1. Introduction

Numerical modeling of Reinforced Concrete (RC) members is a key factor for the seismic assessment of the RC structures. To investigate the inelastic behavior of beams and columns, these members are usually modeled by means of one-dimensional concentrated or distributed plasticity elements. In modeling of framed structures, concentrated plasticity models with plastic hinges of finite length are often preferred to distributed plasticity models to limit the damage localization problems and improve the computational efficiency. Concentrated plasticity elements have two plastic hinges at the ends and an elastic part in the middle. The geometry and the mechanical characterization of the plastic hinges, in particular the length Lpl of the plastic hinges, are of outmost importance for the accuracy of the response of RC members as they govern the load carrying and deformation capacities, as well as the energy dissipation of the member. In the past, several authors proposed formulations for the prediction of the length of the plastic hinge of RC members based on laboratory tests. However, large discrepancies exist among the results of these formulations, mainly because the inelastic behavior of materials is not discontinuous in real members and because different criteria may be considered to identify the length of the plastic hinge.

According to these formulations, several factors contribute to the value of Lpl, e.g., the shear span of the member, the depth of the cross-section, the mechanical properties of concrete (e.g., compressive strength, elastic modulus, compressive fracture energy), the geometric and mechanical properties of the longitudinal and transverse reinforcements (e.g., geometric percentage of steel bars and yield strength of steel), the effectiveness of confinement in the volume of the plastic hinge, and the axial force and the shear force. This makes the research for an analytical expression of the length of the plastic hinge an issue that is still open today.

Most of the proposed formulations are empirical in nature and calibrated against data obtained from laboratory experiments [

1].

In 1956, Baker [

2] elaborated a formula based on an experimental campaign consisting of 94 tests on beams and columns. The main variables considered were the compressive strength of concrete (

fc), the yield stress of the longitudinal rebars (

fyl), and the cross-sectional area of the longitudinal reinforcements in tension and in compression and the normalized axial force (i.e., the ratio of the axial force to the resisting axial force of concrete in the cross-section). According to Baker, the value of

Lpl can vary between 0.4

d and 2.4

d (where

d is the effective depth of the cross-section) in flexural members characterized by usual values of the shear span ratio

Lv/

d.

Later, from 1964 to 1967, Mattock [

3,

4] drew up two proposals based on 37 experimental tests on beams. In his experimental campaign, he took into account the compressive strength of concrete (

fc = 28 ÷ 41 MPa), the effective depth of the cross-section (25.4 ÷ 50.8 cm), the shear span ratio

Lv/

d (2.75 ÷ 11), the yield strength of the longitudinal reinforcement

fyl (324÷414 MPa) and its geometric percentage (ρ

l = 1.0 ÷ 3.0%). The same author stated that the spreading of the inelastic behavior along the element increases with the ratio

Lv/

d.

In 1982, Park et al. [

5] performed tests on four square-section columns with

Lv/

h = 2.0 (where

h is the depth of the cross-section) and normalized axial force ν between 0.2 and 0.6. The authors concluded that the normalized axial force does not play a significant role for the determination of

Lpl and proposed, for columns, the use of a single value of

Lpl = 0.4

h. In a similar way, from 1993 to 1998, Sheikh et al. [

6,

7,

8] conducted other laboratory tests (mostly characterized by high values of the normalized axial force) and observed that the length of the plastic hinge

Lpl was approximately equal to

h.

In 1987, Priestley and Park [

9] proposed a formula that depends on the length of the element and on the diameter of the longitudinal rebars. Later, in 1992, Paulay and Priestley [

10] modified the previous equation to take into account the yield strength of steel. They stated that

Lpl =

h/2 can generally be assumed for typical columns.

In 2001, Mendis [

11] conducted laboratory tests on 13 simply-supported beams and 4 columns with low axial force. He concluded that

Lpl increases with the shear span ratio

Lv/

d and the geometric percentage of longitudinal reinforcement ρ

l, whereas it decreases with the increase of the geometric percentage of the transverse reinforcement ρ

v. Based on the tests on columns, Mendis stated that the length of the plastic hinge is not influenced by the axial force.

In 2008, Bae and Bayrak [

12] performed tests on four squared columns with

Lv/

h ranging from 5 to 7 and normalized axial force ranging from 0.2 to 0.5. They proposed a procedure to evaluate

Lpl under conditions of purely flexural behavior of the element. Through this procedure, validated on the tested columns, the authors performed a parametric analysis to establish that the parameters that mostly influenced

Lpl are the normalized axial force ν, the shear span ratio

Lv/

h and the geometric ratio of the longitudinal reinforcement ρ

l. In particular, according to Bae and Bayrak, the length

Lpl increased with the normalized axial force ν, the aspect ratio

Lv/

h and ρ

l.

More recently, Fardis et al. [

13,

14,

15] proposed two empirical formulations of

Lpl for members with axial force, in the presence of monotonic and cyclic load conditions. The proposed expressions primarily depended on the depth of the cross-section, the shear span ratio and the normalized axial force.

Although there is some agreement between the conclusions of the research studies aiming at the evaluation of the length of the plastic hinge (e.g., the influence of parameters such as the shear span ratio

Lv/

h or the height of the section), there are still some contrasting opinions regarding the influence of some parameters (e.g., the volumetric ratio of transverse reinforcement is considered to be relevant only by Mendis [

11]). In addition, some of the parameters that are considered in the experiments (e.g., mechanical characteristics of materials, normalized axial force) still do not appear in most formulas.

