Structural Fire Protection of Steel Structures in Arctic Conditions

Abstract

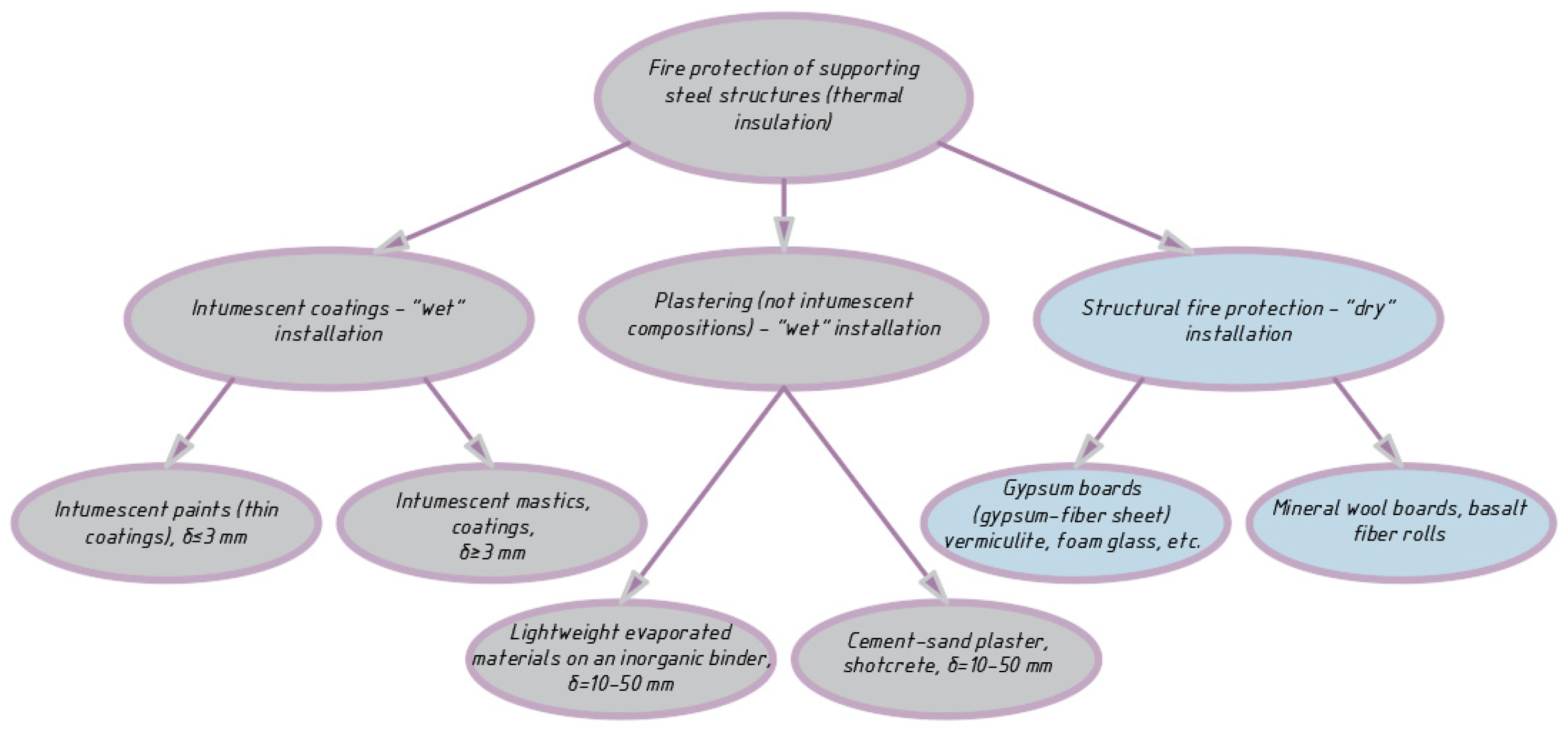

:1. Introduction

