Energy Saving and Thermal Comfort Performance of Passive Retrofitting Measures for Traditional Rammed Earth House in Lingnan, China

Abstract

1. Introduction

2. Methods

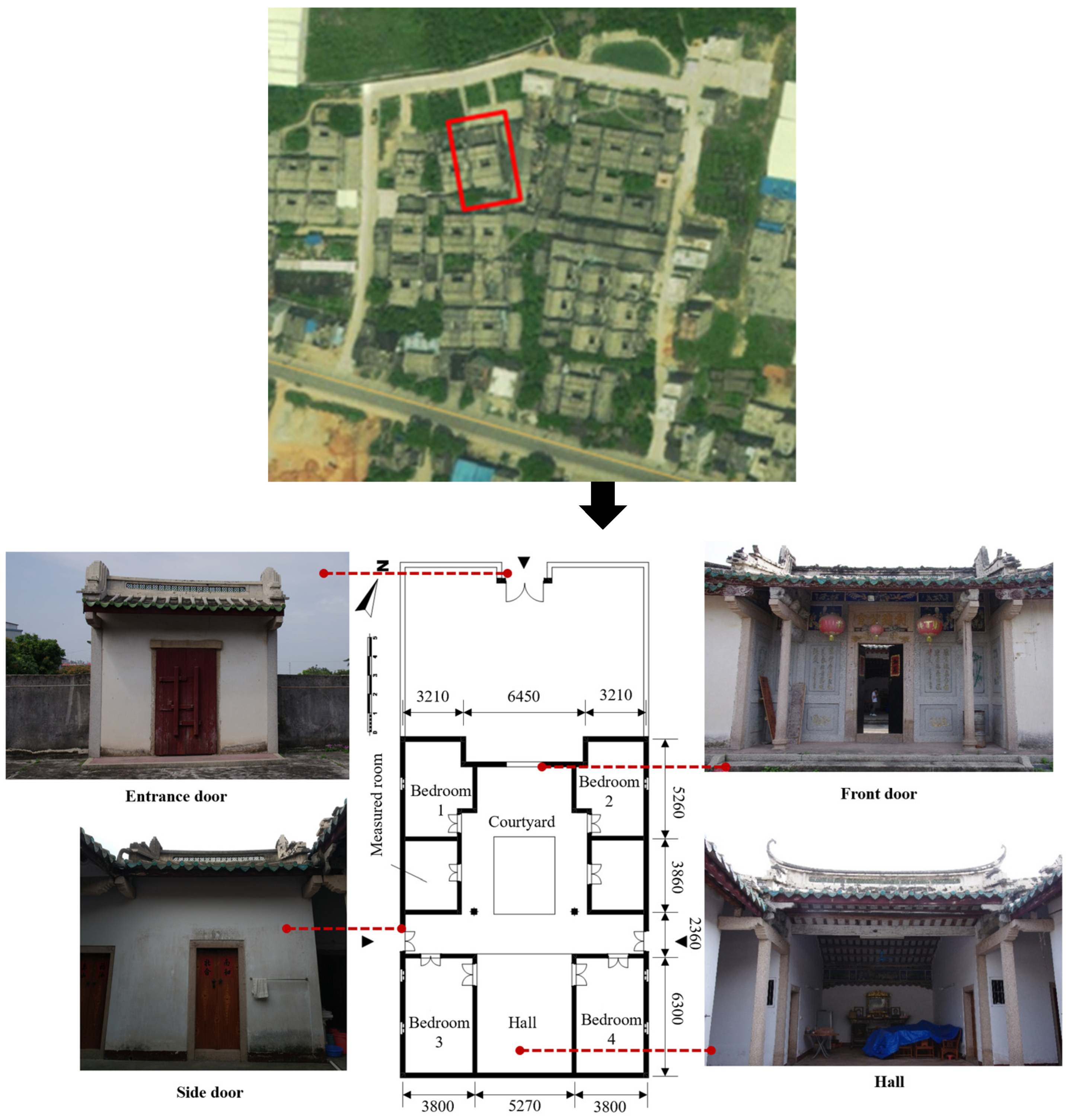

2.1. Field Survey

2.2. Onsite Test

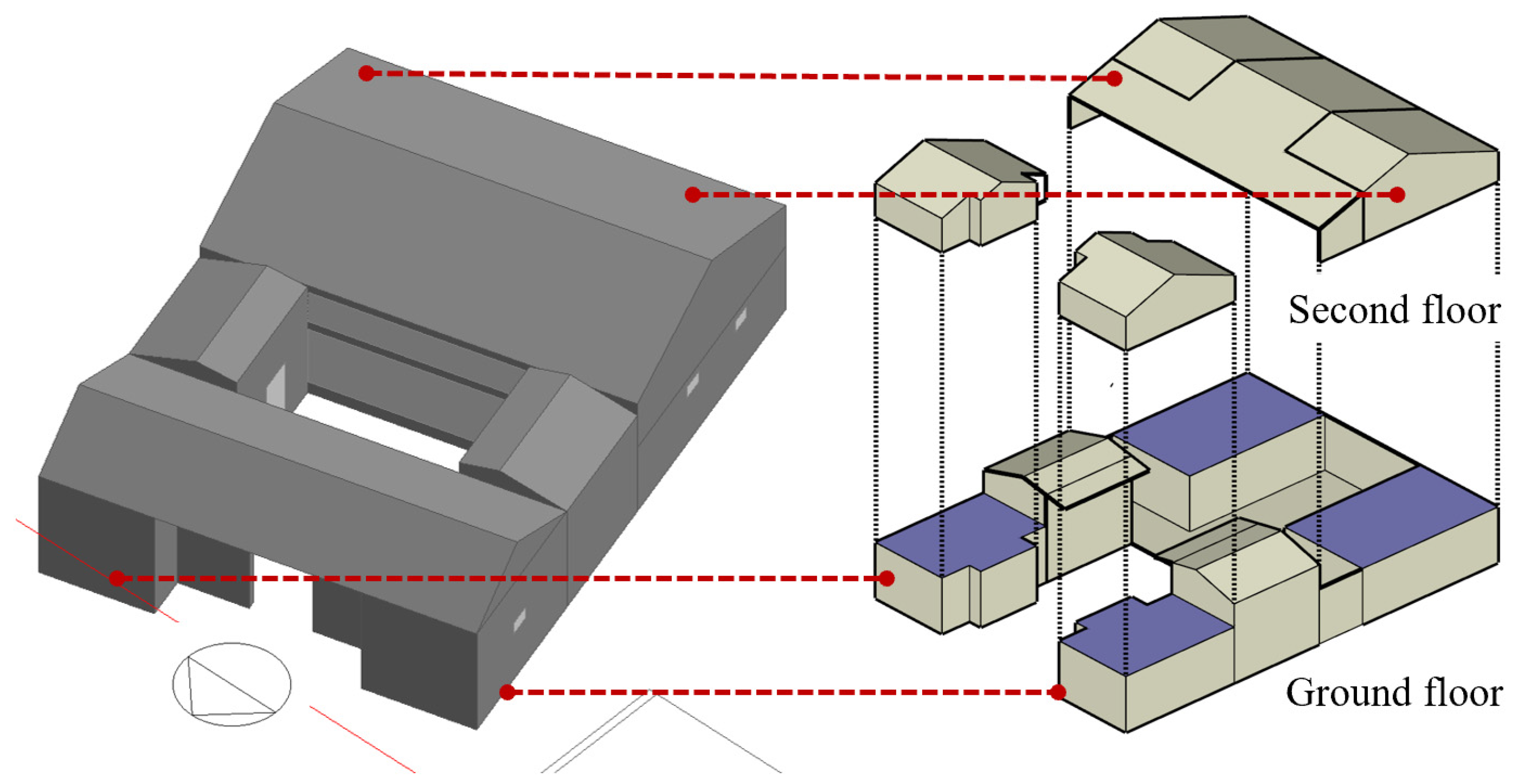

2.3. Building Simulation Model

