Densification, Microstructure and Properties of 90W-7Ni-3Fe Fabricated by Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

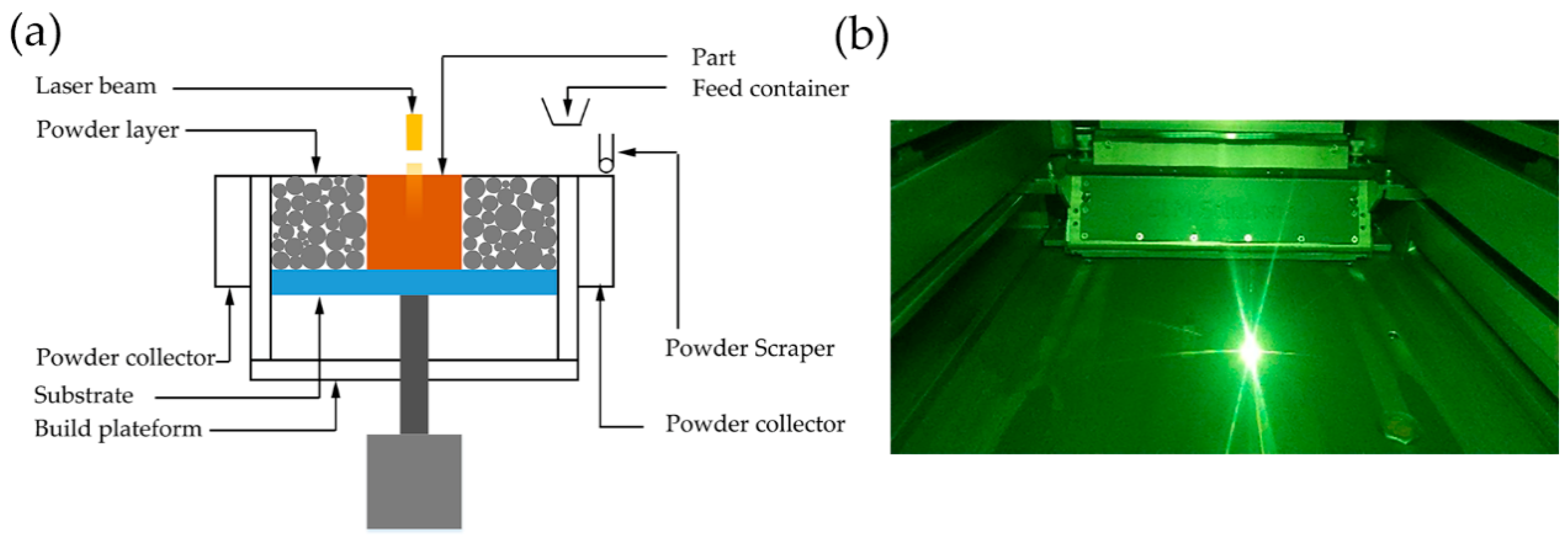

2.1. Experimental Equipment and Preparation

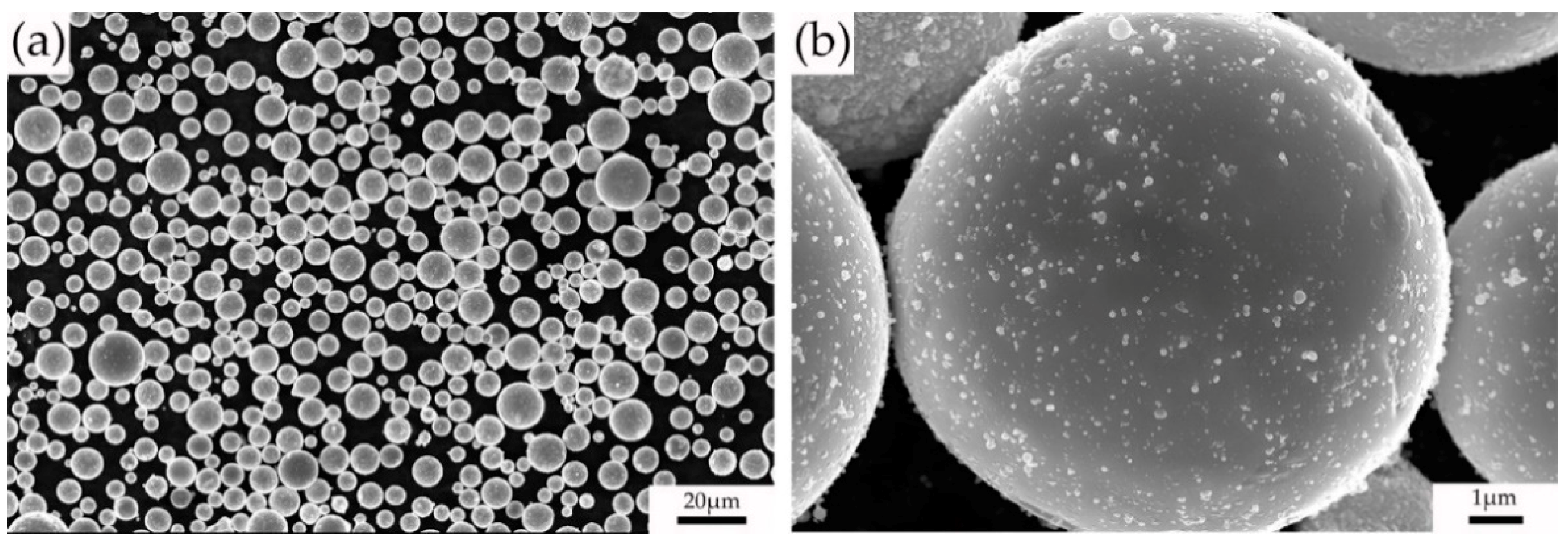

2.2. Powder Material

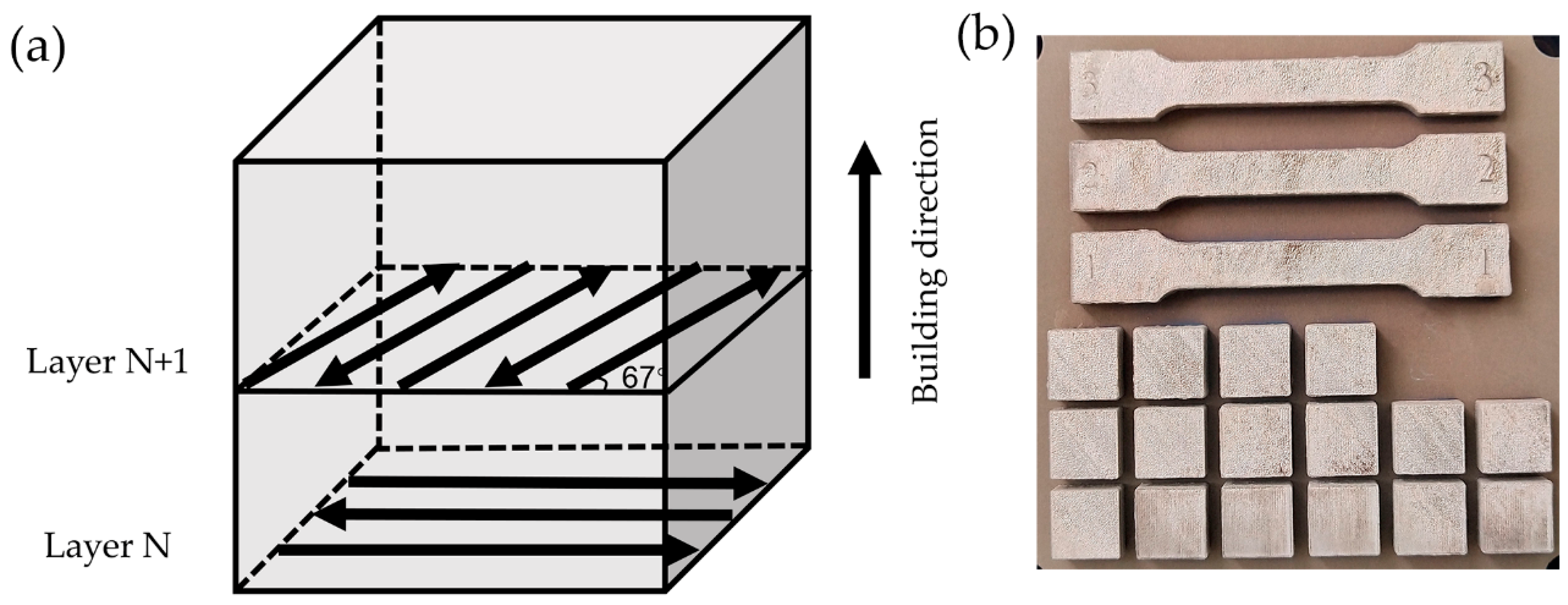

2.3. Process Parameters and Conditions

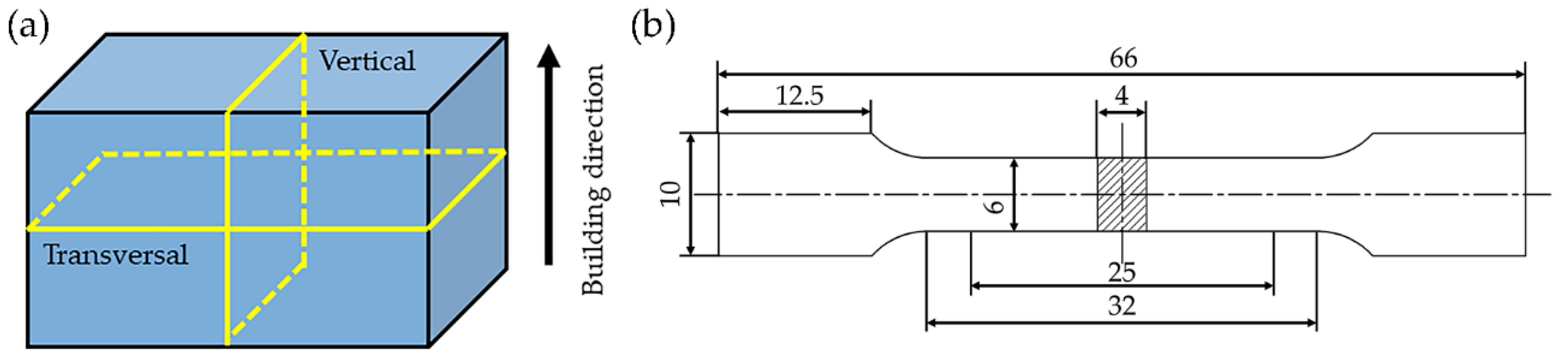

2.4. Characterization and Test

