Author Contributions

Conceptualization, K.Z.; data curation, M.M., K.Z., P.B.; formal analysis, K.Z., P.B.; founding acquisition, K.Z.; investigation, M.M.; methodology, M.M., K.Z., P.B.; project administration, K.Z.; resources, M.M., K.Z., P.B., A.S.; visualization, M.M., K.Z., P.B.; writing—original draft, M.M., K.Z., P.B.; writing—review & editing, K.Z., P.B., A.S.

Funding

This research was funded by MINISTERSTVO ŠKOLSTVA, VEDY, VÝSKUMU A ŠPORTU SLOVENSKEJ REPUBLIKY, grant number KEGA 043TUKE-4/2019 “Improving material engineering and integrated management systems study programs for Industry 4.0”.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study, in the collection, analyses, interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- Eurostat. Persons Killed in Road Accidents by Type of Vehicle (CARE Data). 2018. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=tran_sf_roadve&lang=en (accessed on 10 March 2019).

- PennState. Automotive Manufacturing Industry Analysis. Available online: http://php.scripts.psu.edu/users/l/a/law5039/assign5.html (accessed on 6 May 2019).

- Supply Chain Dive. How Suppliers are Innovating to Keep Pace with the Auto Industry. Available online: https://www.supplychaindive.com/news/auto-series-supplier-innovation-digitization-OEM/516585/ (accessed on 20 February 2019).

- Momeni, A.; Dehghani, K.; Abbasi, S.; Torkan, M. Bake Hardening of a Low Carbon Steel for Automotive Applications. Metalurgija 2007, 13, 131–138. [Google Scholar]

- Pereloma, E.; Timokhina, I. Effect of bake hardening on the performance of automotive steels. In Bake Hardening of Automotive Steels; Design, Metallurgy, Processing and Applications, Effect of Bake Hardening on the Performance of Automotive Steels; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 259–288. [Google Scholar]

- Total Materia. Dent Resistant Steels. Available online: https://www.totalmateria.com/page.aspx?ID=CheckArticle&site=kts&NM=452 (accessed on 10 February 2019).

- NOAA. Storm Prediction Center, National Weather Service. Available online: https://www.spc.noaa.gov/climo/online/monthly/2018_annual_summary.html (accessed on 2 July 2019).

- ESSL. Major Hailstorms of 2018 across Europe, European Severe Storms Laboratory. Available online: https://www.essl.org/cms/major-hailstorms-of-2018-across-europe/ (accessed on 15 June 2019).

- CBS News. Are Hailstorms Getting Worse in US? Why 2019 Could Produce Record Damage. Available online: https://www.cbsnews.com/news/hail-damage-costs-this-year-could-hit-new-annual-high-in-u-s/ (accessed on 2 July 2019).

- Kantereit, H. Bake Hardening Behavior of Advanced High Strength Steels under Manufacturing Conditions; SAE Technical Paper; SAE International: Troy, MI, USA, 2011. [Google Scholar] [CrossRef]

- Das, S.; Singh, S.B.; Mohanty, O.N. Bake Hardening. In Encyclopedia of Iron, Steel, and Their Alloys, 1st ed.; Colás, R., Totten, G.E., Eds.; CRC Press: Boca Raton, FL, USA, 2016; Volume 1, pp. 304–311. [Google Scholar]

- Thuillier, S.; Zang, S.-L.; Troufflard, J.; Manach, P.-I.; Jegat, A. Modeling Bake Hardening Effects in Steel. Metals 2018, 8, 594. [Google Scholar] [CrossRef]

- Seath, P. Study of Bake-Hardening Behaviour of Ultra-Low Carbon BH 220 Steel at Different Strain Rates. Master’s Thesis, National Institute of Technology Rourkela, Department of Metallurgical and Materials Engineering, Rourkela, India, 2014. [Google Scholar]

- Petrov, A. Vplyv BH-efektu na zmenu vlastnosti vybraných automobilových plechov (in Slovak). Bake Hardening Effect on the Change of Properties of Selected Automotive Plates. Master’s Thesis, Technical University of Košice, Košice, Slovakia, 2018. [Google Scholar]

- Ramazani, A.; Mukherjee, K.; Prahl, U.; Bleck, W. Modelling the effect of microstructural banding on the flow curve behaviour of dual-phase (DP) steels. Comput. Mater. Sci. 2012, 52, 46–54. [Google Scholar] [CrossRef]