2.4. Dynamic Investment Payback Period

2.5. K-Means Clustering Based Decision Making

3. Building Simulation Results

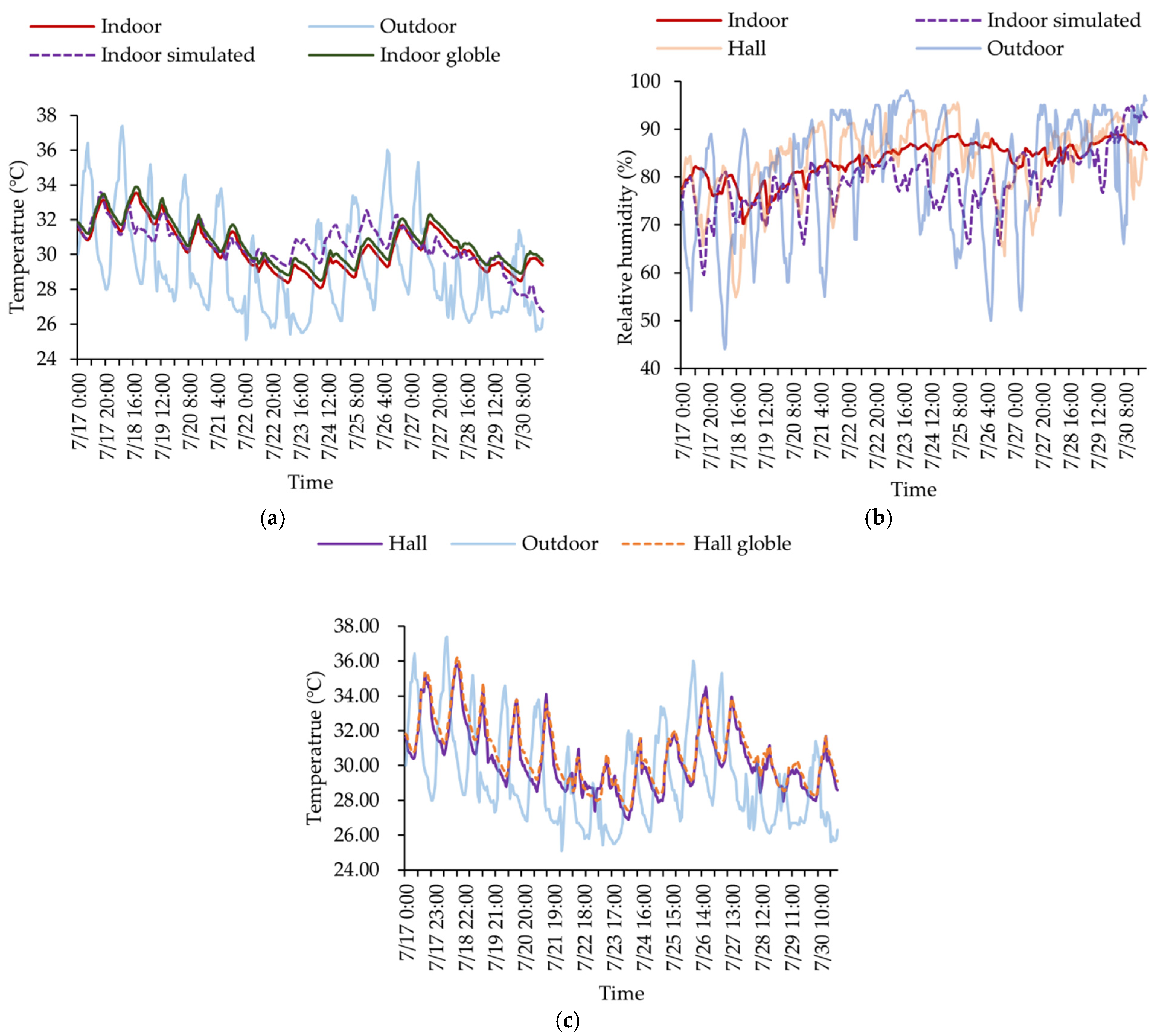

3.1. Model Validation

3.1.1. Winter

3.1.2. Summer

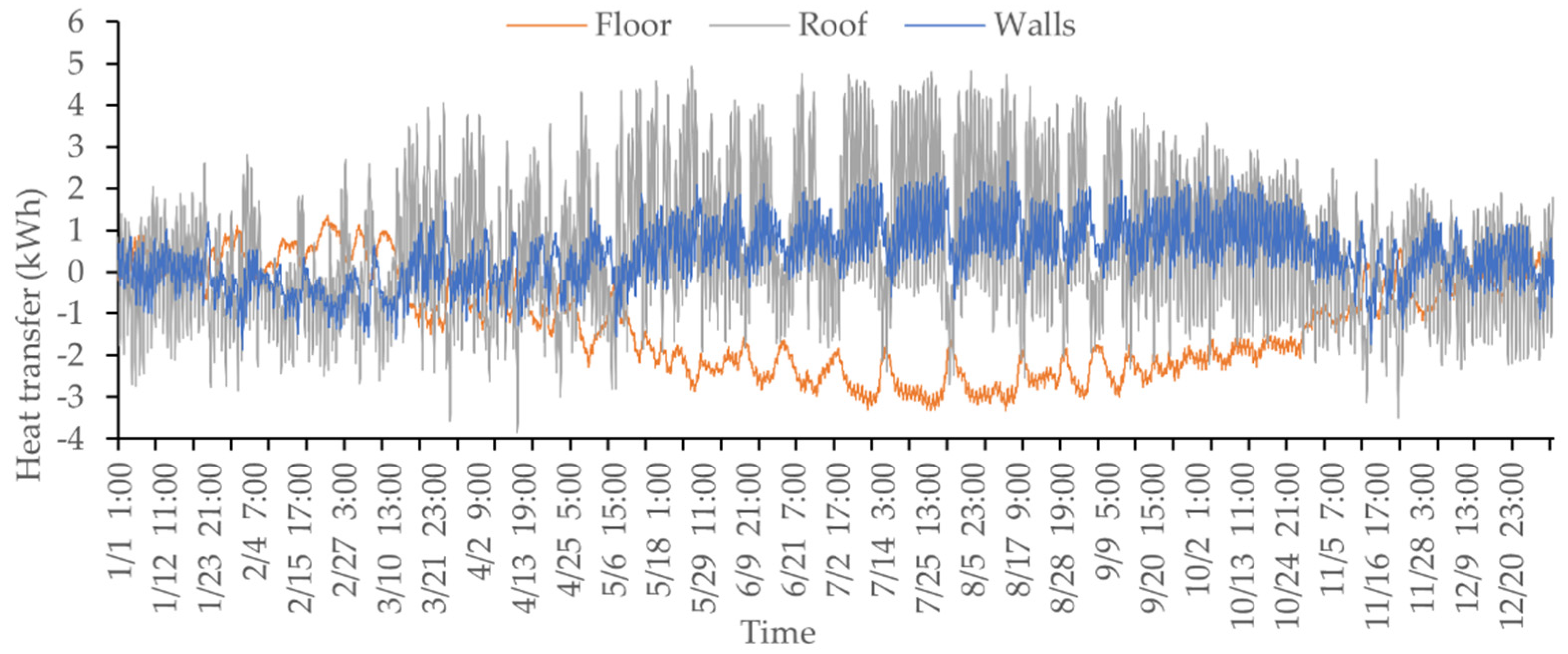

3.2. Heat Gain and Loss

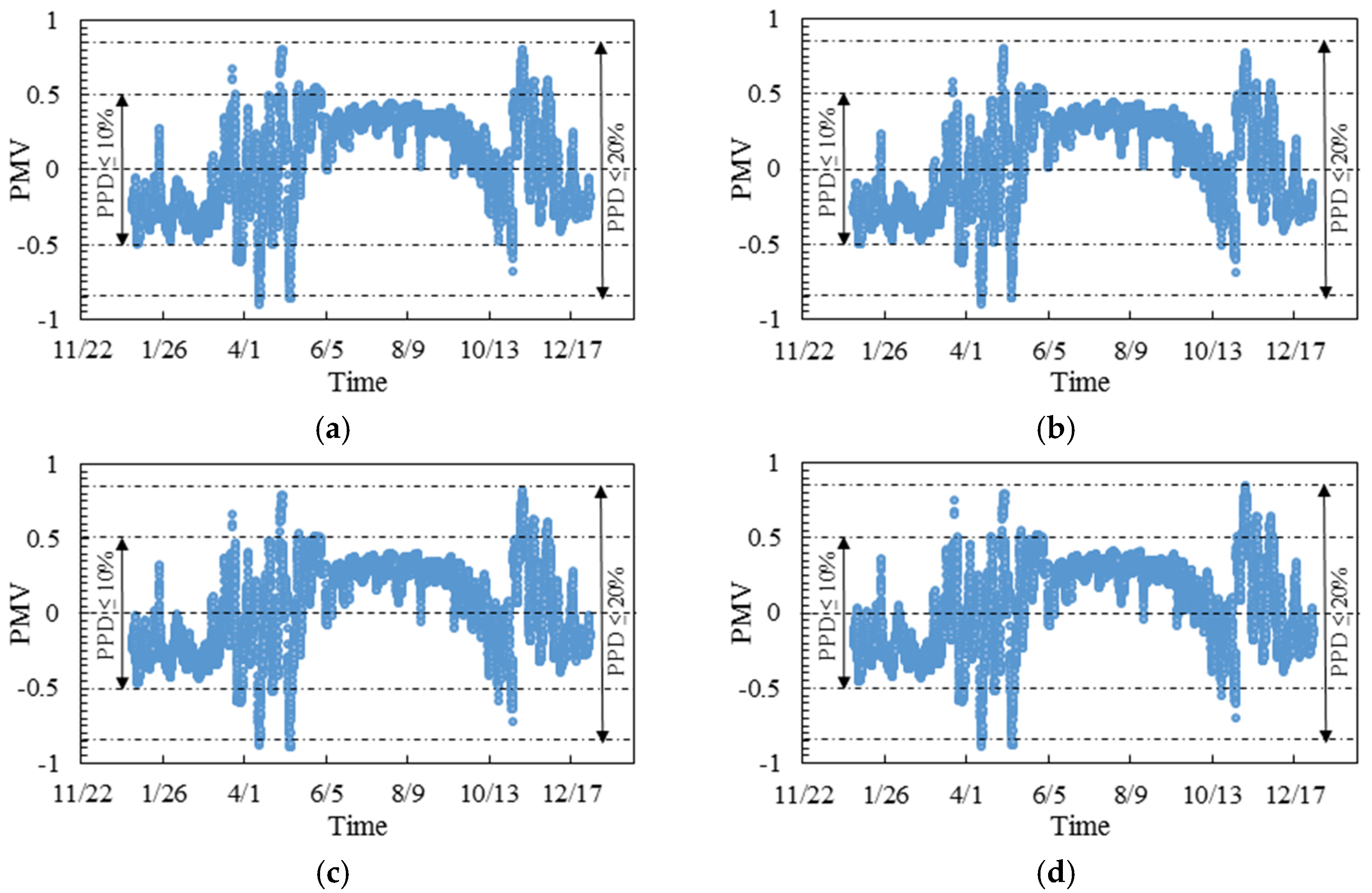

3.3. Indoor Thermal Comfort

3.3.1. Natural Ventilation

3.3.2. HVAC

4. Retrofitting Measures

4.1. Energy Saving and Thermal Performance Retrofitting

4.2. Sensitivity Analysis of Retrofitting Measures

4.2.1. Energy Saving

4.2.2. Economic Performance

4.2.3. Indoor Thermal Environment

4.3. Optimized Scheme

5. Conclusions

6. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Case | Factors | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Natural Ventilation | Roof Reflection | Thermal Insulation | Sunshade Width | Carpet | Energy Saving (kWh/a) | Dynamic Investment Payback Period Year | Annual Indoor Unacceptable Thermal Comfort Hours h | Comprehensive Indicator | |

