Development of Eco-Friendly and Self-Cleaning Lime-Pozzolan Plasters for Bio-Construction and Cultural Heritage

Abstract

:1. Introduction

2. Materials and Methods

- -

- 16 × 4 × 4 cm for mechanical test;

- -

- 4 × 4 × 4 cm for water vapor permeability and aging tests;

- -

- 9 × 9 × 3 cm for solar reflectance and infrared emittance tests;

- -

- 20 × 20 × 2 cm for thermal conductivity test.

3. Results

3.1. Apparent Density

3.2. Water Absorption by Total Immersion

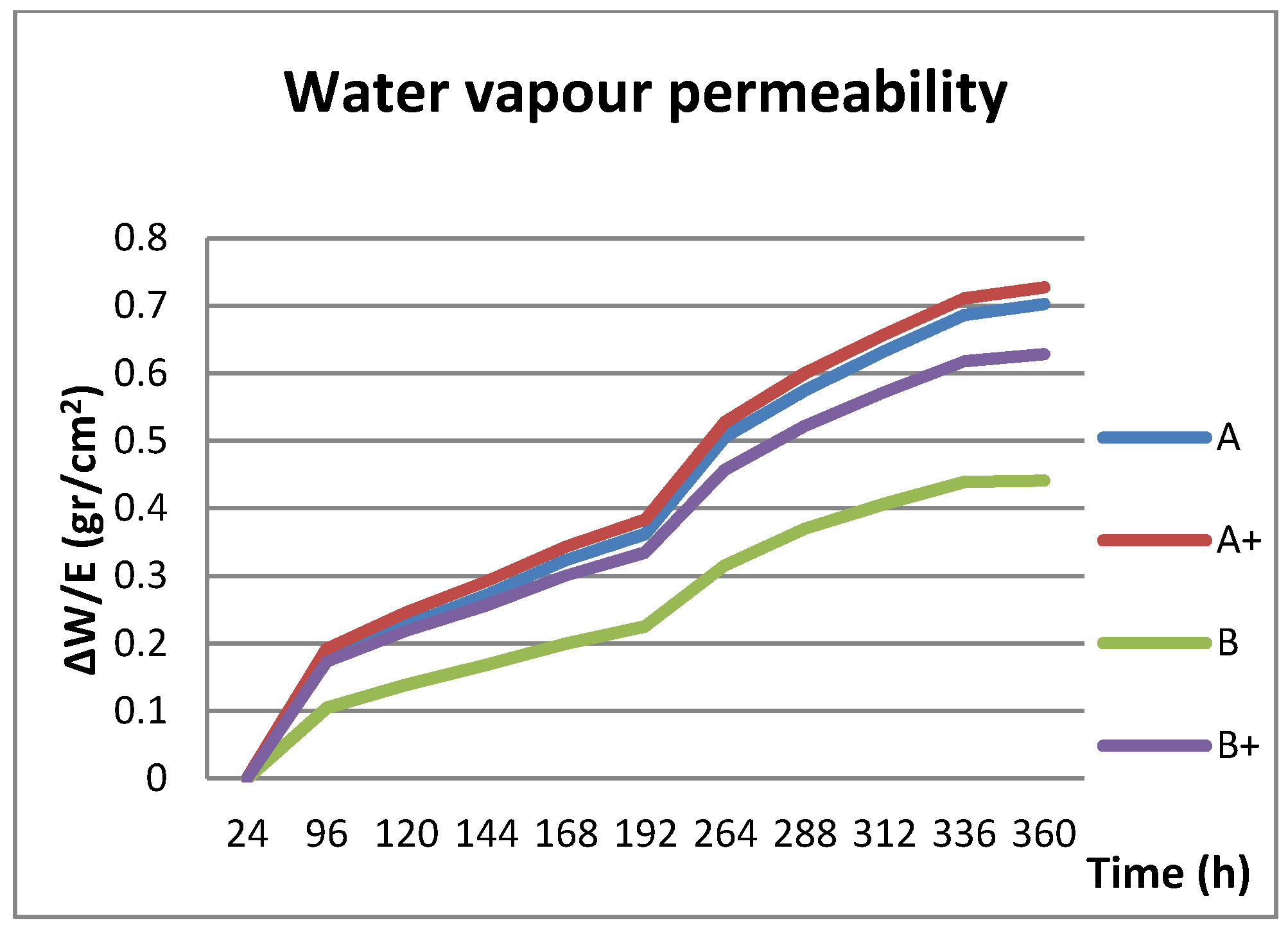

3.3. Water Vapor Permeability

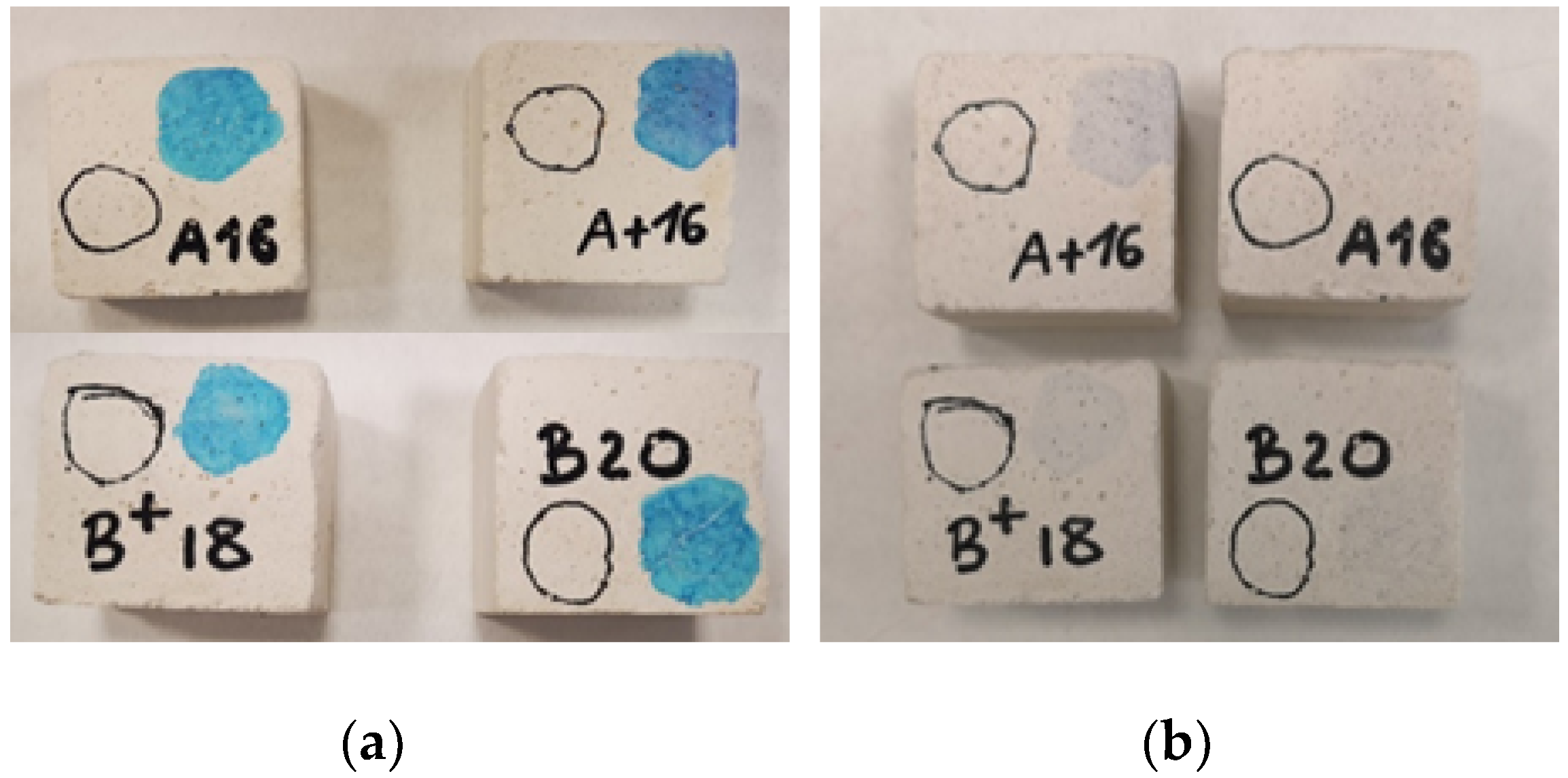

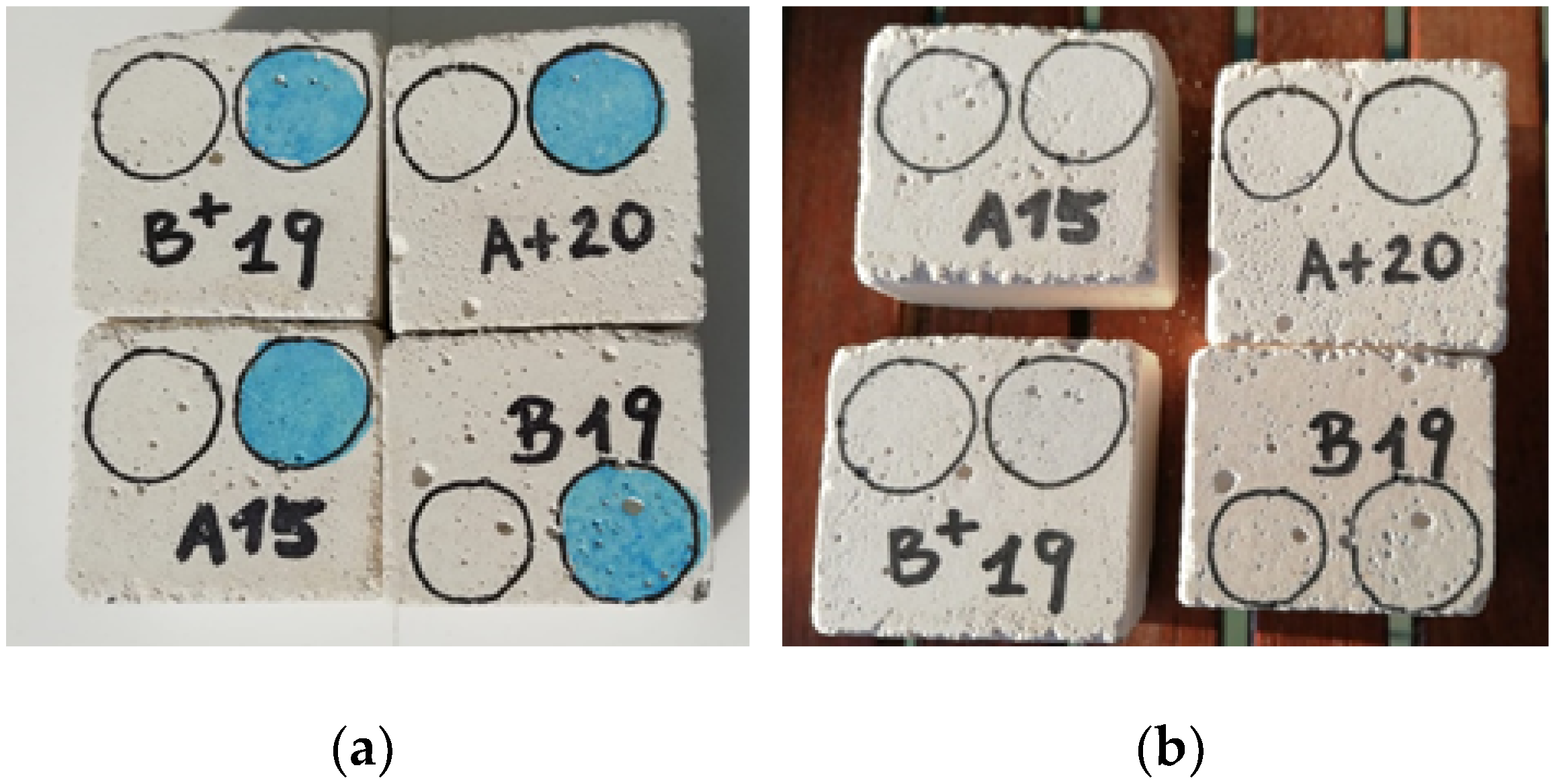

3.4. Photocatalytic Activity

3.5. Energy Efficiency Evaluation

