Mixture Optimization of Sustainable Concrete with Silica Fume Considering CO2 Emissions and Cost

Abstract

1. Introduction

2. Materials and Methods

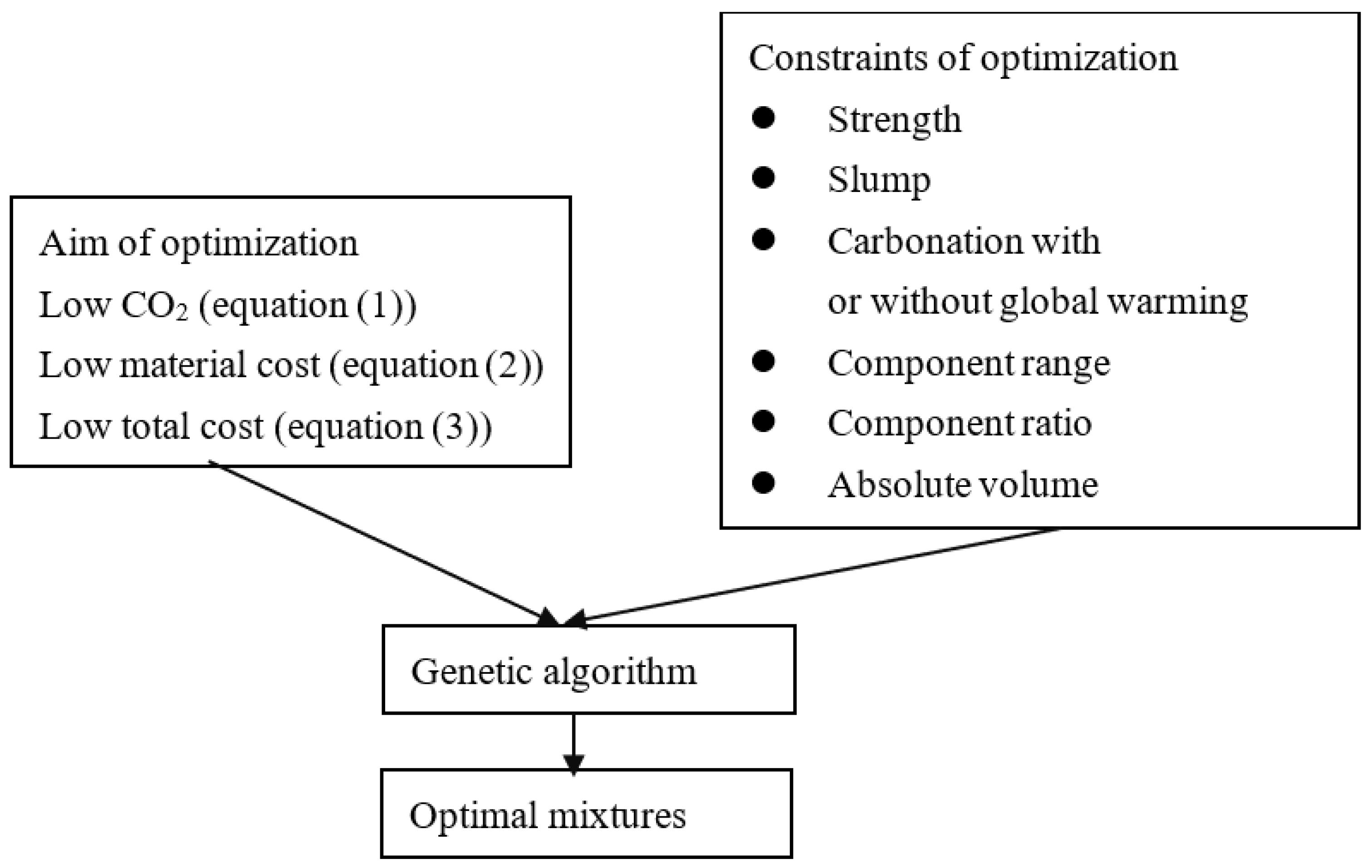

2.1. Aim of Mixture Design

2.2. Constraints of Mixture Design

- (1)

- The mixture design of concrete is subject to numerous constraints, e.g., the component range of concrete, ratio among concrete components, strength, slump, absolute volume, and carbonation durability [27].

