Investigation on the Strain Distribution in Tube High-Pressure Shearing

Abstract

:1. Introduction

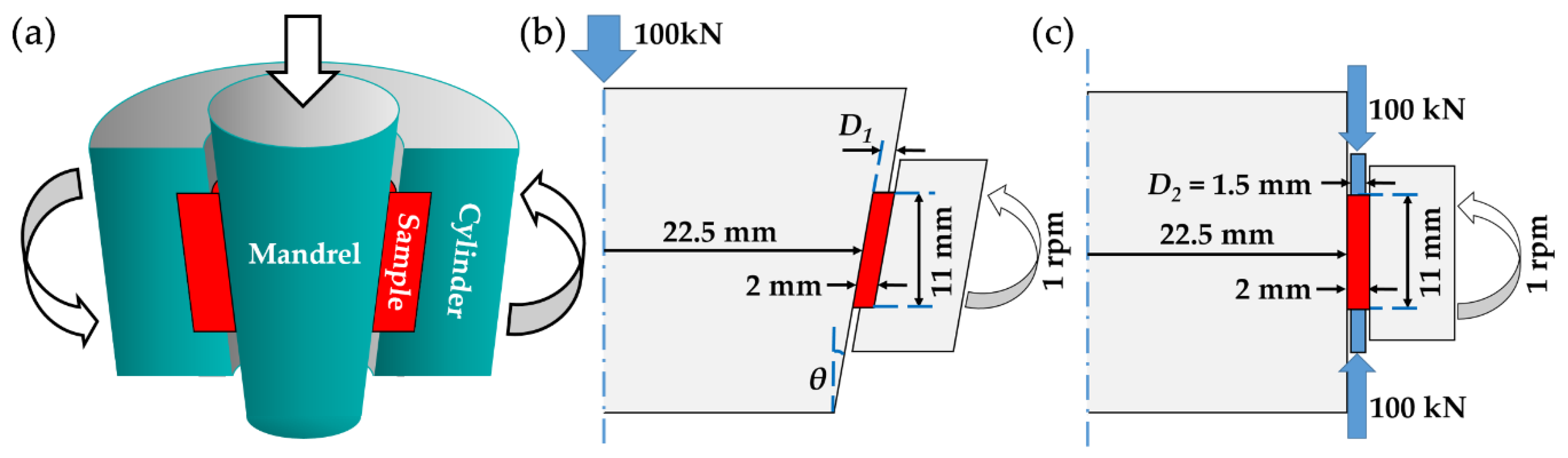

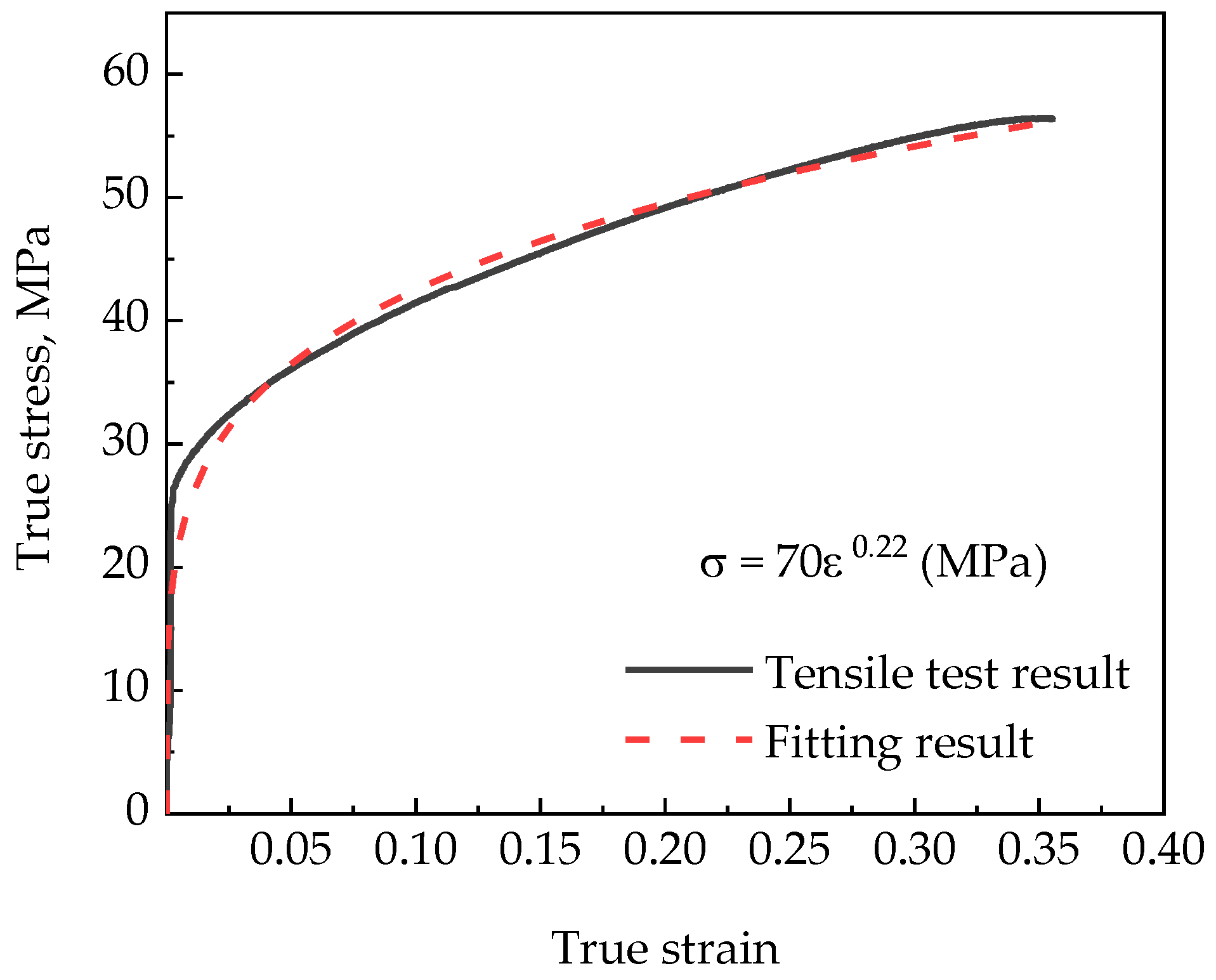

2. Materials and Methods

3. Results

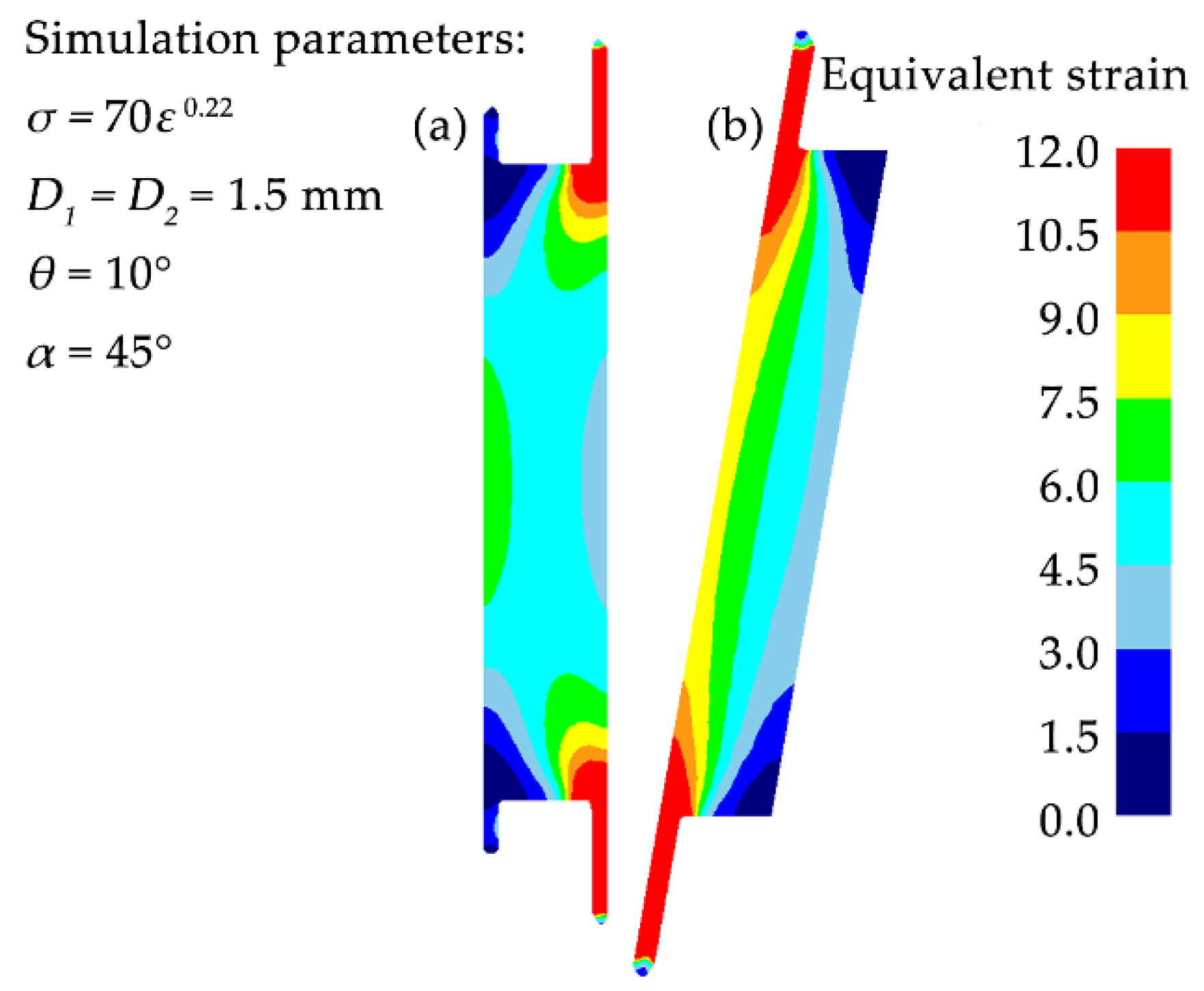

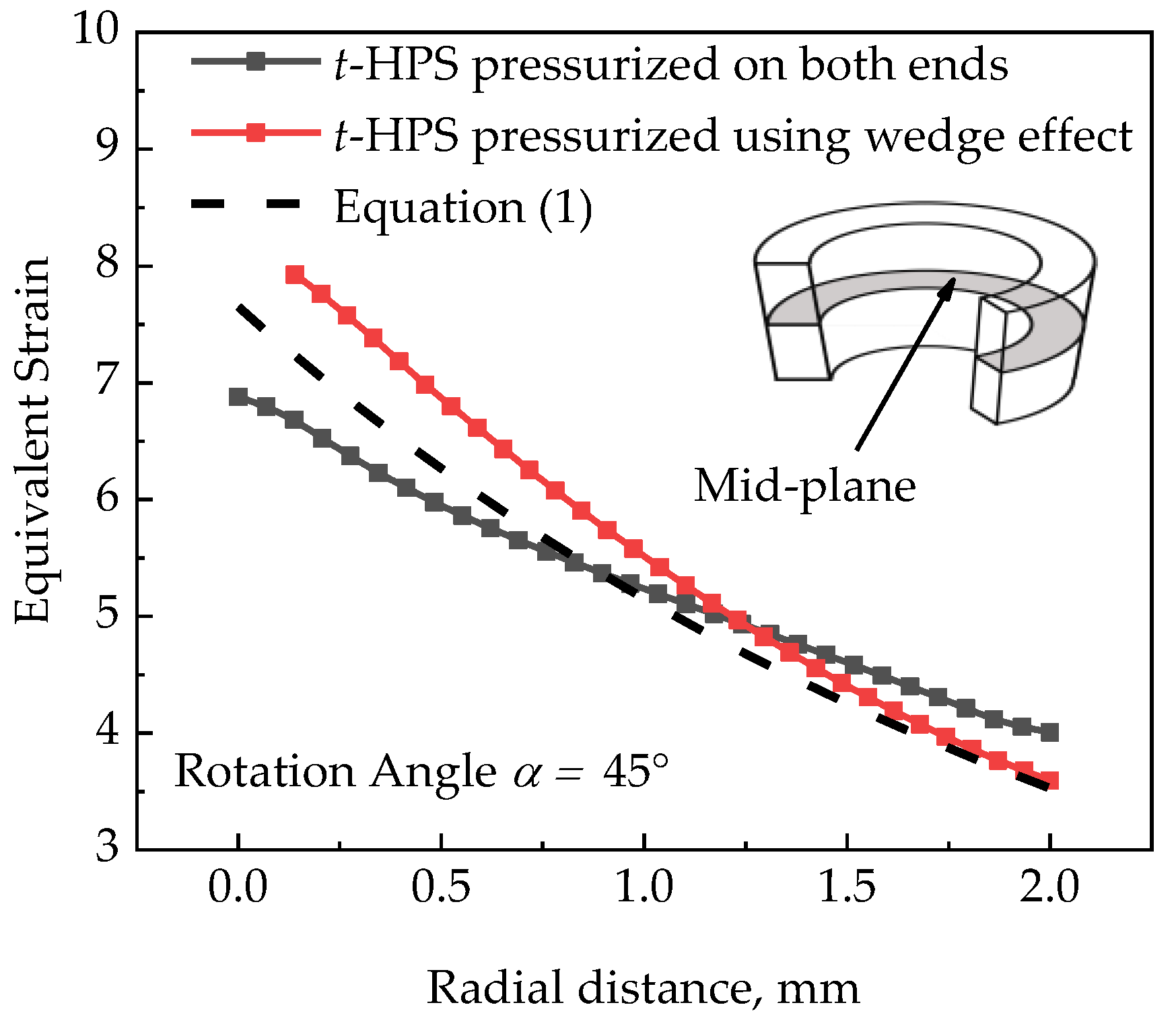

3.1. Comparison between the Two Pressurizing Alternations for t-HPS

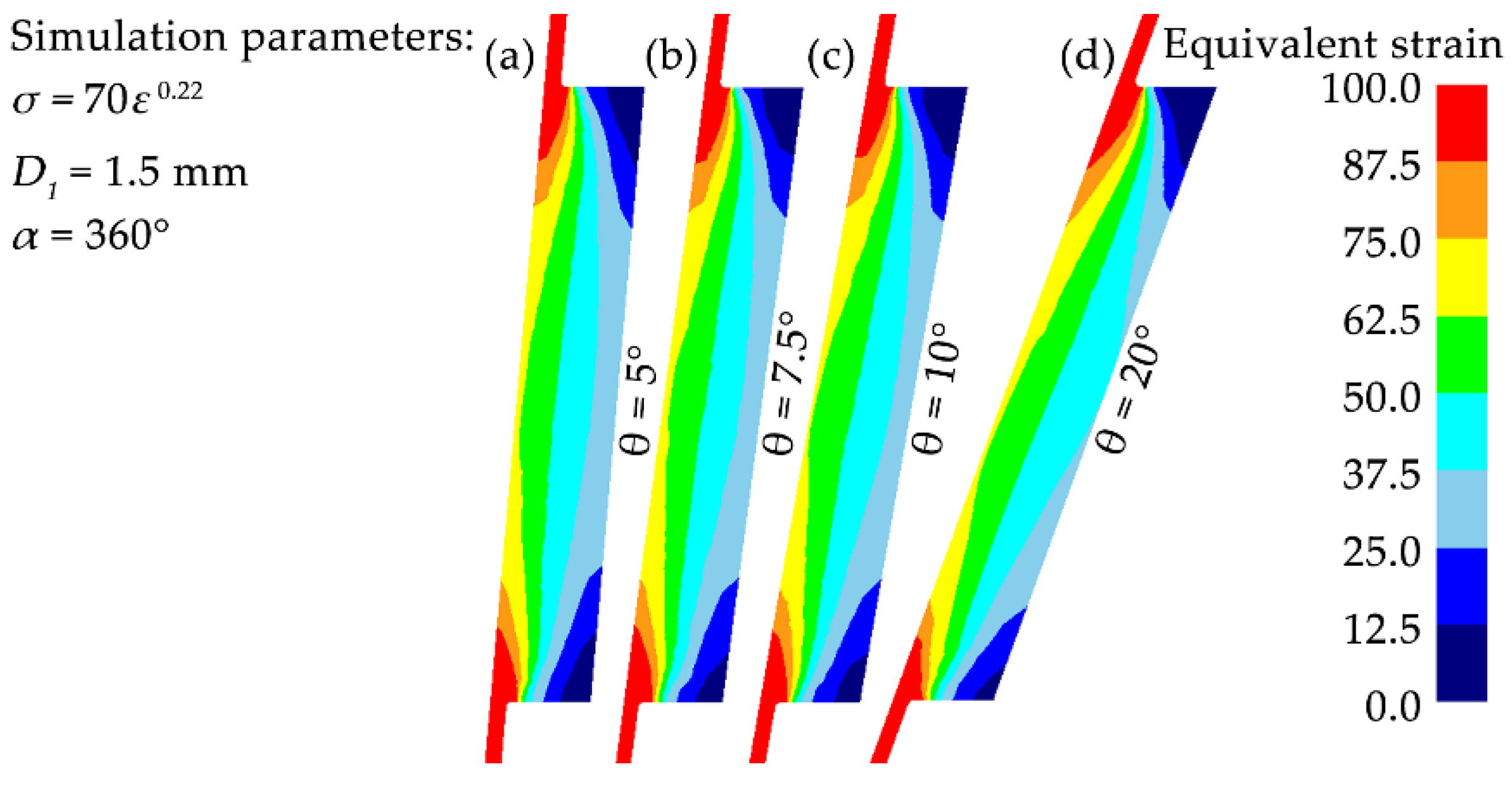

3.2. Effect of the Half Cone Angle for t-HPS Pressurizing Using Wedge Effect

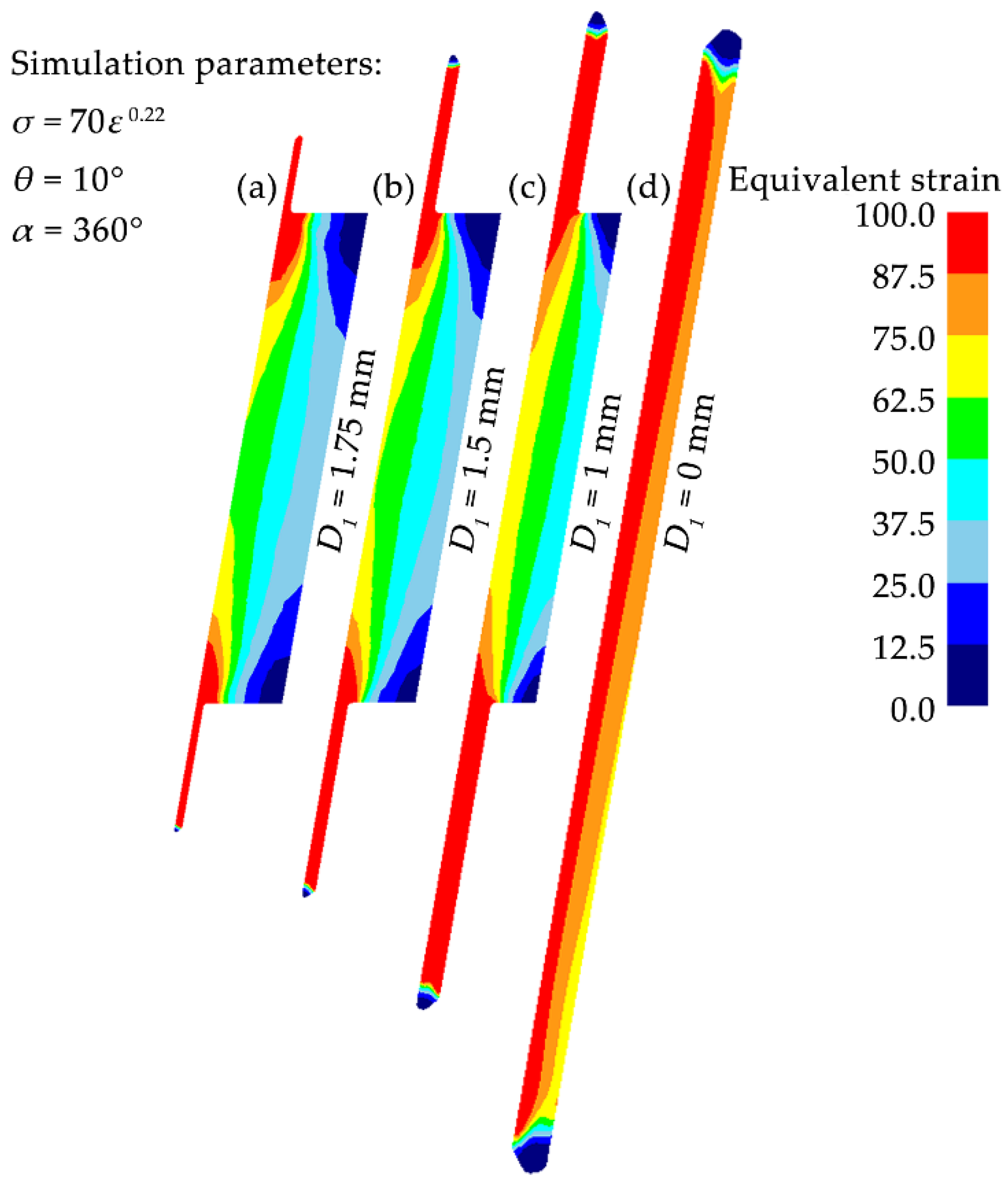

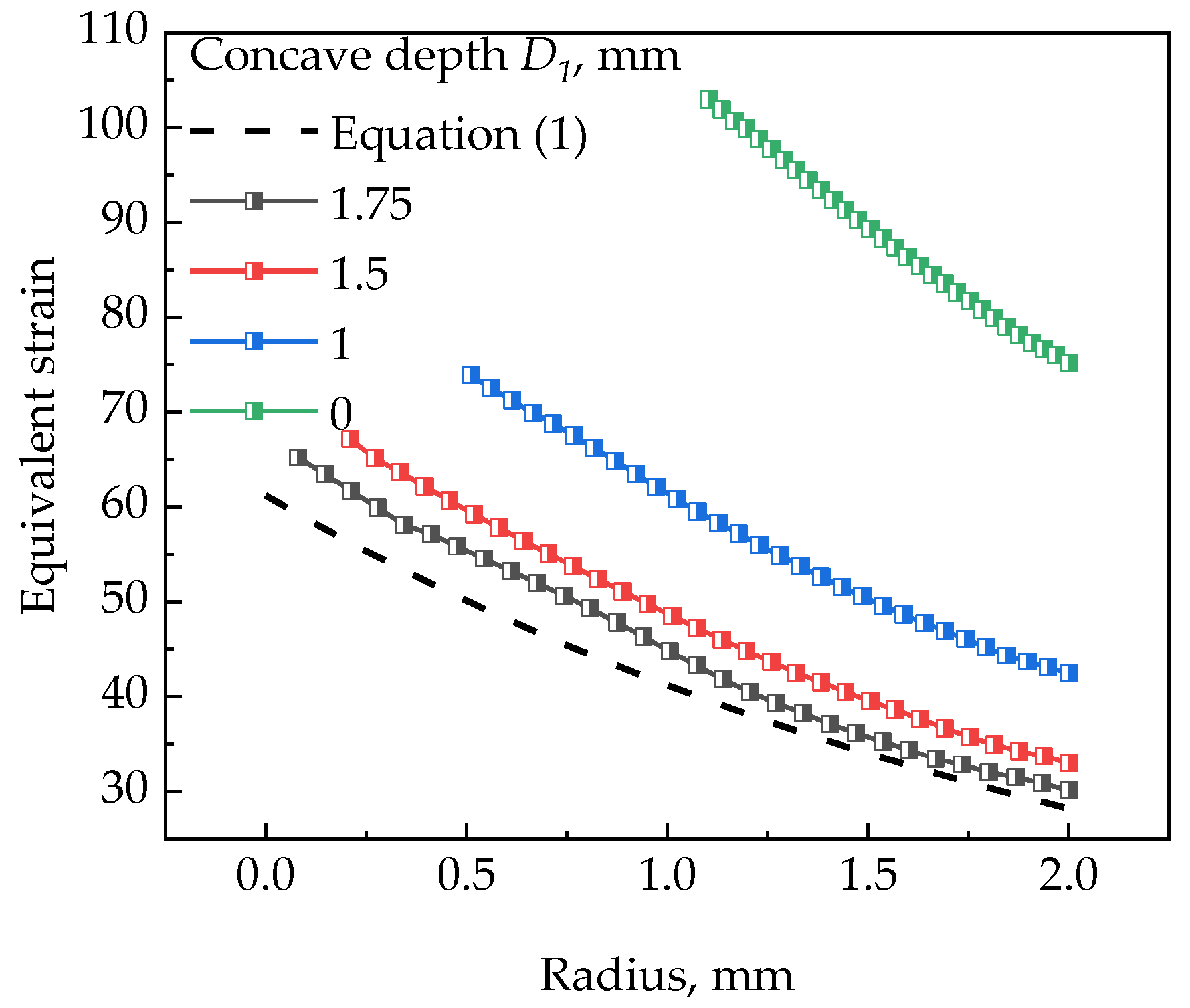

3.3. Effect of the Concave Depth in t-HPS Pressurizing Using Wedge Effect

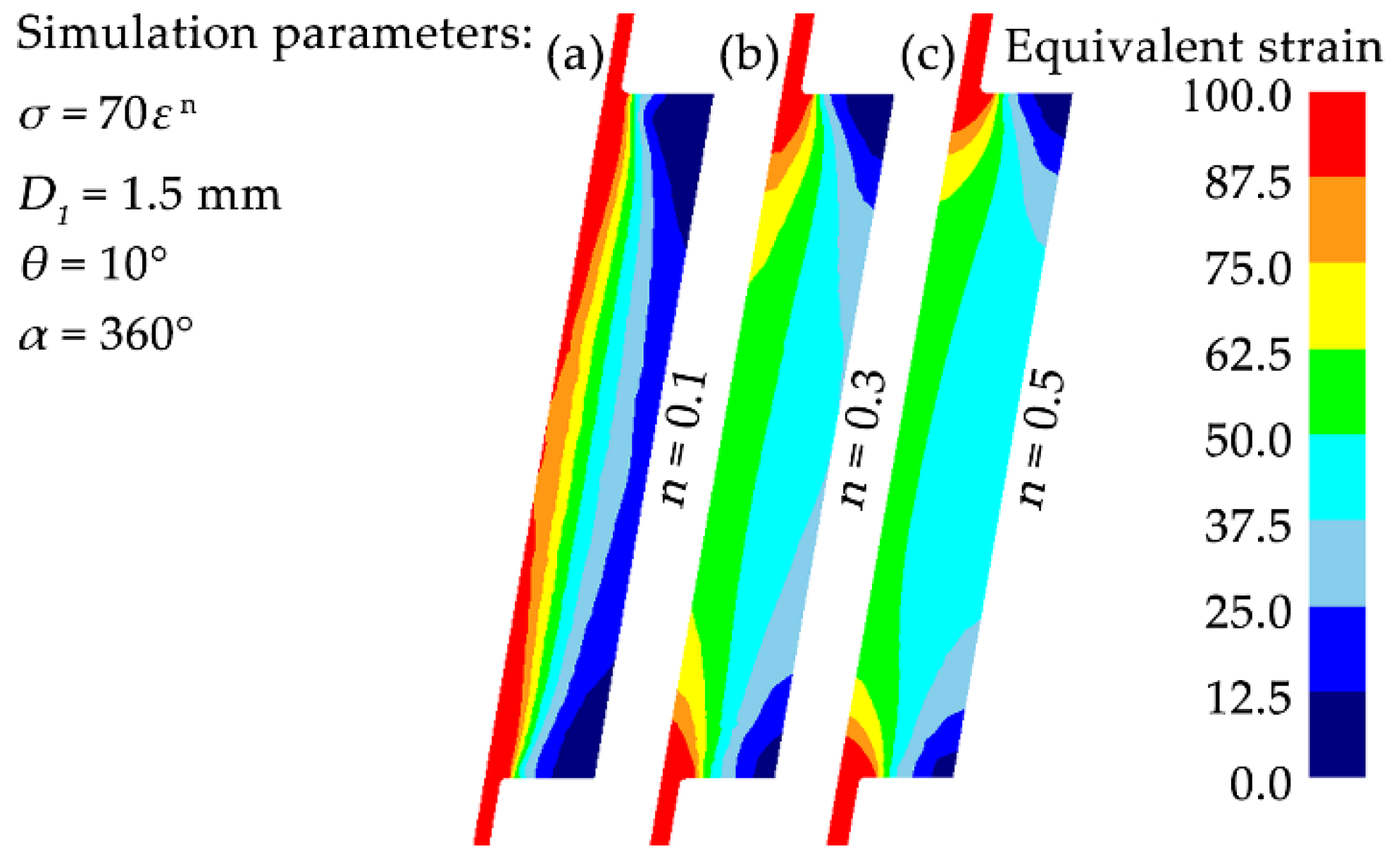

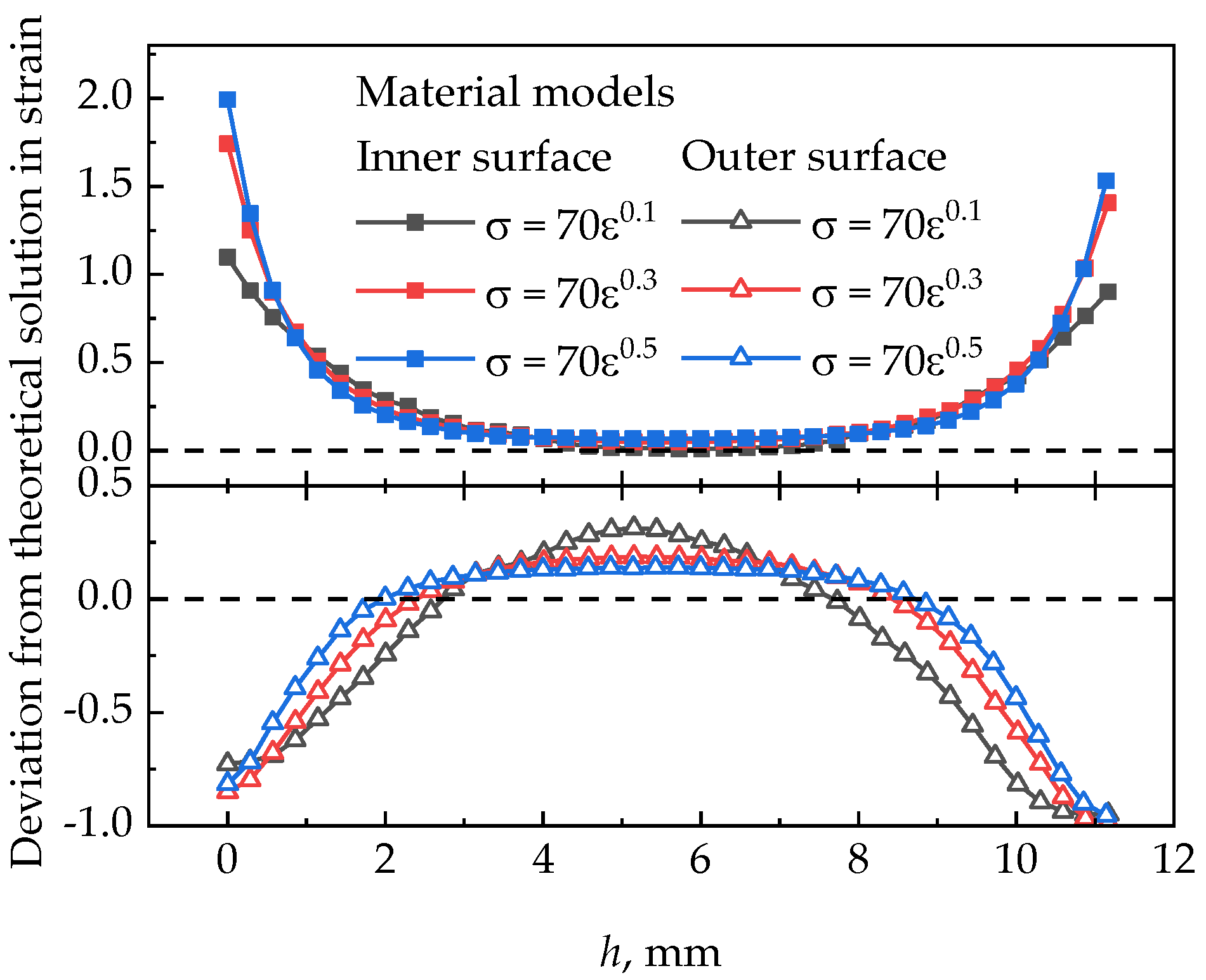

3.4. Effect of the Strain-Hardening Exponent in t-HPS Pressurizing Using Wedge Effect

