Deformability of Glued Laminated Beams with Combined Reinforcement

Abstract

:1. Introduction

2. Basic Materials and Results

3. Discussion

4. Conclusions

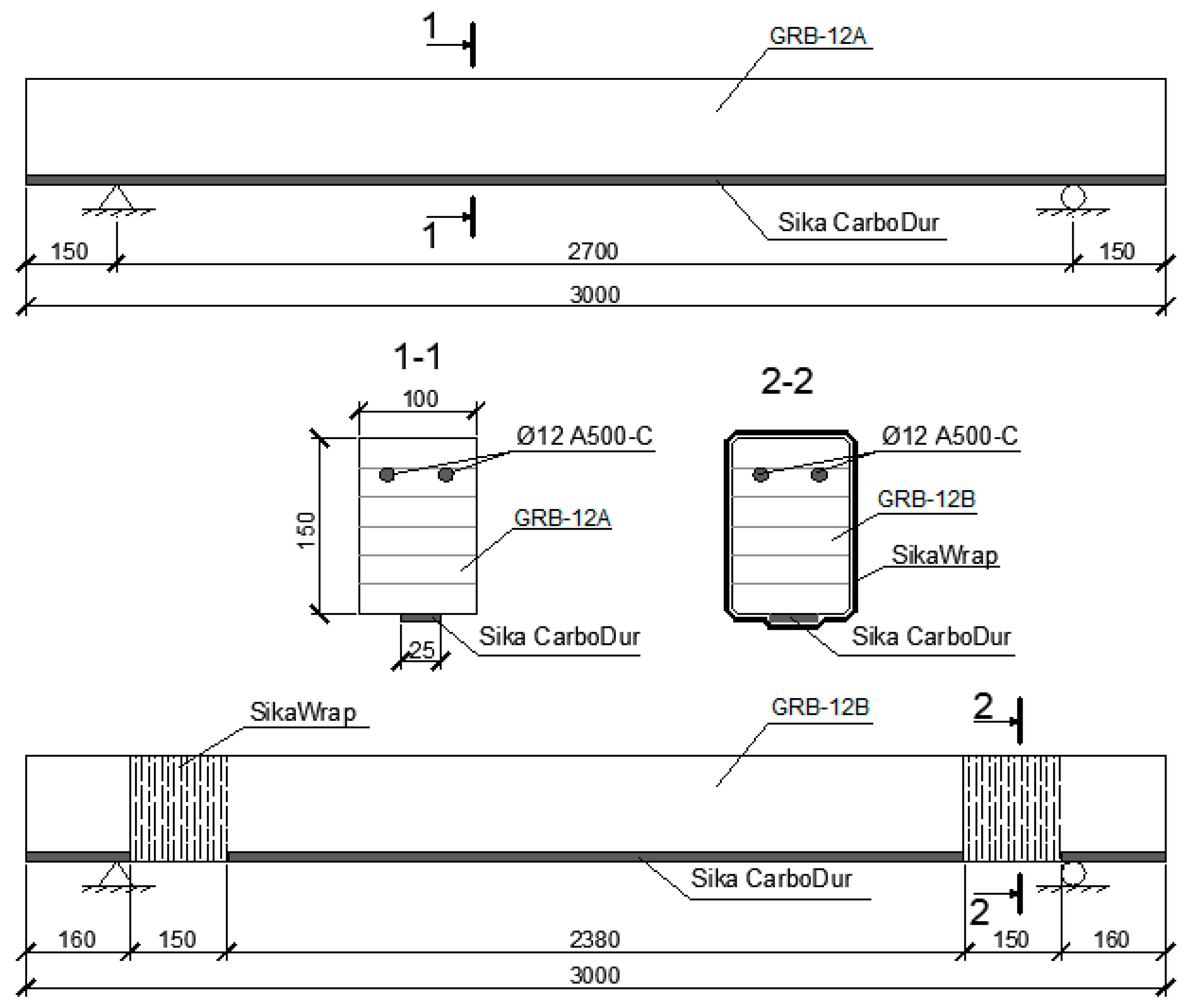

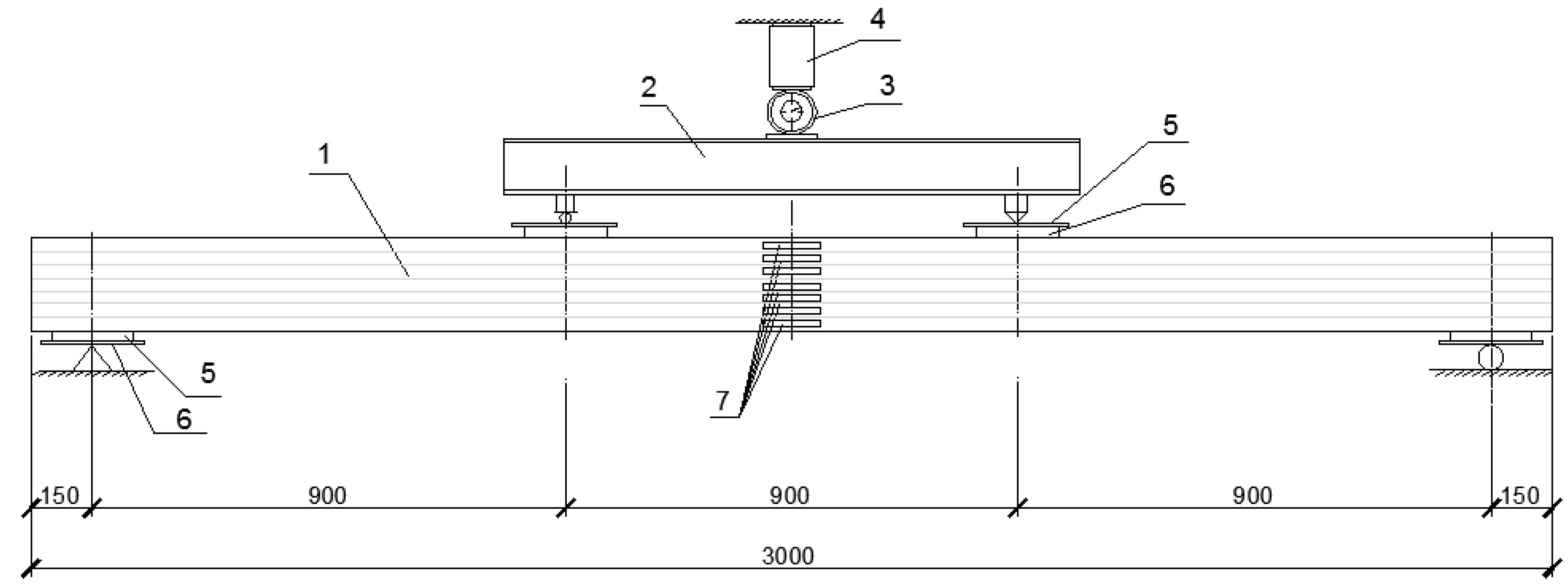

- The deformability of glued laminated beams with combined reinforcement was studied, under which the steel reinforcement of the periodic profile was placed in the dappings of the upper compressed zone, while a ribbon-reinforced composite was glued to the bottom of the stretched zone.

