Laser Powder Bed Fusion of Stainless Steel Grades: A Review

Abstract

1. Introduction

- capability of obtaining the best geometrical and dimensional tolerances;

- low waviness (the low-frequency roughness component) of surfaces, thus minimizing the need for machining allowance;

- capability of achieving the highest relative densities, up to 100%, with respect to wrought or forged metals;

- capability of producing both thin structures, e.g., lattice and trabecular, and heavy cross sections; and

- capability of minimizing oxide impurities, as it works under controlled atmospheres (usually nitrogen, or argon for reactive alloys).

- high-levels of residual stresses, which can cause distortions, cracks and delamination;

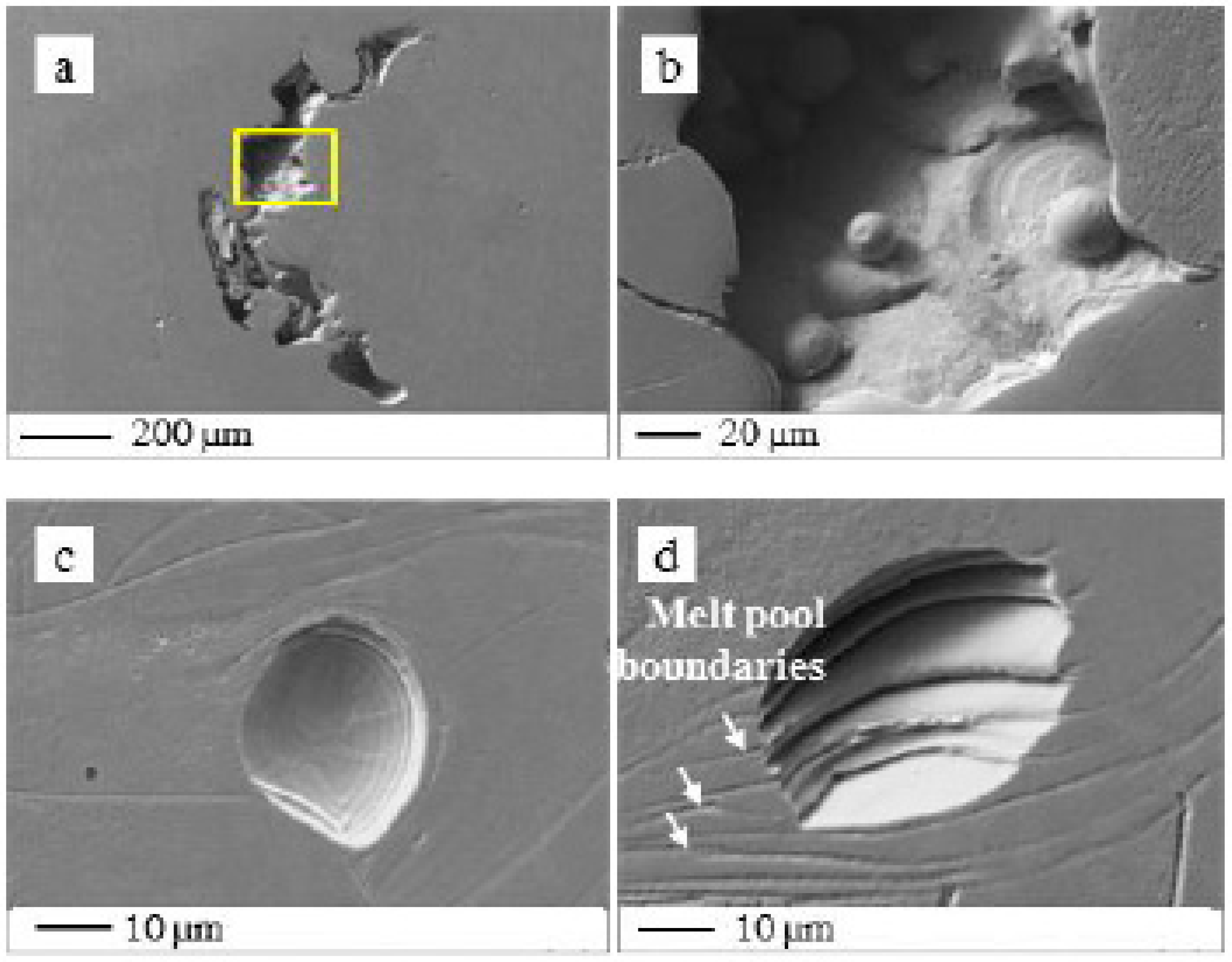

- porosities and incomplete fusion-related defects;

- cracks (in susceptible alloys) and metastable microstructures, as a consequence of high cooling rates;

- balling phenomenon, at the origin of discontinuous scan tracks;

- micro roughness due to partially sintered metal particles, especially experienced on inclined surfaces.

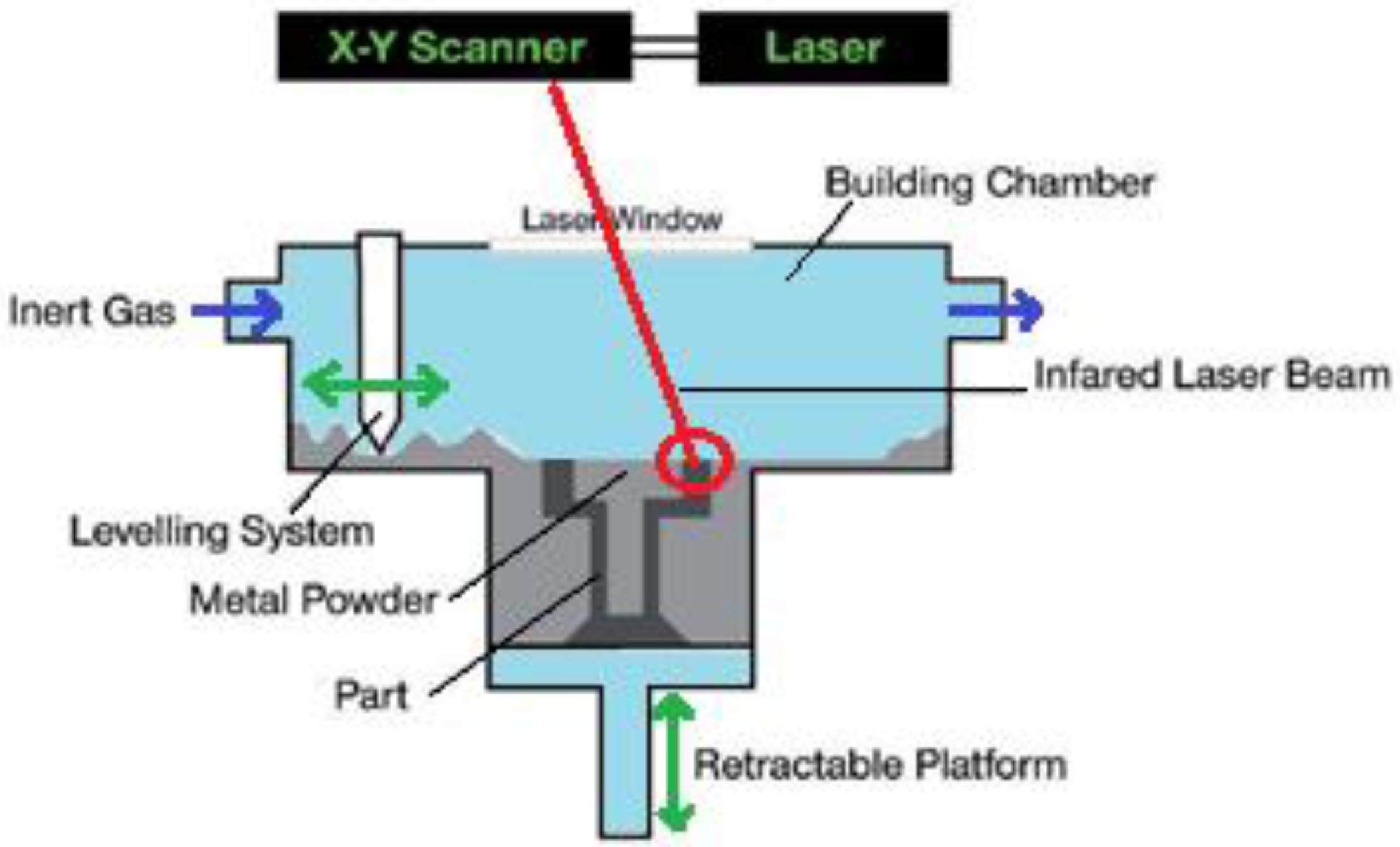

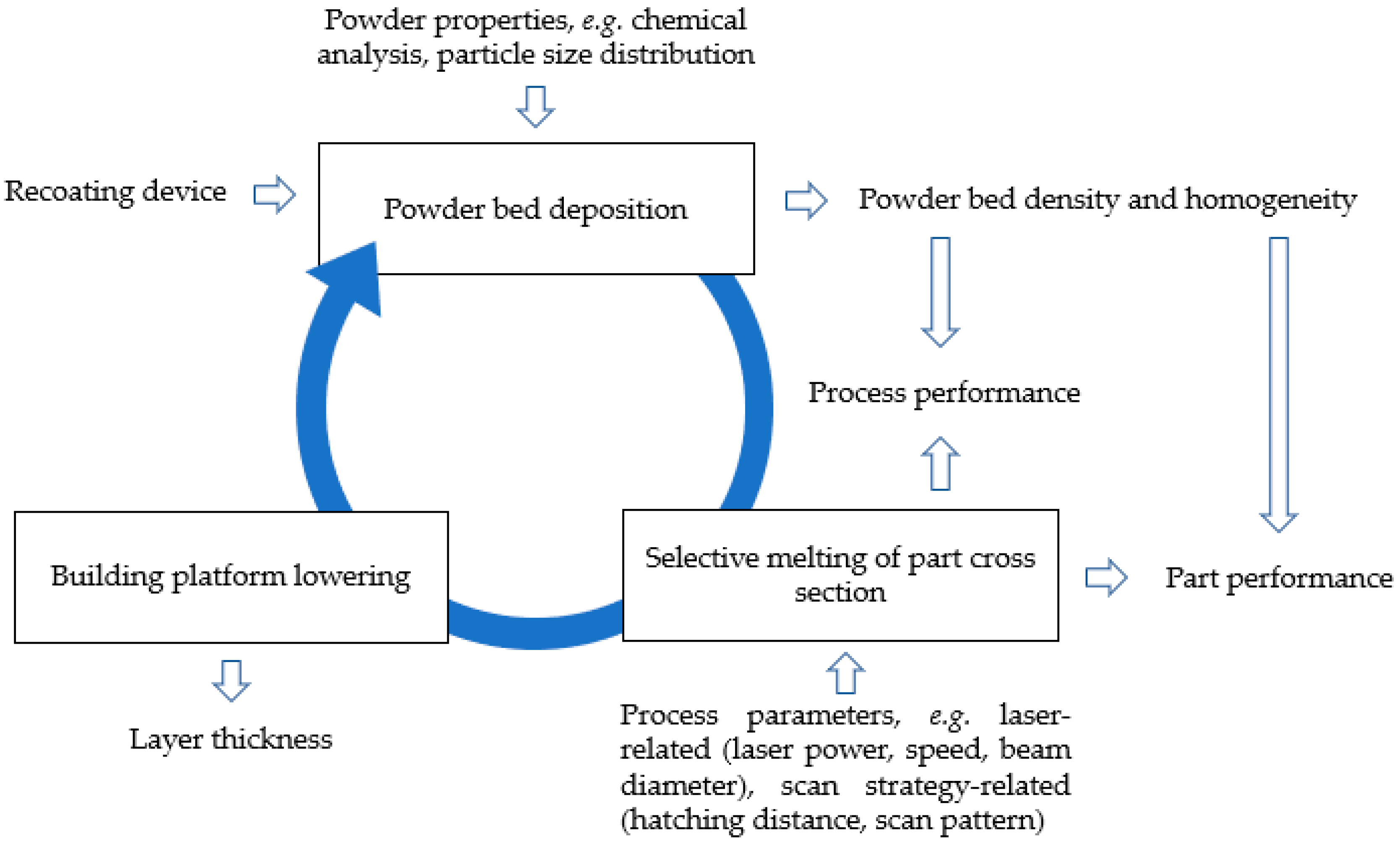

2. Laser Powder Bed Fusion Working Principles and Process-Related Defects

- CAD manipulation and model “slicing”, the latter being performed by specific software properly subdividing the geometry into n slices with a height equal to the selected layer;

- loading data to the L-PBF hardware;

- production stage:

- spreading the powder layer, thanks to a rake or roller (Levelling System in Figure 1);

- switching on the laser, for melting and subsequent solidification;

- lowering of the building platform, which is retractable;

- previous steps 3a–3c repeated until all layers are fused;

- removal of unused powder (“metal powder” in Figure 1) and extraction of the final part.

