The Microstructure, Mechanical Properties, and Corrosion Resistance of UNS S32707 Hyper-Duplex Stainless Steel Processed by Selective Laser Melting

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

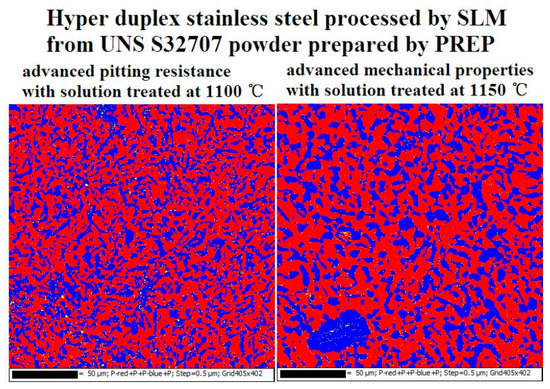

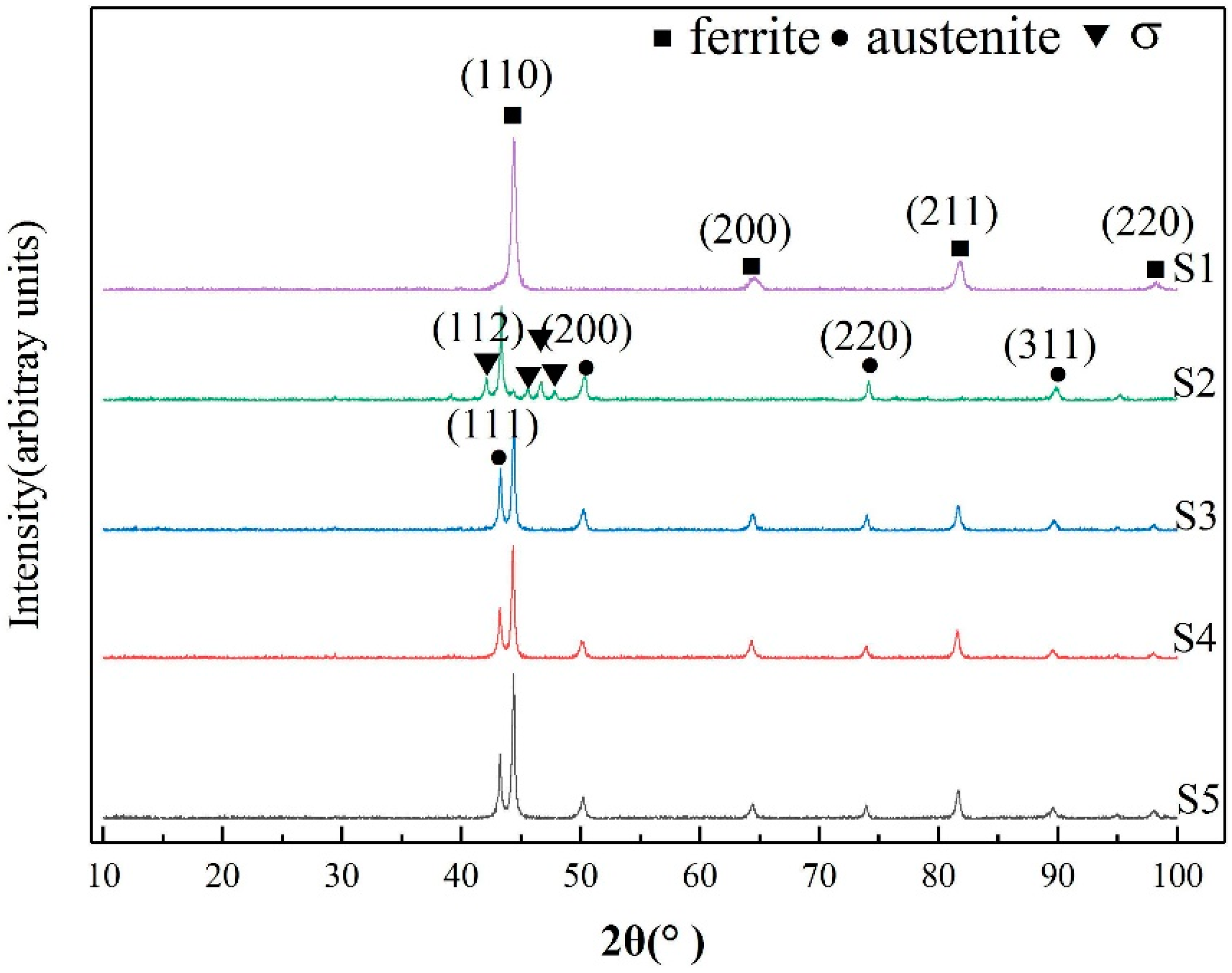