| 1 | 1 | 1 | 1 | 1 | 1 | 1083.34 | N/A | 1361 | 16 |

| 2 | 1 | 2 | 2 | 2 | 2 | 2032.26 | 14.83 | 1110 | 20 |

| 3 | 1 | 3 | 3 | 3 | 3 | 847.24 | N/A | 1766 | 14 |

| 4 | 1 | 4 | 4 | 4 | 4(2) | 2157.65 | 21.19 | 1244 | 21 |

| 5 | 1 | 5 | 5 | 5 | 5(3) | 991.42 | N/A | 1176 | 10 |

| 6 | 2 | 1 | 2 | 3 | 4(2) | 2035.69 | 14.27 | 1307 | 25 |

| 7 | 2 | 2 | 3 | 4 | 5(3) | 909.33 | N/A | 1305 | 12 |

| 8 | 2 | 3 | 4 | 5 | 1 | 2192.27 | 12.29 | 1071 | 23 |

| 9 | 2 | 4 | 5 | 1 | 2 | 833.85 | N/A | 1307 | 11 |

| 10 | 2 | 5 | 1 | 2 | 3 | 1227.55 | N/A | 1110 | 12 |

| 11 | 3(1) | 1 | 3 | 5 | 2 | 838.8 | N/A | 1351 | 13 |

| 12 | 3(1) | 2 | 4 | 1 | 3 | 2150.63 | 11.82 | 1074 | 24 |

| 13 | 3(1) | 3 | 5 | 2 | 4(2) | 900.47 | N/A | 1290 | 12 |

| 14 | 3(1) | 4 | 1 | 3 | 5(3) | 1034.91 | N/A | 1341 | 15 |

| 15 | 3(1) | 5 | 2 | 4 | 1 | 2049.45 | 9.17 | 963 | 23 |

| 16 | 4(2) | 1 | 4 | 2 | 5(3) | 2175.06 | 18.07 | 1226 | 22 |

| 17 | 4(2) | 2 | 5 | 3 | 1 | 961.73 | N/A | 1298 | 13 |

| 18 | 4(2) | 3 | 1 | 4 | 2 | 1173.4 | N/A | 1248 | 14 |

| 19 | 4(2) | 4 | 2 | 5 | 3 | 1997.36 | 13.08 | 1325 | 26 |

| 20 | 4(2) | 5 | 3 | 1 | 4(2) | 994.28 | N/A | 1184 | 10 |

| 21 | 5(1) | 1 | 5 | 4 | 3 | 846.76 | N/A | 1365 | 13 |

| 22 | 5(1) | 2 | 1 | 5 | 4(2) | 1170.98 | N/A | 1234 | 13 |

| 23 | 5(1) | 3 | 2 | 1 | 5(3) | 1328.95 | 28.51 | 1161 | 15 |

| 24 | 5(1) | 4 | 3 | 2 | 1 | 778.24 | N/A | 1304 | 10 |

| 25 | 5(1) | 5 | 4 | 3 | 2 | 2167.08 | 20.95 | 912 | 16 |

References

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture; Birkhäuser: Basel, Switzerland, 2012. [Google Scholar]

- Jaquin, P.A.; Augarde, C.E.; Gerrard, C.M. Chronological description of the spatial development of rammed earth techniques. Int. J. Archit. Herit. 2008, 2, 377–400. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life cycle analysis of environmental impact vs. durability of stabilised rammed earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Kumar, P.P. Embodied energy in cement stabilised rammed earth walls. Energy Build. 2010, 42, 380–385. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Leuzinger, G.; Sreeram, V.S. Low embodied energy cement stabilised rammed earth building—A case study. Energy Build. 2014, 68, 541–546. [Google Scholar] [CrossRef]

- Strazzeri, V.; Karrech, A. Energy and thermal performance of a typical rammed earth residential building in Western Australia. Energy Build. 2022, 260, 111901. [Google Scholar] [CrossRef]

- Fernandes, J.; Mateus, R.; Gervásio, H.; Silva, S.M.; Bragança, L. Passive strategies used in Southern Portugal vernacular rammed earth buildings and their influence in thermal performance. Renew. Energy 2019, 142, 345–363. [Google Scholar] [CrossRef]

- Soudani, L.; Woloszyn, M.; Fabbri, A.; Morel, J.-C.; Grillet, A.-C. Energy evaluation of rammed earth walls using long term in-situ measurements. Sol. Energy 2017, 141, 70–80. [Google Scholar] [CrossRef]

- Soebarto, V. Analysis of indoor performance of houses using rammed earth walls. In Proceedings of the Eleventh International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009; pp. 1530–1537. [Google Scholar]

- Dong, X.; Soebarto, V.; Griffith, M. Strategies for reducing heating and cooling loads of uninsulated rammed earth wall houses. Energy Build. 2014, 77, 323–331. [Google Scholar] [CrossRef]