- (2)

- The component range of concrete positions the mass of concrete components within an upper mass boundary and lower mass boundary, expressed as follows [27]:

- (3)

- The ratio of concrete components, e.g., water/binder ratio, sand/aggregate ratio, SF/binder ratio, water/solid ratio, and aggregate/binder ratio should also be positioned within upper and lower boundaries, expressed as follows:

- (4)

- The strength constraint ensures that the actual strength exceeds the projected strength, expressed as follows:

- (5)

- The slump constraint ensures that the actual slump exceeds the projected slump, expressed as follows for SF-modified concrete:

- (6)

- (7)

- For SF-modified concrete, the carbonation depth increases with SF content. Hence, carbonation durability may limit the use of SF in the concrete industry. This can be expressed as follows:

2.3. Genetic Algorithm

3. Results and Discussion

3.1. Case 1: Low-CO2 Concrete without Carbonation

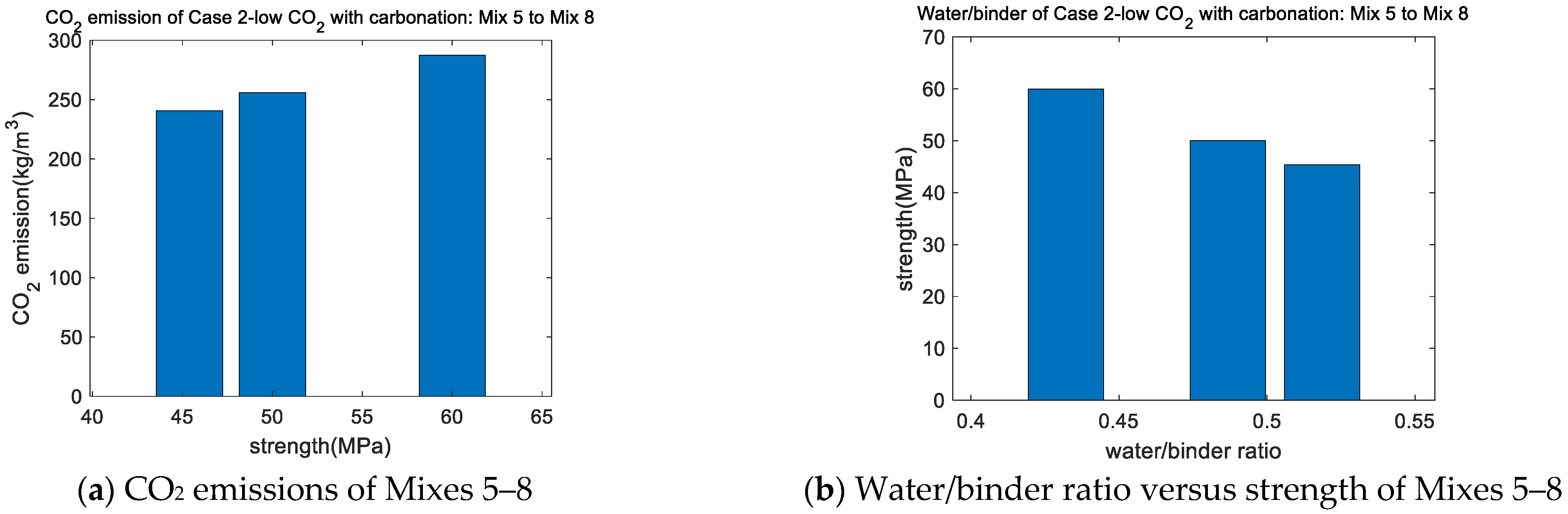

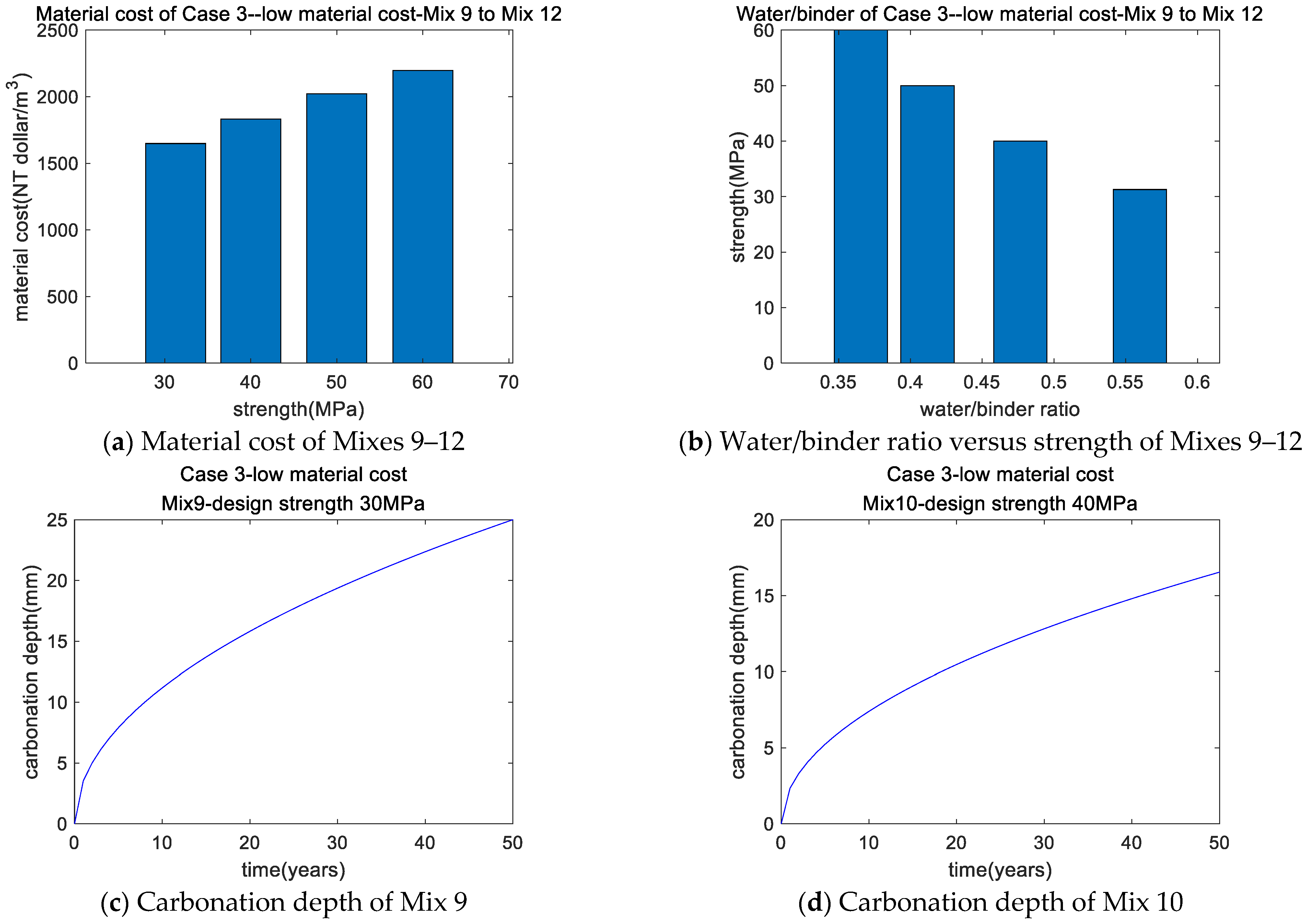

3.2. Case 2: Low-CO2 Concrete with Carbonation

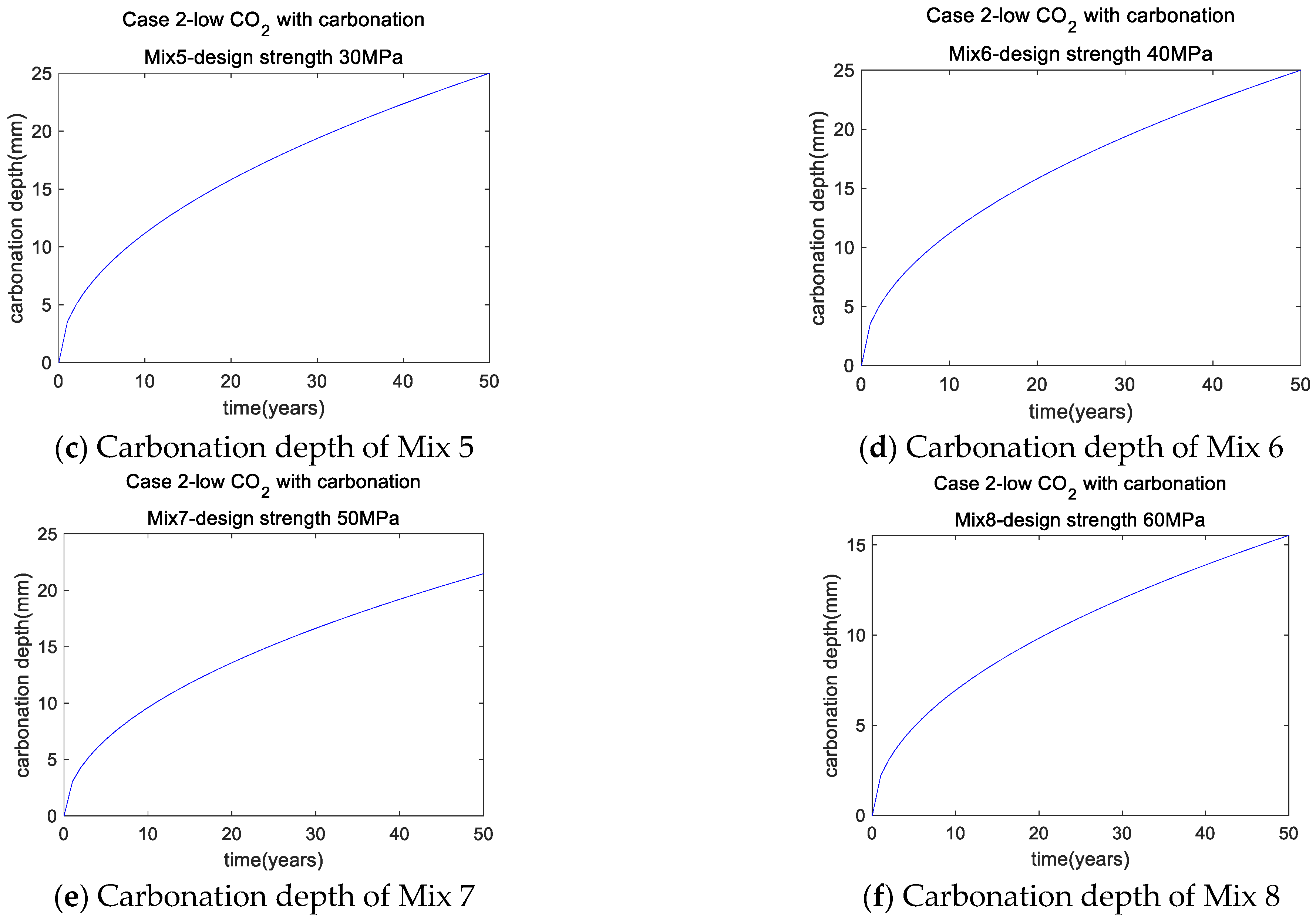

3.3. Case 3: Low-Material-Cost Concrete with Carbonation

