Flexural Performance of Prefabricated Ultra-High-Strength Textile Reinforced Concrete (UHSTRC): An Experimental and Analytical Investigation

Abstract

1. Introduction

2. Experimental Program

2.1. Material Properties

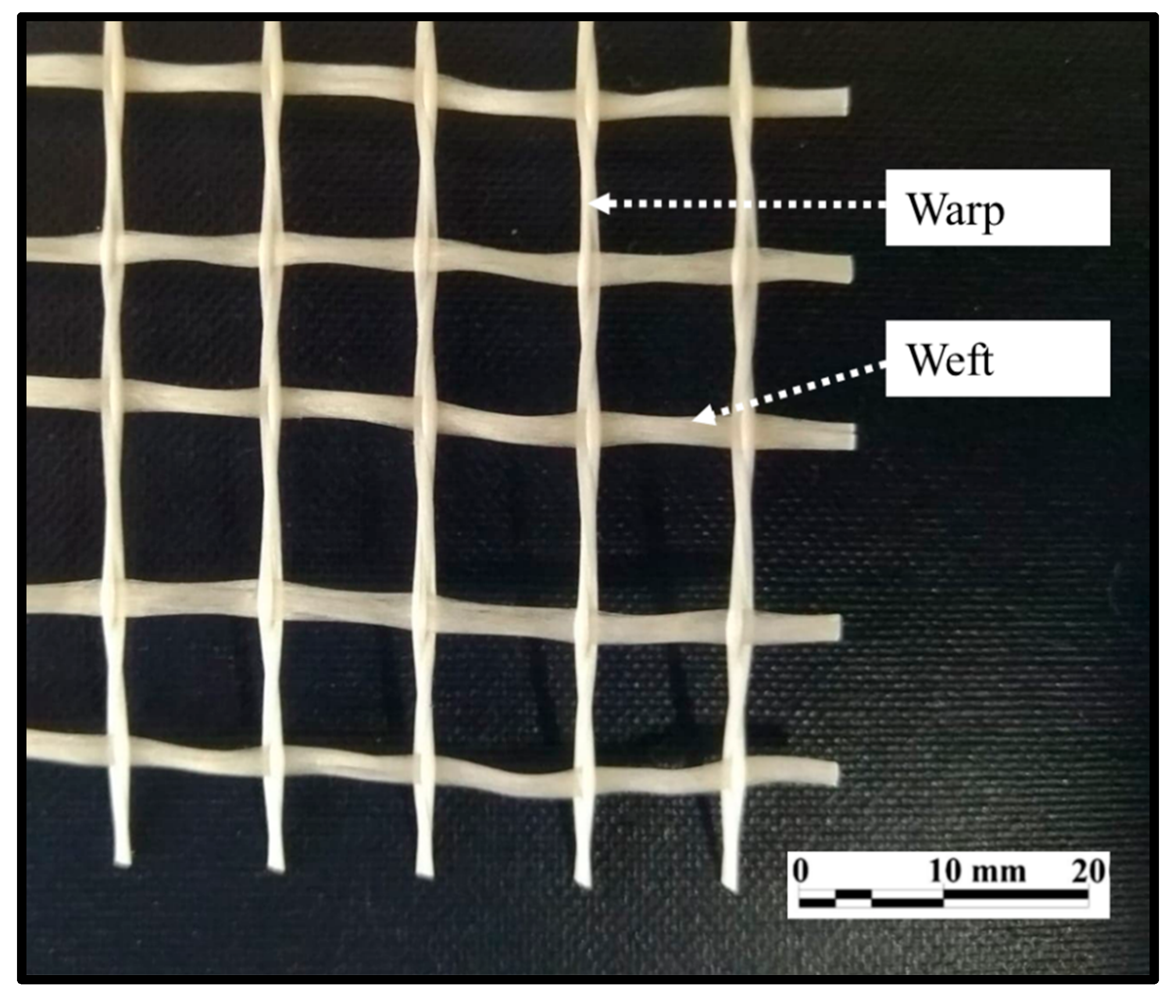

2.1.1. Glass Fiber Textile

2.1.2. Mortar Mix

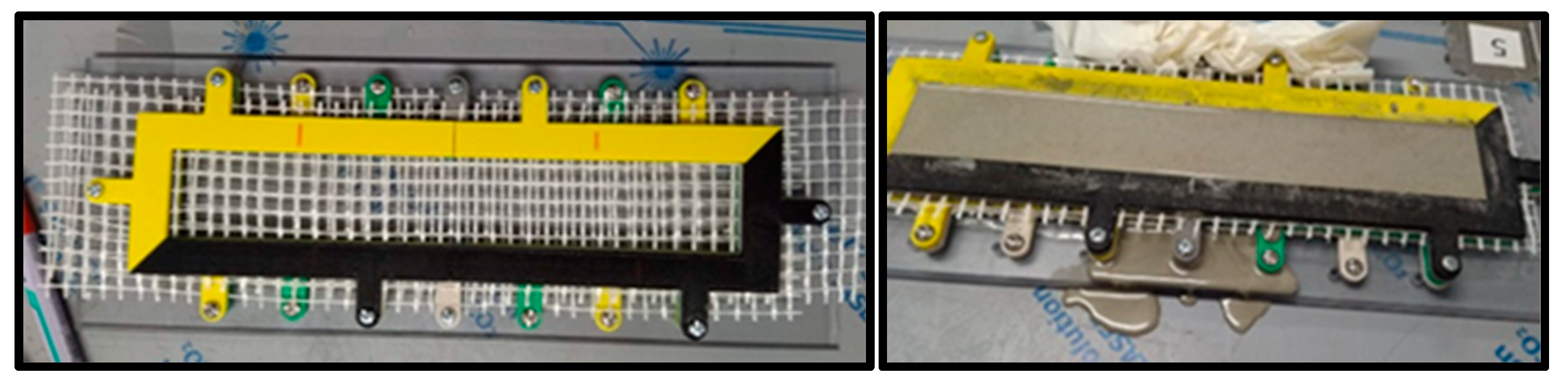