- Taylor, P.; Fuller, R.J.; Luther, M.B. Energy use and thermal comfort in a rammed earth office building. Energy Build. 2008, 40, 793–800. [Google Scholar] [CrossRef]

- Beckett, C.; Cardell-Oliver, R.; Ciancio, D.; Huebner, C. Measured and simulated thermal behaviour in rammed earth houses in a hot-arid climate. Part B Comfort. J. Build. Eng. 2017, 13, 146–158. [Google Scholar]

- Xiang, D.; Soebarto, V.; Griffith, M. Achieving thermal comfort in naturally ventilated rammed earth houses. Build. Environ. 2014, 82, 588–598. [Google Scholar]

- Dong, X.; Soebarto, V.; Griffith, M. Design optimization of insulated cavity rammed earth walls for houses in Australia. Energy Build. 2015, 86, 852–863. [Google Scholar] [CrossRef][Green Version]

- Giuffrida, G.; Detommaso, M.; Nocera, F.; Caponetto, R. Design optimisation strategies for solid rammed earth walls in Mediterranean climates. Energies 2021, 14, 325. [Google Scholar] [CrossRef]

- Fernandes, J.; Pimenta, C.; Mateus, R.; Monteiro Silva, S.; Bragança, L. Contribution of Portuguese Vernacular Building Strategies to Indoor Thermal Comfort and Occupants’ Perception. Buildings 2015, 5, 1242–1264. [Google Scholar] [CrossRef]

- Fernandes, J.; Mateus, R.; Braganca, L.; Silva, J.J.C.D. Portuguese vernacular architecture: The contribution of vernacular materials and design approaches for sustainable construction. Archit. Sci. Rev. 2015, 58, 324–336. [Google Scholar] [CrossRef]

- Martin, S.; Mazarron, F.R.; Canas, I. Study of thermal environment inside rural houses of Navapalos (Spain): The advantages of reuse buildings of high thermal inertia. Constr. Build. Mater. 2010, 24, 666–676. [Google Scholar] [CrossRef]

- Priya, R.S.; Sundarraja, M.C.; Radhakrishnan, S.; Vijayalakshmi, L. Solar passive techniques in the vernacular buildings of coastal regions in Nagapattinam, TamilNadu-India—a qualitative and quantitative analysis. Energy Build. 2012, 49, 50–61. [Google Scholar] [CrossRef]

- Saljoughinejad, S.; Sharifabad, S.R. Classification of climatic strategies, used in Iranian vernacular residences based on spatial constituent elements. Build. Environ. 2015, 92, 475–493. [Google Scholar] [CrossRef]

- Fernandes, J.; Mateus, R.; Bragana, L. The Potential of Vernacular Materials to the Sustainable Building Design. In Proceedings of the International Conference on Vernacular Heritage and Earthen Architecture (CIAV)/VerSus/7th ATP, Vila Nova de Cerveira, Portugal, 16–20 October 2013; pp. 623–629. [Google Scholar]

- Singh, M.K.; Mahapatra, S.; Atreya, S.K. Solar passive features in vernacular architecture of North-East India. Sol. Energy 2011, 85, 2011–2022. [Google Scholar] [CrossRef]

- Gu, Y.; Xu, H. Spatial Representation of Rural Clan-Organized Society Structure: The Case of Chaoshan Culture Area. Urban Plan. Forum 2017, 3, 103–109. [Google Scholar]

- Archaic Pashi House. Available online: http://dz.cppfoto.com/activity/showG.aspx?works=1807770&page-=1 (accessed on 4 January 2022).

- Zeng, Z.; Li, L.; Pang, Y. Analysis on climate adaptability of traditional villages in Lingnan, China–World Cultural Heritage Site of Majianglong Villages as example. Procedia Eng. 2017, 205, 2011–2018. [Google Scholar] [CrossRef]

- Li, Q.; You, R.; Chen, C.; Yang, X. A field investigation and comparative study of indoor environmental quality in heritage Chinese rural buildings with thick rammed earth wall. Energy Build. 2013, 62, 286–293. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Z. Studies on Optimization and Integration of Photovoltaics in traditional Lingnan buildings: A case study in Guangzhou. Procedia Eng. 2017, 205, 3003–3010. [Google Scholar] [CrossRef]

- Mazzarella, L. Energy retrofit of historic and existing buildings. The legislative and regulatory point of view. Energy Build. 2015, 95, 23–31. [Google Scholar]

- Healy, S. Air-conditioning and the ‘homogenization’ of people and built environments. Build. Res. Inf. 2008, 36, 312–322. [Google Scholar] [CrossRef]

- China Development and Reform Commission. Construction Project Economic Evaluation Approaches and Parameters; China Plan Press: Beijing, China, 2006.

- Jain, A.K. Data Clustering: 50 Years Beyond K-means. Pattern Recognit. Lett. 2010, 31, 651–666. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development. Civil Building Thermal and Humid Environment Evaluation Standard; China Construction Industry Press: Beijing, China, 2012; pp. 5–10.

- ANSI/ASHRAE Standard 55-2017; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Atlanta, GA, USA, 2017; pp. 4–18.

