1. Introduction

RC construction involves repetitive activities, with formwork, rebar, and concrete being the main components of these activities in building construction projects [

1]. Formwork accounts for a major part of the RC structure’s cost [

2]. For instance, the selected FWS may contribute to up to two-thirds of the entire cost of the RC structural frame [

3] and 10% of the total construction cost [

4]. In Turkey, the labour cost of formwork accounts for 10 to 15% of the total cost of a building construction project [

5]. Advancements in formwork engineering may significantly reduce the cost and material waste while improving the potential of a project’s success [

6]. In addition, the selected FWS may have a significant impact on the project’s overall duration [

7] as well as the safety and quality of a building construction project [

8]. Therefore, as RC construction developed, construction professionals in the field of formwork engineering were required to provide solutions by developing new FWSs [

9]. The FWS may be selected based on a variety of criteria, some of which are interdependent [

10]. Furthermore, the relative importance level of the FWS selection criteria, and thus the selection of the appropriate FWS, may depend on the perception of different project stakeholders, such as contractors [

11], or on the perception of different construction professionals, such as formwork planning engineers [

12].

Most of the previous studies in the relevant literature identified, ranked, and analysed FWS selection criteria based on a certain group of construction professionals or stakeholders [

7,

11,

12]. In addition, few studies have compared the perspectives and perceptions regarding the relative importance level of FWS selection criteria among a particular group of respondents (e.g., contractors) [

13]. However, no prior study has investigated whether there are any significant statistical differences/disagreements in the relative importance of FWS selection criteria among different groups of construction professionals and/or companies. Moreover, some building structural parameters (e.g., total building area, total building height) of the building construction project may significantly affect the FWS design and selection [

14,

15]. Hence, the effects, if any, of the building structural parameters on the FWS selection criteria may reveal some valuable insights for construction professionals in their decision-making process.

As the selection of the FWS is considered as a difficult task and requires the early involvement of all the stakeholders in the early phases of a project (e.g., formwork fabricator (FWF)) [

16], analysing the perspectives and perceptions of different groups of construction professionals and companies regarding the FWS selection criteria may improve the project performance factors. The main objectives of this study include (1) comparing the perspectives and perceptions of the different groups of construction professionals and companies on the FWS selection criteria, and (2) identifying the effects of the building structural parameters on the FWS selection criteria. The results of this study can also be used by decision-makers and construction professionals involved in the selection process of FWSs.

2. Literature Review

Throughout the twentieth century, formwork engineering developed in lockstep with the expansion of concrete construction [

17]. The developments and technological advancements in formwork engineering led to the widespread use of industrial FWSs across the world [

18]. Since there are many FWSs available, the selection of the appropriate FWS depends on various compromising and conflicting criteria [

7,

19]. Therefore, a number of quantitative and qualitative criteria have been identified in previous studies that may affect the selection of FWSs in building construction projects. The majority of these studies have identified and/or ranked the FWS selection criteria [

13,

20], while others have employed multi-criteria-decision-making (MCDM) methods to solve the FWS selection problem [

2,

21]. The following is a brief chronological summary of these studies.

Initially, Hanna [

22] identified 38 factors for the FWS selection problem in building construction projects in the United States and grouped them into four categories based on expert opinion: building design, job specification, local conditions, and supporting organisation. Then, Hanna and Sanvido [

23] developed an interactive expert system for the vertical FWS selection problem, specifically for contractors, based on Hanna’s [

22] factors and FWS alternatives. Analogously, the study by Hanna et al. [

24] provided a rule-based expert system for decision-makers and formwork design engineers to select the most appropriate FWS (e.g., horizontal and vertical FWS) in building construction projects. Building structural parameters, such as the total building height, total area of building construction, and typical building floor area, were introduced as factors affecting the FWS selection [

20,

22,

23,

24]. Selecting the appropriate FWS can be a complex process [

7]. Therefore, neural network (NN) models [

2,

25,

26,

27] and decision tree (DT) models [

7,

28] have been developed to solve the FWS selection problem based on the factors identified by Hanna’s [