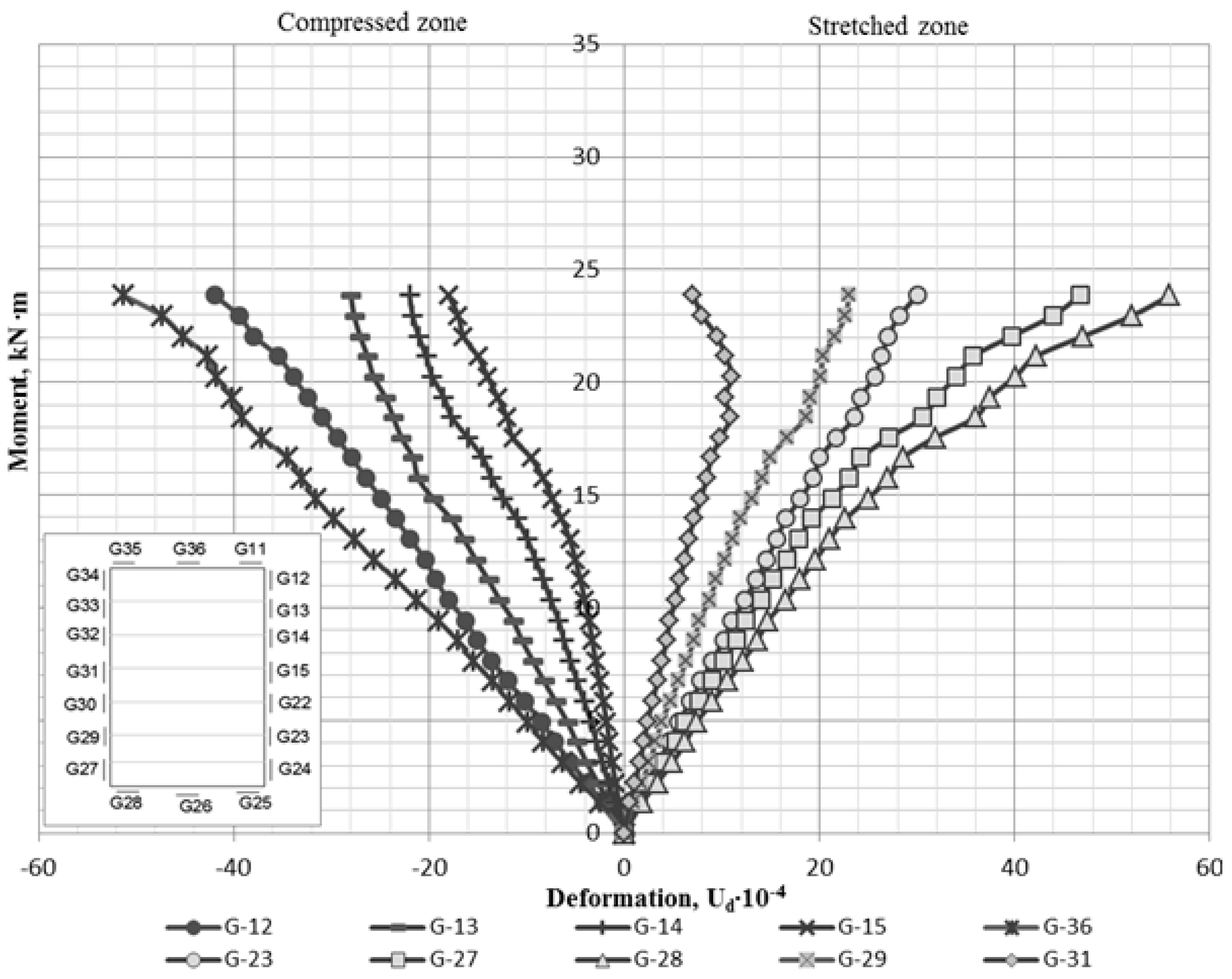

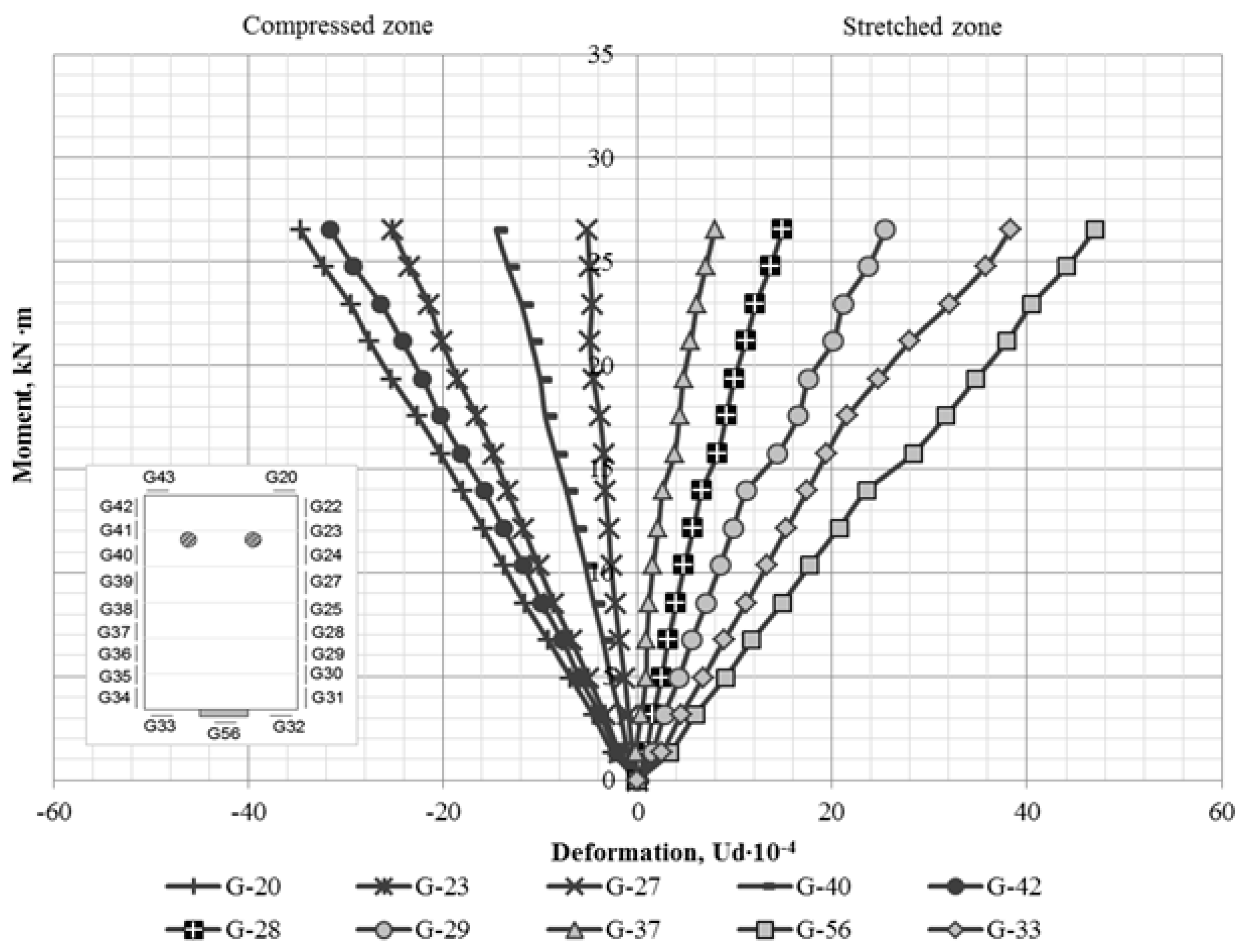

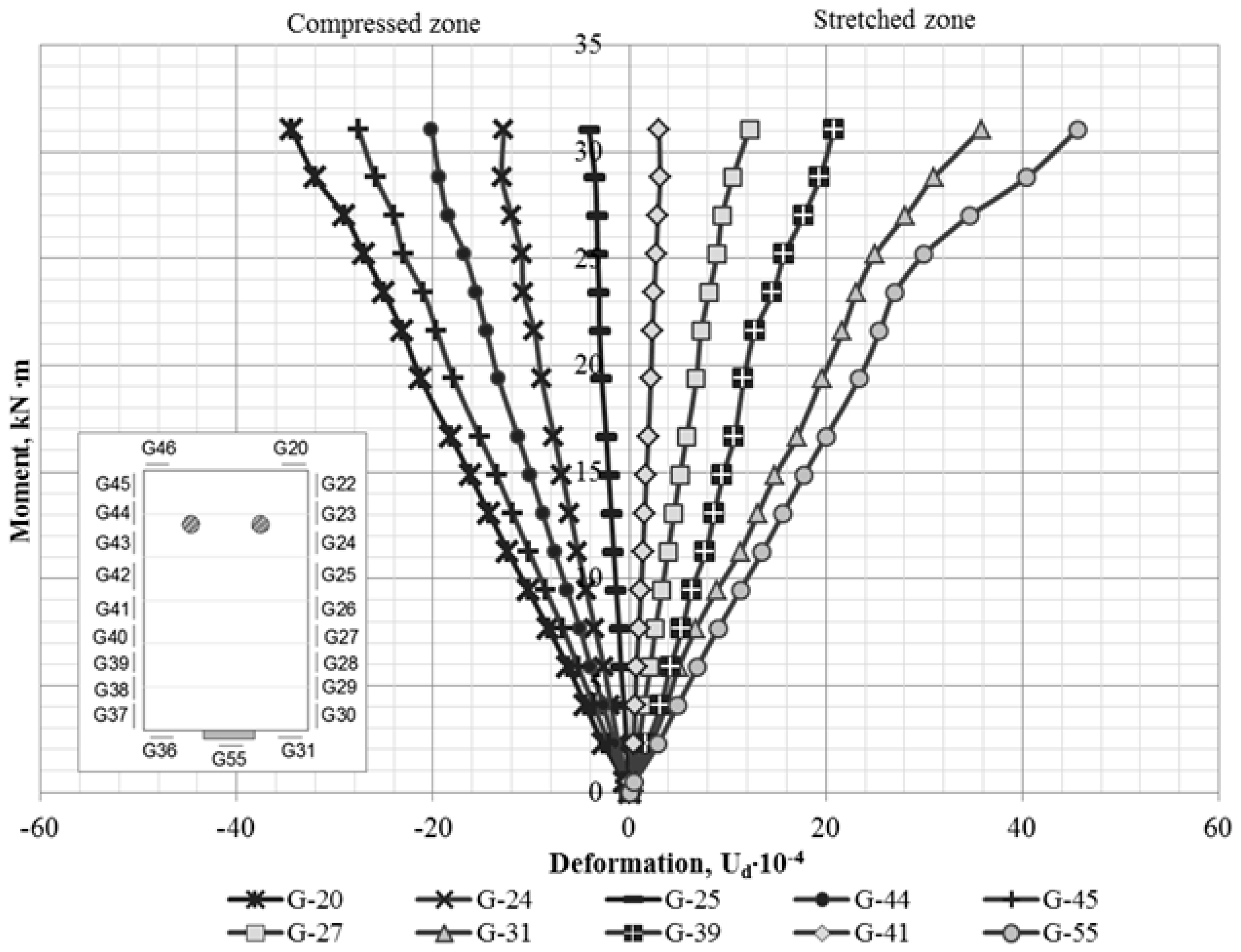

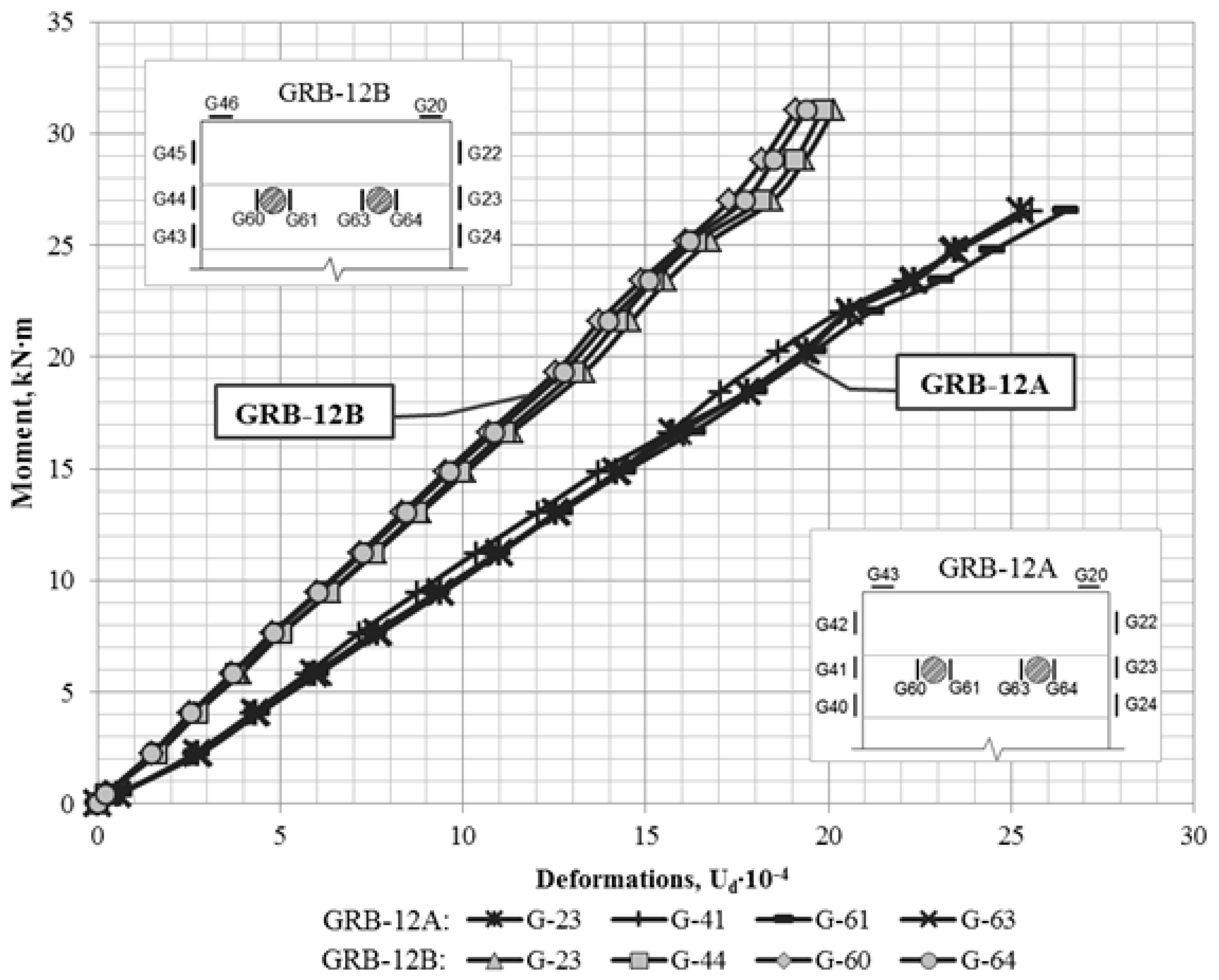

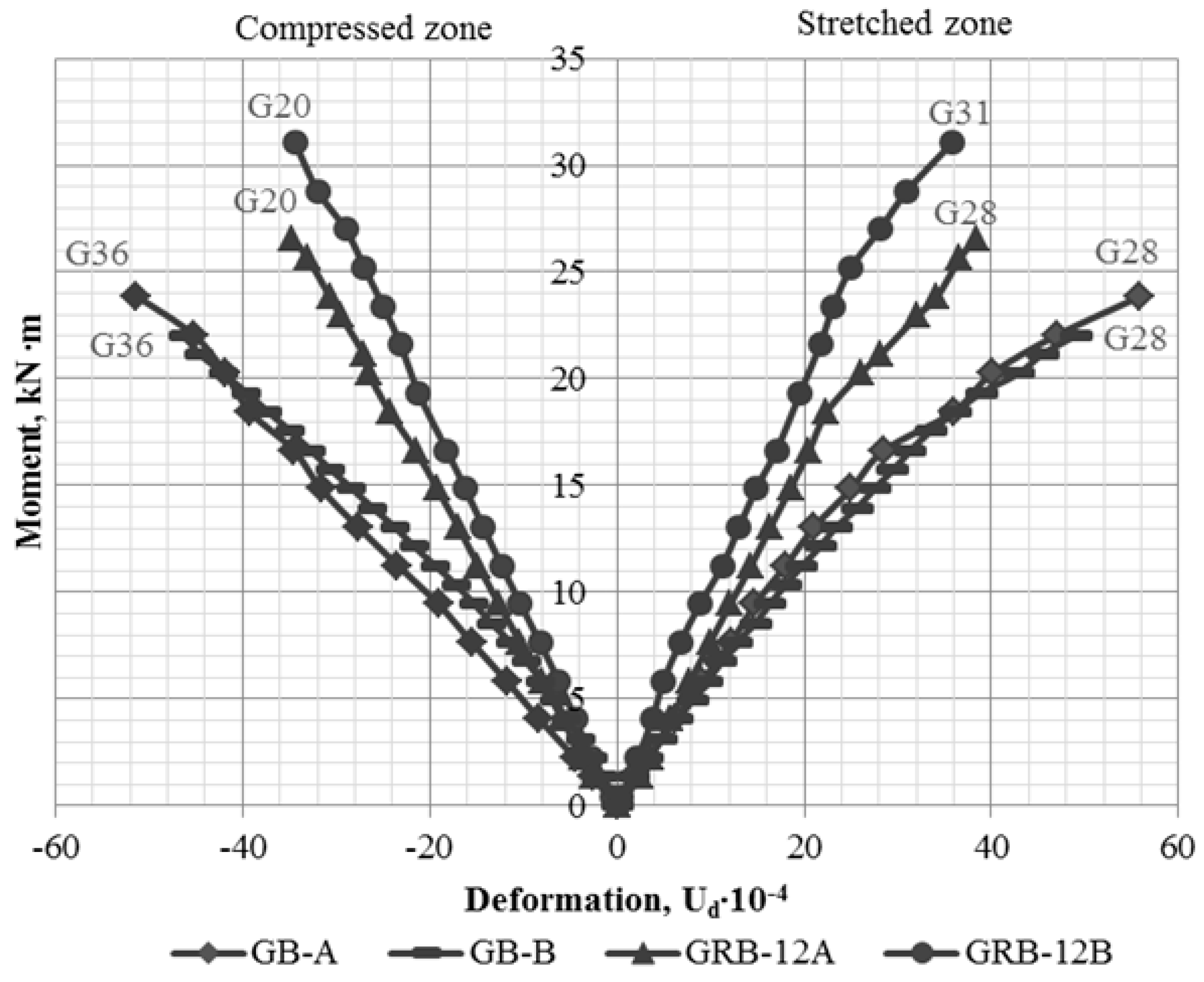

- The relative deformations of different layers of wood on the height of the calculated cross-section, metal, and composite tape reinforcement Sika CarboDur S-512, and the joint work of steel and composite reinforcement with compatible wood layers, were observed.

- The use of a 2 Ø 12 mm steel-bar reinforcement of the A500C class in the compressed zone and the SikaCarboDurS-512 ribbon composite in the stretched zone reduced the maximal