- Li, Z.; Wang, Z.Z.; Sun, Y.; Shao, Z.B. Economic Evaluation of Energy Saving Technology for Building Envelope: Taking a residential building in Henan as an example. Build. Energy Effic. 2017, 7, 123–126. [Google Scholar] [CrossRef]

| Equipment | Specification | Measurement Range | Accuracy |

|---|---|---|---|

| HOBO temperature and humidity recorder | U12-012 | temperature:−20~70 °C relative humidity:5~95% | ±2.5% |

| Global temperature recorder | testo480 | −20~+80 °C | ±0.3 °C |

| Structure | Heat Transfer Coefficient/W/(m2·K) | Thermal Resistance/(m2·K/W) | Thickness /m |

|---|---|---|---|

| Rammed earth wall | 1.754 | 0.570 | 0.24 |

| Roof | 2.790 | 0.358 | 0.3 |

| Floor | 2.098 | 0.477 | 0.3 |

| Parameters | Values |

|---|---|

| Design indoor temperature in winter | 18 °C |

| Design indoor temperature in summer | 25 °C |

| Heat Pump Heating Coil Gross Rated COP | 2.75 |

| Cooling Coil Gross Rated COP | 3 |

| Operational time | 22:00–9:00 |

| Meteorological parameters | Typical meteorological year data of Shantou |

| Air infiltration | 3.5 h−1 |

| Indoor thermal disturbance | People and lighting |

| Bedroom | GB/T 50785-2012 | ASHRAE | ||

|---|---|---|---|---|

| I Level | II Level | 90% Acceptability | 80% Acceptability | |

| 1 | 2069 | 663 | 3847 | 2971 |

| 2 | 2567 | 870 | 4000 | 3126 |

| 3 | 2588 | 816 | 3881 | 3029 |

| 4 | 1852 | 615 | 3716 | 2777 |

| Factors | |||||

|---|---|---|---|---|---|

| Natural Ventilation | Heat-Reflective and Thermal Insulation Coating | Wall Insulation | Sunshade Width | Carpet | |

| Level 1 | Turn on | ZS-221 white | EPS(50 mm) | 0.1 m | Carpet |

| Level 2 | Turn off | Water-based | XPS(30 mm) | 0.2 m | PVC carpet |

| Level 3 | Cool glue | EPS(100 mm | 0.3 m | Textile carpet | |

| Level 4 | Kaisheng | XPS(50 mm) | 0.4 m | ||

| Level 5 | RLHY-A05 | EPS(20 mm) | 0.5 m | ||

| Component | Materials | Heat Conductivity Coefficient (W/(m∙k)) | Specific Heat (J/(kg∙K)) | Density (kg/m3) | Unit Price (¥/m2) | Area (m2) | Total Price (¥) |

|---|---|---|---|---|---|---|---|

| Floor | Carpet | 0.28 | 1000 | 290 | 16.33 | 179.6 | 2932.87 |

| PVC carpet | 0.04 | 750 | 100 | 34.47 | 179.6 | 6190.81 | |

| Textile carpet | 0.06 | 1300 | 200 | 29.1 | 179.6 | 5226.36 | |

| Wall | EPS(50 mm) | 0.8 | 1300 | 16 | 39 | 316 | 12,324 |

| XPS(30 mm) | 0.034 | 1400 | 35 | 18 | 316 | 5688 | |

| EPS(100 mm) | 0.8 | 1300 | 16 | 78 | 316 | 24648 | |

| XPS(50 mm) | 0.034 | 1400 | 35 | 30 | 316 | 9480 | |

| EPS(20 mm) | 0.8 | 1300 | 16 | 15.6 | 316 | 4929.6 |

| Coating | Thermal Reflectivity | Tolar Reflectivity | Hemispheric Emissivity | Unit Price (¥/m2) | Area (m2) | Total Price (¥) |

|---|---|---|---|---|---|---|

| ZS-221 | 0.92 | 0.88 | 0.89 | 7.5 | 232.8 | 1746 |

| Water-based | 0.9 | 0.91 | 0.93 | 8.75 | 232.8 | 2037 |

| Cool glue | 0.85 | 0.89 | 0.89 | 4.25 | 232.8 | 989.4 |

| Kaisheng | 0.85 | 0.85 | 0.88 | 7.5 | 232.8 | 1746 |

| RLHY-A05 | 0.92 | 0.95 | 0.9 | 7.5 | 232.8 | 1746 |

| Width(m) | Unit Price (¥/m2) | Area (m2) | Total Price (¥) |

|---|---|---|---|

| 0.1 | 72 | 0.406 | 29.232 |

| 0.2 | 72 | 0.812 | 58.464 |

| 0.3 | 72 | 1.218 | 87.696 |

| 0.4 | 72 | 1.624 | 116.928 |

| 0.5 | 72 | 2.03 | 146.16 |

| Factors | ||||||

|---|---|---|---|---|---|---|

| Natural Ventilation | Heat-Reflective and Thermal Insulation Coating | Wall Insulation | Sunshade Width | Carpet | ||