- laser power;

- laser speed;

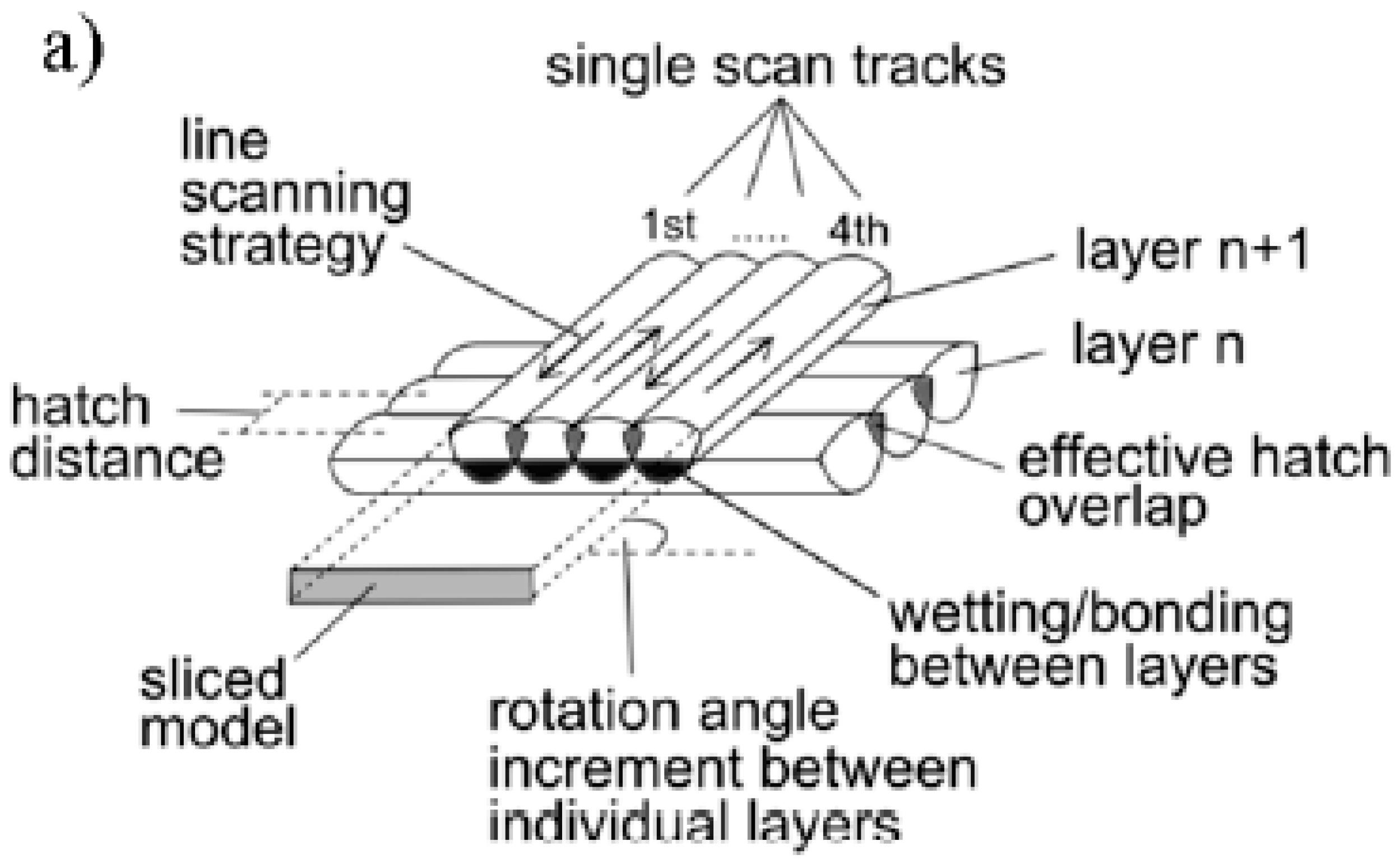

- hatch distance—the distance from the middle line of two consecutive lines, determining the effective hatch overlap, according to Figure 3;

- layer thickness;

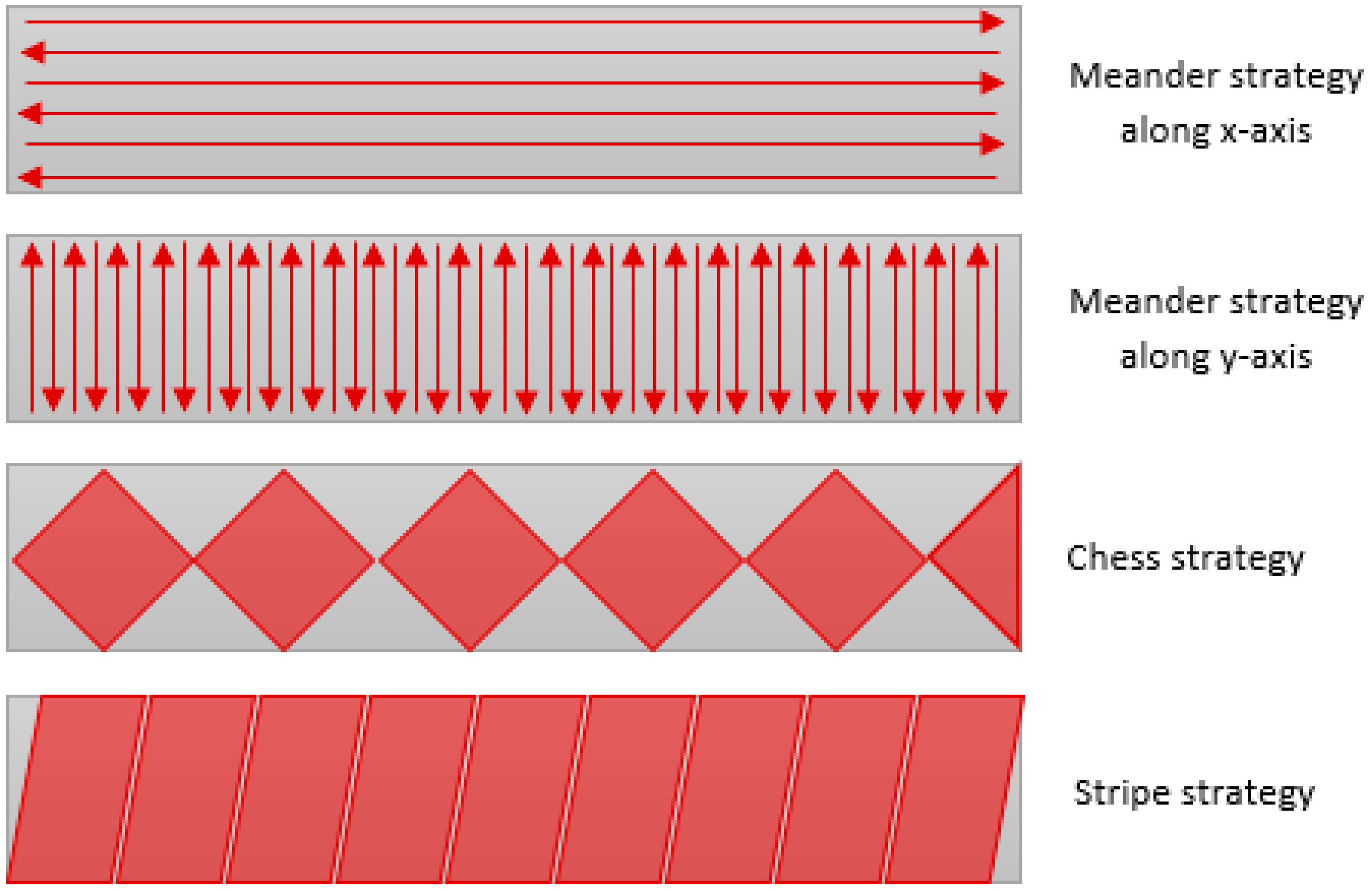

- scan pattern.

| L-PBF Machinery Characteristics | |

|---|---|

| Heat source | One fiber laser, or more |

| Laser power [W] | 50–1000 |

| Laser speed [mm/s] | 10–15,000 |

| Laser beam diameter [µm] | 30–500. Most common, 80–100 |

| Building chamber atmosphere | Inert gas—Typically, Nitrogen or Argon |

| Building rate [cm3/h] | 2–120 |

| Building volume [mm] | Up to 800 × 400 × 500 (width × depth × height)—most common, 250 × 250 × 300 |

| Ref. | [2,10,79,80,81,82,83,84,85] |

| L-PBF Produced Components Features | |

| Relative density 1 [%] | Up to 100 |

| Upper surfaces roughness (Ra,X-Y) [µm] | 4–10 |

| Lateral surfaces roughness (Ra,Z) [µm] | >20 |

| Minimum feature size [µm] | 75–250 |

| Geometric tolerance [mm] | ±0.05–0.1 |

| Impurities | Risk of contamination by process gas (nitrogen) or moisture |

| Effect on chemical composition | Minimum loss of low vapor pressure alloying elements |

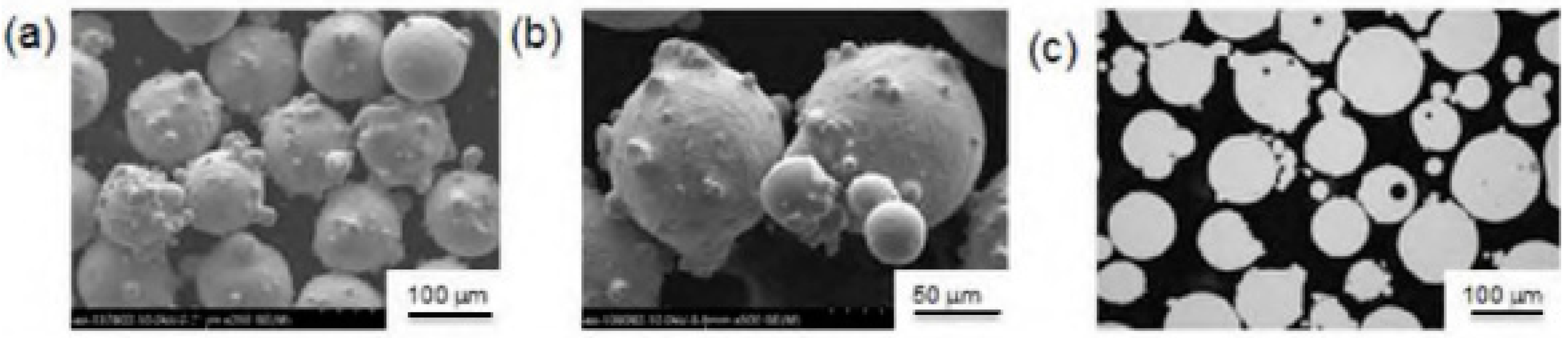

| Powder size requirements [µm] | 10–60 |

| Ref. | [10,51,79,86,87,88] |

- laser energy density E directly impacts melting behavior: at low scan speed and high laser power, E is high, causing evaporation, porosities and potential denudation of near surfaces, while high scan speed and low power determine low E density, which is insufficient to fully melt a proper powder volume and interlayer bonding [23,101];

- increasing the layer thickness, keeping the other parameters unmodified, can result in residual stresses mitigation [102], and a more economical process (i.e., with reduced production times), but it is necessary to evaluate the potential lack-of-fusion defects;

- the effect of laser power on melt pool defects and residual stresses is greater than that of laser speed [104];

- moreover, surface roughness is affected by the width of the melting track, which in turn is controlled by laser power and scan speed values. Inclined surfaces are the most disadvantaged, because heat conduction in the powder bed below is less efficient than the areas over the consolidated material [107];

- porosities must be carefully controlled, as they are detrimental for fatigue resistance of alloys; in particular, pore size has been demonstrated to be the most relevant parameter [108].

3. Stainless Steel Grades Processed in L-PBF Systems

3.1. Austenitic Stainless Steel Grades

- In Table 2, tensile results are reported and compared to the standard minimum requirements:

- tension tests performed at room temperature showed good performance, apart from fracture elongation, with results being higher than the minimum requirements usually applied for the selected stainless steel grades processed with conventional technologies;

- fracture elongation is the most negatively affected parameter, for samples tested under the as-built conditions;

- analyzing the listed tensile properties for 316L stainless steel powders, we can state that the experimental research performed in the cited papers achieved comparable results. It can be assumed that they all used proper parameter sets.

| Grade | Equipment | Relative Density [%] | Cond. | BD | Test Cond. | YS [MPa] | UTS [MPa] | El. [%] | Ref. |

|---|---|---|---|---|---|---|---|---|---|

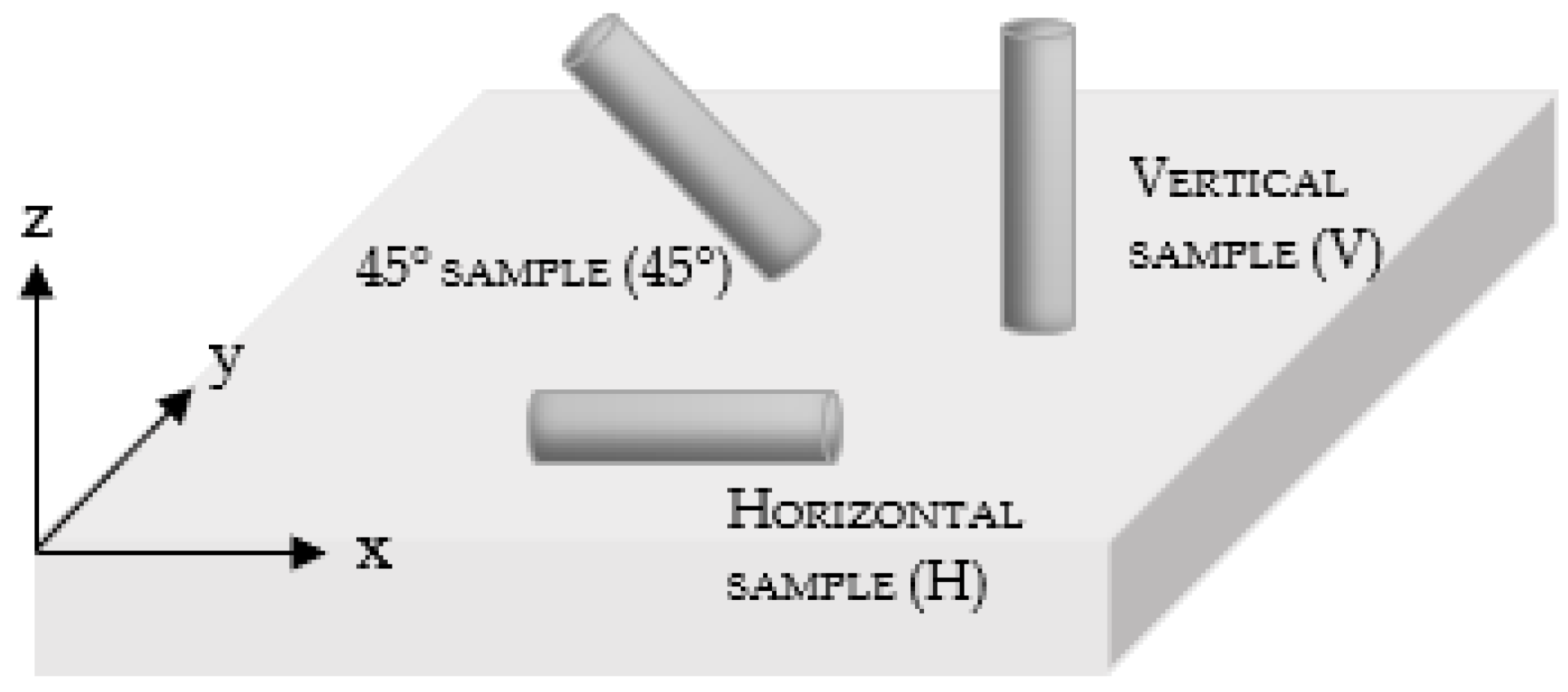

| 304 | SD | NR | As built | H | RT | 530 | 700 | 38 | [105] |

| 45° | 370 | 540 | 29 | ||||||

| V | 450 | 550 | 58 | ||||||

| 304L | 3D Systems ProX-300 | 99.99 | As built | - | RT | 485 | 712 | 61 | [127] |