2. Materials and Methods

2.1. Experiment No. 1

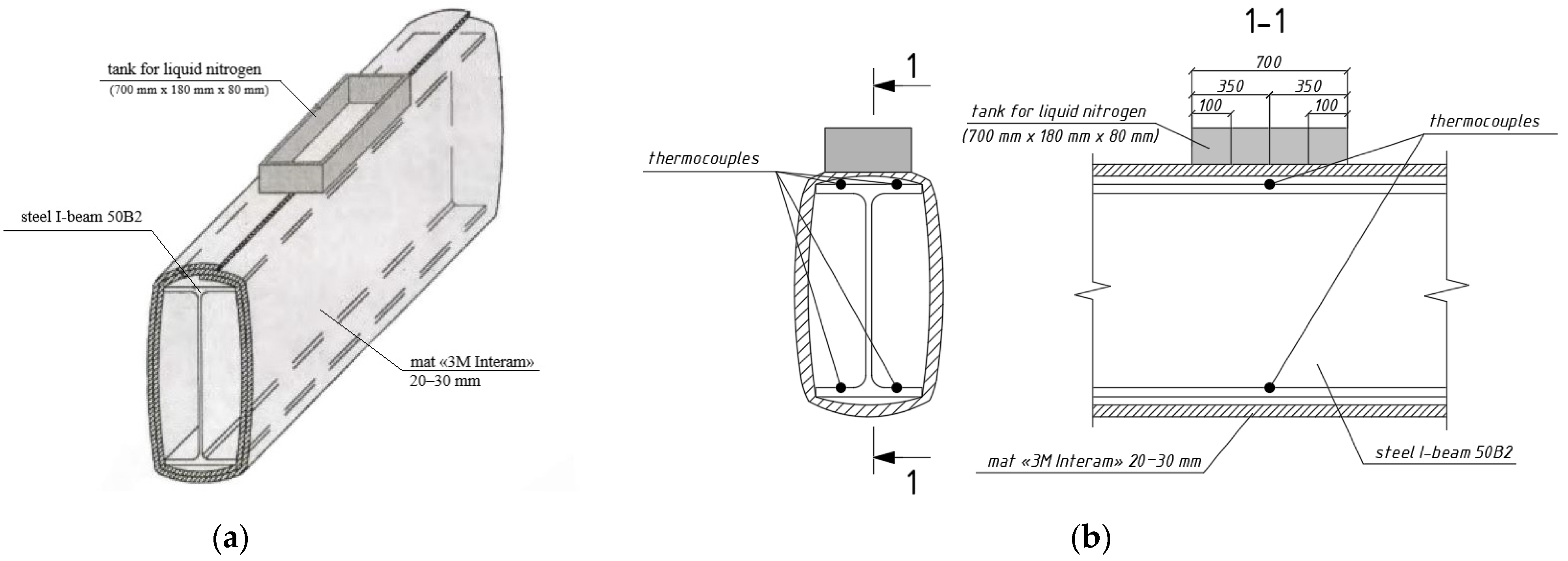

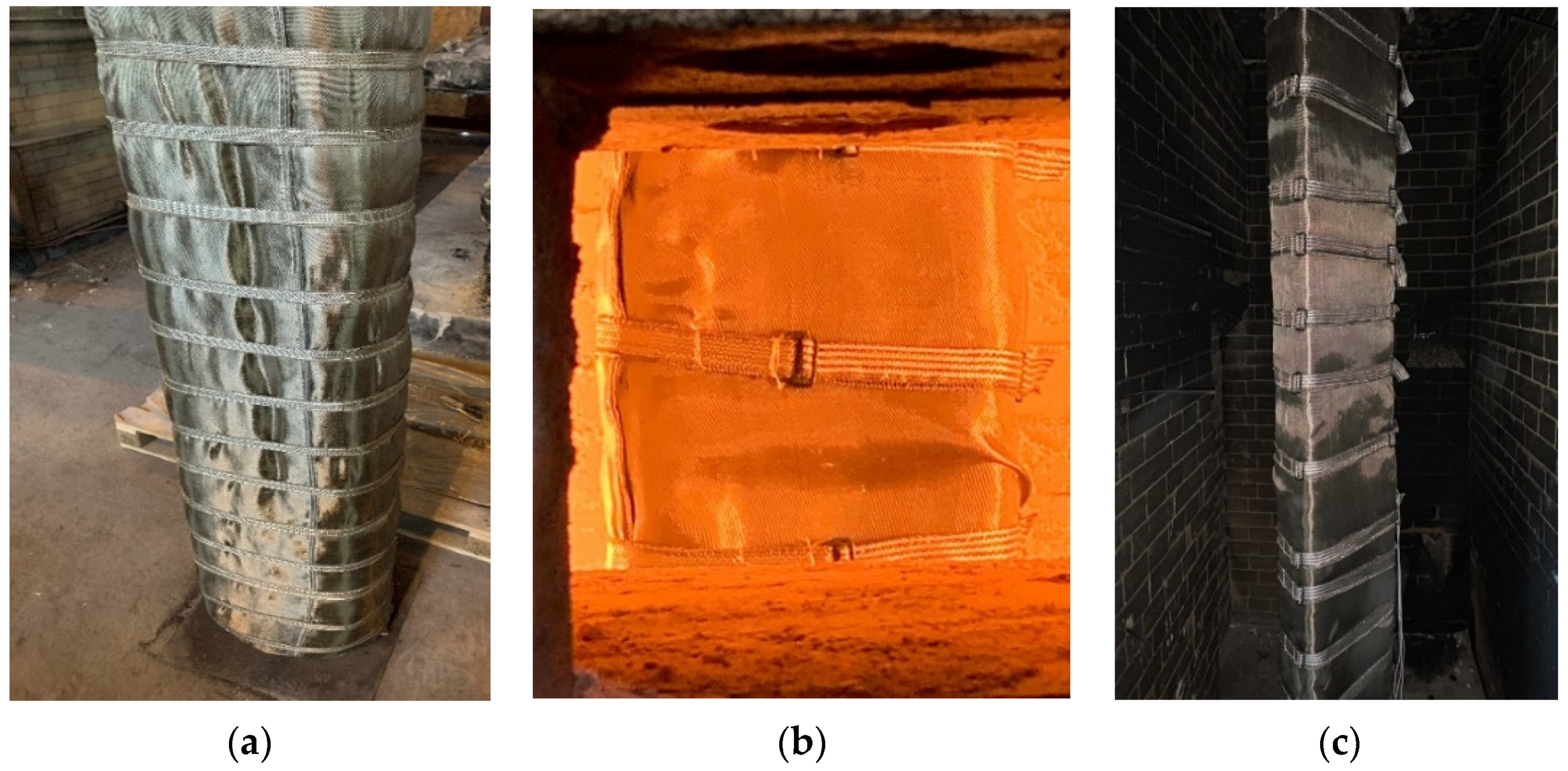

2.2. Experiment No. 2

