Grain Size Effect on the Mechanical Behavior of Metastable Fe-23Cr-8.5Ni Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- (1)

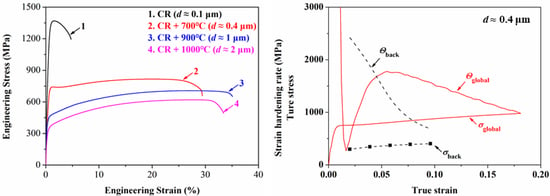

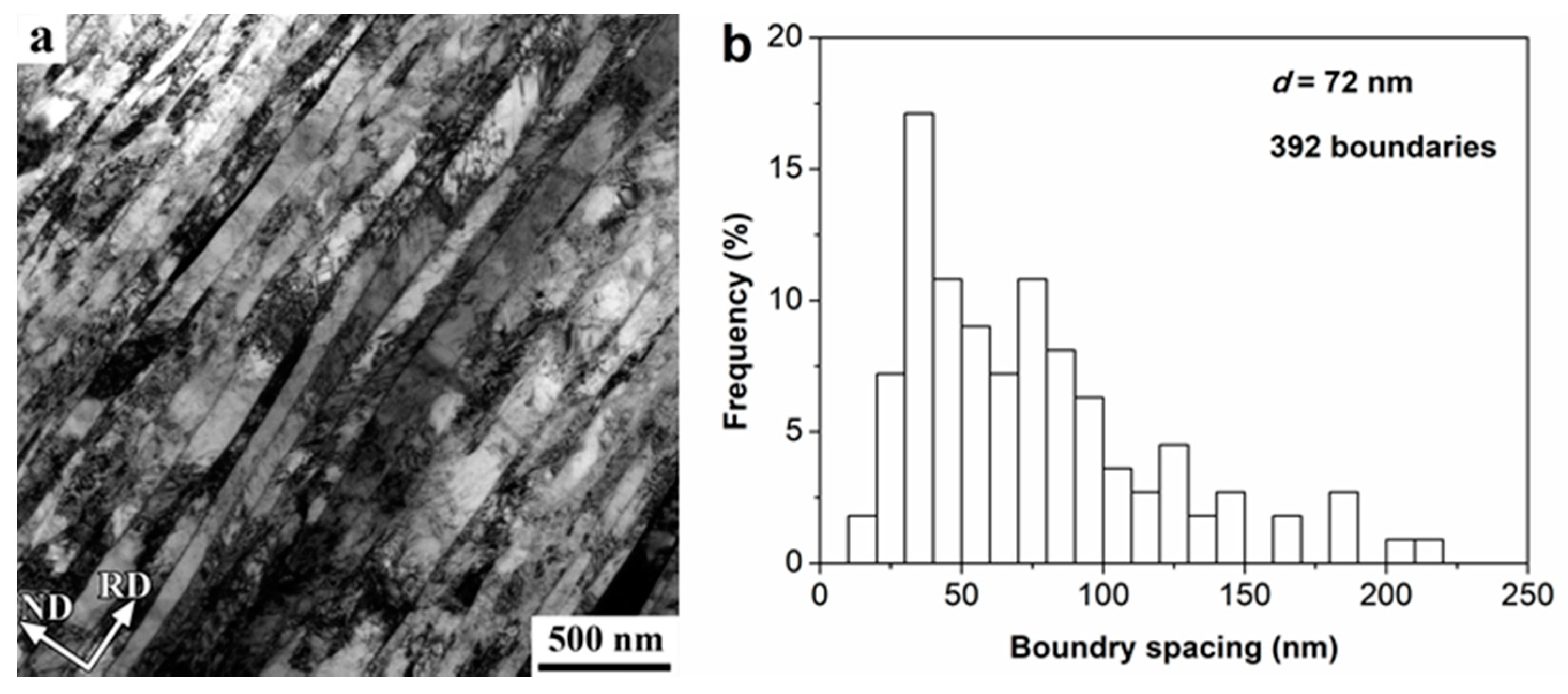

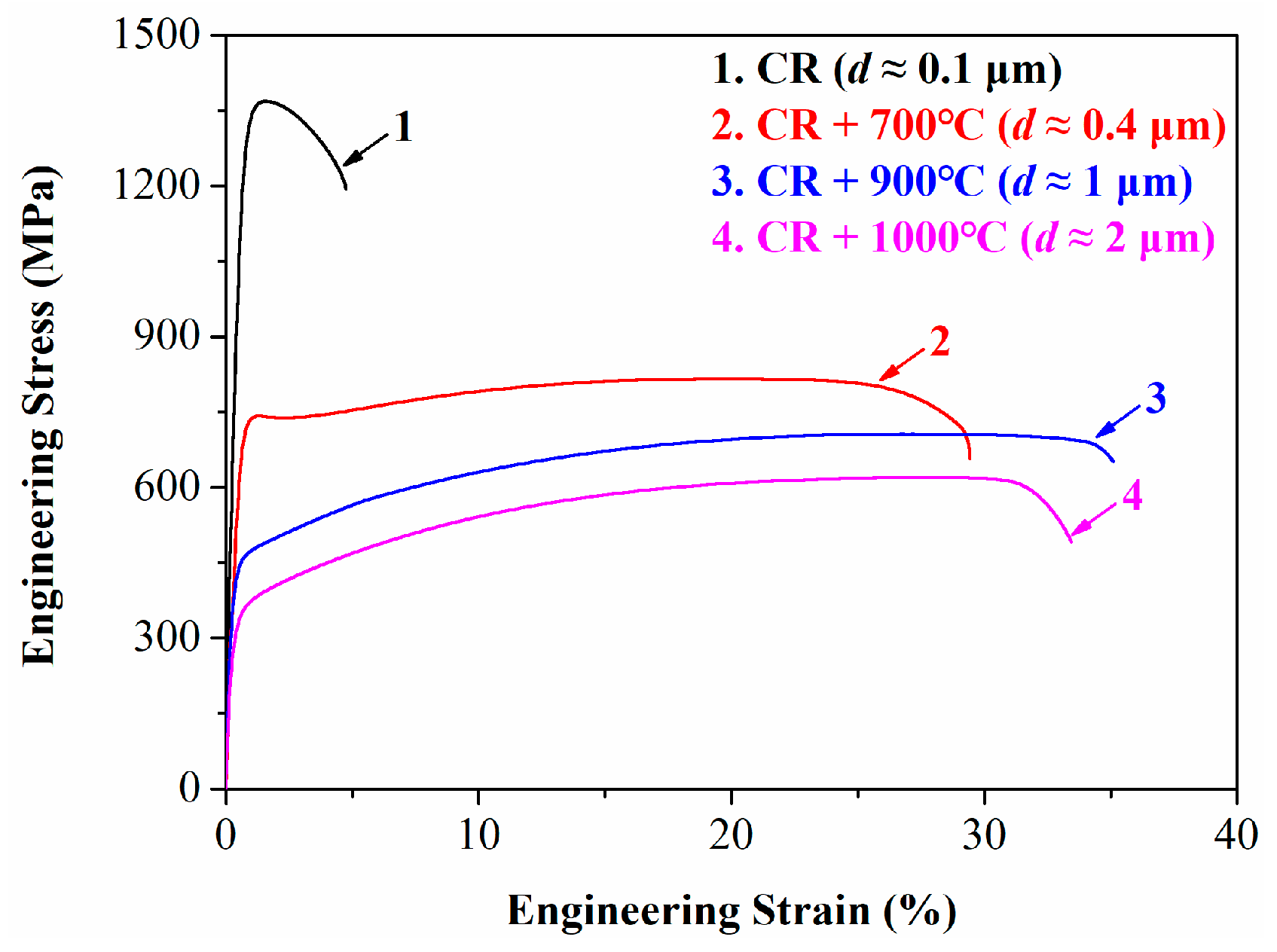

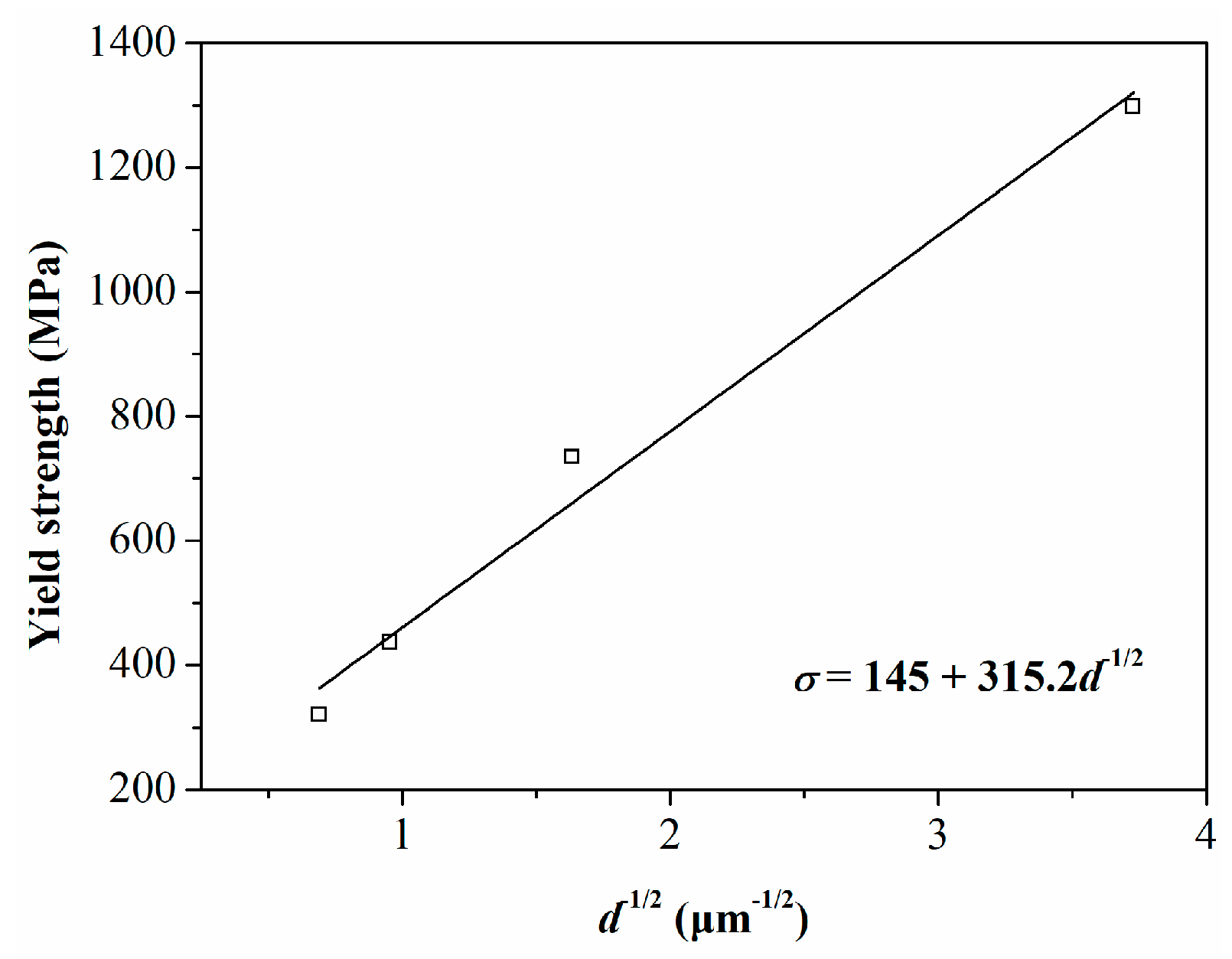

- Heavy cold-rolling leads to complete DIMT and significant structural refinement, resulting in a laminated structure with an average lamellar spacing of 72 nm, which gives the alloy a high yield strength of 1.3 GPa but a limited tensile elongation below 5%.

- (2)

