Old Dumped Fly Ash as a Sand Replacement in Cement Composites

Abstract

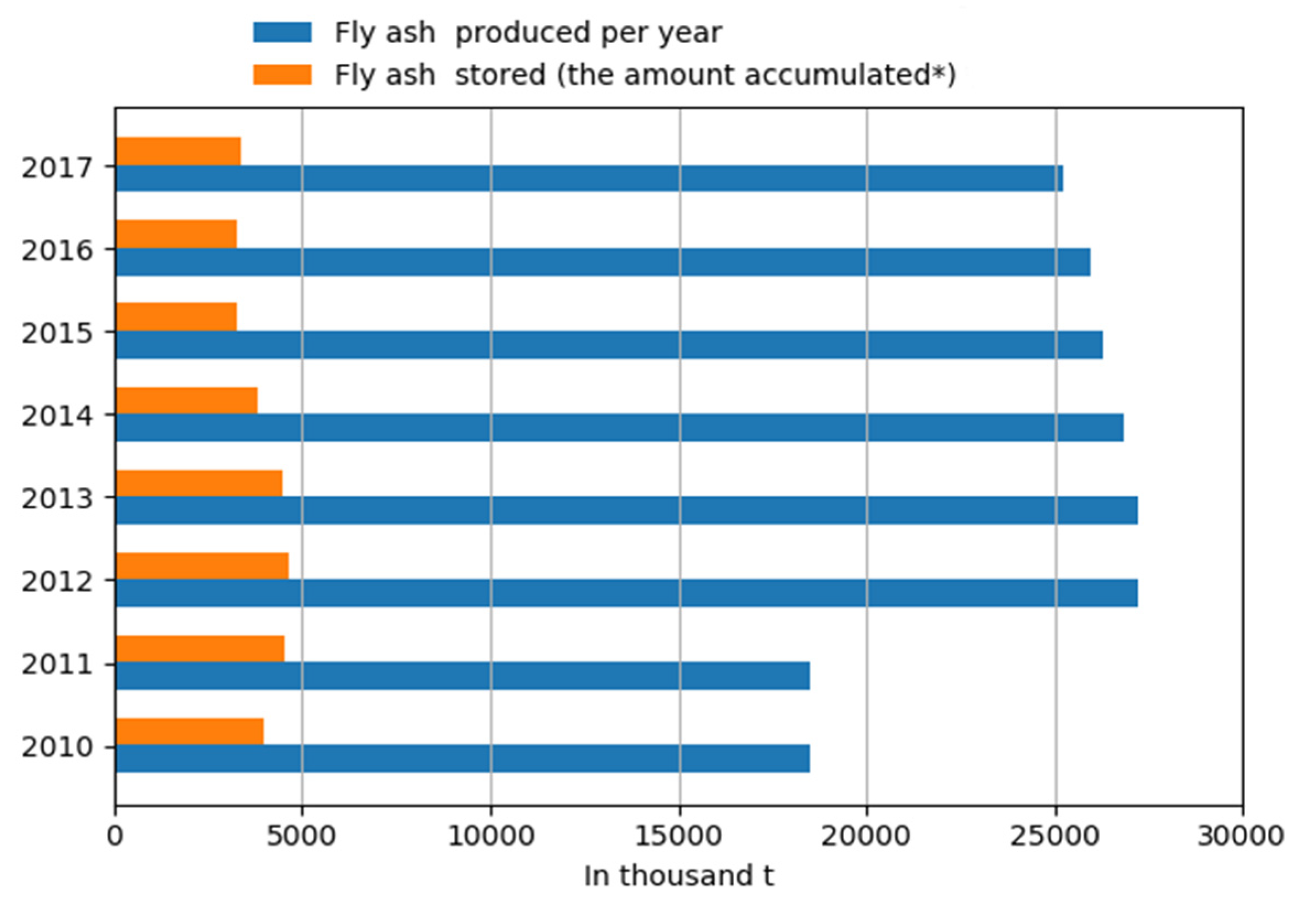

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Testing Methods

3. Results

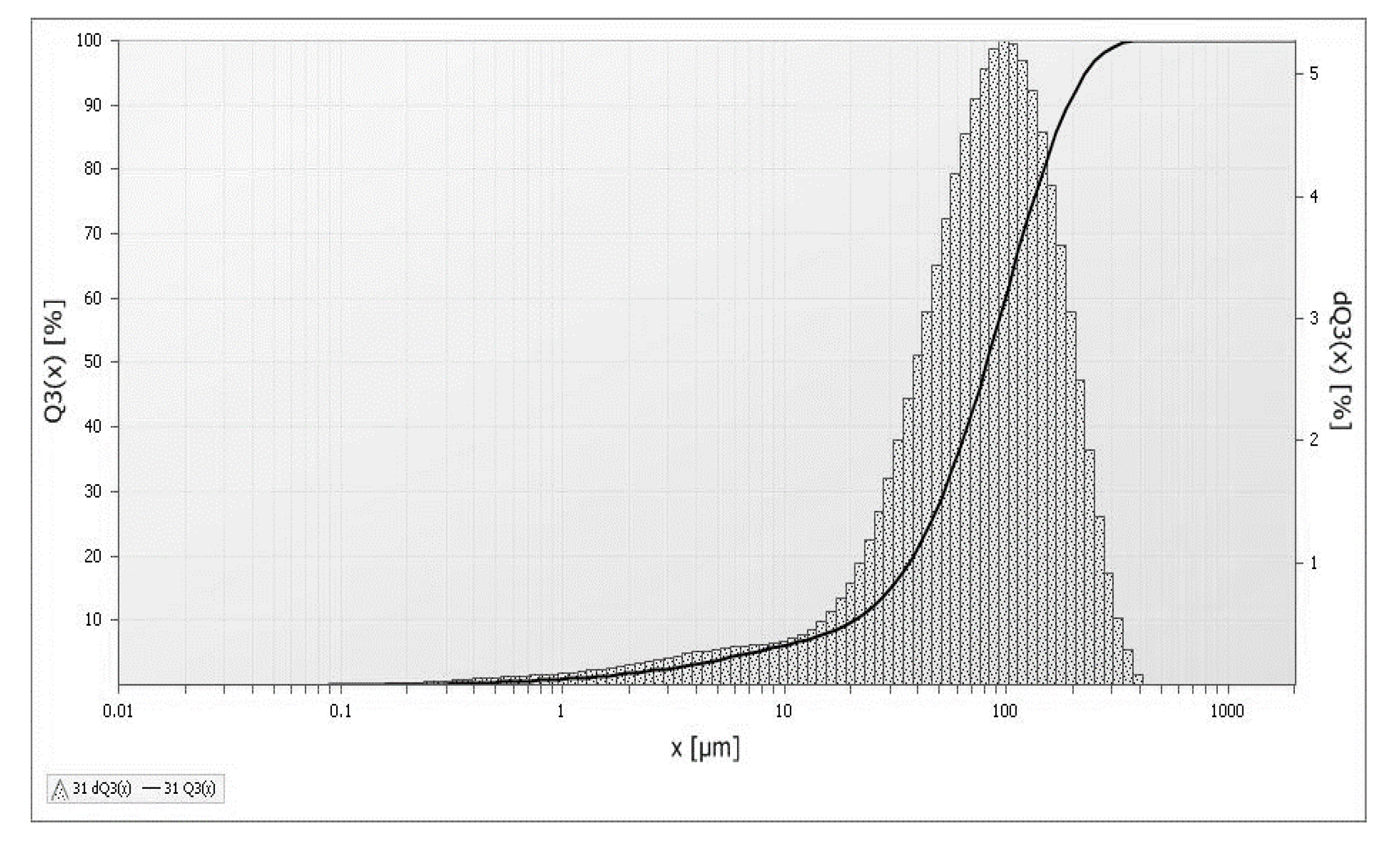

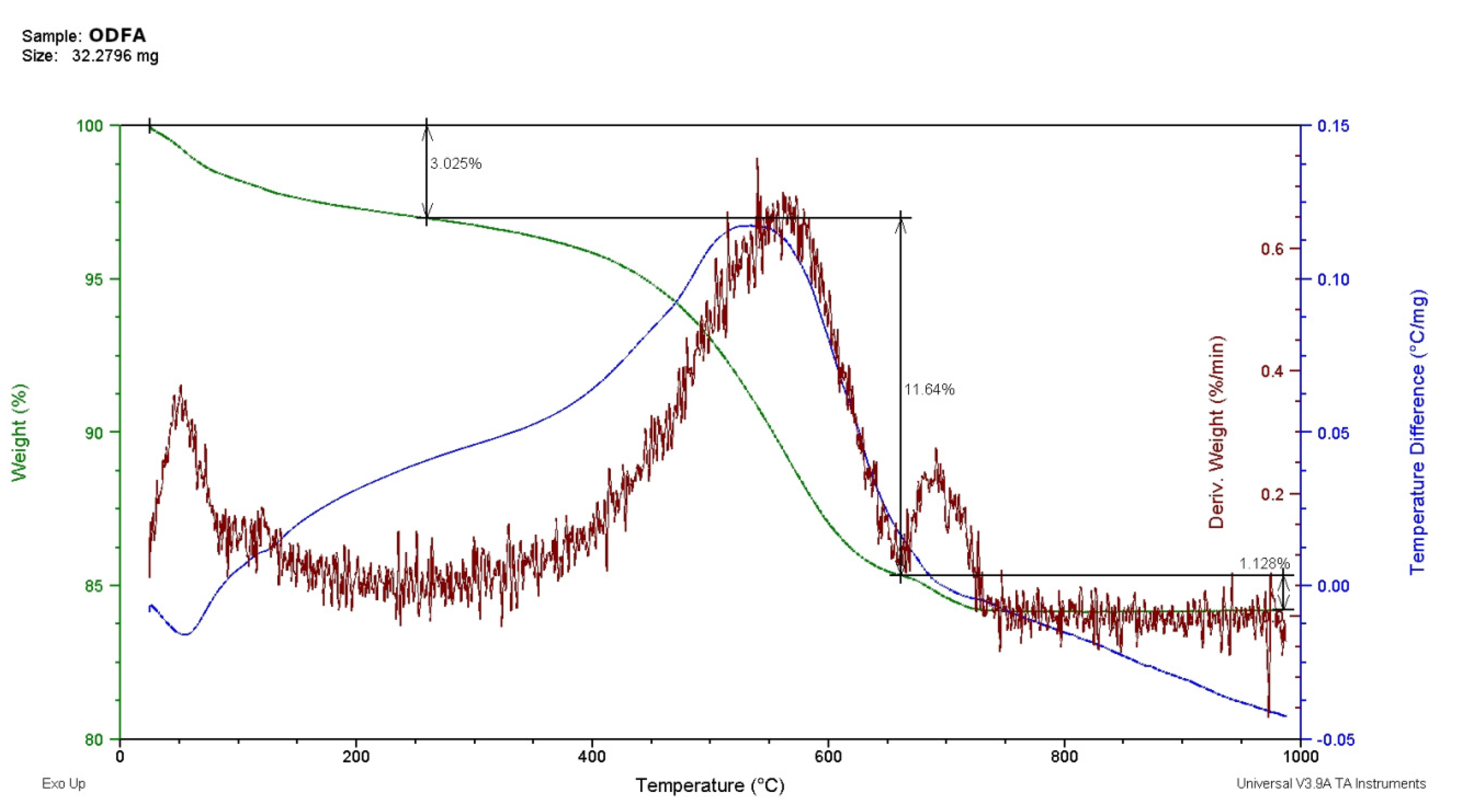

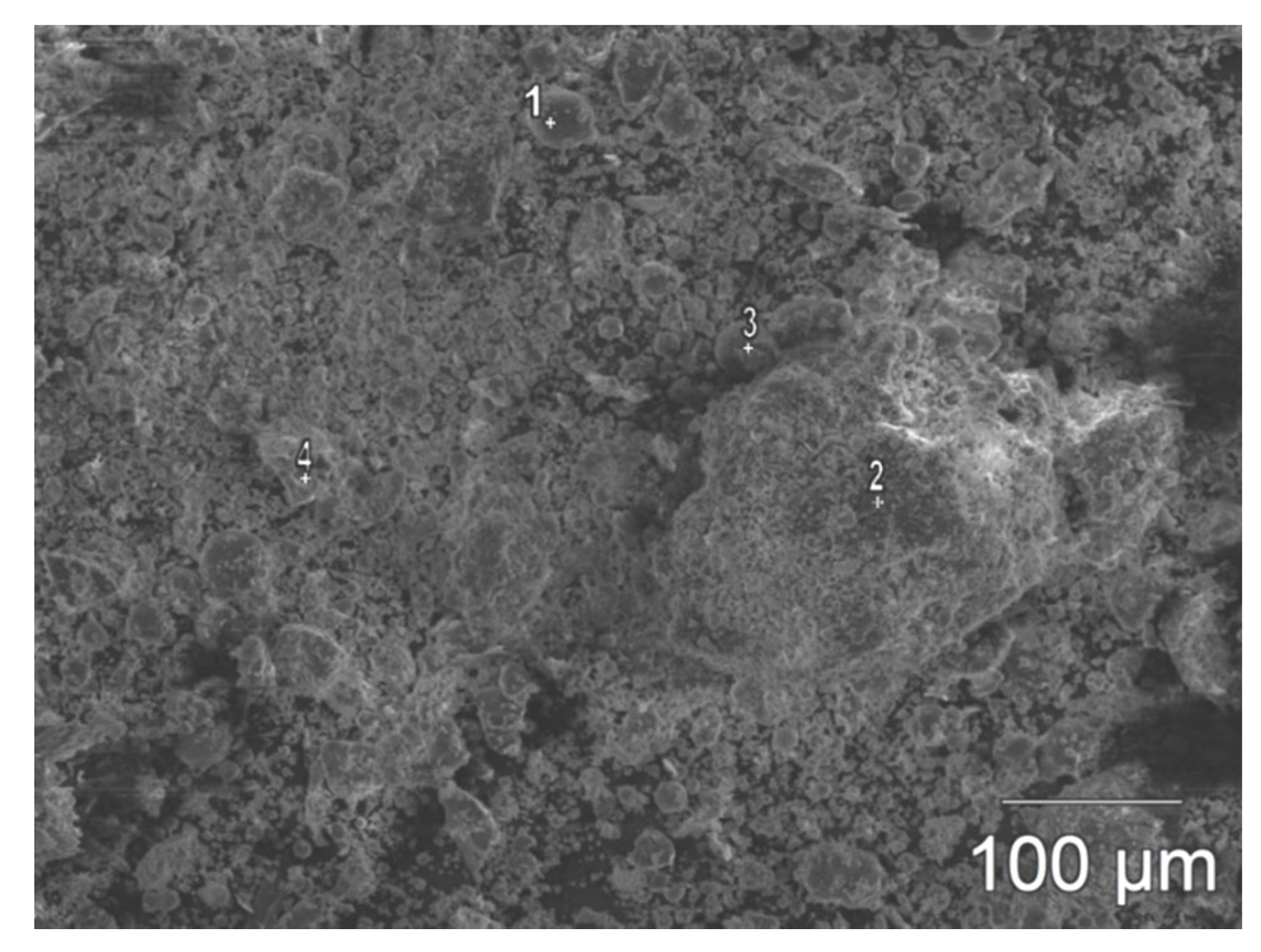

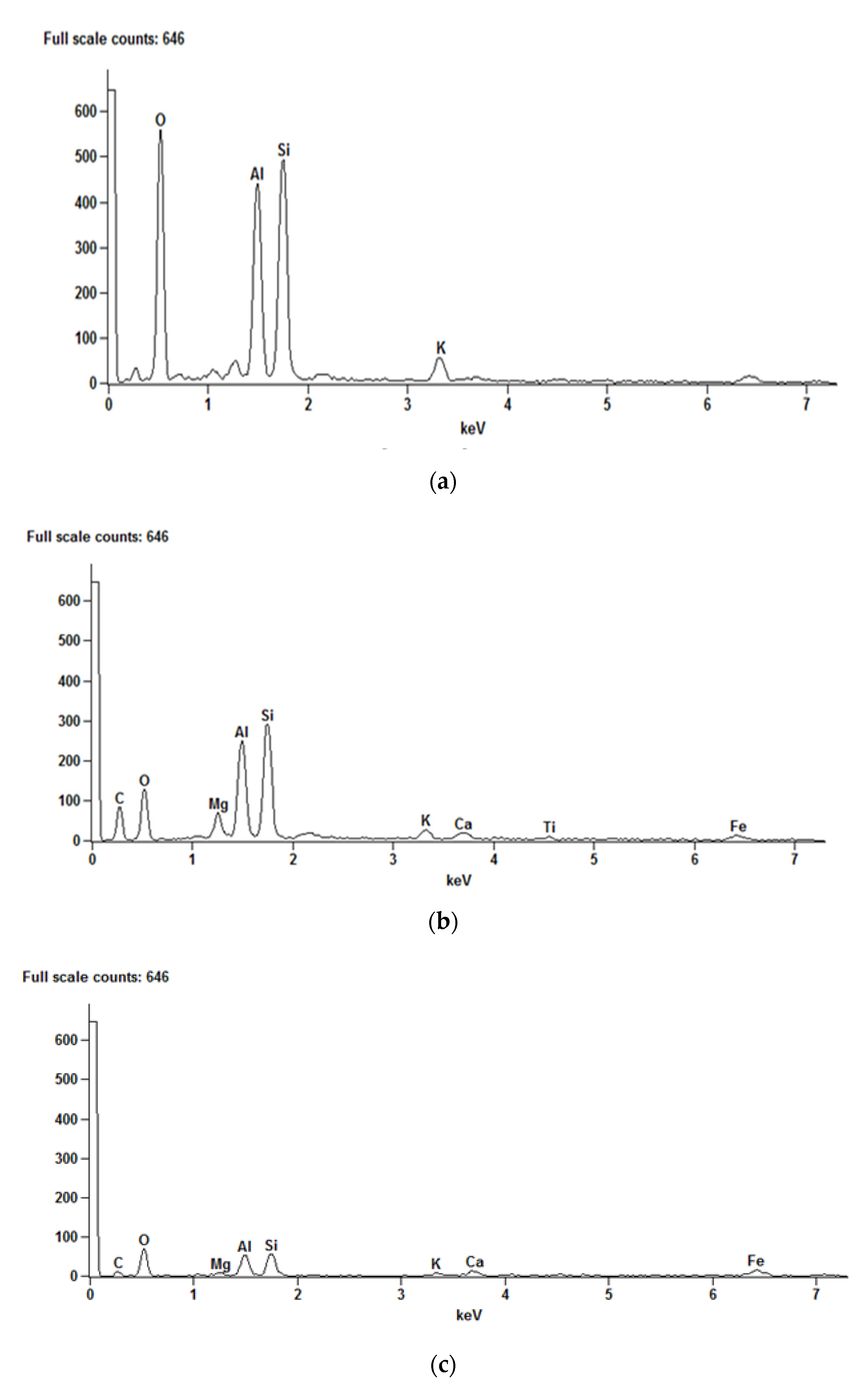