3.4. Case 4: Low-Total-Cost Concrete with Carbonation

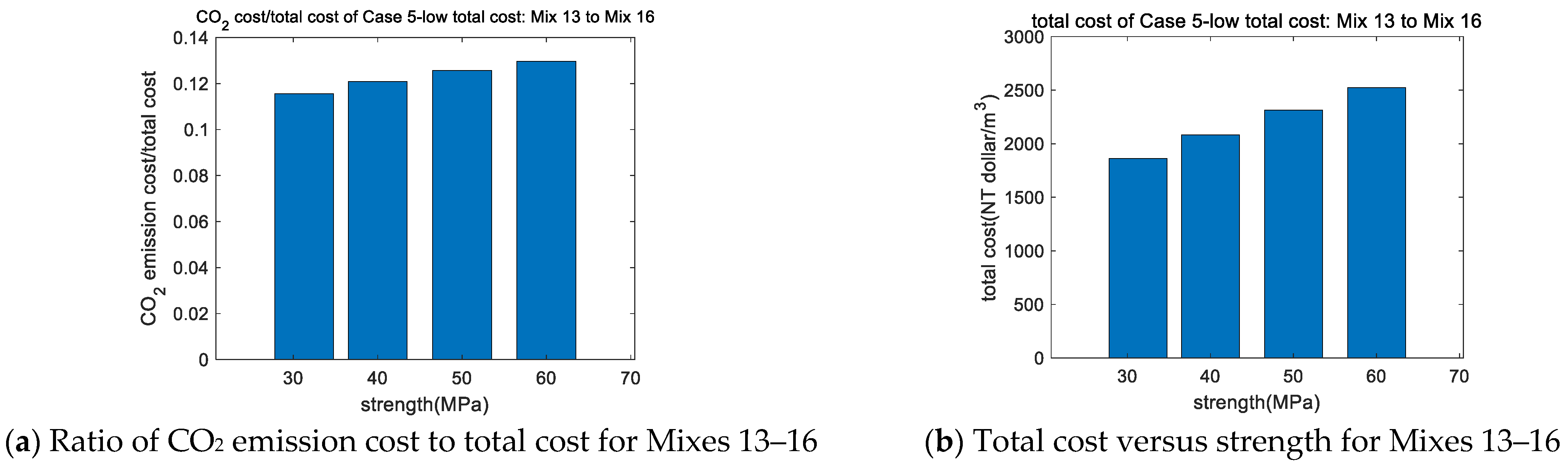

3.5. Case 5: Low-Total-Cost Concrete with Global Warming

3.6. Discussion

4. Conclusions

- (1)

- Case 1 (low-CO2 concrete without carbonation) showed that the carbonation durability constraint could be fulfilled for high-strength concrete (Mixes 3 and 4, 50 MPa and 60 MPa, respectively) but not ordinary-strength concrete (Mixes 1 and 2, 30 MPa and 40 MPa, respectively). For all mixes, the SF/binder ratio was toward the upper limit due to the substantially lower CO2 emissions of SF than cement.