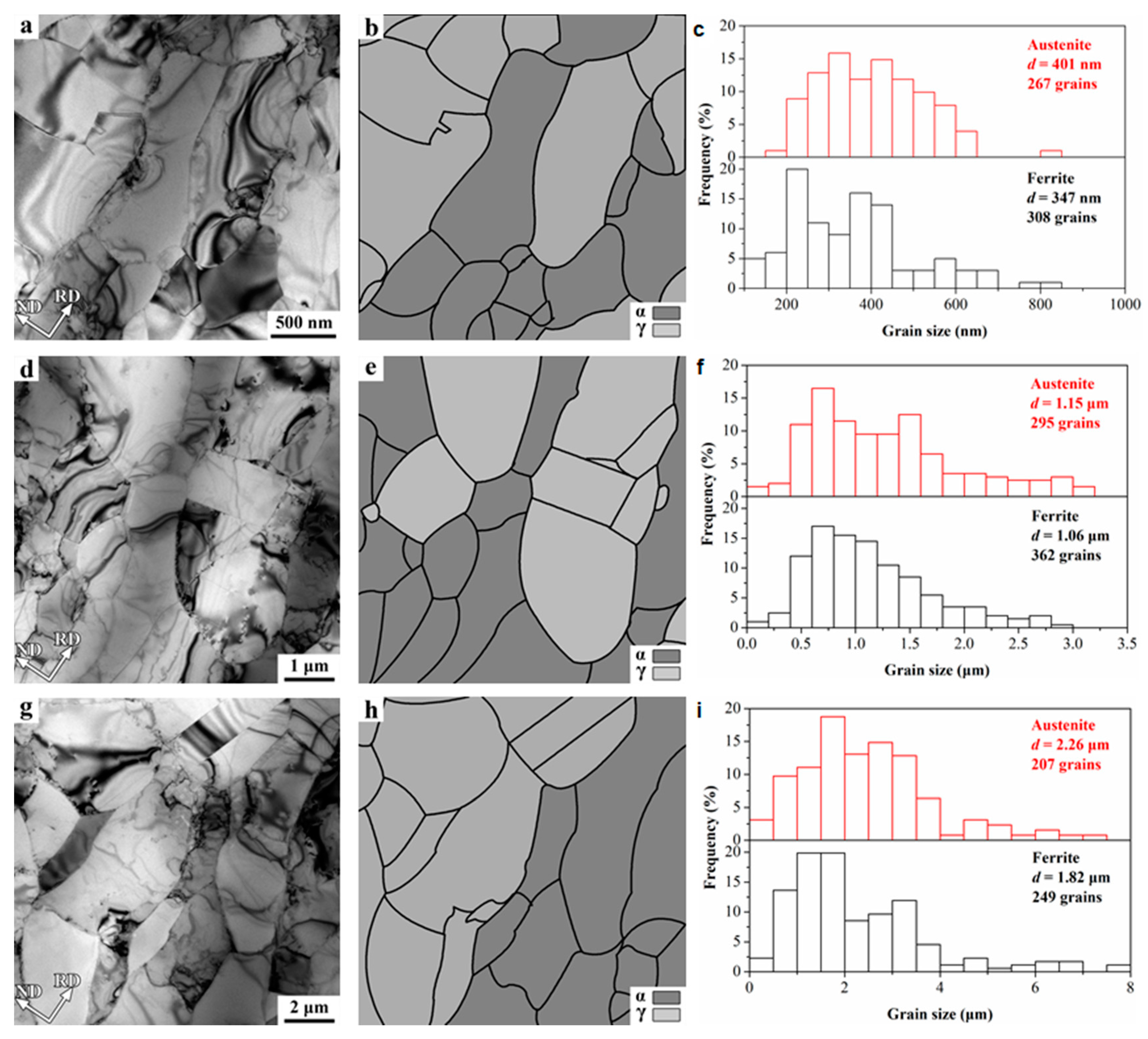

- Annealing of the cold-rolled alloy at 700–1000 °C for 30 min leads to structural coarsening accompanied by a complete austenite reversion, resulting in decreased yield strength and improved ductility.

- (3)

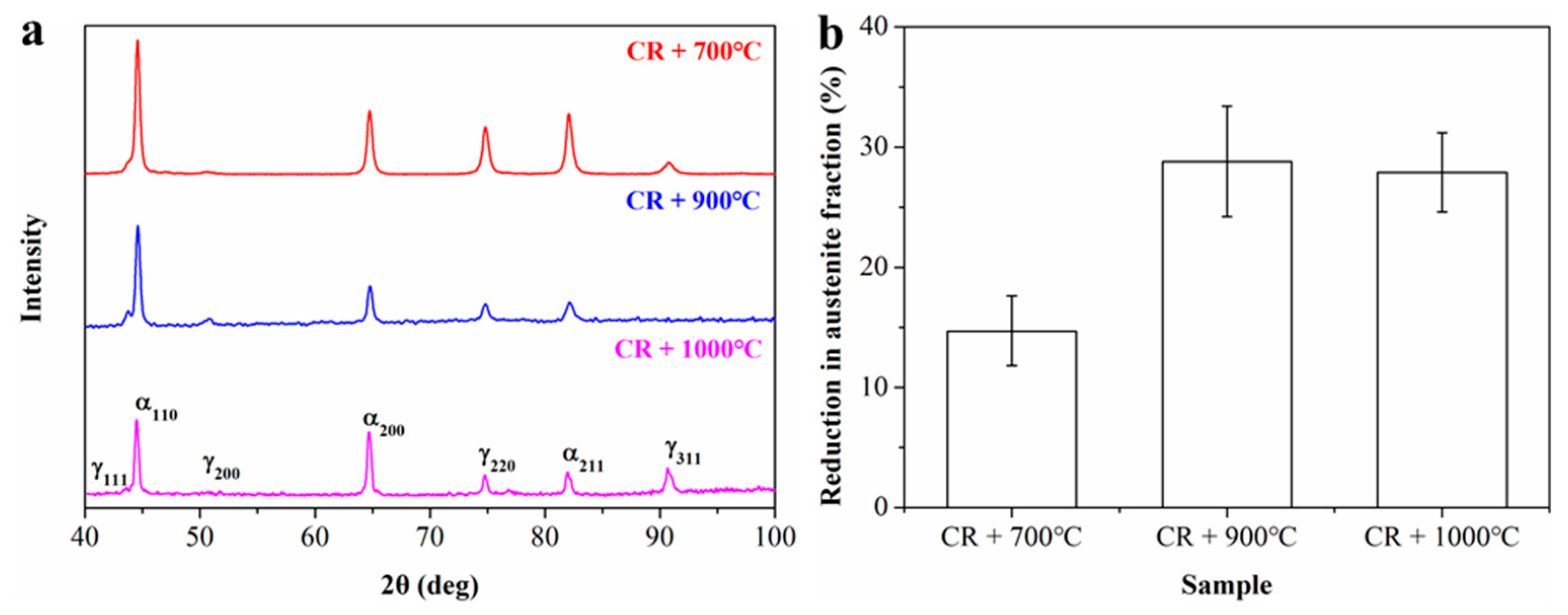

- Quantification of DIMT during tensile tests shows that the increase of austenite grain size from 401 nm to 1.1 μm leads to an increase of the volume fraction of DIMT from 14.7% to 28.4%. A further increase of austenite grain size from 1.1 to 2.3 μm results in negligible change in the DIMT quantification.

- (4)

- An excellent combination of strength and ductility was observed in the sample with an average grain size of 401 nm for austenite and 347 nm for ferrite. The yield strength and tensile elongation are increased up to 738 MPa and 29% as compared to 320 MPa and 33% of its CG (2.3 μm for austenite and 1.8 μm for ferrite) counterpart, respectively.