| 316L | SLM Solutions 125HL | 95.99–99.30 | HT–1040 °C/4h | V | RT | 376 | 637 | 32.4 | [128] |

| 316L | As built | H | RT | 528 | 639 | 38.0 | [78] | ||

| SLM Solutions 280HL | >99 | 45° | 590 | 699 | 34.1 | ||||

| V | 439 | 512 | 11.8 | ||||||

| 316L | Sisma MYSINT100 | 99.3–100 | As built | 45° | RT | 505–515 | 650 | 41 | [89] |

| V | 430–495 | 550-575 | 66–72 | ||||||

| 316L | Renishaw AM250 | NR | As built | H | RT | 554 | 685 | 36 | [129] |

| 316L | NR | NR | As built | - | RT | 456 | 703 | 45 | [118] |

| - | 250 °C | 376 | 461 | 31 | |||||

| - | 1100 °C | - | 300 | 15–18 | |||||

| - | 1200 °C | - | 150 | 20 | |||||

| Standard Reference Values | |||||||||

| Grade | Condition | Test condition | YS [MPa] | UTS [MPa] | El. [%] | Ref. | |||

| 304 | Annealed–hot finished | RT | 205 | 515 | 40 | [130] | |||

| 304L, 316L | Annealed–hot finished | RT | 170 | 485 | 40 | ||||

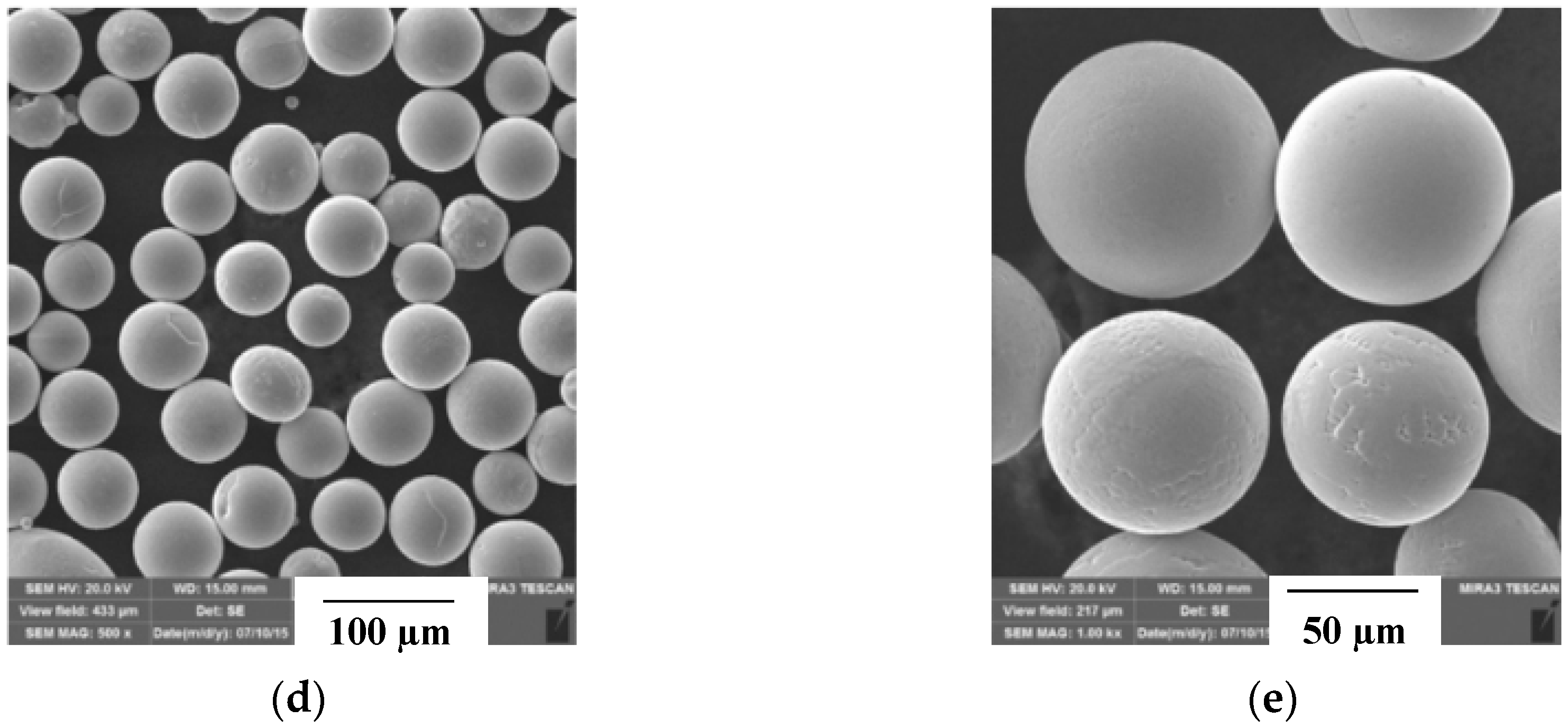

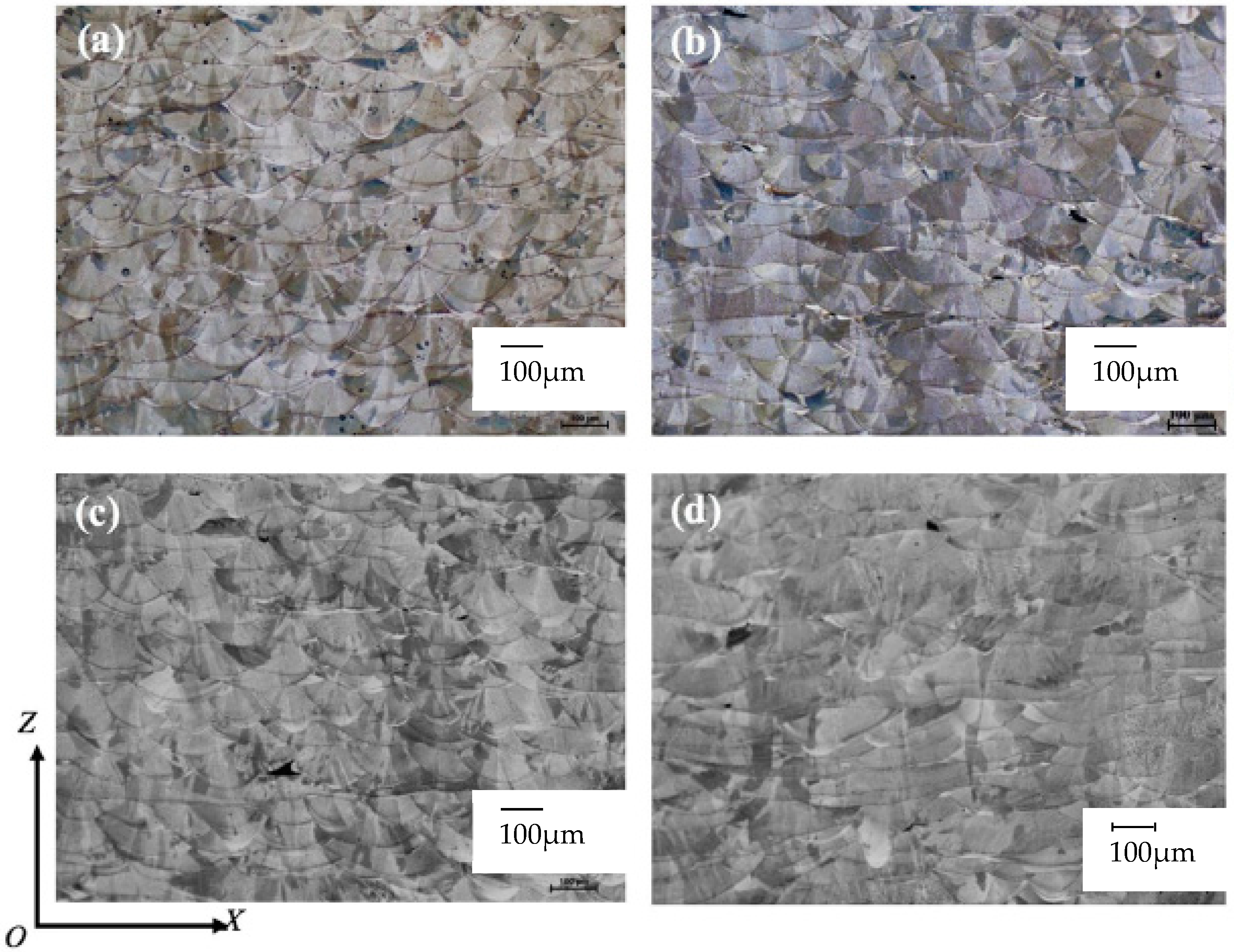

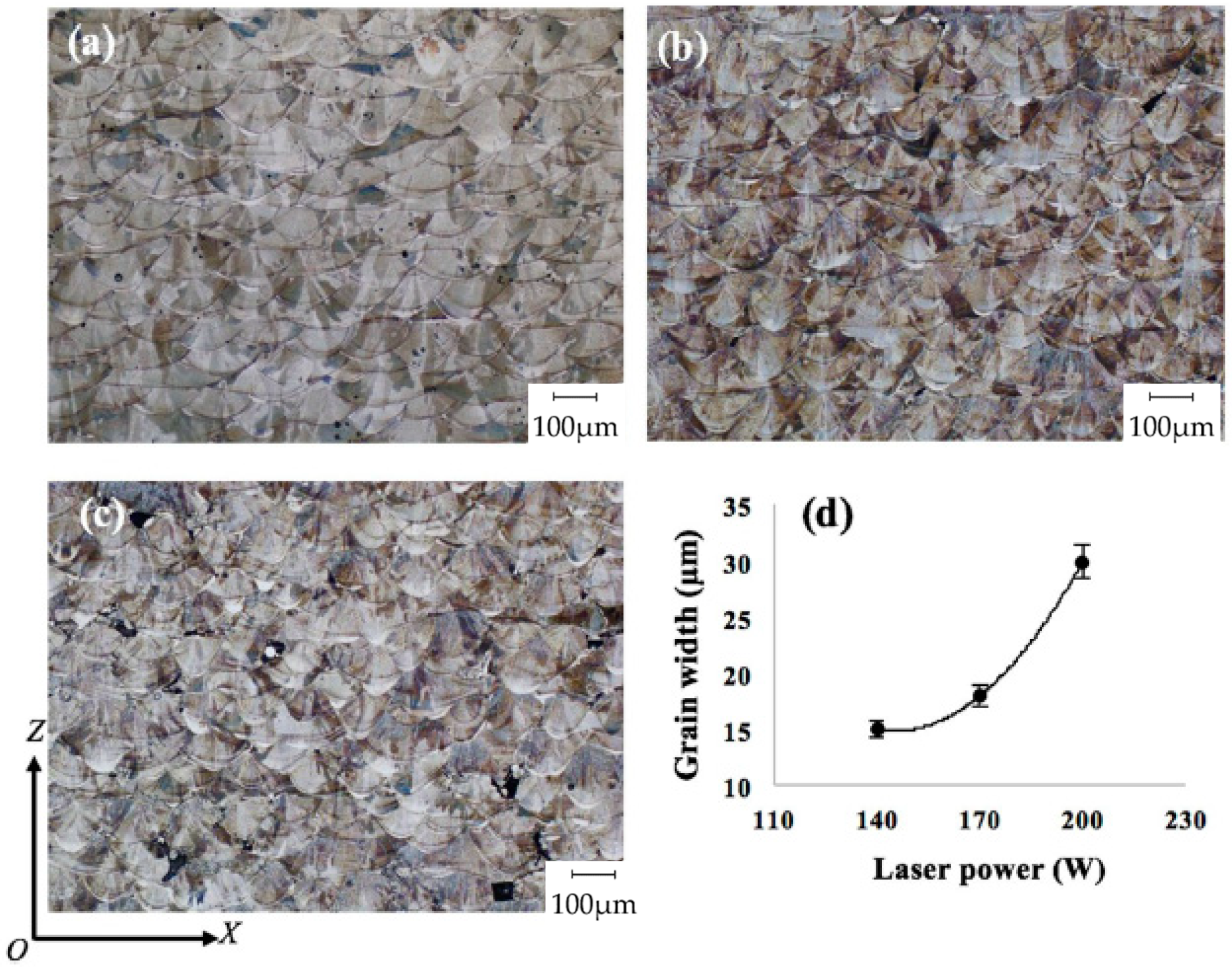

- grain size is basically independent of the selected scanning strategy, as long as the laser power is kept constant (see Figure 9);

