The Effect of Stress Relief on the Mechanical and Fatigue Properties of Additively Manufactured AlSi10Mg Parts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Powder Bed Fusion Processing

2.2. Characterization Techniques

3. Results and Discussion

3.1. Density and Porosity Measurements

3.2. Hardness Measurements

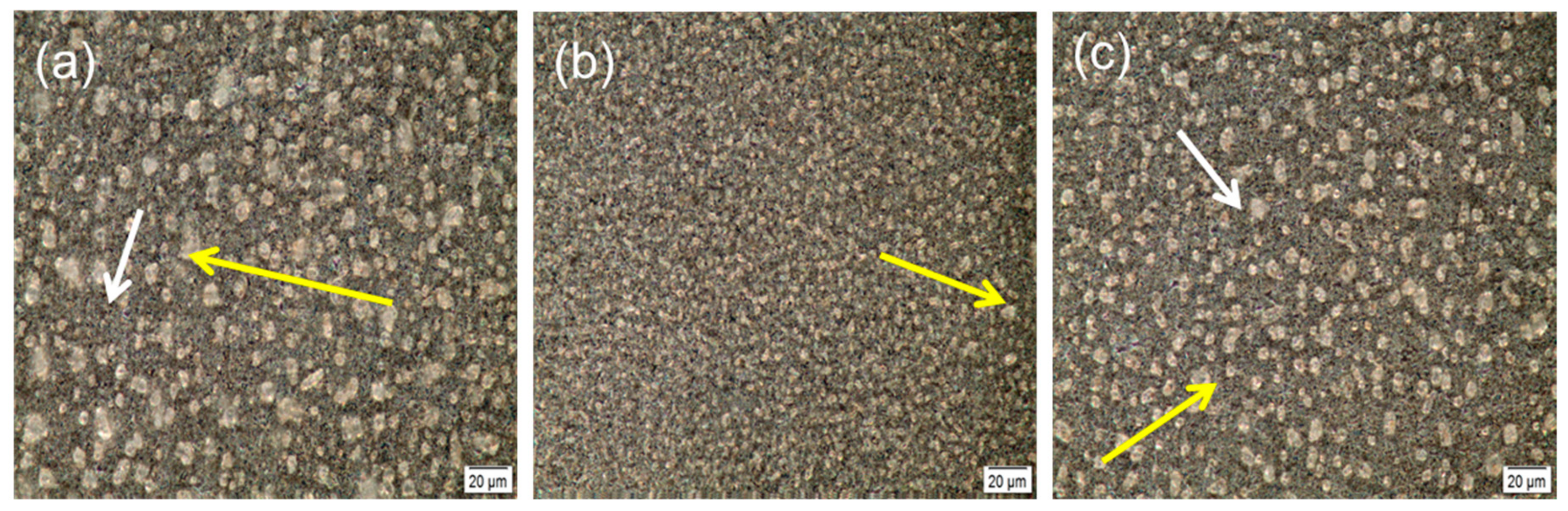