- (5)

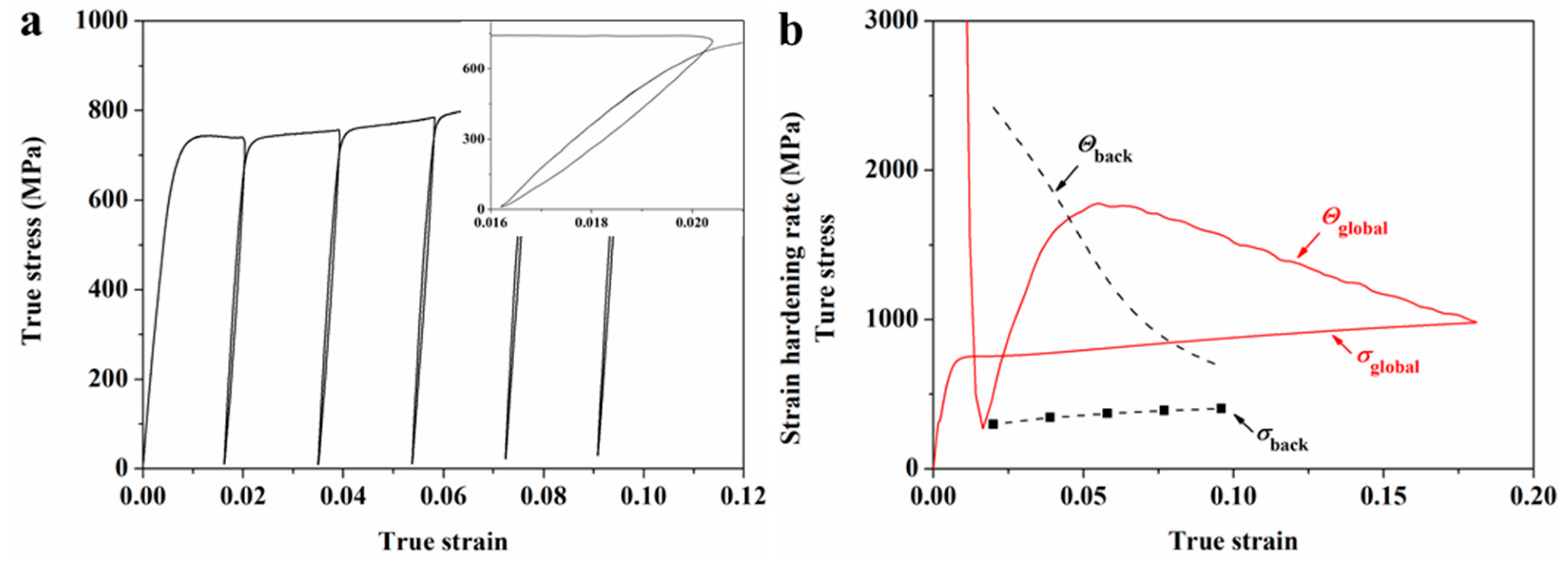

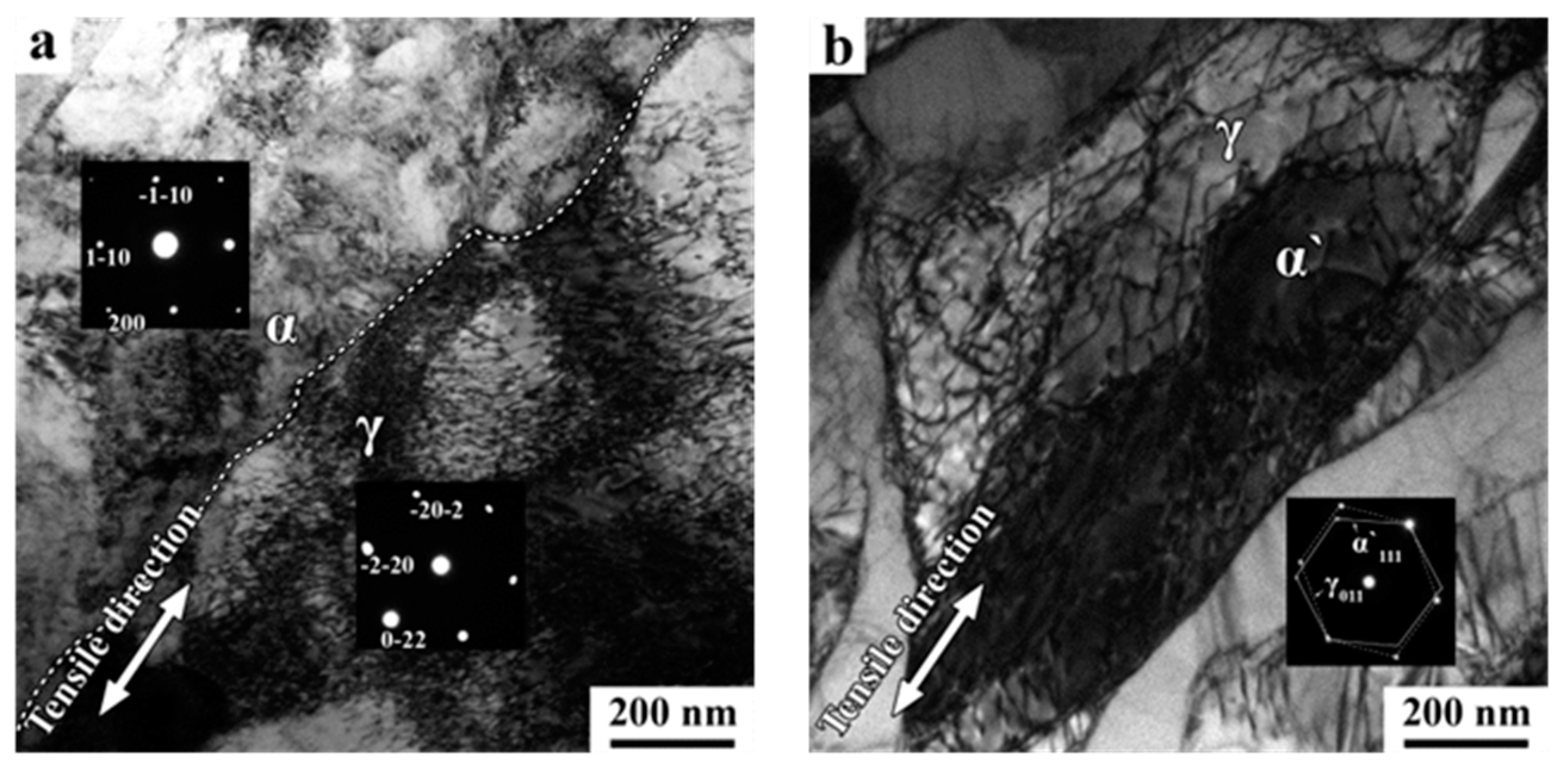

- The excellent strength-ductility balance at the UFG scale can be attributed to the TRIP effect and the development of back stress resulting from the strain incompatibility between austenite, ferrite, and deformation induced martensite.

Author Contributions

Funding

Conflicts of Interest

References

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef] [PubMed]

- Niu, G.; Wu, H.; Zhang, D.; Gong, N.; Tang, D. Study on microstructure and properties of bimodal structured ultrafine-grained ferrite steel. Metals 2017, 7, 316. [Google Scholar] [CrossRef]

- Wu, X.; Tao, N.; Hong, Y.; Lu, J.; Lu, K. γ→ε martensite transformation and twinning deformation in fcc cobalt during surface mechanical attrition treatment. Scr. Mater. 2005, 52, 547–551. [Google Scholar] [CrossRef]

- Ma, Y.; Jin, J.E.; Lee, Y.K. A repetitive thermomechanical process to produce nano-crystalline in a metastable austenitic steel. Scr. Mater. 2005, 52, 1311–1315. [Google Scholar] [CrossRef]

- Koch, C.C.; Scattergood, R.O.; Murty, K.L. The mechanical behavior of multiphase nanocrystalline materials. JOM 2007, 59, 66–70. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, B.; et al. An overview of dual-phase steels: Advances in microstructure-oriented processing and micromechanically guided design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Ankem, S.; Margolin, H.; Greene, C.A.; Neuberger, B.W.; Oberson, P.G. Mechanical properties of alloys consisting of two ductile phases. Prog. Mater. Sci. 2006, 51, 632–709. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, F.P.; Jiang, P.; Xie, J.J.; Wu, X.L. Simultaneous improvement of tensile strength and ductility in micro-duplex structure consisting of austenite and ferrite. Mater. Sci. Eng. A 2014, 618, 563–571. [Google Scholar] [CrossRef]