3. Results and Discussion

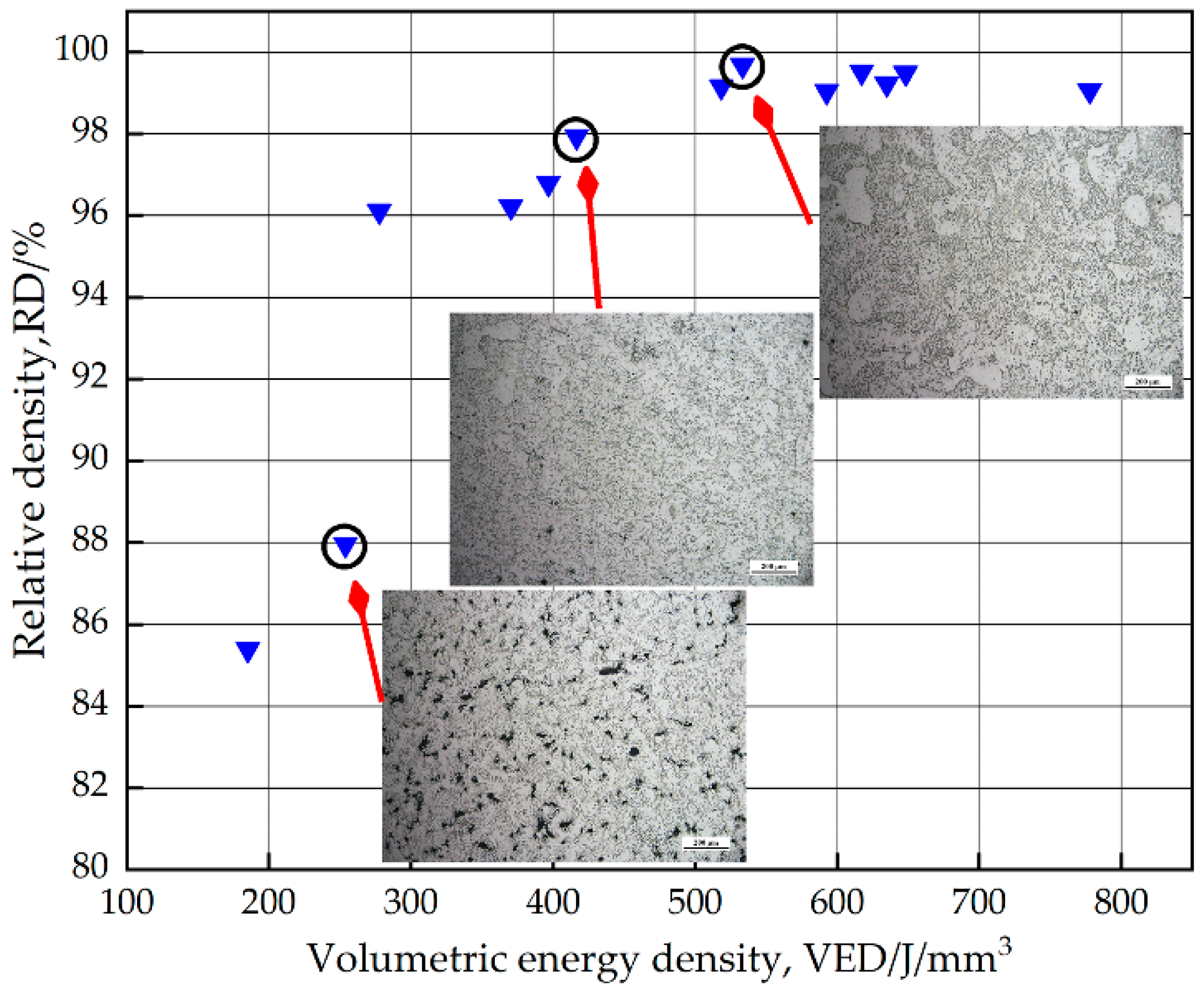

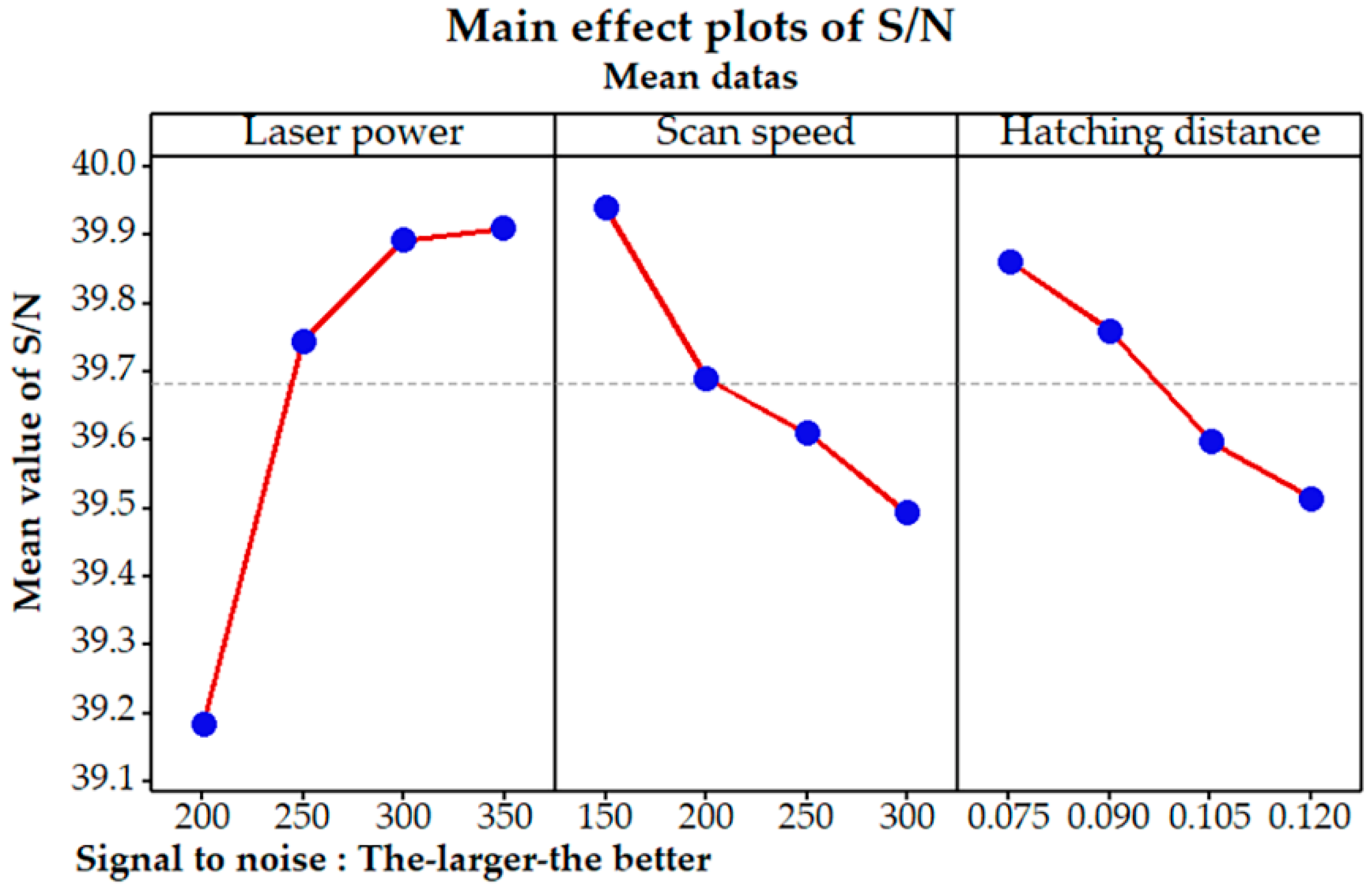

3.1. Densification Analysis

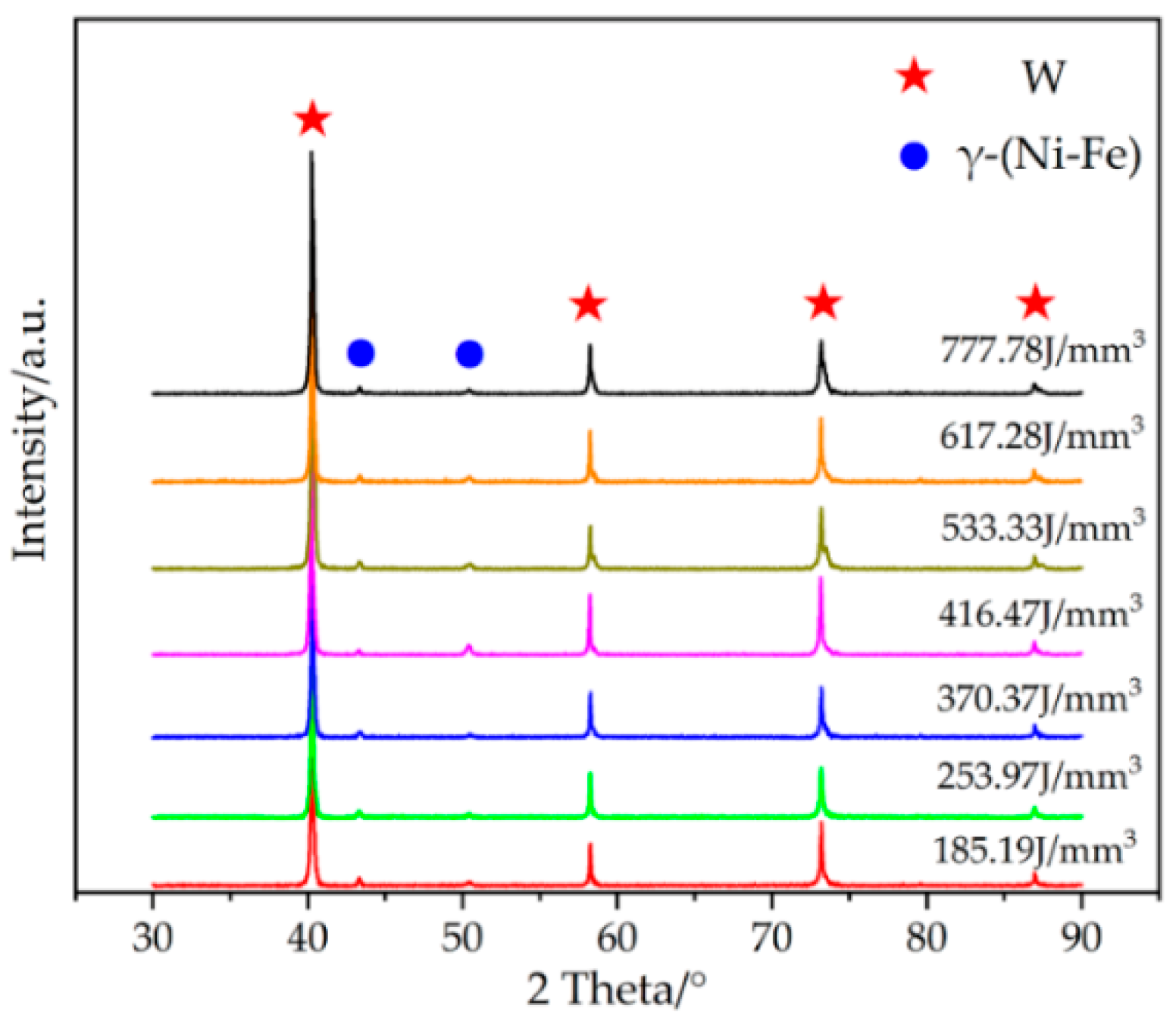

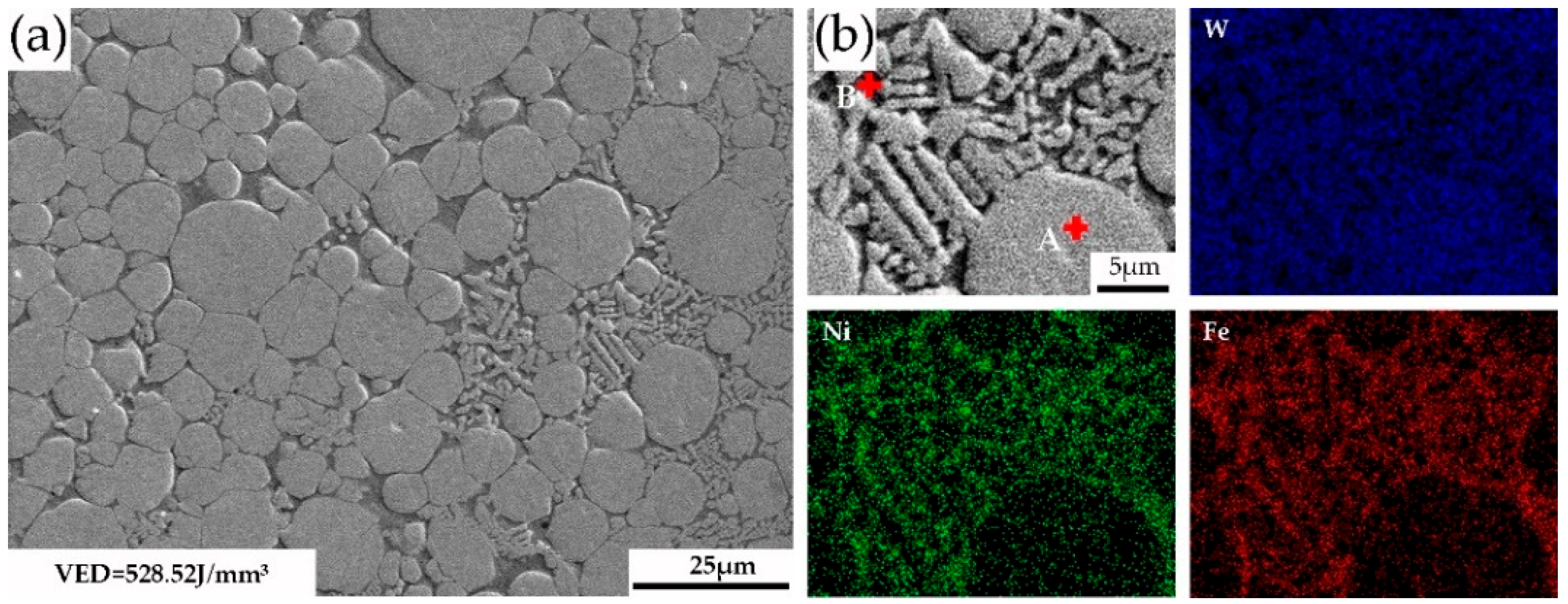

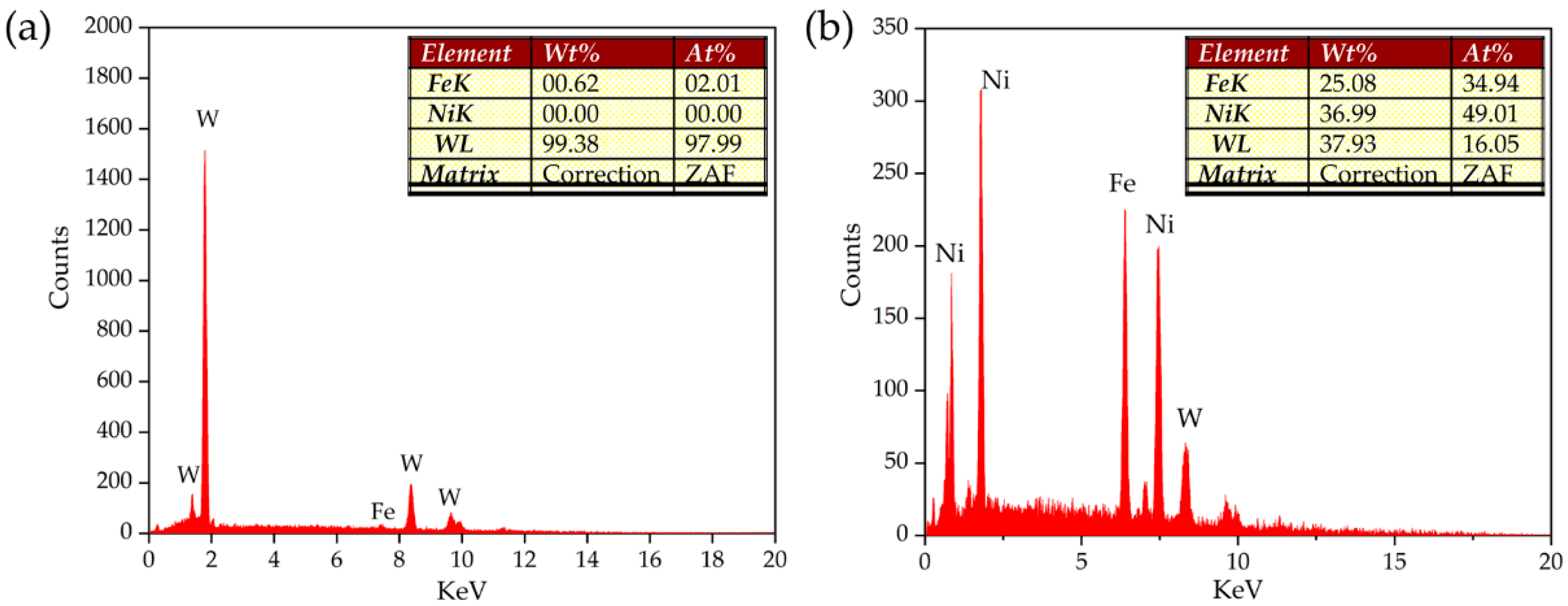

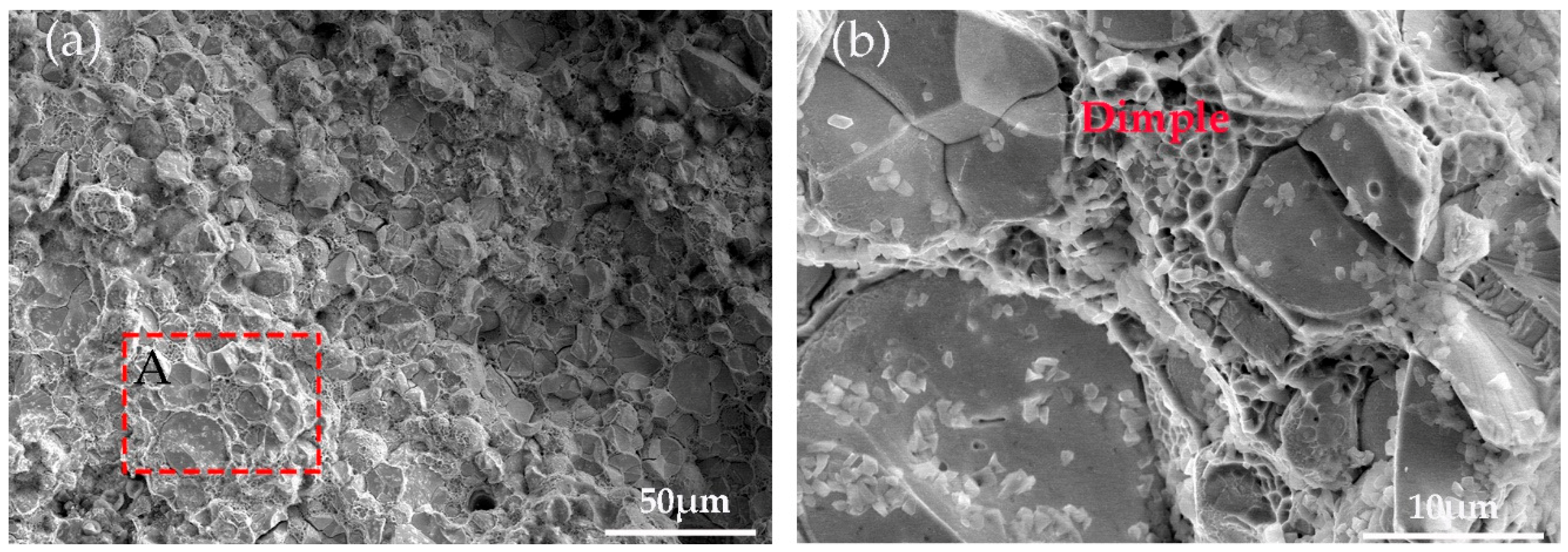

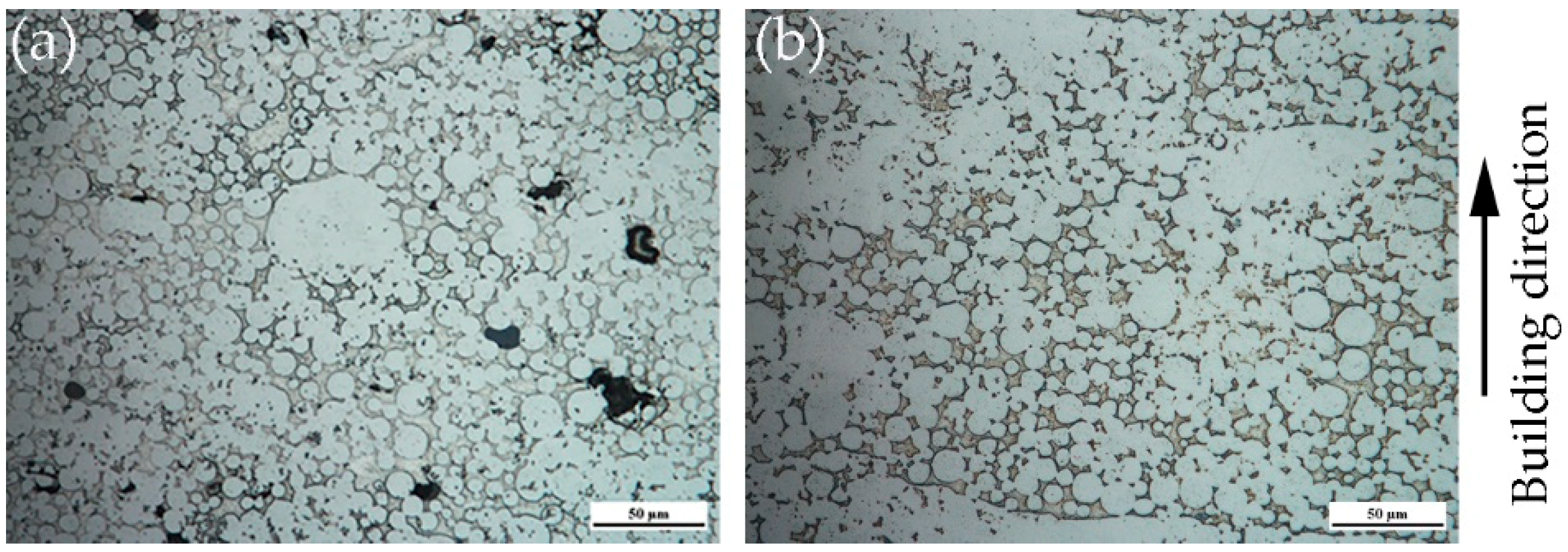

3.2. Phase Identification and Microstructure

3.3. Mechanical Properties

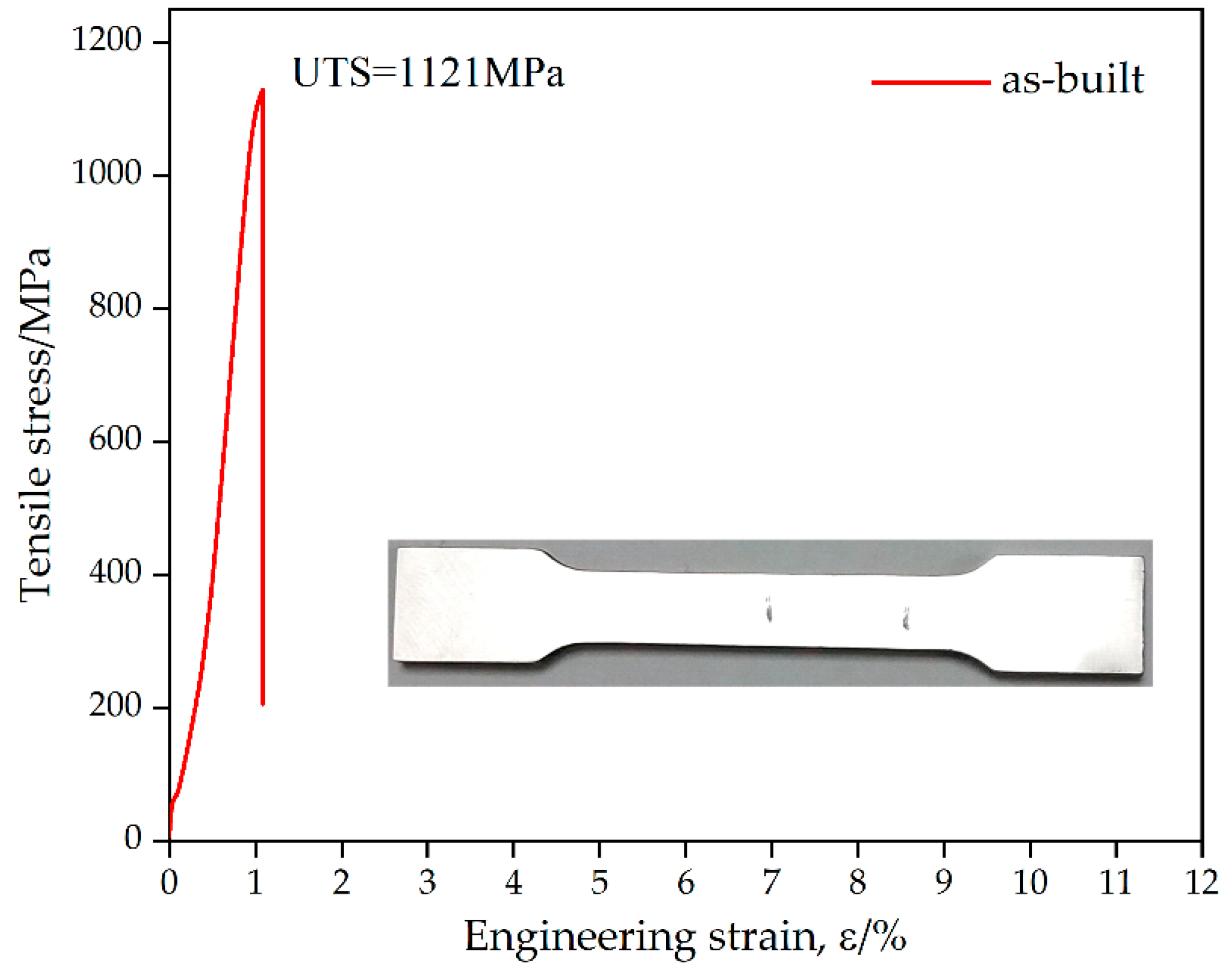