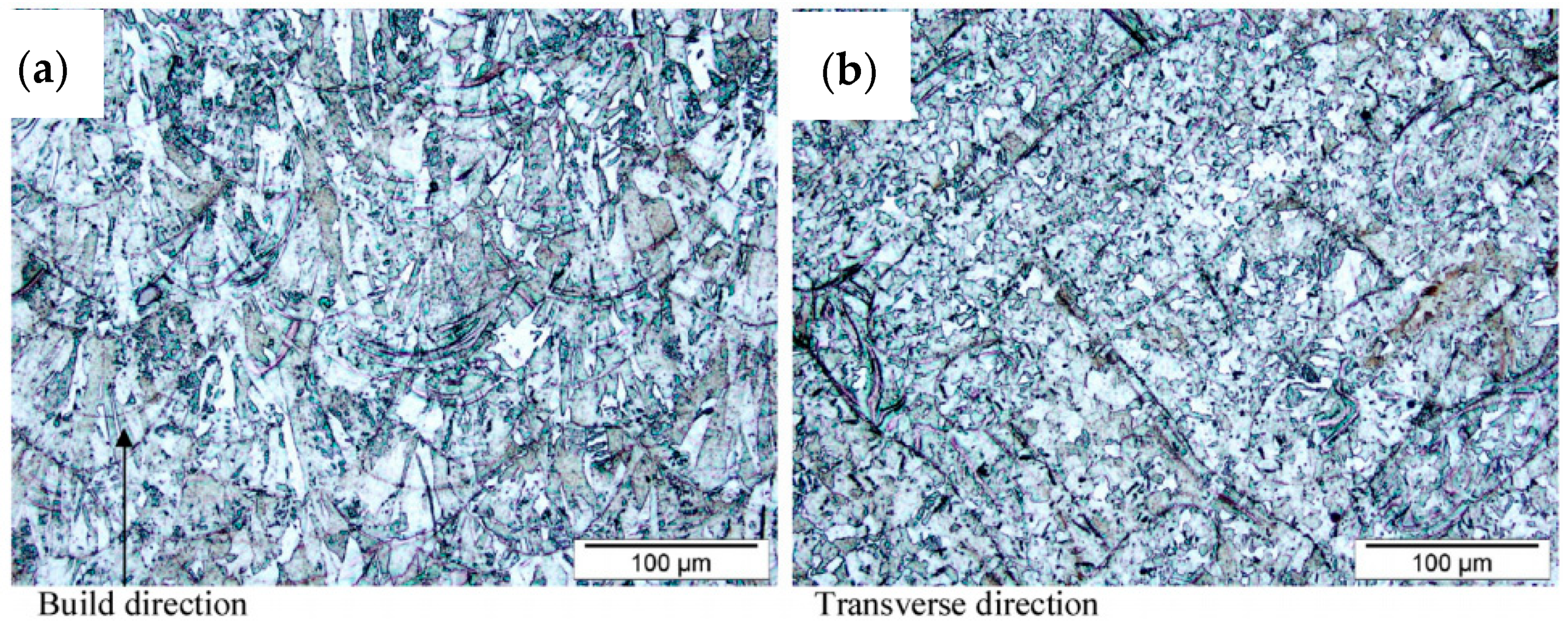

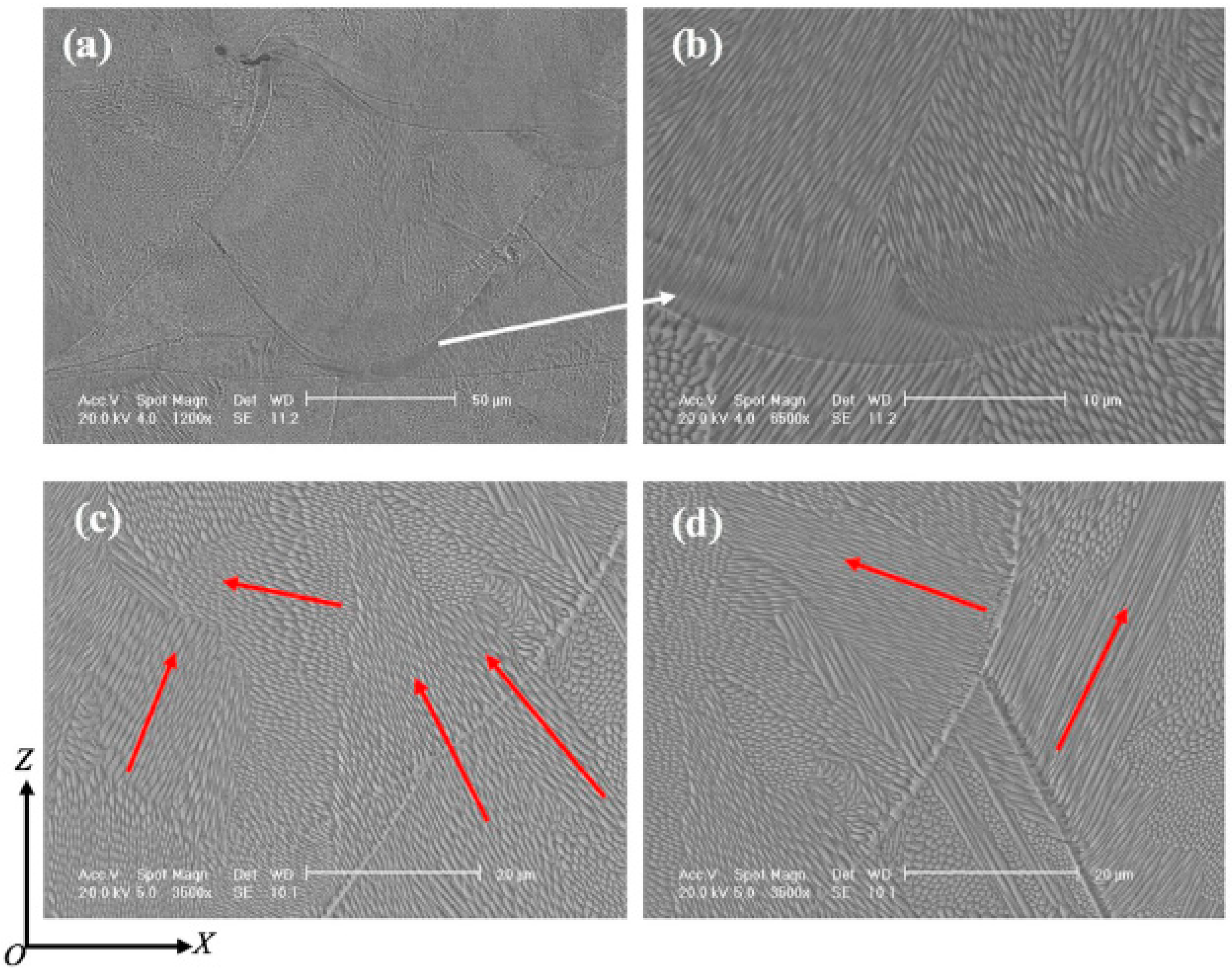

- as-built grains are characterized by needle-like structures with medium sizes of 500–800 nm and a high aspect ratio, oriented along different directions even in a single weld bead (see different growing orientations marked by red arrows in Figure 12);

- two types of boundaries were observed by [135]: cell boundaries (formed by dislocations) and colony boundaries (prior high-angle austenite grain boundaries);

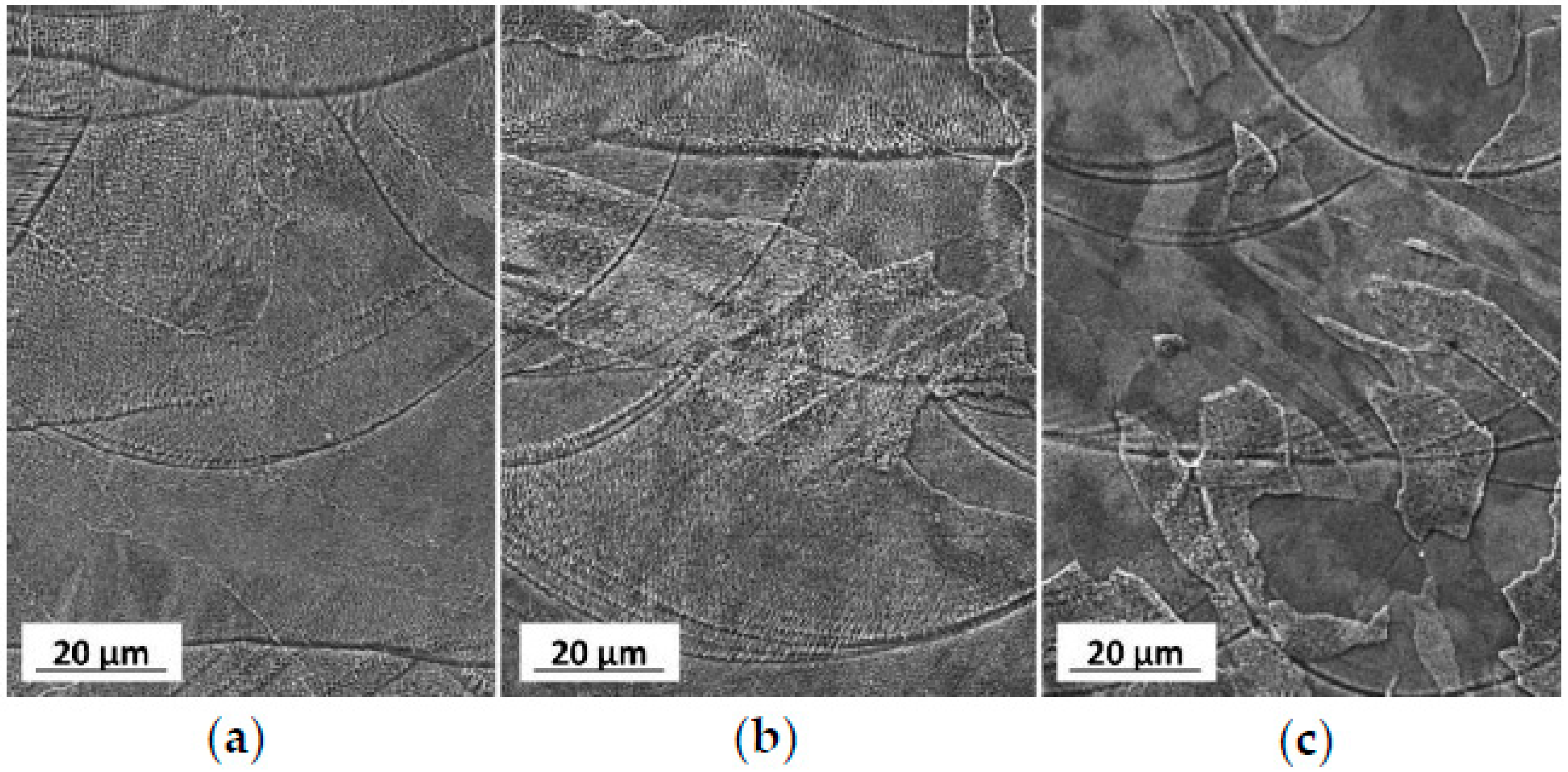

- in Figure 13, it can be seen how annealing heat treatment affects the starting microstructure (in Figure 13a): cell boundaries were unchanged after heat treatment at 800 °C, but they were not present after heat treatment at 900 °C. In contrast, colony boundaries were unmodified, meaning that no recrystallization phenomena had taken place.

