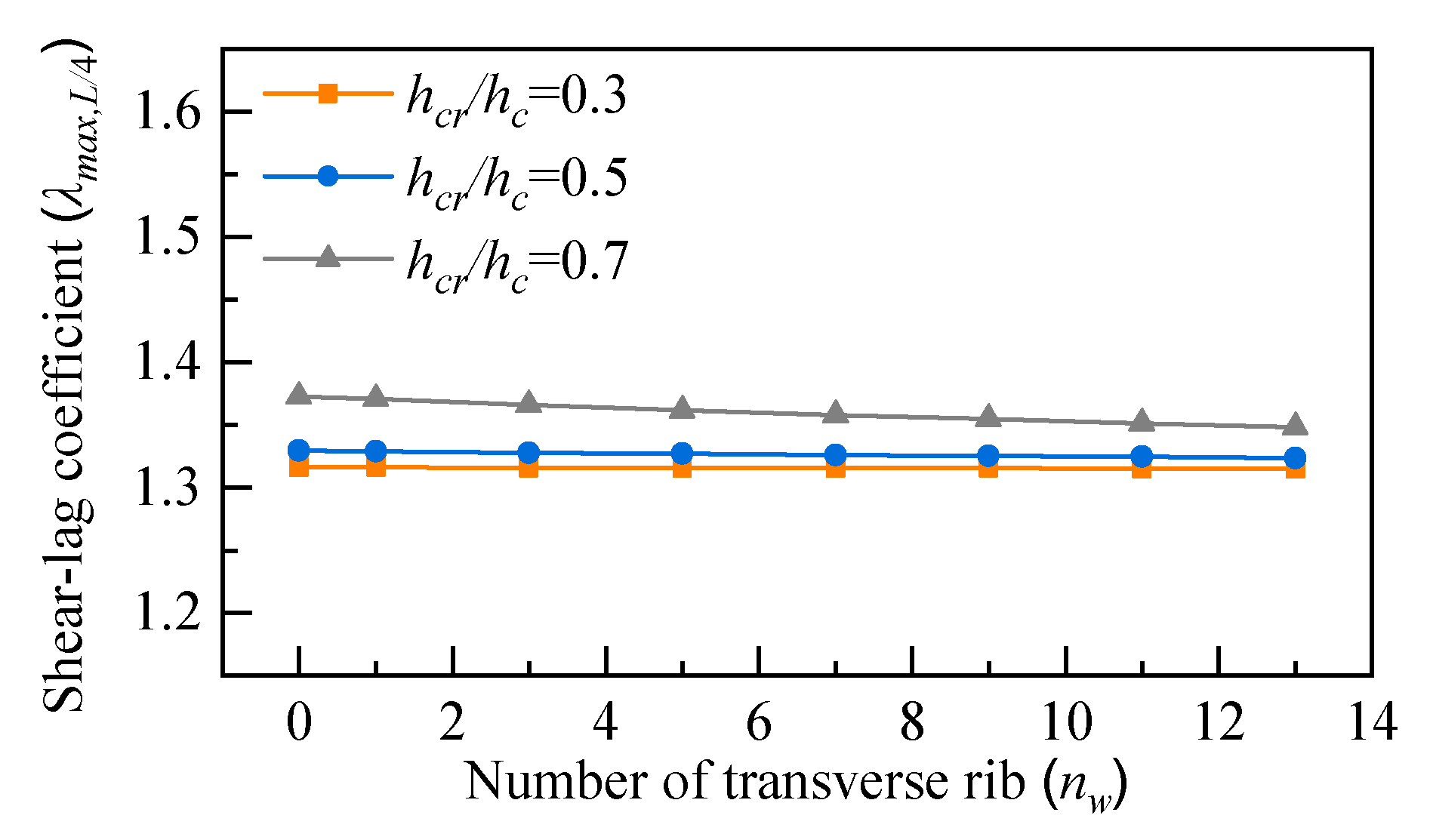

4.4. Effect of Number of Transverse Ribs

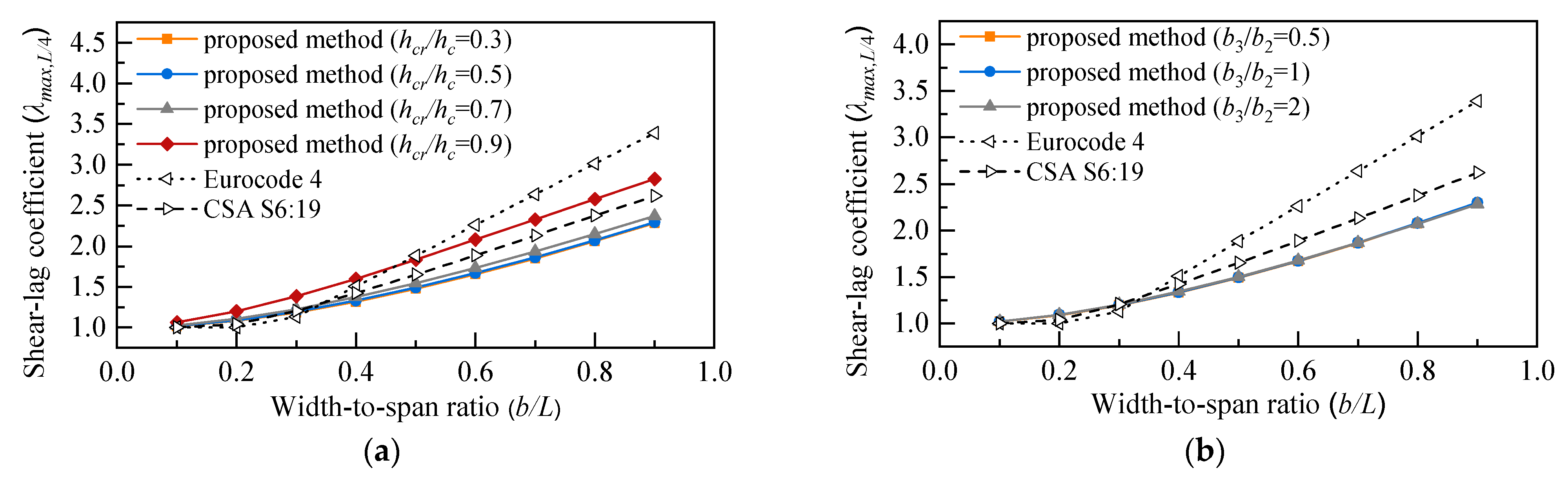

5. Comparison with Specifications

5.1. Eurocode 4: Design of Composite Steel and Concrete Structures

5.2. CSA S6:19: Canadian Highway Bridge Design Code

5.3. Discussion

6. Conclusions

- The proposed theoretical calculation method for the shear-lag effect of SU-RSCS is in good agreement well with the experimental and FEM results under multiple working conditions, which verifies the accuracy and effectiveness of this method.

- According to the principle of a constant volume of transverse rib, a simplified method of converting waffle plate into longitudinal ribbed plate is proposed. The proposed theoretical method has a high accuracy for calculating the shear-lag effect of the simplified structure.

- In ANOVA, F indicates the sensitivity degree of the parameters or interactions. For the shear-lag effect in SU-RSCS, the F values of the width-to-span ratio (A) and the rib height ratio (B) are significantly higher than others, indicating that their influences are extremely significant and deserve more attention in structural design. In addition, the influence of A×B is more significant than that of the rib width ratio (C), indicating that besides the parameters themselves, the influence of their interaction on the shear-lag effect should also be considered. The sensitivity order of the shear-lag effect of the SU-RSCS parameters can be expressed as: A > B > interaction A × B > C > interaction B × C > interaction A × C.

- Increasing the number of transverse ribs can weaken the shear-lag effect of the structure, but is very slight. It is also found that increasing the height of the ribs can enhance this weakening effect to some extent.