- (2)

- Case 2 (low-CO2 concrete with carbonation) showed variations in the actual strength of ordinary-strength concrete with respect to their design strength (Mixes 5 and 6, 45.39 MPa for both), suggesting that carbonation dominated the mixture design. Thus, to satisfy the carbonation durability, greater actual strength can be obtained. On the other hand, no such influence was found on high-strength concrete (Mixes 7 and 8).

- (3)

- Case 3 (low-material-cost concrete with carbonation) revealed that the SF/binder ratio was toward the lower limit for Mixes 9–12, due to the greater material price of SF compared to cement. Additionally, for Mix 9, the actual strength (31.28 MPa) was greater than the design strength (30 MPa), suggesting that carbonation dominated the mixture design. After 50 years of service life, the carbonation depth of Mix 9 was equal to the cover depth.

- (4)

- Case 4 (low-total-cost concrete with carbonation) revealed similar results for Mixes 13–16 to those for Mixes 9–12, respectively, as the cost of CO2 emissions (12% of total cost) was substantially less than the material cost and, thus, did not influence the outcome.

- (5)

- Case 5 (low-total-cost concrete with carbonation and global warming) showed that, for Mix 17 (design strength of 30 MPa), global warming led to an increase in actual strength from 31.28 to 33.44 MPa. Thus, to fulfill the constraints of carbonation with global warming, a greater binder content or greater strength ought to be used. However, global warming was not found to influence the mixture design of higher-strength concretes (40, 50, and 60 MPa).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variable | Definition |

| CO2 emission of concrete | |

| CO2 emission of 1 kg of cement | |

| CO2 emission of 1 kg of silica fume | |

| CO2 emission of 1 kg of water | |

| CO2 emission of 1 kg of sand | |

| CO2 emission of 1 kg of coarse aggregate | |

| CO2 emission of 1 kg of superplasticizer | |

| Mass of cement | |

| Mass of silica fume | |

| Mass of water | |

| Mass of sand | |

| Mass of coarse aggregate | |

| Mass of superplasticizer | |

| Cost of materials | |

| Unit cost of cement | |

| Unit cost of silica fume | |

| Unit cost of water | |

| Unit cost of sand | |

| Unit cost of coarse aggregate | |

| Unit cost of superplasticizer | |

| Unit cost of CO2 emission | |

| cost of CO2 emission | |

| Total cost of concrete (sum of material and CO2 emission) | |

| 28 days strength of concrete | |

| Design strength of concrete | |

| Slump of concrete | |

| Design slump of concrete | |

| Density of water | |

| Density of cement | |

| Density of silica fume | |

| Density of coarse aggregate | |

| Density of sand | |

| Density of superplasticizer | |

| Volume of entrapped air | |

| Carbonation depth | |

| Cover depth | |

| CO2 concentration | |

| Time | |

| CO2 diffusivity | |

| Relative humidity | |

| Reference temperature (293 K) | |

| Environmental temperature | |

| Degree of hydration | |

| Temperature sensitivity factor of CO2 diffusion | |

| Time-averaged CO2 concentration | |

| Time-averaged CO2 diffusivity |

References

- Khatib, J.M.; Jahami, A.; Elkordi, A.; Abdelgader; Sonebi, M. Structural Assessment of Reinforced Concrete Beams Incorporating Waste Plastic Straws. Environments 2020, 7, 96–110. [Google Scholar] [CrossRef]

- Sulthan, S.T.; Anjaiah, Y. A Study on Efficiency Factor of Silica Fume. Int. J. Mod. Trends Sci. Technol. 2018, 4, 55–62. [Google Scholar]

- Ahmad, S.; Umar, A.; Masood, A.; Nayeem, M. Performance of self-compacting concrete at room and after elevated temperature incorporating Silica fume. Adv. Concr. Constr. 2019, 7, 31–37. [Google Scholar] [CrossRef]

- Abdulkareem, O.M.; Ben Fraj, A.; Bouasker, M.; Khelidj, A. Mixture design and early age investigations of more sustainable UHPC. Constr. Build. Mater. 2018, 163, 235–246. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, S.H.; Shi, Y.; Tang, S.W.; Chen, E. Effect of silica fume and PVA fiber on the abrasion resistance and volume stability of concrete. Compos. Part B Eng. 2017, 130, 28–37. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Wu, Y.; Zhou, Y.; Tang, S. Hydration, shrinkage, pore structure and fractal dimension of silica fume modified low heat Portland cement-based materials. Constr. Build. Mater. 2021, 272, 121952. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.; Zheng, J.; Wang, J.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Bajja, Z.; Dridi, W.; Darquennes, A.; Bennacer, R.; Le Bescop, P.; Rahim, M. Influence of slurried silica fume on microstructure and tritiated water diffusivity of cement pastes. Constr. Build. Mater. 2017, 132, 85–93. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M. Carbonation of cement paste: Understanding, challenges, and opportunities. Constr. Build. Mater. 2016, 117, 285–301. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Akalin, O. Eco-Cement Optimization Using Statistical Mixture Design Method. ACI Mater. J. 2014, 111, 391–398. [Google Scholar] [CrossRef]