3.2. Precipitation Hardening Stainless Steel Grades

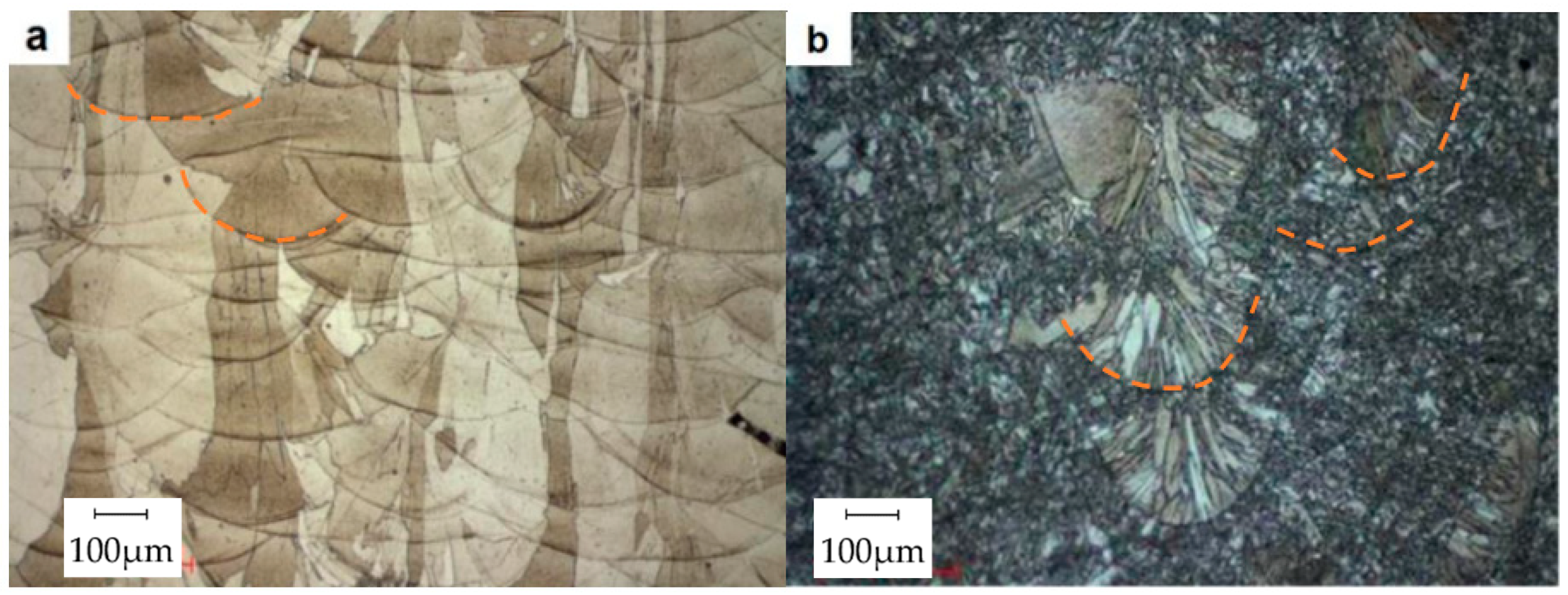

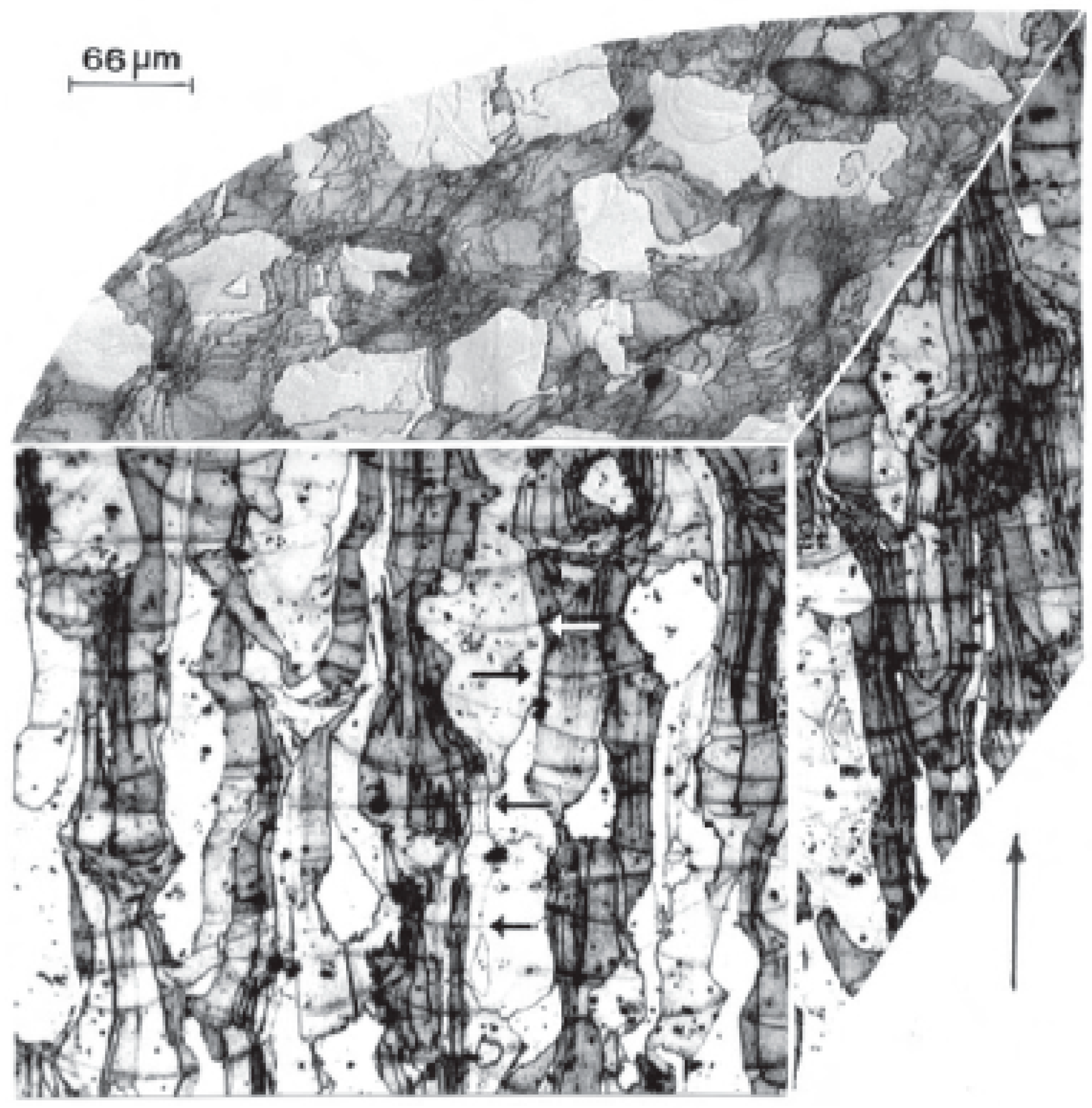

- 17-4 PH samples showed columnar grains oriented along the building direction, clearly visible in the samples in Figure 14a, Figure 15 and Figure 16. These observations are in accordance with those performed on austenitic stainless steels in the previous Section 3.1;

- As-built niobium-rich material, shown in Figure 14a, features mainly ferritic grains, with a minor content of martensite and residual austenite. Ferritic grains are characterized by a high aspect ratio, and the largest dimension reaches hundreds of micrometers. Ferritic microstructure is in contrast to the typical martensitic microstructure observed in this alloy;

- On the other hand, the as-built material shown in Figure 14b shows an overall martensitic microstructure, with a grain size in the range of 1–20 µm;

- Ferrite-rich samples do not show microstructural evolution after tempering at 480 °C (Figure 15a) and 550 °C (Figure 15b) with respect to Figure 14a. Martensitic microstructure and desired mechanical properties were achieved only after full material homogenization (Figure 15d and Table 3). This observation is in line with the thermal stability already underlined in austenitic 316L samples;