3.3. Microstructure Analysis

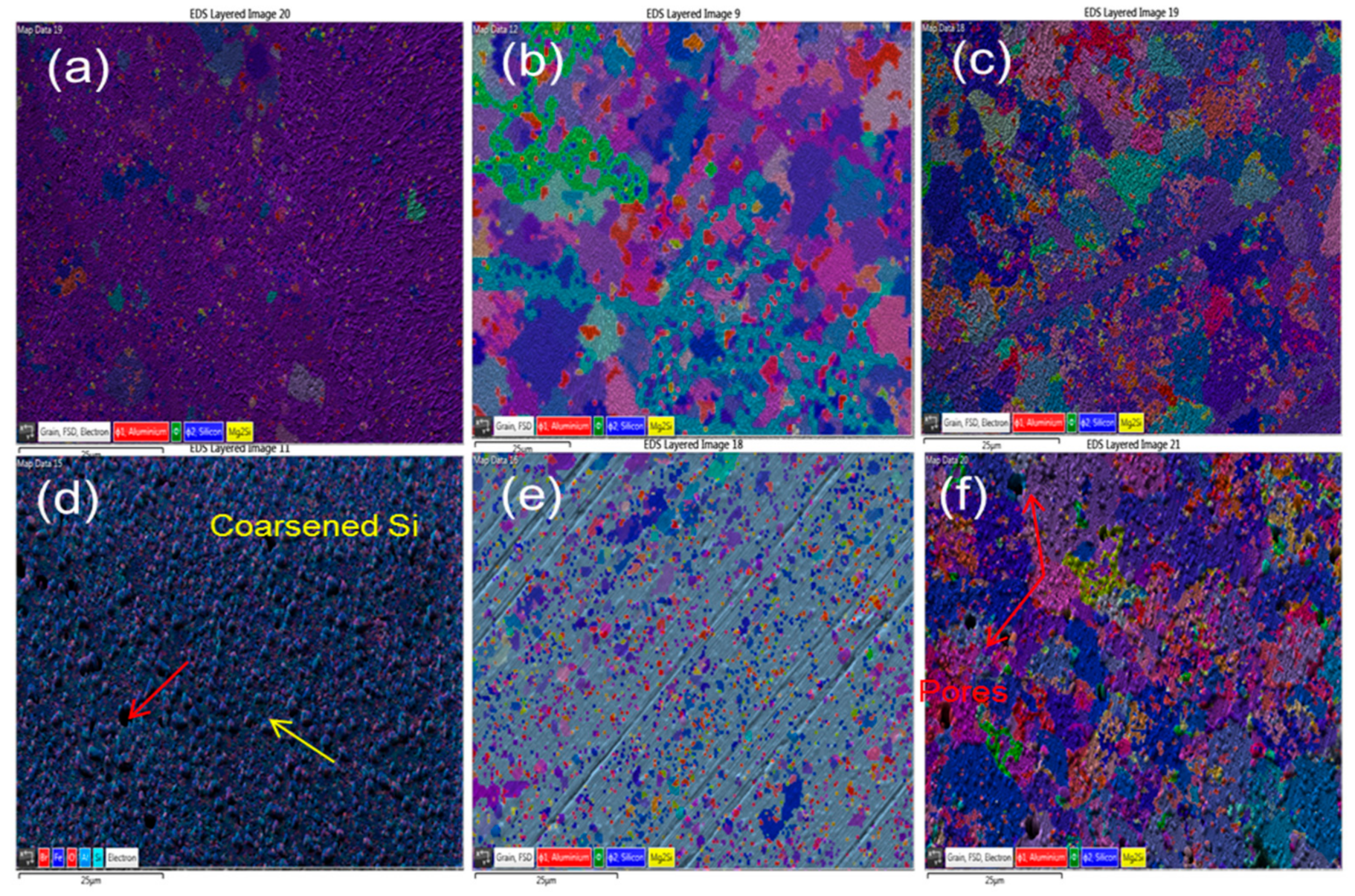

3.4. Electron Backscatter Diffraction (EBSD)

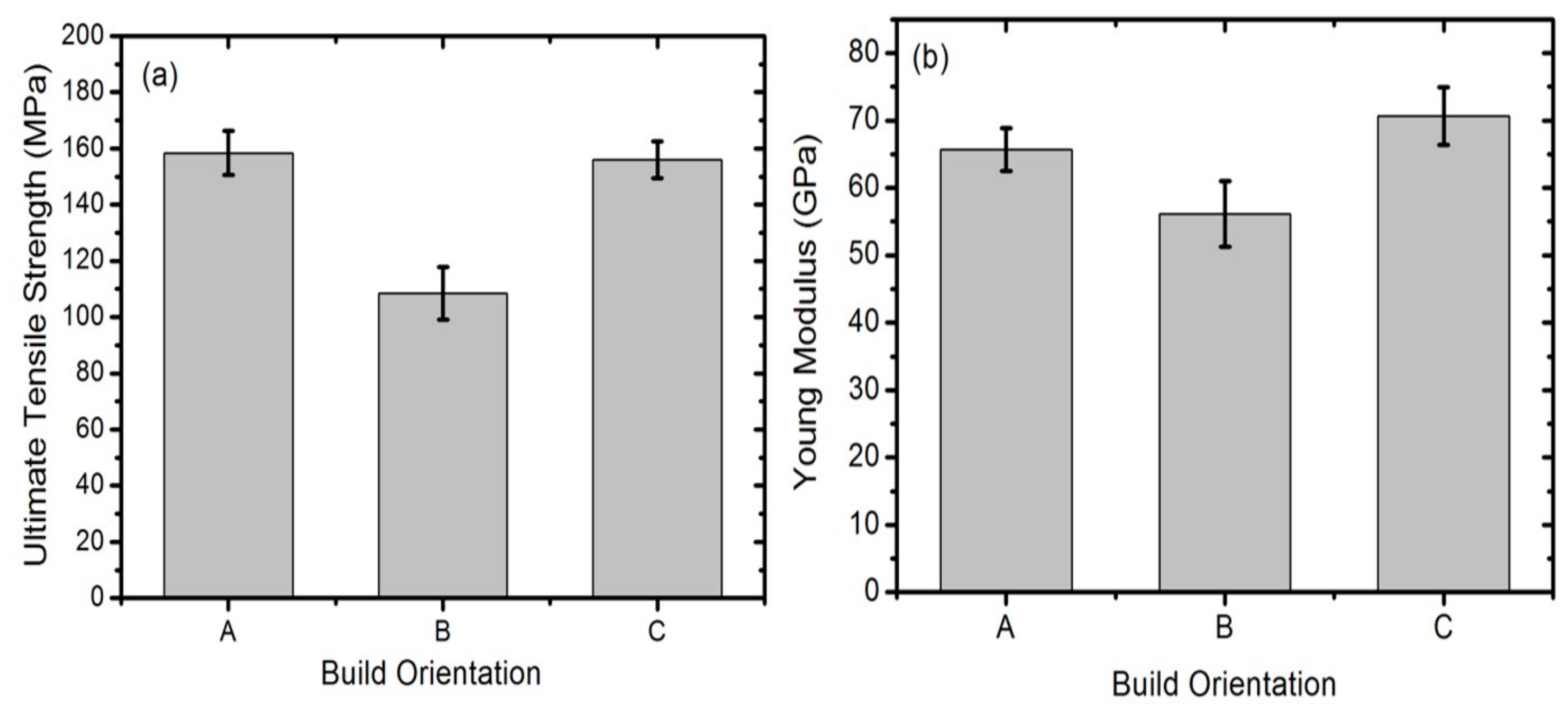