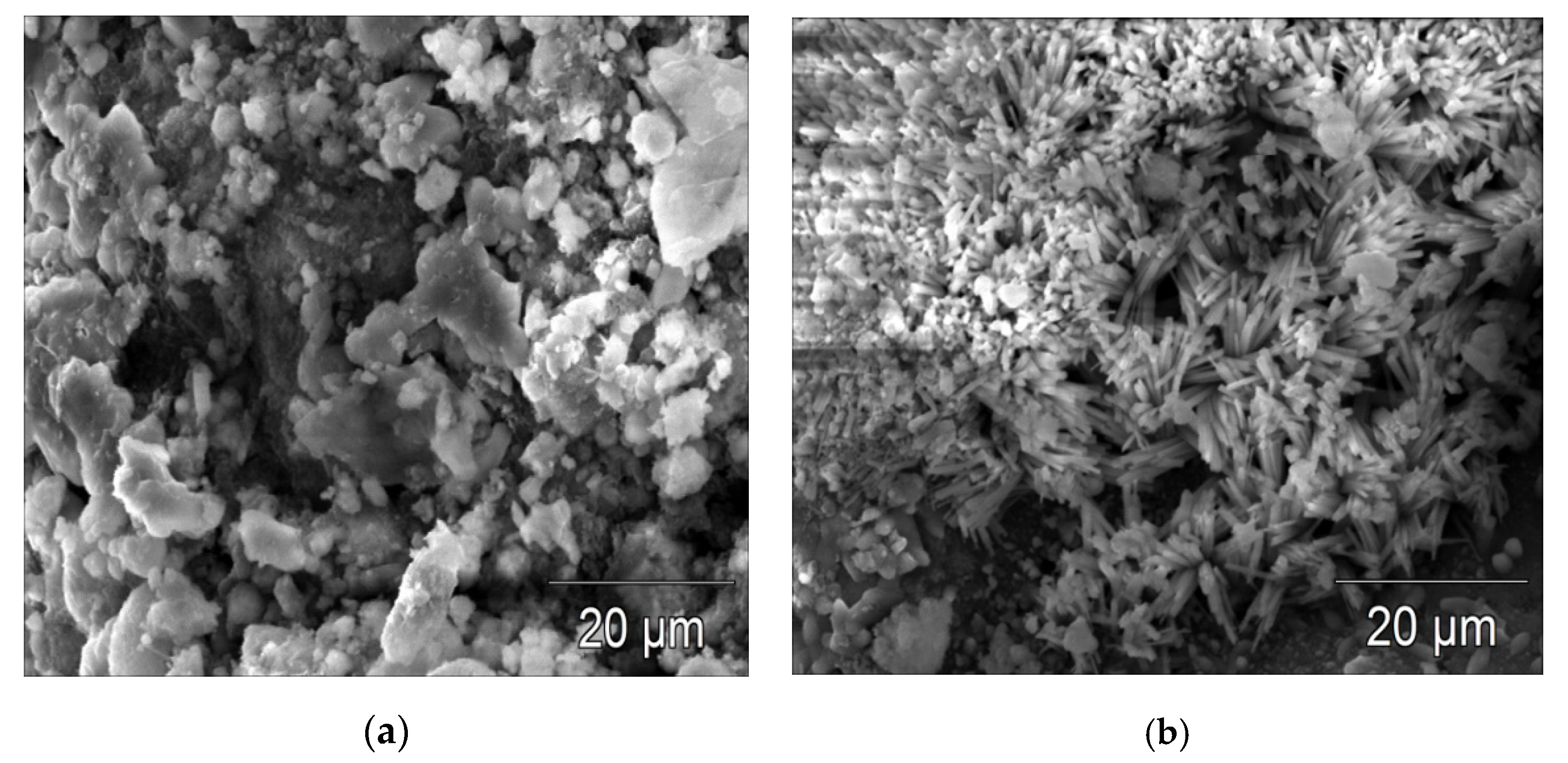

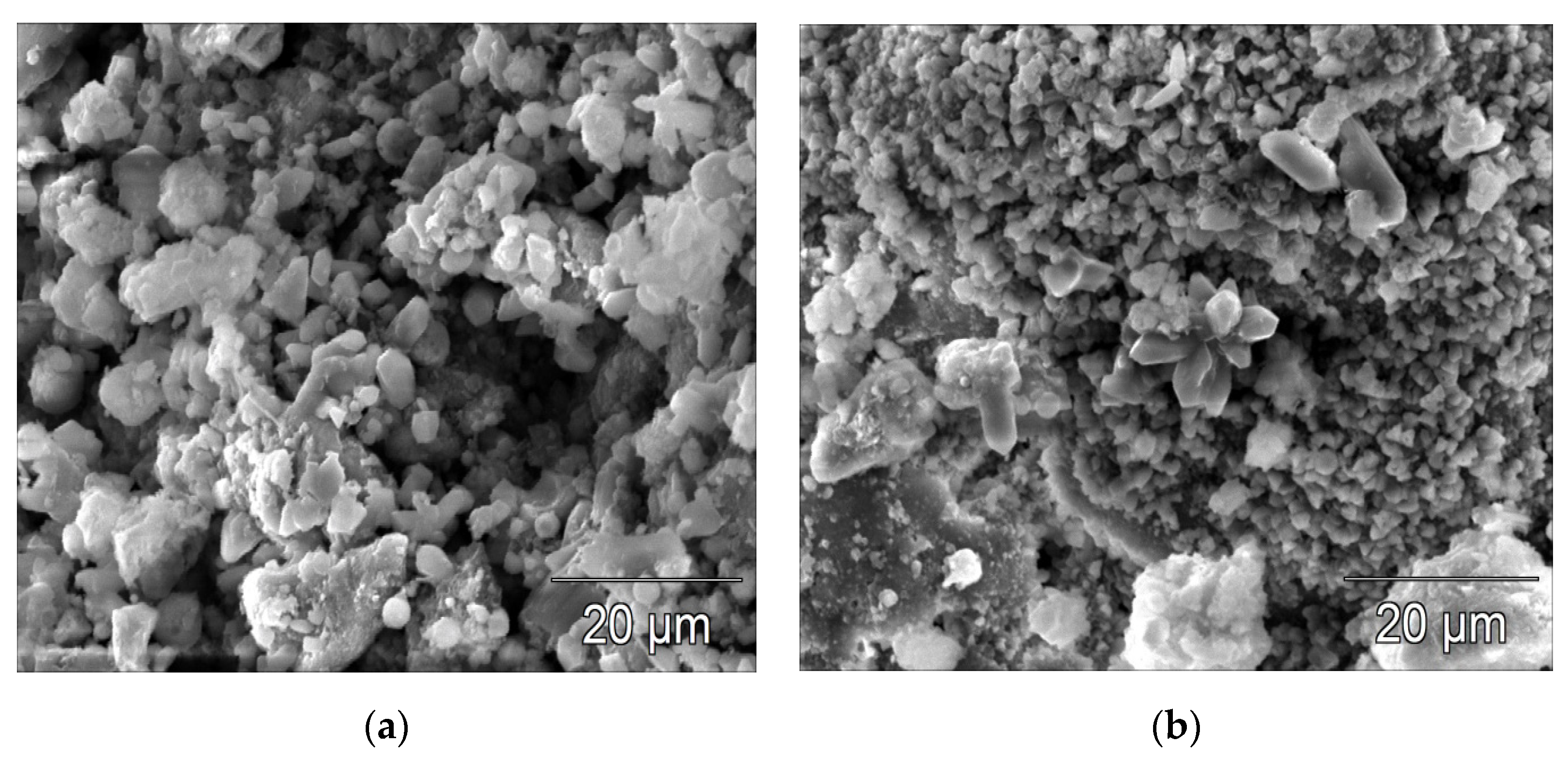

3.1. Old Dumped Fly Ash Tests

3.2. Cement Composite Tests

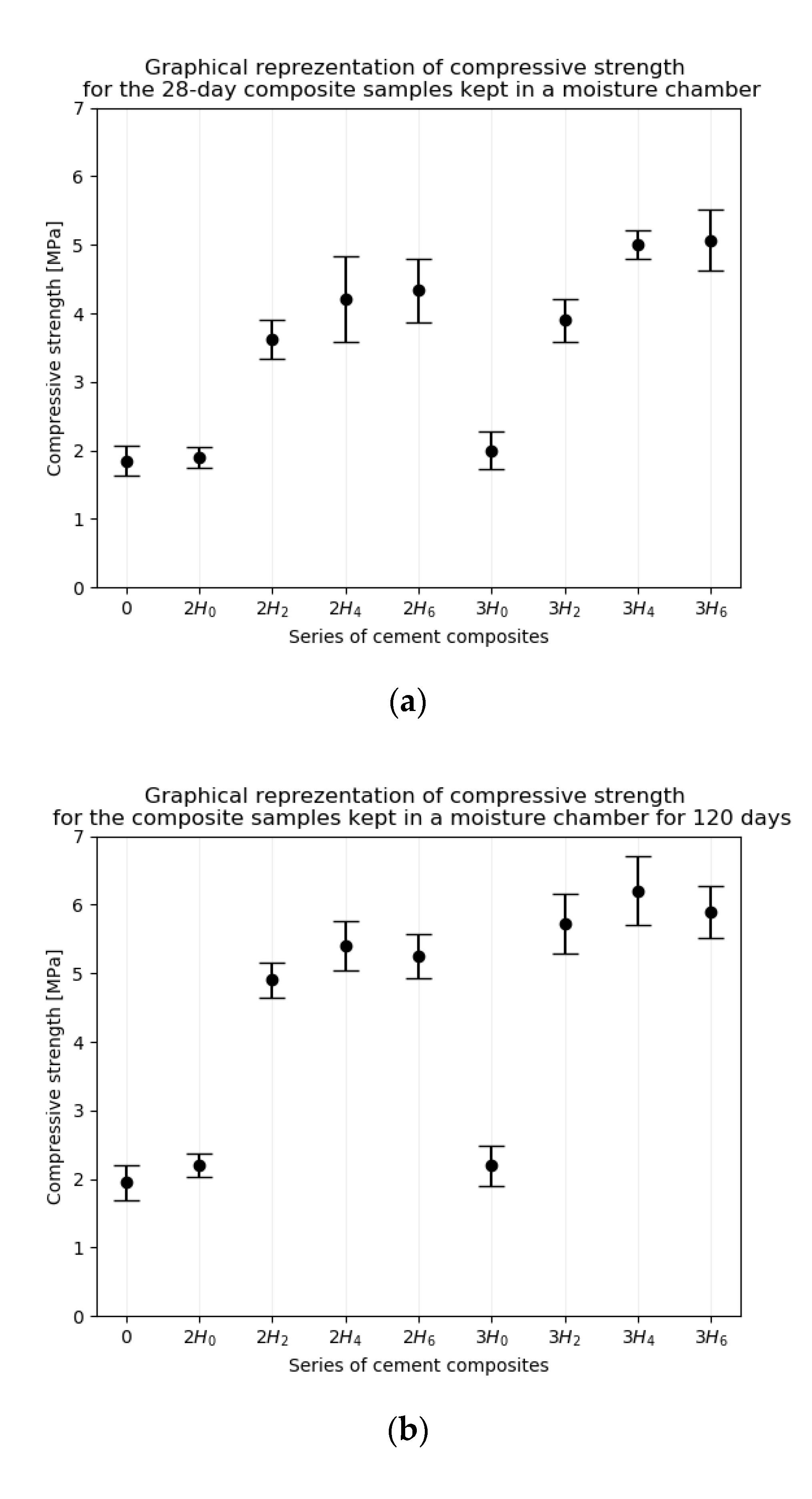

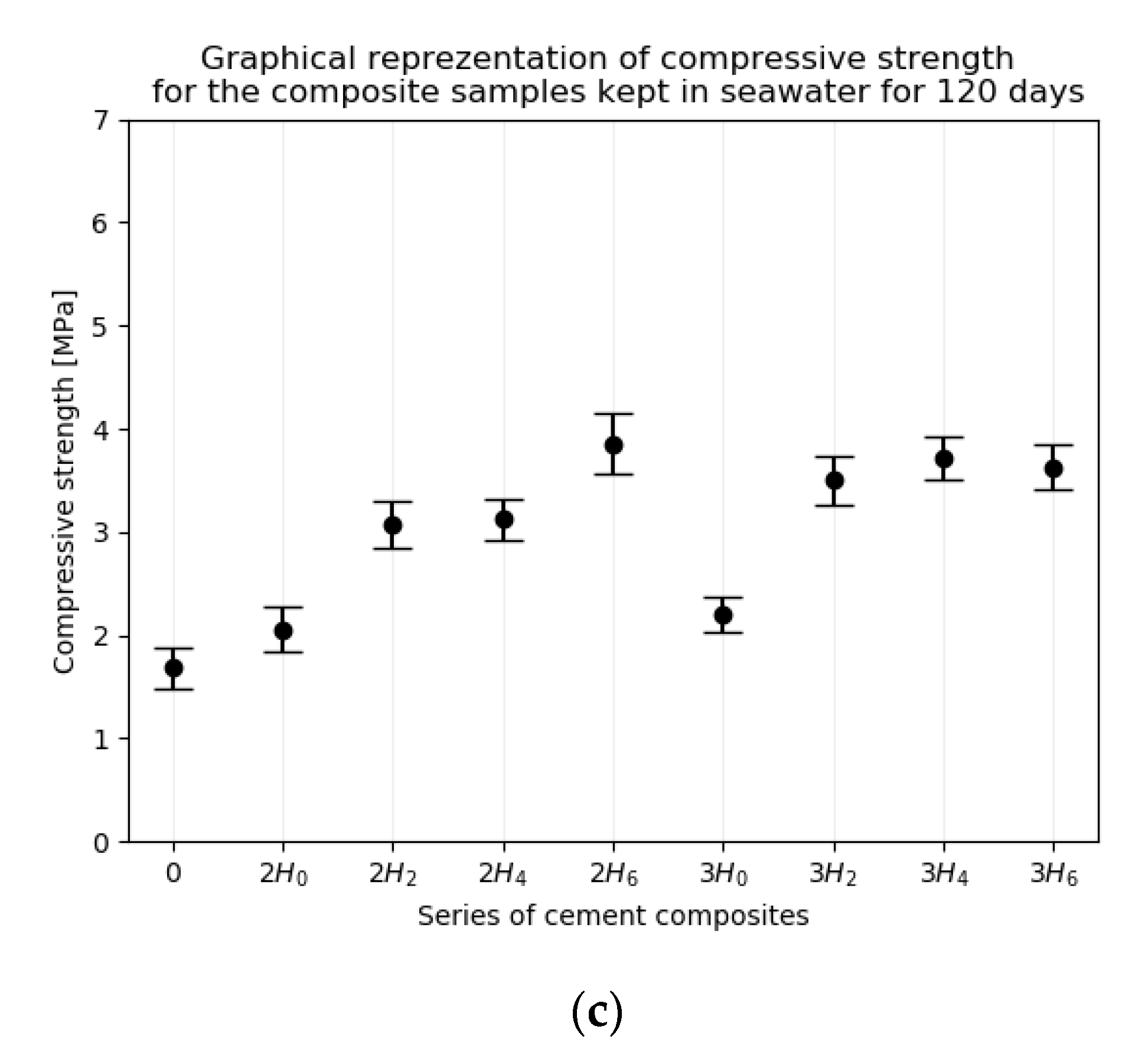

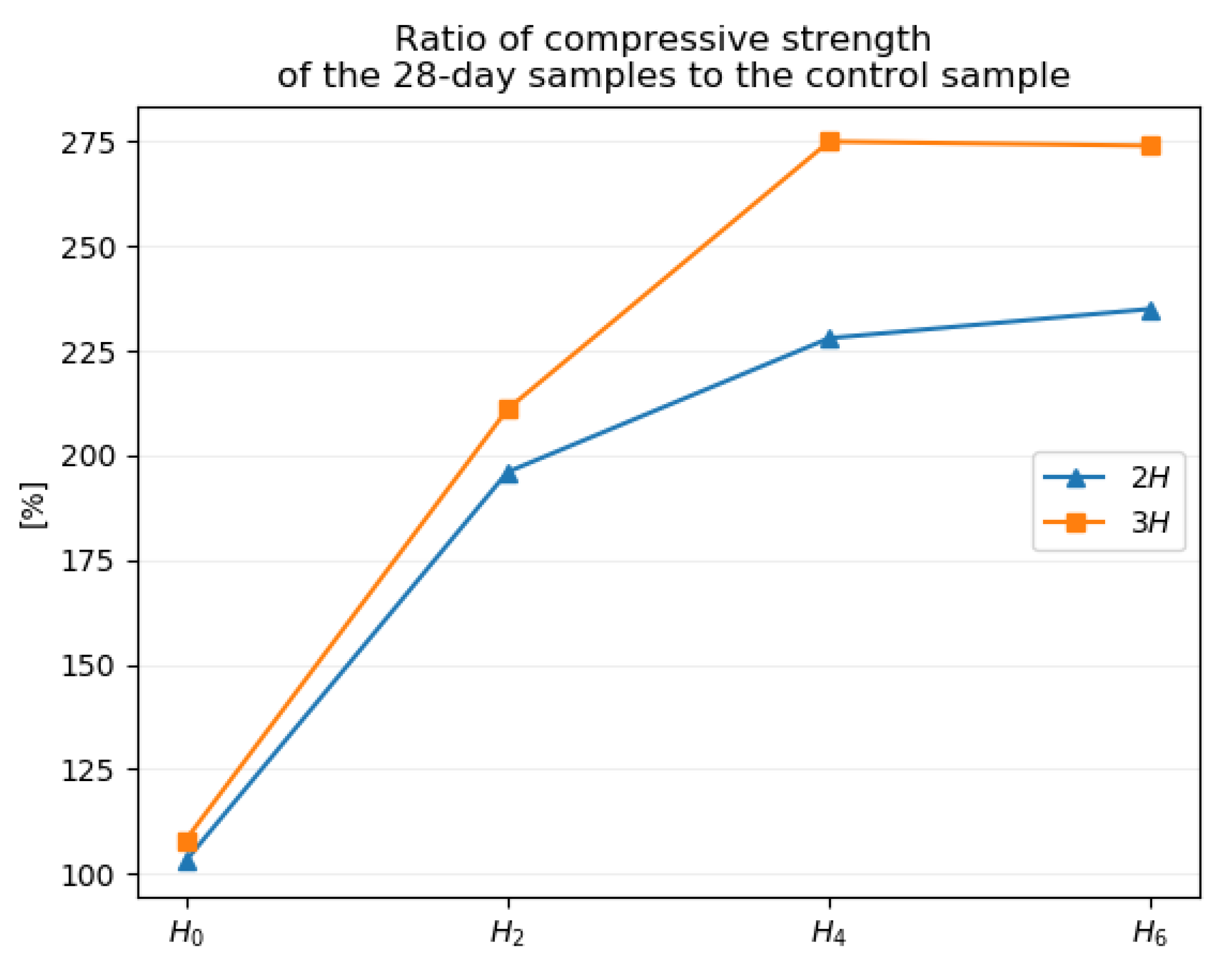

3.2.1. Compressive Strength before and after Seawater Attack

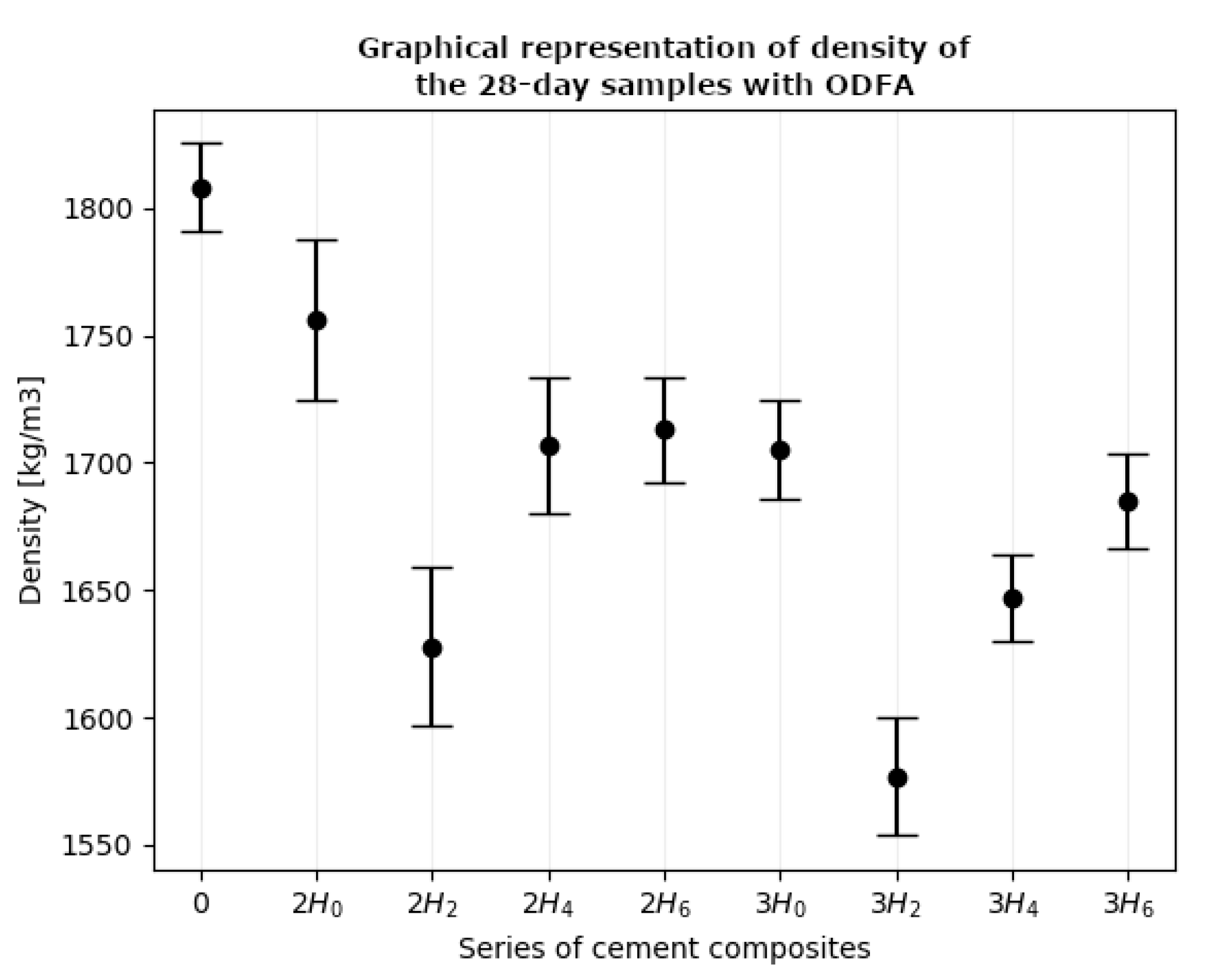

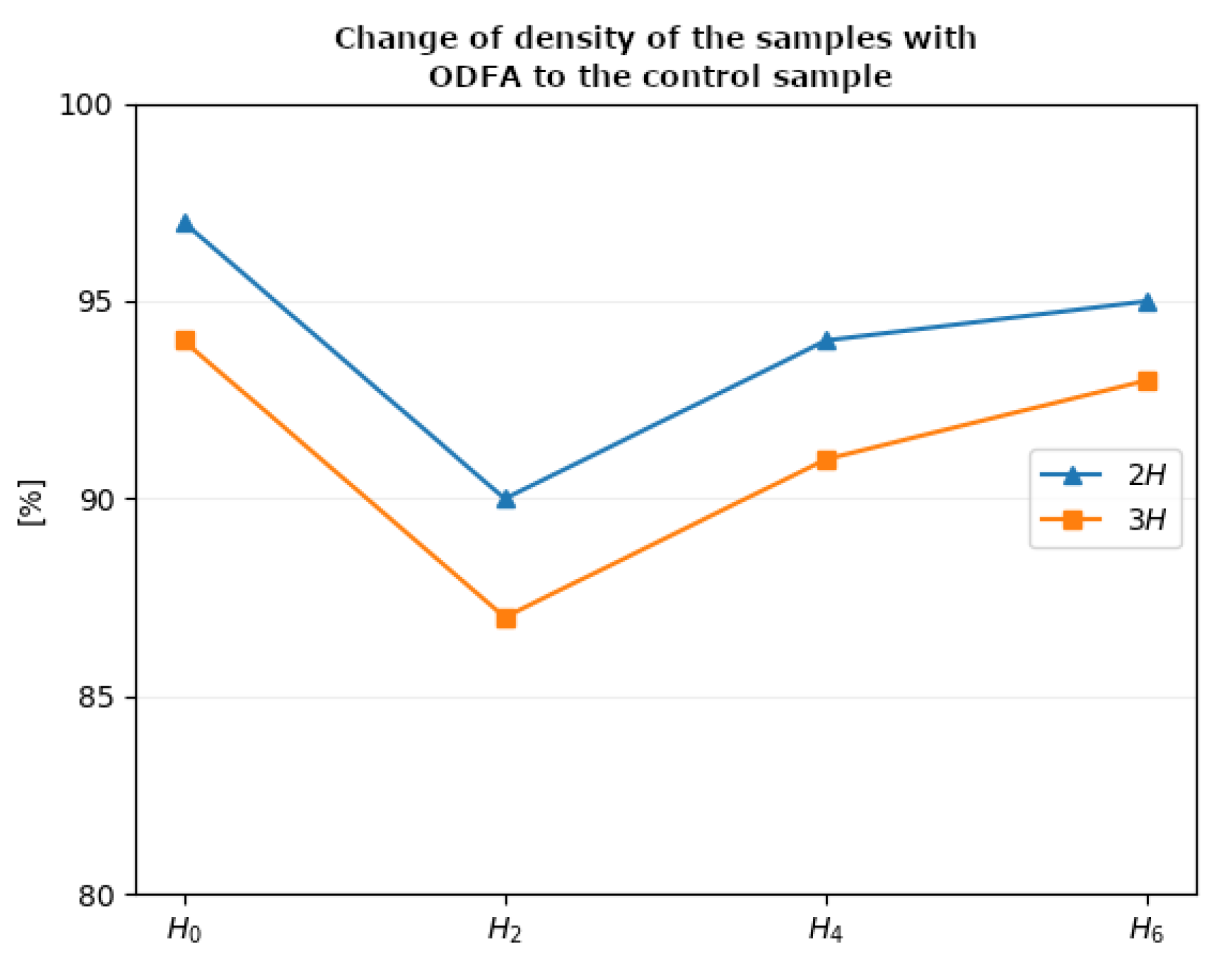

