Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK)

Abstract

:1. Introduction

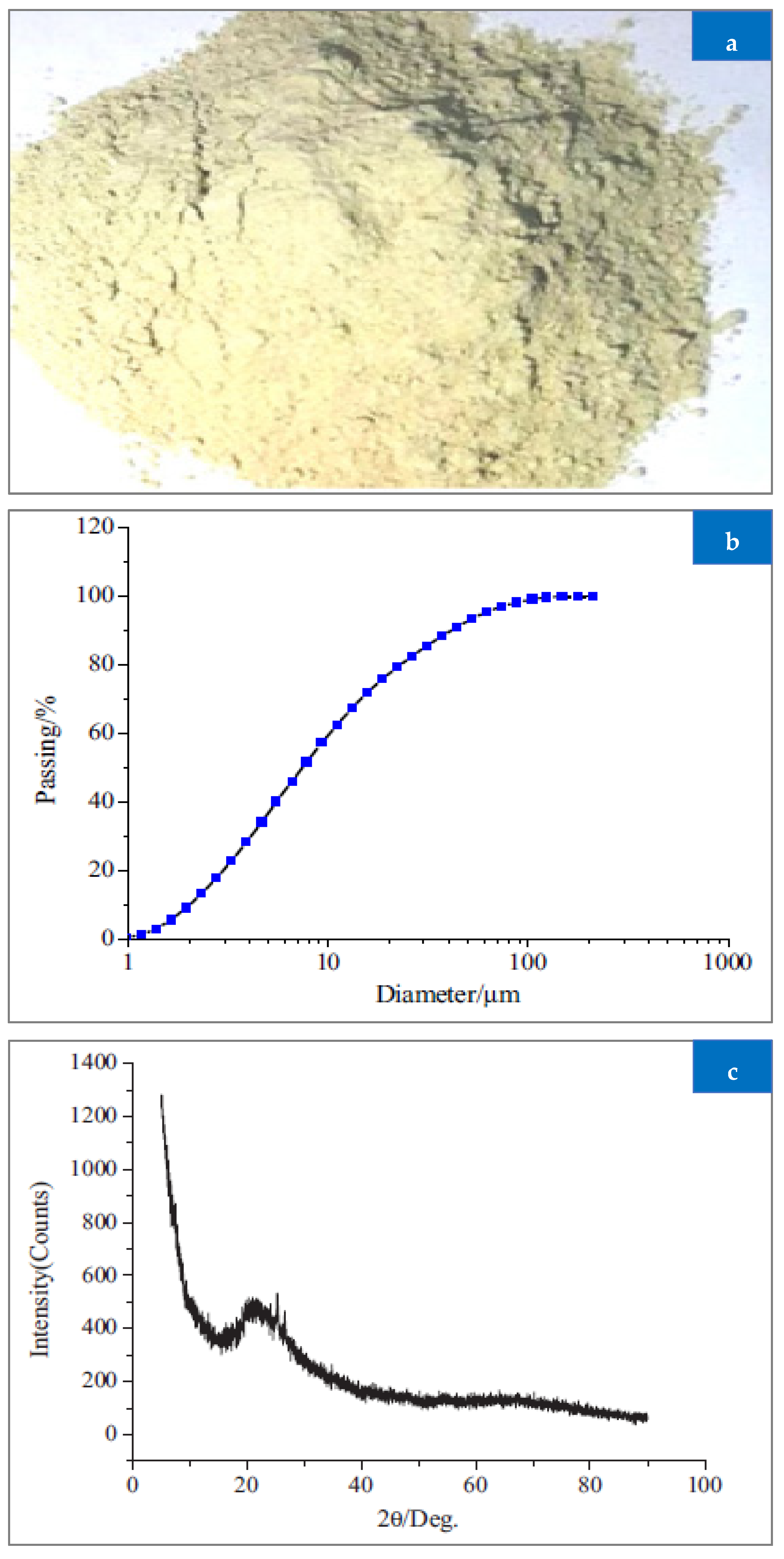

2. Physical Properties

| Reference | [38] | [39] | [40] | [41] | [42] |

|---|---|---|---|---|---|

| Specific gravity | 2.5 | 2.62 | 2.5 | 2.5 | 2.5 |

| Fineness cm2/g | 14,600 | - | 10,200 | - | 12,800 |

| Moisture Content (%) | - | - | - | - | - |

| Specific surface area, (m2/kg) | - | 12,680 | - | 458 | - |

3. Fresh Properties

Workability

4. Mechanical Strength

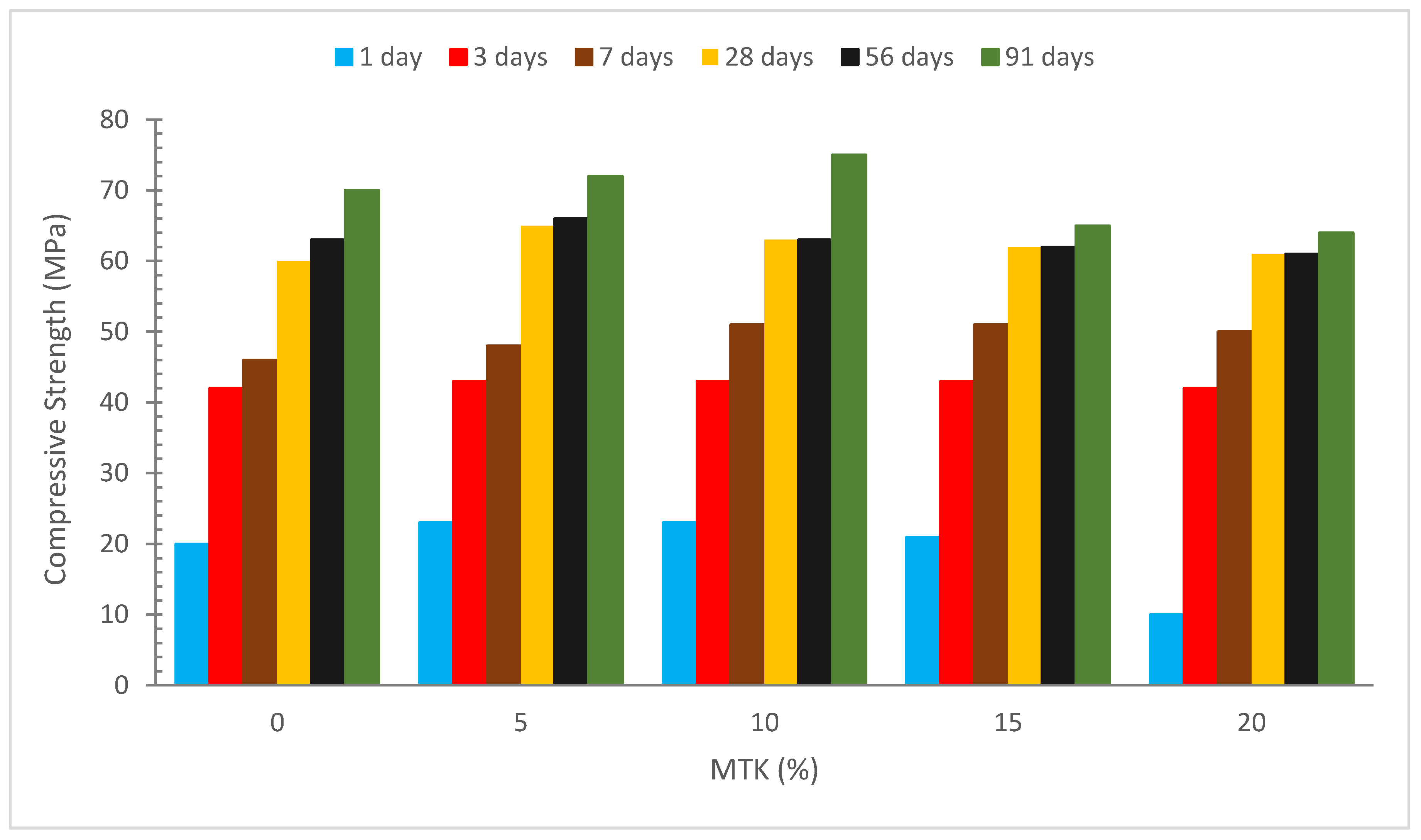

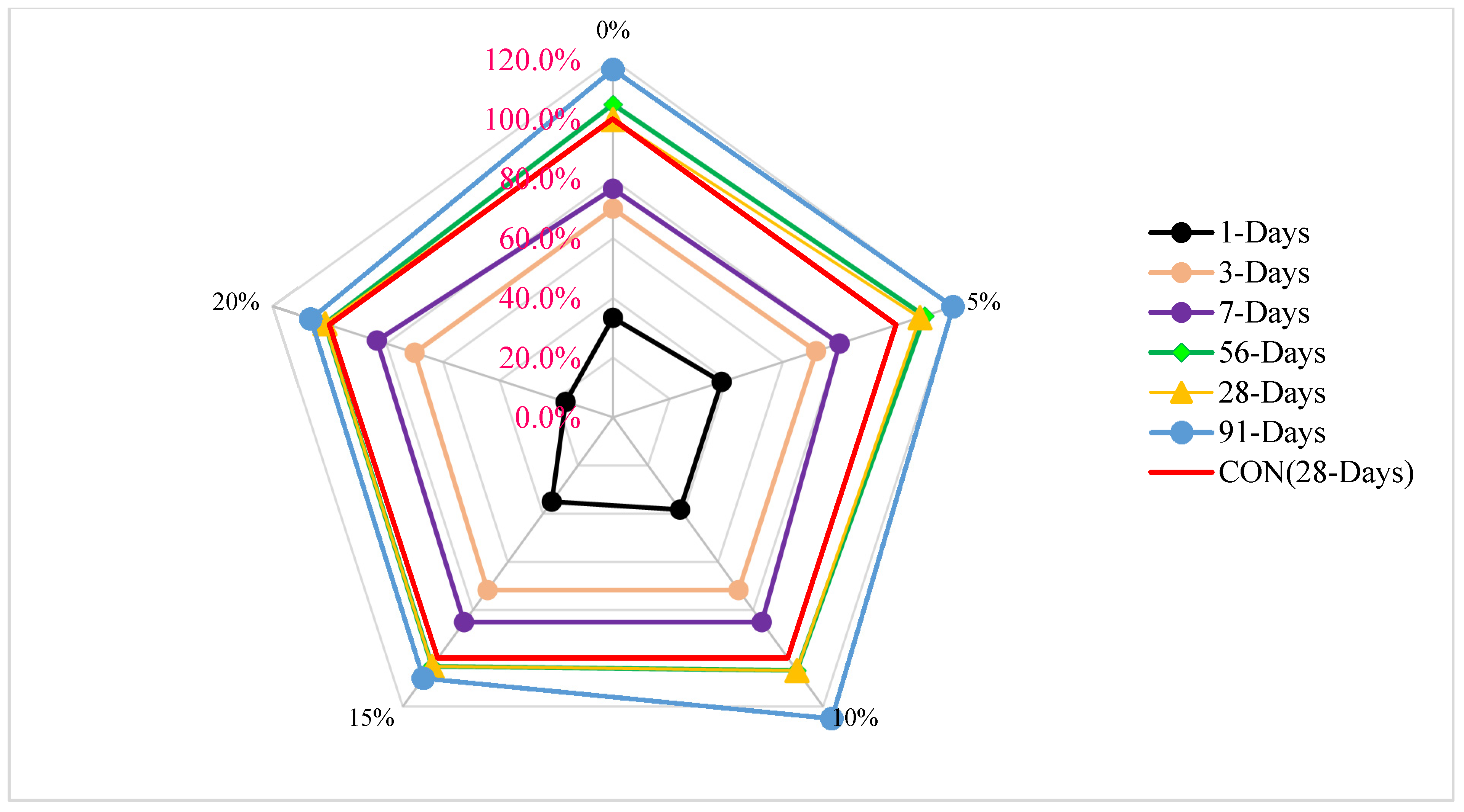

4.1. Compressive Strength (CS)

| Reference | Replacement Ratio of MTK | Optimum | Remarks |

|---|---|---|---|

| [43] | 0%, 10%, 15%, 20%, 30% and 40% | 15% | Increased |

| [46] | 0%, 5%, 10%, 15%, 20% and 25% | - | Decreased |

| [39] | 0%, 5%, 10% and 20% | - | Increased |

| [40] | 0%, 10%, 20% and 30% | - | Increased |

| [63] | 0%, 5%, 10% and 15% | - | Increased |

| [54] | 0%, 6%, 10% and 14% | - | Increased |

| [41] | 0%, 5%, 10%, 15% and 20% | - | Decreased |

| [61] | 0%, 5%, 10%, 15%, 20% and 25% | 15% | Increased |

| [64] | 0%, 5%, 10% and 15% | - | Increased |

| [42] | 0%, 4%, 8%, 16% and 20% | - | Increased |

| [65] | 0%, 5%, 10%, 15% and 20% | 5% | Increased |

| [66] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [67] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [68] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [36] | 0%, 10% and 20% | - | Increased |

| [69] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [44] | 0%,6%,10% and 14% | 10% | Increased |