- Khaloo, A.R.; Karimi, H.; Asadollahi, S.; Dehestani, M. A New Mixture Design Method for Ultra-High-Strength Concrete. ACI Mater. J. 2017, 114, 215–224. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. Statistical mixture design approach for eco-efficient UHPC. Cem. Concr. Compos. 2015, 55, 17–25. [Google Scholar] [CrossRef]

- Naseri, H.; Jahanbakhsh, H.; Hosseini, P.; Moghadas Nejad, F. Designing sustainable concrete mixture by developing a new machine learning technique. J. Clean. Prod. 2020, 258, 120578. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A. Estimating the optimal mix design of silica fume concrete using biogeography-based programming. Cem. Concr. Compos. 2019, 96, 95–105. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Ma, G.; Nener, B. Mixture optimization for environmental, economical and mechanical objectives in silica fume concrete: A novel frame-work based on machine learning and a new meta-heuristic algorithm. Resour. Conserv. Recycl. 2021, 167, 105395. [Google Scholar] [CrossRef]

- Papadakis, V.G. Experimental investigation and theoretical modeling of silica fume activity in concrete. Cem. Concr. Res. 1999, 29, 79–86. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Tsimas, S. Supplementary cementing materials in concrete-Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Park, H.S.; Kwon, B.; Shin, Y.; Kim, Y.; Hong, T.; Choi, S.W. Cost and CO2 Emission Optimization of Steel Reinforced Concrete Columns in High-Rise Buildings. Energies 2013, 6, 5609–5624. [Google Scholar] [CrossRef]

- Stewart, M.G.; Wang, X.; Nguyen, M.N. Climate change adaptation for corrosion control of concrete infrastructure. Struct. Saf. 2012, 35, 29–39. [Google Scholar] [CrossRef]

- Lee, H.-S.; Lim, S.-M.; Wang, X.-Y. Optimal Mixture Design of Low-CO2 High-Volume Slag Concrete Considering Climate Change and CO2 Uptake. Int. J. Concr. Struct. Mater. 2019, 13, 56. [Google Scholar] [CrossRef]

- Lee, H.-S.; Wang, X.-Y. Hydration Model and Evaluation of the Properties of Calcined Hwangtoh Binary Blends. Int. J. Concr. Struct. Mater. 2021, 15, 11. [Google Scholar] [CrossRef]

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Sung-Ho, T. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Yeh, I.-C. Computer-aided design for optimum concrete mixtures. Cem. Concr. Compos. 2007, 29, 193–202. [Google Scholar] [CrossRef]

- Yeh, I.-C. Optimization of concrete mix proportioning using a flattened simplex–centroid mixture design and neural networks. Eng. Comput. 2009, 25, 179–190. [Google Scholar] [CrossRef]

- Babu, K.G.; Prakash, P.V.S. Efficiency of silica fume in concrete. Cem. Concr. Res. 1995, 25, 1273–1283. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E.H. Influence of silica fume on the workability and the compressive strength of high-performance concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Lim, C.-H.; Yoon, Y.-S.; Kim, J.-H. Genetic algorithm in mix proportioning of high-performance concrete. Cem. Concr. Res. 2004, 34, 409–420. [Google Scholar] [CrossRef]

- Kadri, E.H.; Aggoun, S.; De Schutter, G. Interaction between C3A, silica fume and naphthalene sulphonate superplasticiser in high performance concrete. Constr. Build. Mater. 2009, 23, 3124–3128. [Google Scholar] [CrossRef]

- Bilal, H.; Chen, T.; Ren, M.; Gao, X.; Su, A. Influence of silica fume, metakaolin & SBR latex on strength and durability performance of pervious concrete. Constr. Build. Mater. 2021, 275, 122124. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, T.; Gao, X. Incorporation of self-ignited coal gangue in steam cured precast concrete. J. Clean. Prod. 2021, 292, 126004. [Google Scholar] [CrossRef]

- CEN. Eurocode 2: Design of Concrete Structures; British Standards Institution: London, UK, 2006. [Google Scholar]