- Choi, J.Y.; Ji, J.H.; Hwang, S.W.; Park, K.T. Strain induced martensitic transformation of Fe–20Cr–5Mn–0.2 Ni duplex stainless steel during cold rolling: effects of nitrogen addition. Mater. Sci. Eng. A 2011, 528, 6012–6019. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Pardal, J.M.; Da Silva, M.R.; De Oliveira, C.A.S. Martensitic transformation induced by cold deformation of lean duplex stainless steel UNS S32304. Mater. Res. 2014, 17, 381–385. [Google Scholar] [CrossRef]

- Breda, M.; Brunelli, K.; Grazzi, F.; Scherillo, A.; Calliari, I. Effects of cold rolling and strain-induced martensite formation in a SAF 2205 duplex stainless steel. Metall. Mater. Trans. A 2015, 46, 577–586. [Google Scholar] [CrossRef]

- Jacques, P.; Furnémont, Q.; Mertens, A.; Delannay, F. On the sources of work hardening in multiphase steels assisted by transformation-induced plasticity. Philos. Mag. A 2001, 81, 1789–1812. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, D.I.; Kim, H.S.; Bhadeshia, H.K.D.H.; Suh, D.W. Strain partitioning and mechanical stability of retained austenite. Scr. Mater. 2010, 63, 297–299. [Google Scholar] [CrossRef]

- Jin, J.E.; Jung, Y.S.; Lee, Y.K. Effect of grain size on the uniform ductility of a bulk ultrafine-grained alloy. Mater. Sci. Eng. A 2007, 449, 786–789. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Iwasaki, T.; Nakada, N.; Tsuchiyama, T.; Takaki, S. Effect of grain size on thermal and mechanical stability of austenite in metastable austenitic stainless steel. ISIJ Int. 2013, 53, 1224–1230. [Google Scholar] [CrossRef]