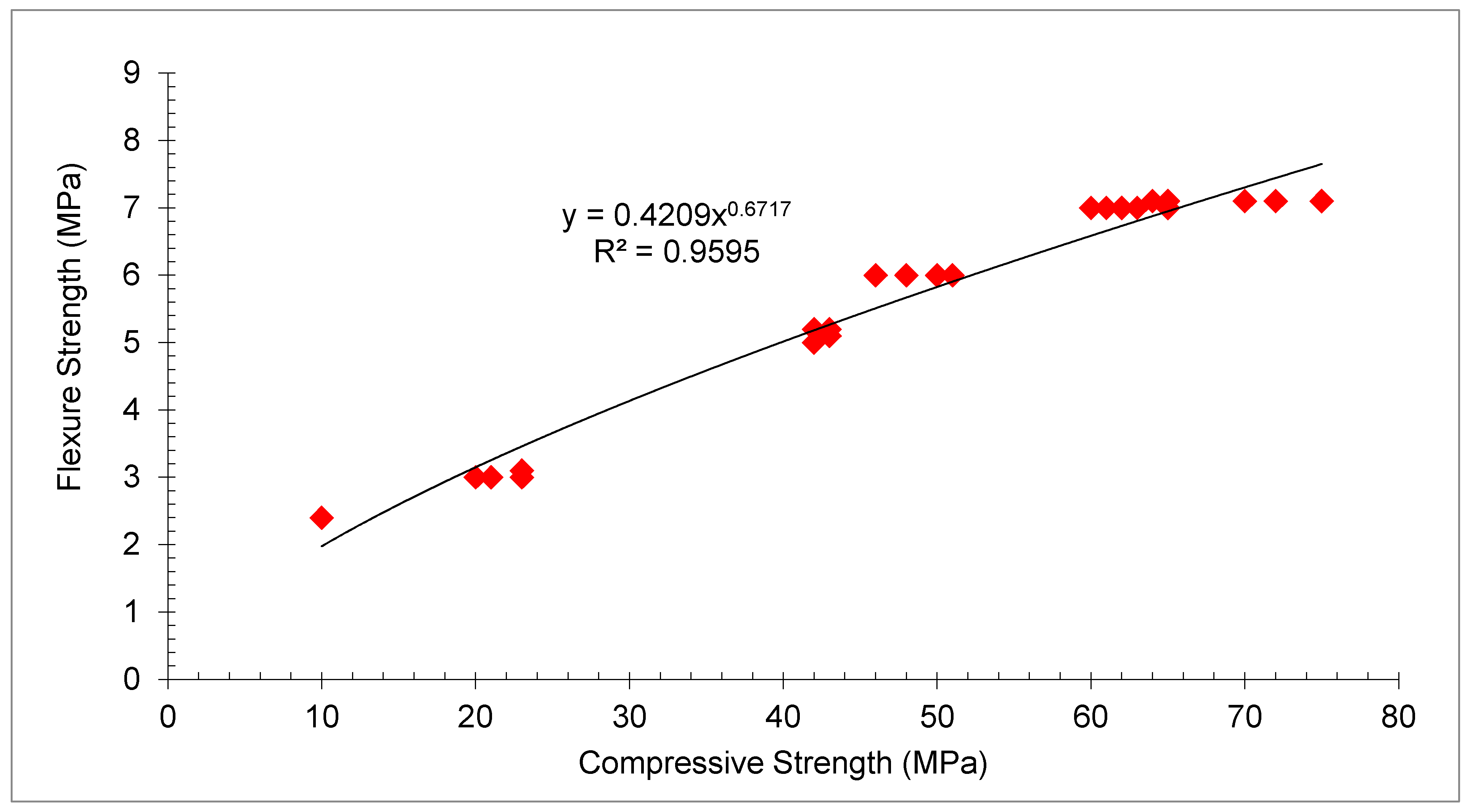

4.2. Flexural Strength (FL)

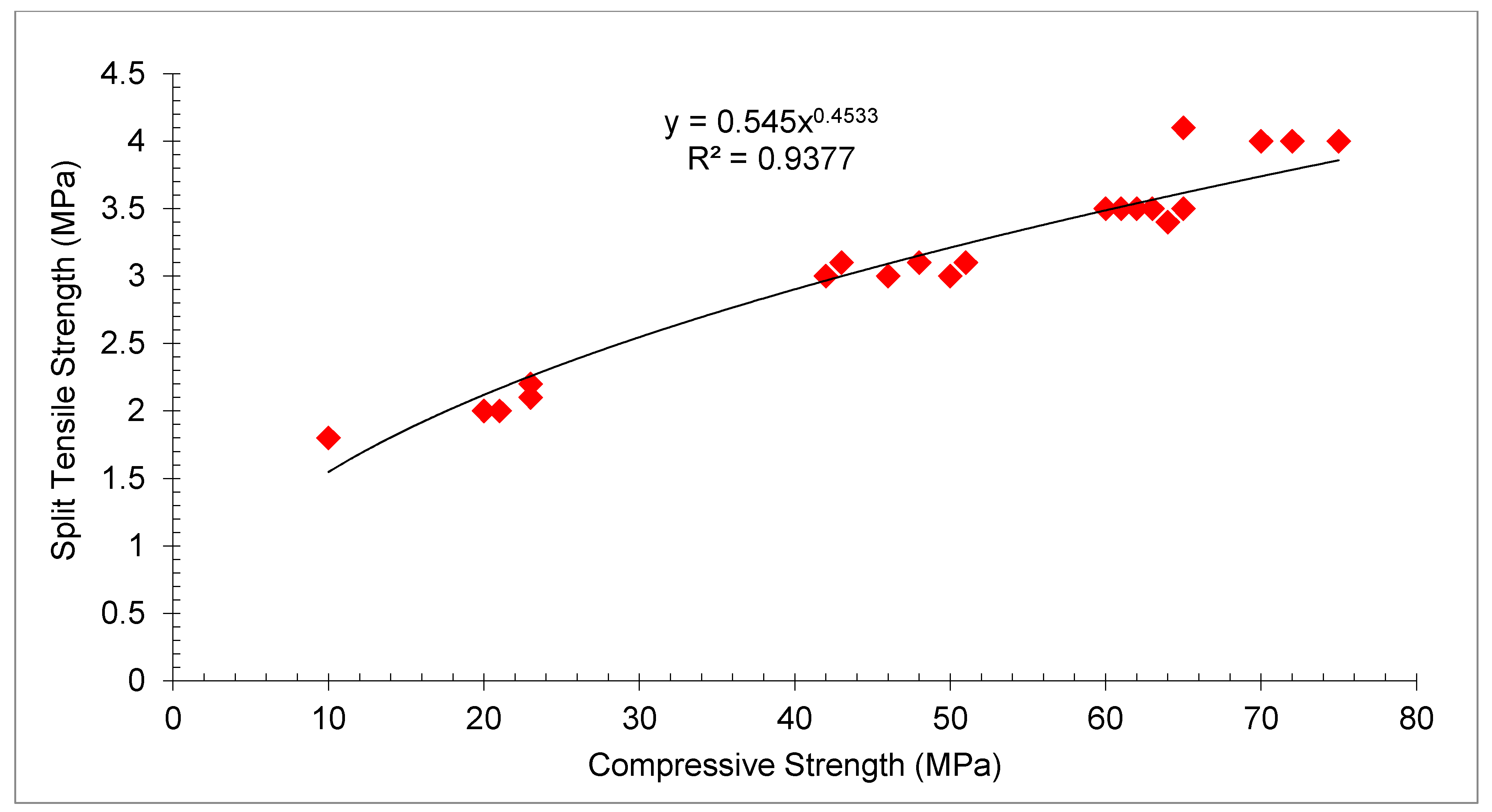

4.3. Split Tensile Strength (STS)

5. Durability

5.1. Chloride Ion Penetration

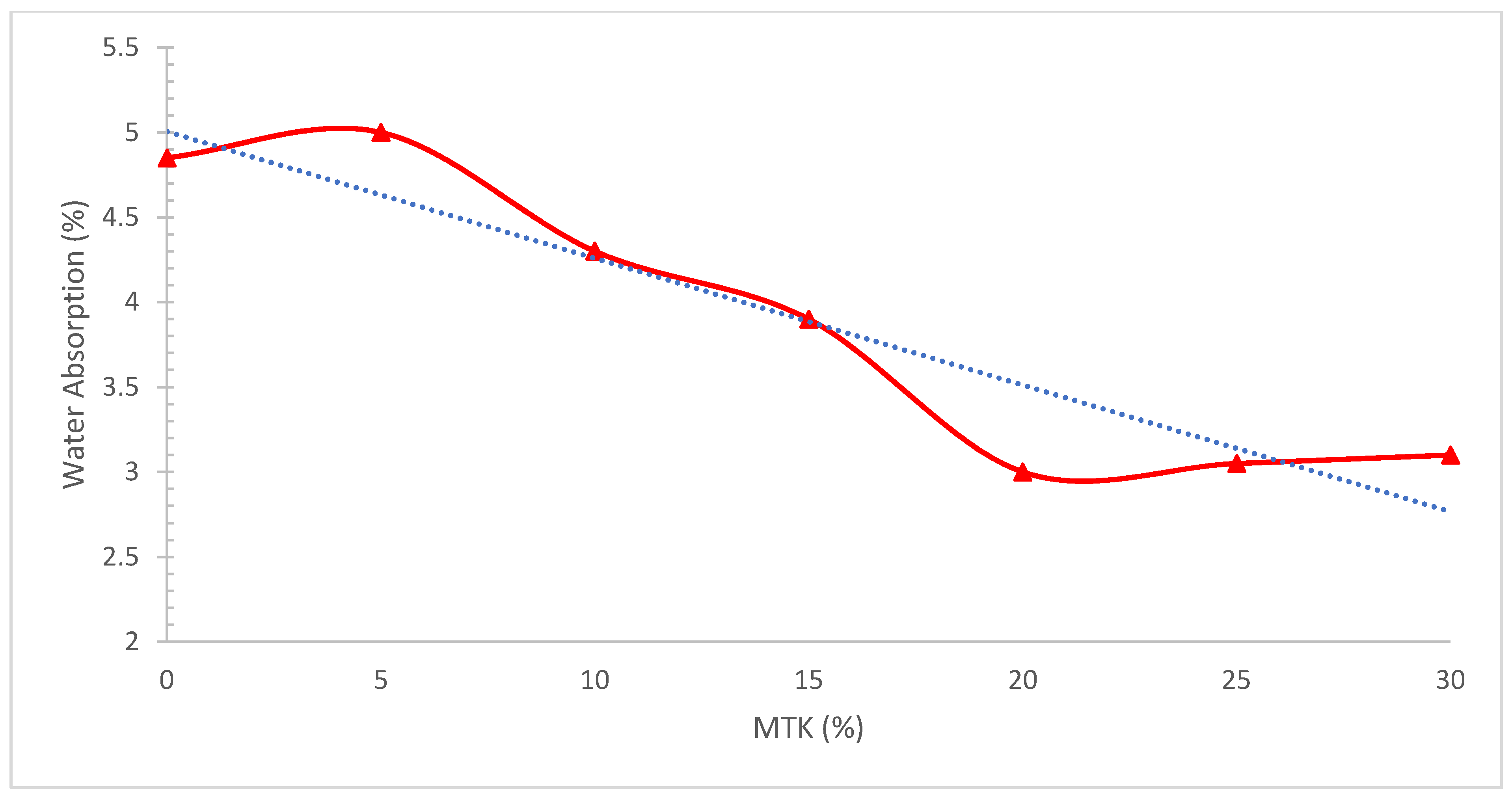

5.2. Water Absorption

5.3. Porosity and Water Sportivity

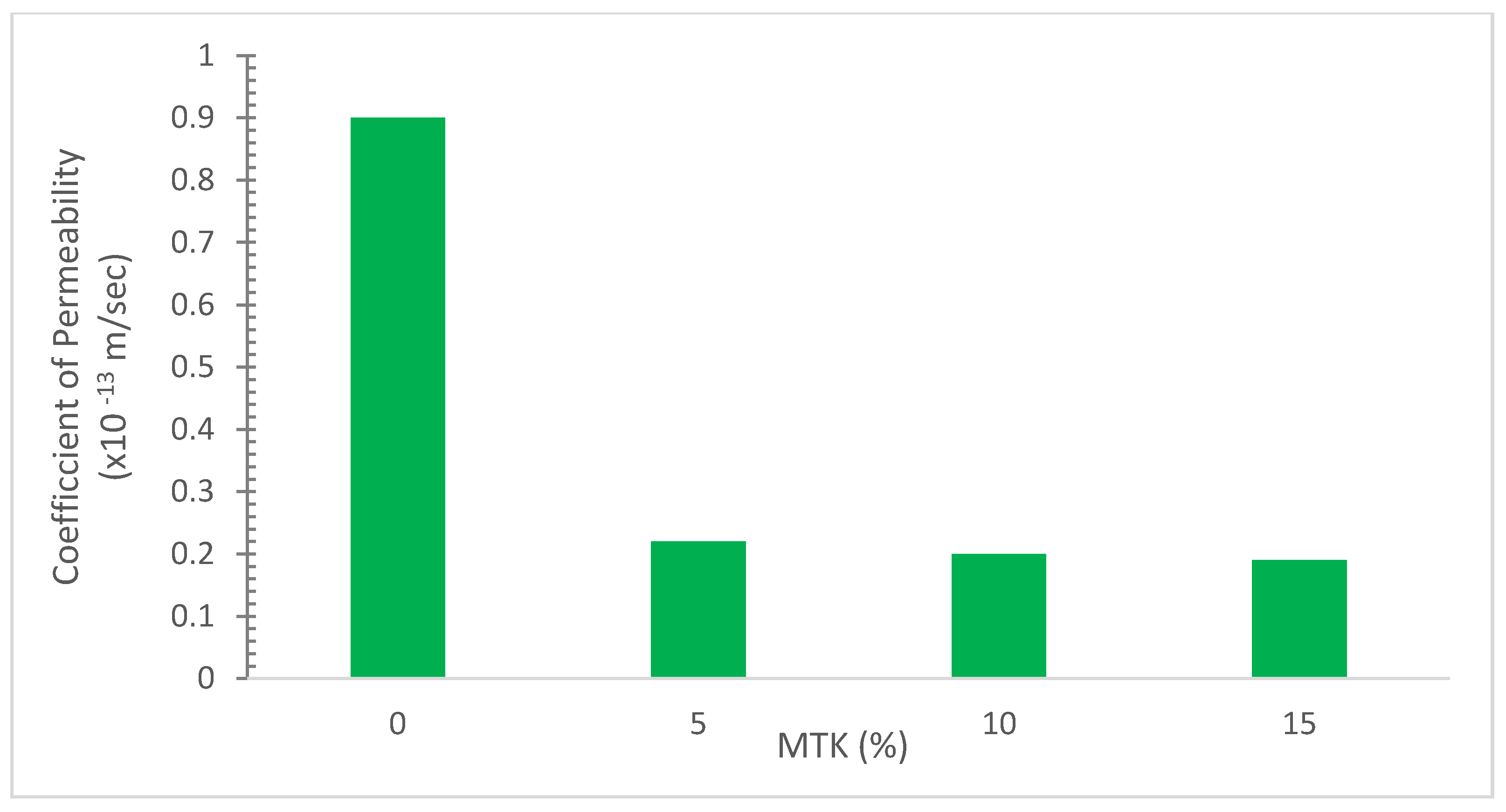

5.4. Permeability

6. Microstructure Analysis

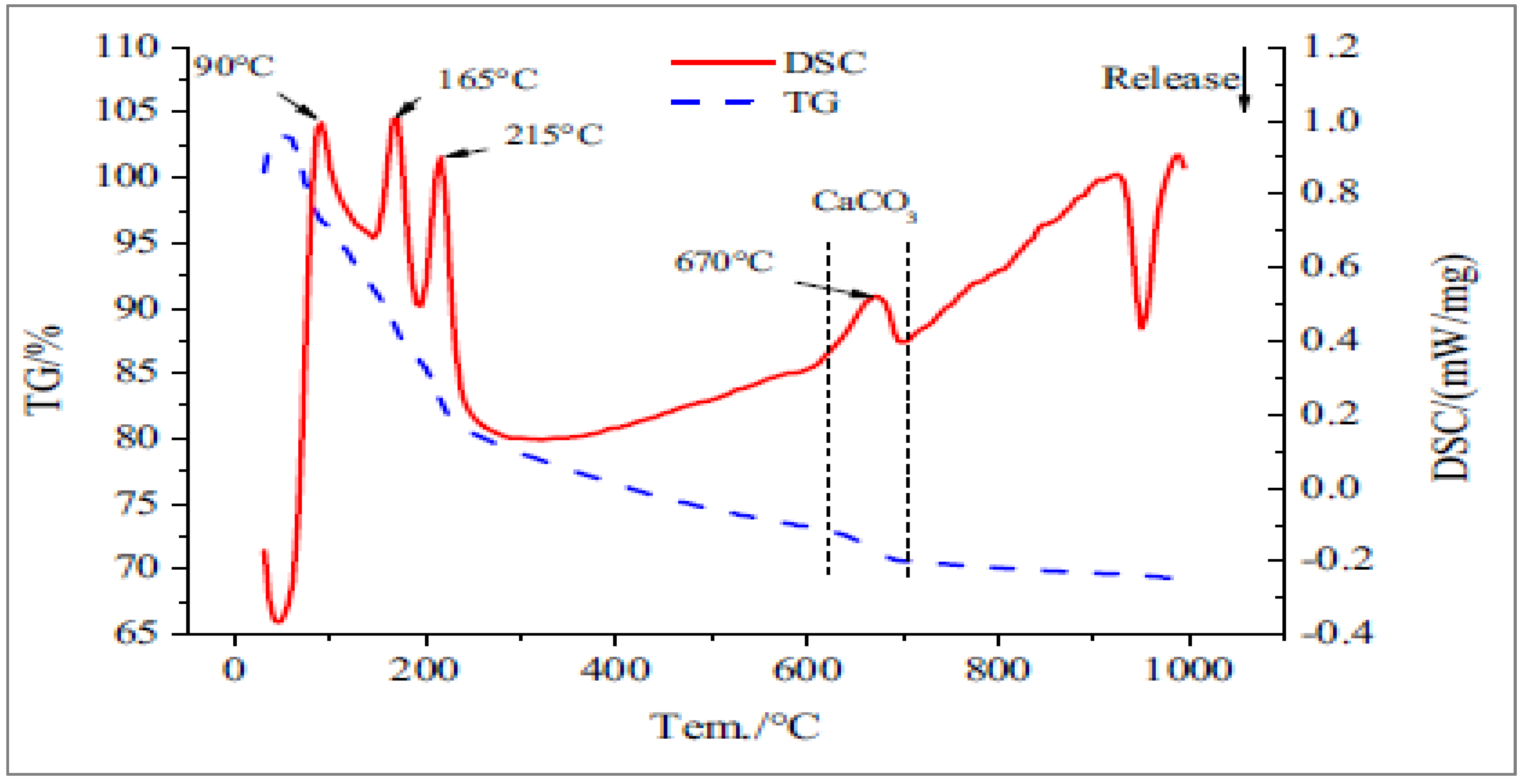

6.1. Pozzolanic Activity

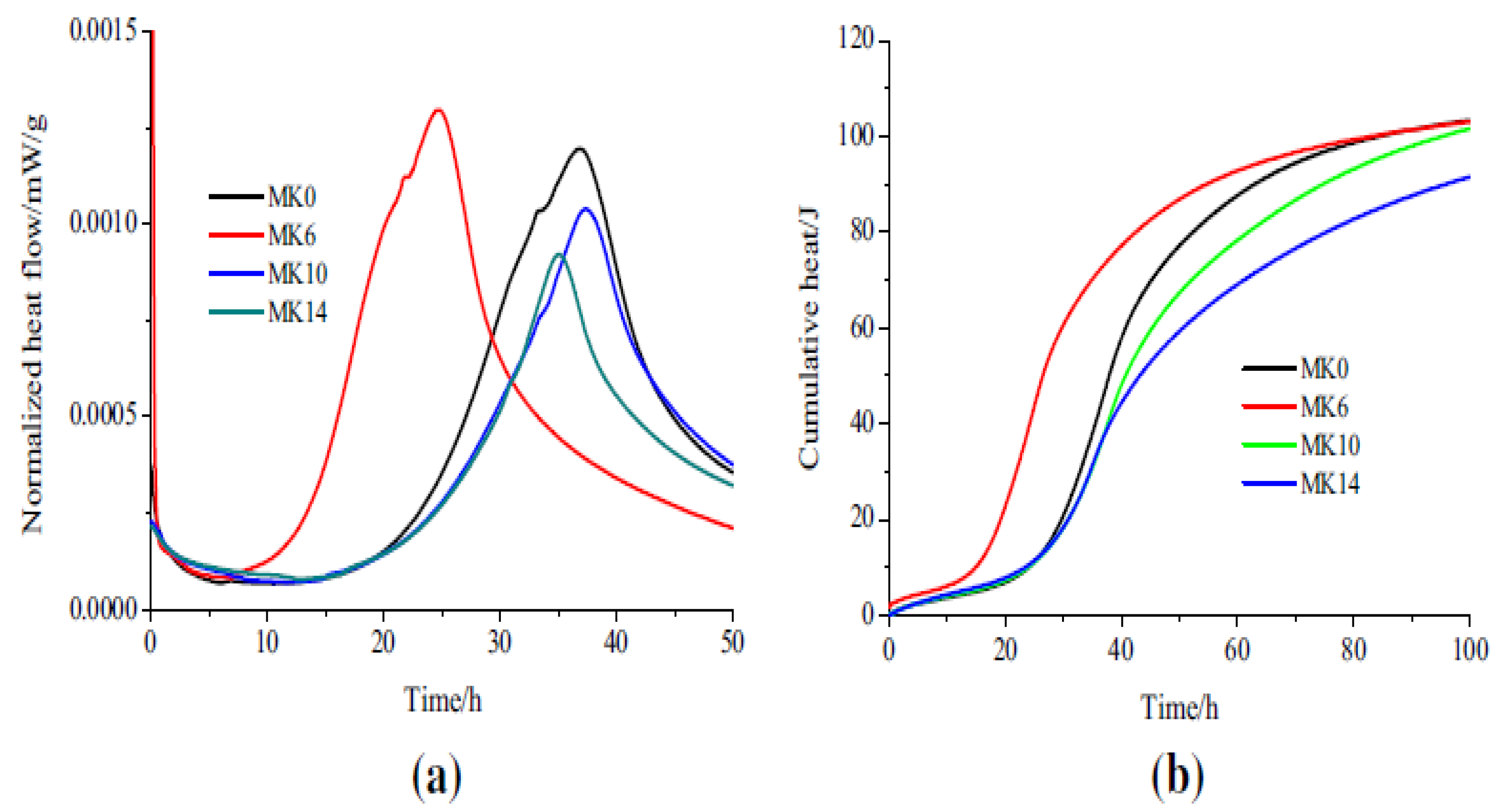

6.2. Heat of Hydration

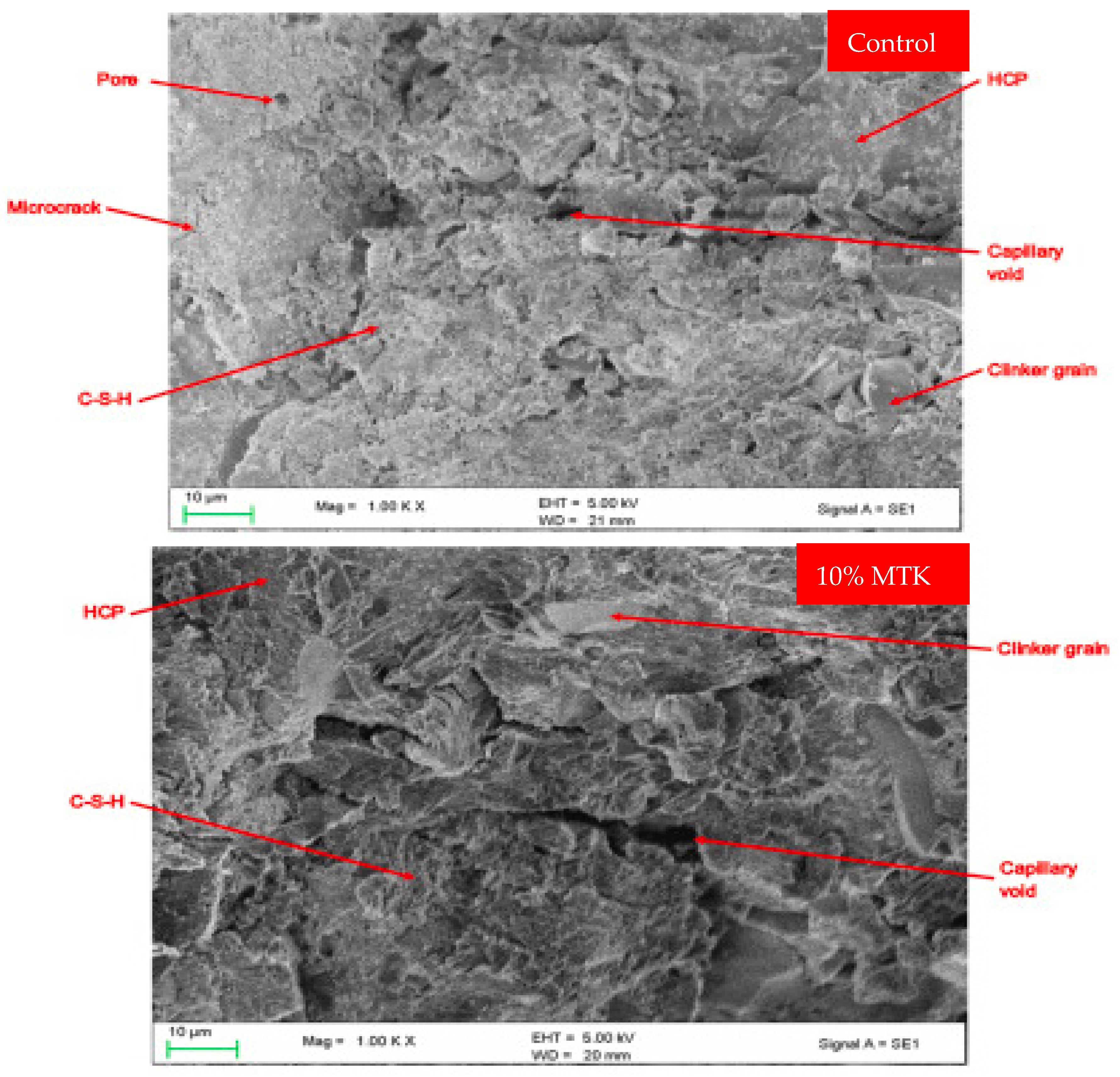

6.3. Scan Electronic Microscopy (SEM)

7. Conclusions

- Physical properties of MTK show rough surface texture which adversely affects the slump flow of concrete.

- The chemical composition of MTK indicates that MTK has the potential to be employed as a cementitious material.

- Increased the workability of concrete with the incorporation of MTK.

- The heat of hydration declined as the percentage of MTK increased. This is owing to the fact that the pozzolanic response is slow.

- Pozzolanic activity of MTK shows an increase in CSH concentrations which improved the binding properties of concrete.