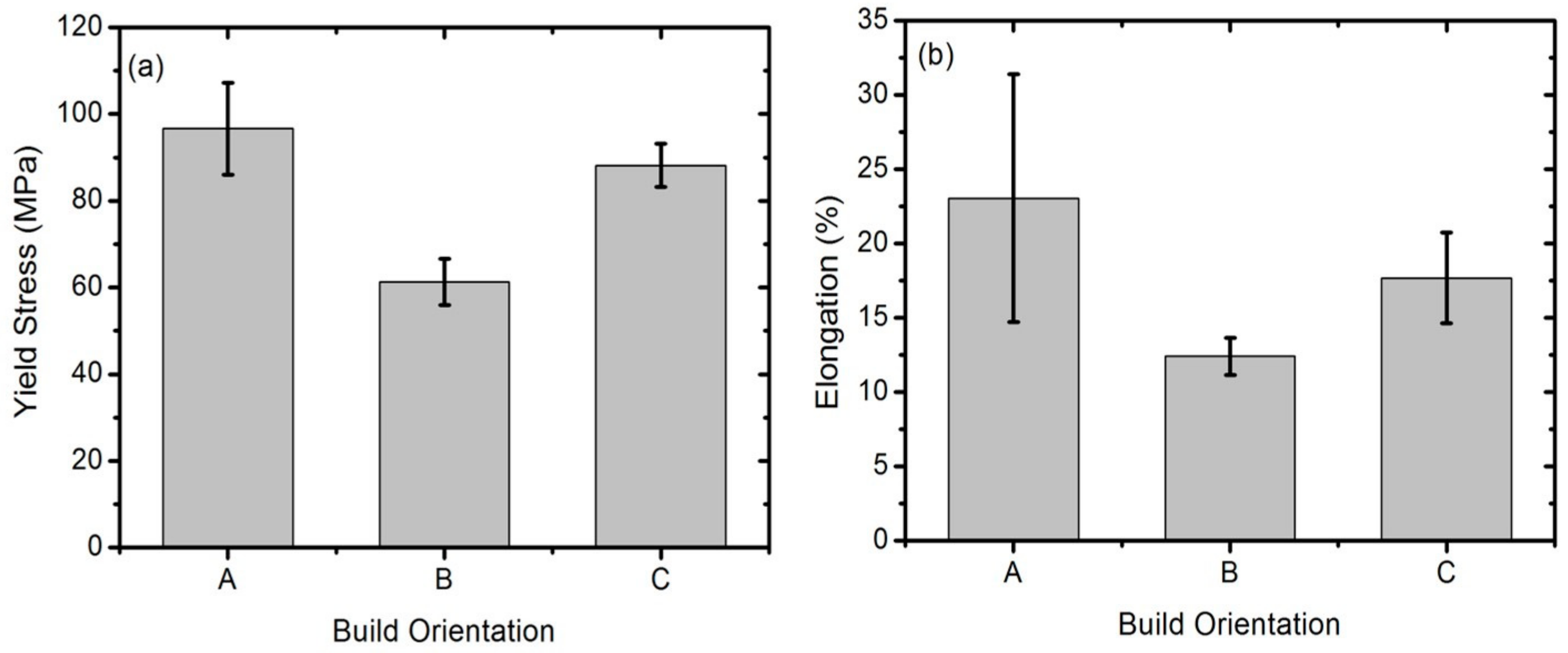

3.5. Tensile Strength after Stress Relieving

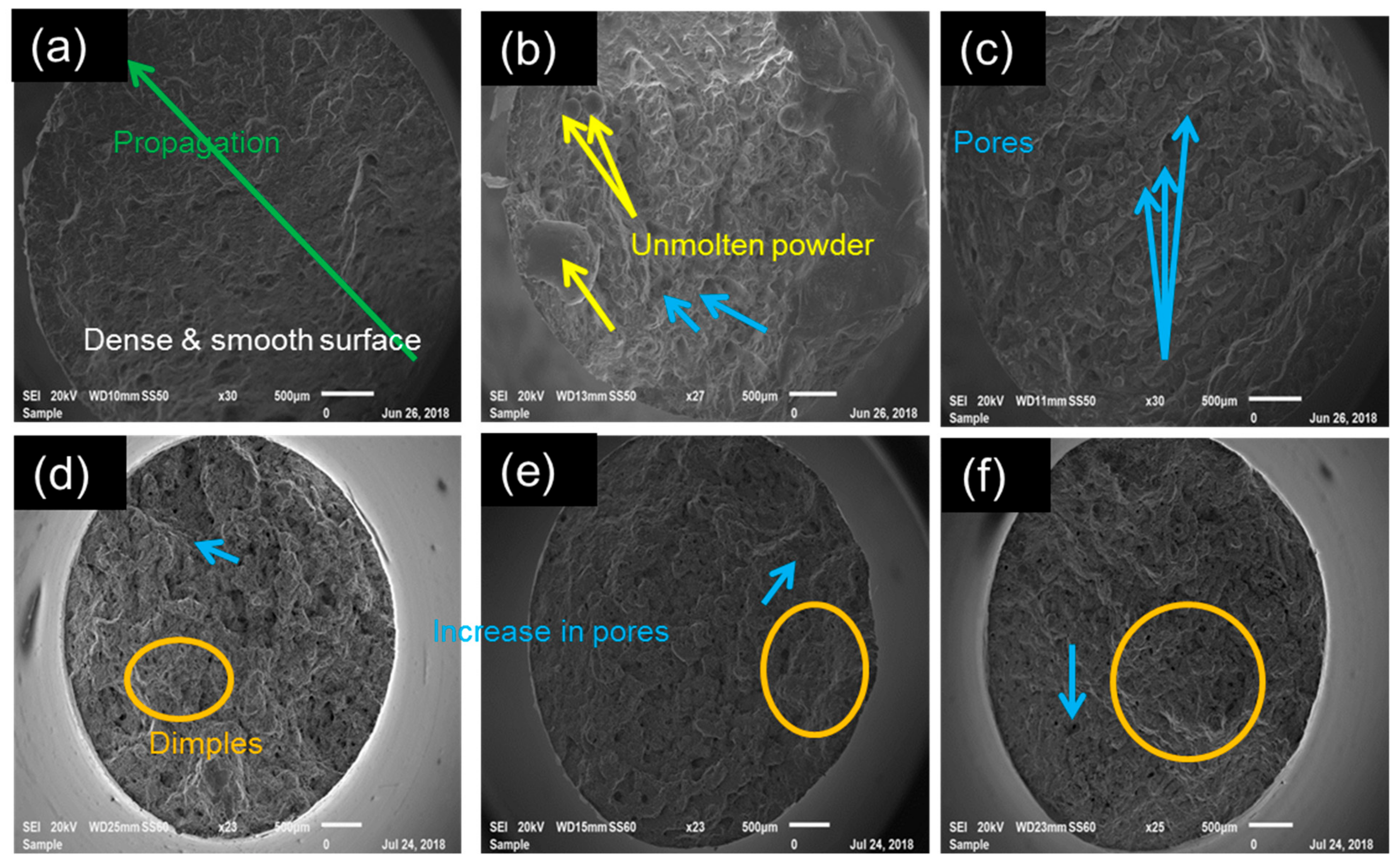

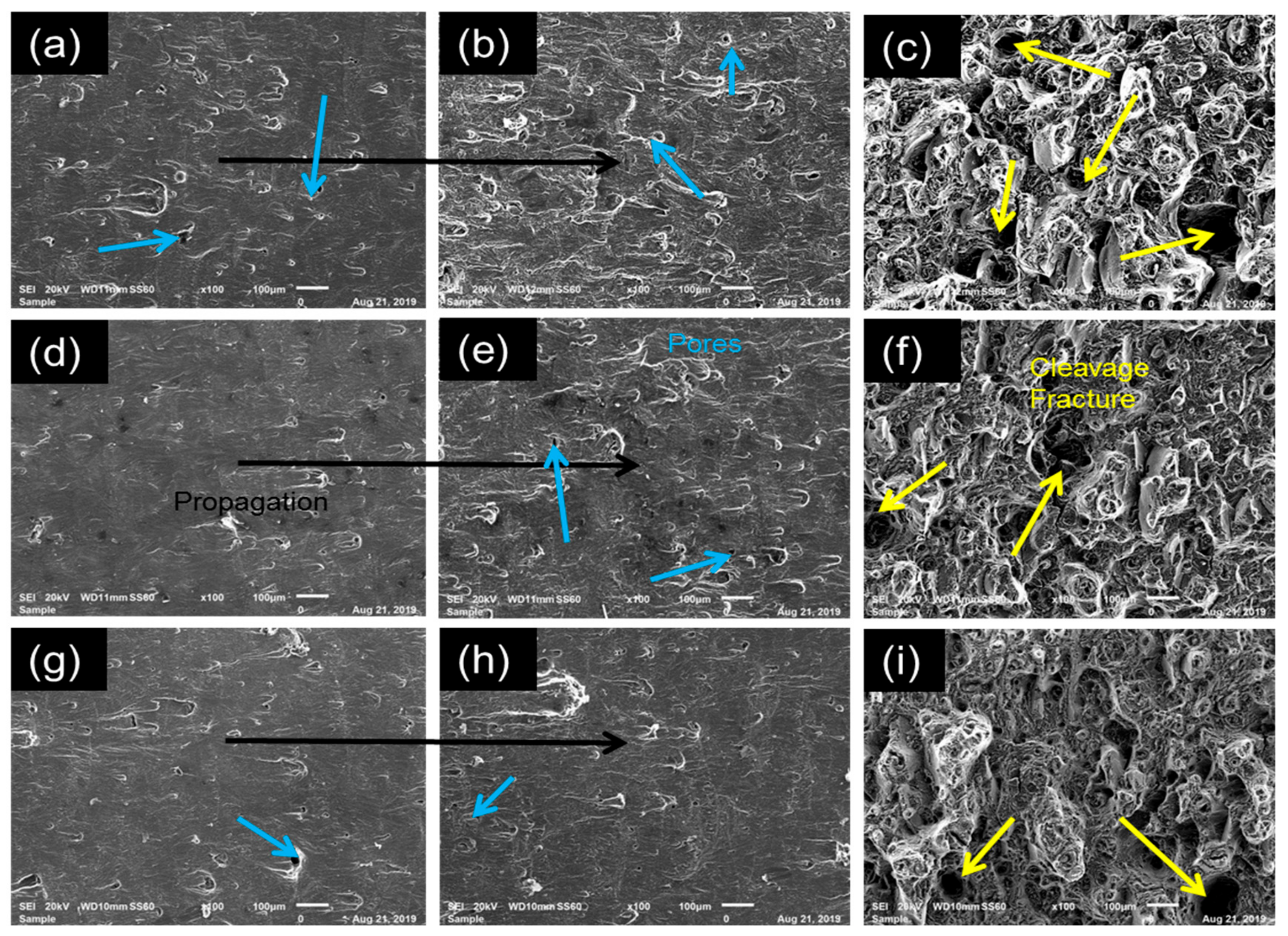