3.2.2. Density

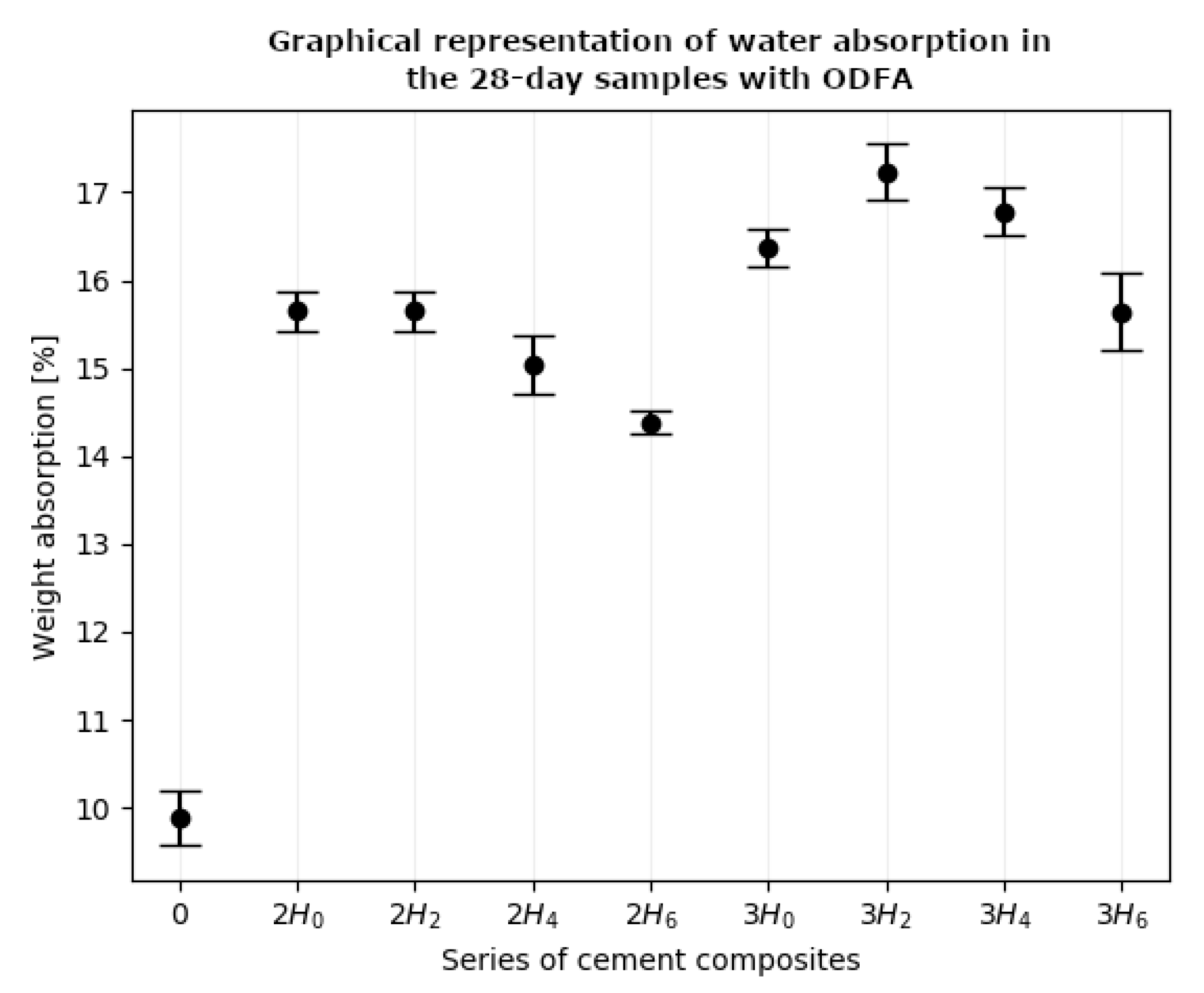

3.2.3. Water Absorption

4. Discussions

5. Conclusions

- Large amounts of ODFA and a limited amount of cement were used in composites. The quantity of ODFA was, respectively, 240% and 360% of the cement mass used. Such volumes of this specific kind of FA are not used for the production of cement composites. This problem has also been virtually unaddressed in the research.

- With the usage of ODFA as a partial replacement of sand (20%–30%), it is possible to obtain the assumed technological properties of cement composites and limit the onerousness of this unwanted waste for the environment to a great degree. This is reasonable, but only with the addition of Ca(OH)2.

- Composites with additives of different quantities of Ca(OH)2 (2%, 4%, 6%) had considerably higher compressive strength than composites with the same quantity of cement and ODFA but without Ca(OH)2.

- The samples with ODFA, but without Ca(OH)2, obtained significantly lower compressive strengths (on average by ca. 2 MPa), both before and after the attack, compared to the samples with ODFA and Ca(OH)2.

- The samples with ODFA and Ca(OH)2 reached the compressive strength of 4.9–6.2 MPa before seawater attack and 3.07–3.85 MPa after it.

- Although ODFA did not meet the requirements of the PN-EN 450-1 standard pertaining to FA for production of concrete, their presence did not lead to a higher destruction in aggressive solutions than in composites made from traditional raw materials.