3.3.1. Tensile Properties

3.3.2. Microhardness

4. Conclusions

- (1)

- Nearly a full densification (≥99%) of the tungsten heavy alloy (WHA) sample was obtained by SLM. With the increase of VED, the relative density of WHA increased significantly. The value of VED should be no less than 300 J/mm3, so that the high relative density of the 90W-7Ni-3Fe components could be obtained. Among the three influencing factors, laser power had the most significant effect on the relative density, and a higher laser power (≥250 W) was preferred. The forming mechanism in this work presented a liquid phase sintering characteristic, which was similar to that in traditional powder metallurgy.

- (2)

- The typical microstructure of WHA was composed of a tungsten particle phase and a γ-(Ni-Fe) matrix phase with dissolved tungsten. Three main regions can be found, including the tungsten particle phase, the fine tungsten dendrite region, and the Ni-Fe matrix region with dissolved W. The tungsten particle gaps were fully filled with the liquid phase, which contributed to the densification behavior. Fine W dendrites formed due to rapid melting and solidification in the process of SLM, and un-melted tungsten particles acted as a heterogenous nucleation site.

- (3)

- The high tensile strength (UTS = 1121 MPa) of WHA was obtained in this work. Compared with traditional liquid phase sintering, SLM realized a significant enhancement of tensile strength but poor elongation. In addition, all samples under different VEDs presented a high microhardness, and the microhardness showed a slight increase with an increase of VED. Microhardness fluctuated along the building direction of the samples. This fluctuation was caused by building defects and an uneven microstructure.