relative deformations of the wood in the sample cross-section by 30% compared to the deformations of the most stressed fibers of the nonreinforced beams.

- The behavior of the GRB-12A and GRB-12B reinforced beams made from glued laminated wood showed the good joint work of both the steel reinforcement with wood in the compressed zone, and the SikaCarboDurS-512 ribbon composite with wood in the stretched zone at all stages of the stress–strain state until destruction.

Author Contributions

Funding

Conflicts of Interest

References

- Gomon, S.S.; Pavlyuk, A.P. Deformity of solid wood beams in oblique bending conditions. Resour. -Sav. Mater. Struct. Build. Struct. 2016, 33, 135–140. [Google Scholar]

- Shchuko, V.Y.; Roshchina, S.I. Reinforced Wooden Constructions in Building; Vl.SU manual: Vladimir, Russia, 2002; p. 68. [Google Scholar]

- Repin, V.A. Wooden Beams with a Rational Reinforcement; The Dissertation: Vladimir, Russia, 2000; p. 158. [Google Scholar]

- Bondarchuk, T.B.; Bashynskyy, O.I.; Peleshko, M.Z. Carrying capacity and fire resistance of wooden beams reinforced with external tape reinforcement. Bull. LSUBZHD 2014, 9, 184–189. [Google Scholar]

- Turkovskiy, S.B.; Pogoreltsev, A.A. Wooden structures based on oblique glued rods. In Building Materials, Equipment, Technologies of the 21st Century; USDA: Washington, DC, USA, 2008; Volume 6. [Google Scholar]