2.2. Preparation of Specimens

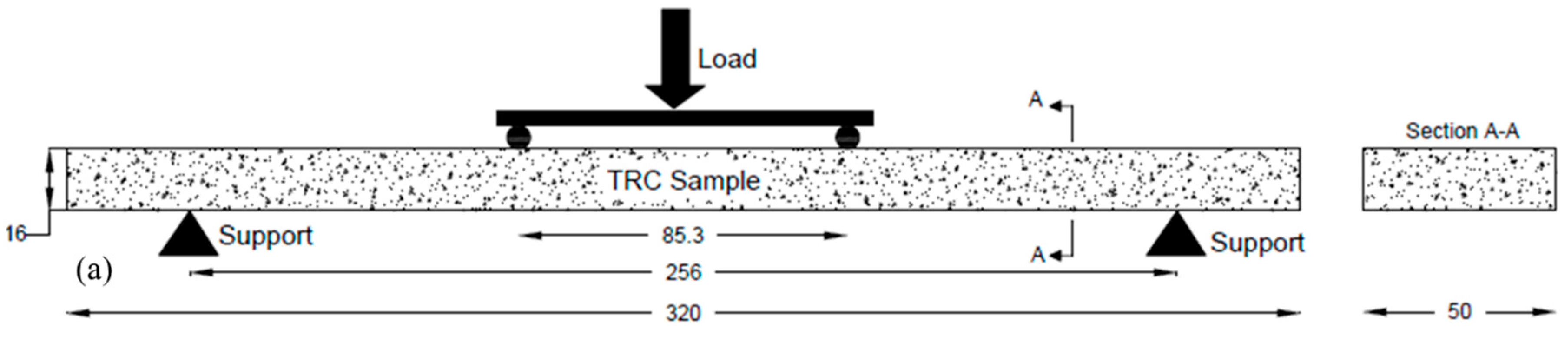

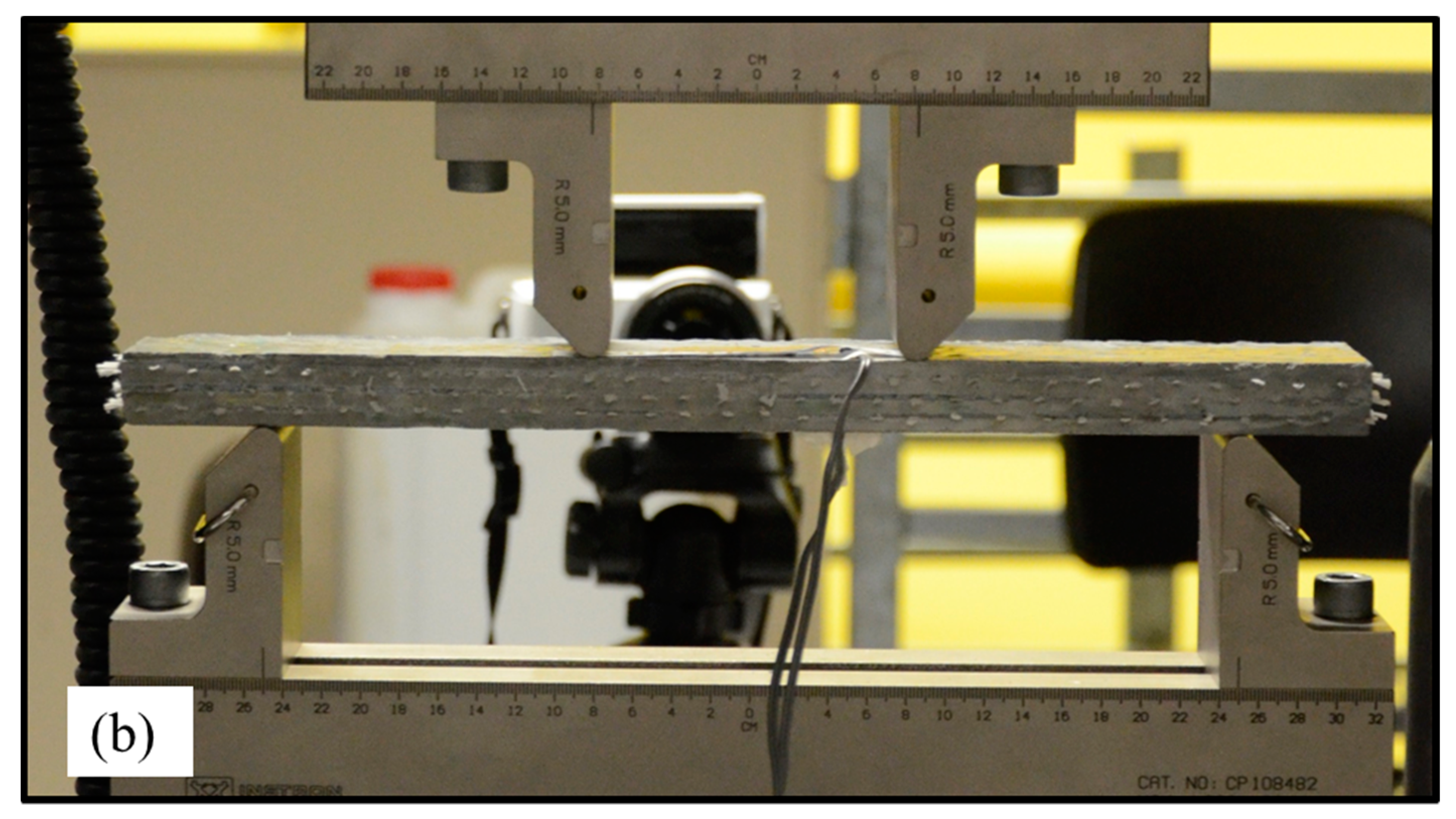

2.3. Flexural Test Set-Up

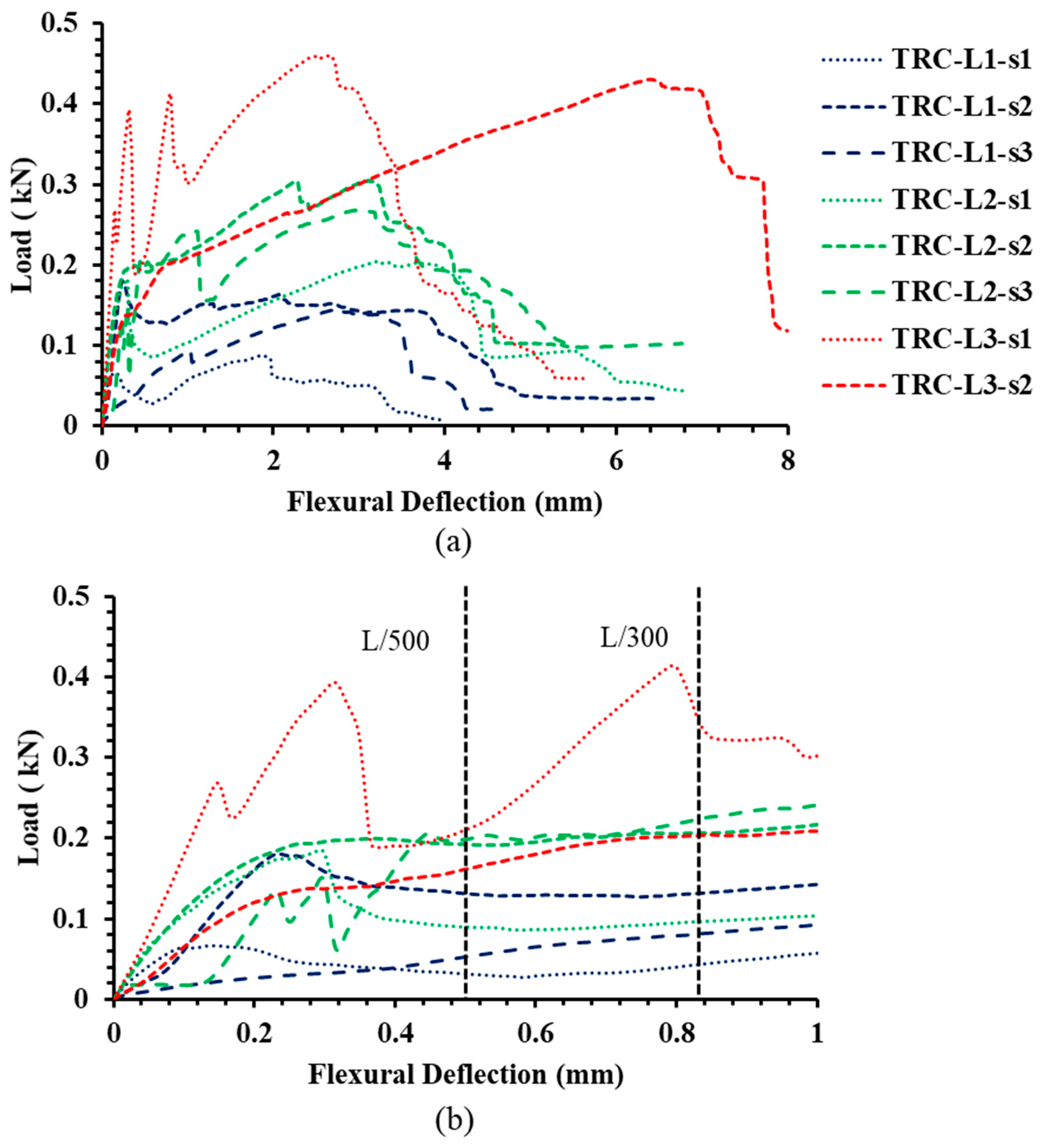

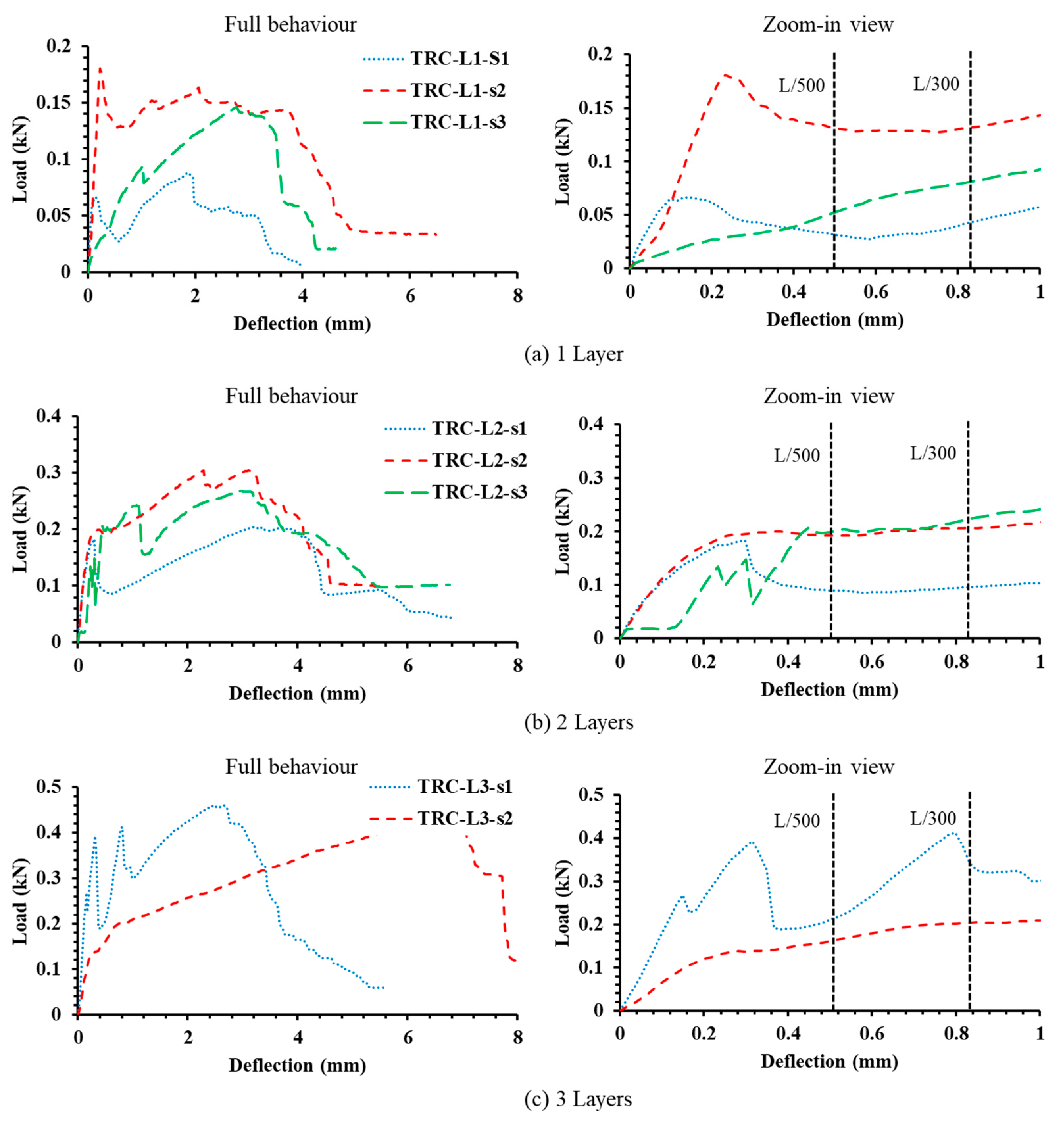

3. Experimental Results

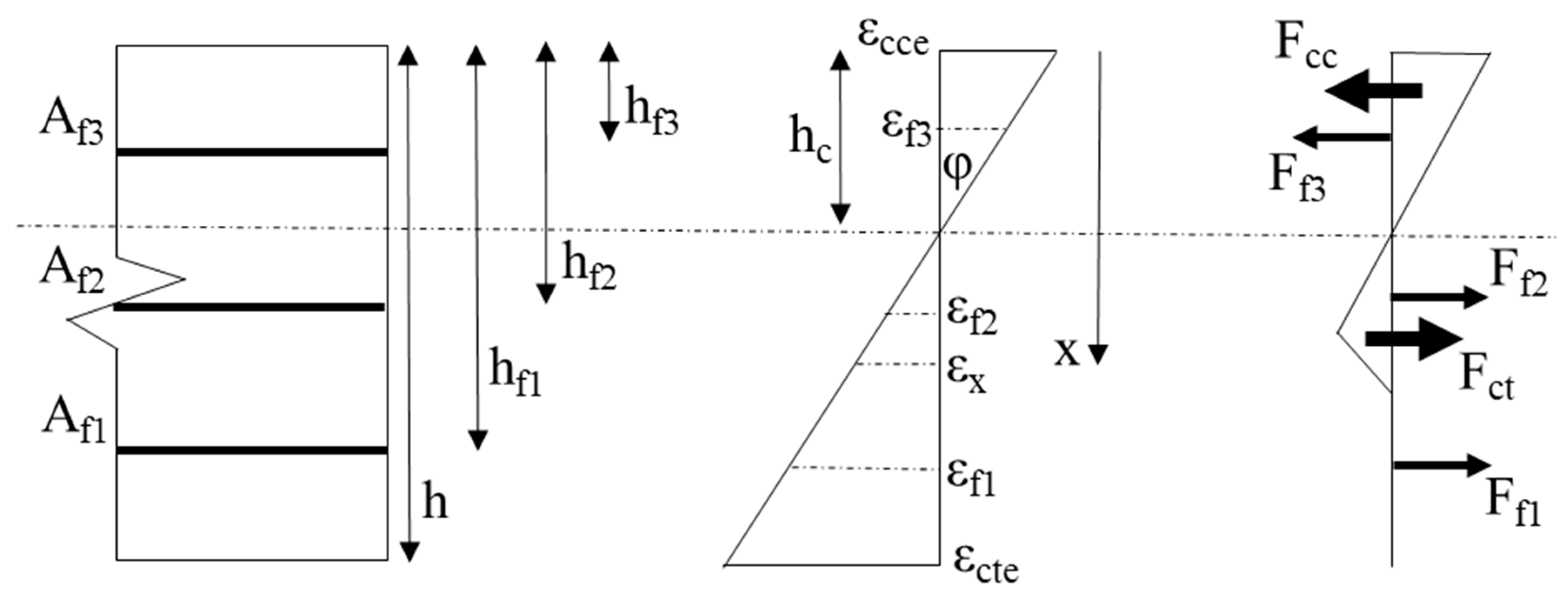

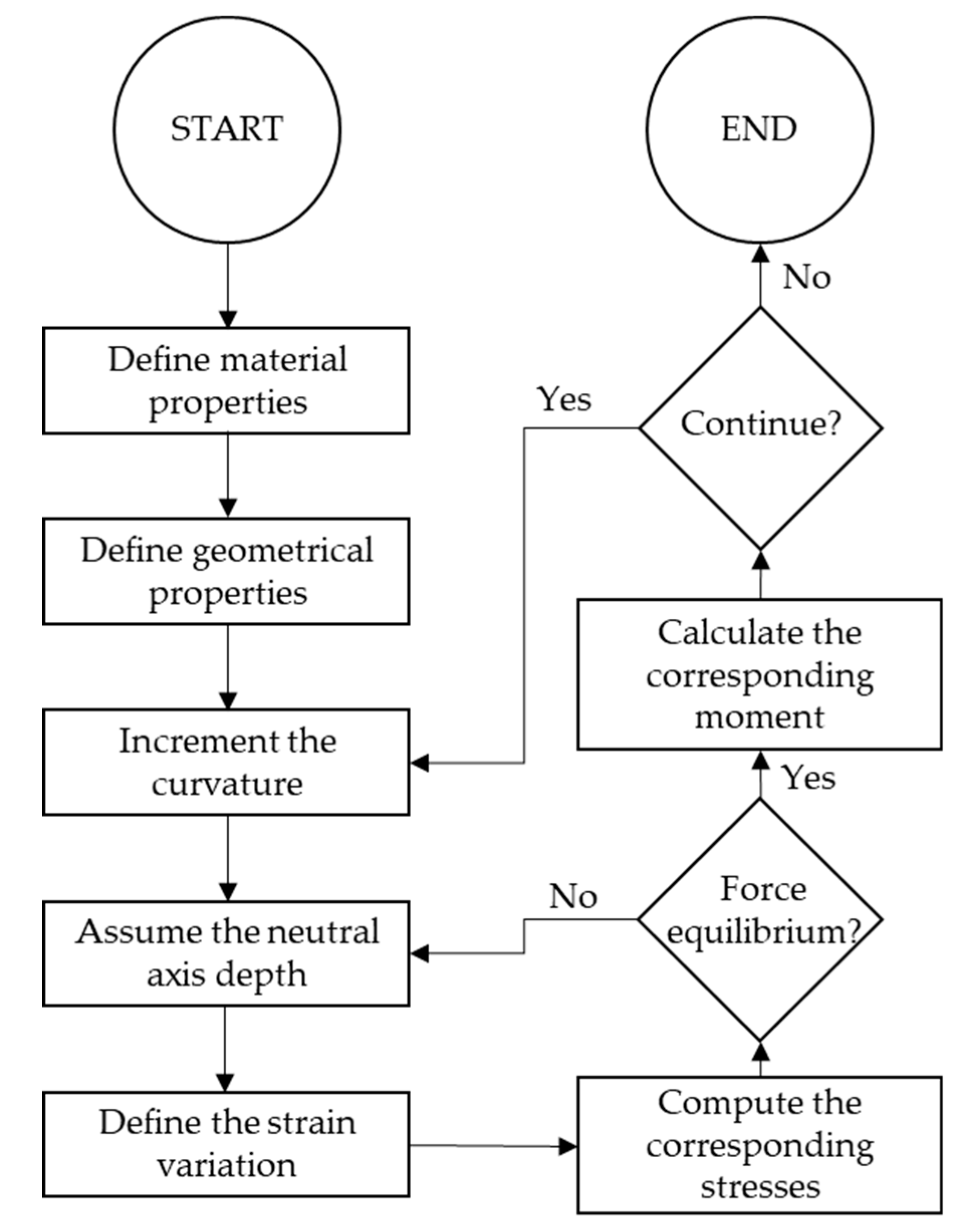

