Industry 4.0, Disaster Risk Management and Infrastructure Resilience: A Systematic Review and Bibliometric Analysis

Abstract

:1. Introduction

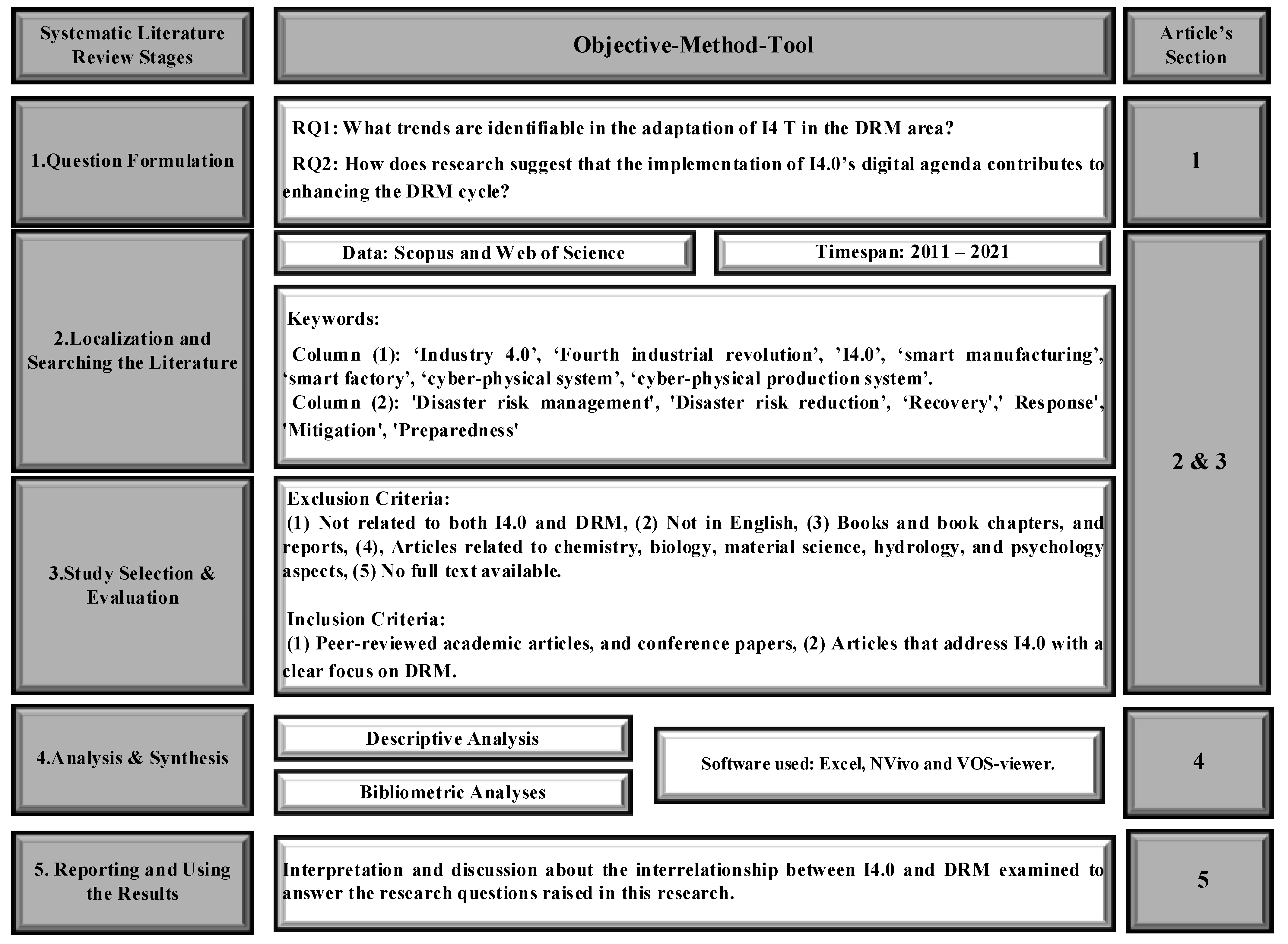

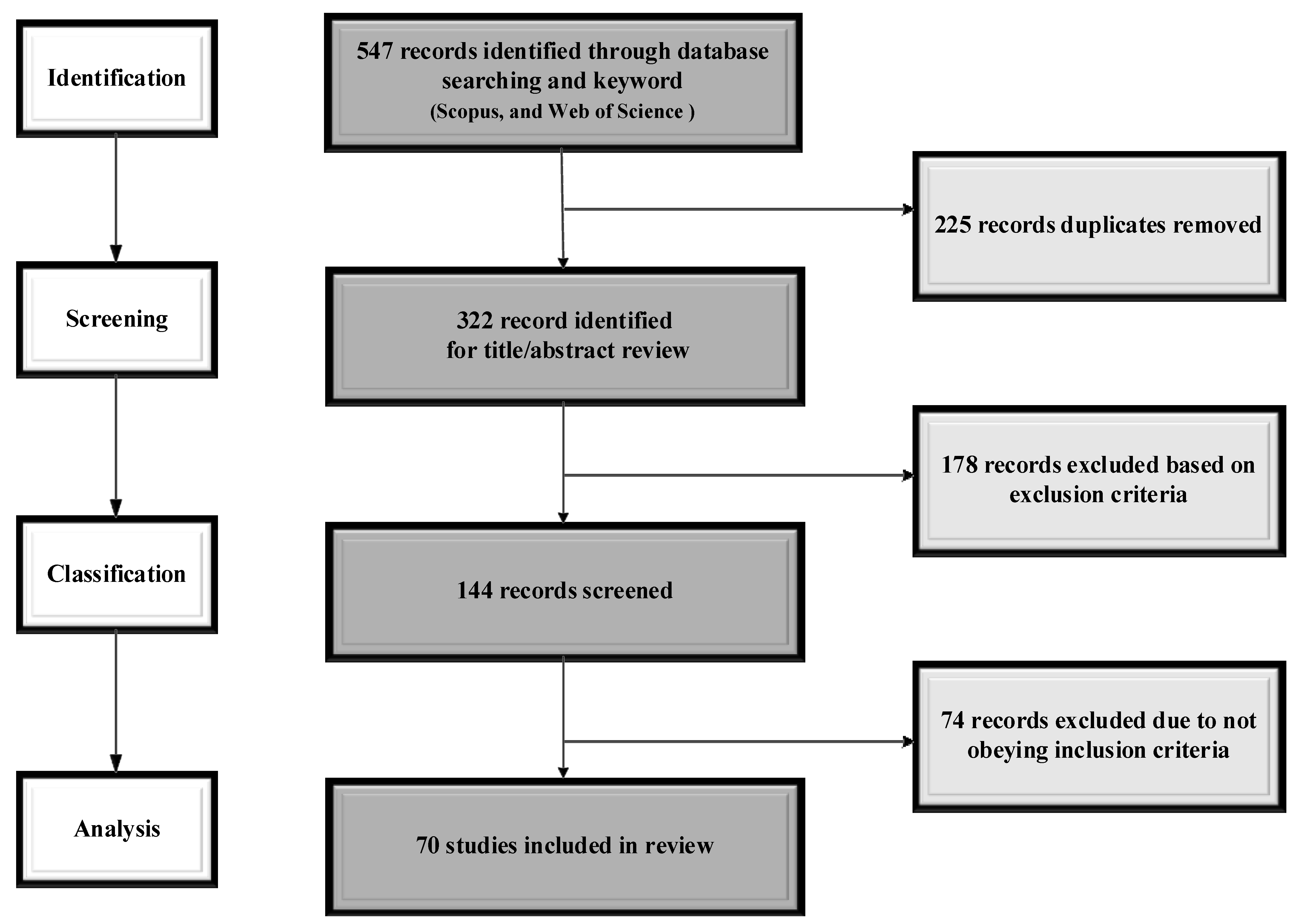

2. Research Methodology

3. Results

3.1. Descriptive Analysis of Results

3.1.1. Sources and Number of Articles per Year

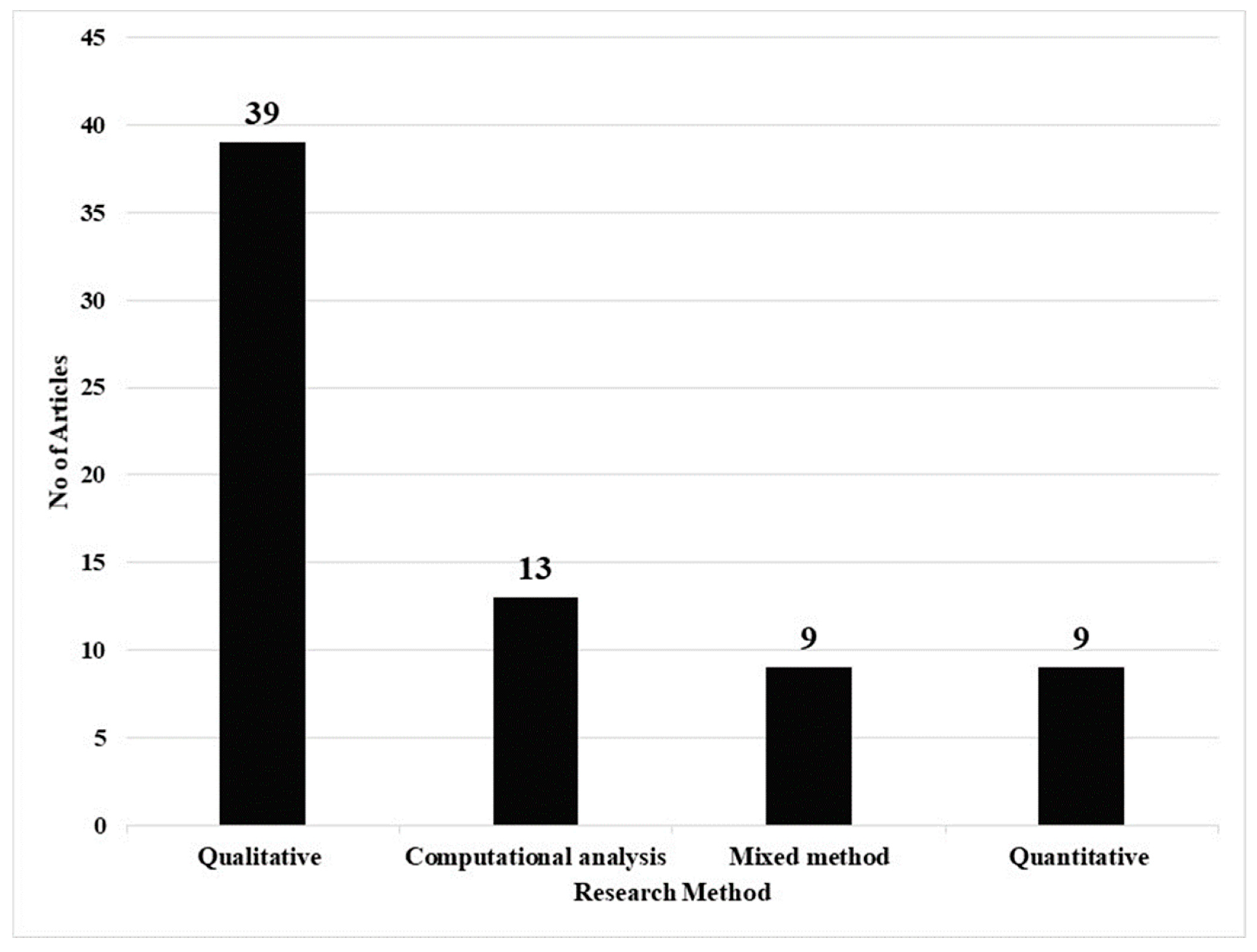

3.1.2. Research Methods Applied in the Articles

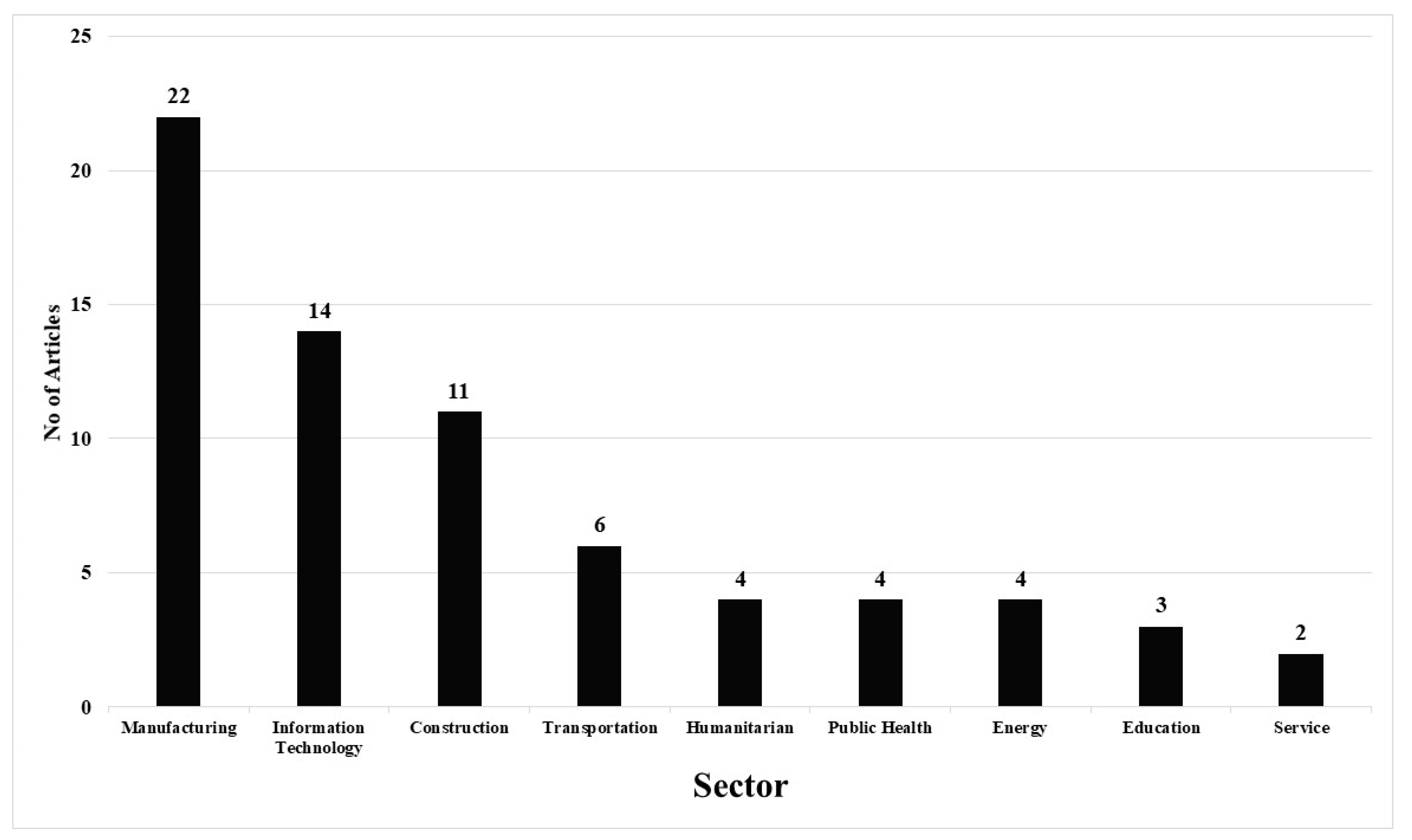

3.1.3. Sectoral Analysis of Findings

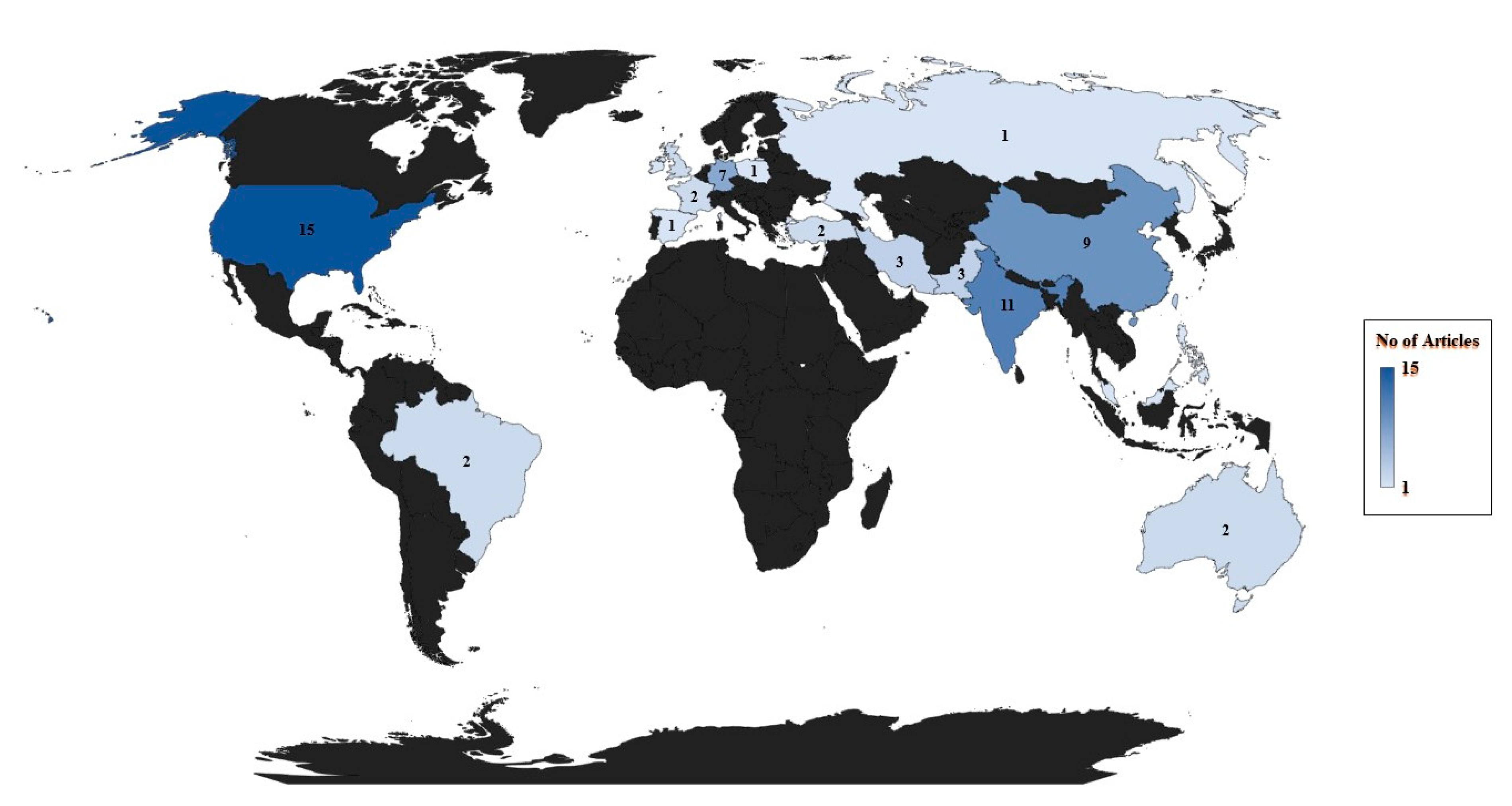

3.1.4. Analysis of Findings by Country of Origin

3.2. Bibliometric and Content Analyses

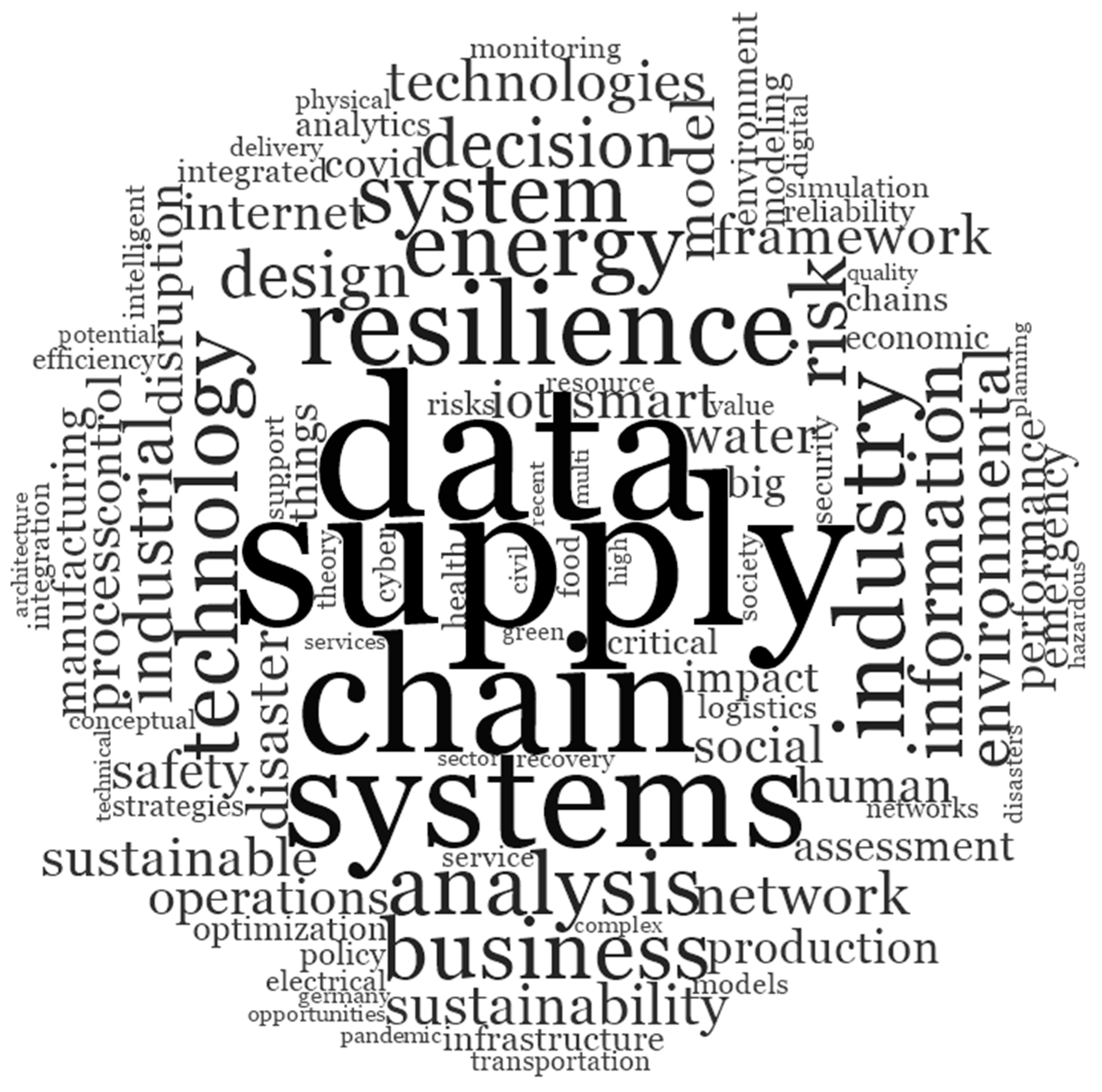

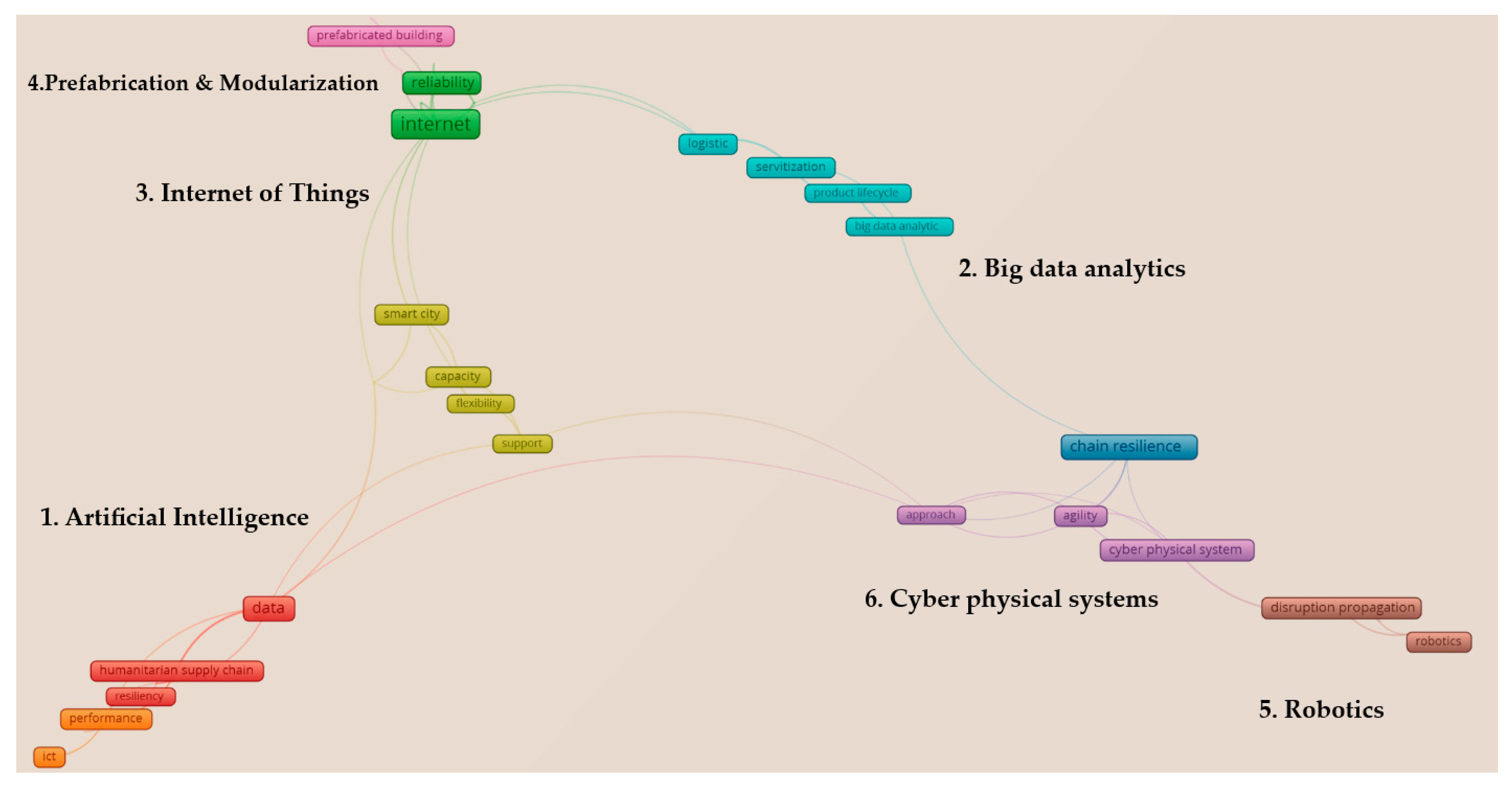

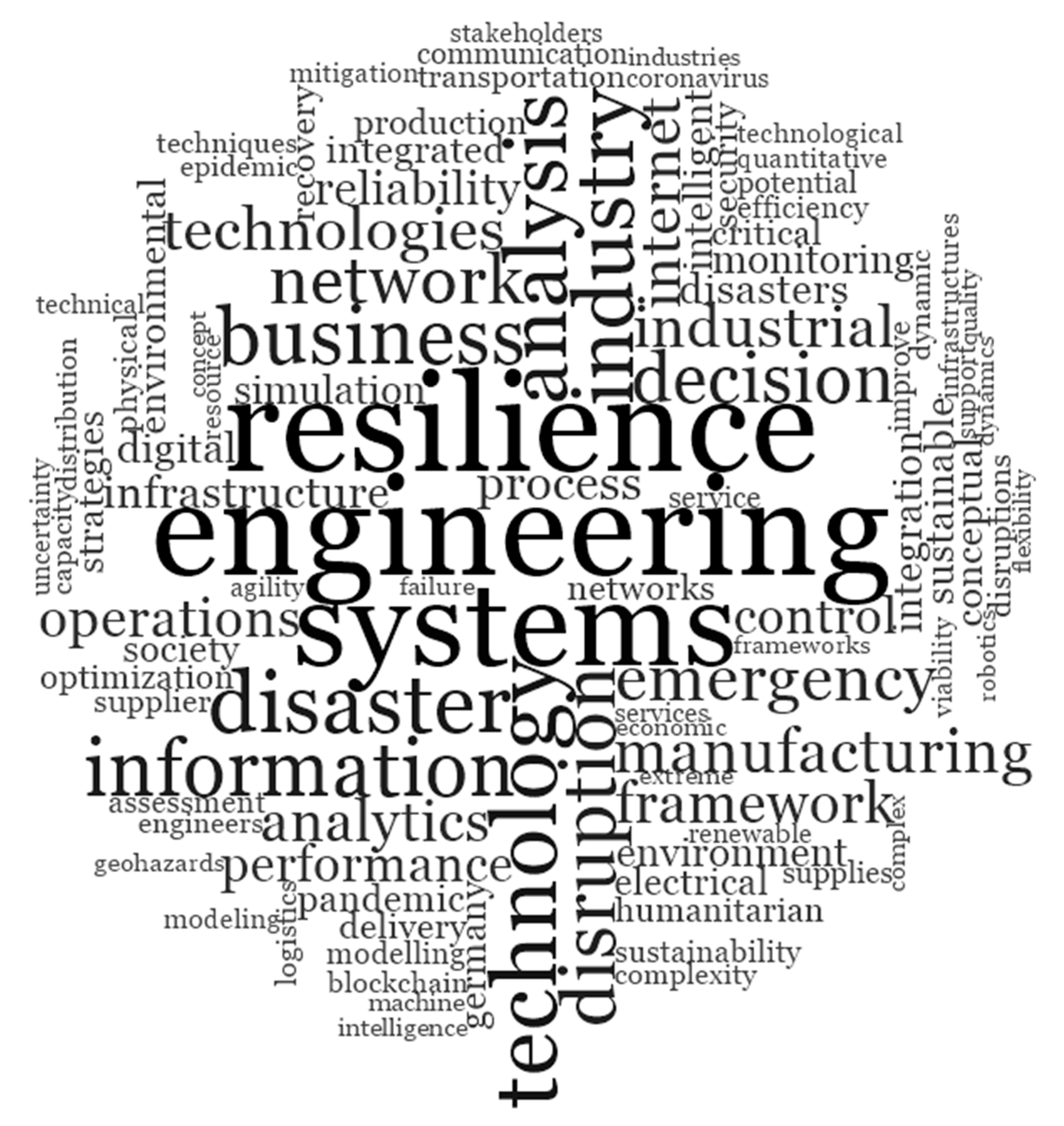

3.2.1. Co-Occurrence Analytical Map and Word Clouds Analysis of Keywords

3.2.2. Clustering and Content Analysis

4. Discussion

4.1. Artificial Intelligence

4.2. Big Data Analytics

4.3. Internet of Things

4.4. Prefabrication and Modularization

4.5. Robotics

4.6. Cyber Physical Systems

4.7. Future Research Agenda