- Relatively speaking, CSA S6:19 provides a closer result of the shear-lag coefficient of SU-RSCS than Eurocode 4. In most cases, both codes give conservative shear-lag coefficients for SU-RSCS.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nie, J.G.; Wang, J.J.; Gou, S.K.; Zhu, Y.Y.; Fan, J.S. Technological development and engineering applications of novel steel-concrete composite structures. Front. Struct. Civ. Eng. 2019, 13, 1–14. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Bao, Y.; Jia, D.; Bu, Y.; Li, Q. Fatigue performance of orthotropic steel-concrete composite deck with large-size longitudinal U-shaped ribs. Eng. Struct. 2017, 150, 864–874. [Google Scholar] [CrossRef]

- Walter, R.; Olesen, J.F.; Stang, H.; Vejrum, T. Analysis of an orthotropic deck stiffened with a cement-based overlay. J. Bridge Eng. 2007, 12, 350–363. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Jong, F.B.P. Renovatie Technieken voor Vermoeiingsscheuren op Orthotrope Stalen Brugdekken. Ph.D. Thesis, TU Delft, Delft, The Netherlands, January 2007. [Google Scholar]

- Shao, X. The Steel-UHPC Lightweight Composite Bridge Structure, 3rd ed.; China Communications Press Co, Ltd.: Beijing, China, 2015. [Google Scholar]

- Svensson, H.S.; Lovett, T.G. The twin cable-stayed Baytown bridge. In Proceedings of the International Conference IABSE-FIP: Ponts suspendus et à haubans = Cable-stayed and suspension bridges, Deauville, France, 12–15 October 1994. [Google Scholar]

- Shao, X.D.; Deng, L.; Cao, J.H. Innovative steel-UHPC composite bridge girders for long-span bridges. Front. Struct. Civ. Eng. 2016, 13, 981–989. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, S.; Zhu, Y.; Fan, L.; Shao, X. Flexural responses of steel-UHPC composite beams under hogging moment. Eng. Struct. 2020, 206, 110134. [Google Scholar] [CrossRef]

- Xiao, J.L.; Zhou, M.; Nie, J.G.; Yang, T.Y.; Fan, J.S. Flexural behavior of steel-UHPC composite slabs with perfobond rib. Eng. Struct. 2021, 245, 112912. [Google Scholar] [CrossRef]

- Qin, S.; Zhang, J.; Huang, C.; Gao, L.; Bao, Y. Fatigue performance evaluation of steel-UHPC composite orthotropic deck in a long-span cable-stayed bridge under in-service traffic. Eng. Struct. 2022, 254, 113875. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Liu, R.; Chen, G. Design and Mechanical Properties of Steel-UHPC Lightweight Composite Decks. Adv. Civ. Eng. 2021, 850, 87–95. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Liu, R.; Hao, C.; Cao, Z. Dynamic properties of a steel–UHPC composite deck with large U-ribs: Experimental measurement and numerical analysis. Eng. Struct. 2020, 213, 110569. [Google Scholar] [CrossRef]

- Cheng, B.; Tian, L.; Sun, B.; Xu, C. Experimental Study of Fatigue Behaviors of Orthotropic Steel Bridge Decks Enhanced by the Ultra-High Performance Concrete Layer. J. Tongji Univ. Nat. Sci. Ed. 2021, 49, 1097–1106. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Shao, X.; Zhang, X.; Cao, J.; Zhao, X.; Deng, S. Structural Behaviors of a Low-Profile Steel Plate Reinforced UHPC Deck Panel with Longitudinal Ribs. J. Bridge Eng. 2021, 26, 4021043.1–4021043.13. [Google Scholar] [CrossRef]

- Zhu, J.; Guo, X.; Kang, J.; Duan, M.; Wang, Y. Experimental Investigation of Flexural Behavior of Steel–UHPC Composite Beam with Waffle-Slab System. J. Bridge Eng. 2021, 26, 04021011. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Y.; Yan, J.; Guo, X. Shear behaviour of steel-UHPC composite beams in waffle bridge deck. Compos. Struct. 2020, 234, 111678. [Google Scholar] [CrossRef]

- Zhou, C.; Li, L.; Wang, J. Modified bar simulation method for shear lag analysis of non-prismatic composite box girders with corrugated steel webs. Thin Wall Struct. 2020, 155, 106957. [Google Scholar] [CrossRef]

- Zhu, L.; Nie, J.G.; Ji, W.Y. Positive and negative shear lag behaviors of composite twin-girder decks with varying cross-section. Sci. China Technol. Sci. 2017, 60, 116–132. [Google Scholar] [CrossRef]