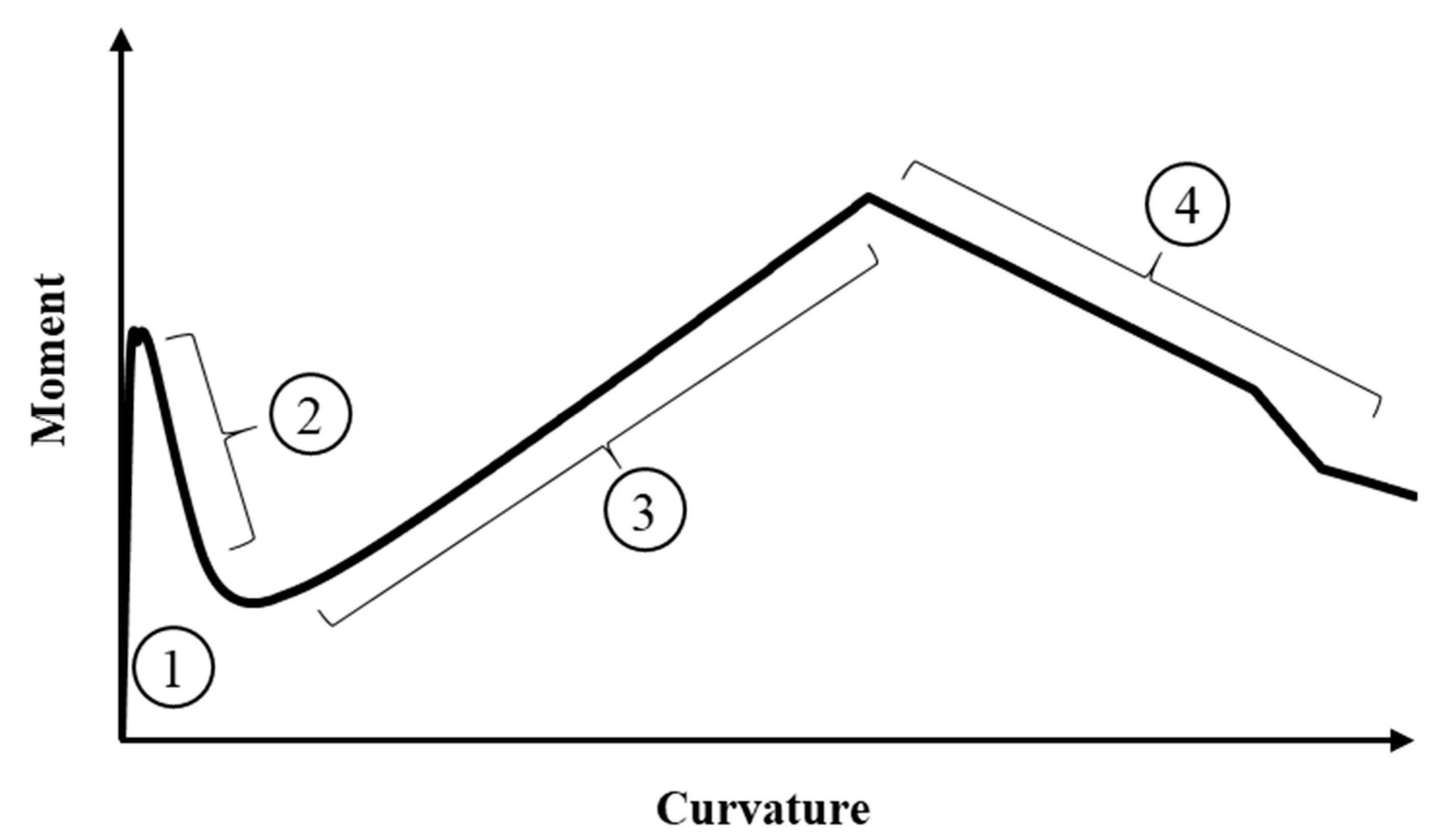

4. Analytical Model to Predict the Moment–Curvature Behavior of TRC Under Flexure

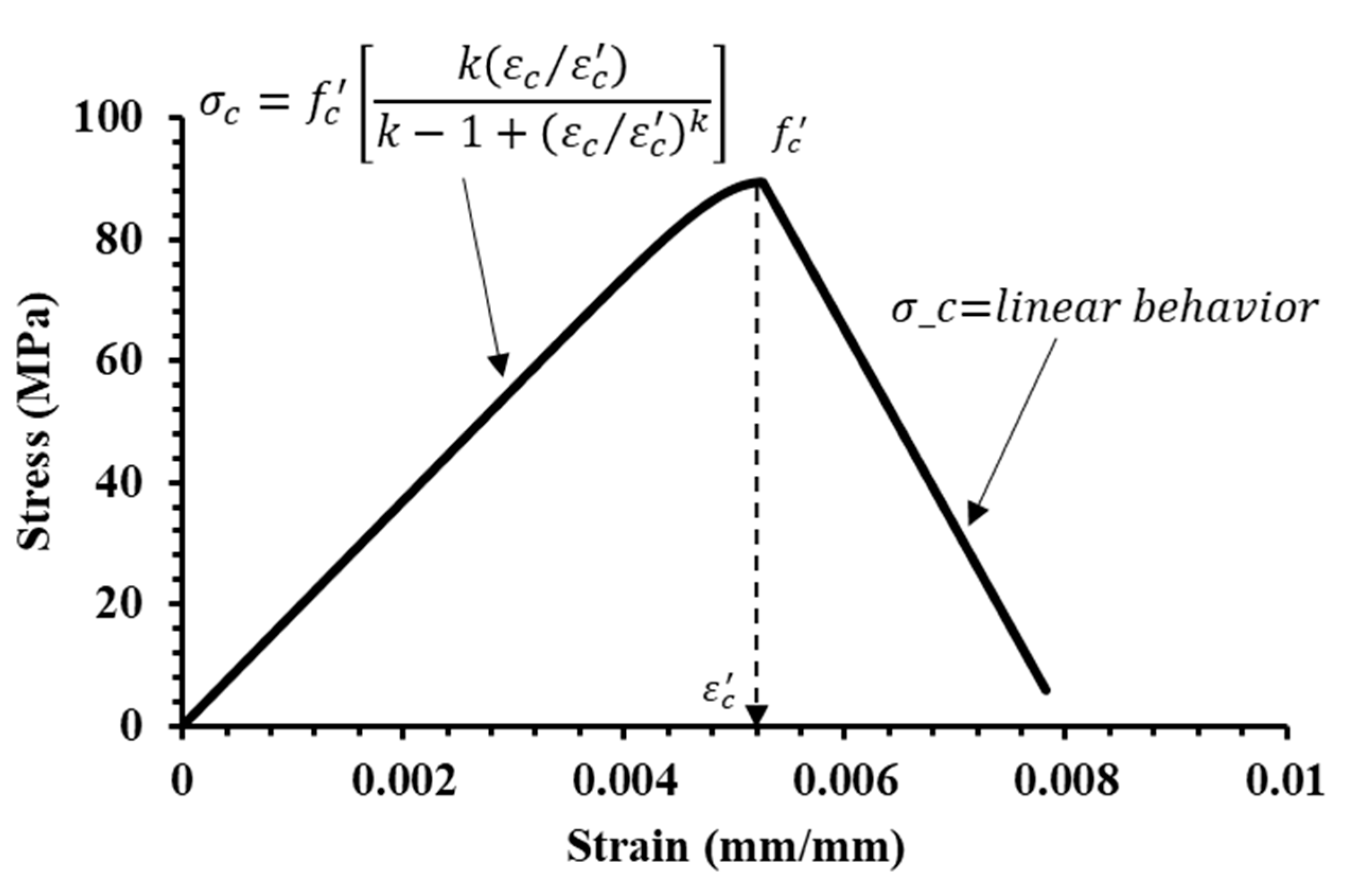

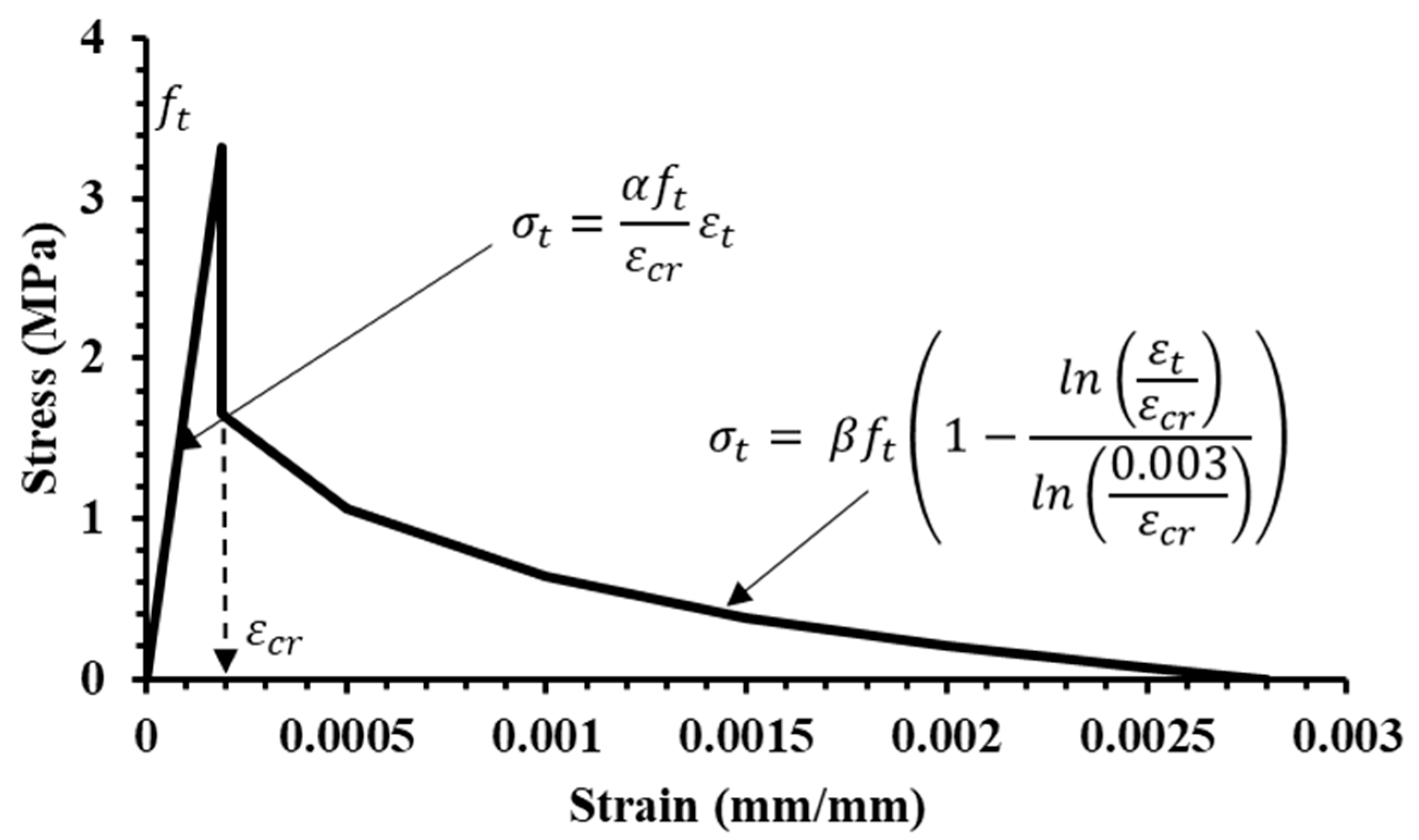

4.1. Material Models

4.1.1. Concrete

4.1.2. Glass Fiber Textile

4.2. Algorithm to Predict the Moment Curvature

- The whole TRC sample behaves as a Bernoulli region throughout loading (plane section remains plane).

- The bond-slip between the textile and concrete matrix was negligible.

- The effect of weft of textile (transverse direction rovings) was considered negligible, and the warp of the textile was considered a continuous longitudinal reinforcement.