- Kuang, C.; Zhang, S.; Li, H.; Wang, I.; Liu, H. Effects of pre-strain and baking parameters on the microstructure and bake-hardening behavior of dual-phase steel. Int. J. Miner. Metall. Mater. 2014, 21, 766. [Google Scholar] [CrossRef]

- Ramazani, A.; Bruehl, S.; Gerber, T.; Bleck, W.; Prahl, U. Quantification of bake hardening effect in DP600 and TRIP700 steels. Mater. Des. 2014, 57, 479–486. [Google Scholar] [CrossRef]

- Elsen, P.; Hougardy, H. On the mechanism of bake-hardening. Mater. Technol. 1993, 64, 431–436. [Google Scholar] [CrossRef]

- Ji, D.; Zhang, M.; Zhu, D.; Luo, S.; Lin, L. Influence of microstructure and pre-straining on the bake hardening. Mater. Sci. Eng. A 2017, 708, 129–141. [Google Scholar] [CrossRef]

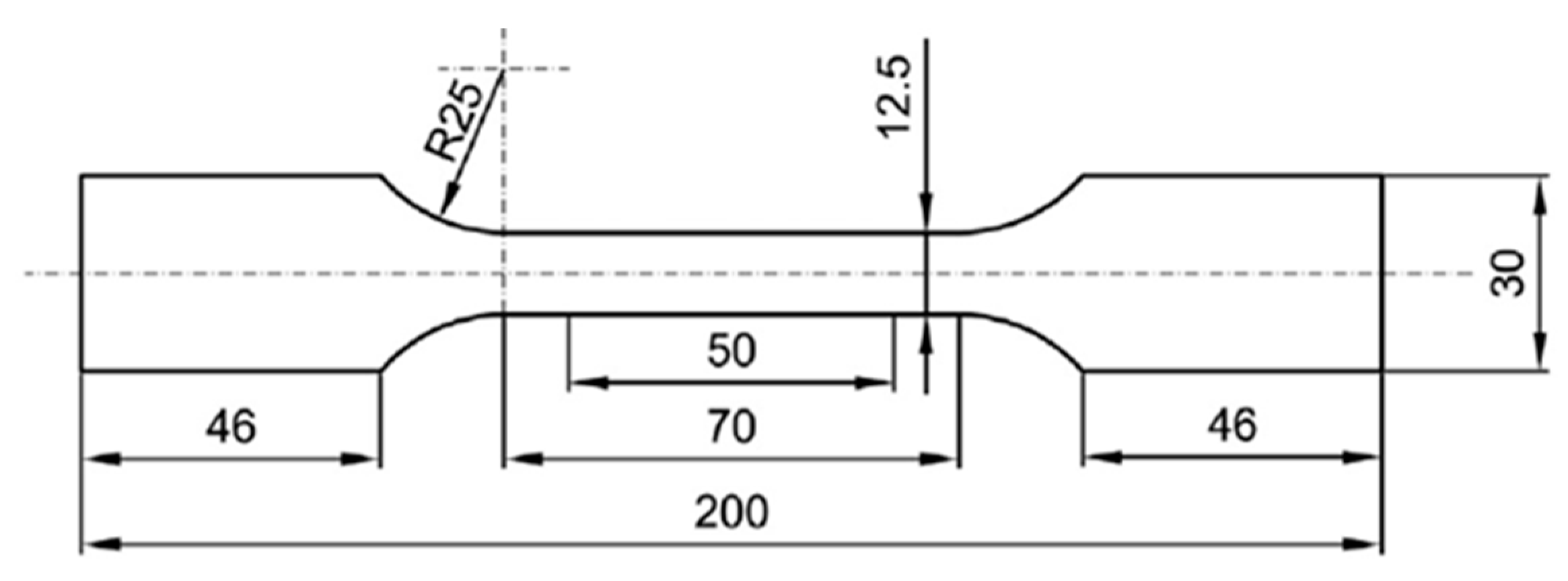

- Deutsche Norm. Steel-Determination of Yield Strength Increase by the Effect of Heat Treatment (Bake-Hardening-Index); English Version (DIN EN 10325:2006); Deutsches Institut für Normung: Berlin, Germany, 2016. [Google Scholar]

