A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit

Abstract

:1. Introduction and Case Background

2. Experimental Methods

3. Results and Discussion

3.1. Visual Examinations

3.2. Chemical Analysis

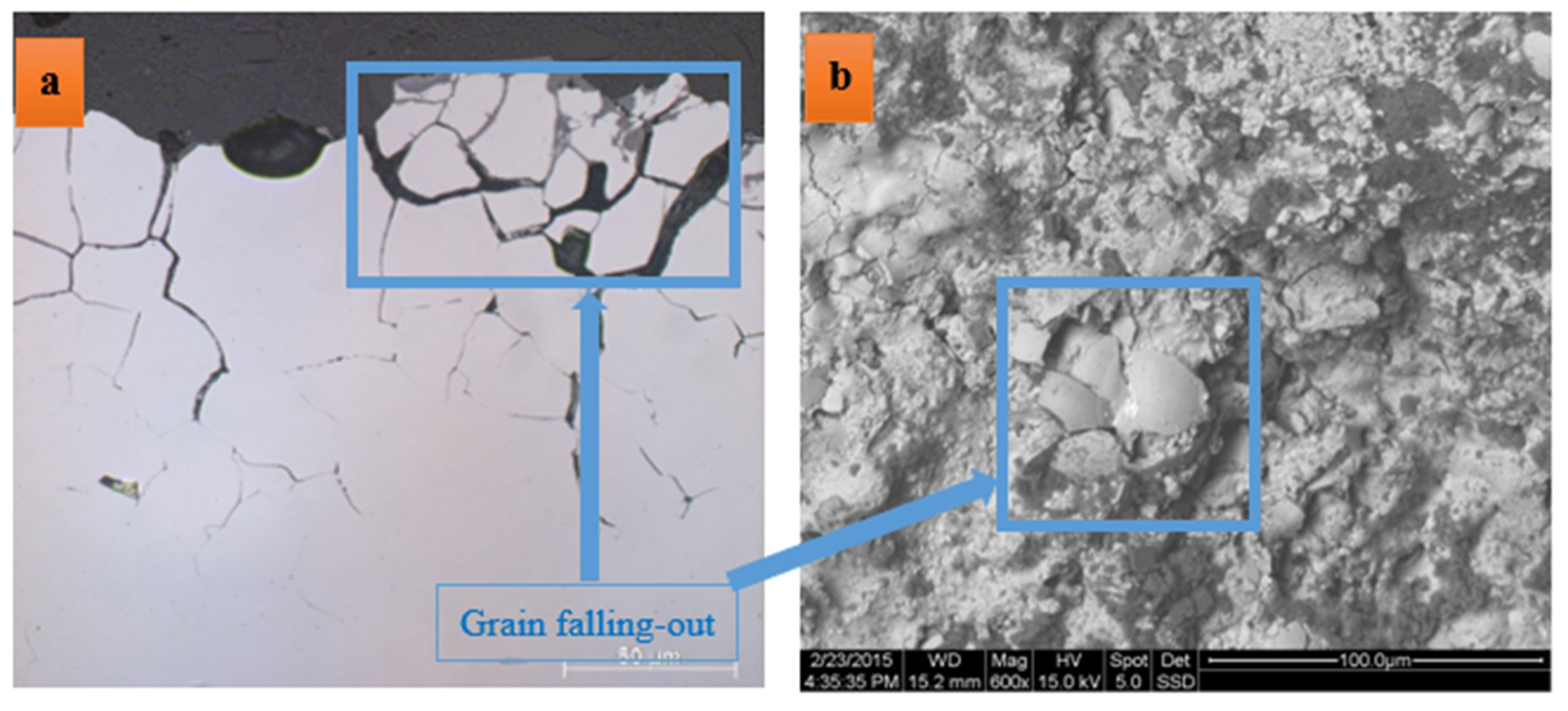

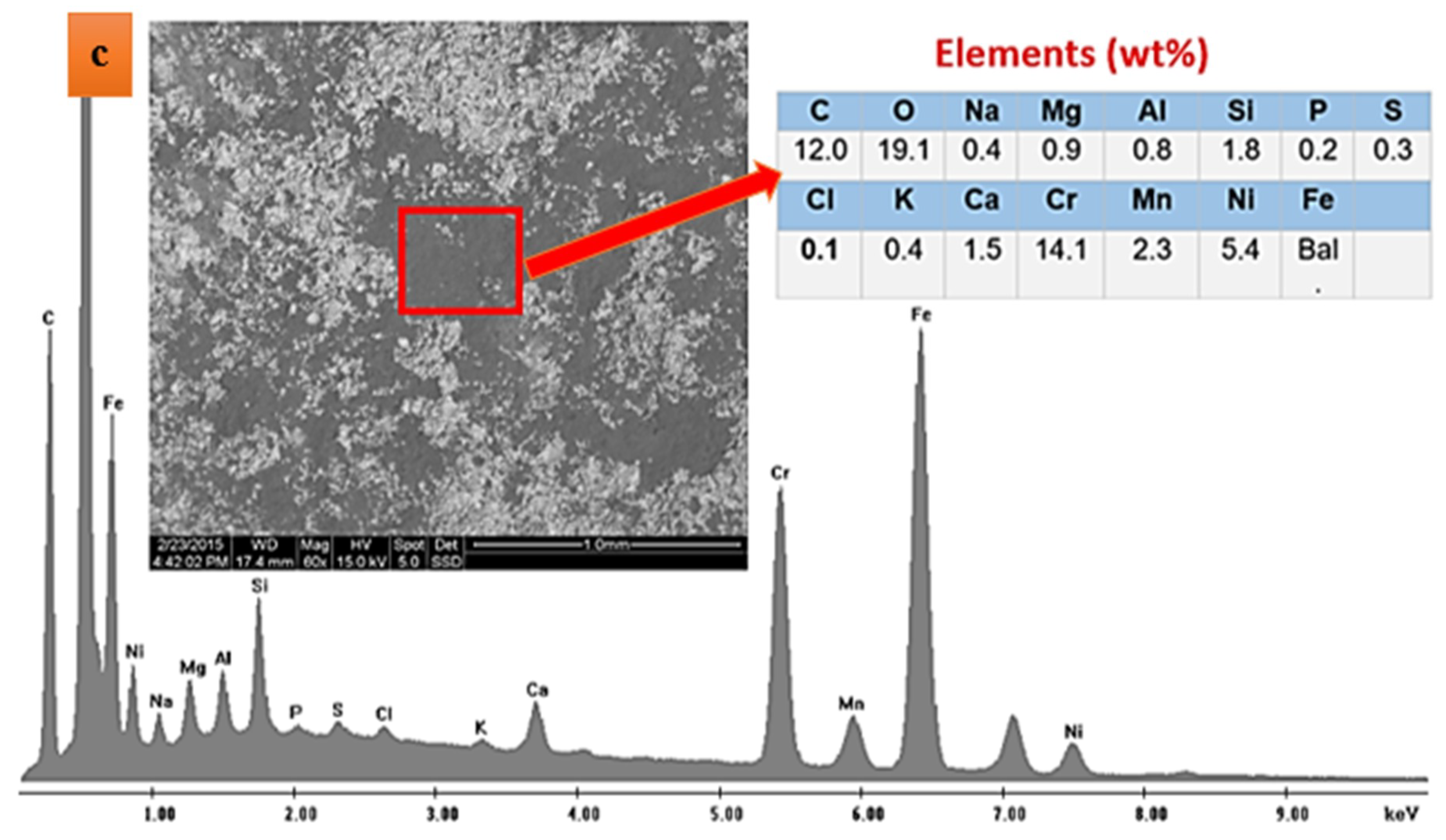

3.3. Analysis of Surface Deposits/Structure

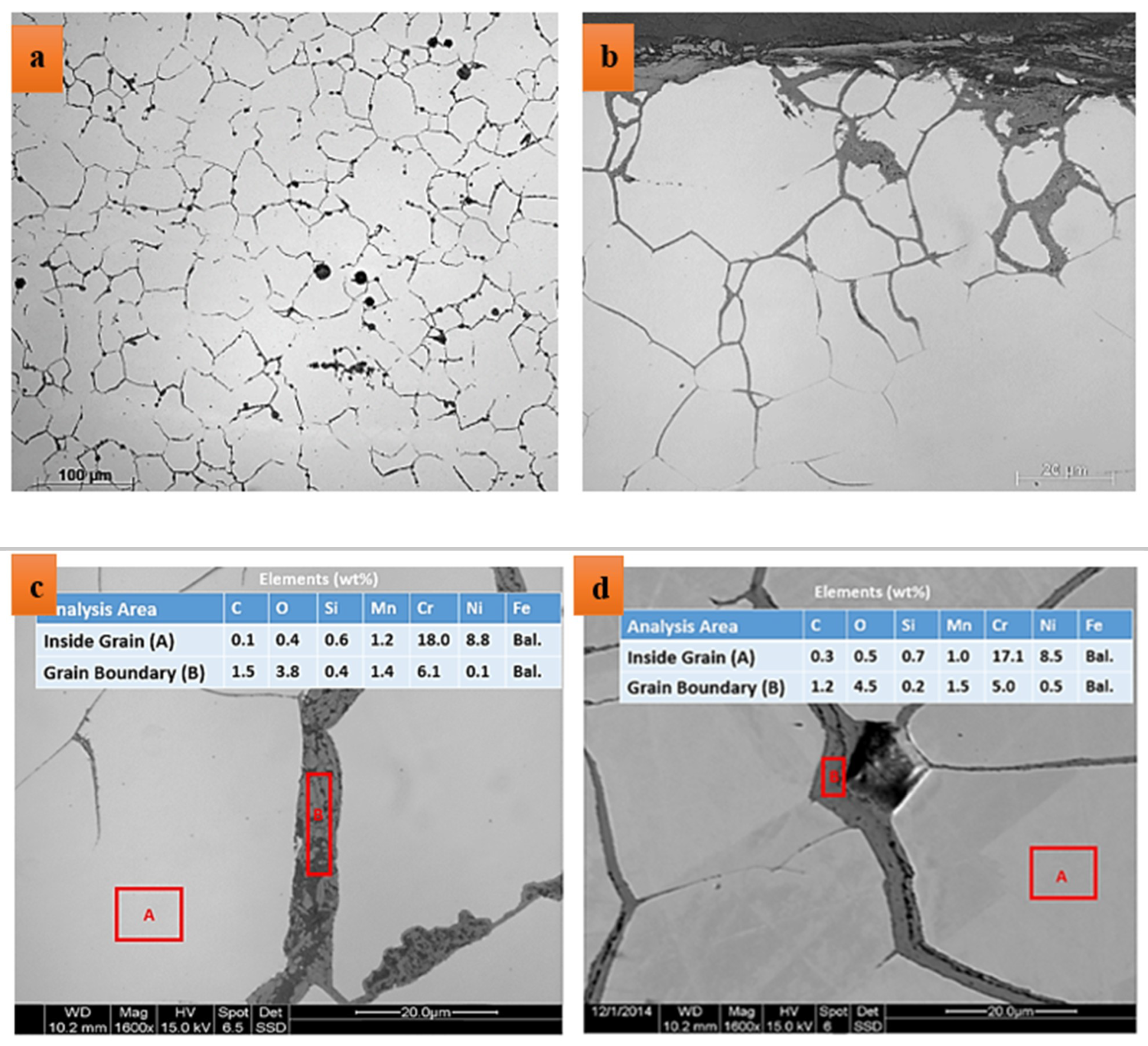

3.4. Microstructure Analysis

3.5. Assessment of Grain Boundary Sensitization

- Step Structure: steps are formed between grains, no ditches at grain boundaries;

- Dual Structure: Some ditches at grain boundaries in addition to steps; and

- Ditch Structure: One or more grains completely surrounded by ditches.

4. Concluding Remarks and Preventive Measures

- Damage has initiated at HAZ area in the vicinity of the weld. Cracks have propagated alongside grain boundaries.

- Grain boundaries in the HAZ area are covered with a rather thick grain boundary phase. Further from the HAZ area in the base metal, there is hardly any indication of such grain boundary phase.