| Level 1 | 1358.55 | 1395.93 | 1138.04 | 1278.21 | 1413.01 | |

| Level 2 | 1450.05 | 1444.99 | 1888.74 | 1422.72 | 1430.45 | |

| Level 3 | 1288.47 | 873.58 | 1409.33 | 1350.92 | ||

| Level 4 | 1360.40 | 2168.54 | 1427.32 | |||

| Level 5 | 1485.96 | 906.85 | 1438.17 | |||

| 91.51 | 197.49 | 1294.96 | 159.96 | 79.53 | ||

| Rank of impact level | Wall insulation > Heat-reflective and thermal insulation coating > Sunshade width > Natural ventilation > Carpet | |||||

| Best scheme | 2 | 5 | 4 | 5 | 2 | |

| Factors | ||||||

|---|---|---|---|---|---|---|

| Natural Ventilation | Heat-Reflective and Thermal Insulation Coating | Wall Insulation | Sunshade Width | Carpet | ||

| Level 1 | N/A | 6.47 | N/A | 8.07 | 4.29 | |

| Level 2 | N/A | 5.33 | 15.97 | 6.58 | 7.12 | |

| Level 3 | 8.16 | N/A | 7.04 | 7.15 | ||

| Level 4 | 6.85 | 16.86 | 6.07 | |||

| Level 5 | 6.02 | N/A | 5.07 | |||

| N/A | 2.83 | N/A | 2.99 | 2.86 | ||

| Rank of impact level | Wall insulation > Sunshade width > Carpet > Heat-reflective and thermal insulation coating | |||||

| Best scheme | N/A | 2 | 2 | 5 | 1 | |

| Factors | ||||||

|---|---|---|---|---|---|---|

| Natural Ventilation | Heat-Reflective and Thermal Insulation Coating | Wall Insulation | Sunshade Width | Carpet | ||

| Level 1 | 1243.47 | 1322.00 | 1258.80 | 1217.40 | 1199.40 | |

| Level 2 | 1238.10 | 1204.20 | 1173.20 | 1208.00 | 1218.70 | |

| Level 3 | 1307.20 | 1382.00 | 1324.80 | 1284.90 | ||

| Level 4 | 1304.20 | 1105.40 | 1225.00 | |||

| Level 5 | 1069.00 | 1287.20 | 1231.40 | |||

| 5.37 | 253.00 | 276.60 | 116.80 | 85.50 | ||

| Rank of impact level | Wall insulation > Heat-reflective and thermal insulation coating > Sunshade width > Carpet > Natural ventilation | |||||

| Best scheme | 1 | 1 | 3 | 3 | 3 | |

| Factors | ||||||

|---|---|---|---|---|---|---|

| Natural Ventilation | Heat-Reflective and Thermal Insulation Coating | Wall Insulation | Sunshade Width | Carpet | ||

| Level 1 | 15.67 | 17.80 | 14.00 | 15.20 | 17.00 | |

| Level 2 | 16.80 | 16.40 | 21.80 | 15.20 | 15.50 | |

| Level 3 | 15.60 | 11.80 | 16.60 | 16.30 | ||

| Level 4 | 16.60 | 21.20 | 16.60 | |||

| Level 5 | 14.20 | 11.80 | 17.00 | |||

| 1.13 | 3.60 | 10.00 | 1.80 | 1.50 | ||

| Rank of impact level | Wall insulation > Heat-reflective and thermal insulation coating > Sunshade width > Carpet > Natural ventilation | |||||

| Best scheme | 2 | 1 | 2 | 5 | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Wang, M.; Shen, P.; Cui, X.; Bu, L.; Wei, R.; Zhang, L.; Wu, C. Energy Saving and Thermal Comfort Performance of Passive Retrofitting Measures for Traditional Rammed Earth House in Lingnan, China. Buildings 2022, 12, 1716. https://doi.org/10.3390/buildings12101716

Li S, Wang M, Shen P, Cui X, Bu L, Wei R, Zhang L, Wu C. Energy Saving and Thermal Comfort Performance of Passive Retrofitting Measures for Traditional Rammed Earth House in Lingnan, China. Buildings. 2022; 12(10):1716. https://doi.org/10.3390/buildings12101716

Chicago/Turabian StyleLi, Shihao, Meilin Wang, Pengyuan Shen, Xue Cui, Linqian Bu, Ruji Wei, Longzhu Zhang, and Chengjia Wu. 2022. "Energy Saving and Thermal Comfort Performance of Passive Retrofitting Measures for Traditional Rammed Earth House in Lingnan, China" Buildings 12, no. 10: 1716. https://doi.org/10.3390/buildings12101716

APA StyleLi, S., Wang, M., Shen, P., Cui, X., Bu, L., Wei, R., Zhang, L., & Wu, C. (2022). Energy Saving and Thermal Comfort Performance of Passive Retrofitting Measures for Traditional Rammed Earth House in Lingnan, China. Buildings, 12(10), 1716. https://doi.org/10.3390/buildings12101716