- Ash concretes are applied in road building and for construction of foundations with compressive strengths from 1.5 to 8 MPa. Composites with ODFA and Ca(OH)2 as an activator can be applied for construction of town district road foundations and bike paths of the compressive strength class C3/4. Moreover, they can be used for foundations subjected to application of de-icing agents.

Author Contributions

Funding

Conflicts of Interest

References

- Szafranko, E.; Harasymiuk, J. Evaluation of the impact of public investments on the environment on the example of stadium implementation. Ecol. Eng. 2017, 18, 58–65. [Google Scholar] [CrossRef]

- Harasymiuk, J.; Szafranko, E.; Tyburski, J. Methods of habitat reports’ evaluation. Open Eng. 2019, 9, 26–33. [Google Scholar] [CrossRef]

- Gicala, M.; Sobotka, A. The analysis of construction and material solutions, taking into account the requirements of sustainable development. Sci. Rev. Eng. Environ. Sci. 2017, 26, 159–170. [Google Scholar]

- Czarnecki, L.; Justnes, H. Sustainable & Durable Concrete. Cem. Lime Concr. 2012, 17, 99–106. [Google Scholar]

- Plebankiewicz, E.; Juszczyk, M.; Kozik, R. Trends, Costs, and Benefits of Green Certification of Office Buildings: A Polish Perspective. Sustainability 2019, 11, 2359. [Google Scholar] [CrossRef]

- Mickaityte, A.; Zavadskas, E.K.; Kaklauskas, A.; Tupenaite, L. The concept model of sustainable buildings refurbishment. Int. J. Strateg. Prop. Manag. 2008, 12, 53–68. [Google Scholar] [CrossRef]

- Bonenberg, W.; Kapliński, O. The Architect and the Paradigms of Sustainable Development: A Review of Dilemmas. Sustainability 2018, 10. [Google Scholar] [CrossRef]

- Zarębska, J.; Joachimiak-Lechman, K. Economic and ecological effects of building waste management in the context of sustainable development. In Support Systems in Production Engineering: Quality and Safety; PA Nova SA: Gliwice, Poland, 2014; pp. 261–282. [Google Scholar]

- Dachowski, R.; Kostrzewa, P. The use of waste materials in the construction industry. World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium, Prague, Czech Republic, 13–17 June 2016. Procedia Eng. 2016, 161, 754–758. [Google Scholar] [CrossRef]

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2011.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2012.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2013.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2014.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2015.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2016.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2017.

- Statistical Yearbook of Industry—Poland; Central Statistical Office: Warsaw, Poland, 2018.

- Manz, O.E. Worldwide production of coal ash and utilization in concrete and other products. Fuel 1997, 76, 691–696. [Google Scholar] [CrossRef]

- Wang, S. Application of solid ash based catalysts in heterogeneous catalysis. Environ. Sci. Technol. 2008, 42, 7055–7063. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Volli, V.; Shu, C.-M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef]

- Zygmunt, J.; Prokopski, G. Properties of cement concretes modified by mechanically activated siliceous fly ash. Roads Bridges 2009, 2, 63–85. [Google Scholar]

- Nowak-Michta, A. Compressive strength of siliceous fly ash concretes. Tech. Trans. 2012, 2, 77–98. [Google Scholar]

- Halbiniak, J. Designing the composition of concrete with fly ashes and their influence on increment rate of strength. Constr. Optim. Energy Potential 2012, 2, 29–36. [Google Scholar]

- PN-EN 206+A1:2016-12 Concrete. Specification, Performance, Production and Conformity; PKN: Warsaw, Poland, 15 December 2017.

- Velandia, D.F.; Lynsdale, C.F.; Provis, J.F.; Ramirez, F. Effects of mix inputs, curing and compressive strength on the durability of Na2SO4 – activated high volume fly ash concretes. Cem. Concr. Compos. 2018, 91, 11–20. [Google Scholar] [CrossRef]

- Nedeljkovic, M.; Ghiassi, B.; van der Laan, S.; Li, Z.; Ye, G. Effects of curing conditions on the pore solution and carbonation resistance of alkali-activated fly ash slag pastes. Cem. Concr. Res. 2019, 116, 146–158. [Google Scholar] [CrossRef]

- Hlavaćek, P.; Śulc, R.; Śmilauer, V.; Robler, C.; Snop, R. Ternary binder made of CFBC fly ash and conventional fly ash, and calcium hydroxide: Phase and strength evolution. Cem. Concr. Compos. 2018, 90, 100–107. [Google Scholar] [CrossRef]

- Kurdowski, W. Chemistry of Cement and Concrete, 2nd ed.; PWN: Warsaw, Poland, 2010. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Polish Cement: Cracow, Poland, 2012. [Google Scholar]

- Ramezanianpour, A.A.; Jovein, H.B. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Silva, H.G.C.; Terradillos, P.G.; Zornoza, E.; Mendoza-Rangel, J.M.; Castro-Borges, P.; Alvarado, C.A.J. Improving Sustainability through Corrosion Resistance of Reinforced Concrete by Using a Manufactured Blended Cement and Fly Ash. Sustainability 2018, 10, 2004. [Google Scholar] [CrossRef]

- PN-EN 450-1:2012 Fly Ash for Concrete—Part 1: Definitions, Specifications, Conformity Criteria; PKN: Warsaw, Poland, 13 February 2014.

- Rudziński, A. Optimization of composition and durability of cement-ash composites with the addition of steel fibers subjected to corrosion. Mar. Eng. Geotech. 2013, 5, 413–421. [Google Scholar]

- Wang, Y.; Ueda, T.; Gong, F.; Zhang, D. Meso-scale mechanical detoriation of mortar due to sodium chloride attack. Cem. Concr. Compos. 2019, 96, 163–173. [Google Scholar] [CrossRef]

- Ribeiro, M.S.; Lage, J.; Goncalves, A. Chloride assessment in structures. Influences of sampling and test location. Cem. Concr. Res. 2019, 117, 82–90. [Google Scholar] [CrossRef]

- Lorente, S.; Yssorche-Cubaynes, M.-P.; Auger, J. Sulfate transfer through concrete: Migration and diffusion results. Cem. Concr. Compos. 2011, 33, 735–741. [Google Scholar] [CrossRef]

- Haufe, J.; Vollpracht, A. Tensile strength of concrete exposed to sulfate attack. Cem. Concr. Res. 2019, 116, 81–88. [Google Scholar] [CrossRef]

- Ragoug, R.; Metalsi, O.O.; Barberon, F.; Torrenti, J.-M.; Roussel, N.; Divet, L.; d’Espinose de Lacaillerie, J.-B. Durability of cement pastes exposed to external sulfate attack and leaching: Physical and chemical aspects. Cem. Concr. Res. 2019, 116, 134–145. [Google Scholar] [CrossRef]

- Ikumi, T.; Cavalaro, S.H.P.; Segura, I. The role of porosity in external sulfate attack. Cem. Concr. Compos. 2019, 97, 1–12. [Google Scholar] [CrossRef]

- Zhang, Z.; Jin, X.; Luo, W. Long term behaviors under low-concentration sulfate attack subjected to natural variation of environmental climate conditions. Cem. Concr. Res. 2019, 116, 217–230. [Google Scholar] [CrossRef]

- Donatello, S.; Palomo, A.; Fernández-Jiménez, A. Durability of very high volume fly ash cement pastes and mortars in aggressive solutions. Cem. Concr. Compos. 2013, 38, 12–20. [Google Scholar] [CrossRef]

- Palin, D.; Jonkers, H.M.; Wiktor, V. Autogenous healing of sea-water exposed mortar: Quantification through a simple and rapid permeability test. Cem. Concr. Res. 2016, 84, 1–7. [Google Scholar] [CrossRef]

- Poteras, G.; Moncea, M.A.; Panait, A.M. Researches regarding marine environment corrosion on coastal structures. Turk. J. Fish. Aquat. Sci. 2014, 14, 965–971. [Google Scholar] [CrossRef]

- PN-EN 932-3:1999 Procedure and Terminology for Simplified Petrographic Description; PKN: Warsaw, Poland, 7 January 1999.

- PN-EN 196-2:2013-11 Methods of Testing Cement. Part 2: Chemical Analysis of Cement; PKN: Warsaw, Poland, 18 January 2019. [Google Scholar]

- PN-EN 197-1:2012 Cement—Part 1: Composition, Requirement and Criteria of Fulfillment Concerning Commonly Used Cements; PKN: Warsaw, Poland, 14 October 2013.