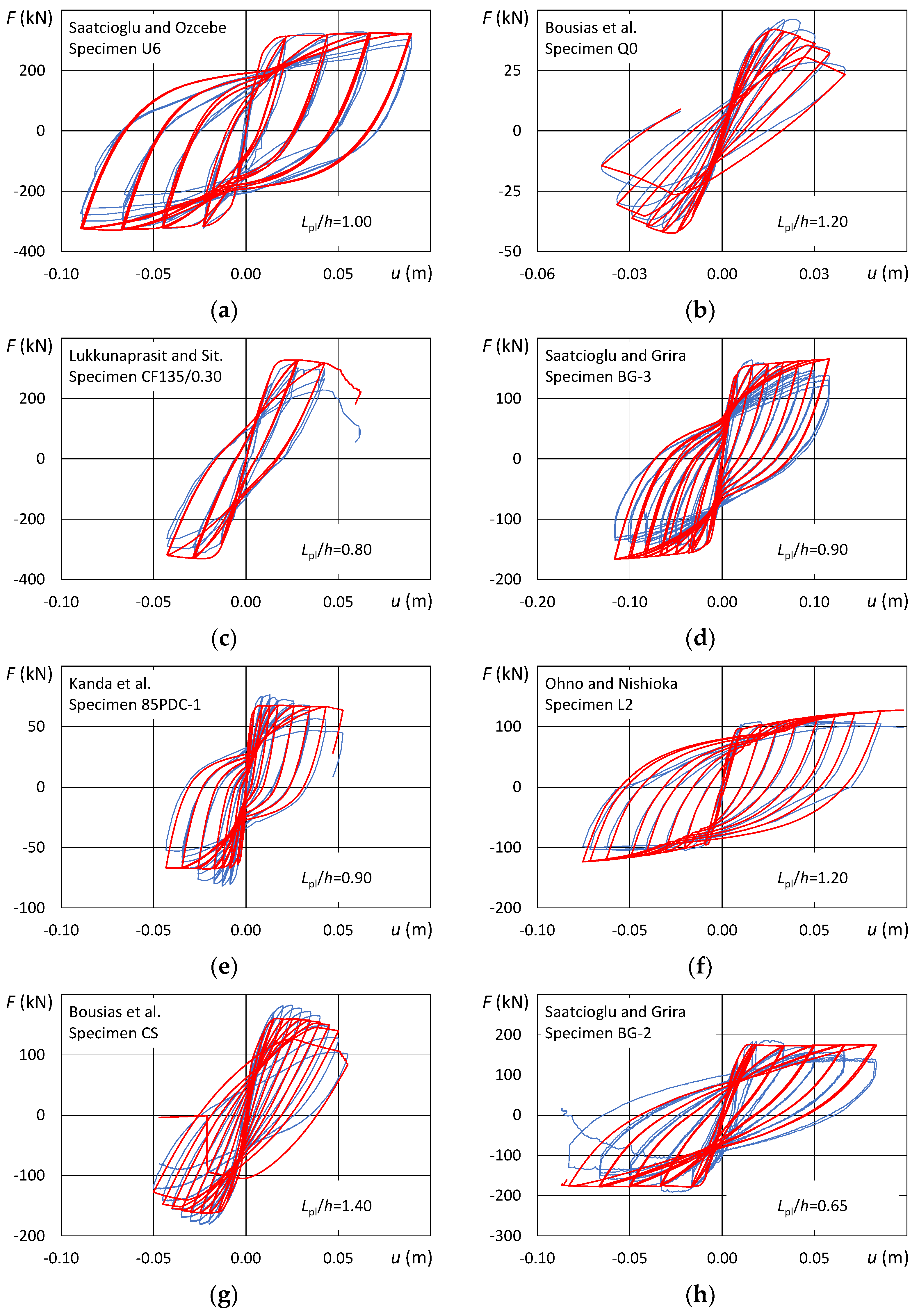

In this scenario, a new formulation of Lpl is proposed here for columns that are common in existing RC framed buildings built in Italy between the 1970s and early 2000s. The optimal length of the plastic hinge is derived from comparison between the cyclic response of laboratory tests and results from numerical simulations. To this end, the authors have first examined the formulations proposed in the literature for the numerical modeling of materials and members. Based on this study, the authors have selected specified formulations of the material and member models and proposed some modifications to the usual simulation of concrete confinement. Second, a set of 33 experimental tests has been collected among those available in the literature. The selected columns have rectangular section and have failed in a flexural mode without slipping of the steel bars. Then, for each test, the value of the plastic hinge length has been calibrated so that the response of the numerical model be as close as possible to that of the laboratory test, in terms of energy dissipation and aspect of the lateral force—lateral displacement plot. Based on the obtained optimal values of the length of the plastic hinge, a relationship has been searched between the optimal value of Lpl and the geometric and mechanical characteristics of the specimens. The proposed relation is simple and reveals to be able to reproduce with satisfying accuracy the results of the considered experimental tests. The validity of this relation is restricted to the investigated ranges of the geometric and mechanical parameters and to the use of the assumed models of materials and members.

4. Confinement of Concrete

When a RC member is subjected to uniaxial compression, the transverse reinforcement (i.e., spirals, stirrups, ties) passively resists the lateral expansion of the concrete volume that is inside the center line of the stirrups. This action results in some lateral compressive stresses on the surface of that concrete volume, which produce an increase in the peak compressive stress and in the ultimate strain of the material.