Author Contributions

Funding

Conflicts of Interest

References

- Jiao, Z.H.; Kang, R.K.; Dong, Z.G.; Guo, J. Microstructure characterization of W-Ni-Fe heavy alloys with optimized metallographic preparation method. Int. J. Refract. Met. Hard Mat. 2019, 80, 114–122. [Google Scholar] [CrossRef]

- Deng, S.H.; Yuan, T.C.; Li, R.D.; Zeng, F.H.; Liu, G.H.; Zhou, X. Spark plasma sintering of pure tungsten powder: Densification kinetics and grain growth. Powder Technol. 2017, 310, 264–271. [Google Scholar] [CrossRef]

- Roedig, M.; Kuehnlein, W.; Linke, J.; Merola, M.; Rigal, E.; Schedler, B.; Visca, E. Investigation of tungsten alloys as plasma facing materials for the ITER divertor. Fusion Eng. Des. 2002, 61, 135–140. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Gumbsch, P. Brittle fracture and the brittle-to-ductile transition of tungsten. J. Nucl. Mater. 2003, 323, 304–312. [Google Scholar] [CrossRef]

- Akhtar, F. An investigation on the solid state sintering of mechanically alloyed nano-structured 90W–Ni–Fe tungsten heavy alloy. Int. J. Refract. Met. Hard Mat. 2008, 26, 145–151. [Google Scholar] [CrossRef]

- Senthilnathan, N.; Annamalai, A.R.; Venkatachalam, G. Sintering of tungsten and tungsten heavy alloys of W–Ni–Fe and W–Ni–Cu: A review. Trans. Indian Inst. Met. 2017, 70, 1161–1176. [Google Scholar] [CrossRef]

- German, R.M.; Churn, K.S. Sintering atmosphere effects on the ductility of W-Ni-Fe heavy metals. Metall. Trans. A 1984, 15, 747–754. [Google Scholar] [CrossRef]

- Durlu, N.; Çalişkan, N.K.; Bor, Ş. Effect of swaging on microstructure and tensile properties of W–Ni–Fe alloys. Int. J. Refract. Met. Hard Mat. 2014, 42, 126–131. [Google Scholar] [CrossRef]

- Das, J.; Rao, G.A.; Pabi, S.K. Microstructure and mechanical properties of tungsten heavy alloys. Mater. Sci. Eng. A 2010, 527, 7841–7847. [Google Scholar] [CrossRef]

- Deprez, K.; Vandenberghe, S.; Van Audenhaege, K.; Van Vaerenbergh, J.; Van Holen, R. Rapid additive manufacturing of MR compatible multipinhole collimators with selective laser melting of tungsten powder. Med. Phys. 2013, 40, 012501. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.Q.; Cai, Q.Z.; Liu, J.H. Formation of nanocrystalline tungsten by selective laser melting of tungsten powder. Mater. Manuf. Process. 2012, 27, 1267–1270. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.H.; Zhang, D.Q.; Shen, Z.J.; Liu, W. Balling phenomena in selective laser melted tungsten. J. Mater. Process. Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Enneti, R.K.; Morgan, R.; Atre, S.V. Effect of process parameters on the Selective Laser Melting (SLM) of tungsten. Int. J. Refract. Met. Hard Mat. 2018, 71, 315–319. [Google Scholar] [CrossRef]

- Wen, S.F.; Wang, C.; Zhou, Y.; Duan, L.C.; Wei, Q.S.; Yang, S.F.; Shi, Y.F. High-density tungsten fabricated by selective laser melting: Densification, microstructure, mechanical and thermal performance. Opt. Laser Technol. 2019, 116, 128–138. [Google Scholar] [CrossRef]

- Tan, C.L.; Zhou, K.S.; Ma, W.Y.; Attard, B.; Zhang, P.P.; Kuang, T.C. Selective laser melting of high-performance pure tungsten: Parameter design, densification behavior and mechanical properties. Sci. Technol. Adv. Mater. 2018, 19, 370–380. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Gu, D.D.; Xi, L.X.; Du, L.; Zhang, H.M.; Zhang, J.Y. Formation of scanning tracks during Selective Laser Melting (SLM) of pure tungsten powder: Morphology, geometric features and forming mechanisms. Int. J. Refract. Met. Hard Mat. 2019, 79, 37–46. [Google Scholar] [CrossRef]

- Wang, D.Z.; Li, K.L.; Yu, C.F.; Ma, J.; Liu, W.; Shen, Z.J. Cracking behavior in additively manufactured pure tungsten. Acta Metall. Sin. 2019, 32, 127–135. [Google Scholar] [CrossRef]

- Müller, A.V.; Schlick, G.; Neu, R.; Anstätt, C.; Klimkait, T.; Lee, J.; Seidel, C. Additive manufacturing of pure tungsten by means of selective laser beam melting with substrate preheating temperatures up to 1000 °C. Nucl. Mater. Energy 2019, 19, 184–188. [Google Scholar] [CrossRef]

- Li, K.L.; Wang, D.Z.; Xing, L.L.; Wang, Y.F.; Yu, C.F.; Chen, J.H.; Zhang, T.; Ma, J.; Liu, W.; Shen, Z.J. Crack suppression in additively manufactured tungsten by introducing secondary-phase nanoparticles into the matrix. Int. J. Refract. Met. Hard Mat. 2019, 79, 158–163. [Google Scholar] [CrossRef]

- Iveković, A.; Omidvari, N.; Vrancken, B.; Lietaert, K.; Thijs, L.; Vanmeensel, K.; Kruth, J.P. Selective laser melting of tungsten and tungsten alloys. Int. J. Refract. Met. Hard Mat. 2018, 72, 27–32. [Google Scholar] [CrossRef]

- Li, R.D.; Shi, Y.S.; Liu, J.H.; Xie, Z.; Wang, Z.G. Selective laser melting W–10 wt.% Cu composite powders. Int. J. Adv. Manuf. Technol. 2010, 48, 597–605. [Google Scholar] [CrossRef]

- Iveković, A.; Montero-Sistiaga, M.L.; Vanmeensel, K.; Kruth, J.P.; Vleugels, J. Effect of processing parameters on microstructure and properties of tungsten heavy alloys fabricated by SLM. Int. J. Refract. Met. Hard Mat. 2019, 82, 23–30. [Google Scholar] [CrossRef]