3.6. Fractography Analysis

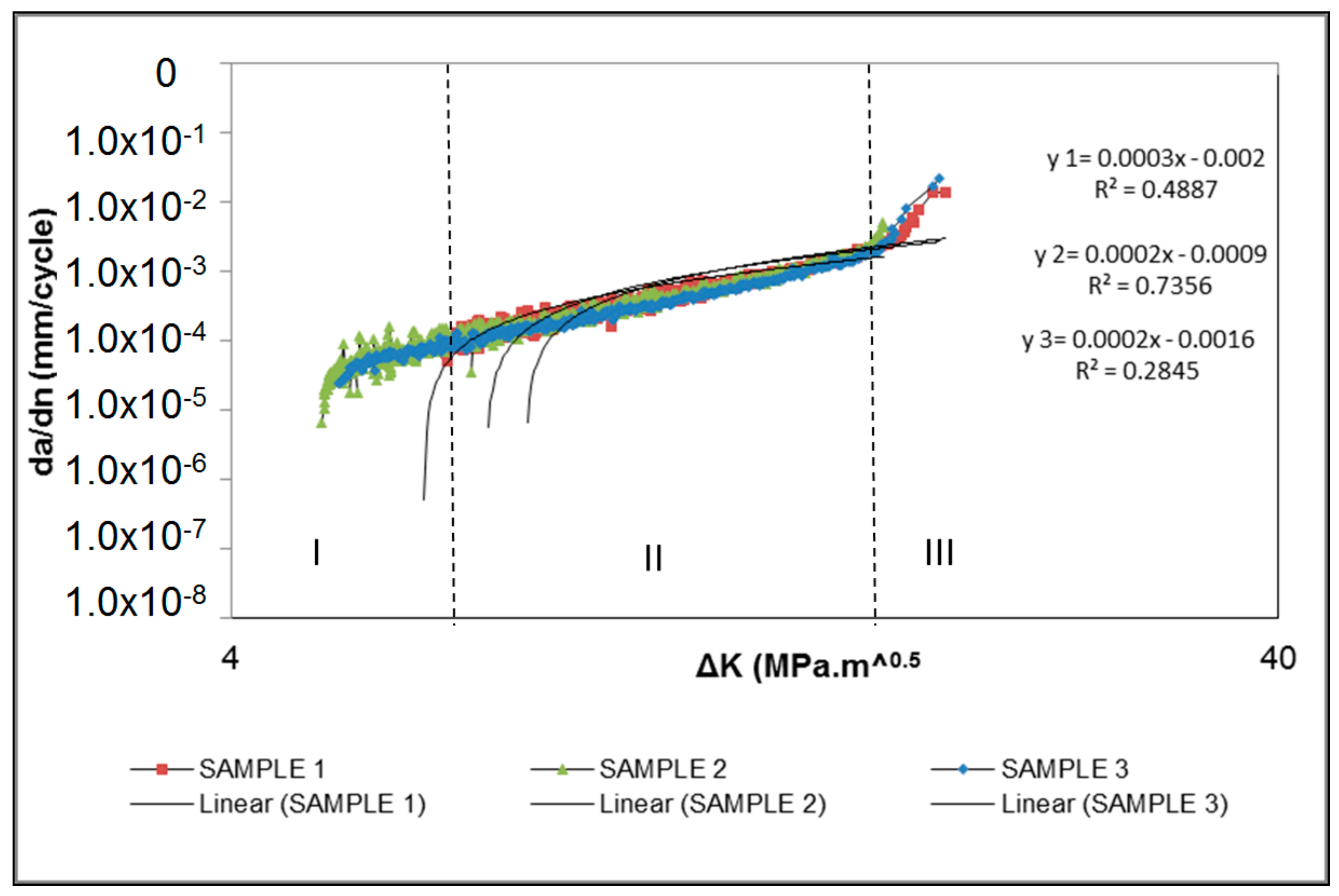

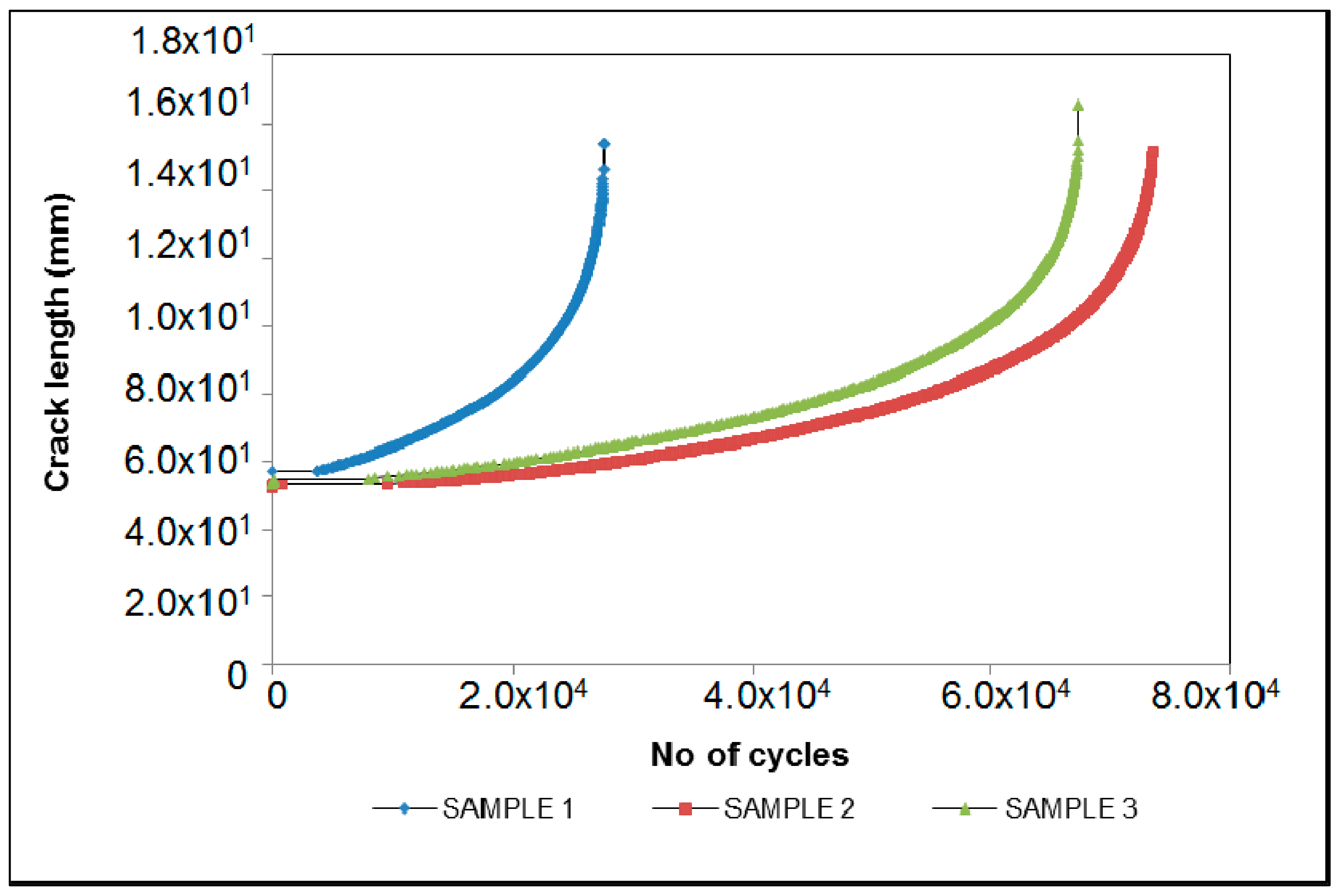

3.7. Fracture Toughness and Fatigue Crack Growth Rate Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- NSAI Standards. Additive Manufacturing–General Principles–Terminology; NSAI Standards: Dublin, Ireland, 2015; p. 2. [Google Scholar]