- Koscheev, A.A.; Lukin, M.V.; Roshchina, S.I. Investigation of glued in bars strength and deformability indexes with in frame work of research of wood reinforcement with cable reinforcement. Mater. Sci. Eng. 2019, 687, 033023. [Google Scholar]

- Demchyna, B.H.; Surmay, M.I.; Kravz, A.R.; Blyakhar, T.Y. Experience of manufacturing laminated-beam beams reinforced with non-metallic reinforcement, Modern building materials, structures and innovative technologies of construction of buildings and structures. Bull. DONNACEA 2010, 5, 193–197. [Google Scholar]

- Stoyanov, V.V. Strengthening of beam structures by reinforcement layer by layer. Construction 2013, 11, 44–47. [Google Scholar]

- Yermolenko, D.A.; Ishchenko, M.S. Strength and deformability of glued wood beams reinforced with polymer mesh. Acad. J. 2017, 2, 140–147. [Google Scholar]

- Gugutsidze, G.; Draškovič, F. Reinforcement of timber beams with carbon fibers reinforced plastics, Slovak. J. Civ. Eng. 2010, 2, 1–6. [Google Scholar]

- Basterra, L.A.; Balmori, J.A.; Morillas, L.; Acuña, L.; Casado, M. Internal reinforcement of laminated duo beams of low—grade timber with GFRP sheets. Constr. Build. Mater. 2017, 154, 914–920. [Google Scholar] [CrossRef]