- Liu, Z.; Li, W.; Shao, X.; Kang, Y.; Li, Y. An Ultra-low-Carbon Steel with Outstanding Fish-Scaling Resistance and Cold Formability for Enameling Applications. Metall. Mater. Trans. A 2019, 50, 1805–1815. [Google Scholar] [CrossRef]

- Kvackaj, T.; Mamuzic, I. Development of bake hardening effect by plastic deformation and annealing. Metalurgija 2006, 45, 51–55. [Google Scholar]

- Palkowski, H.; Anke, T. Bake Hardening of Hot Rolled Multiphase Steels under Biaxial Pre-strained. Steel Res. Int. 2006, 77, 675–679. [Google Scholar] [CrossRef]

- International Standard Organization. Metallic materials—Tensile testing—Part 1: Method of Test at Room Temperature (ISO 6892-1:2016); ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Slovak Technical Standard. Metallography of steel. In Terminology; Slovak Version (STN 420003:1973); UNMS: Bratislava, Slovakia, 1973. [Google Scholar]

- Paris, A.S.; Tarcolea, C.; Croitoru, S.M.; Majstorović, V.D. Statistical Study of Parameters in the Process of Orthogonal Cutting Surface Hardness. In Proceedings of the 4th International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 3–6 June 2019; Monostori, L., Majstorovic, V., Hu, S., Djurdjanovic, D., Eds.; Springer Nature Switzerland AG: Cham, Switzerlan, 2019; pp. 68–77. [Google Scholar]

- Plura, J. Procedures and Methods of Quality Planning and their Use for Forming Process Optimization. In Engineering the Future; Dudas, L., Ed.; IntechOpen Limited: London, UK, 2010; pp. 257–279. [Google Scholar]

- WorldAutoSteels. Facing the Challenge for Crash Safety, Study by Ducker Worldwide. Available online: https://www.worldautosteel.org/why-steel/safety/facing-the-challenge-for-crash-safety/ (accessed on 12 March 2019).

- Evin, E.; Tomas, M.; Katalinic, B.; Wessely, E.; Kmec, J. Design of Dual Phase High Strength Steel Sheets for Autobody. In DAAAM International Scientific Book; Katalinic, B., Tekic, Z., Eds.; DAAAM International: Vienna, Austria, 2013; pp. 767–786. [Google Scholar]

- Thomas, D. The Numerical Prediction of Panel Dent Resistance Incorporating Panel Forming Strains. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2001. [Google Scholar]

- Uz, M.E. Examining Dent Formation Caused by Hailstone Impact. Shock Vib. 2019, 2019, 6175206. [Google Scholar] [CrossRef]

- Gatto, F.; Morri, D. Forming properties of some aluminium alloys sheets for car—Body use. In Proceedings of the 12th Biennial Congress, International Deep Drawing Research Group, Margherita Ligure, Italy, 24–28 May 1982. [Google Scholar]

- Burley, C.E.; Niemeier, B.A.; Koch, G.P. Dynamic Denting of Autobody Panels; Technical Paper 760165; SAE: Troy, MI, USA, 1976. [Google Scholar] [CrossRef]

- Lu, H.; Ma, M.; Jou, J.; Li, Z. A Research Progress of Dent Resistance for Automotive Body Panes. Available online: http://www.paper.edu.cn/scholar/showpdf/MUT2IN4IOTD0Uxzh (accessed on 15 March 2019).

- Dennies, D. How to Organize and Run a Failure Investigation; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Jumbad, V.; Salunke, J.J.; Satpute, M.A. FMEA Methodology for Quality Improvement. Int. J. Eng. Res. Technol. 2016, 5, 122–126. [Google Scholar]

- Monka, P.; Monková, K.; Modrak, V.; Hric, S.; Pastucha, P. Study of a tap failure at the internal threads machining. Eng. Fail. Anal. 2019, 100, 25–36. [Google Scholar] [CrossRef]

- Pantazopoulos, G. A Short Review on Fracture Mechanisms of Mechanical Components Operated under Industrial Process Conditions: Fractographic Analysis and Selected Prevention Strategies. Metals 2019, 9, 148. [Google Scholar] [CrossRef]

- Pačaiová, H.; Sinay, J.; Nagyová, A. Development of GRAM—A risk measurement tool using risk based thinking principles. Measurement 2016, 100, 288–296. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).