22] study. In these studies, additional building structural parameters affecting the FWS selection, such as floor area and number of floors, were incorporated into the relevant literature. Hanna [

20] introduced labour productivity as an additional factor to the relevant literature in an extended version of the previously stated rules and guidelines for selecting FWSs. Proverbs et al. [

13] analysed and compared the relative importance levels of nine factors affecting FWS selection among contractors and planning engineers from the UK, France, and Germany and determined the degree of agreement between them. Jarkas [

29] measured the labour productivity of the selected FWS based on building structural parameters. Elbeltagi et al. [

21] and Elbeltagi et al. [

30] presented fuzzy logic models to select horizontal and vertical FWSs, respectively, based on the five most important FWS selection factors for Egyptian formwork engineering experts.

From 1989 to 2012, the majority of the studies regarding the FWS selection problem focused on the FWS selection criteria under the four main groups presented by Hanna [

24]. Novel challenges in architectural and structural design, such as those in free-form concrete buildings with irregular and curved geometries, required new developments in formwork technology [

31]. In addition, the popularity of industrial FWSs in building construction projects throughout the world, along with the introduction of new FWSs [

32], prompted the inclusion of additional FWS selection criteria in the years that followed. For example, Krawczyska-Piechna [

33], Krawczyska-Piechna [

34], and Krawczyska-Piechna [

35] extended the relevant literature by proposing FWS flexibility, durability, compatibility, safety, and weight as additional criteria focusing on contractor preferences in Poland. In the context of the FWS safety criterion, since on-site formwork activities (e.g., erecting, stripping, or moving of the FWS) are associated with a high level of accidents [

36], research on the safety aspects of these activities [

37] and the safety of the FWS has gained more importance in the field of construction management. Furthermore, the compatibility and durability of the FWS may be critical factors when selecting an appropriate FWS [

38]. Jiang et al. [

39] introduced floor-to-floor height as a building structural parameter to the literature and used it for developing a DT model for the FWS selection problem. Martinez et al. [

40] utilized the Choosing by Advantages (CBA) method with 14 selection factors for the FWS selection problem in Ecuador based on the knowledge of a team of project managers, planning engineers, and procurement engineers. FWS complexity and FWS size were added into the literature as new FWS selection factors. Radziejowska and Sobotka’s [

41] study incorporated the expertise of site managers and contractors in Poland, and eight FWS selection criteria for vertical FWS were identified. In their study, some criteria were related to the characteristics of the FWS, such as FWS durability, weight, and size. Hence, the majority of these recently identified criteria may be grouped under a new category, namely FWS characteristics, because they describe the different properties of the FWS. Loganathan and Viswanathan [

42] evaluated the effects of FWS alternatives on the cost, time, and quality performance of high-rise building construction projects in India.

As material waste in RC construction is common [

43,

44], the sustainability of the FWS has become an important factor in recent years [

45]. In addition, building information modelling (BIM) applications used in formwork engineering can greatly improve the sustainability of a project [

46]. Therefore, some recent studies introduced the degree of formwork material recycling (i.e., FWS sustainability) and the degree of BIM applications for FWSs (i.e., FWF BIM support) to the relevant literature [

4]. For instance, Singh et al. [

47] used a BIM approach to automate the design and selection process of the FWS by utilizing some building structural parameters (e.g., floor height) in their model. Basu and Jha [

12] used factor analysis to group the FWS selection criteria identified by Hanna et al. [

24] and analytical hierarchy process (AHP) to determine the most significant FWS selection criterion groupings for formwork planning engineers in India. Similarly, Rajeshkumar and Sreevidya [

48] and Rajeshkumar et al. [

17] identified and grouped 40 FWS selection criteria into five categories by utilizing factor analysis and investigated the degree of agreement regarding the FWS selection criteria among clients, contractors, and consultants in the Indian building construction sector. Transportation cost was also introduced as a new criterion for selecting FWSs. Pawar et al. [

49] and Teja et al. [

50] determined the relative importance index (RII) of previously identified FWS selection criteria for different FWS alternatives commonly used in India. Lohana’s [