- Li, S.; Hong, Y.; Gou, H.; Pu, Q. An improved method for analyzing shear-lag in thin-walled girders with rectangular ribs. J. Constr. Steel Res. 2021, 177, 106427. [Google Scholar] [CrossRef]

- Li, X.; Wan, S.; Zhang, Y.; Zhou, M.; Mo, Y. Beam finite element for thin-walled box girders considering shear lag and shear deformation effects. Eng. Struct. 2021, 233, 111867. [Google Scholar] [CrossRef]

- Chen, Y.; Dong, J.; Xu, T.; Xiao, Y.; Jiang, R.; Nie, X. The shear-lag effect of composite box girder bridges with corrugated steel webs and trusses. Eng. Struct. 2019, 181, 617–628. [Google Scholar] [CrossRef]

- Cheng, X. Theory and Calculation of Beam Bridge, 3rd ed.; China Communications Press: Beijing, China, 1990. [Google Scholar]

- Luo, D.; Zhang, Z.; Li, B. Shear lag effect in steel-concrete composite beam in hogging moment. Steel Compos. Struct. 2019, 31, 27–41. [Google Scholar] [CrossRef]

- Du, T. Shear Lag Effect Study of Steel-UHPC Composite Beam. Master’s Thesis, Hunan University, Changsha, China, May 2019. [Google Scholar]

- Smith, M. ABAQUS/Standard User’s Manual, Version 6.9; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2009. [Google Scholar]

- Amani, M.; Rafeei, B.; Alinia, M.M. Shear buckling and ultimate capacity of steel plates coupled with cover panels. J. Constr. Steel Res. 2013, 80, 181–187. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Naser, M.; Pakala, P.; Varma, A. Modeling the response of composite beam-slab assemblies exposed to fire. J. Constr. Steel Res. 2013, 80, 163–173. [Google Scholar] [CrossRef]

- Liu, Y.H.; Xie, C.; Li, X.P.; Lu, G.L.; Tang, L.; Tan, X.H. Optimization analysis of structure parameters of downhole vortex tool based on CFD and orthogonal studies. J. Petrol Sci. Eng. 2020, 190, 107030. [Google Scholar] [CrossRef]

- Jiang, J.C.; Hu, G.B.; Li, X.; Xu, X.; Zheng, P.; Stringer, J. Analysis and prediction of printable bridge length in fused deposition modelling based on back propagation neural network. Virtual Phys. Prototyp. 2019, 14, 253–266. [Google Scholar] [CrossRef]

- Ren, L.Q. Optimum Design and Analysis of Experiments, 2nd ed.; Higher Education Press: Beijing, China, 2003. [Google Scholar]

- Plackett, R.L.; Burman, J.P. The Design of Optimum Multifactorial Experiments. Biometrika 1946, 33, 305–325. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Zhao, Y.; Song, B.; Yu, T.B. Interactive optimization of process parameters and coating analysis of laser cladding JG-3 powder. Int. J. Adv. Manuf. Technol. 2020, 107, 2623–2633. [Google Scholar] [CrossRef]

- EN 1994-1-1 (2004); Eurocode 4: Design of Composite Steel and Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- CSA S6:19; Canadian Highway Bridge Design Code. Canadian Standards Association: Toronto, ON, Canada, 2019.

| Section | LC1 | LC2 | ||||

|---|---|---|---|---|---|---|

| RF | Rp | Error (%) | RF | Rp | Error (%) | |

| I-I | 1.072 | 1.120 | 4.5 | 1.073 | 1.110 | 3.4 |

| II-II | 1.103 | 1.154 | 4.6 | 1.084 | 1.112 | 2.6 |

| III-III | 1.066 | 1.074 | 0.8 | 1.111 | 1.140 | 2.6 |

| Load/kN | RE | Rp | Error (%) |

|---|---|---|---|

| 100 | 1.188 | 1.181 | −0.6 |

| 200 | 1.159 | 1.181 | 1.9 |

| 300 | 1.152 | 1.181 | 2.5 |

| 400 | 1.146 | 1.181 | 3.0 |

| Symbol | Structural Parameters | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| A | b/L | 0.2 | 0.4 | 0.6 |