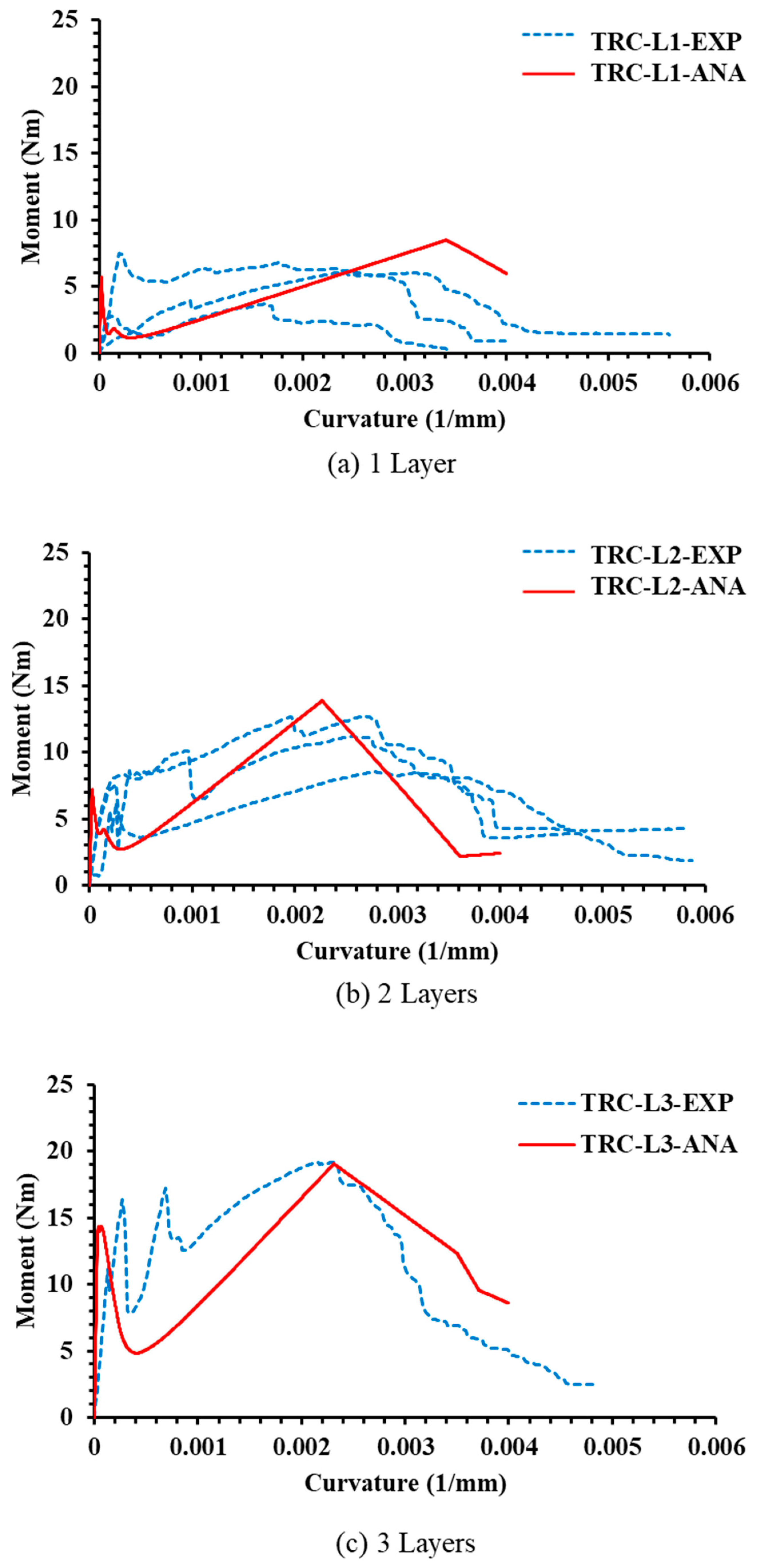

4.3. Validation of Analytical Model

5. Parametric Studies

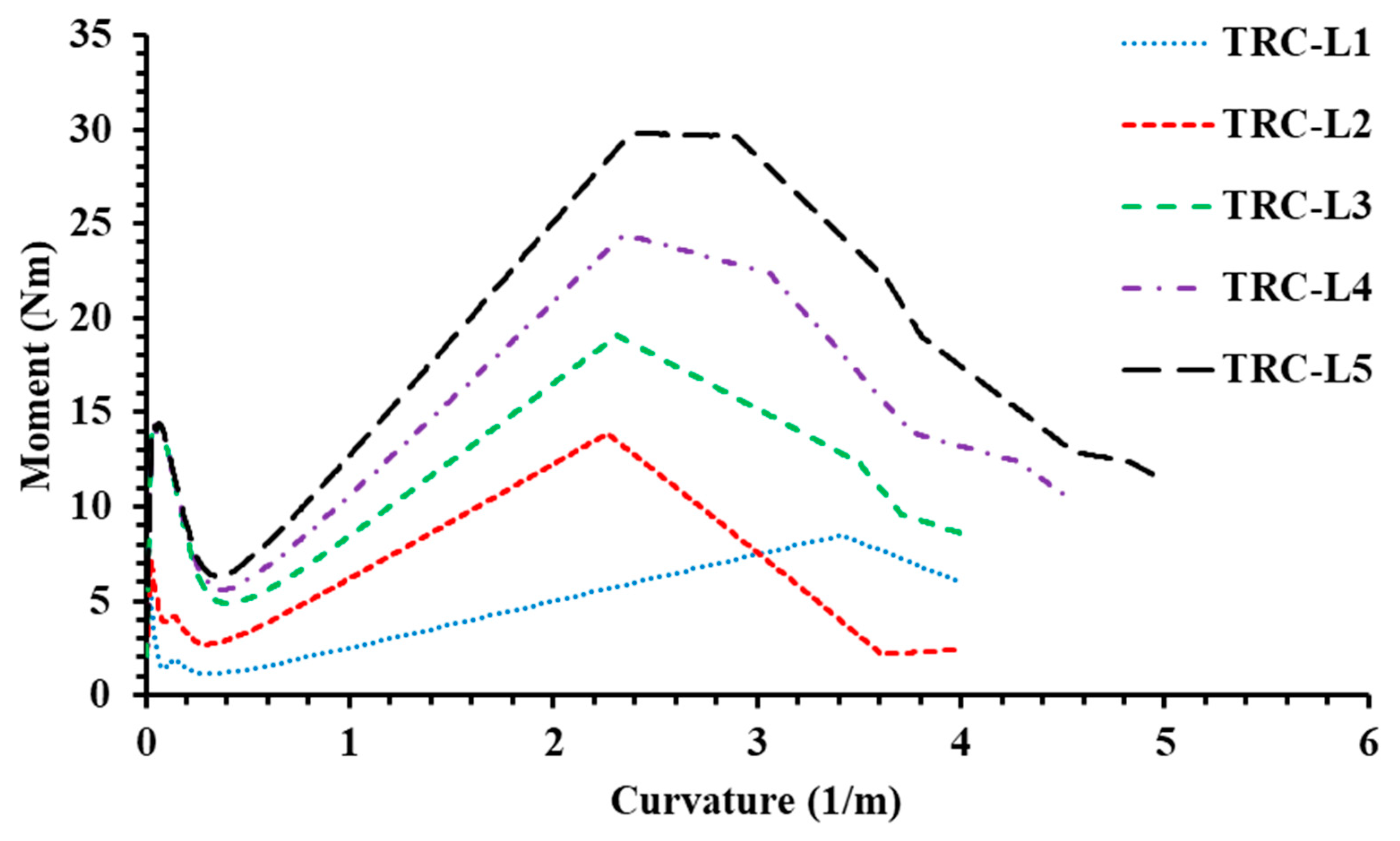

5.1. Effects of Number of Textile Layers

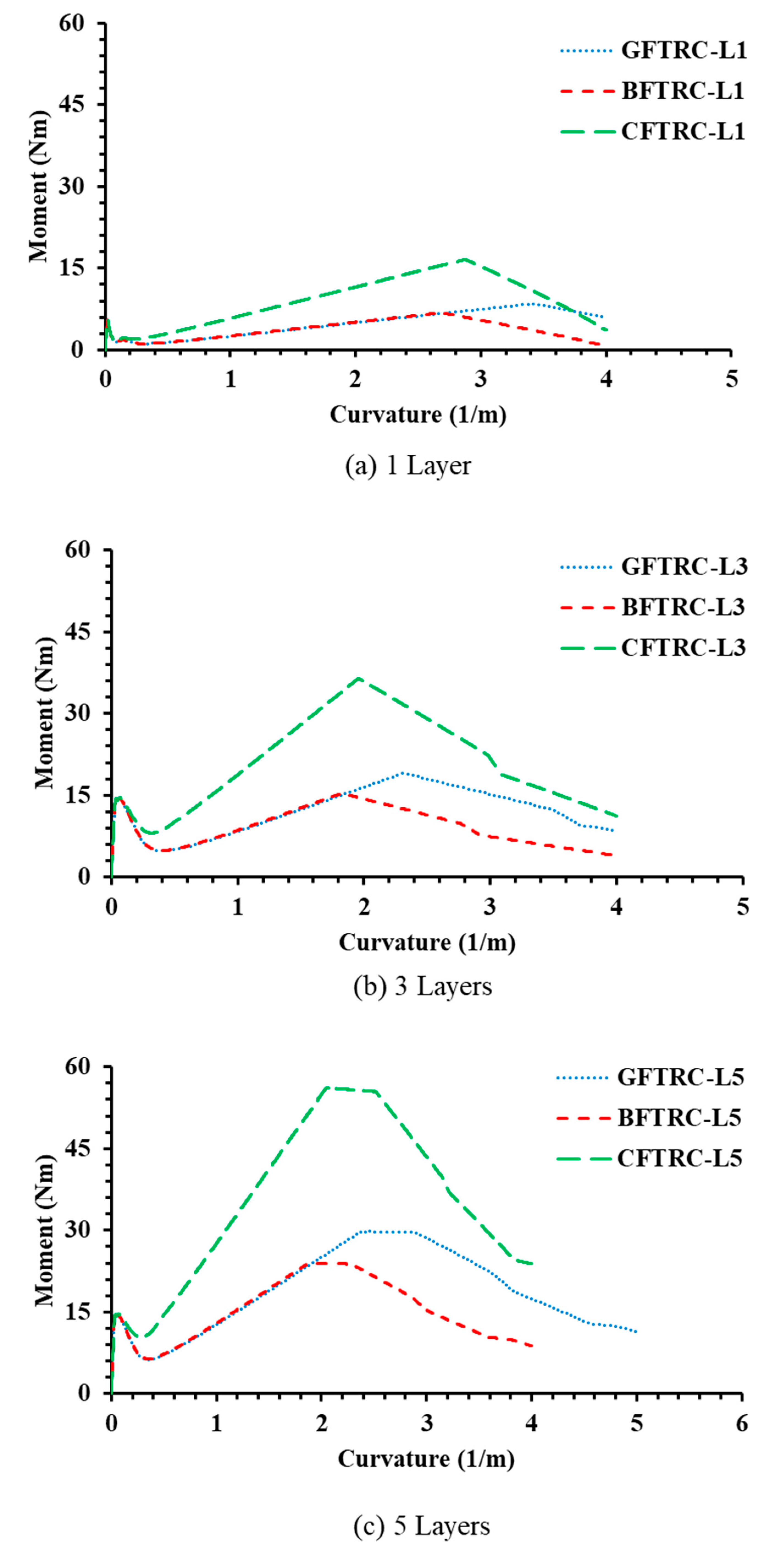

5.2. Effects of Different Textile Materials

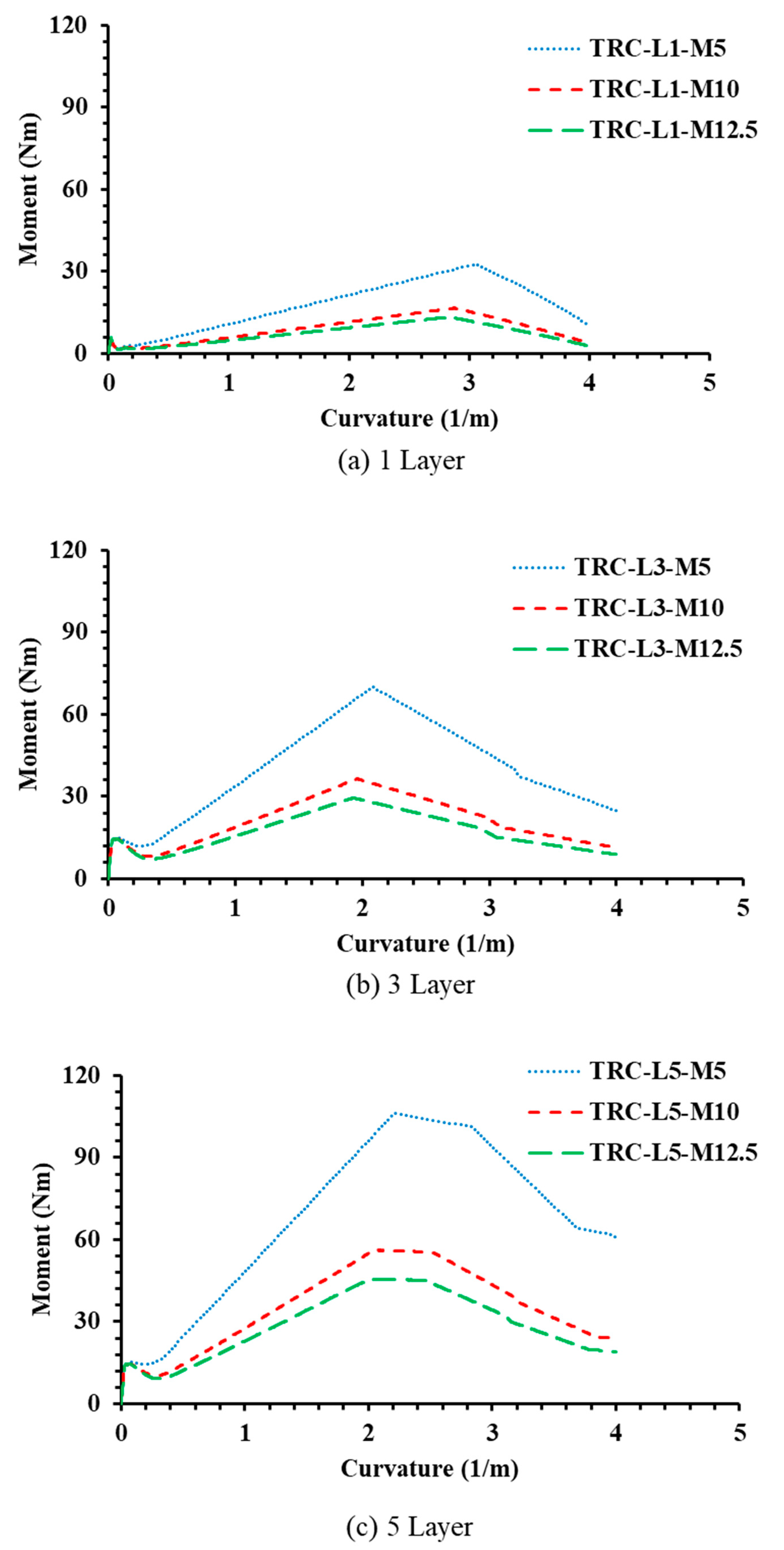

5.3. Effects of Textile Mesh Density

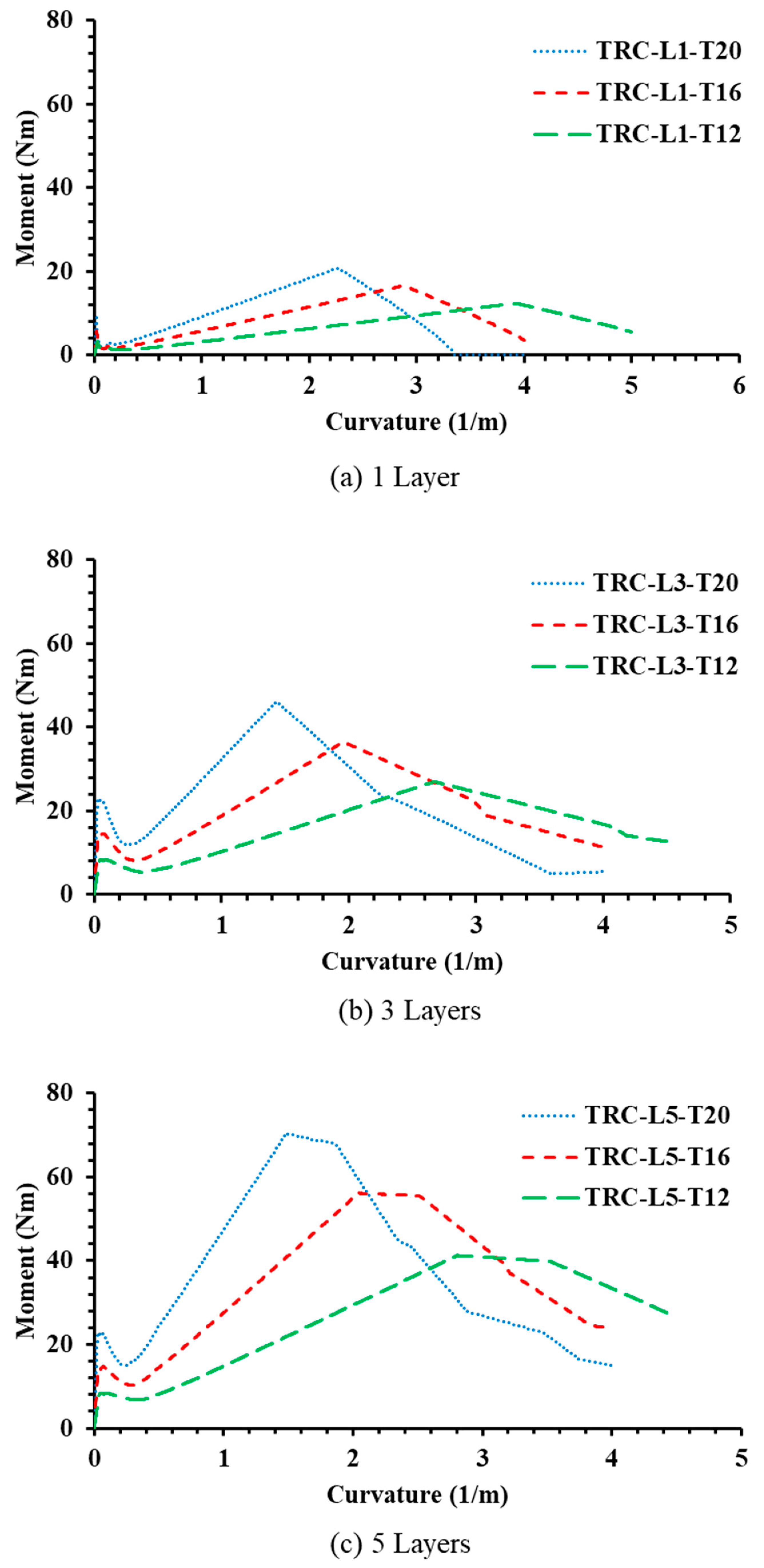

5.4. Effects of TRC Thickness

6. Discussion

7. Conclusions

- The experimental results show that the increase in the number of textile layers improved the performance of UHSTRC considering the ultimate load capacity and serviceability load capacity. The ratio between ultimate and serviceability stress increased with the number of textile layers. However, serviceability conditions will govern the design aspects of UHSTRC, considering the stiffness and high ultimate deflections of UHSTRC.

- It was observed that increasing the number of textile layers can increase the performance of UHSC in tension as well. In particular, the tension softening of UHSC improved due to the bonding between textile and concrete.

- Assumptions such as considering the UHSTRC behavior as the Bernoulli region and no-slip between textile and UHSC can be the cause behind the deviation between analytical and experimental moment–curvature behavior after cracking. However, such assumptions do not interrupt the key outcomes, such as ultimate moment and curvature.

- At the higher mesh densities, the bond performance between the concrete matrix and textile reduces due to the congestion of textile reinforcements. The assumption of considering the perfect bond between the textile and concrete matrix affect the accuracy of the analytical model when the mesh density has higher values. Thus, further investigations are required to assess the effect of bond slip behavior on the flexural behavior of UHSTRC.