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0–a glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative Industrie 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; Forschungsunion: Berlin, Germany, 2013. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. (Eds.) Design Principles for Industrie 4.0 Scenarios; IEEE: Washington, DC, USA, 2016. [Google Scholar]

- Bittencourt, V.L.; Alves, A.C.; Leão, C.P. Industry 4.0 triggered by lean thinking: Insights from a systematic literature review. Int. J. Prod. Res. 2021, 59, 1496–1510. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 ten years on: A bibliometric and systematic review of concepts, sustainability value drivers, and success determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Luz Tortorella, G.; Cauchick-Miguel, P.A.; Li, W.; Staines, J.; McFarlane, D. What does operational excellence mean in the Fourth Industrial Revolution era? Int. J. Prod. Res. 2021, 1–17. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Blunck, E.; Werthmann, H. (Eds.) Industry 4.0-An Opportunity to Realize Sustainable Manufacturing and Its Potential for A Circular Economy; Sveučilište u Dubrovniku: Dubrovnik, Croatia, 2017. [Google Scholar]

- Magid, E.; Zakiev, A.; Tsoy, T.; Lavrenov, R.; Rizvanov, A. Automating pandemic mitigation. Adv. Rob. 2021, 35, 1–8. [Google Scholar] [CrossRef]

- Sobb, T.; Turnbull, B.; Moustafa, N. Supply chain 4.0: A survey of cyber security challenges, solutions and future directions. Electronics 2020, 9, 1864. [Google Scholar] [CrossRef]

- Mohebbi, S.; Zhang, Q.; Wells, E.C.; Zhao, T.; Nguyen, H.; Li, M.; Abdel-Mottaleb, N.; Uddin, S.; Lu, Q.; Wakhungu, M.; et al. Cyber-physical-social interdependencies and organizational resilience: A review of water, transportation, and cyber infrastructure systems and processes. Sustain. Cities Soc. 2020, 62, 102327. [Google Scholar] [CrossRef]

- Craveiroa, F.; Duartec, J.P.; Bartoloa, H.; Bartolod, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on construction 4.0. Sus. Dev. 2019, 4, 251–267. [Google Scholar] [CrossRef]

- Lo, C.K.; Chen, C.H.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A.; Anosike, A. The relationship between lean and environmental performance: Practices and measures. J. Clean. Prod. 2019, 224, 120–131. [Google Scholar] [CrossRef]