2.3. Experiment No. 3

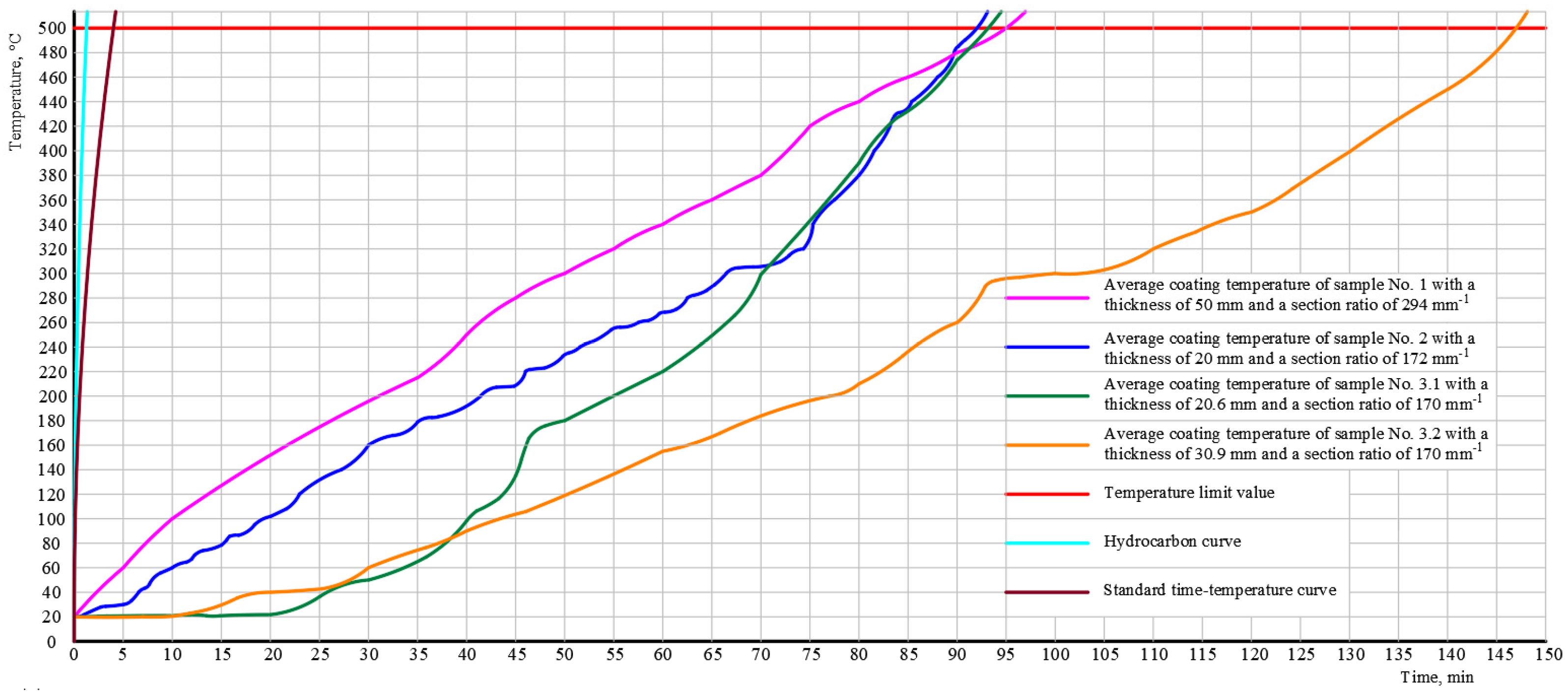

3. Results

3.1. The Results of Experiment No. 1

3.2. The Results of Experiment No. 2