- PN-EN 459-1:2015-06 Building Lime—Part 12. Definition, Specification and Conformity Criteria; PKN: Warsaw, Poland, 15 December 2017. [Google Scholar]

- PN-EN 196-1:2006 Methods of Testing Cement. Part 1: Determination of Strength; PKN: Warsaw, Poland, 11 August 2006. [Google Scholar]

- Yang, T.; Zhu, H.; Zhang, Z.; Gao, X.; Zhang, C.; Wu, Q. Effect of fly ash microsphere on the reology and microstructure of alkali-activated fly ash/slag pastes. Cem. Concr. Res. 2018, 109, 198–207. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in hybrid cements over time. Alkaline activation of fly ash-portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- PN-EN 1015-3:2000/A1:2005 Methods of Test for Mortar for Masonry. Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); PKN: Warsaw, Poland, 24 August 2005. [Google Scholar]

- PN-EN 14227-3:2004 Hydraulically Bound Mixtures; Specifications: Fly Ash Bound Mixtures; PKN: Warsaw, Poland, 13 October 2007.

- Giergiczny, Z.; Ostrowski, M.; Baran, T. Impact of S-category siliceous fly Ash on select properties of cement composites. In Proceedings of the XXIII International Conference “Ash in Energy Production”, Zakopane, Poland, 19–21 October 2016; Available online: http://unia-ups.pl/wp-content/uploads/2016/12/Giergiczny.pdf (accessed on 13 November 2019).

- Wawrzeńczyk, J.; Molendowska, A.; Kłak, A. Results of concrete absorption test related to some particular factors. Build. Archit. 2013, 12, 239–246. Available online: http://wbia.pollub.pl/files/85/attachment/vol12/239-246.pdf (accessed on 20 November 2019).

- Spiesz, P.; Brouwers, H.J.H. The apparent and effective chloride migration coefficients obtained in migration tests. Cem. Concr. Res. 2013, 48, 116–127. [Google Scholar] [CrossRef]

- Amarnath, Y.; Ganesh Babu, K. Transport properties of high volume fly ash roller compacted concrete. Cem. Concr. Compos. 2011, 33, 1057–1062. [Google Scholar]

- Ha-Wong, S.; Chang-Hong, L.; Ki Yong, A. Factors influencing chloride transport in concrete structures exposed to marine environment. Cem. Concr. Compos. 2008, 30, 113–121. [Google Scholar]

- Babaee, M.; Castel, A. Chloride-induced corrosion of reinforcement in low-calcium fly ash-based geopolymer concrete. Cem. Concr. Res. 2016, 88, 96–107. [Google Scholar] [CrossRef]

- Lothenbach, B.; Bary, B.; Le Bescop, P.; Schmidt, T.; Leterrier, N. Sulfate ingress in Portland cement. Cem. Concr. Res. 2010, 40, 1211–1225. [Google Scholar] [CrossRef]

- Ávilaa, R.; Medinaa, E.; Bastidas, D.M. Corrosion and mechanical performance of reinforced mortar and concrete made with MSWI bottom ash. Rev. Metal. 2017, 53, e102. [Google Scholar]

- De Weerdt, K.; Lothenbach, B.; Geiker, M.R. Comparing chloride seawater and NaCl solution in Portland cement mortar. Cem. Concr. Res. 2019, 115, 80–89. [Google Scholar] [CrossRef]

- Shakouri, M.; Trejo, D. A study of factors affecting the chloride maximum phenomenon in submerged concrete samples. Cem. Concr. Compos. 2018, 94, 181–190. [Google Scholar] [CrossRef]

- Qiao, C.; Suraneni, P.; Wei, Y.T.N.; Choudhary, A.; Weiss, J. Chloride binding of cement pastes with fly ash exposed to CaCl2 solutions at 5 and 23 °C. Cem. Concr. Compos 2019, 97, 43–53. [Google Scholar] [CrossRef]

| Materials | Quantitative and Qualitative Characteristics |

|---|---|

| Natural sand with grain size of 0–2 mm obtained from Eco-Ter in Kronowo (Poland) gravel pit | The petrographic composition of sand was classified according to the PN-EN 932-3:1999 standard [44]. The sand contained 80.9% of quartz, chalcedony and opal, 12.5% of magma and metamorphic rocks and 6.6% of sedimentary rocks. The alkaline reactivity was 0. |

| ODFA obtained from Michelin S.A. Company (Poland) | The loss of ignition of ca. 15% classified according to the PN-EN 196-2:2013-11 standard [45], granulation containing ca. 20% of the up to 0.045 mm fraction, yet not containing unbound calcium. |

| CEM I-32, 5R Portland cement obtained from the Ożarów cement plant (Poland) | The Portland cement was classified according to the PN-EN 197-1:2012 standard [46]. |

| Hydrated lime obtained from Natura production facility (Poland) | The lime was classified according to the PN-EN 459-1:2015-06 standard [47]. Its content was CaO + MgO 95.2%, MgO 0.7%, CO2 1.8%, Ca(OH)2 91.4%, SO3 0.1%, H2O 0.8%. |

| Seawater solution | Composition of seawater solution consisted of (in 1 dm3) 30.1 g NaCl, 6.0 g MgCl2, 5.0 g MgSO4, 1.5 g CaSO4, 0.2 g KHCO3 (p.a.), according to [29]. |

| Distilled water | - |

| Series | Cement (kg/m3) | Sand (kg/m3) | ODFA (kg/m3) | Water (kg/m3) | Ca(OH)2 (kg/m3) |

|---|---|---|---|---|---|

| 0 * | 136.3 | 1639.0 | - | 267.1 | - |

| 2H0 | 132.9 | 1288.4 | 319.1 | 307.3 | - |

| 2H2 | 130.2 | 1250.2 | 312.5 | 306.8 | 6.3 |

| 2H4 | 124.7 | 1196.9 | 299.2 | 299.2 | 12.0 |

| 2H6 | 120.3 | 1155.6 | 288.9 | 294.3 | 17.3 |

| 3H0 | 132.3 | 1111.8 | 476.4 | 329.4 | - |

| 3H2 | 129.0 | 1083.9 | 464.5 | 326.9 | 9.3 |

| 3H4 | 127.1 | 1067.9 | 457.7 | 327.7 | 18.3 |

| 3H6 | 123.0 | 1065.7 | 442.7 | 322.4 | 26.6 |

| Oxide | Content (%) |

|---|---|

| SiO2 | 40.46 |

| Al2O3 | 25.00 |

| Fe2O3 | 10.21 |

| CaO | 9.81 |

| MgO | 2.44 |

| SO3 | 0.25 |

| K2O | 0.26 |

| Na2O | 0.49 |

| P2O5 | 0.21 |

| TiO2 | 1.21 |

| MnO | 0.15 |

| SrO | 0.04 |

| Compressive Strength (MPa) | ||||

|---|---|---|---|---|

| Series | 28 Days in a Moisture Chamber | 28 + 120 Days in a Moisture Chamber | 28 + 120 Days in Distilled Water | 28 + 120 Days in Seawater |

| 0 | 1.85 | 1.95 | 2.02 | 1.68 |

| 2H0 | 1.90 | 2.20 | 2.20 | 2.05 |

| 2H2 | 3.62 | 4.90 | 3.50 | 3.07 |

| 2H4 | 4.21 | 5.40 | 3.65 | 3.12 |

| 2H6 | 4.34 | 5.25 | 3.44 | 3.85 |

| 3H0 | 2.00 | 2.20 | 2.25 | 2.20 |

| 3H2 | 3.90 | 5.72 | 3.06 | 3.50 |

| 3H4 | 5.00 | 6.20 | 3.56 | 3.72 |

| 3H6 | 5.07 | 5.90 | 3.78 | 3.63 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harasymiuk, J.; Rudziński, A. Old Dumped Fly Ash as a Sand Replacement in Cement Composites. Buildings 2020, 10, 67. https://doi.org/10.3390/buildings10040067

Harasymiuk J, Rudziński A. Old Dumped Fly Ash as a Sand Replacement in Cement Composites. Buildings. 2020; 10(4):67. https://doi.org/10.3390/buildings10040067

Chicago/Turabian StyleHarasymiuk, Jolanta, and Andrzej Rudziński. 2020. "Old Dumped Fly Ash as a Sand Replacement in Cement Composites" Buildings 10, no. 4: 67. https://doi.org/10.3390/buildings10040067

APA StyleHarasymiuk, J., & Rudziński, A. (2020). Old Dumped Fly Ash as a Sand Replacement in Cement Composites. Buildings, 10(4), 67. https://doi.org/10.3390/buildings10040067