3.6. Mechanical Properties

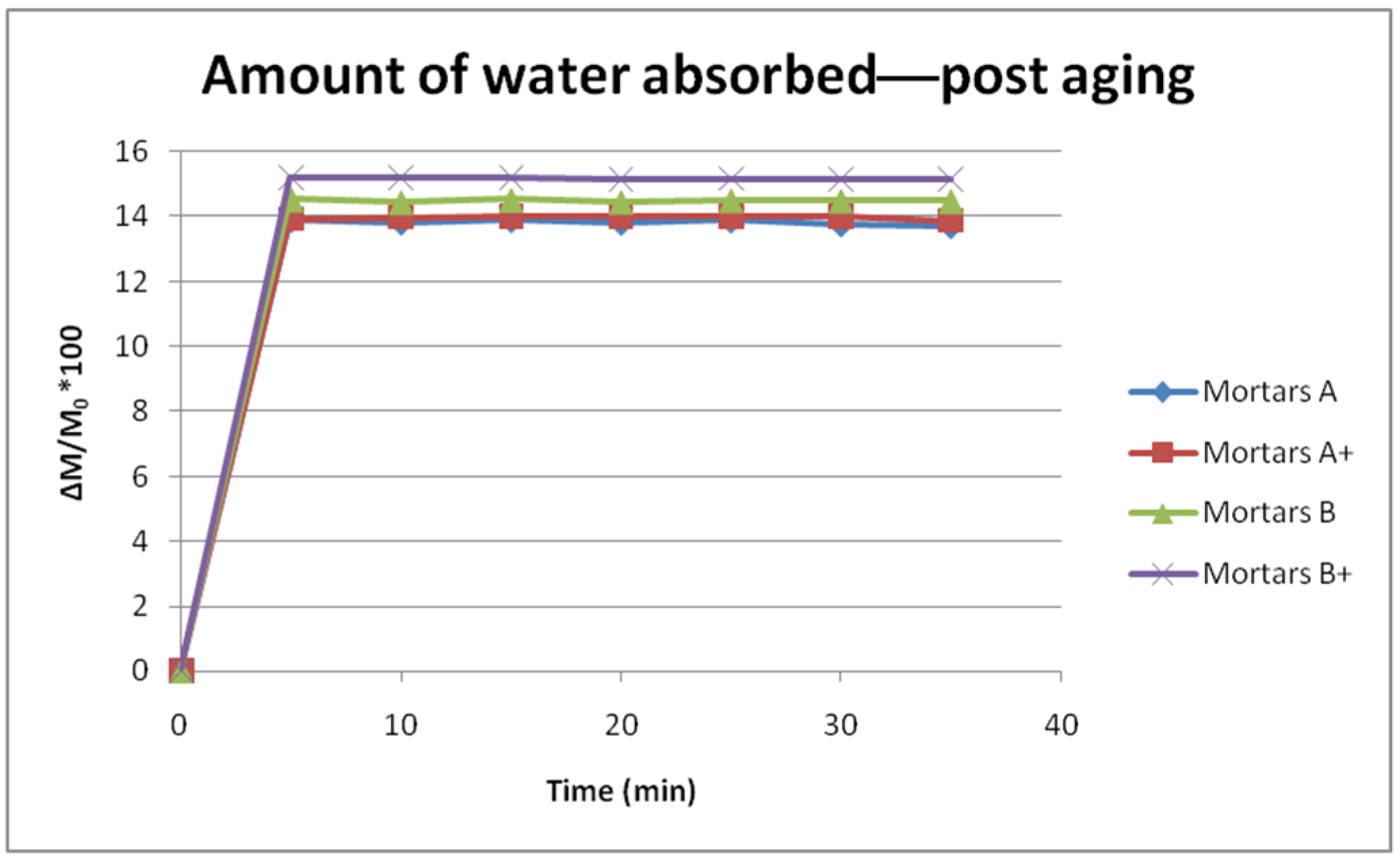

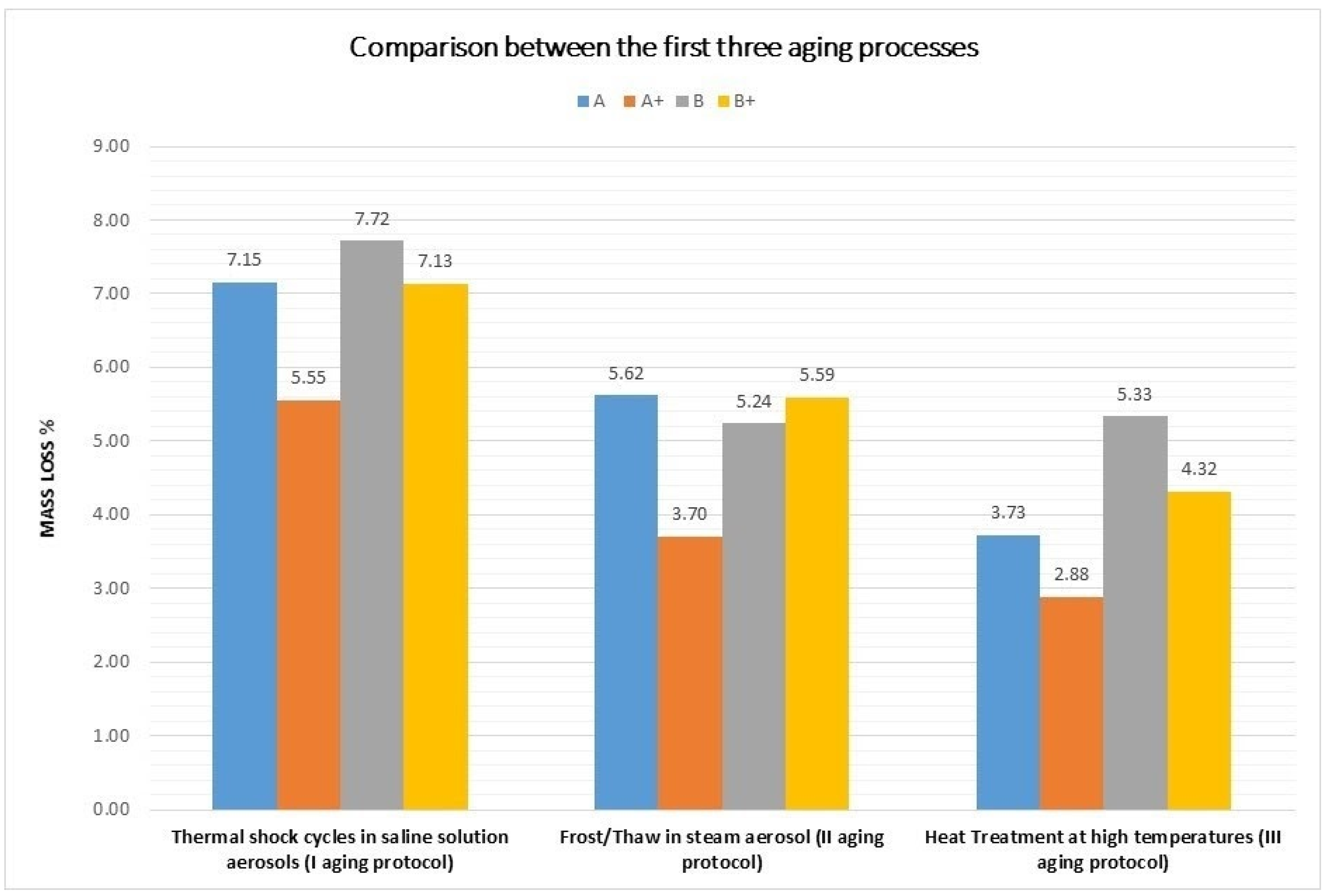

3.7. Durability of Mortars

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pearlmutter, D.; Theochari, D.; Nehls, T.; Pinho, P.; Piro, P.; Korolova, A.; Papaefthimiou, S.; Mateo, M.C.G.; Calheiros, C.; Zluwa, I.; et al. Enhancing the circular economy with nature-based solutions in the built urban environment: Green building materials, systems and sites. Blue-Green Syst. 2019, 2, 46–72. [Google Scholar] [CrossRef] [Green Version]

- European Union 2015 towards an EU Research and Innovation Policy Agenda for Nature-Based Solutions & Re-Naturing Cities Final Report of the