- Manakari, V.; Parande, G.; Gupta, M. Selective laser melting of magnesium and magnesium alloy powders: A review. Metals 2016, 7, 2. [Google Scholar] [CrossRef]

- Danilov, V.; Gorbatenko, V.; Zuev, L.; Orlova, D.; Danilova, L. Luders deformation of low-carbon steel. Steel Trans. 2017, 47, 662–668. [Google Scholar] [CrossRef]

- Romano, S.; Brückner-Foit, A.; Brandão, A.; Gumpinger, J.; Ghidini, T.; Beretta, S. Fatigue properties of AlSi10Mg obtained by additive manufacturing: Defect-based modelling and prediction of fatigue strength. Eng. Fract. Mech. 2018, 187, 165–189. [Google Scholar] [CrossRef]

- Ahmed, A.; Wahab, M.; Raus, A.; Kamarudin, K.; Bakhsh, Q.; Ali, D. Effects of Selective Laser Melting Parameters on Relative Density of AlSi10Mg. Int. J. Eng. Technol. 2016, 8, 2552–2557. [Google Scholar] [CrossRef]

- Mathe, N.R.; Tshabalala, L.C. The validation of the microstructural evolution of selective laser-melted AlSi10Mg on the in-house built machine: Energy density studies. Prog. Addit. Manuf. 2019. [Google Scholar] [CrossRef]

- Ma, P.; Prashanth, K.; Scudino, S.; Jia, Y.; Wang, H.; Zou, C.; Wei, Z.; Eckert, J. Influence of annealing on mechanical properties of Al-20Si processed by selective laser melting. Metals 2014, 4, 28–36. [Google Scholar] [CrossRef]

- Yadollahi, A.; Mahtabi, M.; Khalili, A.; Doude, H.; Newman, J., Jr. Fatigue life prediction of additively manufactured material: Effects of surface roughness, defect size, and shape. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1602–1614. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Pellegrini, S.; Ambrosio, E.P.; Calignano, F.; Manfredi, D.; Pavese, M.; Fino, P. Effect of heat treatment on corrosion resistance of DMLS AlSi10Mg alloy. Electrochim. Acta 2016, 206, 346–355. [Google Scholar] [CrossRef]

- Fiocchi, J.; Tuissi, A.; Bassani, P.; Biffi, C. Low temperature annealing dedicated to AlSi10Mg selective laser melting products. J. Alloys Compd. 2017, 695, 3402–3409. [Google Scholar] [CrossRef]

- Fousová, M.; Dvorský, D.; Michalcová, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Mfusi, B.; Tshabalala, L.C.; Mathe, N.R. The effect of selective laser melting build orientation on the mechanical properties of AlSi10Mg parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012028. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Ambrosio, E.; Lombardi, M.; Pavese, M.; Manfredi, D.; Fino, P. Effects of heat treatments on A357 alloy produced by selective laser melting. In Proceedings of the World Powder Metallurgy Congress 2016, Hamburg, Germany, 9–13 October 2016; pp. 1–6. [Google Scholar]

- Williams, J.C.; Starke, E.A., Jr. Progress in structural materials for aerospace systems. Acta Mater. 2009, 51, 5775–5799. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. Improving the fatigue behaviour of a selectively laser melted aluminium alloy: Influence of heat treatment and surface quality. Mater. Des. 2016, 104, 174–182. [Google Scholar] [CrossRef]

- Tang, M. Inclusions, Porosity, and Fatigue of Alsi 10mg Parts Produced by Selective Laser Melting. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2017. [Google Scholar]

- Zhao, Y.-H.; Liao, X.-Z.; Cheng, S.; Ma, E.; Zhu, Y.T. Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 2006, 18, 2280–2283. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.; Wang, W.; Attallah, M.; Loretto, M. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Javidani, M.; Arreguin-Zavala, J.; Danovitch, J.; Tian, Y.; Brochu, M. Additive manufacturing of AlSi10Mg alloy using direct energy deposition: Microstructure and hardness characterization. J. Ther. Spray Technol. 2017, 26, 587–597. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, H.; Liao, H.; Cheng, Y.; Hu, Z.; Zeng, X. Effect of heat treatments on fatigue property of selective laser melting AlSi10Mg. Int. J. Fatigue 2018, 116, 513–522. [Google Scholar] [CrossRef]

- Anwar, A.B.; Pham, Q.-C. Selective laser melting of AlSi10Mg: Effects of scan direction, part placement and inert gas flow velocity on tensile strength. J. Mater. Proc. Technol. 2017, 240, 388–396. [Google Scholar] [CrossRef]