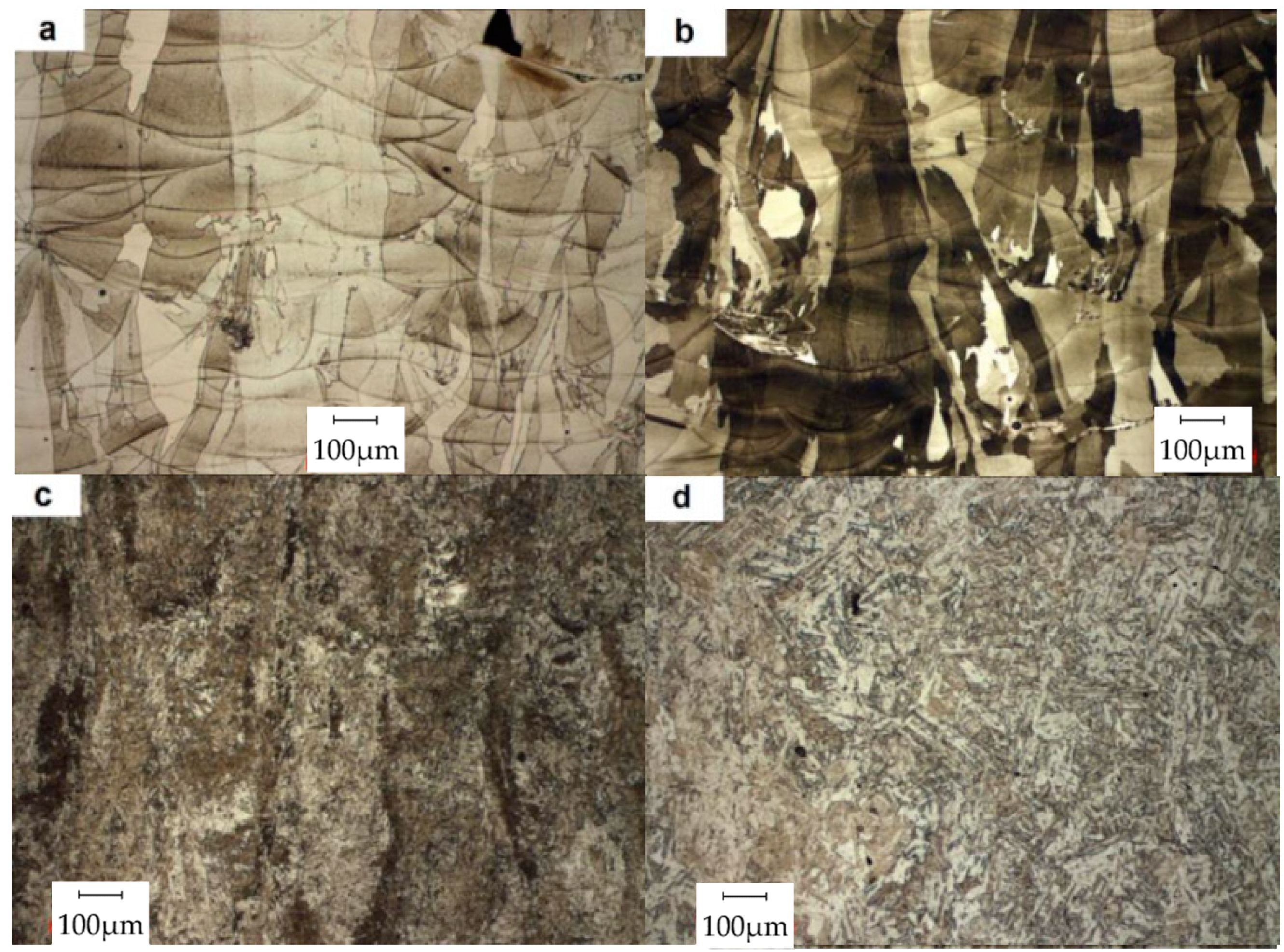

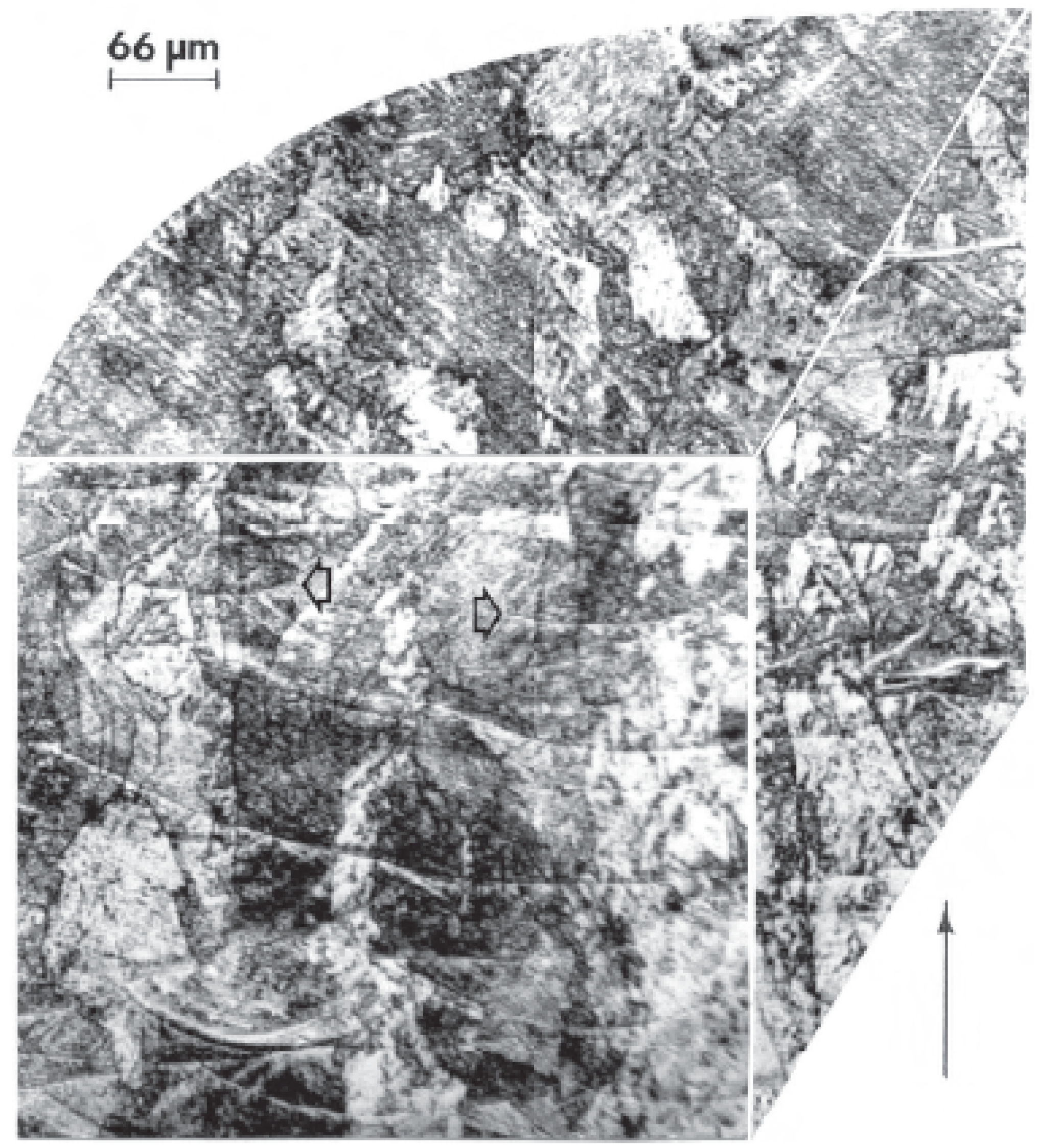

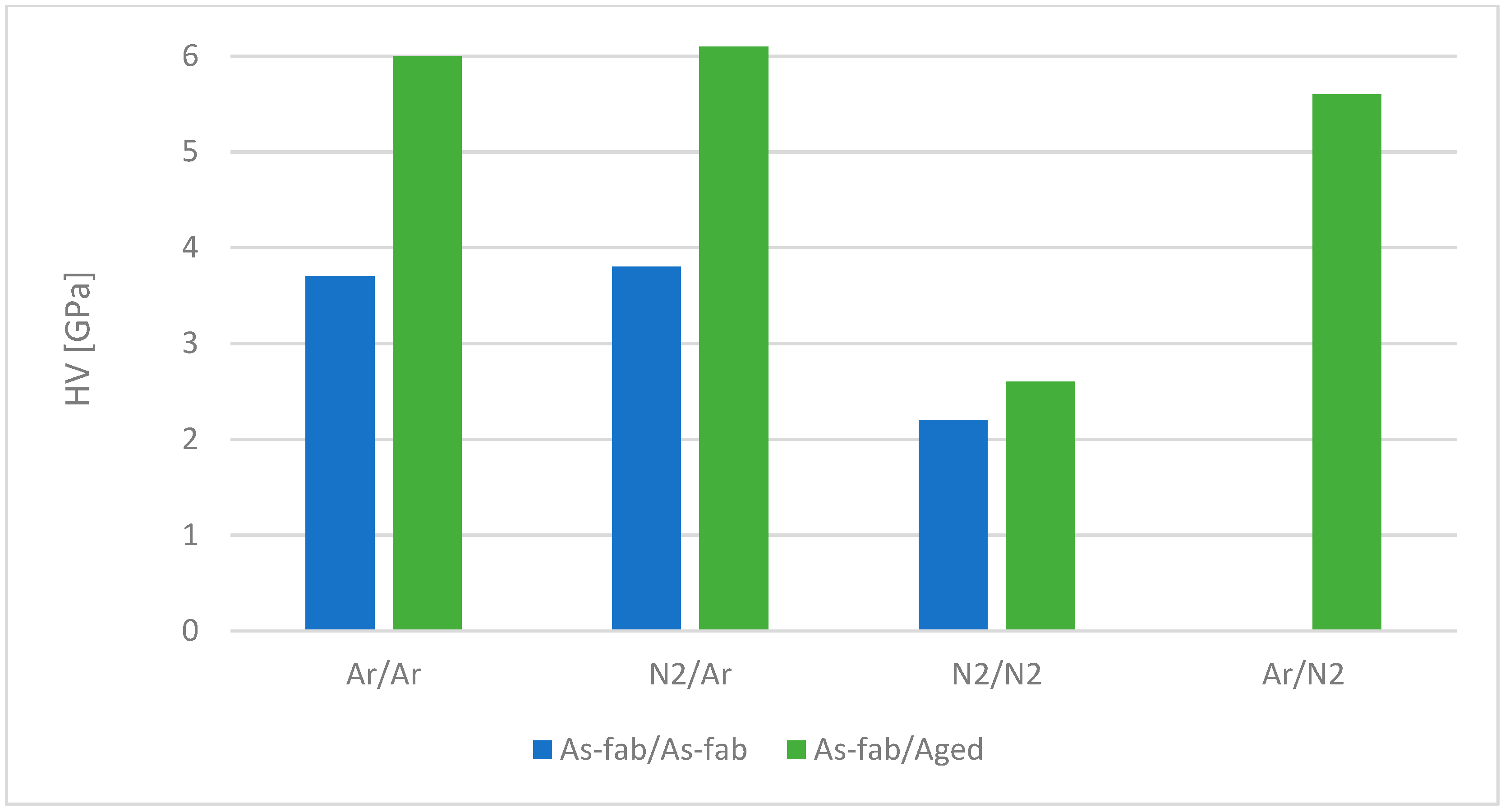

- Ar-atomized and N2-atomized powders produced completely martensitic phase materials when fabricated in an Ar environment (Figure 16 refers to a sample obtained from Ar-processed powders in Ar L-PBF atmosphere). Conversely, Ar-atomized powder and N2-atomized powder showed different behavior after N2 L-PBF processing gas environment; Ar-atomized powders fused in N2 produced fully martensitic components, while the N2-atomized powder fabricated in a N2-gas environment produced austenitic components containing roughly 15% martensite (Figure 17);

- Different microstructural observations obtained comparing Figure 16 and Figure 17 were confirmed by hardness measurements, with the results being reported in Figure 18; the austenitic sample hardness is lower than the martensitic one, and little variation can be appreciated after aging treatment, in contrast to the martensitic one, which underwent second-phase precipitation.

3.3. Other Stainless Steel Grades

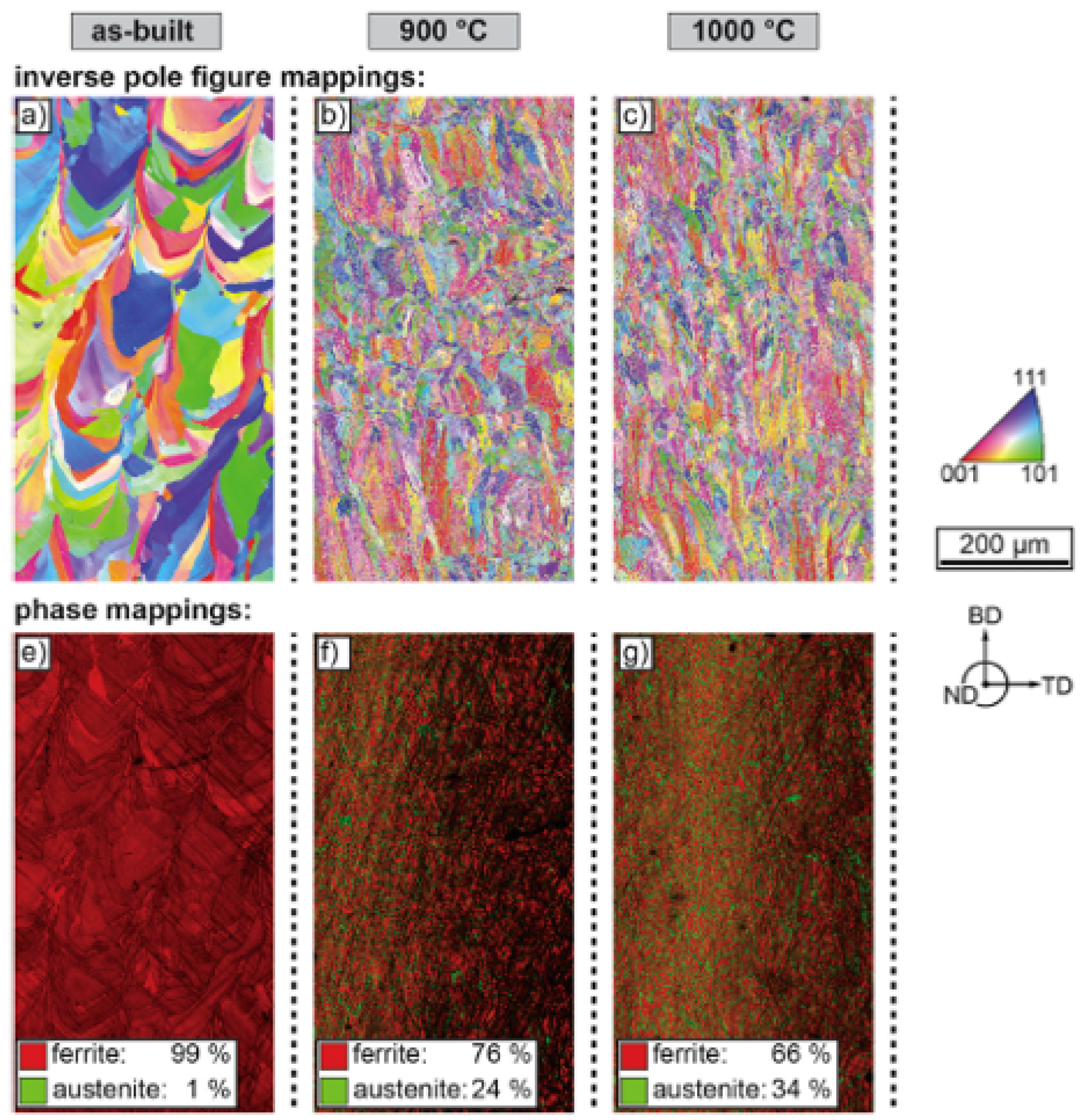

- The as-built SAF 2507 alloy is characterized by an almost completely ferritic microstructure (Figure 19a,e), strongly different from the desired microstructure, caused by rapid cooling rates typical of L-PBF. The cooling rates experienced cause the alloy’s solidification in delta ferrite, suppressing the austenite field;

- Proper heat treating conditions can restore an acceptable ferrite/austenite ratio; in particular, sample solubilization at 1000 °C (Figure 19c,g) made it possible to achieve a 34% austenite content;

- The performed tension tests (shown in Table 5) showed that L-PBF SAF2205 properly heat-treated satisfies the standard minimum requirements, while SAF2507 needs to be further optimized through subsequent heat treatment in order to achieve proper mechanical performances.

| Grade | Equipment | Relative Density [%] | Condition | BD | Test Cond. | YS [MPa] | UTS [MPa] | El. [%] | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| SAF2205 | SLM Solutions 280HL | 99.7–99.85 | As built | V | RT | - | 940 | 12 | [146] |

| HT—1000 °C/0.083 h | - | 770 | 28 | ||||||

| SAF2507 | NR | NR | As built | - | RT | 1214 | 1321 | - | [118] |

| 1200 °C | - | 500 | 30 | ||||||

| SAF2507 | EOS M270 | 99 | HT—1200 °C/0.083 h | - | RT | - | 920 | 1.8 | [147] |

| 1200 °C | - | 400 | 20 | ||||||

| Standard Reference Values | |||||||||

| Grade | Condition | Test Cond. | YS [MPa] | UTS [MPa] | El. [%] | Ref. | |||

| SAF2205 | HT—1020–1100 °C + rapid cooling | RT | >450 | >620 | >25 | [148] | |||

| SAF2507 | HT—1025–1125 °C + rapid cooling | RT | >550 | >800 | >15 | ||||

4. Conclusions

- Artefact weight reduction (made possible, for example, through topology optimization and/or lattice structures);

- Easy customization;

- Complex internal features manufacturing (e.g., inclined ducts).

Funding

Conflicts of Interest

References

- Zhai, Y.; Lados, D.A.; LaGoy, J.L. Additive Manufacturing: Making Imagination the Major Limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef]

- European Powder Metallurgy Association (EPMA)—Introduction to Additive Manufacturing Technology (Brochure). Available online: https://www.epma.com/epma-free-publications/product/introduction-to-additive-manufacturing-brochure (accessed on 3 August 2018).

- Orme, M.; Madera, I.; Gschweitl, M.; Ferrari, M. Topology Optimization for Additive Manufacturing as an Enabler for Light Weight Flight Hardware. Designs 2018, 2, 51. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.A. Overview of Current Additive Manufacturing Technologies and Selected Applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef] [PubMed]

- Shukla, M.; Todorov, I.; Kapletia, D. Application of additive manufacturing for mass customisation: Understanding the interaction of critical barriers. Prod. Plan. Control 2018, 29, 814–825. [Google Scholar] [CrossRef]

- Spallek, J.; Krause, D. Process Types of Customisation and Personalisation in Design for Additive Manufacturing Applied to Vascular Models. Procedia CIRP 2016, 50, 281–286. [Google Scholar] [CrossRef]

- Glasschroeder, J.; Prager, E.; Zaeh, M.F. Powder-bed-based 3D-printing of function integrated parts. Rapid Prototyp. J. 2015, 21, 207–215. [Google Scholar] [CrossRef]

- Sanín Pérez, P. A Study of Additive Manufacturing Applied to the Design and Production of LED Luminaires; Politecnico di Milano: Milano, Italy, 2013. [Google Scholar]

- Tang, Y.; Yang, S.; Zhao, Y.F. Sustainable Design for Additive Manufacturing through Functionality Integration and Part Consolidation. In Handbook of Sustainability in Additive Manufacturing; Muthu, S.S., Savalani, M.M., Eds.; Springer: Singapore, 2016; pp. 101–144. ISBN 978-981-10-0547-3. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Poprawe, R.; Hinke, C.; Meiners, W.; Schrage, J.; Bremen, S.; Merkt, S. SLM Production Systems: Recent Developments in Process Development, Machine Concepts and Component Design. In Advances in Production Technology; Brecher, C., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 49–65. ISBN 978-3-319-12303-5. [Google Scholar]

- Kellner, T. How 3D Printing Will Change Manufacturing. Available online: https://www.ge.com/reports/epiphany-disruption-ge-additive-chief-explains-3d-printing-will-upend-manufacturing/ (accessed on 15 April 2019).

- Wimpenny, D.I.; Pandey, P.M.; Kumar, L.J. (Eds.) Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Singapore, 2017; ISBN 978-981-10-0811-5. [Google Scholar]

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive Manufacturing of Metals: The Technology, Materials, Design and Production; Springer Series in Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-55127-2. [Google Scholar]

- Wohlers, T.; Gornet, T. History of Additive Manufacturing. Wohlers Rep. 2014, 24, 118. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; ISBN 978-1-4939-2112-6. [Google Scholar]

- Milewski, J.O. Additive Manufacturing of Metals; Springer Series in Materials Science; Springer International Publishing: Cham, Switzerland, 2017; Volume 258, ISBN 978-3-319-58204-7. [Google Scholar]

- Your Expert in Additive Manufacturing Since 25 Years. Available online: https://www.eos.info/about_eos/history (accessed on 19 April 2019).

- Deckard, C.R. Apparatus for Producing Parts by Selective Sintering. U.S. Patent 5,597,589, 28 January 1997. [Google Scholar]

- Park, J.H.; Kang, Y. Inclusions in Stainless Steels—A Review. Steel Res. Int. 2017, 88, 1700130. [Google Scholar] [CrossRef]

- Mapelli, C.; Nolli, P. Formation Mechanism of Non-Metallic Inclusions in Different Stainless Steel Grades. ISIJ Int. 2003, 43, 1191–1199. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting—Selection Guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Malekipour, E.; El-Mounayri, H. Common defects and contributing parameters in powder bed fusion AM process and their classification for online monitoring and control: A review. Int. J. Adv. Manuf. Technol. 2018, 95, 527–550. [Google Scholar] [CrossRef]

- Zadpoor, A. Frontiers of Additively Manufactured Metallic Materials. Materials 2018, 11, 1566. [Google Scholar] [CrossRef] [PubMed]

- Nilsson, J.O. Can mankind survive without stainless steel? Stainl. Steel World. 2014. 1–4. Available online: https://pdfs.semanticscholar.org/7bcf/2041cf93f4b5c3db7c7fe27b1d06d92f3602.pdf (accessed on 20 May 2019).