Horizon 2020 Expert Group on Nature-Based Solutions and Re-Naturing Cities. Available online: https://op.europa.eu/it/publication-detail/-/publication/fb117980-d5aa-46df-8edc-af367cddc202 (accessed on 7 June 2020).

- IUCN Commission on Ecosystem Management 2019 Nature-Based Solutions. Available online: https://www.iucn.org/commissions/commission-ecosystem-management/our-work/nature-based-solutions (accessed on 9 September 2020).

- Lazzarini, L.; Laurenzi, T.M. Restauro Della Pietra; CEDAM: Padova, Italy, 1986. [Google Scholar]

- Zehnder, K.; Arnold, A. Crystal growth in salt efflorescence. J. Cryst. Growth 1989, 97, 513–521. [Google Scholar] [CrossRef]

- Zedef, V.; Kocak, K.; Doyen, A.; Ozsen, H.; Kekec, B. Effect of salt crystallization on stones of historical buildings and monuments, Konya, Central Turkey. Build. Environ. 2007, 42, 1453–1457. [Google Scholar] [CrossRef]

- Scherer, G.W. Stress from crystallization of salt. Cem. Concr. Res. 2004, 34, 1613–1624. [Google Scholar] [CrossRef]

- Ruiz-Agudo, E.; Mees, F.; Jacobs, P.; Rodriguez-Navarro, C. The role of saline solution properties on porous limestone salt weathering by magnesium and sodium sulfates. Environ. Earth Sci. 2006, 52, 269–281. [Google Scholar] [CrossRef]

- Benavente, D.; Martínez-Martínez, J.; Cueto, N.; Garcia-Del-Cura, M.A. Salt weathering in dual-porosity building dolostones. Eng. Geol. 2007, 56, 729–740. [Google Scholar] [CrossRef]

- Benavente, D. Why Pore Size Is Important in the Deterioration of Porous Stones Used in the Built Heritage. Rev. Soc. Mineral. 2011, 15, 41–42. [Google Scholar]

- Andriani, G.; Walsh, N. The effects of wetting and drying, and marine salt crystallization on calcarenite rocks used as building material in historic monuments. Geol. Soc. London Speéc. Publ. 2007, 44, 129–141. [Google Scholar] [CrossRef]

- Barbera, G.; Barone, G.; Mazzoleni, P.; Scandurra, A. Laboratory measurement of ultrasound velocity during accelerated aging tests: Implication for the determination of limestone durability. Constr. Build. Mater. 2012, 36, 977–983. [Google Scholar] [CrossRef]