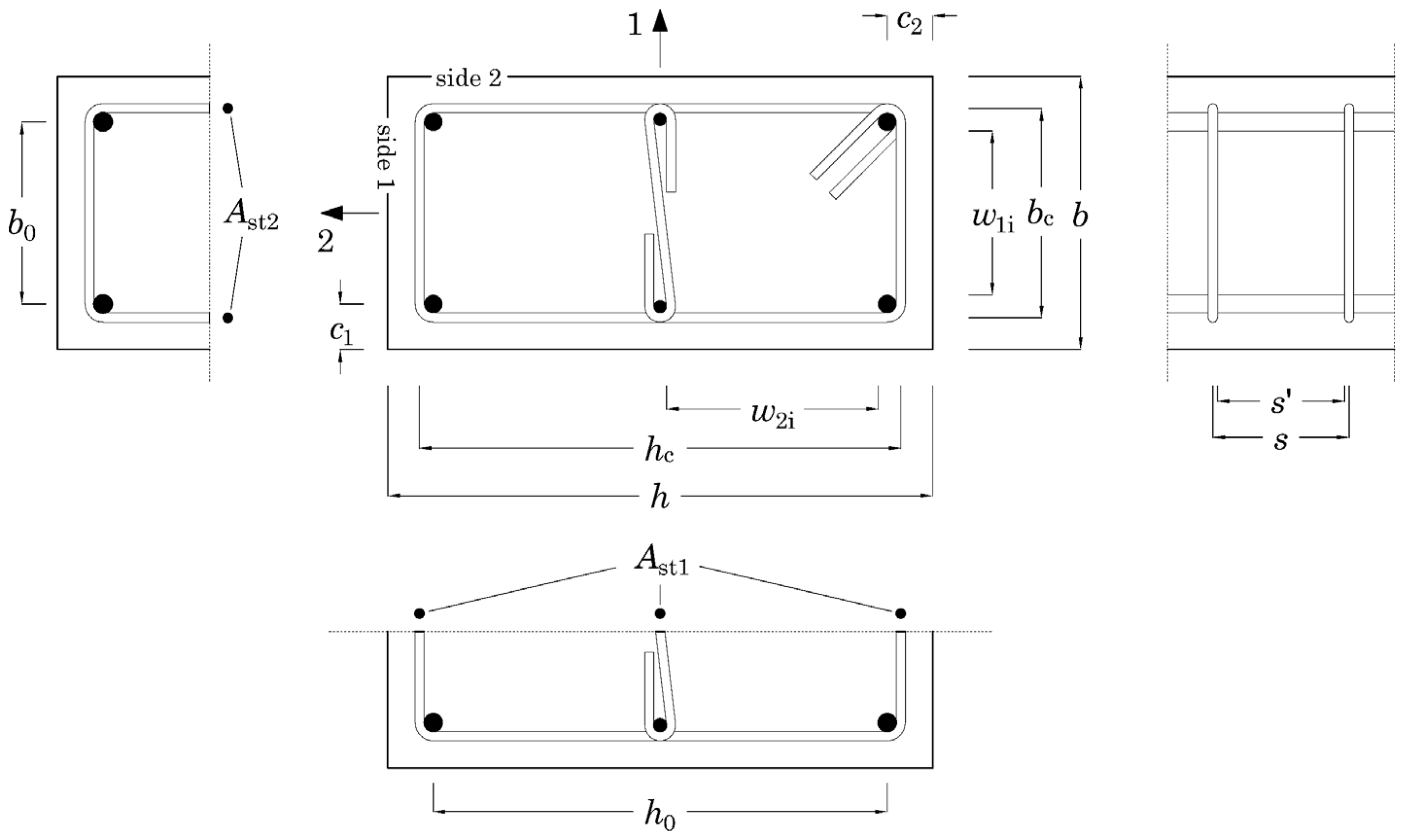

In this research study, the confinement mechanism is investigated with reference to prismatic elements characterized by a rectangular cross-section and endowed with stirrups and ties. Symbols adopted in this paper are shown in

Figure 1. An orthogonal reference system is considered on the cross-section which identifies direction 1 (vertical direction in the figure) and direction 2 (horizontal direction in the figure). The maximum level of confinement may be calculated assuming that stirrups have yielded, and the lateral compressive stresses are uniformly distributed on the lateral surface of the concrete inside the center line of the stirrups. This situation corresponds to a confinement effect caused by stirrup legs with an extremely low spacing both in the cross-section and along the longitudinal axis of the member (later referred to as “uniform” confinement). The magnitude of this lateral compressive stress is, in general, different along the two orthogonal directions previously named 1 and 2. The lateral compressive stresses, σ

l1 and σ

l2, along such directions are given by the translation equilibrium between the lateral compressive force exerted by the transverse reinforcement on concrete and the axial force in the transverse reinforcement at yielding

where ρ

st,1 and ρ

st,2 are the volumetric ratio of the transverse reinforcement in the two orthogonal directions

In the above relations,

nb,1 and

nb,2 are the numbers of stirrups legs producing lateral compressive stresses in directions 1 and 2, respectively;

Ast,i is the cross-sectional area of the single leg of the stirrup (or tie);

bc and

hc are the distances between the opposite legs of the stirrups, as reported in

Figure 1.