- Ciano, M.P.; Dallasega, P.; Orzes, G.; Rossi, T. One-to-one relationships between industry 4.0 technologies and lean production techniques: A multiple case study. Int. J. Prod. Res. 2021, 59, 1386–1410. [Google Scholar] [CrossRef]

- Habibi Rad, M.; Mojtahedi, M.; Ostwald, M.J. The integration of lean and resilience paradigms: A systematic review identifying current and future research directions. Sustainability 2021, 13, 8893. [Google Scholar] [CrossRef]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2020, 58, 1384–1400. [Google Scholar] [CrossRef]

- UNISDR. Sendai Framework for Disaster Risk Reduction 2015–2030; United Nation: New York, NY, USA, 2015. [Google Scholar]

- Izumi, T.; Shaw, R.; Djalante, R.; Ishiwatari, M.; Komino, T. Disaster risk reduction and innovations. Prog. Dis. Sci. 2019, 2, 100033. [Google Scholar] [CrossRef]

- Ogie, R.I.; Rho, J.C.; Clarke, R.J. (Eds.) Artificial Intelligence in Disaster Risk Communication: A Systematic Literature Review; IEEE: Washington, DC, USA, 2018. [Google Scholar]

- Sarkheil, H.; Habibi Rad, M.; Khorasani, N.A. Measuring water use efficiency and productivity of Tehran using data envelopment analysis. J. Nat. Environ. 2015, 68, 595–608. [Google Scholar]

- Ivanov, D. Viable supply chain model: Integrating agility, resilience and sustainability perspectives-lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2020, 1–21. [Google Scholar] [CrossRef]

- Benevolenza, M.A.; DeRigne, L. The impact of climate change and natural disasters on vulnerable populations: A systematic review of literature. J. Hum. Behav. Soc. Environ. 2019, 29, 266–281. [Google Scholar] [CrossRef]

- Panwar, V.; Sen, S. Economic impact of natural disasters: An empirical re-examination. Margin J. Appl. Econ. Res. 2019, 13, 109–139. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and green–a systematic review of the state of the art literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Waltman, L. Large-scale analysis of the accuracy of the journal classification systems of Web of Science and Scopus. J. Inform. 2016, 10, 347–364. [Google Scholar] [CrossRef] [Green Version]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; López-Cózar, E.D. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Inform. 2018, 12, 1160–1177. [Google Scholar] [CrossRef] [Green Version]