- Carbon fiber textiles were found to be performed better compared to glass and basalt fiber textiles in UHSTRC. The higher ultimate load and high energy dissipation were observed in CFTRC.

- The mesh density of textile was found to be heavily affected the moment–curvature behavior of UHSTRC. The 90% increase in ultimate moment was observed when reducing the mesh size by half. The most significant improvement was eliminating the initial moment reduction in UHSTRC after the cracking.

- The increased thickness of UHSTRC was found to be productive in increasing the ultimate moment capacity of UHSTRC. However, the reduction in ultimate curvature with increased thickness adversely affects the performance of UHSTRC by reducing the ductility of UHSTRC.

- The use of UHSTRC as both non-load-bearing and load-bearing elements was feasible due to the high ultimate load-carrying capacity. The UHSTRC in hybrid wall systems can be feasible as it would support the structure to dissipate energy in high loading events, such as seismic events. However, further investigations should be carried out to evaluate the seismic performance of UHSTRC using cyclic loading conditions.

Author Contributions

Funding

Conflicts of Interest

References

- Escrig, C.; Gil, L.; Bernat-Maso, E.; Puigvert, F. Experimental and analytical study of reinforced concrete beams shear strengthened with different types of textile-reinforced mortar. Constr. Build. Mater. 2015, 83, 248–260. [Google Scholar] [CrossRef]