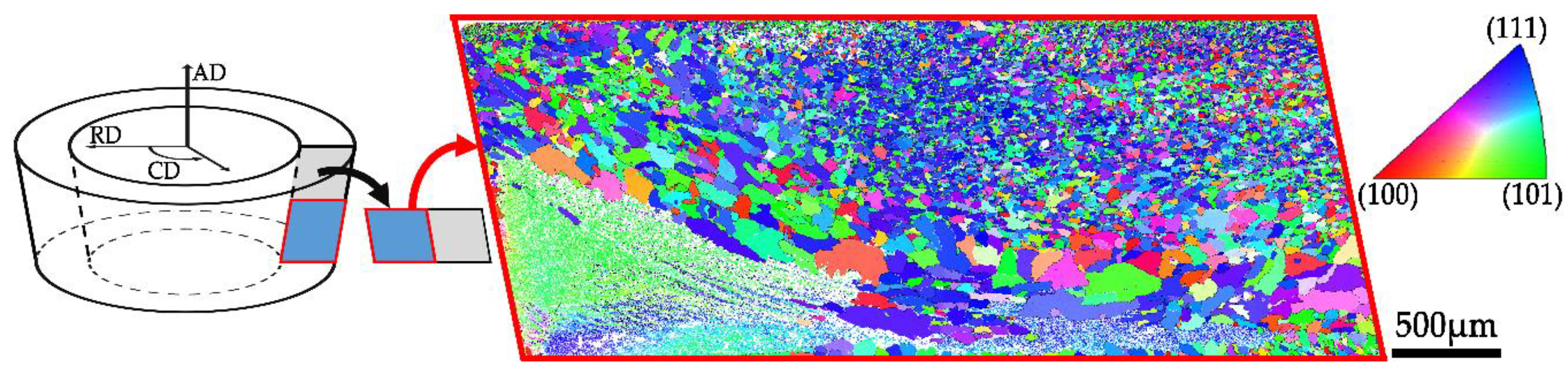

3.5. Grain Structure after t-HPS Pressurizing Using Wedge Effect

4. Discussion

4.1. The Effect of the Concave Depth

4.2. The Effect of Strain-Hardening Exponent: t-HPS Vs HPT

5. Summary and Conclusions

- (1)

- Both alternations of pressurizing method for t-HPS: pressurizing on both ends of the tube and pressurizing using the wedge effect could be successfully used to realize the t-HPS process. Due to the friction effect on the ends of the tube samples, the axial strain distribution is inhomogeneous, and a “dead metal zone” forms at the end edge corner of the tube samples. This was confirmed by the experimental EBSD observations of the grain distributions on the vertical sections of the 5N aluminum after t-HPS processing.