- Kwon, S.J.; Na, U.J.; Park, S.S.; Jung, S.H. Service life prediction of concrete wharves with early-aged crack: Probabilistic approach for chloride diffusion. Struct. Saf. 2009, 31, 75–83. [Google Scholar] [CrossRef]

| Cement | Silica Fume | Water | Coarse Aggregate | Fine Aggregate | Superplasticizer | |

|---|---|---|---|---|---|---|

| CO2 emissions (kg/kg) | 0.83 | 0.00031 | 0.000196 | 0.0075 | 0.0026 | 0.25 |

| Cost (TWD/kg) | 2.25 | 22.5 | 0.01 | 0.30 | 0.25 | 25.1 |

| Density (kg/m3) | 3150 | 2200 | 1000 | 2540 | 2600 | 1200 |

| Cement | Silica Fume | Water | Coarse Aggregate | Fine Aggregate | |

|---|---|---|---|---|---|

| Lower mass boundary | 50 | 0 | 120 | 780 | 600 |

| Upper mass boundary | 540 | 300 | 250 | 1150 | 1100 |

| Water/Binder | SF/Binder | Sand/Aggregate | Aggregate/Binder | Water/Solid | |

|---|---|---|---|---|---|

| Low ratio boundary | 0.25 | 0.05 | 0.40 | 2.7 | 0.08 |

| Upper ratio boundary | 0.85 | 0.15 | 0.52 | 8.4 | 0.12 |

| Cases | Mixtures | Aim | Carbonation Constraint | Design Strength |

|---|---|---|---|---|

| Case 1 | Mixes 1–4 | Low CO2 | No carbonation | 30, 40, 50, 60 MPa |

| Case 2 | Mixes 5–8 | Low CO2 | Carbonation | 30, 40, 50, 60 MPa |

| Case 3 | Mixes 9–12 | Low material cost | Carbonation | 30, 40, 50, 60 MPa |

| Case 4 | Mixes 13–16 | Low total cost | Carbonation | 30, 40, 50, 60 MPa |

| Case 5 | Mixes 17–20 | Low total cost | Carbonation with global warming | 30, 40, 50, 60 MPa |

| Highlighted Point | Comparison |

|---|---|

| Carbonation | Case 1 to Case 2 |

| Difference between low-CO2 and low-material-cost concrete | Case 2 to Case 3 |

| Difference between low-material-cost and low-total-cost concrete | Case 3 to Case 4 |

| Global warming | Case 4 to Case 5 |

| Cement | SF | Water | Fine Aggregate | Coarse Aggregate | Superplasticizer | |

|---|---|---|---|---|---|---|

| Mix 1 | 210.30 | 37.11 | 168.23 | 964.87 | 890.65 | 7.66 |

| Mix 2 | 254.16 | 44.85 | 168.43 | 939.33 | 867.07 | 9.41 |

| Mix 3 | 294.56 | 51.98 | 168.68 | 916.24 | 845.76 | 10.57 |

| Mix 4 | 332.42 | 58.66 | 168.95 | 894.83 | 826.00 | 11.39 |

| Strength (MPa) | Slump (mm) | CO2 Emissions (kg/m3) | Carbonation Depth (mm) | Water/Binder Ratio | SF/Binder Ratio | Water/Solid Ratio | |

|---|---|---|---|---|---|---|---|

| Mix 1 | 30.00 | 261.11 | 185.69 | 43.07 | 0.68 | 0.15 | 0.08 |

| Mix 2 | 40.00 | 239.22 | 222.30 | 30.01 | 0.56 | 0.15 | 0.08 |

| Mix 3 | 50.00 | 225.02 | 255.90 | 21.47 | 0.49 | 0.15 | 0.08 |

| Mix 4 | 60.00 | 214.98 | 287.33 | 15.53 | 0.43 | 0.15 | 0.08 |

| Cement | SF | Water | Fine Aggregate | Coarse Aggregate | Superplasticizer | |

|---|---|---|---|---|---|---|

| Mix 5 | 276.31 | 48.76 | 168.56 | 926.63 | 855.35 | 10.09 |

| Mix 6 (Mix 5) | 276.31 | 48.76 | 168.56 | 926.63 | 855.35 | 10.09 |

| Mix 7 | 294.56 | 51.98 | 168.68 | 916.24 | 845.76 | 10.57 |

| Mix 8 | 332.42 | 58.66 | 168.95 | 894.83 | 826.00 | 11.39 |

| Strength (MPa) | Slump (mm) | CO2 Emissions (kg/m3) | Carbonation Depth (mm) | Water/Binder Ratio | SF/Binder Ratio | |