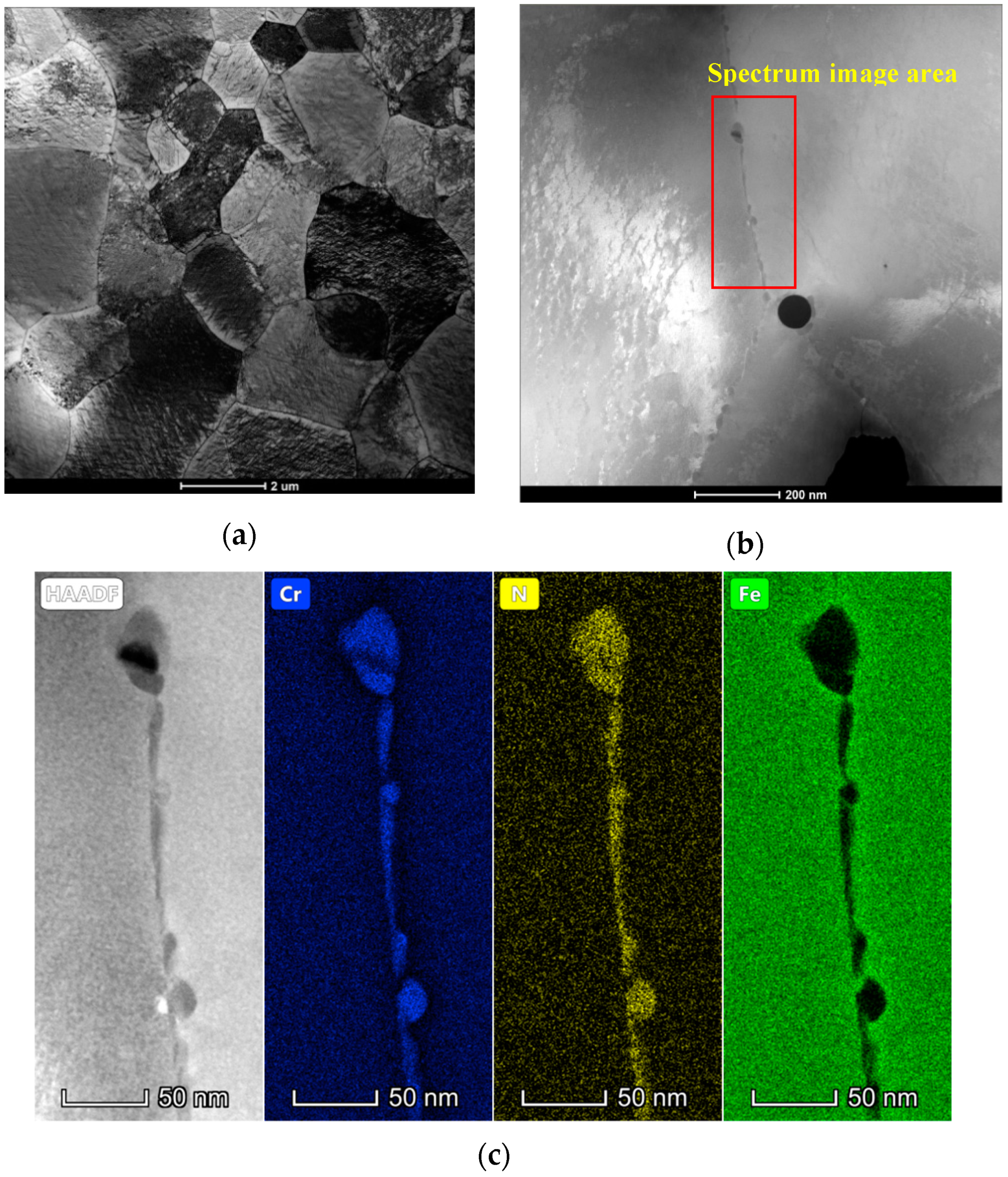

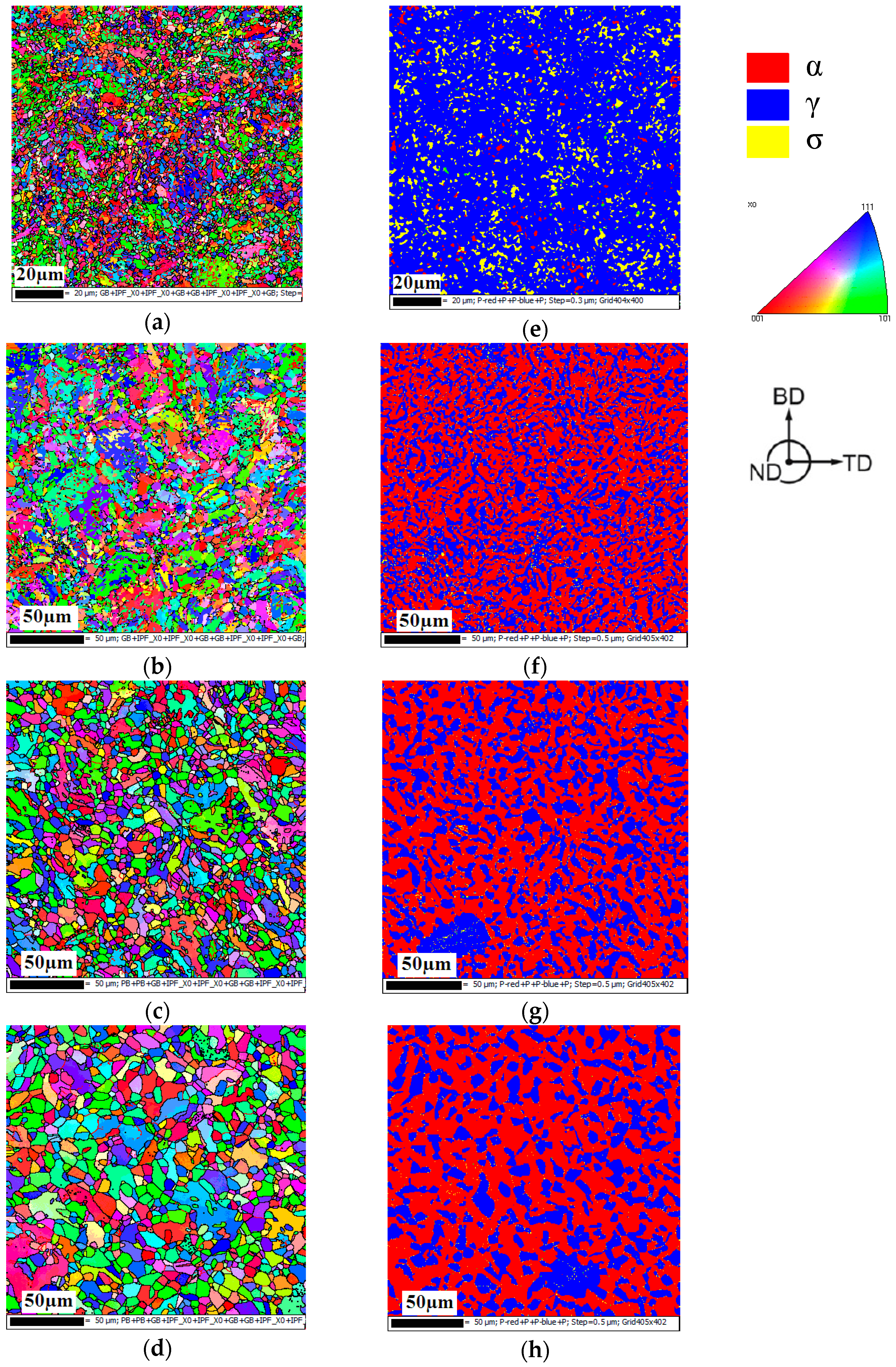

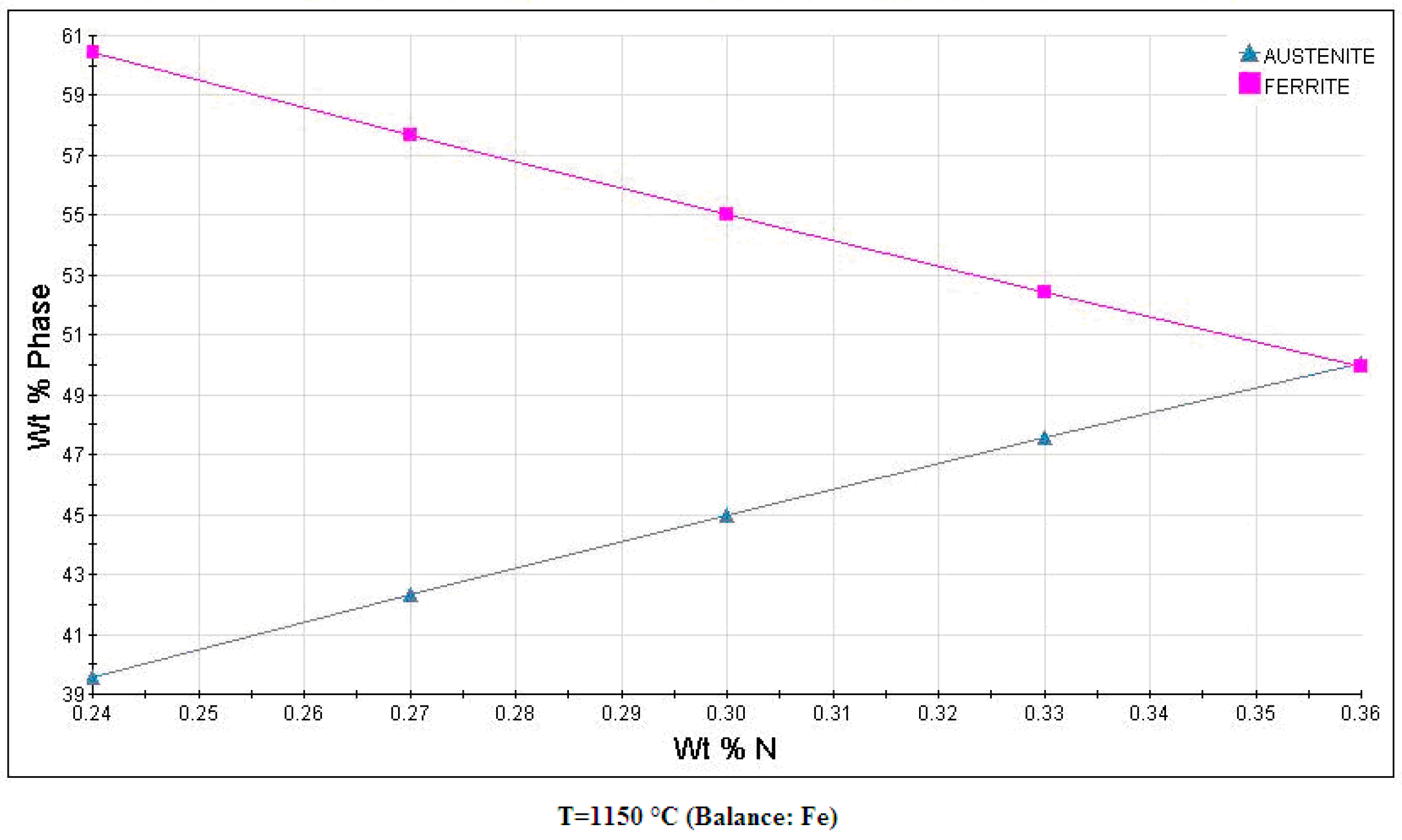

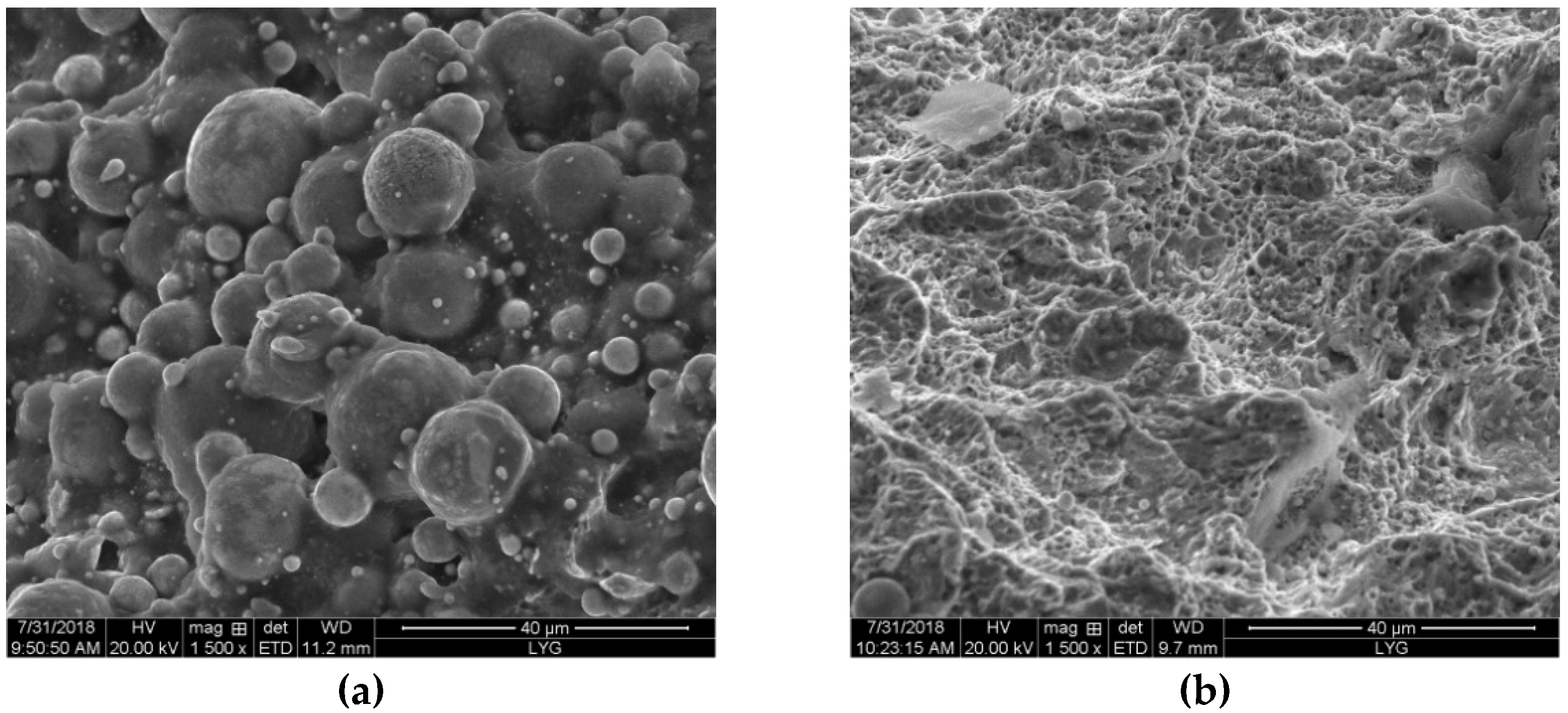