- Kisko, A.; Misra, R.D.K.; Talonen, J.; Karjalainen, L.P. The influence of grain size on the strain-induced martensite formation in tensile straining of an austenitic 15Cr–9Mn–Ni–Cu stainless steel. Mater. Sci. Eng. A 2013, 578, 408–416. [Google Scholar] [CrossRef]

- De, A.K.; Murdock, D.C.; Mataya, M.C.; Speer, J.G.; Matlock, D.K. Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scr. Mater. 2004, 50, 1445–1449. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, F.; Jiang, P.; Wu, X. Mechanical properties and nanostructures in a duplex stainless steel subjected to equal channel angular pressing. Mater. Sci. Eng. A 2012, 551, 154–159. [Google Scholar] [CrossRef]

- Dakhlaoui, R.; Braham, C.; Baczmański, A. Mechanical properties of phases in austeno-ferritic duplex stainless steel—Surface stresses studied by X-ray diffraction. Mater. Sci. Eng. A 2007, 444, 6–17. [Google Scholar] [CrossRef]

- Sinclair, C.W.; Saada, G.; Embury, J.D. Role of internal stresses in co-deformed two-phase materials. Philos. Mag. 2006, 86, 4081–4098. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: a new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Hu, J.C.; Song, H.M.; Jin, X.J. Compatible strain evolution in two phases due to epsilon martensite transformation in duplex TRIP-assisted stainless steels with high hydrogen embrittlement resistance. J. Int. Plast. 2017, 88, 53–69. [Google Scholar] [CrossRef]

- Sowerby, R.; Uko, D.K.; Tomita, Y. A review of certain aspects of the Bauschinger effect in metals. Mater. Sci. Eng. 1979, 41, 43–58. [Google Scholar] [CrossRef]

- Yang, M.; Pan, Y.; Yuan, F.; Zhu, Y.; Wu, X. Back stress strengthening and strain hardening in gradient structure. Mater. Res. Lett. 2016, 4, 145–151. [Google Scholar] [CrossRef]

- Yang, M.X.; Yuan, F.P.; Xie, Q.G.; Wang, Y.D.; Ma, E.; Wu, X.L. Strain hardening in Fe–16Mn–10Al–0.86 C–5Ni high specific strength steel. Acta Mater. 2016, 109, 213–222. [Google Scholar] [CrossRef]

- Jia, N.; Peng, R.L.; Wang, Y.D.; Chai, G.C.; Johansson, S.; Wang, G.; Liaw, P.K. Interactions between the phase stress and the grain-orientation-dependent stress in duplex stainless steel during deformation. Acta Mater. 2006, 54, 3907–3916. [Google Scholar] [CrossRef]

- Fang, X.; Yin, W.; Qin, C.; Wang, W.; Lo, K.H.; Shek, C.H. The interface character distribution of cold-rolled and annealed duplex stainless steel. Mater. Charact. 2016, 118, 397–404. [Google Scholar] [CrossRef]

- Ashby, M.F. The deformation of plastically non-homogeneous materials. Philos. Mag. A 1970, 21, 399–424. [Google Scholar] [CrossRef]

- Mughrabi, H. On the role of strain gradients and long-range internal stresses in the composite model of crystal plasticity. Mater. Sci. Eng. A 2001, 317, 171–180. [Google Scholar] [CrossRef]

- Ma, E. Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scr. Mater. 2003, 49, 663–668. [Google Scholar] [CrossRef]

- Koch, C.C. Ductility in nanostructured and ultrafine-grained materials: Recent evidence for optimism. J. Metastab. Nanocrystalline Mater. 2003, 18, 9–20. [Google Scholar] [CrossRef]

- Tsuji, N.; Ito, Y.; Saito, Y.; Minamino, Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 2002, 47, 893–899. [Google Scholar] [CrossRef]

- Kamikawa, N.; Huang, X.; Tsuji, N.; Hansen, N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater. 2009, 57, 4198–4208. [Google Scholar] [CrossRef]

- Huang, T.; Dong, Q.; Gong, X.; Hansen, N.; Liu, Q.; Huang, X. Cold rolled nanostructured super-pure Al (99.9996%) containing 1% Si particles: Structure and strength. J. Mater. Sci. 2012, 47, 7914–7920. [Google Scholar] [CrossRef]

- Li, Z.; Fu, L.; Fu, B.; Shan, A. Yield point elongation in fine-grained titanium. Mater. Lett. 2013, 96, 1–4. [Google Scholar] [CrossRef]