- (2)

- For t-HPS pressurizing using wedge effect, the half cone angle has little effect on the strain inhomogeneity of the t-HPS, therefore, there is no strong limitation on the selection of the half cone angle from the view point of strain distribution.

- (3)

- Although the axial strain inhomogeneity of the sample can be reduced by decreasing the concave depth of the cylinder, this may cause excessive thinning of the sample in the meantime when the concave depth is too low. Therefore, this strategy should be used with care to avoid such negative effects.

- (4)

- The radial strain gradient is related to strain-hardening exponent in both ideal t-HPS described by theoretical equation and practical t-HPS described by FEM. This feature of t-HPS stands out from other SPD processes like HPT, where although materials parameters like the strain hardening exponent have an obvious effect of strain distribution, although it does not have any influence on ideal corresponding processes. This makes practical t-HPS behavior more predictable in its analytical formation than any other SPD processes, and places it in an advantageous position in understanding the basics of deformation physics through the coupling between practical experiments and theoretical approaches.

Author Contributions

Funding

Conflicts of Interest

References

- Bridgman, P.W. Effects of High Shearing Stress Combined with High Hydrostatic Pressure. Phys. Rev. 1935, 48, 825. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103. [Google Scholar] [CrossRef]

- Wang, J.T.; Li, Z.; Wang, J.; Langdon, T.G. Principles of severe plastic deformation using tube high-pressure shearing. Scr. Mater. 2012, 67, 810. [Google Scholar] [CrossRef]

- Toth, L.; Arzaghi, M.; Fundenberger, J.; Beausir, B.; Bouaziz, O.; Arruffatmassion, R. Severe plastic deformation of metals by high-pressure tube twisting. Scr. Mater. 2009, 60, 175. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, P.F.; Yuan, H.; Lin, K.; Liu, Y.; Yin, D.L.; Wang, J.T.; Langdon, T.G. Principle of one-step synthesis for multilayered structures using tube high-pressure shearing. Mat. Sci. Eng. A. 2016, 658, 367. [Google Scholar] [CrossRef]

- Wang, J.T.; Li, Z.; Wang, J.; An, Y.K. Method and device for realizing tube high-pressure shearing pressurized using wedge effect. China patent CN 102500632 A, 30 September 2011. [Google Scholar]