- Mechanical performance such as compressive, flexural and tensile capacity improved significantly with the replacement of MTK. The highest compressive capacity was obtained at a 10% substation of MTK which is 25% more than the control sample (28 days). However, the optimum amount is important. Based on the review, the optimum dose differs from 10 to 20% changing on the basis of MTK. It can be also noted that the enhancement in the initial age mechanical performance of concrete with MTK was not significant. However, at a later age (91 days) considerable improvement in strength was observed.

- An increase in durability performance of concrete with MTK was observed up to some extent but less information is available.

- SEM results confirm the micro filling creditability MTK which gives more dense concrete.

8. Recommendations

- Thermal activation of MTK to improve further its pozzolanic activity should be explored.

- The creep and shrinkage properties of concrete with MTK should be investigated.

- Detailed study on durability characteristics of concrete (particularly acid attacks) with MTK should be investigated.

- No data is available on the alkali-silica reaction (ASR).

- Thermal assets such as thermal conductivity and heat insulation with MTK should be investigated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smirnova, O.M.; Menéndez Pidal de Navascués, I.; Mikhailevskii, V.R.; Kolosov, O.I.; Skolota, N.S. Sound-Absorbing Composites with Rubber Crumb from Used Tires. Appl. Sci. 2021, 11, 7347. [Google Scholar] [CrossRef]

- Smirnova, O. Compatibility of Shungisite Microfillers with Polycarboxylate Admixtures in Cement Compositions. ARPN J. Eng. Appl. Sci. 2019, 14, 600–610. [Google Scholar]

- Alvee, A.R.; Malinda, R.; Akbar, A.M.; Ashar, R.D.; Rahmawati, C.; Alomayri, T.; Raza, A.; Shaikh, F.U.A. Experimental Study of the Mechanical Properties and Microstructure of Geopolymer Paste Containing Nano-Silica from Agricultural Waste and Crystalline Admixtures. Case Stud. Constr. Mater. 2022, 16, e00792. [Google Scholar] [CrossRef]

- Rahmawati, C.; Aprilia, S.; Saidi, T.; Aulia, T.B.; Hadi, A.E. The Effects of Nanosilica on Mechanical Properties and Fracture Toughness of Geopolymer Cement. Polymers 2021, 13, 2178. [Google Scholar] [CrossRef]

- Althoey, F. Compressive Strength Reduction of Cement Pastes Exposed to Sodium Chloride Solutions: Secondary Ettringite Formation. Constr. Build. Mater. 2021, 299, 123965. [Google Scholar] [CrossRef]

- Marie, I.; Quiasrawi, H. Closed-Loop Recycling of Recycled Concrete Aggregates. J. Clean. Prod. 2012, 37, 243–248. [Google Scholar] [CrossRef]