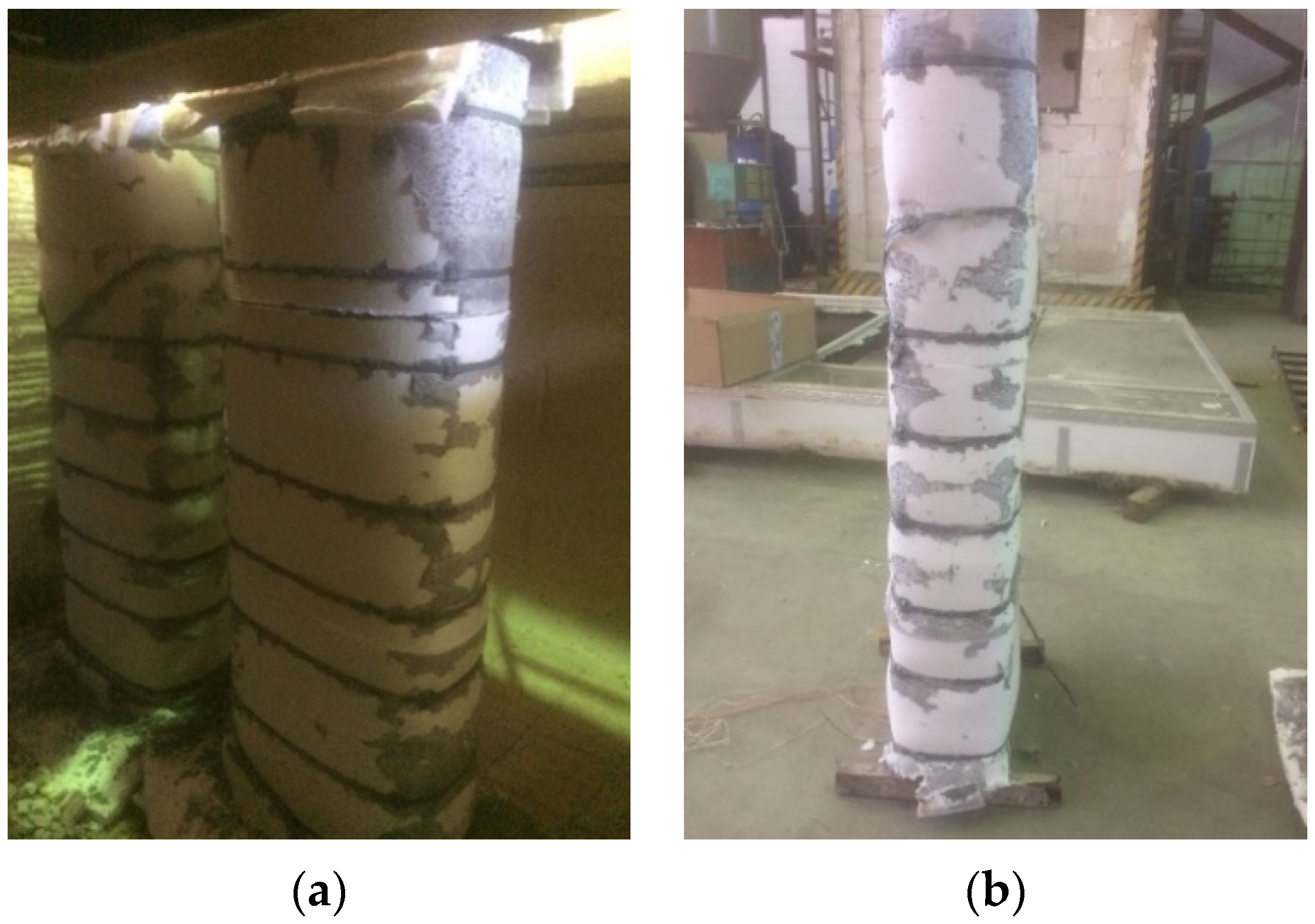

3.3. The Results of Experiment No. 3

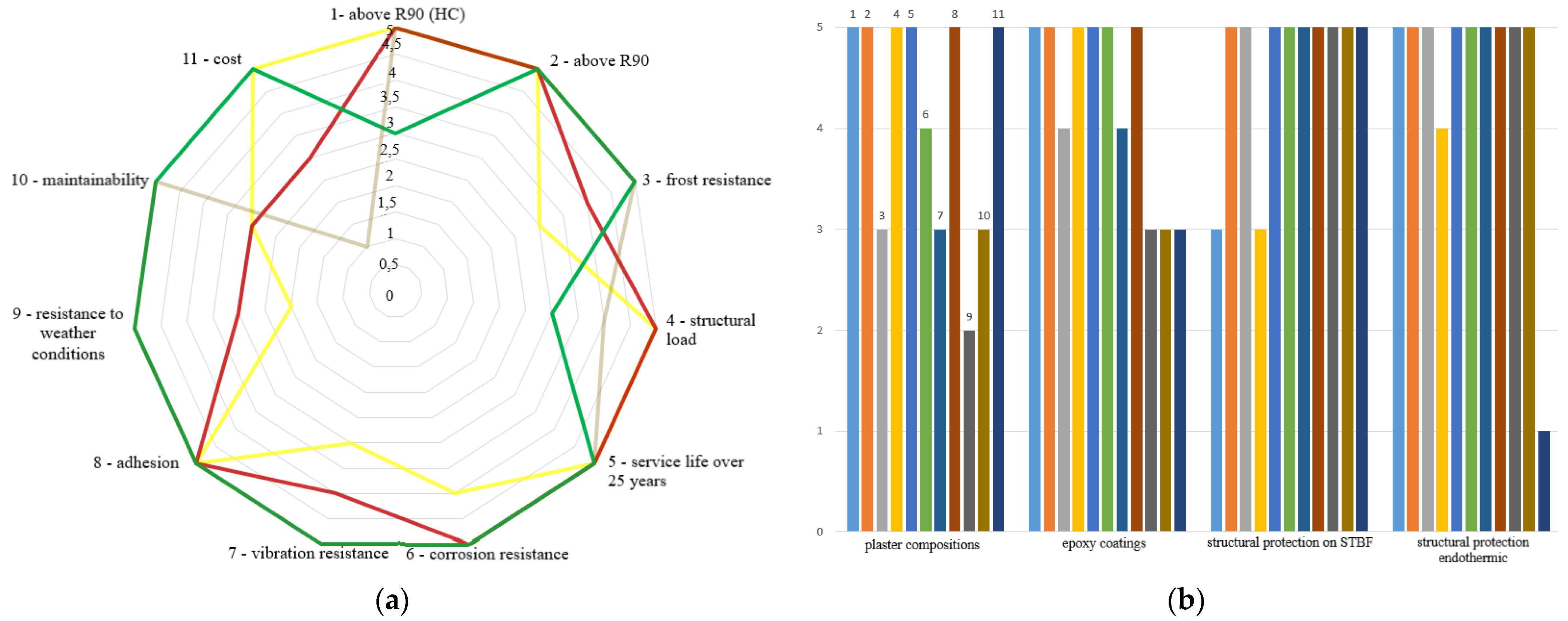

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ACIA. Arctic Climate Impact Assessment; Cambridge University Press: Cambridge, UK, 2005; p. 1072. [Google Scholar]