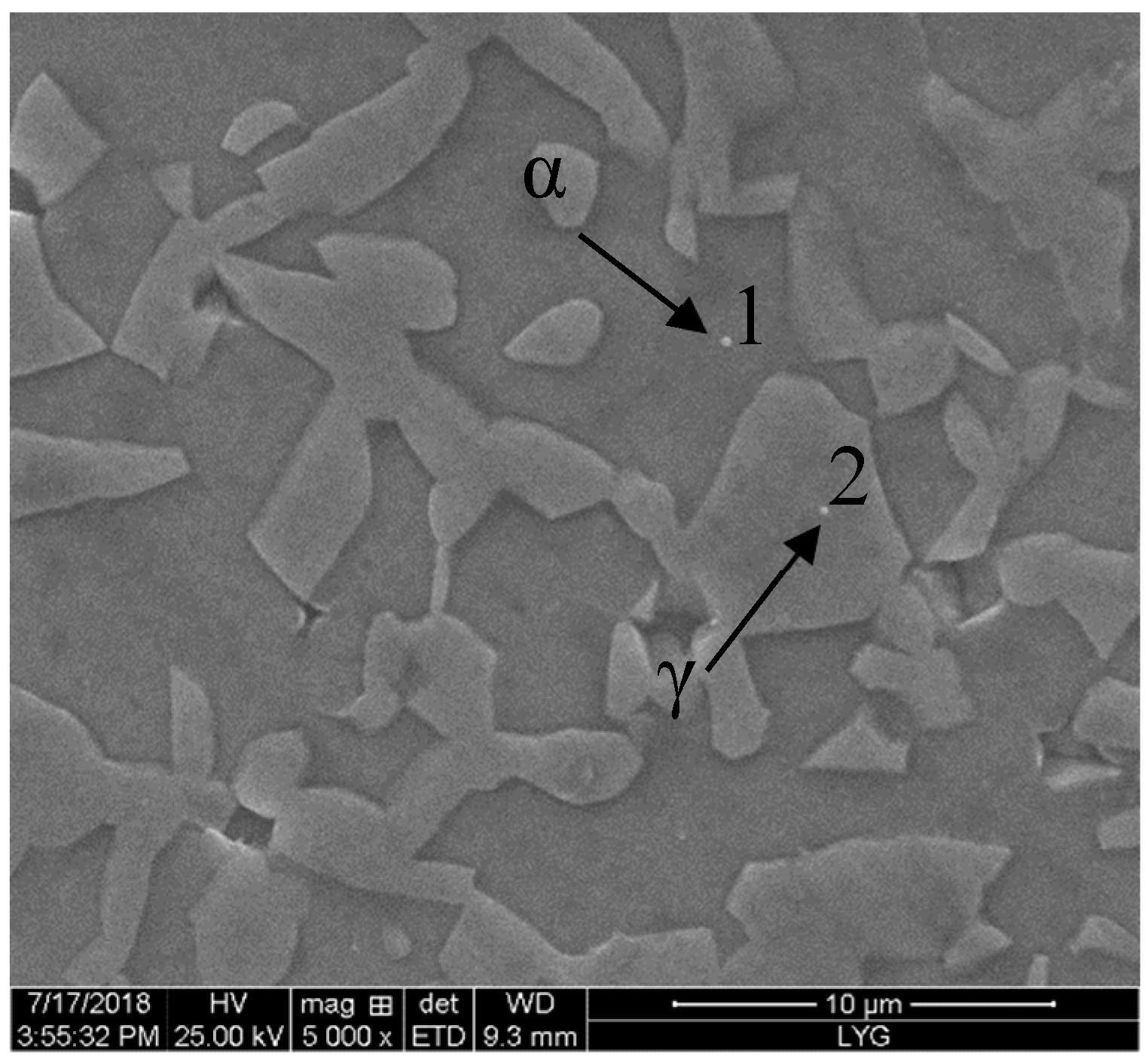

3.1. Microstructure

3.2. Mechanical Properties

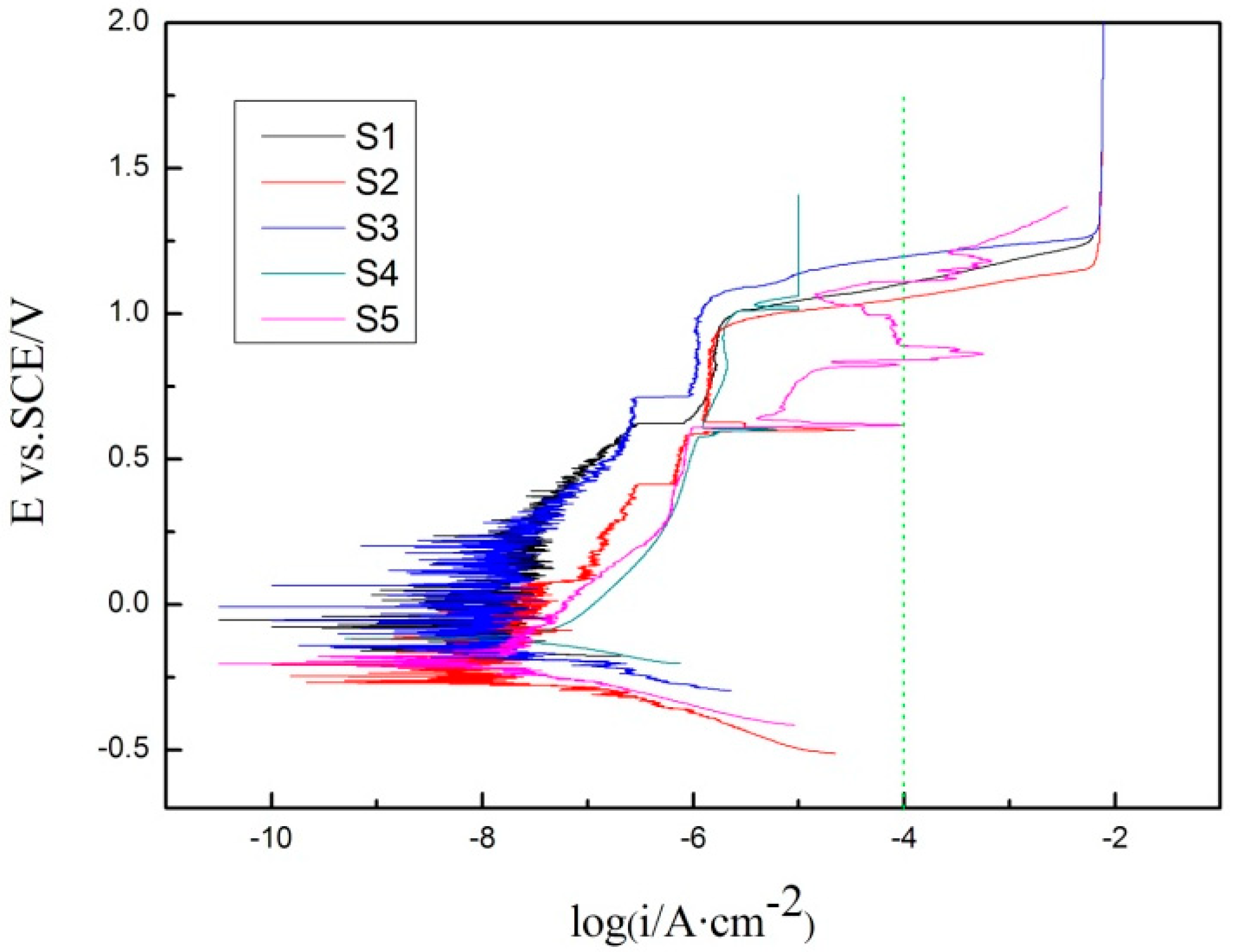