- Kim, Y.J.; Harries, K.A. Modeling of timber beams strengthened with various CFRP composites. Eng. Struct. 2010, 32, 3225–3234. [Google Scholar] [CrossRef]

- Yahyaei-Moayyed, M.; Taheri, F. Experimental and computational investigations into creep response of AFRP reinforced timber beams. Compos. Struct. 2011, 93, 616–628. [Google Scholar] [CrossRef]

- Rajczyk, M.; Jończyk, D. Behavior of glulam beams strengthened with BFRP bars. Mater. Sci. Eng. 2019, 603. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Valverde-Palacios, I.; Suarez, E.; Gallego, A. Experimental and analytical analysis for bending load capacity of old timber beams with defects when reinforced with carbon fiber strips. Compos. Struct. 2018, 186, 29–38. [Google Scholar] [CrossRef]

- Gomon, S.S.; Polishchuk, M.V. Combined reinforcement of glued timber beams, Effective technologies and structures in construction and village architecture. Development of innovative models of ecological settlements of Carpathian and Carpathian Mountains. In Proceedings of the Abstracts of the International Scientific and Practical Conference, Dublin, Ireland, 15–17 May 2019; pp. 99–100. [Google Scholar]

- Gomon, S.; Gomon, S.; Karavan, V.; Gomon, P.; Sobczak-Piastka, J. Investigation of solid and glued wood on the effect of variables of low-cycle repeated loads. In AIP Conference Proceedings; AIP Publishing Center: New York, NY, USA, 2019; Volume 2077, p. 020020. [Google Scholar]

- Gomon, S.; Gomon, S.; Karavan, V.; Gomon, P.; Podhorecki, A. Calculated cross-sectional model and stages of the stress–strain state of the wood element for transverse bending. In AIP Conference Proceedings; AIP Publishing Center: New York, NY, USA, 2019; Volume 2077, p. 020019. [Google Scholar]

- Gomon, S.; Gomon, S.; Gomon, P.; Pavluk, A.; Sobczak-Piastka, J. Complete deflections of glued beams in the conditions of oblique bend for the effects of low cycle loads. In AIP Conference Proceedings; AIP Publishing Center: New York, NY, USA, 2019; Volume 2077, p. 020021. [Google Scholar]

- Bedon, C.; Louter, C. Numerical analysis of glass-FRP post tension beams—Review and assessment. Compos. Struct. 2017, 177, 129–140. [Google Scholar] [CrossRef] [Green Version]

- Kononchuk, O. The results of experimental studies of reinforced concrete beams reinforced with composite materials. Resour. Sav. Mater. Struct. Build. Struct. 2012, 23, 479–486. [Google Scholar]

- Gomon, S.S.; Polishchuk, M.V. The patent for the utility model No. 135229 Ukraine, IPC E04C 3/12 (2006.01). Glued wooden beam. No. u 201900104, 25 June 2019. Bulletin No. 12.

| Series Number | Marking | Number of Samples | Reinforcement |

|---|---|---|---|

| I | GB-A | 1 | Nonreinforced |

| GB-B | 1 | Nonreinforced | |

| II | GRB-12A | 1 | 2Ø12 A500C + SikaCarboDurS-512 |

| GRB-12B | 1 | 2Ø12 A500C + SikaCarboDurS-512 + SikaWrap-230 C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobczak-Piąstka, J.; Gomon, S.S.; Polishchuk, M.; Homon, S.; Gomon, P.; Karavan, V. Deformability of Glued Laminated Beams with Combined Reinforcement. Buildings 2020, 10, 92. https://doi.org/10.3390/buildings10050092

Sobczak-Piąstka J, Gomon SS, Polishchuk M, Homon S, Gomon P, Karavan V. Deformability of Glued Laminated Beams with Combined Reinforcement. Buildings. 2020; 10(5):92. https://doi.org/10.3390/buildings10050092

Chicago/Turabian StyleSobczak-Piąstka, Justyna, Svyatoslav S. Gomon, Mykola Polishchuk, Sviatoslav Homon, Petro Gomon, and Victor Karavan. 2020. "Deformability of Glued Laminated Beams with Combined Reinforcement" Buildings 10, no. 5: 92. https://doi.org/10.3390/buildings10050092