- Gravit, M.; Golub, E.; Klementev, B.; Dmitriev, I. Fire Protective Glass Fiber Reinforced Concrete Plates for Steel Structures under Different Types of Fire Exposure. Buildings 2021, 11, 187. [Google Scholar] [CrossRef]

- Kim, J.H.; Baeg, D.Y.; Seo, J.K. Numerical Investigation of Residual Strength of Steel Stiffened Panel Exposed to Hydrocarbon Fire. J. Ocean. Eng. Technol. 2021, 35, 203–215. [Google Scholar] [CrossRef]

- Imran, M.; Liew, M.S.; Nasif, M.S.; Niazi, U.M.; Yasreen, A. Hazard Assessment Studies on Hydrocarbon Fire and Blast: An Overview. Adv. Sci. Lett. 2017, 23, 1243–1247. [Google Scholar] [CrossRef]

- ISO 20088-1:2016. Determination of the Resistance to Cryogenic Spillage of Insulation Materials—Part 1: Liquid Phase. Available online: https://www.iso.org/ru/standard/67009.html (accessed on 21 August 2021).

- ISO 20088-2:2020. Determination of the Resistance to Cryogenic Spill of Insulation Materials—Part 2: Vapour Exposure. Available online: https://www.iso.org/ru/standard/67010.html (accessed on 21 August 2021).

- ISO 20088-3:2018. Determination of the Resistance to Cryogenic Spillage of Insulation Materials—Part 3: Jet Release. Available online: https://www.iso.org/ru/standard/67011.html (accessed on 21 August 2021).

- UL 1709. Rapid Rise Fire Tests of Protection Materials for Structural Steel. Available online: http://nd.gostinfo.ru/print.aspx?control=27&id=4546871&print=yes (accessed on 24 August 2021).

- Russian Government Standard GOST 1363-2-2014. Fire Resistance Tests. Alternative and Additional Procedures. Available online: https://docs.cntd.ru/document/1200113419 (accessed on 8 August 2021).

- EN 1363-2:1999. Fire Resistance Tests—Part 2: Alternative and Additional Procedures. Available online: https://nd.gostinfo.ru/document/6239985.aspx (accessed on 10 August 2021).

- Gravit, M. Modeling and standardization of flame retardants for hydrocarbon fire regime. J. Coat. Sci. Technol. 2020. Available online: https://www.lkmportal.com/articles/modelirovanie-i-standartizaciya-sredstv-ognezashchity-dlya-uglevodorodnogo-rezhima-pozhara (accessed on 15 August 2021).

- Reid, M. The Piper Alpha Disaster: A Personal Perspective with Transferrable Lessons on the Long-Term Moral Impact of Safety Failures. ACS Chem. Health Saf. 2020, 27, 88–95. [Google Scholar] [CrossRef]

- Zybina, O.; Gravit, M. Intumescent Coatings for Fire Protection of Building Structures and Materials; Springer Series on Polymer and Composite Materials; Springer International Publishing: New York, NY, USA, 2020; Volume XI, p. 210. ISBN 978-3-030-59422-0. [Google Scholar] [CrossRef]

- McClain, C.R.; Nunnally, C.; Benfield, M.C. Persistent and substantial impacts of the Deepwater Horizon oil spill on deep-sea megafauna. R. Soc. Open Sci. 2019, 6, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evangelista, H.; Sodré, E.D.; Castagna, A. Preliminary Investigation on the Atmospheric Dispersion of Pollutants Due to Ferraz Fire. INCT-APA Annu. Act. Rep. 2013, 35–42. [Google Scholar] [CrossRef]

- Hassel, M.; Utne, I.B.; Vinnem, J.E. Allision risk analysis of offshore petroleum installations on the Norwegian Continental Shelf—an empirical study of vessel traffic patterns. WMU J. Marit. Aff. 2017, 16, 175–195. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Hao, H. Internal and external pressure prediction of vented gas explosion in large rooms by using analytical and CFD methods. J. Loss Prev. Process. Ind. 2017, 49, 367–381. [Google Scholar] [CrossRef] [Green Version]

- Abramov, I.; Gravit, M.; Gumerova, E. Increase in the Fire Resistance Limits of Ship and Building Structures with Hydro-Carbon Fire. GAS Industry; (Gazovaya promyshlennost’); No 5. 2018, pp. 108–117. (In Russian). Available online: https://www.neftegas.info/upload/iblock/cf0/cf0b020575328defe0b0961c2c0c4e0b.pdf (accessed on 15 August 2021).