- Bonilla, S.H.; Silva, H.R.O.; Da Terra Silva, M.; Franco Gonçalves, R.; Sacomano, J.B. Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef] [Green Version]

- Saunders, M.N.K.; Lewis, P.; Thornhill, A. Research Methods for Business Students; Pearson Education: New York, NY, USA, 2015. [Google Scholar]

- White, M.D.; Marsh, E.E. Content analysis: A flexible methodology. Libr. Trends 2006, 55, 22–45. [Google Scholar] [CrossRef] [Green Version]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. J. Clin. Epidemiol. 2009, 62, e1–e34. [Google Scholar] [CrossRef] [Green Version]

- AlHinai, Y.S. Disaster management digitally transformed: Exploring the impact and key determinants from the UK national disaster management experience. Int. J. Disaster Risk Reduct. 2020, 51. [Google Scholar] [CrossRef] [PubMed]

- Taylor, G.R. Integrating Quantitative and Qualitative Methods in Research; University Press of America: Lanham, MD, USA, 2005. [Google Scholar]

- Pearce, A.; Pons, D. Advancing lean management: The missing quantitative approach. Oper. Res. Perspect. 2019, 6, 100114. [Google Scholar] [CrossRef]

- Bosher, L.; Dainty, A.; Carrillo, P.; Glass And, J.; Price, A. Integrating disaster risk management into construction: A UK perspective. Build. Res. Inf. 2007, 35, 163–177. [Google Scholar] [CrossRef] [Green Version]

- Farooq, M.U.; Hussain, A.; Masood, T.; Habib, M.S. Supply chain operations management in pandemics: A state-of-the-art review inspired by COVID-19. Sustainability 2021, 13, 2504. [Google Scholar] [CrossRef]

- Inderwildi, O.; Zhang, C.; Wang, X.; Kraft, M. The impact of intelligent cyber-physical systems on the decarbonization of energy. Energy Environ. Sci. 2020, 13, 744–771. [Google Scholar] [CrossRef]

- Khanra, S.; Dhir, A.; Mäntymäki, M. Big data analytics and enterprises: A bibliometric synthesis of the literature. Enterp. Inf. Syst. 2020, 14, 737–768. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Marra, M. The state of the art development of AHP (1979–2017): A literature review with a social network analysis. Int. J. Prod. Res. 2017, 55, 6653–6675. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yu, Y.; Zhang, N. Sustainable supply chain management under big data: A bibliometric analysis. J. Enterp. Inf. Manag. 2020. [Google Scholar] [CrossRef]

- Sahoo, S. Big data analytics in manufacturing: A bibliometric analysis of research in the field of business management. Int. J. Prod. Res. 2021, 1–29. [Google Scholar] [CrossRef]

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.L. Blockchain applications in supply chains, transport and logistics: A systematic review of the literature. Int. J. Prod. Res. 2020, 58, 2063–2081. [Google Scholar] [CrossRef]

- Aldrighetti, R.; Battini, D.; Ivanov, D.; Zennaro, I. Costs of resilience and disruptions in supply chain network design models: A review and future research directions. Int. J. Prod. Econ. 2021, 235, 108103. [Google Scholar] [CrossRef]

- Bastian, M.; Heymann, S.; Jacomy, M. (Eds.) Gephi: An Open Source Software for Exploring and Manipulating Networks; AAAI Press: Palo Alto, CA, USA, 2009. [Google Scholar]

- Persson, O.; Danell, R.; Schneider, J.W. How to use bibexcel for various types of bibliometric analysis. Celebrating Scholarly Communication Studies: A Festschrift for Olle Persson at his 60th Birthday. ISSI 2009, 5, 9–24. [Google Scholar]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef] [Green Version]

- Thomas, J.; Harden, A. Methods for the thematic synthesis of qualitative research in systematic reviews. BMC Med. Res. Methodol. 2008, 8, 45. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shirowzhan, S.; Sepasgozar, S.M.E.; Edwards, D.J.; Li, H.; Wang, C. BIM compatibility and its differentiation with interoperability challenges as an innovation factor. Autom. Constr. 2020, 112, 103086. [Google Scholar] [CrossRef]

- Leung, X.Y.; Sun, J.; Bai, B. Bibliometrics of social media research: A co-citation and co-word analysis. Int. J. Hosp. Manag. 2017, 66, 35–45. [Google Scholar] [CrossRef]

- Chen, N.; Liu, W.; Bai, R.; Chen, A. Application of computational intelligence technologies in emergency management: A literature review. Artif. Intell. Rev. 2019, 52, 2131–2168. [Google Scholar] [CrossRef]

- Sun, W.; Bocchini, P.; Davison, B.D. Applications of artificial intelligence for disaster management. Nat. Hazards 2020, 1–59. [Google Scholar] [CrossRef]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97. [Google Scholar] [CrossRef]

- Dong, S.; Yu, T.; Farahmand, H.; Mostafavi, A. Bayesian modeling of flood control networks for failure cascade characterization and vulnerability assessment. Comput.-Aided Civ. Inf. Eng. 2020, 35, 668–684. [Google Scholar] [CrossRef]

- Gupta, R.; Tanwar, S.; Tyagi, S.; Kumar, N. Machine learning models for secure data analytics: A taxonomy and threat model. Comput. Commun. 2020, 153, 406–440. [Google Scholar] [CrossRef]

- Li, R.; Tian, X.; Yu, L.; Kang, R. A systematic disturbance analysis method for resilience evaluation: A case study in material handling systems. Sustainability 2019, 11, 1447. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Chen, K.; Collignon, S.; Ivanov, D. Ripple effect in the supply chain network: Forward and backward disruption propagation, network health and firm vulnerability. Eur. J. Oper. Res. 2021, 291, 1117–1131. [Google Scholar] [CrossRef]

- Manandhar, A.; Fischer, A.; Bradley, D.J.; Salehin, M.; Islam, M.S.; Hope, R.; Clifton, D.A. Machine learning to evaluate impacts of flood protection in Bangladesh, 1983–2014. Water 2020, 12, 483. [Google Scholar] [CrossRef] [Green Version]

- Dick, K.; Russell, L.; Souley Dosso, Y.; Kwamena, F.; Green, J.R. Deep learning for critical infrastructure resilience. J. Inf. Syst. 2019, 25, 5019003. [Google Scholar] [CrossRef]

- Jeble, S.; Kumari, S.; Venkatesh, V.G.; Singh, M. Influence of big data and predictive analytics and social capital on performance of humanitarian supply chain: Developing framework and future research directions. Benchmarking 2019, 27, 606–633. [Google Scholar] [CrossRef]

- Akter, S.; Wamba, S.F. Big data and disaster management: A systematic review and agenda for future research. Ann. Oper. Res. 2019, 283, 939–959. [Google Scholar] [CrossRef] [Green Version]

- Sarker, M.N.I.; Peng, Y.; Yiran, C.; Shouse, R.C. Disaster resilience through big data: Way to environmental sustainability. Int. J. Dis. Risk Reduc. 2020, 51, 101769. [Google Scholar] [CrossRef]

- Masood, T.; So, E.; McFarlane, D. Disaster Management Operations–Big Data Analytics to Resilient Supply Networks. In Proceedings of the 24th EurOMA Conference, Edinburgh, UK, 1–5 July 2017. [Google Scholar]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The role of big data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef] [Green Version]