- Yavuz, H.; Demirdag, S.; Caran, S. Thermal effect on the physical properties of carbonate rocks. Int. J. Rock Mech. Min. Sci. 2010, 47, 94–103. [Google Scholar] [CrossRef]

- Cantisani, E.; Pecchioni, E.; Fratini, F.; Garzonio, C.A.; Malesani, P.; Molli, G. Thermal stress in the Apuan marbles: Relationship between microstructure and petrophysical characteristics. Int. J. Rock Mech. Min. Sci. 2009, 46, 128–137. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.; Rodríguez-Gordillo, J. Structural and compositional anisotropy in Macael marble (Spain) by ultrasonic, XRD and optical microscopy methods. Constr. Build. Mater. 2009, 23, 21–26. [Google Scholar] [CrossRef]

- Rodríguez-Gordillo, J.; Sáez-Pérez, M. Effects of thermal changes on Macael marble: Experimental study. Constr. Build. Mater. 2006, 20, 355–365. [Google Scholar] [CrossRef]

- Andriani, G.; Germinario, L. Thermal decay of carbonate dimension stones: Fabric, physical and mechanical changes. Environ. Earth Sci. 2014, 72, 2523–2539. [Google Scholar] [CrossRef]

- Siegesmund, S.; Ullemeyer, K.; Weiss, T.; Tschegg, E.K. Physical weathering of marbles caused by anisotropic thermal expansion. Acta Diabetol. 2000, 89, 170–182. [Google Scholar] [CrossRef]

- Fernandez, F.; Germinario, S. Alteration and deterioration of natural stone materials: Artificial aging as a tool of knowledge. Conserv. Valorization Cult. Herit. 2017, 10, 324–333. [Google Scholar]

- Ozcelik, Y.; Careddu, N.; Yilmazkaya, E. The effects of freeze–thaw cycles on the gloss values of polished stone surfaces. Cold Reg. Sci. Technol. 2012, 82, 49–55. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 82, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Theodoridou, M.; Charalambous, E.; Maravelaki, P.-N.; Ioannou, I. Amelioration of crushed brick-lime composites using nano-additives. Cem. Concr. Compos. 2016, 68, 77–87. [Google Scholar] [CrossRef]

- Maravelaki, N.; Kapridaki, C.; Lionakis, E.; Verganelaki, A. Improvement of properties of hydraulic mortars with addition of nano-titania. In Adhesives Mechanical Properties, Technologies and Economic Importance; Dario, C., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2014; pp. 79–92. [Google Scholar]

- Sierra-Fernandez, A.; De La Rosa-García, S.C.; Gomez-Villalba, L.S.; Gómez-Cornelio, S.; Rabanal, M.E.; Fort, R.; Quintana, P.; Rosa-García, S.D.C.D.L. Synthesis, Photocatalytic, and Antifungal Properties of MgO, ZnO and Zn/Mg Oxide Nanoparticles for the Protection of Calcareous Stone Heritage. ACS Appl. Mater. Interfaces 2017, 9, 24873–24886. [Google Scholar] [CrossRef]

- Nicolás-Pérez, M.; Kuchling, F.; Letelier, J.; Polvillo, R.; Wittbrodt, J.; Martinez-Morales, J.-R. Analysis of cellular behavior and cytoskeletal dynamics reveal a constriction mechanism driving optic cup morphogenesis. Elife 2016, 5, e15797. [Google Scholar] [CrossRef] [PubMed]

- Gherardi, F.; Goidanich, S.; Dal Santo, V.; Toniolo, L. Layered Nano-TiO2 Based Treatments for the Maintenance of Natural Stones in Historical Architecture. Angew. Chem. Int. Ed. Engl. 2018, 57, 7360–7363. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kapridaki, C.; Verganelaki, A.; Dimitriadou, P.; Maravelaki, P.-N. Conservation of Monuments by a Three-Layered Compatible Treatment of TEOS-Nano-Calcium Oxalate Consolidant and TEOS-PDMS-TiO2 Hydrophobic/Photoactive Hybrid Nanomaterials. Material 2018, 11, 684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kapridaki, C.; Xynidis, N.; Vazgiouraki, E.; Kallithrakas-Kontos, N.; Maravelaki, P.-N. Characterization of Photoactive Fe-TiO2 Lime Coatings for Building Protection: The Role of Iron Content. Material 2019, 12, 1847. [Google Scholar] [CrossRef] [Green Version]

- Daniyal; Akhtar, S.; Azam, A. Effect of nano-TiO2 on the properties of cementitious composites under different exposure environments. J. Mater. Res. Technol. 2019, 8, 6158–6172. [Google Scholar] [CrossRef]