51] study revealed that the productivity criterion for selecting FWSs in building construction projects can be quantified as a function of cost, cycle time, and the degree of repetition of FWS. Ray et al. [

52] performed a break-even analysis on two commonly used industrial FWSs in India, considering the total cost of the FWS by incorporating the degree of repetition, initial cost, and maintenance cost of the FWS in their calculation. Huszar and Lubloy [

53] compared the cost of the FWS to the total cost of a building construction project while citing the initial cost of the FWS, speed of construction, FWS flexibility, and FWS safety as attributes of the selected FWS. Rajeshkumar et al. [

54] compared the cost, time, productivity, and quality performance factors of three commonly used FWSs in building construction projects. Terzioglu et al. [

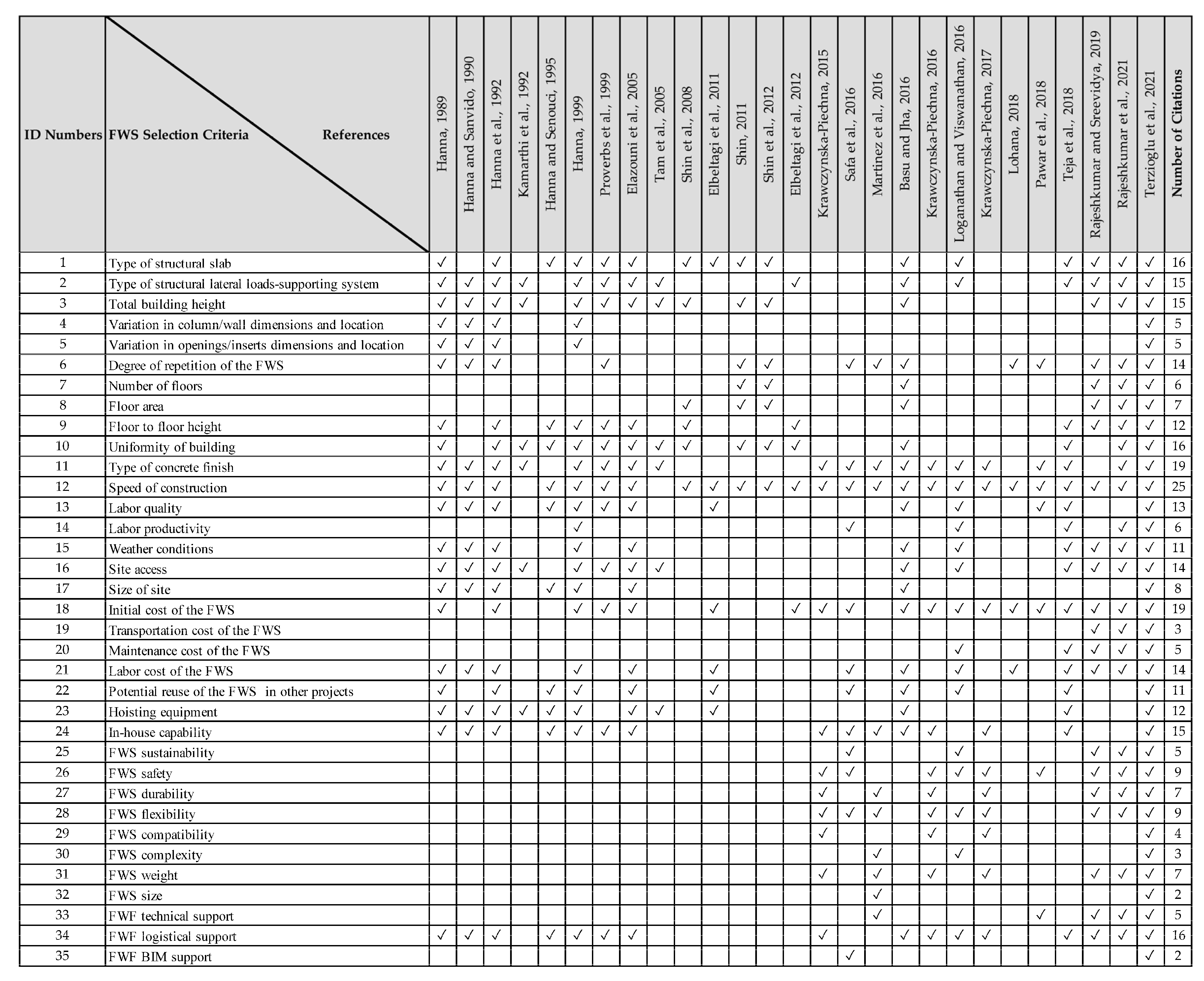

10] carried out a critical review of the literature on FWS selection criteria for building construction projects, identifying 35 FWS selection criteria in total and demonstrating that several structural design criteria are interdependent with FWS characteristics-related criteria.

In the literature, several researchers focused on identifying the FWS selection criteria and/or determining their relative importance levels through interviews with experts and questionnaire surveys conducted in different countries, such as Korea, UK, France, Germany, India, Egypt, and Ecuador [

7,

13,

17,

21,

30,

40]. However, there has been no study conducted in order to identify and/or rank the FWS selection criteria in the Turkish building construction sector. The Turkish construction sector has an annual GDP share of 5 to 6.5% and an employment share of 5 to 7% [

55]. In addition, Turkish contractors have completed 10,725 projects in 128 countries, with a total value of 424.5 billion US dollars from 1971 to 2021 [

56]. In 2020, Turkish contracting companies have undertaken 348 projects in 57 countries with a total value of 15.1 billion US dollars [

56]. Moreover, according to Engineering News-Record (ENR), 44 Turkish construction companies were listed among the top 250 international contractors in 2020, placing Turkish contractors in the second place after China [

57]. Therefore, there is a need to identify and/or rank the FWS selection criteria in the Turkish building construction sector. This issue raises a research question:

- -

Q1: Which of the identified FWS selection criteria are being considered by the companies and construction professionals in their decision-making process, and what are the relative importance levels of these FWS selection criteria in the Turkish building construction sector?