- Mesticou, Z.; Bui, L.; Junes, A.; Si Larbi, A. Experimental investigation of tensile fatigue behaviour of Textile-Reinforced Concrete (TRC): Effect of fatigue load and strain rate. Compos. Struct. 2017, 160, 1136–1146. [Google Scholar] [CrossRef]

- Colombo, I.G.; Magri, A.; Zani, G.; Colombo, M.; di Prisco, M. Textile Reinforced Concrete: Experimental investigation on design parameters. Mater. Struct. 2013, 46, 1933–1951. [Google Scholar] [CrossRef]

- Tlaiji, T.; Vu, X.H.; Ferrier, E.; Si Larbi, A. Thermomechanical behaviour and residual properties of textile reinforced concrete (TRC) subjected to elevated and high temperature loading: Experimental and comparative study. Compos. Part B Eng. 2018, 144, 99–110. [Google Scholar] [CrossRef]

- Hempel, R.; Butler, M.; Hempel, S.; Schorn, H.J.S.P. Durability of textile reinforced concrete. ACI Symposium Publ. 2007, 244, 87–108. [Google Scholar]

- Butler, M.; Mechtcherine, V.; Hempel, S.J.M. Durability of textile reinforced concrete made with AR glass fibre: Effect of the matrix composition. Mater. Struct. 2010, 43, 1351–1368. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, X.; Zhou, F.; Zhu, D.; Zhang, M.; Pan, W.J.C.; Materials, B. Flexural behavior of basalt textile-reinforced concrete. Constr. Build. Mater. 2018, 183, 7–21. [Google Scholar] [CrossRef]

- Hegger, J.; Zell, M.; Horstmann, M. Textile reinforced concrete–realization in applications. In Proceedings of the International Fib Symposium Tailor Made Concrete Structures: New Solutions for Our Society, Amsterdam, Netherlands,, 19–22 May 2008. [Google Scholar]

- Kulas, C.J.G. Actual Applications and Potential of Textile-Reinforced Concrete. Available online: https://www.semanticscholar.org/paper/Actual-applications-and-potential-of-concrete-Kulas-Solidian/0cafa4b696994d68afdc17604f69f236a8cb4137 (accessed on 1 May 2019).