- Valiev, R.Z.; Ivanisenko, Y.V.; Rauch, E.F.; Baudelet, B. Structure and deformaton behaviour of Armco iron subjected to severe plastic deformation. Acta Mater. 1996, 44, 4705. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Aguilar, M.T.P.; Cetlin, P.R.; Langdon, T.G. Analysis of plastic flow during high-pressure torsion. J. Mater. Sci. 2012, 47, 7807. [Google Scholar] [CrossRef]

- Lee, D.J.; Kim, H.S. Finite element analysis for the geometry effect on strain inhomogeneity during high-pressure torsion. J. Mater. Sci. 2014, 49, 6620. [Google Scholar] [CrossRef]

- Hohenwarter, A.; Bachmaier, A.; Gludovatz, B.; Scheriau, S.; Reinhard Pippana, B. Technical parameters affecting grain refinement by high pressure torsion. Int. J. Mater. Res. 2009, 100, 1653. [Google Scholar] [CrossRef]

- Halloumi, A.; Busquet, M.; Descartes, S. Parametric study of unconstrained high-pressure torsion- Finite element analysis. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 12036. [Google Scholar] [CrossRef]

- Kamrani, M.; Levitas, V.I.; Feng, B. FEM simulation of large deformation of copper in the quasi-constrain high-pressure-torsion setup. Mat. Sci. Eng. A. 2017, 705, 219. [Google Scholar] [CrossRef]

- Lee, D.J.; Yoon, E.Y.; Park, L.J.; Kim, H.S. The dead metal zone in high-pressure torsion. Scr. Mater. 2012, 67, 384. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; de Faria, G.C.V.; Cetlin, P.R.; Langdon, T.G. Three-dimensional analysis of plastic flow during high-pressure torsion. J. Mater. Sci. 2013, 48, 4524. [Google Scholar] [CrossRef]