The supply chain activities associated with formwork and the selection of the FWS may be performed by different project stakeholder groups (e.g., engineer, contractor, FWF) at different phases of a building construction project [

16]. In addition, stakeholders, such as contractors, may be more inclined to minimize the cost and maximize the quality and safety of the FWS [

3], while FWFs may mostly be concerned with the technical and design aspects of the FWS [

58]. Therefore, FWS selection may vary depending on the perspectives and perceptions of the different project stakeholder groups. However, the majority of the former studies concentrated solely on the contractors or their employees as project stakeholder groups [

11,

13,

33,

34,

35]. Moreover, none of these studies have investigated if any disagreements exist among different groups of construction professionals and/or companies regarding the importance level of the FWS selection criteria. Potential differences in the perspectives and perceptions of different project stakeholder groups (i.e., construction professionals and companies) on the importance levels of the FWS selection criteria raise two important questions.

- -

Q2: What are the differences, if any, in the relative importance levels of FWS selection criteria according to the “professional title” of the construction professionals?

- -

Q3: What are the differences, if any, in the relative importance levels of FWS selection criteria according to the “field of specialization” of the companies?

These are legitimate research questions to address because identifying the agreements or disagreements regarding FWS selection criteria among all the stakeholder groups can improve the selection process and thereby the overall project performance by taking their perspectives and perceptions into account at the early phases of the project.

It is generally claimed that building structural parameters (i.e., typical building floor area, total area of building construction, typical building floor-to-floor height, total building height) play a significant role in the FWS selection process [

7,

26,

30,

50]. For example, conventional FWSs are suitable for buildings with a total building height up to 36.5 m (i.e., low-rise buildings) [

2,

24] and a floor-to-floor height less than 5 m [

30]. As another example, modern and modular FWSs (i.e., industrial FWSs) are typically suitable for a total building height greater than 36.5 m (i.e., mid-rise and/or high-rise buildings) [

4,

20,

24,

25,

49] and a floor-to-floor height greater than 4–5 m [

14,

20]. Similarly, conventional FWSs are usually selected if the total area of construction is less than 20,000 m

2, and industrial FWSs are selected if the total area of construction is more than 20,000 m

2 [

20,

26]. As a result, changes in the values of the building structural parameters have a significant impact on the FWS selection process.