- Fireproofing for Hydrocarbon Fire Exposures // GAPS Guidelines. Publication of Global Asset Protection Services LLC. Available online: https://www.appliedbuildingtech.com/system/files/gap2.5.1.fireproofingforhydrocarbonexposures.pdf (accessed on 24 August 2021).

- Palazzi, E.; Fabiano, B. Analytical modelling of hydrocarbon pool fires: Conservative evaluation of flame temperature and thermal power. Process. Saf. Environ. Prot. 2012, 90, 121–128. [Google Scholar] [CrossRef]

- Cirpici, K.B.; Wang, Y.C.; Rogers, B.D. An analytical approach for predicting expansion of intumescent coating with different heating conditions. In Proceedings of the 12th International Congress on Advances in Civil Engineering, Istanbul, Turkey, 21–23 September 2016; pp. 1–8. [Google Scholar]

- Hiroya, Y.; Tanabe, M.; Kataoka, S.; Yamada, Y.; Miyashita, T. Simplified Method to Define the Cryogenic Spill Hazard in LNG Liquefaction Facility. Chem. Eng. Trans. 2019, 77, 505–510. [Google Scholar] [CrossRef]

- Hiroya, Y.; Tanabe, M.; Kataoka, S.; Yamada, Y.; Miyashita, T. Optimization of cryogenic spill protection insulation thickness. Chem. Eng. Trans. 2016, 48, 643–648. [Google Scholar] [CrossRef]

- Mikalsen, R.F.; Glansberg, K.; Wormdahl, E.D.; Stolen, R. Jet fires and cryogenic spills: How to document extreme industrial incidents. In Proceedings of the Sixth Magdeburg Fire and Explosion Days conference proceedings, Magdeburg, Germany, 25–26 March 2019; pp. 1–6. [Google Scholar]

- UL 263. Fire Tests of Building Construction and Materials. Available online: https://standardscatalog.ul.com/ProductDetail.aspx?productId=UL263 (accessed on 24 August 2021).

- UL 1724. Investigation for Fire Tests for Electrical Circuit Protective Systems. Available online: https://standards.globalspec.com/std/260679/UL%201724%20OUTLINE (accessed on 24 August 2021).

- Akaa, O.; Abu, A.; Spearpoint, M.; Giovinazzi, S. Optimising design decision-making for steel structures in fire using a hybrid analysis technique. Fire Saf. J. 2017, 91, 532–541. [Google Scholar] [CrossRef]

- Eremina, T.; Korolchenko, D. Fire Protection of Building Constructions with the Use of Fire-Retardant Intumescent Compositions. Buildings 2020, 10, 185. [Google Scholar] [CrossRef]

- Oliveira, R.B.R.; Junior, L.C.M.V.; Vieira, L.C.M. Intumescent paint as fire protection coating. Rev. IBRACON Estrut. Mater. 2017, 10, 220–231. [Google Scholar] [CrossRef] [Green Version]

- Gravit, M.V.; Golub, E.V.; Antonov, S.P. Fire protective dry plaster composition for structures in hydrocarbon fire. ICE Pro-Ceedings Civ. Eng. 2018, 3. [Google Scholar] [CrossRef]

- Rivera, M.M.; Vaz, M.A.; Julio, C.; Cyrino, R.; Landesmann, A. A study on the use of PFP in off-shore topside structures subject to localised fires. In Proceedings of the 28th International Congress on Waterborne Transportation, Shipbuilding and Offshore Constructions, Rio de Janeiro, Brazil, 26–29 October 2020. [Google Scholar] [CrossRef]

- Park, D.K.; Kim, J.H.; Park, J.S.; Ha, Y.C.; Seo, J.K. Effects of the structural strength of fire protection insulation systems in offshore installations. Int. J. Nav. Arch. Ocean. Eng. 2021, 13, 493–510. [Google Scholar] [CrossRef]

- Kremnev, V.; Basok, B.; Timoshchenko, A.; Tymchyshyn, S. Energy Saving in Construction by Wide Application of High-Quality Insulation Based on Basalt Fibers. J. Mod. Phys. 2018, 9, 1724–1734. [Google Scholar] [CrossRef] [Green Version]

- Russian Federal Law No. 123-FZ. Technical Regulation of Fire Safety. Available online: http://www.consultant.ru/document/cons_doc_LAW_78699/ (accessed on 25 August 2021).