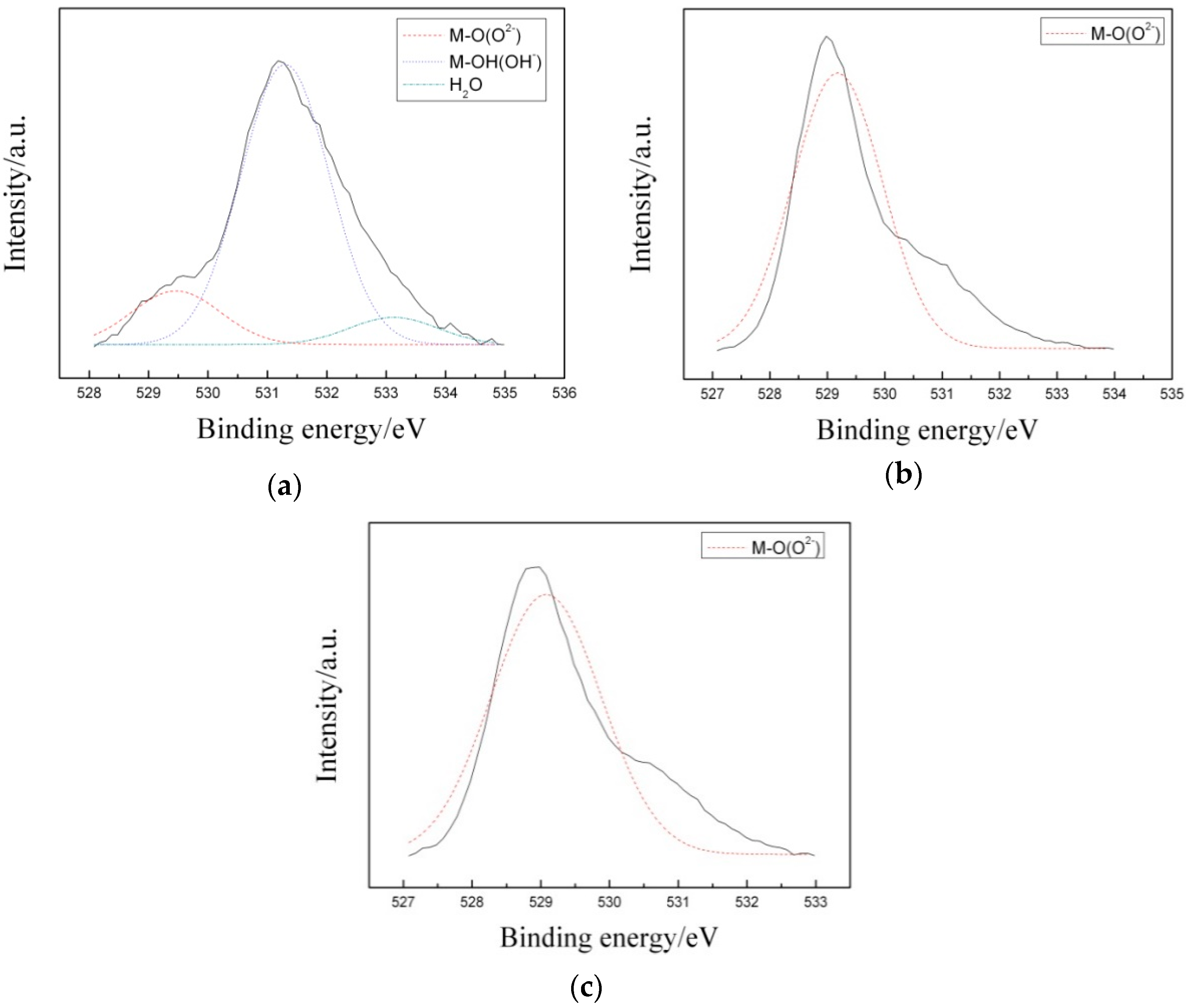

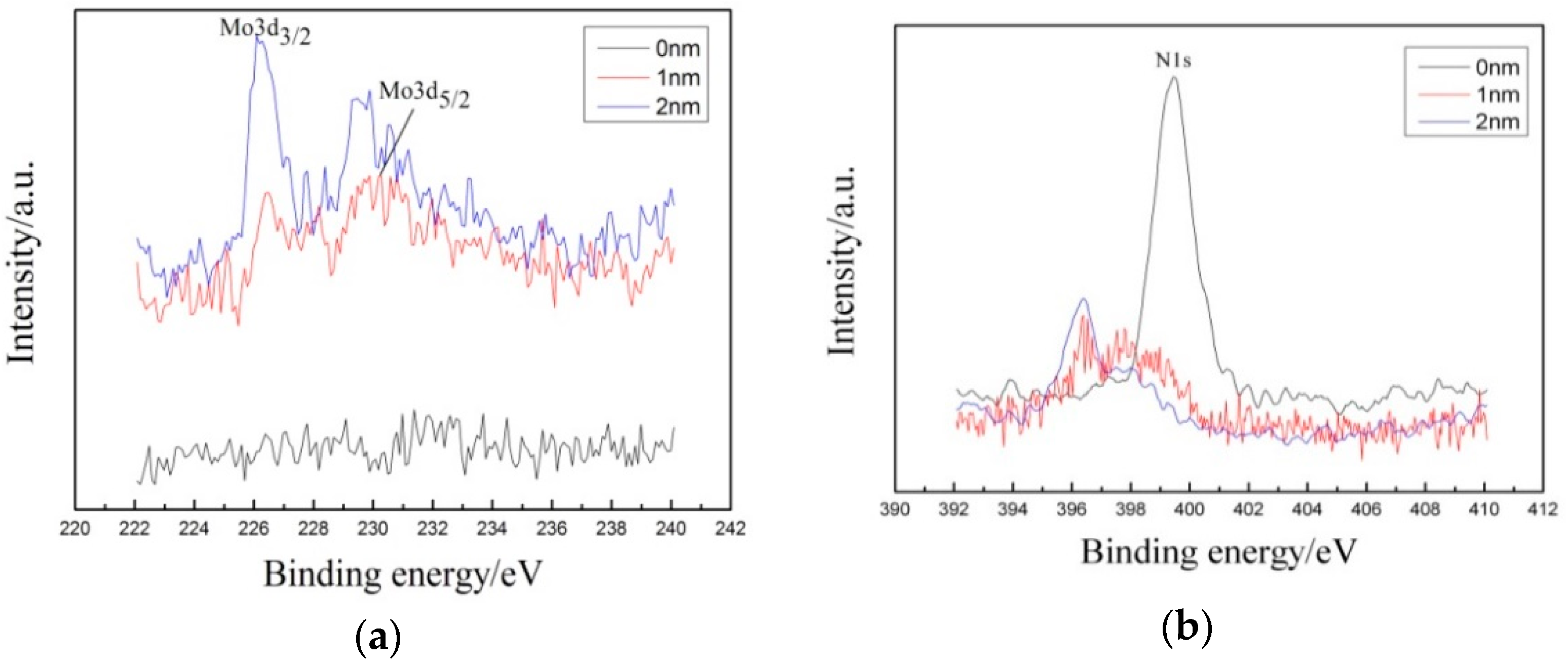

3.3. Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chail, G.C.; Kangas, P. Super and hyper duplex stainless steels: Structures, properties and applications. Procedia Struct. Integr. 2016, 2, 1755–1762. [Google Scholar] [CrossRef]