The selection of an appropriate FWS is based on a number of conflicting and compromising criteria. Therefore, changes in the values of the building structural parameters may affect the importance levels of the FWS selection criteria. However, no research has been conducted to investigate how the importance levels of FWS selection criteria differ depending on the changes in the values of the building structural parameters. This is a research gap. This potential relationship raises another research question:

- -

Q4: What are the differences, if any, in the relative importance levels of FWS selection criteria according to the changes in the values of the “building structural parameters” (e.g., building type, total building area, total building height, typical building floor area, typical building floor-to-floor height)?

Finally, the most critical FWS selection criteria should be identified. In this context, the final research question is:

- -

Q5: What are the critical FWS selection criteria in building construction projects?

The main objective of this study is to answer these research questions and to fill the important knowledge gap by comparing the perspectives and perceptions of different construction professionals and stakeholder groups in building construction projects in Turkey, and analysing the FWS selection criteria in relation to some building structural parameters and to determine how the importance levels of the FWS selection criteria differ according to the changes in the values of the building structural parameters.

6. Conclusions

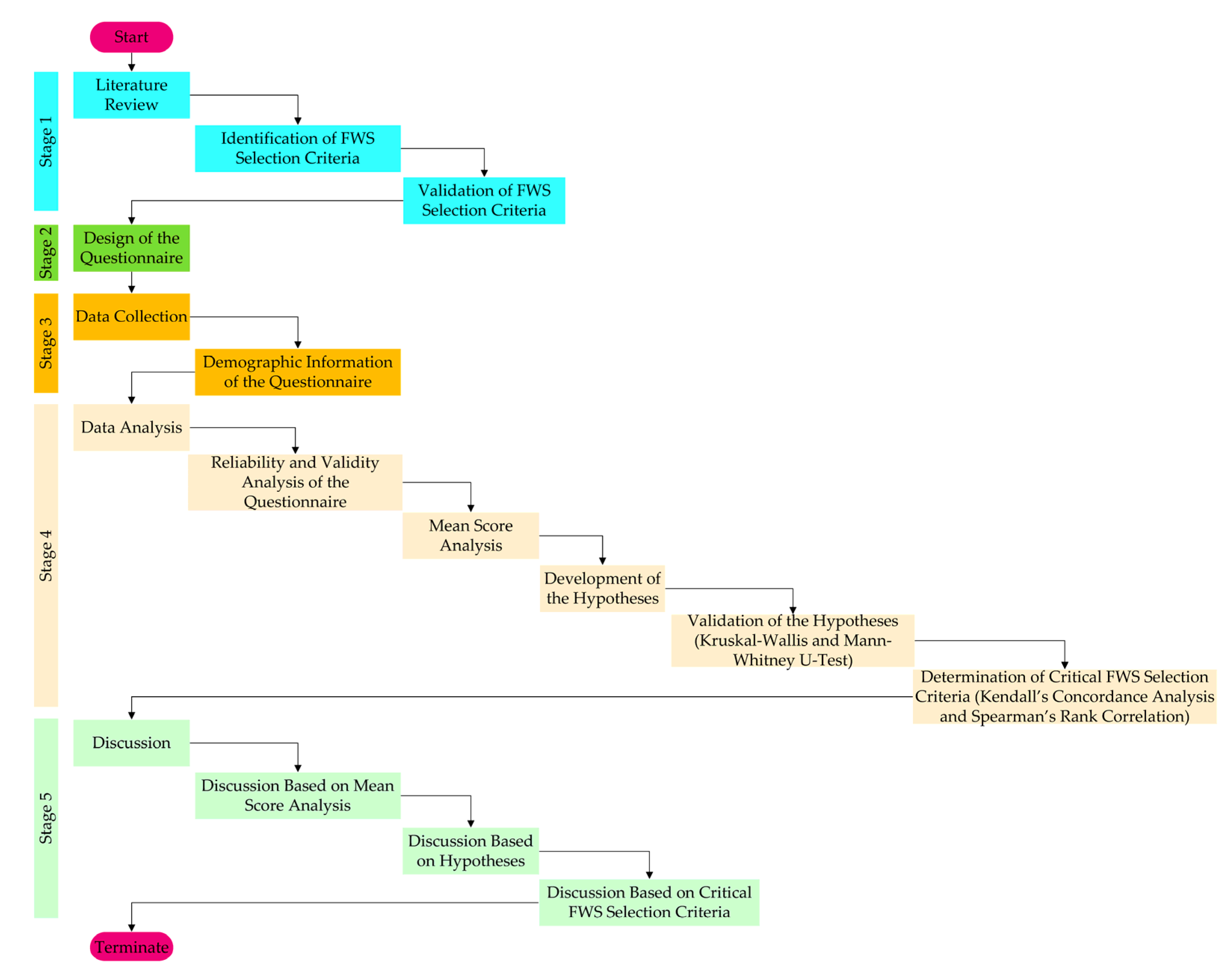

The purpose of this study was to analyse the FWS selection criteria by comparing the perspectives and perceptions of various construction professionals and stakeholder groups involved in building construction projects in Turkey. For this purpose, first, an intensive literature review was conducted and 35 FWS selection criteria for building construction projects were identified. Then, a questionnaire was developed to measure the relative importance level of the identified FWS selection criteria. Subsequently, the data obtained for the FWS selection criteria were analysed utilizing statistical tests based on the research questions and the demographic background of the respondent groups.

This study has revealed that different groups of construction professionals and companies involved in the decision-making process of FWSs mostly agreed on the relative importance level of FWS selection criteria. However, formwork and scaffolding companies and employees of these companies had significant statistical differences regarding FWS selection criteria, especially among structural design and FWS–FWF characteristics-related criteria. The main reason for this result is that these criteria are typically considered during the FWS’s planning, designing, and detailing phases, which are traditionally done by the FWF. Since