- Bui, T.-D.; Tsai, F.M.; Tseng, M.-L.; Tan, R.R.; Yu, K.; Lim, M.K. Sustainable supply chain management towards disruption and organizational ambidexterity: A data driven analysis. Sustain. Prod. Consum. 2021, 26, 373–410. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plann. Control. 2020, 1–14. [Google Scholar] [CrossRef]

- Shah, S.A.; Seker, D.Z.; Rathore, M.M.; Hameed, S.; Yahia, S.B.; Draheim, D. Towards disaster resilient smart cities: Can Internet of Things and big data analytics be the game changers? IEEE Access 2019, 7, 91885–91903. [Google Scholar] [CrossRef]

- Singh, N. Developing business risk resilience through risk management infrastructure: The moderating role of big data analytics. Inf. Syst. Manag. 2020, 1–19. [Google Scholar] [CrossRef]

- Mei, G.; Xu, N.; Qin, J.; Wang, B.; Qi, P. A Survey of Internet of Things (IoT) for Geohazard Prevention: Applications, technologies, and challenges. IEEE Int. Things J. 2020, 7, 4371–4386. [Google Scholar] [CrossRef]

- Yang, J.; Hou, H.; Chen, Y.; Han, L. An Internet of Things based material delivery model for disaster management in libraries. Libr. Hi Tech 2019, 38, 181–194. [Google Scholar] [CrossRef]

- Hou, H.; Yang, J.; Chen, Y.; Yu, M. A material delivery system built on Internet of Things and the role of libraries. Libr. Hi Tech. 2019, 38, 195–209. [Google Scholar] [CrossRef]

- Xing, L. Reliability in Internet of Things: Current status and future perspectives. IEEE Internet Things J. 2020, 7, 6704–6721. [Google Scholar] [CrossRef]

- Chen, H.Y.; Das, A.; Ivanov, D. Building resilience and managing post-disruption supply chain recovery: Lessons from the information and communication technology industry. Int. J. Inf. Manag. 2019, 49, 330–342. [Google Scholar] [CrossRef]

- Chen, Y. Industrial information integration—A literature review 2006–2015. J. Ind. Inf. Integr. 2016, 2, 30–64. [Google Scholar] [CrossRef]

- Kumar, A.; Rajalakshmi, K.; Jain, S.; Nayyar, A.; Abouhawwash, M. A novel heuristic simulation-optimization method for critical infrastructure in smart transportation systems. Int. J. Commun. Syst. 2020, 33. [Google Scholar] [CrossRef]

- Sood, S.K. Bibliometric monitoring of research performance in ICT-based disaster management literature. Qual. Quant. 2021, 55, 103–132. [Google Scholar]

- Soyata, T.; Habibzadeh, H.; Ekenna, C.; Nussbaum, B.; Lozano, J. Smart city in crisis: Technology and policy concerns. Sustain. Cities Soc. 2019, 50. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for manufacture and assembly-oriented parametric design of prefabricated buildings. Autom Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Luo, L.; Liang, X.; Fang, C.; Wu, Z.; Wang, X.; Wang, Y. How to promote prefabricated building projects through Internet of Things? A game theory-based analysis. J. Clean. Prod. 2020, 276, 124325. [Google Scholar] [CrossRef]

- Ghannad, P.; Lee, Y.-C.; Choi, J.O. Feasibility and implications of the modular construction approach for rapid post-disaster recovery. Int. J. Ind. Constr. 2020, 1, 64–75. [Google Scholar] [CrossRef]

- Ghannad, P.; Lee, Y.-C.; Choi, J.O. Investigating stakeholders’ perceptions of feasibility and implications of modular construction-based post-disaster reconstruction. In Proceedings of the Modular and Offsite Construction (MOC) Summit Proceedings 2019, Banff, AB, Canada, 21–24 May 2019; pp. 504–513. [Google Scholar] [CrossRef] [Green Version]

- Saeed, Z.O.; Almukhtar, A.; Salih, K. (Eds.) Construction Beyond War: Assessing Time and Cost of Prefabrication in Rebuilding Post-Disaster Cities; Saeed; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Yaacoub, J.-P.; Noura, H.N.; Salman, O.; Chehab, A. Robotics cyber security: Vulnerabilities, attacks, countermeasures, and recommendations. Int. J. Inf. Secur. 2021. [Google Scholar] [CrossRef] [PubMed]

- Fuentes, R.; Chapman, T.; Cook, M.; Scanlan, J.; Li, Z.; Richardson, R.C. Briefing: UK-RAS white paper in robotics and autonomous systems for resilient infrastructure. Proc. Inst. Civ. Eng. -Smart Inf. Cons. 2017, 170, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Wagner, H.J.; Alvarez, M.; Groenewolt, A.; Menges, A. Towards digital automation flexibility in large-scale timber construction: Integrative robotic prefabrication and co-design of the BUGA Wood Pavilion. Constr. Robot. 2020, 4, 187–204. [Google Scholar] [CrossRef]

- Nguyen, W.; Nof, S.Y. Collaborative response to disruption propagation (CRDP) in cyber-physical systems and complex networks. Decis. Support Syst. 2019, 117, 1–13. [Google Scholar] [CrossRef]

- Green, A.; Dodson, K.; Woszczynski, A.B.; Easton, P. Responding to cybersecurity challenges: Securing vulnerable U.S. emergency alert systems. Commun. Assoc. Inf. Syst. 2020, 46, 187–208. [Google Scholar] [CrossRef]

- Rasouli, M.R. Intelligent process-aware information systems to support agility in disaster relief operations: A survey of emerging approaches. Int. J. Prod. Res. 2019, 57, 1857–1872. [Google Scholar] [CrossRef]

- Sarkheil, H.; Rad, M.H. (Eds.) 4D Electrical Resistivity Tomography Monitoring of Talesh Mahaleh-Rasht Coastal Aquifer Polluted by Caspian Seawater; European Association of Geoscientists & Engineers: Turin, Italy, 2015. [Google Scholar]

- Bosher, L.; Chmutina, K. Disaster Risk Reduction for The Built Environment; Wiley Online Library: Hoboken, NJ, USA, 2017. [Google Scholar]

- Fernando, R.L.S. (Ed.) Artificial Intelligence and Disaster Management in Sri Lanka: Problems and Prospects; Springer: New York, NY, USA, 2020. [Google Scholar]

- Mitsova, D.; Escaleras, M.; Sapat, A.; Esnard, A.-M.; Lamadrid, A.J. The effects of infrastructure service disruptions and socio-economic vulnerability on hurricane recovery. Sustainability 2019, 11, 516. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Wang, X.; Tan, Y.; Wu, P.; Sutrisna, M.; Cheng, J.; Hampson, K. Trends and opportunities of BIM-GIS integration in the architecture, engineering and construction industry: A review from a spatio-temporal statistical perspective. ISPRS Int. J. Geo-Inf. 2017, 6, 397. [Google Scholar] [CrossRef] [Green Version]

- Moşteanu, N.R.; Faccia, A.; Cavaliere, L.P.L. Disaster Management, Digitalization and Financial Resources: Key Factors to Keep The Organization Ongoing. In Proceedings of the 4th International Conference on Cloud and Big Data Computing, ICCBDC 2020, Virtual, Online, UK, 26–28 August 2020. [Google Scholar]