4.1. Confinement Effectiveness Factor

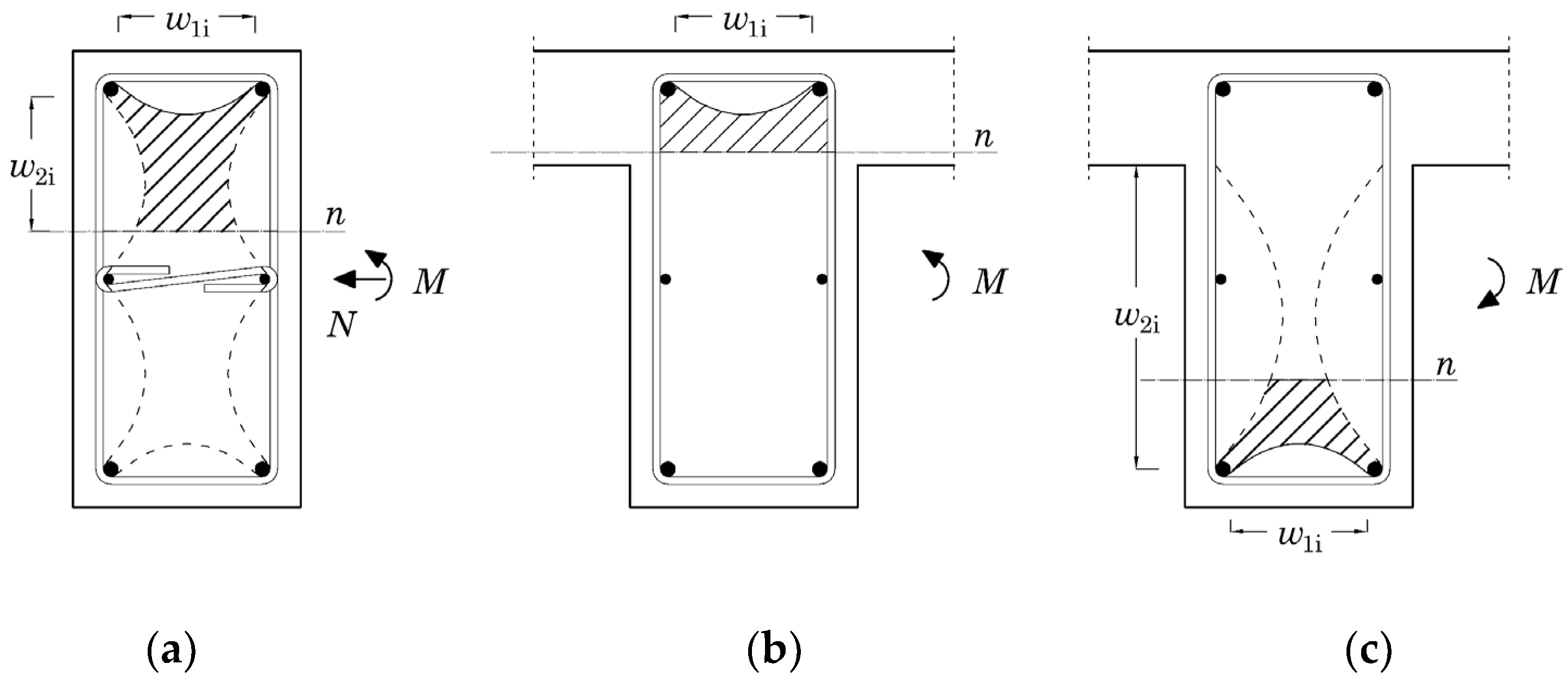

In the case of stirrups arranged with moderate or high spacing (

s > 5 cm), the confinement effects are concentrated, in the plane of the transverse reinforcement, close to the longitudinal bars blocked to the transverse movement by stirrups or ties, as shown in

Figure 2a. Starting from these blocked points the lateral confinement stresses spread towards the inside of the element, both in the plane of the transverse reinforcement and along the longitudinal axis of the member between two subsequent stirrups, as shown in

Figure 2b. The three-dimensional spreading of the confinement stresses defines an effectively confined concrete volume that is smaller than the prismatic volume enclosed by the transverse reinforcement. The ratio between these two volumes provides an index of the effectiveness of confinement called “confinement effectiveness factor” (

ke). Applying this factor to the confinement stresses associated with a uniform confinement, the “effective” values of the confinement stresses are obtained.

To calculate

ke, the evaluation of the effectively confined volume is necessary. In the literature ([

17,

18,

28]), it is commonly accepted that the lateral compressive stresses spread from the blocked points following parabolic arcs with ending tangents at 45° both in the plane of the cross-section and along the longitudinal axis of the member, as shown in

Figure 2a,b. Even though a geometric description of the confined solid is possible, the rigorous calculation of its volume is not straightforward, particularly for complex arrangements of stirrups and ties. A conservative estimate of this volume is obtained by means of the approach introduced by Mander et al. [

17] and currently adopted by standards, by means of two partial confinement effectiveness factors, named α

n and α

s, that embody the effects of confinement in the plane of the cross-section and along the longitudinal axis of the member.

The partial confinement effectiveness factor α

n is calculated in the plane of the cross-section and is the ratio of the area

Ac,n that is effectively confined to the area enclosed by the center line of the stirrups. The factor α

s, instead, is calculated along the longitudinal axis of the member and is the ratio of the effectively confined area to the area enclosed by the center line of the longitudinal bars between two successive stirrups. The cross-sectional area of the effectively confined concrete

Ae is obtained through the following relation as a function of both α

n and α

s, i.e.,

where

Ac is the cross-sectional area of concrete inside the center line of stirrups. The area

Ae is considered constant along the longitudinal axis of the element (where spacing and layout of the stirrups are constant).

To evaluate α

n, let us consider the confinement stresses in the plane of the stirrups, i.e., where the effectively confined area is maximum and calculate the area

Ac,n subtended by the parabolic arcs. If

wi is the inner distance between two adjacent bars blocked by stirrups, the area subtended by the single parabola is obtained through simple geometric considerations: a parabola with a tangent at 45° has a maximum height equal to

wi/4 and an average height equal to 2/3 of the maximum height. The area subtended by the single parabolic arc is therefore:

The area

Ac,n is obtained by subtracting the area subtended by the parabolic arcs from the area enclosed by the center line of the stirrups:

where

w1,i and

w2,i are the distances between adjacent blocked bars in the two directions.

The partial confinement effectiveness factor α

n is obtained dividing

Ac,n by the area enclosed by the center line of the stirrups, i.e.,

To evaluate α

s, let us consider the parabolic arcs between two subsequent stirrups in the direction of the longitudinal axis. At a distance

s′/2 from the stirrups, where

s′ is the inner distance between two successive stirrups, the confined area reduces to the value given by the following relation

Dividing the area

Ac,s by the area enclosed by the centerline of the stirrups, the partial confinement effectiveness factor α

s is obtained:

This expression is the one proposed by Chang and Mander [

18]. A similar expression is reported in Eurocode 8 [

29], where, however, the distances

wi and

s′ are measured from the centroid of the bars and from the centerline of the stirrups, respectively.

4.2. Proposed Volume of Confined Concrete

The procedure set out in the previous section brings the effectively confined volume, defined in three dimensions by the spreading of the confinement stresses, back to a prismatic volume having cross-sectional area

Ae, as described in Equation (10). To investigate the effects of the simplifications reported in Eurocode 8 for the evaluation of this latter cross-sectional area, Vulinovic et al. [

30] have recently calculated the exact value of the above effectively confined concrete volume starting from the geometrical assumptions of Eurocode 8, i.e., assuming that the ends of the parabolic arcs are inclined at an angle of 45°. The rigorous calculation was performed graphically by means of the software Autocad. In particular, the external surface of the effectively confined volume was obtained by translating the parabolic arcs that lie on a cross-section along the longitudinal axis of the member on the parabolic arcs that go from one stirrup to another. The resulting volume obtained by the rigorous calculation was assumed to be the “exact” volume of the effectively confined concrete. Then, the “exact” confinement effectiveness factor was calculated as the ratio of the exact volume of the effectively confined concrete to the volume of the concrete inside the center lines of the stirrups. This exact value of the confinement effectiveness factor was compared with the value of the confinement effectiveness factor calculated according to Eurocode 8. The investigation was conducted on a series of columns with square cross-section characterized by different arrangements of the transverse reinforcement.

The results showed that, in all the considered cases, the analytical evaluation performed according to EC8 led to conservative evaluations of the confinement effectiveness factor, i.e., the value of the confinement effectiveness factor determined by EC8 was always lower than the geometrically rigorous confinement effectiveness factor. Specifically, the “exact” confinement effectiveness factor was, on the average, 32% higher than the factor evaluated according to EC8. This proved that the simplifications that are usually introduced for the evaluation of the confinement effectiveness factor led to a significant underestimation of this factor.