|---|---|---|---|---|---|---|

| Mix 5 | 45.39 | 230.90 | 240.73 | 25.00 | 0.52 | 0.15 |

| Mix 6 | 45.39 | 230.90 | 240.73 | 25.00 | 0.52 | 0.15 |

| Mix 7 | 50.00 | 225.02 | 255.90 | 21.47 | 0.49 | 0.15 |

| Mix 8 | 60.00 | 214.98 | 287.33 | 15.53 | 0.43 | 0.15 |

| Cement | SF | Water | Fine Aggregate | Coarse Aggregate | Superplasticizer | |

|---|---|---|---|---|---|---|

| Mix 9 | 287.79 | 15.15 | 169.60 | 944.90 | 872.21 | 6.40 |

| Mix 10 | 338.99 | 17.84 | 170.08 | 919.96 | 849.19 | 7.25 |

| Mix 11 | 393.54 | 20.71 | 170.62 | 893.61 | 824.87 | 7.91 |

| Mix 12 | 444.78 | 23.41 | 171.15 | 868.99 | 802.14 | 8.38 |

| Strength (MPa) | Slump (mm) | Material Cost (TWD/m3) | Carbonation Depth (mm) | Water/Binder Ratio | SF/binder Ratio | |

|---|---|---|---|---|---|---|

| Mix 9 | 31.28 | 243.11 | 1648.56 | 25.00 | 0.56 | 0.05 |

| Mix 10 | 40.00 | 227.42 | 1832.50 | 16.55 | 0.48 | 0.05 |

| Mix 11 | 50.00 | 215.44 | 2022.50 | 10.34 | 0.41 | 0.05 |

| Mix 12 | 60.00 | 207.06 | 2197.35 | 7.73 | 0.37 | 0.05 |

| Cement | SF | Water | Fine Aggregate | Coarse Aggregate | Superplasticizer | |

|---|---|---|---|---|---|---|

| Mix 13 (Mix 9) | 287.79 | 15.15 | 169.60 | 944.90 | 872.21 | 6.40 |

| Mix 14 (Mix 10) | 338.99 | 17.84 | 170.08 | 919.96 | 849.19 | 7.25 |

| Mix 15 (Mix 11) | 393.54 | 20.71 | 170.62 | 893.61 | 824.87 | 7.91 |

| Mix 16 (Mix 12) | 444.78 | 23.41 | 171.15 | 868.99 | 802.14 | 8.38 |

| Cement | SF | Water | Fine Aggregate | Coarse Aggregate | Superplasticizer | |

|---|---|---|---|---|---|---|

| Mix 17 | 300.83 | 15.83 | 169.72 | 938.52 | 866.33 | 6.64 |

| Mix 18 (Mix 10) | 338.99 | 17.84 | 170.08 | 919.96 | 849.19 | 7.25 |

| Mix 19 (Mix 11) | 393.54 | 20.71 | 170.62 | 893.61 | 824.87 | 7.91 |

| Mix 20 (Mix 12) | 444.78 | 23.41 | 171.15 | 868.99 | 802.14 | 8.38 |

| Strength (MPa) | Slump (mm) | Total Cost (TWD/m3) | Carbonation Depth (mm) | Water/Binder Ratio | SF/Binder Ratio | |

|---|---|---|---|---|---|---|

| Mix 17 | 33.44 | 238.58 | 1920.72 | 25.00 | 0.54 | 0.05 |

| Mix 18 | 40.00 | 227.42 | 2084.45 | 18.35 | 0.48 | 0.05 |

| Mix 19 | 50.00 | 215.44 | 2313.43 | 11.47 | 0.41 | 0.05 |

| Mix 20 | 60.00 | 207.06 | 2524.89 | 8.58 | 0.37 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-S.; Cho, H.-K.; Wang, X.-Y. Mixture Optimization of Sustainable Concrete with Silica Fume Considering CO2 Emissions and Cost. Buildings 2022, 12, 1580. https://doi.org/10.3390/buildings12101580

Wang Y-S, Cho H-K, Wang X-Y. Mixture Optimization of Sustainable Concrete with Silica Fume Considering CO2 Emissions and Cost. Buildings. 2022; 12(10):1580. https://doi.org/10.3390/buildings12101580

Chicago/Turabian StyleWang, Yi-Sheng, Hyeong-Kyu Cho, and Xiao-Yong Wang. 2022. "Mixture Optimization of Sustainable Concrete with Silica Fume Considering CO2 Emissions and Cost" Buildings 12, no. 10: 1580. https://doi.org/10.3390/buildings12101580

APA StyleWang, Y.-S., Cho, H.-K., & Wang, X.-Y. (2022). Mixture Optimization of Sustainable Concrete with Silica Fume Considering CO2 Emissions and Cost. Buildings, 12(10), 1580. https://doi.org/10.3390/buildings12101580