- Li, R.D.; Liu, J.H.; Shi, Y.S.; Zhang, L.; Du, M.Z. Effects of processing parameters on rapid manufacturing 90W–7Ni–3Fe parts via selective laser melting. Powder Metall. 2010, 53, 310–317. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Cai, Q.Z.; Liu, J.H.; Zhang, L.; Li, R.D. Select laser melting of W–Ni–Fe powders: Simulation and experimental study. Int. J. Adv. Manuf. Technol. 2010, 51, 649–658. [Google Scholar] [CrossRef]

- Ding, L.; Xiang, D.P.; Li, Y.Y.; Li, C.; Li, J.B. Effects of sintering temperature on fine-grained tungsten heavy alloy produced by high-energy ball milling assisted spark plasma sintering. Int. J. Refract. Met. Hard Mat. 2012, 33, 65–69. [Google Scholar] [CrossRef]

- Bollina, R.; German, R.M. Heating rate effects on microstructural properties of liquid phase sintered tungsten heavy alloys. Int. J. Refract. Met. Hard Mat. 2004, 22, 117–127. [Google Scholar] [CrossRef]

- Joguet, D.; Costil, S.; Liao, H.; Danlos, Y. Porosity content control of CoCrMo and titanium parts by Taguchi method applied to selective laser melting process parameter. Rapid Prototyp. J. 2016, 22, 20–30. [Google Scholar] [CrossRef]

- Sun, J.F.; Yang, Y.Q.; Wang, D. Parametric optimization of selective laser melting for forming Ti6Al4V samples by Taguchi method. Opt. Laser Technol. 2013, 49, 118–124. [Google Scholar] [CrossRef]

- Kong, X.; Yang, L.; Zhang, H.; Chi, G.; Wang, Y. Optimization of surface roughness in laser-assisted machining of metal matrix composites using Taguchi method. Int. J. Adv. Manuf. Technol. 2017, 89, 529–542. [Google Scholar] [CrossRef]

- Leitz, K.H.; Singer, P.; Plankensteiner, A.; Tabernig, B.; Kestler, H.; Sigl, L.S. Multi-physical simulation of selective laser melting. Metal Powder Rep. 2017, 72, 331–338. [Google Scholar] [CrossRef]

- Erol, M.; Erdoğan, M.; Karakaya, İ. Effects of fabrication method on initial powder characteristics and liquid phase sintering behaviour of tungsten. Int. J. Refract. Met. Hard Mat. 2018, 77, 82–89. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Liu, Z.H.; Cai, Q.Z.; Liu, J.H.; Chua, C.K. Influence of Ni content on microstructure of W–Ni alloy produced by selective laser melting. Int. J. Refract. Met. Hard Mat. 2014, 45, 15–22. [Google Scholar] [CrossRef]

- Wang, M.; Li, R.; Yuan, T.; Chen, C.; Zhang, M.; Weng, Q.; Yuan, J. Selective laser melting of W-Ni-Cu composite powder: Densification, microstructure evolution and nano-crystalline formation. Int. J. Refract. Met. Hard Mat. 2018, 70, 9–18. [Google Scholar] [CrossRef]

- Liu, W.; Ma, Y.; Zhang, J. Properties and microstructural evolution of W-Ni-Fe alloy via microwave sintering. Int. J. Refract. Met. Hard Mat. 2012, 35, 138–142. [Google Scholar] [CrossRef]

- Hitzler, L.; Janousch, C.; Schanz, J.; Merkel, M.; Heine, B.; Mack, F.; Öchsner, A. Direction and location dependency of selective laser melted AlSi10Mg specimens. J. Mater. Process Tech. 2017, 243, 48–61. [Google Scholar] [CrossRef]

| Process Parameter/Unit | Value |

|---|---|

| Laser power, LP/W | 200, 250, 300, 350 |

| Scan speed, SS/(mm/s) | 150, 200, 250, 300 |

| Hatching distance, HD/mm | 0.075, 0.09, 0.105, 0.12 |

| Layer thickness, LT/mm | 0.03 |

| NO. | LP/W | SS/(mm/s) | HD/mm | VED/(J/mm3) |

|---|---|---|---|---|

| 1 | 200 | 150 | 0.075 | 592.59 |

| 2 | 200 | 200 | 0.09 | 370.37 |

| 3 | 200 | 250 | 0.105 | 253.97 |

| 4 | 200 | 300 | 0.12 | 185.19 |

| 5 | 250 | 150 | 0.09 | 617.28 |

| 6 | 250 | 200 | 0.105 | 396.83 |

| 7 | 250 | 250 | 0.12 | 277.78 |

| 8 | 250 | 300 | 0.075 | 370.37 |

| 9 | 300 | 150 | 0.105 | 634.92 |

| 10 | 300 | 200 | 0.12 | 416.47 |

| 11 | 300 | 250 | 0.09 | 533.33 |

| 12 | 300 | 300 | 0.075 | 370.37 |

| 13 | 350 | 150 | 0.12 | 648.15 |

| 14 | 350 | 200 | 0.09 | 777.78 |

| 15 | 350 | 250 | 0.075 | 518.52 |

| 16 | 350 | 300 | 0.105 | 370.37 |

| Levels | 1 | 2 | 3 | 4 | Delta | Rank |

|---|---|---|---|---|---|---|

| Laser power/W | 39.18 | 39.75 | 39.89 | 39.91 | 0.73 | 1 |

| Scan speed/(mm/s) | 39.94 | 39.69 | 39.61 | 39.49 | 0.45 | 2 |

| Hatch distance/mm | 39.86 | 39.76 | 39.60 | 39.51 | 0.35 | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wei, Z.; Zhou, B.; Wu, Y.; Chen, S.-G.; Sun, Z. Densification, Microstructure and Properties of 90W-7Ni-3Fe Fabricated by Selective Laser Melting. Metals 2019, 9, 884. https://doi.org/10.3390/met9080884

Li J, Wei Z, Zhou B, Wu Y, Chen S-G, Sun Z. Densification, Microstructure and Properties of 90W-7Ni-3Fe Fabricated by Selective Laser Melting. Metals. 2019; 9(8):884. https://doi.org/10.3390/met9080884

Chicago/Turabian StyleLi, Junfeng, Zhengying Wei, Bokang Zhou, Yunxiao Wu, Sheng-Gui Chen, and Zhenzhong Sun. 2019. "Densification, Microstructure and Properties of 90W-7Ni-3Fe Fabricated by Selective Laser Melting" Metals 9, no. 8: 884. https://doi.org/10.3390/met9080884

APA StyleLi, J., Wei, Z., Zhou, B., Wu, Y., Chen, S.-G., & Sun, Z. (2019). Densification, Microstructure and Properties of 90W-7Ni-3Fe Fabricated by Selective Laser Melting. Metals, 9(8), 884. https://doi.org/10.3390/met9080884