- Song, Z.G.; Feng, H.; Hu, S.M. Development of Chinese duplex stainless steel in recent years. J. Iron Steel Res. Int. 2017, 24, 121–130. [Google Scholar] [CrossRef]

- Pilhagen, J.; Sieurin, H.; Sandström, R. Fracture toughness of a welded super duplex stainless steel. Mater. Sci. Eng. A 2014, 606, 40–45. [Google Scholar] [CrossRef]

- Kim, H.J.; Jeon, S.H.; Kim, S.T.; Park, Y.S. Influence of the shielding gas composition on the passive film and erosion corrosion of tube-to-tube sheet welds of hyper duplex stainless steel. Corros. Sci. 2015, 91, 140–150. [Google Scholar] [CrossRef]

- Saeidi, K.; Kevetkova, L.; Lofaj, F.; Shen, Z. Novel ferritic stainless steel formed by laser melting from duplex stainless steel powder with advanced mechanical properties and high ductility. Mater. Sci. Eng. A 2016, 665, 59–65. [Google Scholar] [CrossRef]

- Martín, F.; García, C.; Blanco, Y.; Rodriguez-Mendez, M.L. Influence of sinter-cooling rate on the mechanical properties of powder metallurgy austenitic, ferritic, and duplex stainless steels sintered in vacuum. Mater. Sci. Eng. A 2015, 642, 360–365. [Google Scholar] [CrossRef]

- Trelewicz, J.R.; Halada, G.P.; Donaldson, O.K.; Manogharan, G.P. Microstructure and corrosion resistance of laser additively manufactured 316L stainless steel. JOM 2016, 68, 850–859. [Google Scholar] [CrossRef]

- Akita, M.; Uematsu, Y.; Kakiuchi, T.; Nakajima, M.; Kawaguchi, R. Defect-dominated fatigue behavior in type 630 stainless steel fabricated by selective laser melting. Mater. Sci. Eng. A 2016, 666, 19–26. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Yadroitsava, I.; Fredriksson, G.; Yadroitsev, I. In situ heat treatment in selective laser melted martensitic AISI420 stainless steels. Mater. Design. 2015, 87, 380–385. [Google Scholar] [CrossRef]

- Haase, C.; Bültmann, J.; Hof, J.; Ziegler, S.; Bremen, S.; Hinke, C.; Schwedt, A.; Prahl, U.; Bleck, W. Exploiting process-related advantages of selective laser melting for the production of high-manganese steel. Materials 2017, 10, 56. [Google Scholar] [CrossRef]

- Davidson, K.P.; Singamneni, S. Magnetic characterization of selective laser-melted Saf 2507 duplex stainless steel. JOM 2017, 69, 569–574. [Google Scholar] [CrossRef]

- Davidson, K.P.; Singamneni, S. Selective laser melting of duplex stainless steel powders: An investigation. Manuf. Processes. 2016, 31, 1543–1555. [Google Scholar] [CrossRef]

- Davidson, K.P.; Singamneni, S. Metallographic evaluation of duplex stainless steel powders processed by selective laser melting. Rapid. Prototyping. J. 2017, 23, 1146–1163. [Google Scholar] [CrossRef]

- Hengsbach, F.; Koppa, P.; Duschik, K.; Holzweissig, M.J.; Burns, M.; Nellesen, J.; Tillmann, W.; Troster, T.; Hoyer, K.P.; Schaper, M. Duplex stainless steel fabricated by selective laser melting—Microstructural and mechanical properties. Mater. Design. 2017, 133, 136–142. [Google Scholar] [CrossRef]

- Shang, F.; Chen, X.Q.; Zhang, P.; Ji, Z.C.; Ming, F.; Ren, S.B.; Qu, X.H. Novel Ferritic Stainless Steel with Advanced Mechanical Properties and Significant Magnetic Responses Processed by Selective Laser Melting. Mater. Trans. 2019, 60, 1096–1102. [Google Scholar] [CrossRef]

- Topolska, S.; Labanowski, J. Effect of microstructure on impact toughness of duplex and superduplex stainless steels. J. Ach. Mater. Manuf. Eng. 2009, 36, 142–149. [Google Scholar]

- Chan, K.W.; Tjong, S.C. Effect of secondary phase precipitation on the corrosion behavior of duplex stainless steels. Materials 2014, 7, 5268–5304. [Google Scholar] [CrossRef] [PubMed]

- Maki, T.; Furuhara, T.; Tsuzaki, K. Microstructure development by thermomechnical processing in duplex stainless steel. ISIJ Int. 2001, 41, 571–579. [Google Scholar] [CrossRef]

- Zhang, B.B.; Jiang, Z.H.; Li, H.B.; Zhang, S.C.; Feng, H.; Li, H. Precipitation behavior and phase transformation of hyper duplex stainless steel UNS S32707 at nose temperature. Mater. Charact. 2017, 129, 31–39. [Google Scholar] [CrossRef]