- Rufini, R.; Di Pietro, O.; Di Schino, A. Predictive Simulation of Plastic Processing of Welded Stainless Steel Pipes. Metals 2018, 8, 519. [Google Scholar] [CrossRef]

- Saha Podder, A.; Bhanja, A. Applications of Stainless Steel in Automobile Industry. Adv. Mater. Res. 2013, 794, 731–740. [Google Scholar] [CrossRef]

- Baddoo, N.R. Stainless steel in construction: A review of research, applications, challenges and opportunities. J. Constr. Steel Res. 2008, 64, 1199–1206. [Google Scholar] [CrossRef]

- Corradi, M.; Di Schino, A.; Borri, A.; Rufini, R. A review of the use of stainless steel for masonry repair and reinforcement. Constr. Build. Mater. 2018, 181, 335–346. [Google Scholar] [CrossRef]

- Di Schino, A. Analysis of heat treatment effect on microstructural features evolution in a micro-alloyed martensitic steel. Acta Metall. Slov. 2017, 22, 266–270. [Google Scholar] [CrossRef]

- Di Schino, A.; Di Nunzio, P.E. Metallurgical aspects related to contact fatigue phenomena in steels for back-up rolls. Acta Metall. Slov. 2017, 23, 62–71. [Google Scholar] [CrossRef]

- Di Schino, A.; Porcu, G. Metallurgical design and development of C125 grade for mild sour service application. In Proceedings of the Corrosion; NACE Corrosion Paper: San Diego, CA, USA, 2006; pp. 1–14. [Google Scholar]

- Kumar Sharma, D.; Filipponi, M.; Di Schino, A.; Rossi, F.; Castaldi, J. Corrosion behaviour of high temperature fuel cells: Issues for materials selection. Metalurgija 2019, 58, 347–351. [Google Scholar]

- Di Schino, A.; Di Nunzio, P.E.; Turconi, G.L. Microstructure evolution during tempering of martenite in e medium C steel. Mater. Sci. Forum 2007, 558, 1435–1441. [Google Scholar] [CrossRef]

- Cianetti, F.; Ciotti, M.; Palmieri, M.; Zucca, G. On the Evaluation of Surface Fatigue Strength of a Stainless-Steel Aeronautical Component. Metals 2019, 9, 455. [Google Scholar] [CrossRef]

- Talha, M.; Behera, C.K.; Sinha, O.P. A review on nickel-free nitrogen containing austenitic stainless steels for biomedical applications. Mater. Sci. Eng. C 2013, 33, 3563–3575. [Google Scholar] [CrossRef] [PubMed]

- Boulané-Petermann, L. Processes of bioadhesion on stainless steel surfaces and cleanability: A review with special reference to the food industry. Biofouling 1996, 10, 275–300. [Google Scholar] [CrossRef]

- Bregliozzi, G.; Ahmed, S.I.-U.; Di Schino, A.; Kenny, J.M.; Haefke, H. Friction and Wear Behavior of Austenitic Stainless Steel: Influence of Atmospheric Humidity, Load Range, and Grain Size. Tribol. Lett. 2004, 17, 697–704. [Google Scholar] [CrossRef]

- Di Schino, A.; Valentini, L.; Kenny, J.M.; Gerbig, Y.; Ahmed, I.; Haefke, H. Wear resistance of a high-nitrogen austenitic stainless steel coated with nitrogenated amorphous carbon films. Surf. Coat. Technol. 2002, 161, 224–231. [Google Scholar] [CrossRef]

- Di Schino, A.; Kenny, J.M.; Abbruzzese, G. Analysis of the recrystallization and grain growth processes in AISI 316 stainless steel. J. Mater. Sci. 2002, 37, 5291–5298. [Google Scholar] [CrossRef]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Leach, R. Metrology for Additive Manufacturing. Available online: http://eprints.nottingham.ac.uk/33924/1/AM%20metrology%20for%20MC.pdf (accessed on 20 May 2019).

- Jurrens, K. Measurement Science and Standards for Metals-Based Additive Manufacturing. Available online: https://www.nrc.gov/docs/ML1815/ML18150A368.pdf (accessed on 20 May 2019).

- Slotwinski, J.A.; Garboczi, E.J. Metrology Needs for Metal Additive Manufacturing Powders. JOM 2015, 67, 538–543. [Google Scholar] [CrossRef]

- Mani, M.; Lane, B.M.; Donmez, M.A.; Feng, S.C.; Moylan, S.P. A review on measurement science needs for real-time control of additive manufacturing metal powder bed fusion processes. Int. J. Prod. Res. 2017, 55, 1400–1418. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- ASTM and ISO Additive Manufacturing Committees Approve Joint Standards under Partner Standards Developing Organization Agreement|www.astm.org. Available online: https://www.astm.org/cms/drupal-7.51/newsroom/astm-and-iso-additive-manufacturing-committees-approve-joint-standards-under-partner (accessed on 23 May 2019).

- Committee F42 on Additive Manufacturing Technologies. Available online: https://www.astm.org/COMMITTEE/F42.htm (accessed on 23 May 2019).

- Clayton, J.; Deffley, R. Optimising Metal Powders for Additive Manufacturing. Met. Powder Rep. 2014, 69, 14–17. [Google Scholar] [CrossRef]

- He, X.; DebRoy, T.; Fuerschbach, P.W. Alloying element vaporization during laser spot welding of stainless steel. J. Phys. Appl. Phys. 2003, 36, 3079–3088. [Google Scholar] [CrossRef]

- DebRoy, T.; David, S.A. Physical processes in fusion welding. Rev. Mod. Phys. 1995, 67, 85–112. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2003; ISBN 978-0-471-43491-7. [Google Scholar]

- Walton, O.R. Review of Adhesion Fundamentals for Micron-Scale Particles. KONA Powder Part. J. 2008, 26, 129–141. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Kruth, J.P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and materials in selective laser sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Bidare, P.; Bitharas, I.; Ward, R.M.; Attallah, M.M.; Moore, A.J. Fluid and particle dynamics in laser powder bed fusion. Acta Mater. 2018, 142, 107–120. [Google Scholar] [CrossRef]

- Özel, T.; Arısoy, Y.M.; Criales, L.E. Computational Simulation of Thermal and Spattering Phenomena and Microstructure in Selective Laser Melting of Inconel 625. Phys. Procedia 2016, 83, 1435–1443. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.-W.; N’Dri, N.; Duan, H.; Desmaison, O. Metal additive-manufacturing process and residual stress modeling. Integr. Mater. Manuf. Innov. 2016, 5, 61–93. [Google Scholar] [CrossRef]

- Körner, C.; Attar, E.; Heinl, P. Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 2011, 211, 978–987. [Google Scholar] [CrossRef]

- Conti, P.; Cianetti, F.; Pilerci, P. Parametric Finite Elements Model of SLM Additive Manufacturing process. Procedia Struct. Integr. 2018, 8, 410–421. [Google Scholar] [CrossRef]

- Manvatkar, V.; De, A.; DebRoy, T. Spatial variation of melt pool geometry, peak temperature and solidification parameters during laser assisted additive manufacturing process. Mater. Sci. Technol. 2015, 31, 924–930. [Google Scholar] [CrossRef]

- Gürtler, F.-J.; Karg, M.; Leitz, K.-H.; Schmidt, M. Simulation of Laser Beam Melting of Steel Powders using the Three-Dimensional Volume of Fluid Method. Phys. Procedia 2013, 41, 881–886. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, Y.; Rani Kasinathan, A.; Imani Shahabad, S.; Ali, U.; Mahmoodkhani, Y.; Toyserkani, E. 3-Dimensional heat transfer modeling for laser powder-bed fusion additive manufacturing with volumetric heat sources based on varied thermal conductivity and absorptivity. Opt. Laser Technol. 2019, 109, 297–312. [Google Scholar] [CrossRef]

- Foteinopoulos, P.; Papacharalampopoulos, A.; Stavropoulos, P. On thermal modeling of Additive Manufacturing processes. CIRP J. Manuf. Sci. Technol. 2018, 20, 66–83. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Madison, J.D.; Tikare, V. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput. Mater. Sci. 2017, 135, 78–89. [Google Scholar] [CrossRef]

- Alimardani, M.; Toyserkani, E.; Huissoon, J.P. A 3D dynamic numerical approach for temperature and thermal stress distributions in multilayer laser solid freeform fabrication process. Opt. Lasers Eng. 2007, 45, 1115–1130. [Google Scholar] [CrossRef]

- Ganeriwala, R.; Zohdi, T.I. Multiphysics Modeling and Simulation of Selective Laser Sintering Manufacturing Processes. Procedia CIRP 2014, 14, 299–304. [Google Scholar] [CrossRef]

- Ren, K.; Chew, Y.; Fuh, J.Y.H.; Zhang, Y.F.; Bi, G.J. Thermo-mechanical analyses for optimized path planning in laser aided additive manufacturing processes. Mater. Des. 2019, 162, 80–93. [Google Scholar] [CrossRef]

- Alimardani, M.; Toyserkani, E.; Huissoon, J.P.; Paul, C.P. On the delamination and crack formation in a thin wall fabricated using laser solid freeform fabrication process: An experimental–numerical investigation. Opt. Lasers Eng. 2009, 47, 1160–1168. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Using machine learning to identify in-situ melt pool signatures indicative of flaw formation in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2019, 25, 151–165. [Google Scholar] [CrossRef]

- Coeck, S.; Bisht, M.; Plas, J.; Verbist, F. Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit. Manuf. 2019, 25, 347–356. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Zhang, Z.H.; Wang, Y.P.; Liu, G.; Zhou, S.Y.; Li, Y.L.; Shen, J.; Yan, M. Selective laser melting of typical metallic materials: An effective process prediction model developed by energy absorption and consumption analysis. Addit. Manuf. 2019, 25, 204–217. [Google Scholar] [CrossRef]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef]

- Parry, L.A.; Ashcroft, I.A.; Wildman, R.D. Geometrical effects on residual stress in selective laser melting. Addit. Manuf. 2019, 25, 166–175. [Google Scholar] [CrossRef]

- Hitzler, L.; Hirsch, J.; Heine, B.; Merkel, M.; Hall, W.; Öchsner, A. On the Anisotropic Mechanical Properties of Selective Laser-Melted Stainless Steel. Materials 2017, 10, 1136. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.-G.; Lee, J.-H.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Concept Laser X LINE 2000R Metal Laser Melting System. Available online: https://www.concept-laser.de/fileadmin/Machine_brochures/CL_X_LINE_2000R_DS_EN_US_4_v1.pdf (accessed on 29 April 2019).

- Machine Search|Senvol. Available online: http://senvol.com/machine-search/ (accessed on 5 May 2019).

- MYSINT100, Stampante 3D a Fusione Laser Selettiva di Polvere Metallica. SISMA. Available online: https://www.sisma.com/prodotti/mysint100/ (accessed on 29 April 2019).

- MYSINT 300, Stampante 3D a Fusione Laser Selettiva di Polvere Metallica. SISMA. Available online: https://www.sisma.com/prodotti/mysint300/ (accessed on 29 April 2019).

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Cordova, L.; Campos, M.; Tinga, T. Assessment of Moisture Content and Its Influence on Laser Beam Melting Feedstock. In Proceedings of the Euro PM2017 Congress & Exhibition: European Annual Powder Metallurgy congress and exhibition, Milan, Italy, 1–5 October 2017. [Google Scholar]

- Zhao, X.; Song, B.; Zhang, Y.; Zhu, X.; Wei, Q.; Shi, Y. Decarburization of stainless steel during selective laser melting and its influence on Young’s modulus, hardness and tensile strength. Mater. Sci. Eng. A 2015, 647, 58–61. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Stugelmayer, E. Characterization of Process Induced Effects in Laser Powder Bed Fusion Processed AlSi10Mg alloy; Master of Science Degree, Montana Tech: Butte, MT, USA, 2018. [Google Scholar]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Robinson, J.; Ashton, I.; Fox, P.; Jones, E.; Sutcliffe, C. Determination of the effect of scan strategy on residual stress in laser powder bed fusion additive manufacturing. Addit. Manuf. 2018, 23, 13–24. [Google Scholar] [CrossRef]

- Liu, B.; Wildman, R.; Tuck, C.R.; Ashcroft, I.; Hague, R.J.M. Investigaztion the Effect of Particle Size Distribution on Processing Parameters Optimisation in Selective Laser Melting Process; Additive Manufacturing Research Group, Loughborough University: Loughborough, UK, 2011. [Google Scholar]

- Clayton, J.; Millington-Smith, D.; Armstrong, B. The Application of Powder Rheology in Additive Manufacturing. JOM 2015, 67, 544–548. [Google Scholar] [CrossRef]

- Rausch, A.M.; Markl, M.; Körner, C. Predictive simulation of process windows for powder bed fusion additive manufacturing: Influence of the powder size distribution. Comput. Math. Appl. 2018, S0898122118303535. [Google Scholar] [CrossRef]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef]

- Dowson, G. Introduction to Powder Metallurgy—The Process and its Products; EPMA: Mannheim, Germany, 2008. [Google Scholar]

- Sames, W.J.; Medina, F.; Peter, W.H.; Babu, S.S.; Dehoff, R.R. Effect of Process Control and Powder Quality on Inconel 718 Produced Using Electron Beam Melting. In 8th International Symposium on Superalloy 718 and Derivatives; Ott, E., Banik, A., Andersson, J., Dempster, I., Gabb, T., Groh, J., Heck, K., Helmink, R., Liu, X., Wusatowska-Sarnek, A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 409–423. ISBN 978-1-119-01685-4. [Google Scholar]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D. Producing hip implants of titanium alloys by additive manufacturing. Int. J. Bioprinting 2016, 2, 78–84. [Google Scholar] [CrossRef]

- Choo, H.; Sham, K.-L.; Bohling, J.; Ngo, A.; Xiao, X.; Ren, Y.; Depond, P.J.; Matthews, M.J.; Garlea, E. Effect of laser power on defect, texture, and microstructure of a laser powder bed fusion processed 316L stainless steel. Mater. Des. 2019, 164, 107534. [Google Scholar] [CrossRef]

- Vrancken, B. Study of Residual Stresses in Selective Laser Melting. Ph.D. Thesis, KU Leuven—Faculty of Engineering Science, Leuven, Belgium, June 2016. [Google Scholar]