- Hegger, J.; Kulas, C.; Horstmann, M. Realization of TRC Façades with Impregnated AR-Glass Textiles. Key Eng. Mater. 2011, 466, 121–130. [Google Scholar] [CrossRef]

- Hegger, J.; Schneider, M.; Kulas, C. Dimensioning of TRC with application to ventilated facade systems. In Proceedings of the International RILEM Conference on Material Science, Aachen, Germany, 6–8 September 2010. [Google Scholar]

- Hegger, J.; Voss, S. Investigations on the bearing behaviour and application potential of textile reinforced concrete. Eng. Struct. 2008, 30, 2050–2056. [Google Scholar] [CrossRef]

- Murgul, V.; Volkova, A.; Paykov, A.; Semenov, S.; Stolyarov, O.; Melnikov, B. Flexural Behavior of Textile-Reinforced Concrete. MATEC Web Conf. 2016, 53. [Google Scholar] [CrossRef]

- Zhu, D.; Gencoglu, M.; Mobasher, B. Low velocity flexural impact behavior of AR glass fabric reinforced cement composites. Cem. Concr. Compos. 2009, 31, 379–387. [Google Scholar] [CrossRef]

- Baduge, S.K.; Mendis, P.; Ngo, T.; Portella, J.; Nguyen, K.J.C.; Materials, B. Understanding failure and stress-strain behavior of very-high strength concrete (>100 MPa) confined by lateral reinforcement. Constr. Build. Mater. 2018, 189, 62–77. [Google Scholar] [CrossRef]

- Baduge, S.K.; Mendis, P.; Ngo, T. Stress-strain relationship for very-high strength concrete (>100 MPa) confined by lateral reinforcement. Eng. Struct. 2018, 177, 795–808. [Google Scholar] [CrossRef]

- Graybeal, B. Ultra-High Performance Concrete; Federal Highway Administration: McLean, VA, USA, 2011. [Google Scholar]

- Kristombu Baduge, S.; Mendis, P.; San Nicolas, R.; Rupasinghe, M.; Portella, J. Aggregate-Dependent Approach to Formulate and Predict Properties of High-Strength and Very-High-Strength Concrete. J. Mater. Civ. Eng. 2020, 32, 04020053. [Google Scholar] [CrossRef]

- Mendis, P.; Nguyen, K.; Baduge, S.; Chandrathilaka, E. Textile reinforced concrete composite for advanced construction applications. In Proceedings of the international conference on composites materials (ICCM22), Melbourne, Australia, 11–16 August 2019. [Google Scholar]

- Nguyen, K.; Navaratnam, S.; Mendis, P.; Zhang, K.; Barnett, J.; Wang, H.J. Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. Compos. Part B Eng. 2020, 187, 107815. [Google Scholar] [CrossRef]

- Kristombu Baduge, S.; Mendis, P.; Ngo, T.D.; Sofi, M. Ductility Design of Reinforced Very-High Strength Concrete Columns (100–150 MPa) Using Curvature and Energy-Based Ductility Indices. Int. J. Concr. Struct. Mater. 2019, 13. [Google Scholar] [CrossRef]

- Ashour, S.A. Effect of compressive strength and tensile reinforcement ratio on flexural behavior of high-strength concrete beams. Eng. Struct. 2000, 22, 413–423. [Google Scholar] [CrossRef]

- Kristombu Baduge, S.; Mendis, P. Novel energy-based rational for nominal ductility design of very-high strength concrete columns (>100 MPa). Eng. Struct. 2019, 198. [Google Scholar] [CrossRef]

- Abouelleil, A.; Rasheed, H.A. Shear Crack Prediction in Shallow Reinforced Concrete Beams Using a Nonlinear Approach. ACI Struct. J. 2019, 116. [Google Scholar] [CrossRef]

- ASTM, A.J.A.I., West Conshohocken, PA. AI" ASTM C. ASTM C39/C39M-18: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Available online: https://www.astm.org/Standards/C39 (accessed on 1 May 2019).

- ASTM. D 7264/D 7264M – 07- Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials ASTM International: ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States. 2007. Available online: https://www.researchgate.net/publication/339947727_Designation_D_7264D_7264M_-07_Standard_Test_Method_for_Flexural_Properties_of_Polymer_Matrix_Composite_Materials_1 (accessed on 1 May 2019).

- Oktavianus, Y.; Kristombu Baduge, K.S.; Orlowski, K.; Mendis, P. Structural behaviour of prefabricated load bearing braced composite timber wall system. Eng. Struct. 2018, 176, 555–568. [Google Scholar] [CrossRef]

- Cusson, D.; Paultre, P. Stress-strain model for confined high-strength concrete. J. Struct. Eng. 1995, 121, 468–477. [Google Scholar] [CrossRef]

- Shin, H.-O.; Min, K.-H.; Mitchell, D. Confinement of ultra-high-performance fiber reinforced concrete columns. Compos. Struct. 2017, 176, 124–142. [Google Scholar] [CrossRef]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Elmenshawi, A.A.A. Ductility of Ultra-High Strength Concrete Flexural Elements Subjected to Seismic Shear; University of Calgary: Calgary, AB, Canada, 2008. [Google Scholar]

| Material | Cement (GP) | Sand | Fly Ash | Silica Fume | Slag | Water | Superplasticizer | Viscosity Modifier | Retarder |

|---|---|---|---|---|---|---|---|---|---|

| Content (kg/m3) | 783 | 705 | 258 | 78 | 282 | 287 | 11 | 2 | 4 |

| Mesh Size (mm × mm) | Tensile Load Bearing Capacity of 50 mm Strip (N) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Ultimate Strain (mm/mm) |

|---|---|---|---|---|

| 10 × 10 | 1078 | 1100 | 41 | 0.025 |

| Specimen ID | No. of TRC Layers | Ultimate Load (N) | Ultimate Flexural Stress (MPa) | Peak Deflection | First Crack Load (N) | First Crack Deflection (mm) |

|---|---|---|---|---|---|---|

| TRC-L1-s1 | 1 | 88.2 | 1.72 | 1.96 | 66.5 | 0.15 |

| TRC-L1-s2 | 1 | 159.2 | 3.11 | 2.08 | 180.5 | 0.23 |

| TRC-L1-s3 | 1 | 146.7 | 2.87 | 2.93 | 9.9 | 0.048 |

| TRC-L2-s1 | 2 | 205.1 | 4.01 | 3.40 | 183.1 | 0.299 |

| TRC-L2-s2 | 2 | 304.8 | 5.95 | 3.10 | 193.5 | 0.265 |

| TRC-L2-s3 | 2 | 268.1 | 5.24 | 3.20 | 134.8 | 0.232 |

| TRC-L3-s1 | 3 | 461.1 | 9.01 | 2.71 | 268.5 | 0.149 |

| TRC-L3-s2 | 3 | 431.1 | 8.42 | 6.53 | 149.9 | 0.415 |

| Material | Tensile strength (MPa) | Elastic modulus (GPa) | Ultimate strain (mm/mm) |

|---|---|---|---|

| Basal fiber textile | 884 | 45 | 0.022 |

| Carbon fiber textile | 2180 | 109 | 0.02 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chandrathilaka, E.R.K.; Baduge, S.K.; Mendis, P.; Thilakarathna, P.S.M. Flexural Performance of Prefabricated Ultra-High-Strength Textile Reinforced Concrete (UHSTRC): An Experimental and Analytical Investigation. Buildings 2020, 10, 68. https://doi.org/10.3390/buildings10040068

Chandrathilaka ERK, Baduge SK, Mendis P, Thilakarathna PSM. Flexural Performance of Prefabricated Ultra-High-Strength Textile Reinforced Concrete (UHSTRC): An Experimental and Analytical Investigation. Buildings. 2020; 10(4):68. https://doi.org/10.3390/buildings10040068

Chicago/Turabian StyleChandrathilaka, Egodawaththa Ralalage Kanishka, Shanaka Kristombu Baduge, Priyan Mendis, and Petikirige Sadeep Madhushan Thilakarathna. 2020. "Flexural Performance of Prefabricated Ultra-High-Strength Textile Reinforced Concrete (UHSTRC): An Experimental and Analytical Investigation" Buildings 10, no. 4: 68. https://doi.org/10.3390/buildings10040068

APA StyleChandrathilaka, E. R. K., Baduge, S. K., Mendis, P., & Thilakarathna, P. S. M. (2020). Flexural Performance of Prefabricated Ultra-High-Strength Textile Reinforced Concrete (UHSTRC): An Experimental and Analytical Investigation. Buildings, 10(4), 68. https://doi.org/10.3390/buildings10040068