| B | hcr/hc | 0.3 | 0.5 | 0.7 |

| C | b3/b2 | 0.5 | 1 | 2 |

| Tes. No. | A | B | (A × B)1 | (A × B)2 | C | (A × C)1 | (A × C)2 | (B × C)1 | (B × C)2 | λmax,L/4 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1.082 |

| 2 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 1.083 |

| 3 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 1.084 |

| 4 | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 1.089 |

| 5 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 | 1.091 |

| 6 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 1 | 1 | 1 | 2 | 2 | 2 | 1.095 |

| 7 | 1 | 3 | 3 | 3 | 1 | 1 | 1 | 3 | 3 | 3 | 2 | 2 | 2 | 1.107 |

| 8 | 1 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 | 3 | 3 | 3 | 1.115 |

| 9 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 1 | 1 | 1 | 1.123 |

| 10 | 2 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1.316 |

| 11 | 2 | 1 | 2 | 3 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 1.317 |

| 12 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 1.318 |

| 13 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 2 | 3 | 1 | 3 | 1 | 2 | 1.329 |

| 14 | 2 | 2 | 3 | 1 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 | 1.335 |

| 15 | 2 | 2 | 3 | 1 | 3 | 1 | 2 | 1 | 2 | 3 | 2 | 3 | 1 | 1.341 |

| 16 | 2 | 3 | 1 | 2 | 1 | 2 | 3 | 3 | 1 | 2 | 2 | 3 | 1 | 1.373 |

| 17 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 3 | 1 | 2 | 1.393 |

| 18 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 2 | 3 | 1 | 1 | 2 | 3 | 1.413 |

| 19 | 3 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1.653 |

| 20 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 1.653 |

| 21 | 3 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 2 | 1 | 1.650 |

| 22 | 3 | 2 | 1 | 3 | 1 | 3 | 2 | 2 | 1 | 3 | 3 | 2 | 1 | 1.668 |

| 23 | 3 | 2 | 1 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 1.673 |

| 24 | 3 | 2 | 1 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 2 | 1 | 3 | 1.676 |

| 25 | 3 | 3 | 2 | 1 | 1 | 3 | 2 | 3 | 2 | 1 | 2 | 1 | 3 | 1.732 |

| 26 | 3 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 | 3 | 2 | 1 | 1.760 |

| 27 | 3 | 3 | 2 | 1 | 3 | 2 | 1 | 2 | 1 | 3 | 1 | 3 | 2 | 1.782 |

| Variance Source | Si | f | F | Sensitivity Ranking |

|---|---|---|---|---|

| A | 0.730720 | 2 | 12,653.160 | 1 |

| B | 0.025288 | 2 | 437.887 | 2 |

| C | 0.000966 | 2 | 16.727 | 4 |

| A × B | 0.004802 | 4 | 41.576 | 3 |

| A × C | 0.000109 | 4 | 0.944 | 6 |

| B × C | 0.001029 | 4 | 8.909 | 5 |

| Empty columns | 0.000231 | 8 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, C.; Zhang, Y.; Zhao, H.; Zhang, B.; Du, T. Study on Shear-Lag Effect of Steel–UHPC Ribbed Slab Composite Structures Using Bar Simulation Method. Buildings 2022, 12, 1884. https://doi.org/10.3390/buildings12111884

Tan C, Zhang Y, Zhao H, Zhang B, Du T. Study on Shear-Lag Effect of Steel–UHPC Ribbed Slab Composite Structures Using Bar Simulation Method. Buildings. 2022; 12(11):1884. https://doi.org/10.3390/buildings12111884

Chicago/Turabian StyleTan, Chengjun, Yufei Zhang, Hua Zhao, Bin Zhang, and Tie Du. 2022. "Study on Shear-Lag Effect of Steel–UHPC Ribbed Slab Composite Structures Using Bar Simulation Method" Buildings 12, no. 11: 1884. https://doi.org/10.3390/buildings12111884

APA StyleTan, C., Zhang, Y., Zhao, H., Zhang, B., & Du, T. (2022). Study on Shear-Lag Effect of Steel–UHPC Ribbed Slab Composite Structures Using Bar Simulation Method. Buildings, 12(11), 1884. https://doi.org/10.3390/buildings12111884