- Kamath, C.; El-dasher, B.; Gallegos, G.F.; King, W.E.; Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 2014, 74, 65–78. [Google Scholar] [CrossRef]

- Keshavarzkermani, A.; Marzbanrad, E.; Esmaeilizadeh, R.; Mahmoodkhani, Y.; Ali, U.; Enrique, P.D.; Zhou, N.Y.; Bonakdar, A.; Toyserkani, E. An investigation into the effect of process parameters on melt pool geometry, cell spacing, and grain refinement during laser powder bed fusion. Opt. Laser Technol. 2019, 116, 83–91. [Google Scholar] [CrossRef]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. 2013, 50, 581–586. [Google Scholar] [CrossRef]

- Jeon, T.; Hwang, T.; Yun, H.; VanTyne, C.; Moon, Y. Control of Porosity in Parts Produced by a Direct Laser Melting Process. Appl. Sci. 2018, 8, 2573. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Yadollahi, A.; Mahtabi, M.J.; Khalili, A.; Doude, H.R.; Newman, J.C. Fatigue life prediction of additively manufactured material: Effects of surface roughness, defect size, and shape. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1602–1614. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater. Des. 2009, 30, 2903–2910. [Google Scholar] [CrossRef]

- Metelkova, J.; Kinds, Y.; Kempen, K.; de Formanoir, C.; Witvrouw, A.; Van Hooreweder, B. On the influence of laser defocusing in Selective Laser Melting of 316L. Addit. Manuf. 2018, 23, 161–169. [Google Scholar] [CrossRef]

- Bassoli, E.; Sola, A.; Celesti, M.; Calcagnile, S.; Cavallini, C. Development of Laser-Based Powder Bed Fusion Process Parameters and Scanning Strategy for New Metal Alloy Grades: A Holistic Method Formulation. Materials 2018, 11, 2356. [Google Scholar] [CrossRef] [PubMed]

- Mishurova, T.; Artzt, K.; Haubrich, J.; Requena, G.; Bruno, G. New aspects about the search for the most relevant parameters optimizing SLM materials. Addit. Manuf. 2019, 25, 325–334. [Google Scholar] [CrossRef]

- Bruna-Rosso, C.; Demir, A.G.; Previtali, B. Selective laser melting finite element modeling: Validation with high-speed imaging and lack of fusion defects prediction. Mater. Des. 2018, 156, 143–153. [Google Scholar] [CrossRef]

- Huang, Z.; Dantan, J.-Y.; Etienne, A.; Rivette, M.; Bonnet, N. Geometrical deviation identification and prediction method for additive manufacturing. Rapid Prototyp. J. 2018, 24, 1524–1538. [Google Scholar] [CrossRef]

- Hussain, B.; El-Gizawy, A.S. Development of 3D Finite Element Model for Predicting Process-Induced Defects in Additive Manufacturing by Selective Laser Melting (SLM). In Proceedings of the Volume 2: Advanced Manufacturing; ASME: Phoenix, ZA, USA, 2016; p. V002T02A065. [Google Scholar]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. JOM 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Saeidi, K.; Akhtar, F. Microstructure-Tailored Stainless Steels with High Mechanical Performance at Elevated Temperature. In Stainless Steels and Alloys; Duriagina, Z., Ed.; IntechOpen: London, UK, 2019; ISBN 978-1-78985-369-8. [Google Scholar]

- Hooper, P.A. Melt pool temperature and cooling rates in laser powder bed fusion. Addit. Manuf. 2018, 22, 548–559. [Google Scholar] [CrossRef]

- Molinari, A. La metastabilità strutturale delle leghe metalliche ottenute per Selective Laser Melting. Metall. Ital. 2017, 21–27. [Google Scholar]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- EOS Metal Materials for Additive Manufacturing. Available online: https://www.eos.info/material-m (accessed on 20 April 2019).

- Renishaw Renishaw: Metal Powders Supply. Available online: http://www.renishaw.com/en/metal-powders-supply--31458 (accessed on 5 May 2019).

- SLM Solutions Group AG: SLM® Metal Powder. Available online: https://www.slm-solutions.com/en/products/accessories-consumables/slmr-metal-powder/ (accessed on 5 May 2019).

- Metal Materials. Available online: https://it.3dsystems.com/materials/metal (accessed on 21 April 2019).

- Materials Laser Melting—Concept Laser. Available online: https://www.concept-laser.de/en/products/materials.html (accessed on 30 March 2019).

- Nguyen, Q.B.; Zhu, Z.; Ng, F.L.; Chua, B.W.; Nai, S.M.L.; Wei, J. High mechanical strengths and ductility of stainless steel 304L fabricated using selective laser melting. J. Mater. Sci. Technol. 2019, 35, 388–394. [Google Scholar] [CrossRef]

- Marbury, F. Characterization of SLM Printed 316L Stainless Steel and Investigation of Micro Lattice Geometry; California Polytechnic State University: San Luis Obispo, CA, USA, 2017. [Google Scholar]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- ASTM A276/A276M—Standard Specification for Stainless Steel Bars and Shapes; ASTM International: West Conshohocken, PA, USA, 2017.

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Uhlmann, E.; Fleck, C.; Gerlitzky, G.; Faltin, F. Dynamical fatigue behavior of additive manufactured products for a fundamental life cycle approach. Procedia CIRP 2017, 61, 588–593. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Qiu, C.; Kindi, M.A.; Aladawi, A.S.; Hatmi, I.A. A comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci. Rep. 2018, 8, 7785. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Fredriksson, G.; Svensson, K.; Yadroitsev, I.; Yadroitsava, I.; Thuvander, M.; Peng, R. Microstructure, Solidification Texture, and Thermal Stability of 316 L Stainless Steel Manufactured by Laser Powder Bed Fusion. Metals 2018, 8, 643. [Google Scholar] [CrossRef]

- Auguste, P.; Mauduit, A.; Fouquet, L.; Pillot, S. Study on 17-4 PH stainless steel produced by selective laser melting. UPB Sci. Bull. Ser. B-chem. Mater. Sci. 2018, 80, 197–210. [Google Scholar]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting. J. Mater. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel. Int. J. Fatigue 2017, 94, 218–235. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Elwany, A.; Yadollahi, A.; Thompson, S.M.; Bian, L.; Shamsaei, N. Mechanical properties and microstructural characterization of selective laser melted 17-4 PH stainless steel. Rapid Prototyp. J. 2017, 23, 280–294. [Google Scholar] [CrossRef]

- Luecke, W.E.; Slotwinski, J.A. Mechanical Properties of Austenitic Stainless Steel Made by Additive Manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 398. [Google Scholar] [CrossRef] [PubMed]

- Nezhadfar, P.D.; Masoomi, M.; Thompson, S.; Pham, N.; Shamsaei, N. Mechanical Properties of 17-4 Ph Stainless Steel Additively Manufactured Under Ar and N2 Shielding Gas. In Proceedings of the 29th Annual International Solid Freeform Fabrication, Austin, TX, USA, 13–15 August 2018; p. 10. [Google Scholar]

- Ali, U.; Esmaeilizadeh, R.; Ahmed, F.; Sarker, D.; Muhammad, W.; Keshavarzkermani, A.; Mahmoodkhani, Y.; Marzbanrad, E.; Toyserkani, E. Identification and characterization of spatter particles and their effect on surface roughness, density and mechanical response of 17-4 PH stainless steel laser powder-bed fusion parts. Mater. Sci. Eng. A 2019, 756, 98–107. [Google Scholar] [CrossRef]

- Rafi, H.K.; Starr, T.L.; Stucker, B.E. A comparison of the tensile, fatigue, and fracture behavior of Ti–6Al–4V and 15-5 PH stainless steel parts made by selective laser melting. Int. J. Adv. Manuf. Technol. 2013, 69, 1299–1309. [Google Scholar] [CrossRef]

- ASTM A564/A564M—Standard Specification for Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and Shapes; ASTM International: West Conshohocken, PA, USA, 2013.

- EN 10088-3: Stainless Steels—Part 3: Technical Delivery Conditions for Semi-Finished Products, Bars, Rods, Wire, Sections and Bright Products of Corrosion Resisting Steels for General Purposes; CEN-CENELEC Management Centre: Brussels, Belgium, 2014.

- Hengsbach, F.; Koppa, P.; Duschik, K.; Holzweissig, M.J.; Burns, M.; Nellesen, J.; Tillmann, W.; Tröster, T.; Hoyer, K.-P.; Schaper, M. Duplex stainless steel fabricated by selective laser melting—Microstructural and mechanical properties. Mater. Des. 2017, 133, 136–142. [Google Scholar] [CrossRef]

- Saeidi, K.; Alvi, S.; Lofaj, F.; Petkov, V.I.; Akhtar, F. Advanced Mechanical Strength in Post Heat Treated SLM 2507 at Room and High Temperature Promoted by Hard/Ductile Sigma Precipitates. Metals 2019, 9, 199. [Google Scholar] [CrossRef]

- ASTM A789/A789M—Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service; ASTM International: West Conshohocken, PA, USA, 2017.

| Alloy | Fatigue Endurance at 106 Cycles [MPa] | R | Surface Condition | Ra [µm] | Ref. |

|---|---|---|---|---|---|

| 316L | 130 | −1 | As built | 13.29 | [132] |

| 316L | 170 | −1 | Vibratory finished | 1.74 | |

| 316L | 240 | −1 | Turned | 1.08 | |

| 316L | 200 | 0.1 | As built | 10.0 | [131] |

| 316L | 256 | 0.1 | Machined | 0.4 | |

| 316L | 269 | 0.1 | Polished | 0.1 | |

| 316L | 108 | −1 | As built | NR | [133] |

| 316L | 267 | −1 | Turned | NR |

| Grade | Equipment | Relative Density [%] | Condition | BD | Test Cond. | YS [MPa] | UTS [MPa] | El. [%] | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 17-4 PH | EOS M270 | NR | As built | H | RT | 523 | 1028 | - | [140] |

| V | 494 | 979 | - | ||||||

| HT—650 °C/1 h | H | 436 | 1295 | - | |||||

| V | 483 | 1298 | - | ||||||

| 17-4 PH | EOS M290 | NR | As built | V | RT | 835 | 1169 | 48.42 | [141] |

| HT—1050 °C/0.5 h + 552 °C/4 h | 1176 | 1170 | 32.7 | ||||||

| 17-4 PH | SLM Solutions 280HL | >99 average 99.6 | As built | H | RT | 850 | 890 | 13 | [136] |

| V | 760 | 785 | 2.5 | ||||||

| HT—480 °C/1 h | H | - | 780 | - | |||||

| V | - | 560 | - | ||||||

| HT—550 °C/4 h | H | 1210 | 1220 | 0.5 | |||||

| V | - | 550 | - | ||||||

| HT—1040 °C/1.5 h + quenching + 480 °C/1 h | H | 785 | 990 | 4.6 | |||||

| V | 590 | 680 | 1 | ||||||

| HT—1190 °C/2 h + 1040 °C/1.5 h + quenching + 480 °C/1 h | H | 1400 | 1295 | 3 | |||||

| V | 1240 | 1305 | 1 | ||||||

| 17-4 PH | EOS M290 | NR | As built | H | RT | - | 710 | 6.7–7.2 | [142] |

| 17-4 PH | 3D Systems ProX 100 | NR | As-built | H | RT | 650 | 1050 | 9.8 | [139] |

| V | 600–720 | 950–1050 | 3.5–6.4 | ||||||

| HT—1038 °C/0.5 h + 482 °C/1 h | H | 910 | 1220 | 7.8 | |||||

| V | 730–950 | 970–1120 | 2.5–3.5 | ||||||

| 15-5 PH | EOS M270 | NR | As built | H | RT | 1297 | 1450 | 12.53 | [143] |

| V | 1100 | 1467 | 14.92 | ||||||

| Standard Reference Values | |||||||||

| Grade | Condition | Test Condition | YS [MPa] | UTS [MPa] | El. [%] | Ref. | |||

| 17-4 PH | H900 aging—482 °C/1 h | RT | >1170 | >1310 | >10 | [144] | |||

| 15-5 PH | H900 aging—482 °C/1 h | RT | >1170 | >1310 | >6 (transv.) | ||||

| >10 (long.) | |||||||||

| Grade | Equipment | Relative Density [%] | Cond. | BD | Test Cond. | YS [MPa] | UTS [MPa] | El. [%] | Ref. | |

|---|---|---|---|---|---|---|---|---|---|---|

| 420 | NR | NR | As built | RT | 800 | 1800 | 5 | [118] | ||

| 420 | SD | NR | As built | H | RT | - | 505 | - | [88] | |

| V | - | 1045 | - | |||||||

| Standard Reference Values | ||||||||||

| Grade | Condition | Test Condition | YS [MPa] | UTS [MPa] | El. [%] | Ref. | ||||

| 420 | Annealed—holding T: 745–825 °C + air cooling | RT | - | <760 | - | [145] | ||||

| QT800—quench at 950–1050 °C + oil or air cooling + tempering at 600–700 °C | >600 | 800–950 | >12 | |||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zitelli, C.; Folgarait, P.; Di Schino, A. Laser Powder Bed Fusion of Stainless Steel Grades: A Review. Metals 2019, 9, 731. https://doi.org/10.3390/met9070731

Zitelli C, Folgarait P, Di Schino A. Laser Powder Bed Fusion of Stainless Steel Grades: A Review. Metals. 2019; 9(7):731. https://doi.org/10.3390/met9070731

Chicago/Turabian StyleZitelli, Chiara, Paolo Folgarait, and Andrea Di Schino. 2019. "Laser Powder Bed Fusion of Stainless Steel Grades: A Review" Metals 9, no. 7: 731. https://doi.org/10.3390/met9070731

APA StyleZitelli, C., Folgarait, P., & Di Schino, A. (2019). Laser Powder Bed Fusion of Stainless Steel Grades: A Review. Metals, 9(7), 731. https://doi.org/10.3390/met9070731