- Althoey, F.; Farnam, Y. The Effect of Using Supplementary Cementitious Materials on Damage Development Due to the Formation of a Chemical Phase Change in Cementitious Materials Exposed to Sodium Chloride. Constr. Build. Mater. 2019, 210, 685–695. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of Waste Glass and Waste Marble on Mechanical and Durability Performance of Concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef]

- Naik, T.R. Sustainability of Concrete Construction. Pract. Period. Struct. Des. Constr. 2008, 13, 98–103. [Google Scholar] [CrossRef]

- Rahmawati, C.; Aprilia, S.; Saidi, T.; Aulia, T.B. Current Development of Geopolymer Cement with Nanosilica and Cellulose Nanocrystals. In Journal of Physics: Conference Series, Proceedings of the Annual Conference on Science and Technology Research (ACOSTER), Medan, Indonesia, 20–21 June 2021; IOP Publishing: Bristol, UK, 2021; pp. 1–8. [Google Scholar]

- Ahmad, J.; Tufail, R.F.; Aslam, F.; Mosavi, A.; Alyousef, R.; Faisal Javed, M.; Zaid, O.; Khan Niazi, M.S. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Singh, M.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Bhunia, D. A Study on Environmental and Economic Impacts of Using Waste Marble Powder in Concrete. J. Build. Eng. 2017, 13, 87–95. [Google Scholar] [CrossRef]

- Fediuk, R.S.; Yushin, A.M. The Use of Fly Ash the Thermal Power Plants in the Construction. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 93, p. 12070. [Google Scholar]

- Taskin, A.; Fediuk, R.; Grebenyuk, I.; Elkin, O.; Kholodov, A. Effective Cement Binders on Fly and Slag Waste from Heat Power Industry of the Primorsky Krai, Russian Federation. Int. J. Sci. Technol. Res. 2020, 9, 3509–3512. [Google Scholar]

- Abdelgader, H.; Fediuk, R.; Kurpińska, M.; Elkhatib, J.; Murali, G.; Baranov, A.V.; Timokhin, R.A. Mechanical Properties of Two-Stage Concrete Modified by Silica Fume. Mag. Civ. Eng. 2019, 89, 26–38. [Google Scholar]

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Wang, J.; Li, Q.; Lu, Y.; Luo, S. Effect of Waste-Oil Regenerant on Diffusion and Fusion Behaviors of Asphalt Recycling Using Molecular Dynamics Simulation. Constr. Build. Mater. 2022, 343, 128043. [Google Scholar] [CrossRef]

- Dinakar, P.; Sethy, K.P.; Sahoo, U.C. Design of Self-Compacting Concrete with Ground Granulated Blast Furnace Slag. Mater. Des. 2013, 43, 161–169. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and Calcined Clays as Pozzolans for Concrete: A Review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Wang, J.; Li, Q.; Song, G.; Luo, S.; Ge, D. Investigation on the Comprehensive Durability and Interface Properties of Coloured Ultra-Thin Pavement Overlay. Case Stud. Constr. Mater. 2022, 17, e01341. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Lee, G.; Ling, T.-C.; Wong, Y.-L.; Poon, C.-S. Effects of Crushed Glass Cullet Sizes, Casting Methods and Pozzolanic Materials on ASR of Concrete Blocks. Constr. Build. Mater. 2011, 25, 2611–2618. [Google Scholar] [CrossRef]

- Vizcayno, C.; de Gutiérrez, R.M.; Castello, R.; Rodriguez, E.; Guerrero, C.E. Pozzolan Obtained by Mechanochemical and Thermal Treatments of Kaolin. Appl. Clay Sci. 2010, 49, 405–413. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of Metakaolin on the Properties of Mortar and Concrete: A Review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Karaoğlu, S.; Mermerdaş, K. Strength, Permeability and Shrinkage Cracking of Silica Fume and Metakaolin Concretes. Constr. Build. Mater. 2012, 34, 120–130. [Google Scholar] [CrossRef]

- Ambroise, J.; Murat, M.; Pera, J. Hydration Reaction and Hardening of Calcined Clays and Related Minerals V. Extension of the Research and General Conclusions. Cem. Concr. Res. 1985, 15, 261–268. [Google Scholar] [CrossRef]

- Narmatha, M.; Felixkala, T. Meta Kaolin–the Best Material for Replacement of Cement in Concrete. IOSR J. Mech. Civ. Eng. 2016, 13, 66–71. [Google Scholar] [CrossRef]

- Badogiannis, E.; Tsivilis, S. Exploitation of Poor Greek Kaolins: Durability of Metakaolin Concrete. Cem. Concr. Compos. 2009, 31, 128–133. [Google Scholar] [CrossRef]

- Ding, J.-T.; Li, Z. Effects of Metakaolin and Silica Fume on Properties of Concrete. Mater. J. 2002, 99, 393–398. [Google Scholar]

- Khatib, J.M.; Clay, R.M. Absorption Characteristics of Metakaolin Concrete. Cem. Concr. Res. 2004, 34, 19–29. [Google Scholar] [CrossRef]

- Bai, J.; Wild, S.; Sabir, B.B. Sorptivity and Strength of Air-Cured and Water-Cured PC–PFA–MK Concrete and the Influence of Binder Composition on Carbonation Depth. Cem. Concr. Res. 2002, 32, 1813–1821. [Google Scholar] [CrossRef]

- Güneyisi, E.; Mermerdaş, K. Comparative Study on Strength, Sorptivity, and Chloride Ingress Characteristics of Air-Cured and Water-Cured Concretes Modified with Metakaolin. Mater. Struct. 2007, 40, 1161–1171. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. Characteristics of a Thermally Activated Alumino-Silicate Pozzolanic Material and Its Use in Concrete. Cem. Concr. Res. 1995, 25, 1713–1725. [Google Scholar] [CrossRef]

- Khatri, R.P.; Sirivivatnanon, V.; Kin yu, L. Effect of Curing on Water Permeability of Concretes Prepared with Normal Portland Cement and with Slag and Silica Fume. Mag. Concr. Res. 1997, 49, 167–172. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Mermerdaş, K. Improving Strength, Drying Shrinkage, and Pore Structure of Concrete Using Metakaolin. Mater. Struct. 2008, 41, 937–949. [Google Scholar] [CrossRef]

- Danish, P.; Ganesh, M.G. Behaviour of Self-Compacting Concrete Using Different Mineral Powders Additions in Ternary Blends. Rev. Rom. Mater. 2020, 50, 232–239. [Google Scholar]

- Girgin, Z.C. Effect of Slag, Nano Clay and Metakaolin on Mechanical Performance of Basalt Fibre Cementitious Composites. Constr. Build. Mater. 2018, 192, 70–84. [Google Scholar] [CrossRef]

- Nadeem, A.; Memon, S.A.; Lo, T.Y. The Performance of Fly Ash and Metakaolin Concrete at Elevated Temperatures. Constr. Build. Mater. 2014, 62, 67–76. [Google Scholar] [CrossRef]

- Yaba, H.K.; Naji, H.S.; Younis, K.H.; Ibrahim, T.K. Compressive and Flexural Strengths of Recycled Aggregate Concrete: Effect of Different Contents of Metakaolin. Mater. Today Proc. 2021, 45, 4719–4723. [Google Scholar] [CrossRef]

- Salimi, J.; Ramezanianpour, A.M.; Moradi, M.J. Studying the Effect of Low Reactivity Metakaolin on Free and Restrained Shrinkage of High Performance Concrete. J. Build. Eng. 2020, 28, 101053. [Google Scholar] [CrossRef]

- Younis, K.H.; Amin, A.A.; Ahmed, H.G.; Maruf, S.M. Recycled Aggregate Concrete Including Various Contents of Metakaolin: Mechanical Behavior. Adv. Mater. Sci. Eng. 2020, 2020, 8829713. [Google Scholar] [CrossRef]

- El-Din, H.K.S.; Eisa, A.S.; Aziz, B.H.A.; Ibrahim, A. Mechanical Performance of High Strength Concrete Made from High Volume of Metakaolin and Hybrid Fibers. Constr. Build. Mater. 2017, 140, 203–209. [Google Scholar] [CrossRef]

- Jiang, G.; Rong, Z.; Sun, W. Effects of Metakaolin on Mechanical Properties, Pore Structure and Hydration Heat of Mortars at 0.17 w/b Ratio. Constr. Build. Mater. 2015, 93, 564–572. [Google Scholar] [CrossRef]

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2013. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=Standard+Specification+for+Coal+Fly+Ash+and+Raw+or+Calcined+Natural+Pozzolan+for+Use+in+Concrete%3B+ASTM+international%3A+West+Conshohocken%2C+PA%2C+USA%2C+2013.&btnG= (accessed on 1 August 2022).