- Zhou, C.P.; Li, Z.; Liu, F.; Wang, J.T. Influence of Strain Rate on Recrystallization Behavior of High Purity Aluminum by Tube High-Pressure Shearing. Mater. Sci. Forum. 2015, 817, 516. [Google Scholar] [CrossRef]

- Yang, L.; He, Y.; Qu, J. Investigation on large deformation constitutive model based on solid cylinder torsion test. In Proceedings of the 5th International Conference on Nonlinear Mechanics, Shanghai, China, 11–14 June 2007; Civil Engineering College and Haibin Engineering University: Harbin, China, 2007; pp. 309–312. [Google Scholar]

- Dienes, J.K. On the analysis of rotation and stress rate in deforming bodies. Acta Mech. 1979, 32, 217. [Google Scholar] [CrossRef]

- Wu, P.D.; Van der Giessen, E. Analysis of elastic-plastic torsion of circular bars at large strains. Arch. Appl. Mech. 1991, 61, 89. [Google Scholar]

- Estrin, Y.; Tóth, L.S.; Molinari, A.; Bréchet, Y. A dislocation-based model for all hardening stages in large strain deformation. Acta Mater. 1998, 46, 5509. [Google Scholar] [CrossRef]

- Baik, S.C.; Estrin, Y.; Kim, H.S.; Hellmig, R.J. Dislocation density-based modeling of deformation behavior of aluminium under equal channel angular pressing. Mat. Sci. Eng. A. 2003, 351, 86. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Cetlin, P.R.; Langdon, T.G. Using finite element modeling to examine the flow processes in quasi-constrained high-pressure torsion. Mat. Sci. Eng. A. 2011, 528, 8198. [Google Scholar] [CrossRef]

- Edalati, K.; Miresmaeili, R.; Horita, Z.; Kanayama, H.; Pippan, R. Significance of temperature increase in processing by high-pressure torsion. Mat. Sci. Eng. A. 2011, 528, 7301. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Pereira, P.H.R.; Aguilar, M.T.P.; Cetlin, P.R.; Langdon, T.G. Using finite element modeling to examine the temperature distribution in quasi-constrained high-pressure torsion. Acta Mater. 2012, 60, 3190. [Google Scholar] [CrossRef]

- Ito, Y.; Horita, Z. Microstructural evolution in pure aluminum processed by high-pressure torsion. Mat. Sci. Eng. A. 2009, 503, 32. [Google Scholar] [CrossRef]

- Salem, A.A.; Langdon, T.G.; Mcnelley, T.R.; Kalidindi, S.R.; Semiatin, S.L. Strain-path effects on the evolution of microstructure and texture during the severe-plastic deformation of aluminum. Metall. Mater. Trans. A 2006, 37, 2879. [Google Scholar] [CrossRef]

- Skrotzki, W.; Scheerbaum, N.; Oertel, C.G.; Brokmeier, H.G.; Suwas, S.; Tóth, L.S. Recrystallization of high-purity aluminium during equal channel angular pressing. Acta Mater. 2007, 55, 2211. [Google Scholar] [CrossRef]

- Degtyarev, M.V.; Chashchukhina, T.I.; Voronova, L.M.; Patselov, A.M.; Pilyugin, V.P. Influence of the relaxation processes on the structure formation in pure metals and alloys under high-pressure torsion. Acta Mater. 2007, 55, 6039. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Wang, J.; Horita, Z.; Nemoto, M.; Langdon, A.T.G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 1996, 35, 143. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mat. Sci. Eng. A 1995, 197, 157. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuj, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221. [Google Scholar] [CrossRef]

- Kawasaki, M.; Figueiredo, R.B.; Langdon, T.G. An investigation of hardness homogeneity throughout disks processed by high-pressure torsion. Acta Mater. 2011, 59, 308. [Google Scholar] [CrossRef]

| Investigation Theme | θ, ° | D1 or D2, mm | Strain-Hardening Exponent, n | α, ° |

|---|---|---|---|---|

| Comparison between pressurizing on both ends and by wedge effect | 10 | 1.5 | 0.22 | 45 |

| The effect of half cone angle in t-HPS by wedge effect | 5, 10, 20 | 1.5 | 0.22 | 360 |

| The effect of concave depth in t-HPS by wedge effect | 10 | 0, 1, 1.5, 1.75 | 0.22 | 360 |

| The effect of strain-hardening exponent in t-HPS by wedge effect | 10 | 1.5 | 0.1, 0.3, 0.5 | 360 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, J.J.; Li, Z.; Liu, Y.; Zhu, Y.B.; Wang, S.; Lin, K.; Tao, J.Q.; Wang, J.T. Investigation on the Strain Distribution in Tube High-Pressure Shearing. Metals 2019, 9, 1117. https://doi.org/10.3390/met9101117

Meng JJ, Li Z, Liu Y, Zhu YB, Wang S, Lin K, Tao JQ, Wang JT. Investigation on the Strain Distribution in Tube High-Pressure Shearing. Metals. 2019; 9(10):1117. https://doi.org/10.3390/met9101117

Chicago/Turabian StyleMeng, Jia Jie, Zheng Li, Ying Liu, Ye Bin Zhu, Shun Wang, Kui Lin, Jia Qiang Tao, and Jing Tao Wang. 2019. "Investigation on the Strain Distribution in Tube High-Pressure Shearing" Metals 9, no. 10: 1117. https://doi.org/10.3390/met9101117

APA StyleMeng, J. J., Li, Z., Liu, Y., Zhu, Y. B., Wang, S., Lin, K., Tao, J. Q., & Wang, J. T. (2019). Investigation on the Strain Distribution in Tube High-Pressure Shearing. Metals, 9(10), 1117. https://doi.org/10.3390/met9101117