- Ha, H.Y.; Jang, M.H.; Lee, T.H.; Moon, J.O. Interpretation of the relation between ferrite fraction and pitting corrosion resistance of commercial 2205 duplex stainless steel. Corros. Sci. 2014, 89, 154–162. [Google Scholar] [CrossRef]

- He, Y.J.; Guo, X.Y.; Wu, Y.M.; Jiang, J.; Li, J. Effect of solution annealing temperature on pitting behavior of duplex stainless steel 2204 in chloride solutions. J. Iron Steel Res. Int. 2016, 23, 357–363. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Gao, Y.; Gui, Y.; Zhu, M. Corrosion behaviour of nanocrystalline 304 stainless steel prepared by equal channel angular pressing. Corros. Sci. 2012, 54, 60–67. [Google Scholar] [CrossRef]

- Wang, Z.C.; Zhang, Y.Z.; Zhou, S.M. Corrosion compositions of carbon steel under ion-selective coatings by XPS. J. Chin. Soc. Corros. Prot. 2001, 21, 273–279. [Google Scholar] [CrossRef]

| Element | Cr | Ni | Mo | N | Si | Mn | Co | Cu | Al | C | O | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mass% | 27.19 | 6.48 | 5.00 | 0.36 | 0.58 | 1.5 | 1.03 | 0.98 | 0.02 | 0.02 | 0.018 | Bal. |

| Processing Technology | Sample Number |

|---|---|

| SLM | S1 |

| SLM+ solution annealing (1050 °C × 1 h) + water quenching | S2 |

| SLM+ solution annealing (1100 °C × 1 h) + water quenching | S3 |

| SLM+ solution annealing (1150 °C × 1 h) + water quenching | S4 |

| SLM+ solution annealing (1200 °C × 1 h) + water quenching | S5 |

| Casting bar UNS S32707 for PREP+ solution annealing (1150 °C × 1 h) + water quenching | S6 |

| Welded and seamless UNS S32707stainless steel pipe (ASTM A790) | S7 |

| Sample Number | The Content of Ferrite Phase/vol. % | Average Grain Size of Ferrite/µm | The Content of Austenite Phase/vol. % | Average Grain Size of Austenite/µm | The Content of Sigma Phase/vol. % | Average Grain Size of Sigma Phase/µm |

|---|---|---|---|---|---|---|

| S1 | 98.5 | 3.68 | 0.2 | 1.66 | - | - |

| S2 | 1.6 | 1.24 | 88.4 | 2.27 | 10.0 | 1.08 |

| S3 | 59.5 | 4.21 | 40.5 | 2.80 | - | - |

| S4 | 61.4 | 5.72 | 38.6 | 3.96 | - | - |

| S5 | 63.4 | 7.58 | 36.6 | 5.25 | - | - |

| Sample Number | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% | Section Shrinkage/% | Impact Absorbing Energy/J | Hardness/HV |

|---|---|---|---|---|---|---|

| S1 | 1493 ± 6 | 1391 ± 9 | 13.2 ± 1 | 24.1 ± 3 | 18 ± 3 | 528.7 ± 4 |

| S2 | 593 ± 20 | - | - | - | - | 523.8 ± 8 |

| S3 | 941 ± 10 | 665 ± 7 | 24.6 ± 2 | 25.8 ± 3 | - | 321.8 ± 7 |

| S4 | 901 ± 4 | 658 ± 10 | 36.4 ± 2 | 48.4 ± 2 | 132 ± 5 | 291.5 ± 6 |

| S5 | 893 ± 1 | 646 ± 3 | 38.7 ± 2 | 52.6 ± 3 | - | 286.7 ± 5 |

| S6 | 851 ± 7 | 614 ± 10 | 29.2 ± 2 | 59.4 ± 3 | 128 ± 6 | 285.4 ± 4 |

| S7 | 920 (min) | 700 (min) | 25 (min) | - | - | 34 HRC (max) |

| Sample Number | Pitting Potential/mV |

|---|---|

| S1 | 1109 |

| S2 | 1055 |

| S3 | 1196 |

| S4 | 1109 |

| S5 | 1109 |

| Phase | Fe | Cr | Ni | Mo | N |

|---|---|---|---|---|---|

| α | 58.51 | 29.96 | 5.49 | 6.04 | 0.05 |

| γ | 59.41 | 25.81 | 9.78 | 5.00 | 0.52 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, F.; Chen, X.; Wang, Z.; Ji, Z.; Ming, F.; Ren, S.; Qu, X. The Microstructure, Mechanical Properties, and Corrosion Resistance of UNS S32707 Hyper-Duplex Stainless Steel Processed by Selective Laser Melting. Metals 2019, 9, 1012. https://doi.org/10.3390/met9091012

Shang F, Chen X, Wang Z, Ji Z, Ming F, Ren S, Qu X. The Microstructure, Mechanical Properties, and Corrosion Resistance of UNS S32707 Hyper-Duplex Stainless Steel Processed by Selective Laser Melting. Metals. 2019; 9(9):1012. https://doi.org/10.3390/met9091012

Chicago/Turabian StyleShang, Feng, Xiaoqiu Chen, Zhiyong Wang, Zuchun Ji, Fei Ming, Shubin Ren, and Xuanhui Qu. 2019. "The Microstructure, Mechanical Properties, and Corrosion Resistance of UNS S32707 Hyper-Duplex Stainless Steel Processed by Selective Laser Melting" Metals 9, no. 9: 1012. https://doi.org/10.3390/met9091012

APA StyleShang, F., Chen, X., Wang, Z., Ji, Z., Ming, F., Ren, S., & Qu, X. (2019). The Microstructure, Mechanical Properties, and Corrosion Resistance of UNS S32707 Hyper-Duplex Stainless Steel Processed by Selective Laser Melting. Metals, 9(9), 1012. https://doi.org/10.3390/met9091012