In addition to these observations, it is important to keep in mind that the confinement mechanism is based on the hypothesis that the confinement stresses spread towards the interior of the member following parabolic arcs with tangents at 45°. To the knowledge of the authors, this assumption was introduced by Sheikh and Uzumeri [

28] without any supporting experimental justification. In light of these considerations, the evaluation of the confinement effectiveness factor with the method based on factors α

n and α

s described above appears to be rather penalizing. In line with these conclusions, Ghersi [

31] suggested reducing the subtractive terms of the factor α

n by 2/3 and thus proposed the following relation:

It should be noted that the calculation of the confinement effectiveness factor shown above refers to the case of members subjected to axial force only and thus to members not in a seismic condition. In fact, in the occurrence of earthquakes, columns are always subjected to the combined action of axial force and bending moment and often are cracked because of these internal forces. Beams can even be cracked because of the action of the sole effect of gravity loads. In any case, cracking causes confinement conditions that are different from those in uniformly compressed members. However, in the conventional analysis of structures the confinement effectiveness factor remains equal to the one determined assuming that the section is entirely and uniformly compressed.

More specifically, close to the neutral axis of the cross-section, concrete subjected to low positive strains offers an efficient confinement to the adjacent compressed material, as shown in

Figure 3a. This is valid for both columns and beams. Beams, however, deserve a separate comment owing to their partial embedment in the slab. In fact, if the beam is subjected to positive bending moment and the compressed part of the cross-section falls within the depth of the slab, the concrete in the compressed part of the beam cross-section is confined by the slab. In such cases, a less effective confinement action can occur only on the upper side of the member, as shown in

Figure 3b [

31]. If the bending moment is negative, the concrete subjected to low positive longitudinal strains provides an efficient confinement at the level of the neutral axis; on the remaining sides of the cross-section the confinement effectiveness is governed by the presence of longitudinal bars that are blocked to the lateral movement by stirrups and ties. However, the parabolic arcs on the left and right sides of the beam extend from the longitudinal bars in compression to the intrados of the slab, and not from the longitudinal bars in compression to the longitudinal bars in tension. This determines a lower height of the parabolic arcs that develop on the left and right sides of the cross-section, as shown in

Figure 3c [

31]. Referring to the case of columns, the authors note that the simulation of the response of the specimens on the basis of the confinement effectiveness factors calculated according to Eurocode 8 has revealed the impossibility to reproduce with satisfying accuracy the response of some members, particularly of those with low values of the volumetric ratio of the transverse reinforcement, owing to the low values of the corresponding confinement effectiveness factors.

Based on the above considerations and to the evidence of the numerical simulations, the authors propose here to use (for members subjected to combined axial force and moderate-to-large bending moments) a diffusion angle of the confinement stresses lower than 45° and such as to reduce the height of the parabolic arcs by 50%, compared with the case with a tangent at 45° (the proposed angle is equal to 26.57°). This means considering a similar reduction for the subtractive terms that appear in the expressions of the coefficients α

n and α

s, i.e.,

4.3. Application of Confinement to the Numerical Model

According to the approach proposed by Mander et al. [

17], the properties of the unconfined concrete are assigned to the concrete fibers that fall outside the center line of the outermost stirrups, whereas those determined through the confinement model by means of the effective confinement stresses [Equations (8) and (9)] are assigned to the fibers inside the center line of the outermost stirrups. Thereby, the confinement effectiveness coefficient affects the strength and ductility properties of the entire prismatic volume of concrete inside the center line of the outermost stirrups.

To arrive at a simpler and more accurate description of the confinement mechanism in the column, the authors propose here to apply the mechanical properties of the “uniformly” confined concrete to a part of the concrete fibers that are inside the center line of the outermost stirrups and that are characterized by a total area equal to Ae [see Equation (10)]. This approach is consistent with the geometric meaning of the confinement effectiveness factor.

Virtually, it would be possible to discretize the cross-section so as to reproduce the spreading of the confinement stresses in the cross-section (

Figure 4a). However, as resulting from the numerical analyses, such a level of detail is not advantageous, also because of the inevitable complications in the description of the concrete patches. The solution suggested herein envisages the search for a rectangular perimeter of the “uniformly” confined concrete which is obtained through an offset of the center line of the outermost stirrups (

Figure 4b,c). The distance from the proposed perimeter to the center line of the outermost stirrups is defined as a function of a scale factor β and of the lengths

bc and

hc, as shown in

Figure 4c. The scale factor is obtained equating the area of the new rectangular patch of confined concrete to the area of the rectangle defined by the center lines of the outermost stirrups times the effectiveness confinement factor, i.e.,

Reordering and solving the above equation for β leads to the following relation:

The sign corresponding to the desired solution is the one for which, if ke = 1, the β scale factor is equal to 0, i.e., the minus sign.