the involvement of the FWF with other stakeholder groups during the design phase can improve the constructability of the building construction project, the perspectives and perceptions of the FD/FSL group or the FW/SCF group (i.e., FWF) should be considered in parallel with other groups of construction professionals and companies. Furthermore, the selected FWS, based on the FWS selection criteria, may have a significant impact on the cost and time performance factors in the later phases of a building construction project. In addition, this study determined that some of the “building structural parameters” had significant effects on the FWS selection criteria in building construction projects. The project size (i.e., total area of building construction) and total building height, in particular, affected the “speed of construction,” “hoisting equipment,” and “labour productivity” in the building construction projects. Therefore, decision-makers and construction professionals may need to consider these FWS selection criteria and the relevant building structural parameters in the selection process of the FWS to improve the performance factors of the project.

As the formwork-related activities and the selected FWS affect the overall performance of a building construction project, the identification of the critical FWS selection criteria can provide construction professionals with a useful guide in their decision-making process. The results of this study indicate that, although differences between the FD/FSL or FW/SCF and the other groups exist, there was a significant agreement among the overall respondents. Hence, it was determined that the “initial cost of the FWS”, “speed of construction”, “degree of repetition of the FWS”, “type of structural slab”, and “type of structural lateral loads-supporting system” are the critical FWS selection criteria in the building construction projects in Turkey. In this regard, since there are many FWS selection criteria, decision-makers and construction professionals may use these critical criteria in MCDM methods to ease computational efforts and improve the FWS selection process.

There are some limitations to this study. The first limitation is that this study was carried out only in Turkey. However, since Turkish construction professionals and companies operate in domestic as well as in international markets, the results of this study may benefit the global construction community as well. Second, this study focused on FWS selection criteria in building construction projects. For different types of projects, such as industrial or infrastructural projects, other FWS selection criteria can be identified and analysed. In addition, based on the quantitative data presented in this study, factor analysis and structural equation modelling (SEM) may be utilized to group the FWS selection criteria and determine the effects among the FWS selection criteria groupings.