- Ng, D.S.; Paul, S.C.; Anggraini, V.; Kong, S.Y.; Qureshi, T.S.; Rodriguez, C.R.; Liu, Q.-F.; Šavija, B. Influence of SiO2, TiO2 and Fe2O3 nanoparticles on the properties of fly ash blended cement mortars. Constr. Build. Mater. 2020, 258, 119627. [Google Scholar] [CrossRef]

- Maury-Ramirez, A.; Demeestere, K.; De Belie, N. Photocatalytic activity of titanium dioxide nanoparticle coatings applied on autoclaved aerated concrete: Effect of weathering on coating physical characteristics and gaseous toluene removal. J. Hazard. Mater. 2012, 212, 218–225. [Google Scholar] [CrossRef]

- Hassan, M.; Dylla, H.; Mohammad, L.N.; Rupnow, T. Evaluation of the durability of titanium dioxide photocatalyst coating for concrete pavement. Constr. Build. Mater. 2010, 24, 1456–1461. [Google Scholar] [CrossRef]

- Diamanti, M.V.; Brunella, M.F.; Pedeferri, M.P.; Pirotta, C.; Manzocchi, P.; Curtoni, S. Selfcleaning and Antipolluting Properties of TiO2 -Containing Cementitious Materials; NSTI Nanotech: Santa Clara, CA, USA, 2007; pp. 1–5. [Google Scholar]

- Zhang, S.-H.; Tanadi, D.; Li, W. Effect of photocatalyst TiO2 on workability, strength and self-cleaning efficiency of mortars for applications in tropical environment. In Proceedings of the 35th Conference our world Concrete Structure 2010, Singapore, 25–27 August 2010. [Google Scholar]

- Midtdal, K.; Jelle, B.P. Self-cleaning glazing products: A state-of-the-art review and future research pathways. Sol. Energy Mater. Sol. Cells 2008, 43, 2124–2131. [Google Scholar] [CrossRef] [Green Version]

- Maggos, T.; Plassais, A.; Bartzis, J.G.; Vasilakos, C.; Moussiopoulos, N.; Bonafous, L. Photocatalytic degradation of NOx in a pilot street canyon configuration using TiO2-mortar panels. Environ. Monit. Assess. 2008, 136, 35–44. [Google Scholar] [CrossRef]

- UNI EN 1015-10, Metodi di Prova per Malte per Opere Murarie-Parte 10: Determinazione Della Massa Volumica Apparente Della Malta Indurita Essiccata; UNI—Ente Italiano di Normazione: Milan, Italy, 2007.

- UNI EN 12087, Isolanti Termici per Edilizia-Determinazione Dell’assorbimento D’acqua a Lungo Termine: Prova Attraverso Immersione; UNI—Ente Italiano di Normazione: Milan, Italy, 2013.

- UNI EN 15803, Conservazione dei Beni Culturali-Metodi di Prova-Determinazione Della Permeabilità al Vapore D’acqua (dp); UNI—Ente Italiano di Normazione: Milan, Italy, 2010.

- ASTM E903–96, Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres; ASTM International: West Conshohocken, PA, USA, 2005.

- UNI EN 1015-11, Metodi di Prova per Malte per Opere Murarie-Parte 11: Determinazione Della Resistenza a Flessione e a Compressione Della Malta Indurita; UNI—Ente Italiano di Normazione: Milan, Italy, 2019.

- Maravelaki-Kalaitzaki, P.; Agioutantis, Z.; Lionakis, E.; Stavroulaki, M.; Perdikatsis, V. Physico-chemical and mechanical characterization of hydraulic mortars containing nano-titania for restoration applications. Cem. Concr. Compos. 2013, 36, 33–41. [Google Scholar] [CrossRef]

- Larsen, P.K. Climatic Protection of Historical Vaults with Lime–perlite Mortar. Stud. Conserv. 2020, 1–6. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials. Int. J. Sustain. Built Environ. 2016, 5, 46–82. [Google Scholar] [CrossRef] [Green Version]

- Kolokotsa, D.; Maravelaki, P.-N.; Papantoniou, S.; Vangeloglou, E.; Saliari, M.; Karlessi, T.; Santamouris, M. Development and analysis of mineral based coatings for buildings and urban structures. Sol. Energy 2012, 86, 1648–1659. [Google Scholar] [CrossRef]

- Gobakis, K.; Kolokotsa, D.; Maravelaki, P.-N.; Perdikatsis, V.; Santamouris, M. Development and analysis of advanced inorganic coatings for buildings and urban structures. Energy Build. 2015, 89, 196–205. [Google Scholar] [CrossRef]

- Valentini, F.; Morandini, F.; Bergamo, M.; Dorigato, A. Development of eco-sustainable plasters with thermal energy storage capability. J. Appl. Phys. 2020, 128, 075103. [Google Scholar] [CrossRef]