- Barkat, A.; Kenai, S.; Menadi, B.; Kadri, E.; Soualhi, H. Effects of Local Metakaolin Addition on Rheological and Mechanical Performance of Self-Compacting Limestone Cement Concrete. J. Adhes. Sci. Technol. 2019, 33, 963–985. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.; Wang, J.; Guo, J.; Ling, Y. Macroscopic and Microscopic Analyses on Mechanical Performance of Metakaolin/Fly Ash Based Geopolymer Mortar. J. Clean. Prod. 2021, 294, 126193. [Google Scholar] [CrossRef]

- Pillay, D.L.; Olalusi, O.B.; Awoyera, P.O.; Rondon, C.; Echeverría, A.M.; Kolawole, J.T. A Review of the Engineering Properties of Metakaolin Based Concrete: Towards Combatting Chloride Attack in Coastal/Marine Structures. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Scherb, S.; Köberl, M.; Beuntner, N.; Thienel, K.-C.; Neubauer, J. Reactivity of Metakaolin in Alkaline Environment: Correlation of Results from Dissolution Experiments with XRD Quantifications. Materials 2020, 13, 2214. [Google Scholar] [CrossRef]

- Owens, G. Fundamentals of Concrete; Cement and Concrete Institute: Midrand, South Africa, 2013; ISBN 0992217601. [Google Scholar]

- Babafemi, A.J.; Šavija, B.; Paul, S.C.; Anggraini, V. Engineering Properties of Concrete with Waste Recycled Plastic: A Review. Sustainability 2018, 10, 3875. [Google Scholar] [CrossRef]

- Fang, S.-E.; Hong, H.-S.; Zhang, P.-H. Mechanical Property Tests and Strength Formulas of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials 2018, 11, 1851. [Google Scholar] [CrossRef]

- Neto, J.D.S.A.; Santos, T.A.; de Andrade Pinto, S.; Dias, C.M.R.; Ribeiro, D.V. Effect of the Combined Use of Carbon Nanotubes (CNT) and Metakaolin on the Properties of Cementitious Matrices. Constr. Build. Mater. 2021, 271, 121903. [Google Scholar] [CrossRef]

- Rong, Z.; Jiang, G.; Sun, W. Effects of Metakaolin on Mechanical and Microstructural Properties of Ultra-High Performance Cement-Based Composites. J. Sustain. Cem. Mater. 2018, 7, 296–310. [Google Scholar] [CrossRef]

- Badogiannis, E.; Kakali, G.; Dimopoulou, G.; Chaniotakis, E.; Tsivilis, S. Metakaolin as a Main Cement Constituent. Exploitation of Poor Greek Kaolins. Cem. Concr. Compos. 2005, 27, 197–203. [Google Scholar] [CrossRef]

- Karahan, O.; Hossain, K.M.A.; Ozbay, E.; Lachemi, M.; Sancak, E. Effect of Metakaolin Content on the Properties Self-Consolidating Lightweight Concrete. Constr. Build. Mater. 2012, 31, 320–325. [Google Scholar] [CrossRef]

- Sonebi, M. Report on Measurements of Workability and Rheology of Fresh Concrete; American Concrete Institute: Indianapolis, IN, USA, 2008. [Google Scholar]

- Cassagnabère, F.; Diederich, P.; Mouret, M.; Escadeillas, G.; Lachemi, M. Impact of Metakaolin Characteristics on the Rheological Properties of Mortar in the Fresh State. Cem. Concr. Compos. 2013, 37, 95–107. [Google Scholar] [CrossRef]

- Madandoust, R.; Mousavi, S.Y. Fresh and Hardened Properties of Self-Compacting Concrete Containing Metakaolin. Constr. Build. Mater. 2012, 35, 752–760. [Google Scholar] [CrossRef]

- Özcan, F.; Kaymak, H. Utilization of Metakaolin and Calcite: Working Reversely in Workability Aspect—As Mineral Admixture in Self-Compacting Concrete. Adv. Civ. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Liu, K.; Wang, S.; Quan, X.; Duan, W.; Nan, Z.; Wei, T.; Xu, F.; Li, B. Study on the Mechanical Properties and Microstructure of Fiber Reinforced Metakaolin-Based Recycled Aggregate Concrete. Constr. Build. Mater. 2021, 294, 123554. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, S.-H.; Moon, H.-Y. Strength Properties and Durability Aspects of High Strength Concrete Using Korean Metakaolin. Constr. Build. Mater. 2007, 21, 1229–1237. [Google Scholar] [CrossRef]

- Parande, A.K.; Babu, B.R.; Karthik, M.A.; Kumaar, K.K.D.; Palaniswamy, N. Study on Strength and Corrosion Performance for Steel Embedded in Metakaolin Blended Concrete/Mortar. Constr. Build. Mater. 2008, 22, 127–134. [Google Scholar] [CrossRef]

- Dinakar, P.; Sahoo, P.K.; Sriram, G. Effect of Metakaolin Content on the Properties of High Strength Concrete. Int. J. Concr. Struct. Mater. 2013, 7, 215–223. [Google Scholar] [CrossRef]

- Kaur, G.; Siddique, R.; Rajor, A. Properties of Concrete Containing Fungal Treated Waste Foundry Sand. Constr. Build. Mater. 2012, 29, 82–87. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Performance Assessment of Concrete Incorporating Recycled Coarse Aggregates and Metakaolin: A Systematic Approach. Constr. Build. Mater. 2020, 233, 117223. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical Performances and Microstructures of Metakaolin Contained UHPC Matrix under Steam Curing Conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Effect of Incorporation of Metakaolin and Recycled Coarse Aggregate on Properties of Concrete. J. Clean. Prod. 2019, 209, 398–414. [Google Scholar] [CrossRef]

- Mo, Z.; Wang, R.; Gao, X. Hydration and Mechanical Properties of UHPC Matrix Containing Limestone and Different Levels of Metakaolin. Constr. Build. Mater. 2020, 256, 119454. [Google Scholar] [CrossRef]

- Wild, S.; Khatib, J.M.; Jones, A. Relative Strength, Pozzolanic Activity and Cement Hydration in Superplasticised Metakaolin Concrete. Cem. Concr. Res. 1996, 26, 1537–1544. [Google Scholar] [CrossRef]

- Kumar, K.R.; Shyamala, G.; Awoyera, P.O.; Vedhasakthi, K.; Olalusi, O.B. Cleaner Production of Self-Compacting Concrete with Selected Industrial Rejects-an Overview. Silicon 2021, 13, 2809–2820. [Google Scholar] [CrossRef]

- Shoukry, H.; Kotkata, M.F.; Abo-el-Enein, S.A.; Morsy, M.S. Flexural Strength and Physical Properties of Fiber Reinforced Nano Metakaolin Cementitious Surface Compound. Constr. Build. Mater. 2013, 43, 453–460. [Google Scholar] [CrossRef]

- Nadeem, A.; Memon, S.A.; Lo, T.Y. Mechanical Performance, Durability, Qualitative and Quantitative Analysis of Microstructure of Fly Ash and Metakaolin Mortar at Elevated Temperatures. Constr. Build. Mater. 2013, 38, 338–347. [Google Scholar] [CrossRef]

- Younis, K.H.; Mustafa, S.M. Feasibility of Using Nanoparticles of SiO2 to Improve the Performance of Recycled Aggregate Concrete. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Habeeb, G.M.; Al-Jeabory, J.M.; Majeed, M.H. Sustainable Performance of Reactive Powder Concrete by Using Nano Meta Kaolin. J. Eng. Sustain. Dev. 2018, 22, 96–106. [Google Scholar] [CrossRef]

- Ibrahem, A.M.; Al-Mishhadani, S.A.; Naji, Z.H. The Effect of Nano Metakaolin Material on Some Properties of Concrete. Diyala J. Eng. Sci. 2013, 6, 50–61. [Google Scholar] [CrossRef]

- Sajedi, F.; Razak, H.A. Comparison of Different Methods for Activation of Ordinary Portland Cement-Slag Mortars. Constr. Build. Mater. 2011, 25, 30–38. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahmad, S.; Al-Gahtani, H.J. Chloride-Induced Corrosion of Steel in Concrete: An Overview on Chloride Diffusion and Prediction of Corrosion Initiation Time. Int. J. Corros. 2017, 2017, 1–9. [Google Scholar] [CrossRef]

- Awoyera, P.; Adesina, A.; Olalusi, O.B.; Viloria, A. Reinforced Concrete Deterioration Caused by Contaminated Construction Water: An Overview. Eng. Fail. Anal. 2020, 116, 104715. [Google Scholar] [CrossRef]

- Chalee, W.; Jaturapitakkul, C.A.; Chindaprasirt, P. Predicting the Chloride Penetration of Fly Ash Concrete in Seawater. Mar. Struct. 2009, 22, 341–353. [Google Scholar] [CrossRef]