- Results show that grain boundaries are rich in chromium and are sensitized. Sensitization of grain boundaries is associated with the formation of a narrow Cr-depleted region in the vicinity of grain boundaries. This makes grain boundaries susceptible against corrosion.

- The test method, proposed in ASTM A262, confirms the susceptibility of grain boundaries in the HAZ area to intergranular attack.

- Some deposits on the outer surface of tubes are observed. These deposits are rich in C, Cl, Mg, Na, Si, Al, and Ca, indicating that these residues on the surface are fly ashes.

- Carbon content has a very decisive influence on the susceptibility of grain boundaries. Superior resistance to grain boundary susceptibility can be achieved by reducing the carbon content values less than 0.03 wt%. It is highly recommended to use AISI 304L or other low-carbon stainless steel grades instead of AISI 304.

- Stabilizing elements like Nb and Ti can also enhance the resistance to sensitization. These elements form stable carbides at high temperature. This way less carbon is available for the formation of chromium carbides at grain boundaries. Commonly used stabilized austenitic stainless steel grades are AISI 321 and AISI 347. Replacement of currently used AISI 304 alloy with stabilized grades is also highly recommended.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghalambaz, M.; Abdollahi, M.; Eslami, A.; Bahrami, A. A case study on failure of AISI 347H stabilized stainless steel pipe in a petrochemical plant. Case Stud. Eng. Fail. Anal. 2017, 9, 52–62. [Google Scholar] [CrossRef]

- Mousavi Anijdan, S.H.; Madaah-Hosseini, H.R.; Bahrami, A. Flow stress optimization for 304 stainless steel under cold and warm compression by artificial neural network and genetic algorithm. Mater. Des. 2007, 28, 609–615. [Google Scholar] [CrossRef]

- Jafarian, H.; Eivani, A.R. Texture development and microstructure evolution in metastable austenitic steel processed by accumulative roll bonding and subsequent annealing. J. Mater. Sci. 2014, 49, 6570–6578. [Google Scholar] [CrossRef]