- ISO 834-1:1999. Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. Available online: https://www.iso.org/standard/2576.html (accessed on 24 August 2021).

- Russian Government Standard GOST 53295–2009. Fire Retardant Compositions for Steel Constructions. General Requirement. Method for Determining Fire Retardant Efficiency. Available online: https://docs.cntd.ru/document/1200071913 (accessed on 28 August 2021).

- Russian Government Standard GOST 57837-2017. Hot-Rolled Steel I-Beams with Parallel Edges of Flanges. Specifications. Available online: https://docs.cntd.ru/document/1200157342 (accessed on 28 August 2021).

- Eurocode 3: Design of Steel Structures—Part 1–2: General Rules Structural Fire Design. Available online: https://www.phd.eng.br/wp-content/uploads/2015/12/en.1993.1.2.2005.pdf (accessed on 10 September 2021).

| Name of Parameters | Slag Wool | Glass Wool | TBF | STBF |

|---|---|---|---|---|

| Limit temperature application, °C | up to 250 | from −60 to +450 | from −190 to +700 | from −190 to +1000 |

| Sintering temperature, °C | 250–300 | 450–500 | 700–1000 | 1100–1500 |

| Average fiber diameter, μm | 4 to 12 | 4 to 12 | 5 to 15 | 1 to 3 |

| Length of fibers, mm | 16 | 15–50 | 20–50 | 50–70 |

| Sorption humidification per 24 h. (max),% | 1.9 | 1.7 | 0.035 | 0.02 |

| Using the binder | yes | yes | yes | no |

| Presence of binder, % | 2.5 to 10 | 2.5 to 10 | 2.5 to 10 | - |

| Thermal conductivity coefficient, W/(m·K) | 0.46–0.48 | 0.038–0.046 | 0.038–0.046 | 0.035–0.046 |

| Heat capacity, J/kg·K | 1000 | 1050 | 500–800 | 800–1000 |

| Density, kg/m3 | 75–400 | 10–130 | 26–36 | 18–25 |

| Sound absorption coefficient | 0.75 to 0.82 | 0.8 to 92 | 0.8 to 95 | 0.95 to 99 |

| Vibration resistance | no | no | no | yes |

| Parameters/Names of Flame Retardant Coatings | Sample No. 1 | Sample No. 2 | Sample No. 3.1/Sample No. 3.2 |

|---|---|---|---|

| Tested samples | I-section column No.20B1 | I-section column No.50B2 | I-section column No.50B2 |

| Ap/V, mm−1 | 294 | 172 | 170 |

| Thickness of dry layer of fire retardant, mm | 50 | 20 | 20.6/30.9 |

| Presence of cryogenic test | no | no | yes |

| Cryogenic test time, min | - | - | 60 (without reaching critical temperature) |

| Moment of the start of the fire test | as the sample is ready and the furnace is prepared | as the sample is ready and the furnace is prepared | 2.5 h after cryogenic test |

| Fire regime | hydrocarbon | hydrocarbon | hydrocarbon |

| Fire protection efficiency | 90 | 90 | 90/147 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gravit, M.; Shabunina, D. Structural Fire Protection of Steel Structures in Arctic Conditions. Buildings 2021, 11, 499. https://doi.org/10.3390/buildings11110499

Gravit M, Shabunina D. Structural Fire Protection of Steel Structures in Arctic Conditions. Buildings. 2021; 11(11):499. https://doi.org/10.3390/buildings11110499

Chicago/Turabian StyleGravit, Marina, and Daria Shabunina. 2021. "Structural Fire Protection of Steel Structures in Arctic Conditions" Buildings 11, no. 11: 499. https://doi.org/10.3390/buildings11110499

APA StyleGravit, M., & Shabunina, D. (2021). Structural Fire Protection of Steel Structures in Arctic Conditions. Buildings, 11(11), 499. https://doi.org/10.3390/buildings11110499