- Rosenthal, I.; Tiferet, E.; Ganor, M.; Stern, A. Post-processing of AM-SLM AlSi10Mg specimens: Mechanical properties and fracture behavior. Ann. Dunarea Jos Univ. Galati Fascicle XII Weld. Equip. Technol. 2015, 26, 33–38. [Google Scholar]

- Brandão, A.D.; Gumpinger, J.; Gschweitl, M.; Seyfert, C.; Hofbauer, P.; Ghidini, T. Fatigue properties of additively manufactured AlSi10Mg–surface treatment effect. Procedia Struct. Integr. 2017, 7, 58–66. [Google Scholar] [CrossRef]

- Al-Saedi, D.S.; Masood, S.; Faizan-Ur-Rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar] [CrossRef]

- Wang, L.; Jue, J.; Xia, M.; Guo, L.; Yan, B.; Gu, D. Effect of the thermodynamic behavior of selective laser melting on the formation of in situ oxide dispersion-strengthened aluminum-based composites. Metals 2016, 6, 286. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Yasa, E.; Badrossamay, M.; Kruth, J.P. Process optimization and microstructural analysis for selective laser melting of AlSi10Mg. In Proceedings of the Solid Free Form Fabrication Symposium, Texas, TX, USA, 8–10 August 2011; pp. 484–495. [Google Scholar]

- Zaretsky, E.; Stern, A.; Frage, N. Dynamic response of AlSi10Mg alloy fabricated by selective laser melting. Mater. Sci. Eng. A 2017, 688, 364–370. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Kobayashi, T. Strength and fracture of aluminum alloys. Mater. Sci. Eng. A 2000, 280, 8–16. [Google Scholar] [CrossRef]

- Ruggieri, C.; Dodds, R.H., Jr. A local approach to cleavage fracture modeling: An overview of progress and challenges for engineering applications. Eng. Fract. Mech. 2018, 187, 381–403. [Google Scholar] [CrossRef]

- Scibetta, M. Application of a new cleavage fracture framework to ferritic steels. Procedia Struct. Integr. 2016, 2, 1610–1618. [Google Scholar] [CrossRef]

- Shlyannikov, V. Creep–fatigue crack growth rate prediction based on fracture damage zone models. Eng. Fract. Mech. 2019, 214, 449–463. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

| Orientation | Density (g/cm3) | Porosity (%) | Relative Density (%) |

|---|---|---|---|

| A (0°) | 2.61 ± 0.025 | 2.67 ± 0.92 | 97.33 ± 0.92 |

| B (45°) | 2.60 ± 0.023 | 3.19 ± 0.86 | 96.81 ± 0.86 |

| C (90°) | 2.58 ± 0.027 | 3.82 ± 1.00 | 96.18 ± 1.00 |

| Orientation | HV |

|---|---|

| A (0°) | 43.91 ± 2.44 |

| B (45°) | 47.32 ± 3.35 |

| C (90°) | 47.14 ± 4.16 |

| AS-BUILT | ||||

|---|---|---|---|---|

| Orientation | EBSD Phase Fraction (%) | |||

| Al | Si | Mg2Si | Zero solution | |

| A (0°) | 2.02 | 8.52 | 1.04 | 88.42 |

| B (45°) | 8.80 | 54.17 | 1.19 | 35.84 |

| C (90°) | 11.48 | 37.23 | 3.47 | 47.82 |

| STRESS RELIEVED | ||||

| Orientation | EBSD Phase Fraction (%) | |||

| Al | Si | Mg2Si | Zero solution | |

| A (0°) | 8.13 | 29.13 | 3.20 | 59.54 |

| B (45°) | 3.09 | 10.15 | 1.67 | 85.09 |

| C (90°) | 11.56 | 37.49 | 2.57 | 48.38 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mfusi, B.J.; Mathe, N.R.; Tshabalala, L.C.; Popoola, P.A. The Effect of Stress Relief on the Mechanical and Fatigue Properties of Additively Manufactured AlSi10Mg Parts. Metals 2019, 9, 1216. https://doi.org/10.3390/met9111216

Mfusi BJ, Mathe NR, Tshabalala LC, Popoola PA. The Effect of Stress Relief on the Mechanical and Fatigue Properties of Additively Manufactured AlSi10Mg Parts. Metals. 2019; 9(11):1216. https://doi.org/10.3390/met9111216

Chicago/Turabian StyleMfusi, Busisiwe J., Ntombizodwa R. Mathe, Lerato C. Tshabalala, and Patricia AI. Popoola. 2019. "The Effect of Stress Relief on the Mechanical and Fatigue Properties of Additively Manufactured AlSi10Mg Parts" Metals 9, no. 11: 1216. https://doi.org/10.3390/met9111216

APA StyleMfusi, B. J., Mathe, N. R., Tshabalala, L. C., & Popoola, P. A. (2019). The Effect of Stress Relief on the Mechanical and Fatigue Properties of Additively Manufactured AlSi10Mg Parts. Metals, 9(11), 1216. https://doi.org/10.3390/met9111216