- Kiani Khouzani, M.; Bahrami, A.; Eslami, A. Metallurgical aspects of failure in a broken femoral HIP prosthesis. Eng. Fail. Anal. 2018, 90, 168–178. [Google Scholar] [CrossRef]

- Lavvafi, H. Effects of Laser Machining on Structure and Fatigue of 316LVM Biomedical Wires. Ph.D. Thesis, Case Western Reserve University, Cleveland, OH, USA, 2013. [Google Scholar]

- Bahrami, A.; Mousavi Anijdan, S.H.; Taheri, P.; Yazdan Mehr, M. Failure of AISI 304H stainless steel elbows in a heat exchanger. Eng. Fail. Anal. 2018, 90, 397–403. [Google Scholar] [CrossRef]

- Lavvafi, H.; Lewandowski, M.E.; Schwam, D.; Lewandowski, J.J. Effects of surface laser treatments on microstructure, tension, and fatigue behavior of AISI 316LVM biomedical wires. Mater. Sci. Eng. A 2017, 688, 101–113. [Google Scholar] [CrossRef]

- Natesan, K.; Park, J.H. Fireside and steamside corrosion of alloys for USC plants. Int. J. Hydrog. Energy 2007, 32, 3689–3697. [Google Scholar] [CrossRef]

- Ahmad, J.; Rahman, M.M.; Zuhairi, M.H.A. High operating steam pressure and localized overheating of a primary superheater tube. Eng. Fail. Anal. 2012, 26, 344–348. [Google Scholar] [CrossRef]

- Ananda Rao, M.; Sankara Narayanan, T.S.N. Failure investigation of a boiler bank tube from a 77 × 2 MW coal based thermal power plant in the northwest region of India. Eng. Fail. Anal. 2012, 26, 325–331. [Google Scholar] [CrossRef]

- Almazrouee, A.; Singh, R.K. Role of oxide notching and degraded alloy microstructure in remarkably premature failure of steam generator tubes. Eng. Fail. Anal. 2011, 11, 2288–2295. [Google Scholar] [CrossRef]

- Movahedi-Rad, A.; Plasseyed, S.S.; Attarian, M. Failure analysis of superheater tube. Eng. Fail. Anal. 2015, 48, 94–104. [Google Scholar] [CrossRef]

- Psyllaki, P.P.; Pantazopoulos, G.; Lefakis, H. Metallurgical evaluation of creep-failed superheater. Eng. Fail. Anal. 2009, 16, 1420–1431. [Google Scholar] [CrossRef]

- Khodamorad, S.H.; Alinezhad, N.; Haghshenas Fatmehsari, D.; Ghahtan, K. Stress corrosion cracking in Type.316 plates of a heat exchanger. Case Stud. Eng. Fail. Anal. 2016, 5–6, 59–66. [Google Scholar] [CrossRef]

- Corleto, C.R.; Argade, G.R. Failure analysis of dissimilar weld in heat exchanger. Case Stud. Eng. Fail. Anal. 2017, 9, 27–34. [Google Scholar] [CrossRef]

- Corte, J.S.; Rebello, J.M.A.; Areiza, M.C.L.; Tavares, S.S.M.; Araujo, M.D.A. Failure analysis of AISI 321 tubes of heat exchanger. Eng. Fail. Anal. 2015, 56, 170–176. [Google Scholar] [CrossRef]

- Laurent, M.; Estevez, R.; Fabregue, D.; Ayax, E. Thermomechanical fatigue life prediction of 316L compact heat exchanger. Eng. Fail. Anal. 2016, 68, 138–149. [Google Scholar] [CrossRef]

- Fly Ash. Available online: https://www.corrosionpedia.com/definition/1624/fly-ash (accessed on 1 August 2019).

- Corrosion: Intergranular Corrosion. Available online: http://www.ssina.com/corrosion/igc.html (accessed on 1 August 2019).

- ASTM A262-15. Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

| AISI 304 | C | Si | Mn | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| Measured | - | 0.7 | 1.40 | 0.011 | 0.006 | 18.10 | 10.00 | Bal. |

| Standard | - | 0.75 | 2.00 | 0.045 | 0.030 | 18.00–20.00 | 8.00–10.50 | Bal. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahrami, A.; Taheri, P. A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit. Metals 2019, 9, 969. https://doi.org/10.3390/met9090969

Bahrami A, Taheri P. A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit. Metals. 2019; 9(9):969. https://doi.org/10.3390/met9090969

Chicago/Turabian StyleBahrami, Abbas, and Peyman Taheri. 2019. "A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit" Metals 9, no. 9: 969. https://doi.org/10.3390/met9090969

APA StyleBahrami, A., & Taheri, P. (2019). A Study on the Failure of AISI 304 Stainless Steel Tubes in a Gas Heater Unit. Metals, 9(9), 969. https://doi.org/10.3390/met9090969