- Mottahedi, A.; Sereshki, F.; Ataei, M.; Qarahasanlou, A.N.; Barabadi, A. Resilience estimation of critical infrastructure systems: Application of expert judgment. Reliab. Eng. Syst. Saf. 2021, 215, 107849. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A. Big data-driven supply chain performance measurement system: A review and framework for implementation. Int. J. Prod. Res. 2020, 58, 65–86. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recyc. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Ahmed, V.; Tezel, A.; Aziz, Z.; Sibley, M. The future of big data in facilities management: Opportunities and challenges. Facilities 2017, 35, 725–745. [Google Scholar] [CrossRef] [Green Version]

- Inamdar, Z.; Raut, R.; Narwane, V.S.; Gardas, B.; Narkhede, B.; Sagnak, M. A systematic literature review with bibliometric analysis of big data analytics adoption from period 2014 to 2018. J. Enterp. Inf. Manag. 2020. [Google Scholar] [CrossRef]

- van Westen, C.J. Remote sensing and GIS for natural hazards assessment and disaster risk management. Treatise Geomorphol. 2013, 3, 259–298. [Google Scholar]

- Xiao, Y.; Huang, Q.; Wu, K. Understanding social media data for disaster management. Nat. Hazards 2015, 79, 1663–1679. [Google Scholar] [CrossRef]

- Ghaffarian, S.; Kerle, N.; Filatova, T. Remote sensing-based proxies for urban disaster risk management and resilience: A review. Remote Sens. 2018, 10, 1760. [Google Scholar] [CrossRef] [Green Version]

- UNISDR. Sharing Innovations to Improve Implementation and Reporting of the Sendai Framework for Disaster Risk Reduction; UNISDR: Geneva, Switzerland, 2016. [Google Scholar]

- Giusto, D.; Iera, A.; Morabito, G.; Atzori, L. The Internet of Things: 20th Tyrrhenian Workshop on Digital Communications; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Gamil, Y.; Abdullah, M.A.; Abd Rahman, I.; Asad, M.M. Internet of Things in construction industry revolution 4.0. J. Eng. Des. Technol. 2020, 18. [Google Scholar] [CrossRef]

- Malik, P.K.; Sharma, R.; Singh, R.; Gehlot, A.; Satapathy, S.C.; Alnumay, W.S. Industrial Internet of Things and its Applications in Industry 4.0: State of The Art. Comput. Commun. 2021, 166, 125–139. [Google Scholar] [CrossRef]

- Al-Turjman, F. Cognitive routing protocol for disaster-inspired Internet of Things. Future Gener. Comput. Syst. 2019, 92, 1103–1115. [Google Scholar] [CrossRef]

- Russell, L.; Goubran, R.; Kwamena, F.; Knoefel, F. Agile IoT for critical infrastructure resilience: Cross-modal sensing as part of a situational awareness approach. IEEE Int. Things J. 2018, 5, 4454–4465. [Google Scholar] [CrossRef]

- Golpîra, H.; Khan, S.; Safaeipour, S. A review of logistics Internet-of-Things: Current trends and scope for future research. J. Ind. Infor. Integr. 2021, 22. [Google Scholar] [CrossRef]

- Lizarralde, G.; Johnson, C. Myths and realities of prefabrication for post-disaster reconstruction. In Building Resilience Achieving Effective Post-Disaster Reconstruction; I-Rec: Latham, NY, USA, 2008. [Google Scholar]

- Bertram, N.; Fuchs, S.; Mischke, J.; Palter, R.; Strube, G.; Woetzel, J. Modular Construction: From Projects to Products; McKinsey & Company: Brussels, Belgium, 2019; pp. 1–34, Capital Projects & Infrastructure. [Google Scholar]

- Alvanchi, A.; Azimi, R.; Lee, S.; AbouRizk, S.M.; Zubick, P. Off-site construction planning using discrete event simulation. J. Archit. Eng. 2012, 18, 114–122. [Google Scholar] [CrossRef]

- Innella, F.; Arashpour, M.; Bai, Y. Lean methodologies and techniques for modular construction: Chronological and critical review. J. Constr. Eng. Manag. 2019, 145, 4019076. [Google Scholar] [CrossRef]

- Blismas, N. Off-site Manufacture in Australia: Current State and Future Directions; CRC for Construction Innovation: Queensland, Australia, 2007. [Google Scholar]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Murphy, R.R. Disaster Robotics; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Rad, M.H.; Sarkheil, H.; Khojastehpour, R. (Eds.) Analysing Water Use Efficiency and Productivity in Iran’s Metropolises; Thomas Telford Ltd.: London, UK, 2019. [Google Scholar] [CrossRef]

- Norouzalizadeh, G.R.; Habibi, R.M. Improving energy consumption in building products using life cycle assessment and energy analysis. Asian J. Civ. Eng. (Build. Hous.) 2016, 17, 443–457. [Google Scholar]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Lee, E.A. (Ed.) Cyber Physical Systems: Design Challenges; IEEE: Washington, DC, USA, 2008. [Google Scholar]

- Bonci, A.; Carbonari, A.; Cucchiarelli, A.; Messi, L.; Pirani, M.; Vaccarini, M. A cyber-physical system approach for building efficiency monitoring. Autom. Constr. 2019, 102, 68–85. [Google Scholar] [CrossRef]

- Lei, Y.; Rao, Y.; Wu, J.; Lin, C.-H. BIM based cyber-physical systems for intelligent disaster prevention. J. Ind. Infor. Integr. 2020, 20, 100171. [Google Scholar] [CrossRef]

| Cluster | Thematic Area | Articles |

|---|---|---|

| Cluster 1 | Artificial Intelligence | [23,55,56,57,58,59,60,61,62,63,64] |

| Cluster 2 | Big data analytics | [65,66,67,68,69,70,71,72,73] |

| Cluster 3 | Internet of Things | [74,75,76,77,78,79,80,81,82] |

| Cluster 4 | Prefabrication & Modularization | [83,84,85,86,87] |

| Cluster 5 | Robotics | [12,88,89,90] |

| Cluster 6 | Cyber physical systems | [14,91,92,93] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habibi Rad, M.; Mojtahedi, M.; Ostwald, M.J. Industry 4.0, Disaster Risk Management and Infrastructure Resilience: A Systematic Review and Bibliometric Analysis. Buildings 2021, 11, 411. https://doi.org/10.3390/buildings11090411

Habibi Rad M, Mojtahedi M, Ostwald MJ. Industry 4.0, Disaster Risk Management and Infrastructure Resilience: A Systematic Review and Bibliometric Analysis. Buildings. 2021; 11(9):411. https://doi.org/10.3390/buildings11090411

Chicago/Turabian StyleHabibi Rad, Mahyar, Mohammad Mojtahedi, and Michael J. Ostwald. 2021. "Industry 4.0, Disaster Risk Management and Infrastructure Resilience: A Systematic Review and Bibliometric Analysis" Buildings 11, no. 9: 411. https://doi.org/10.3390/buildings11090411

APA StyleHabibi Rad, M., Mojtahedi, M., & Ostwald, M. J. (2021). Industry 4.0, Disaster Risk Management and Infrastructure Resilience: A Systematic Review and Bibliometric Analysis. Buildings, 11(9), 411. https://doi.org/10.3390/buildings11090411