- Dénes, T.-O.; Tămaş-Gavrea, D.-R. Mechanical Properties of Lime Based Composites. Procedia Manuf. 2020, 46, 19–26. [Google Scholar] [CrossRef]

| Code | Binder wt.% | TiO2 wt.% | Perlite wt.% | Carbonaceous Sand wt.% | B/A* | W/B* | Consistency (mm) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| NHL* | L* | Poz* | Mt* | |||||||

| A | 20 | 6.7 | 6.7 | - | 66.7 | 1/2 | 0.8 (±0.21) | 133.5 | ||

| A+ | 19.4 | 6.5 | 6.5 | 1.6 | 1.6 | 64.5 | 1/2 | 0.8 (±0.23) | 128.3 | |

| B | 10 | 10 | 6.7 | 6.7 | 66.7 | 1/2 | 0.8 (±0.19) | 134.7 | ||

| B+ | 9.7 | 9.7 | 6.5 | 6.5 | 1.6 | 1.6 | 64.5 | 1/2 | 0.7 (±0.07) | 149.3 |

| Aging Protocol | Aging Process | ||

|---|---|---|---|

| I | 2 series (1 cycle) | 2 h | Salt fog steam (9 g/L) |

| 3 h | Heat Treatment +60 °C | ||

| II | 2 series (1 cycle) | 2 h | Steam |

| 3 h | Heat Treatment −20 °C | ||

| III | 1 series (1 cycle) | 12 h | Heat Treatment +60 °C |

| 12 h | Heat Treatment +100 °C | ||

| IV | 1 series (1 cycle) | 1 h | Immersion in demineralized water |

| 3 h | Heat Treatment −20 °C | ||

| 6 h | Heat Treatment +60 °C | ||

| V | 1 series (1 cycle) | 1 h | Salt fog steam (9 g/L) |

| 3 h | Heat Treatment −20 °C | ||

| 6 h | Heat Treatment +80 °C | ||

| Type of Sample | Apparent ρ (Kg/m³) before Aging | Apparent ρ (Kg/m³) after Aging |

|---|---|---|

| Mortar A | 1812.23 | 1783.11 |

| Mortar A+ | 1761.25 | 1745.06 |

| Mortar B | 1772.42 | 1745.63 |

| Mortar B+ | 1725.37 | 1706.44 |

| Synthesis | SR (%) | SRNIR (%) | SRVIS (%) | SRUV (%) | IE | λ W/(mK) |

|---|---|---|---|---|---|---|

| A | 80.9 | 80.9 | 76.25 | 47.11 | 0.89 | 0.32 |

| A+ | 73.1 | 76.15 | 71.05 | 30.10 | 0.92 | 0.29 |

| B | 79.64 | 81.04 | 79.73 | 54.82 | 0.91 | 0.32 |

| B+ | 75.99 | 78.76 | 74.13 | 37.37 | 0.90 | 0.28 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandez, F.; Germinario, S.; Basile, R.; Montagno, R.; Kapetanaki, K.; Gobakis, K.; Kolokotsa, D.; Lagou, A.M.; Dania, P.; Enna, M.T.; et al. Development of Eco-Friendly and Self-Cleaning Lime-Pozzolan Plasters for Bio-Construction and Cultural Heritage. Buildings 2020, 10, 172. https://doi.org/10.3390/buildings10100172

Fernandez F, Germinario S, Basile R, Montagno R, Kapetanaki K, Gobakis K, Kolokotsa D, Lagou AM, Dania P, Enna MT, et al. Development of Eco-Friendly and Self-Cleaning Lime-Pozzolan Plasters for Bio-Construction and Cultural Heritage. Buildings. 2020; 10(10):172. https://doi.org/10.3390/buildings10100172

Chicago/Turabian StyleFernandez, Federica, Silvia Germinario, Roberta Basile, Roberta Montagno, Kali Kapetanaki, Konstantinos Gobakis, Dionysia Kolokotsa, Anna Maria Lagou, Panagiota Dania, Maria Teresa Enna, and et al. 2020. "Development of Eco-Friendly and Self-Cleaning Lime-Pozzolan Plasters for Bio-Construction and Cultural Heritage" Buildings 10, no. 10: 172. https://doi.org/10.3390/buildings10100172

APA StyleFernandez, F., Germinario, S., Basile, R., Montagno, R., Kapetanaki, K., Gobakis, K., Kolokotsa, D., Lagou, A. M., Dania, P., Enna, M. T., Mangiapane, M., & Maravelaki, P.-N. (2020). Development of Eco-Friendly and Self-Cleaning Lime-Pozzolan Plasters for Bio-Construction and Cultural Heritage. Buildings, 10(10), 172. https://doi.org/10.3390/buildings10100172