- Aguirre-Guerrero, A.M.; de Gutiérrez, R.M. Assessment of Corrosion Protection Methods for Reinforced Concrete. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 315–353. [Google Scholar]

- Srinivasu, K.; Sai, M.; Kumar, N.V.S. A Review on Use of Metakaolin in Cement Mortar and Concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 14697–14701. [Google Scholar]

- Li, Q.; Geng, H.; Huang, Y.; Shui, Z. Chloride Resistance of Concrete with Metakaolin Addition and Seawater Mixing: A Comparative Study. Constr. Build. Mater. 2015, 101, 184–192. [Google Scholar] [CrossRef]

- Shoukry, H.; Kotkata, M.F.; Abo-EL-Enein, S.A.; Morsy, M.S.; Shebl, S.S. Enhanced Physical, Mechanical and Microstructural Properties of Lightweight Vermiculite Cement Composites Modified with Nano Metakaolin. Constr. Build. Mater. 2016, 112, 276–283. [Google Scholar] [CrossRef]

- Ghazy, M.F.; Elaty, M.A.A.; Elkhoriby, R.S. Performance of Blended Cement Mortars Incorporating Nano-Metakaolin Particles at Elevated Temperatures. In Proceedings of the International Conference on Advances in Structural and Geotechnical Engineering, Hurghada, Egypt, 6–9 April 2015; pp. 6–9. [Google Scholar]

- Kannan, V.; Ganesan, K. Strength and Water Absorption Properties of Ternary Blended Cement Mortar Using Rice Husk Ash and Metakaolin. Sch. J. Eng. Res. 2012, 1, 51–59. [Google Scholar]

- Maes, M.; Gruyaert, E.; de Belie, N. Resistance of Concrete against Combined Attack of Chlorides and Sulphates. In Proceedings of the International Congress on Durability of Concrete, Trondheim, Norway, 18–21 June 2012; Volume 53. [Google Scholar] [CrossRef]

- Pillay, D.L.; Olalusi, O.B.; Kiliswa, M.W.; Awoyera, P.O.; Kolawole, J.T.; Babafemi, A.J. Engineering Performance of Metakaolin Based Concrete. Clean. Eng. Technol. 2022, 6, 100383. [Google Scholar] [CrossRef]

- Razak, H.A.; Wong, H.S. Strength Estimation Model for High-Strength Concrete Incorporating Metakaolin and Silica Fume. Cem. Concr. Res. 2005, 35, 688–695. [Google Scholar] [CrossRef]

- Poon, C.-S.; Kou, S.C.; Lam, L. Compressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume Concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Zain, M.F.M.; Safiuddin, M.; Mahmud, H. Development of High Performance Concrete Using Silica Fume at Relatively High Water–Binder Ratios. Cem. Concr. Res. 2000, 30, 1501–1505. [Google Scholar] [CrossRef]

- Ahmad, J.; Majdi, A.; Babeker Elhag, A.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A Step towards Sustainable Concrete with Substitution of Plastic Waste in Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Gabrovšek, R.; Vuk, T.; Kaučič, V. Evaluation of the Hydration of Portland Cement Containing Various Carbonates by Means of Thermal Analysis. Acta Chim. Slov 2006, 53, 159–165. [Google Scholar]

- Ukrainczyk, N.; Matusinovic, T.; Kurajica, S.; Zimmermann, B.; Sipusic, J. Dehydration of a Layered Double Hydroxide—C2AH8. Thermochim. Acta 2007, 464, 7–15. [Google Scholar] [CrossRef]

- Sha, W.; O’Neill, E.A.; Guo, Z. Differential Scanning Calorimetry Study of Ordinary Portland Cement. Cem. Concr. Res. 1999, 29, 1487–1489. [Google Scholar] [CrossRef]

- Rojas, M.F.; Cabrera, J. The Effect of Temperature on the Hydration Rate and Stability of the Hydration Phases of Metakaolin–Lime–Water Systems. Cem. Concr. Res. 2002, 32, 133–138. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.A.; Amin, M.S.; El-Hosiny, F.I.; Hanafi, S.; ElSokkary, T.M.; Hazem, M.M. Pozzolanic and Hydraulic Activity of Nano-Metakaolin. HBRC J. 2014, 10, 64–72. [Google Scholar] [CrossRef]

- Sonebi, M.; Lachemi, M.; Hossain, K.M.A. Optimisation of Rheological Parameters and Mechanical Properties of Superplasticised Cement Grouts Containing Metakaolin and Viscosity Modifying Admixture. Constr. Build. Mater. 2013, 38, 126–138. [Google Scholar] [CrossRef]

- Ambroise, J.; Maximilien, S.; Pera, J. Properties of Metakaolin Blended Cements. Adv. Cem. Based Mater. 1994, 1, 161–168. [Google Scholar] [CrossRef]

- Frıas, M.; De Rojas, M.I.S.; Cabrera, J. The Effect That the Pozzolanic Reaction of Metakaolin Has on the Heat Evolution in Metakaolin-Cement Mortars. Cem. Concr. Res. 2000, 30, 209–216. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014; ISBN 0071797874. [Google Scholar]

| Reference | [43] | [46] | [47] | [38] | [39] |

|---|---|---|---|---|---|

| SiO2 | 53.26 | 53.15 | 54 | 56.10 | 53.2 |

| Al2O3 | 43.93 | 38.44 | 43 | 40.23 | 43.9 |

| Fe2O3 | 0.3 | 2.65 | <1.3 | 0.85 | 0.38 |

| MgO | 0.49 | 0.47 | <0.8 | 0.16 | 0.05 |

| CaO | 0.36 | 0.17 | <0.8 | 0.19 | 0.02 |

| Na2O | - | 0.08 | <0.7 | - | 0.17 |

| K2O | - | 3.43 | <0.7 | - | 0.10 |

| Reference | Replacement Ratio of MTK | Optimum | Remarks |

|---|---|---|---|

| [40] | 0%, 10%, 20% and 30% | 20% | Increased |

| [54] | 0%, 6%, 10% and 14% | - | Increased |

| [61] | 0%, 5%, 10%, 15%,20% and 25% | 15% | Increased |

| [64] | 0%, 5%, 10% and 15% | - | Increased |

| [42] | 0%, 4%, 8%, 16% and 20% | - | Increased |

| [65] | 0%, 5%, 10%, 15% and 20% | - | Increased |

| [66] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [67] | 0%, 5%, 10%, 15% and 20% | - | Increased |

| [68] | 0%, 5%, 10%, 15% and 20% | 10% | Increased |

| [69] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [44] | 0%, 6%, 10% and 14% | 10% | Increased |

| Reference | Replacement Ratio of MTK | Optimum | Remarks |

|---|---|---|---|

| [43] | 0%, 10%, 15%, 20%, 30% and 40% | 15% | Increased |

| [63] | 0%, 5%, 10% and 15% | 10% | Increased |

| [41] | 0%, 5%, 10%, 15% and 20% | - | Decreased |

| [61] | 0%, 5%, 10%, 15%, 20% and 25% | 15% | Increased |

| [64] | 0%, 5%, 10% and 15% | - | Increased |

| [42] | 0%, 4%, 8%, 16% and 20% | - | Decreased |

| [65] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [66] | 0%, 5%, 10%, 15% and 20% | 15% | Increased |

| [68] | 0%, 5%, 10%, 15% and 20% | 10% | Increased |

| [36] | 0%, 10% and 20% | 10% | Increased |

| Time (days) | Ca(OH)2 | CaCO3 | Total Ca(OH)2 | Reactivity Index |

|---|---|---|---|---|

| 3 | 7.39 | 4.21 | 38.41 | 23.2 |

| 7 | 7.01 | 1.46 | 31.56 | 36.9 |

| 28 | 0 | 1.68 | 2.89 | 94.3 |

| 56 | 0 | 1.45 | 2.46 | 95.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, J.; Majdi, A.; Arbili, M.M.; Deifalla, A.F.; Naqash, M.T. Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK). Buildings 2022, 12, 1401. https://doi.org/10.3390/buildings12091401

Ahmad J, Majdi A, Arbili MM, Deifalla AF, Naqash MT. Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK). Buildings. 2022; 12(9):1401. https://doi.org/10.3390/buildings12091401

Chicago/Turabian StyleAhmad, Jawad, Ali Majdi, Mohamed Moafak Arbili, Ahmed Farouk Deifalla, and Muhammad Tayyab Naqash. 2022. "Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK)" Buildings 12, no. 9: 1401. https://doi.org/10.3390/buildings12091401

APA StyleAhmad, J., Majdi, A., Arbili, M. M., Deifalla, A. F., & Naqash, M. T. (2022). Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK). Buildings, 12(9), 1401. https://doi.org/10.3390/buildings12091401