5. Modeling of Members

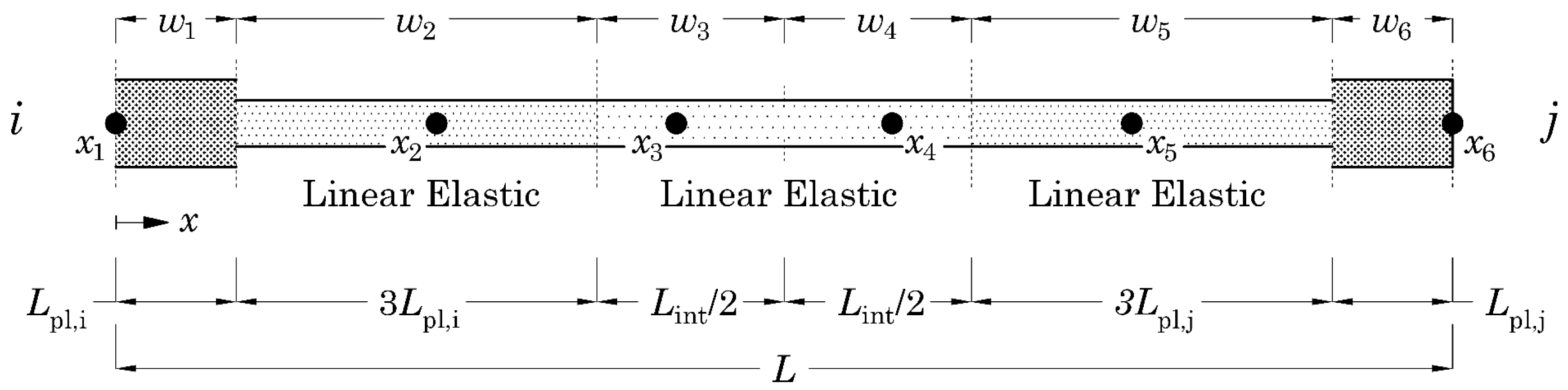

In this research study, the authors have used the forceBeamColumn element implemented in OpenSees with the “HingeRadau” integration rule. The choice of using a model with concentrated plasticity instead of distributed plasticity is justified by the following reasons: (1) In general, in the study of framed buildings in seismic situations, the formation of plastic hinges is expected at the ends of members and is rare in the middle of a member (e.g., beam) and (2) the adoption of a simpler model of a member implies greater computational effectiveness, which translates into a greater numerical stability of the model and higher processing rate.

The formulation of the element used for the analyses was proposed by Scott and Fenves [

32] (Modified Two-Point Gauss Radau) and considers a total of six integration points: while the first and last points fall into the inelastic parts at the ends of the element, the other four points fall into the central elastic section, as shown in

Figure 5. The ending sections have length equal to

Lpl,i and

Lpl,j. The elastic section is further divided into three sub-sections of lengths equal to 3

Lpl,i,

L-4(

Lpl,i+

Lpl,j), and 3

Lpl,j, respectively. The weights corresponding to the integration points 1 and 6 (

x1 = 0,

x6 =

L) are equal to

Lpl,i and

Lpl,j, whereas the weights corresponding to points 2 and 5 (

x2 = 8/3

Lpl,i,

x5 =

L-8/3

Lpl,j) are equal to

3Lpl,i and

3Lpl,j, respectively.

The formulation above was preferred to others since it allows the user to govern the localization of damage in the plastic hinge region by simply adjusting the values of Lpl,i and Lpl,j.

For more details on the formulation of the considered forceBeamColumn element, the readers are invited to refer to reference [

32], as an exhaustive discussion of the subject is beyond the scope of this work.

6. Laboratory Tests

The considered laboratory tests have been selected from the database of the European Union Seventh Framework Program [FP7/2007-2013] [

33]. This database contains data on hundreds of experiments divided by type of RC element (beams, columns and walls). The available information includes (1) geometry of the cross-section, (2) size of the specimen and configuration of the test setup, (3) cross-sectional area and arrangement of the longitudinal and transverse reinforcements, (4) axial force, (5) mechanical properties of concrete and steel, and (6) cyclic force-displacement data recorded during the laboratory test.

The selected specimens are representative of RC columns that are common in existing buildings built between the 1970s and early 2000s. In particular, the authors have selected tests conducted on columns (i.e., members with axial force and symmetric longitudinal reinforcement) with a rectangular cross-section and failing in a flexural mode without slippage of the steel bars. Some other filters were placed (with a few exceptions) on material properties, loading conditions, and geometry. In particular, the compressive strength of concrete fc is in the range from 18 to 48 MPa, the yielding strength of the longitudinal bars fyl is in the range from 313 to 586 MPa, the shear span ratio Lv/h is in the range from 3 to 7.6; the diameter of the bars is in the range from 14 mm to 20 mm and the normalized axial force ν is in the range from 0 to 0.77.