- Gao, S.; Chen, M.; Joshi, M.; Shibata, A.; Tsuji, N. Yielding behavior and its effect on uniform elongation in IF steel with various grain sizes. J. Mater. Sci. 2014, 49, 6536–6542. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Raabe, D. Effect of grain refinement to 1 μm on strength and toughness of dual-phase steels. Mater. Sci. Eng. A 2010, 527, 7832–7840. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Adachi, Y.; Ponge, D.; Raabe, D. Deformation and fracture mechanisms in fine-and ultrafine-grained ferrite/martensite dual-phase steels and the effect of aging. Acta Mater. 2011, 59, 658–670. [Google Scholar] [CrossRef]

- Tomota, Y.; Kuroki, K.; Mori, T.; Tamura, I. Tensile deformation of two-ductile-phase alloys: Flow curves of α-γ Fe-Cr-Ni alloys. Mater. Sci. Eng. 1976, 24, 85–94. [Google Scholar] [CrossRef]

- Sohn, S.S.; Choi, K.; Kwak, J.H.; Kim, N.J.; Lee, S. Novel ferrite–austenite duplex lightweight steel with 77% ductility by transformation induced plasticity and twinning induced plasticity mechanisms. Acta Mater. 2014, 78, 181–189. [Google Scholar] [CrossRef]

- Berrahmoune, M.R.; Berveiller, S.; Inal, K.; Moulin, A.; Patoor, E. Analysis of the martensitic transformation at various scales in TRIP steel. Mater. Sci. Eng. A 2004, 378, 304–307. [Google Scholar] [CrossRef]

- Van Dijk, N.H.; Butt, A.M.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; Van der Zwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439–5447. [Google Scholar] [CrossRef]

- Saha, R.; Ueji, R.; Tsuji, N. Fully recrystallized nanostructure fabricated without severe plastic deformation in high-Mn austenitic steel. Scr. Mater. 2013, 68, 813–816. [Google Scholar] [CrossRef]

- Hahn, G.T. A model for yielding with special reference to the yield-point phenomena of iron and related bcc metals. Acta Metall. 1962, 10, 727–738. [Google Scholar] [CrossRef]

- Yu, C.Y.; Kao, P.W.; Chang, C.P. Transition of tensile deformation behaviors in ultrafine-grained aluminum. Acta Mater. 2005, 53, 4019–4028. [Google Scholar] [CrossRef]

- Sugimoto, K.I.; Usui, N.; Kobayashi, M.; Hashimoto, S.I. Effects of volume fraction and stability of retained austenite on ductility of TRIP-aided dual-phase steels. ISIJ Int. 1992, 32, 1311–1318. [Google Scholar] [CrossRef]

- Sugimoto, K.I.; Iida, T.; Sakaguchi, J.; Kashima, T. Retained austenite characteristics and tensile properties in a TRIP type bainitic sheet steel. ISIJ Int. 2000, 40, 902–908. [Google Scholar] [CrossRef]

- Jacques, P.J.; Delannay, F.; Ladrière, J. On the influence of interactions between phases on the mechanical stability of retained austenite in transformation-induced plasticity multiphase steels. Metall. Mater. Trans. A 2001, 32, 2759–2768. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, J.; Peng, Y.; Wang, T.; Hansen, N.; Huang, X. Laminated Fe-34.5Mn-0.04C composite with high strength and ductility. J. Mater. Sci. Technol. 2018, 34, 1939–1943. [Google Scholar] [CrossRef]

| Sample | Structural Feature | Grain Size (α) | Grain Size (γ) | Volume Fraction (γ) |

|---|---|---|---|---|

| CR | UFG lamellar structure (α + α´) | 72 ± 24 nm | —— | 0% |

| CR + 700 °C | UFG recrystallized structure (α +γ) | 347 ± 137 nm | 401 ± 122 nm | 51.1 ± 1.4% |

| CR + 900 °C | CG * recrystallized structure (α +γ) | 1.06 ± 0.37 μm | 1.15 ± 0.43 μm | 57.2 ± 2.2% |

| CR + 1000 °C | CG recrystallized structure (α +γ) | 1.82 ± 0.55 μm | 2.26 ± 0.69 μm | 56.1 ± 3.1% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, L.; Wang, C.; Wang, Y.; Wu, G.; Huang, X. Grain Size Effect on the Mechanical Behavior of Metastable Fe-23Cr-8.5Ni Alloy. Metals 2019, 9, 734. https://doi.org/10.3390/met9070734

Xie L, Wang C, Wang Y, Wu G, Huang X. Grain Size Effect on the Mechanical Behavior of Metastable Fe-23Cr-8.5Ni Alloy. Metals. 2019; 9(7):734. https://doi.org/10.3390/met9070734

Chicago/Turabian StyleXie, Lin, Chunpeng Wang, Yuhui Wang, Guilin Wu, and Xiaoxu Huang. 2019. "Grain Size Effect on the Mechanical Behavior of Metastable Fe-23Cr-8.5Ni Alloy" Metals 9, no. 7: 734. https://doi.org/10.3390/met9070734

APA StyleXie, L., Wang, C., Wang, Y., Wu, G., & Huang, X. (2019). Grain Size Effect on the Mechanical Behavior of Metastable Fe-23Cr-8.5Ni Alloy. Metals, 9(7), 734. https://doi.org/10.3390/met9070734