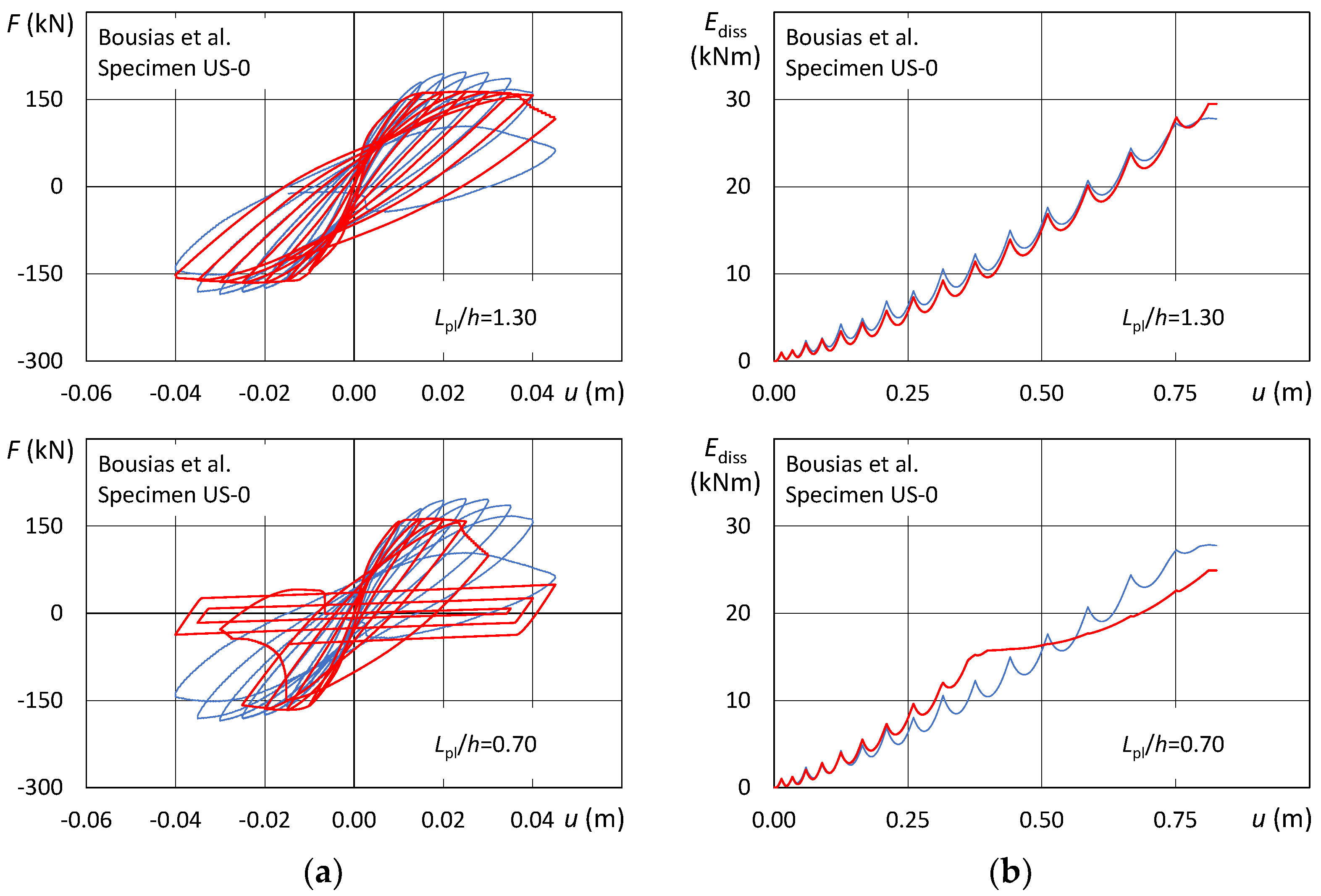

As a result, a total of 33 tests were selected from the following research: Bousias et al. [

34,

35], Saatcioglu and Ozcebe [

36], Saatcioglu and Grira [

37], Sheikh and Khoury [

38], Kanda et al. [

39], Ohno and Nishioka [

40], Lukkunaprasit and Sittipunt [

41], and Matamoros [

42].

Table 1 summarizes the tests selected together with the main geometric and mechanical characteristics of the specimens, including the geometric percentage of the volumetric ratio of the transverse reinforcement ρ

vol,

st and the geometric ratio of the longitudinal reinforcement ρ

s,tot.

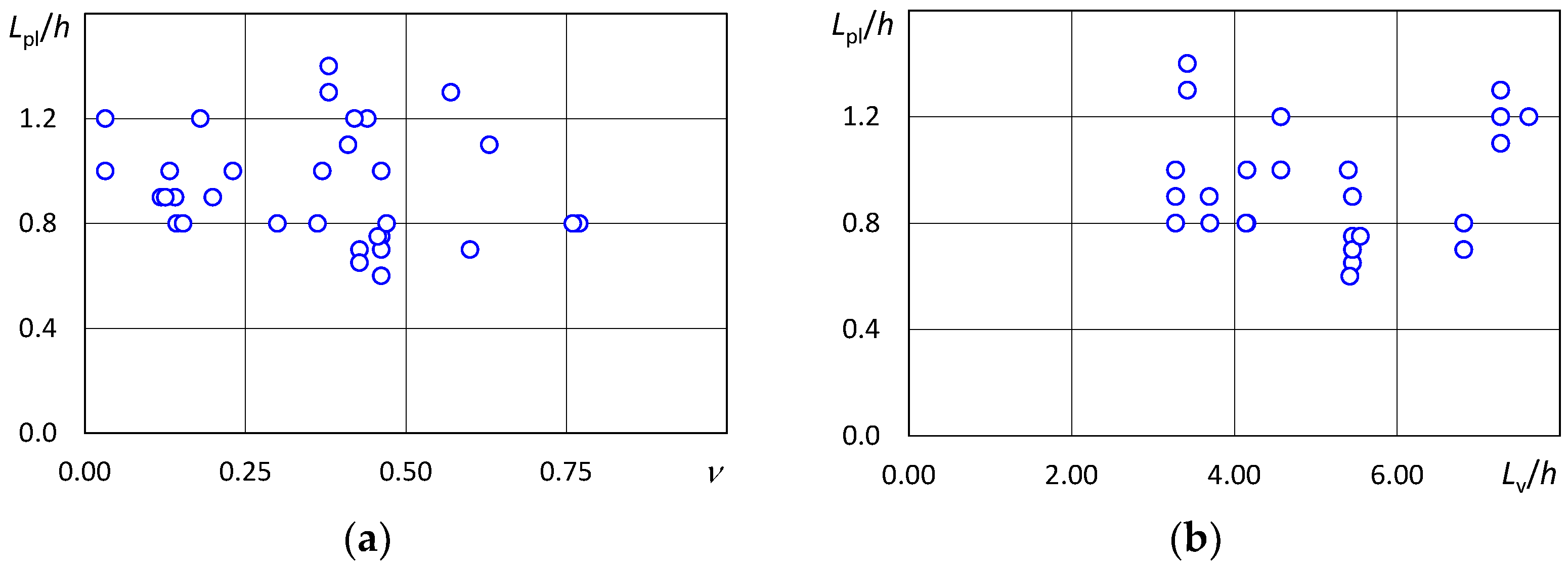

9. Proposed Expression of the Length of the Plastic Hinge

To propose a relation for the determination of the length of the plastic hinge, the values of

Lpl obtained through calibration have been plotted as a function of the main geometric and mechanical parameters of the specimens. First, the dependence of

Lpl on the normalized axial force ν has been investigated. Among the selected tests, the values of ν (0.0 ÷ 0.77) vary in a wide range of values and this should be sufficient to identify any possible dependence of

Lpl on ν. However, the plot of the normalized length of the plastic hinge

Lpl/

h versus ν, reported in

Figure 8a, does not show a clear trend. Equally dispersed are also the points that represent

Lpl/

h as a function of the shear span ratio

LV/

h of the specimen, as shown in

Figure 8b. The trend of

Lpl/

h as a function of the compressive strength of the concrete

fc seems to reveal an inverse proportionality relationship, as shown in

Figure 8c. However, the authors of the present paper believe that the values of the compressive strength considered here, with a single exception, vary in a narrow range (i.e., 18-40 MPa) and do not allow general and reliable conclusions. On the other hand, for the considered specimens,

Lpl/

h does not show any appreciable trend as a function of the yield strength of the longitudinal steel bars

fyl, as shown in

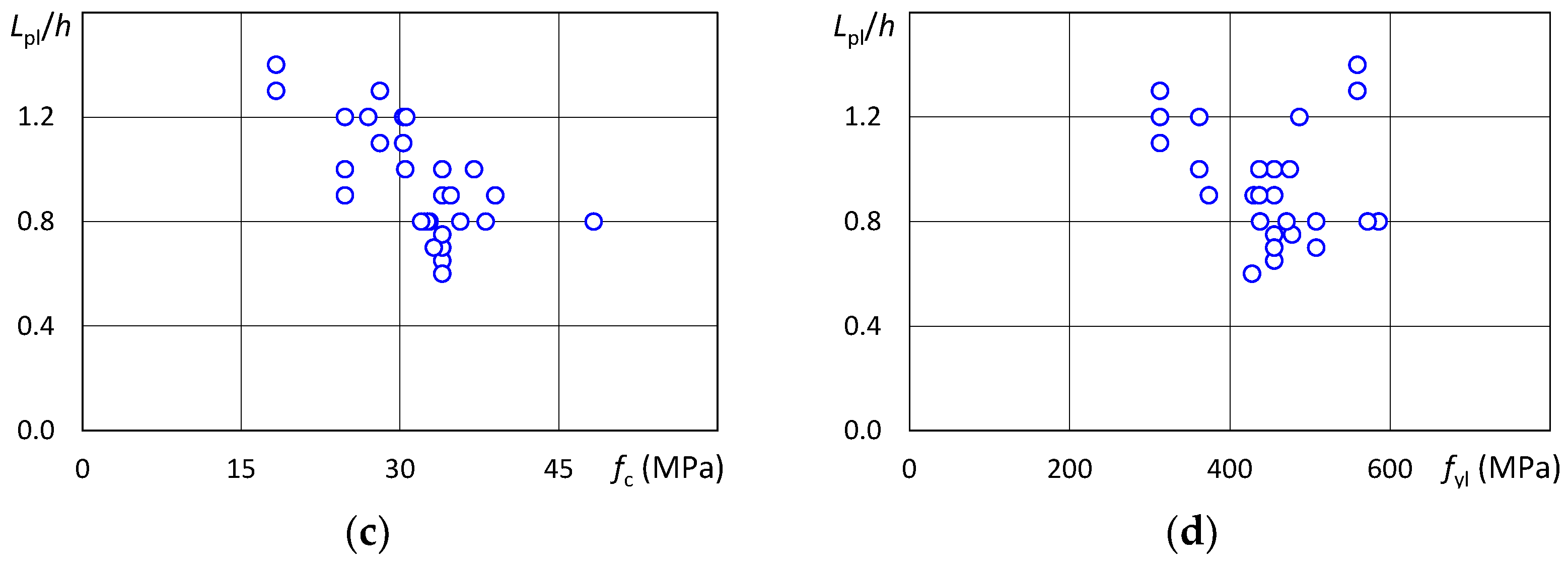

Figure 8d. Finally, the optimal length of the plastic hinge

Lpl/

h is represented as a function of ρ

vol,st by blue circles in

Figure 9. In this case, an inverse proportionality relationship is evident between

Lpl/

h and ρ

vol,st. In particular, for values of ρ

vol,st between 0.50% and 1.50%, the value of

Lpl/

h varies from a maximum value of about 1.50 up to about 0.70. The value of

Lpl/

h remains almost constant for ρ

vol,st greater than 2.00%. This trend is effectively interpreted through a power function of the type:

where the values of the coefficients

a,

b and

c have been obtained through an optimization procedure performed using the Excel Solver. Specifically, starting from tentative values of

a,

b, and

c, the optimization procedure searches for a combination of the three coefficients which minimizes the sum of the squares of the differences between the optimal values of

Lpl/

h and the predicted values. In order to consider more mathematical solutions, the optimization procedure has been repeated 20 times with different tentative values. Based on the values of

a,

b, and

c giving the optimal solutions, the following formula is proposed:

Coefficient “c” resulting from the optimization process was always negligible and then has been assumed equal to zero in the proposed equation. Further, it has been chosen to limit the proposed value of

Lpl/

h to 1.40 from above and to 0.70 from below. These limitations come into play for values of ρ

vol,st lower than 0.33% and greater than 2.41%, respectively.

Figure 9 shows the prediction of the optimal values of

Lpl/

h in the range of values of ρ

vol,st of practical interest.

10. Conclusions

This paper deals with the problem of numerical modeling of members of existing reinforced concrete buildings and specifically with two crucial aspects in modeling of reinforced concrete members: (1) the application of the confinement model to RC members and (2) the calibration of the length of the plastic hinge. Both issues have been treated to achieve accuracy of response, numerical stability, and computational efficiency.

The proposed numerical model uses the element with concentrated plasticity proposed by Scott and Fenves [

32]. The uniaxial material model considered for concrete is named “Concrete04” in Opensees whereas the uniaxial material model considered for the longitudinal bars is named “ReinforcingSteel”.

The value of the plastic hinge length that leads to the best prediction of the cyclic response of laboratory tests available in the literature has been determined. The examined specimens are representative of reinforced concrete columns of existing buildings built between the 1970s and early 2000s. In particular, the authors have selected tests conducted on columns with rectangular cross-section and failing in a flexural mode without slipping of steel bars. In most cases, the shear span ratio of the specimens is in the range from 3 to 6 and the normalized axial force is in the range from 0.2 to 0.4. The average compressive strength of concrete is in the range from 20 to 40 MPa and the yielding strength of the longitudinal bars is in the range from 350 to 500 MPa.

The main conclusions of the study are here reported:

- -

The confinement effectiveness factor calculated according to Eurocode 8 penalizes the response of RC columns, particularly those with low values of the volumetric ratio of the transverse reinforcement. The authors have proposed a less restrictive volume of confined concrete, in addition to a fiber discretization technique that is consistent with the geometric meaning of the confinement effectiveness factor.

- -

A simple relation has been proposed to calculate the optimum length of the plastic hinge of the numerical element with concentrated plasticity. The optimum length of the plastic hinge decreases with the increase of the volumetric ratio of the transverse reinforcement and ranges from 0.7 to 1.4 times the depth of the cross-section.

The conclusions are drawn based on a set of specimens with moderate variation of the geometric and mechanical properties of the materials in order to represent the response of usual members of existing reinforced concrete buildings. A greater number of laboratory tests will be considered in the future to extend the proposed modeling to a broader range of the considered parameters.