3. Results

In the following test series, the hybrid manufacturing process from FSSW and bonding is investigated. The aim is to realize high weld spot strengths without strength-reducing adhesive burn-off in order to be able to exploit the positive mechanical properties of this hybrid process. From previous investigations, the welding stud geometry GewN (M5 thread with three spiral grooves) and the shoulder SS (shoulder with worm) emerged as optimal tools. Additionally, the optimum speed for the FSSW tests has already been worked out, which is now also used in the FSSBW. For the following test series, therefore, only the dwell time is varied. Based on preliminary investigations of the temperature behavior, damage to the adhesive layer is to be expected with increasing residence time.

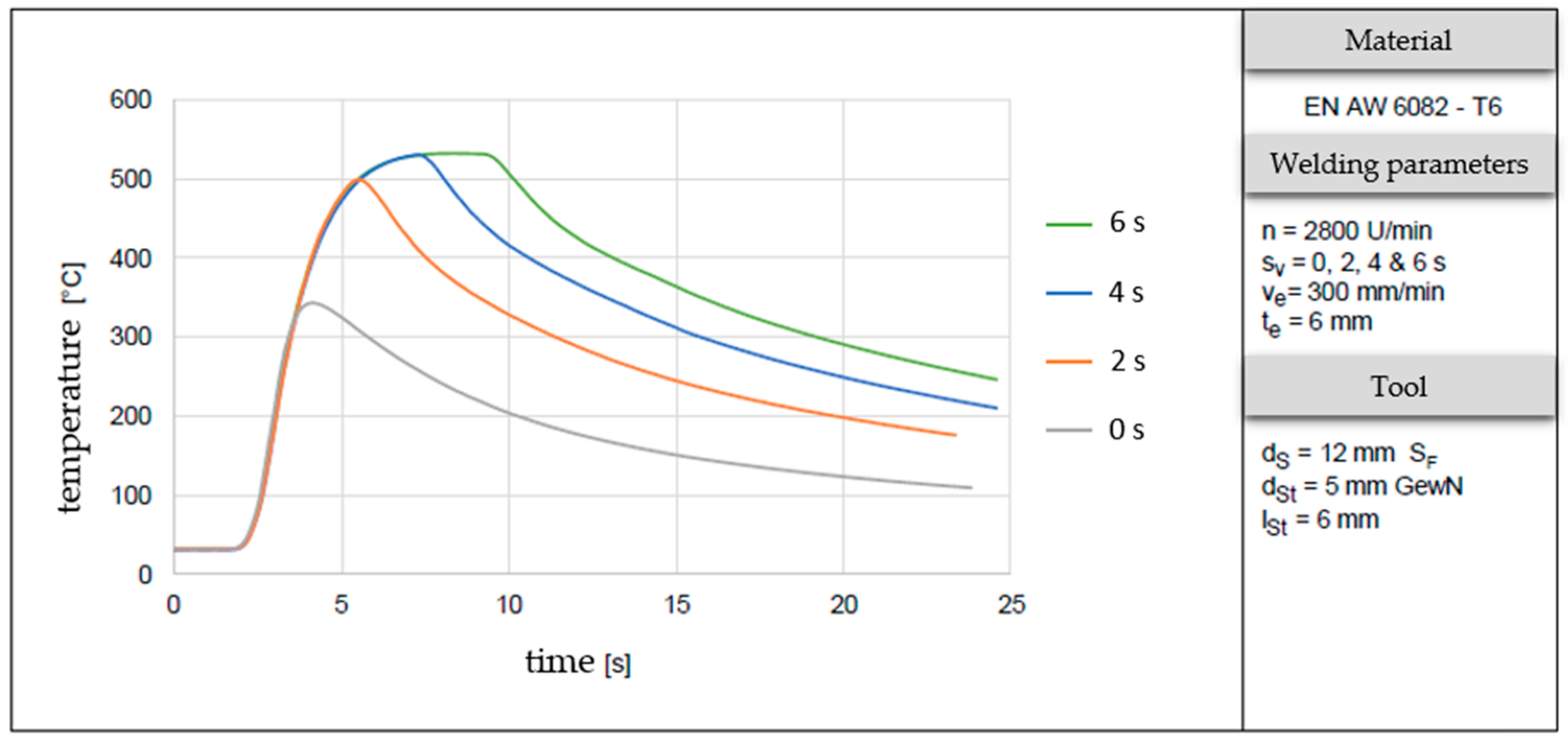

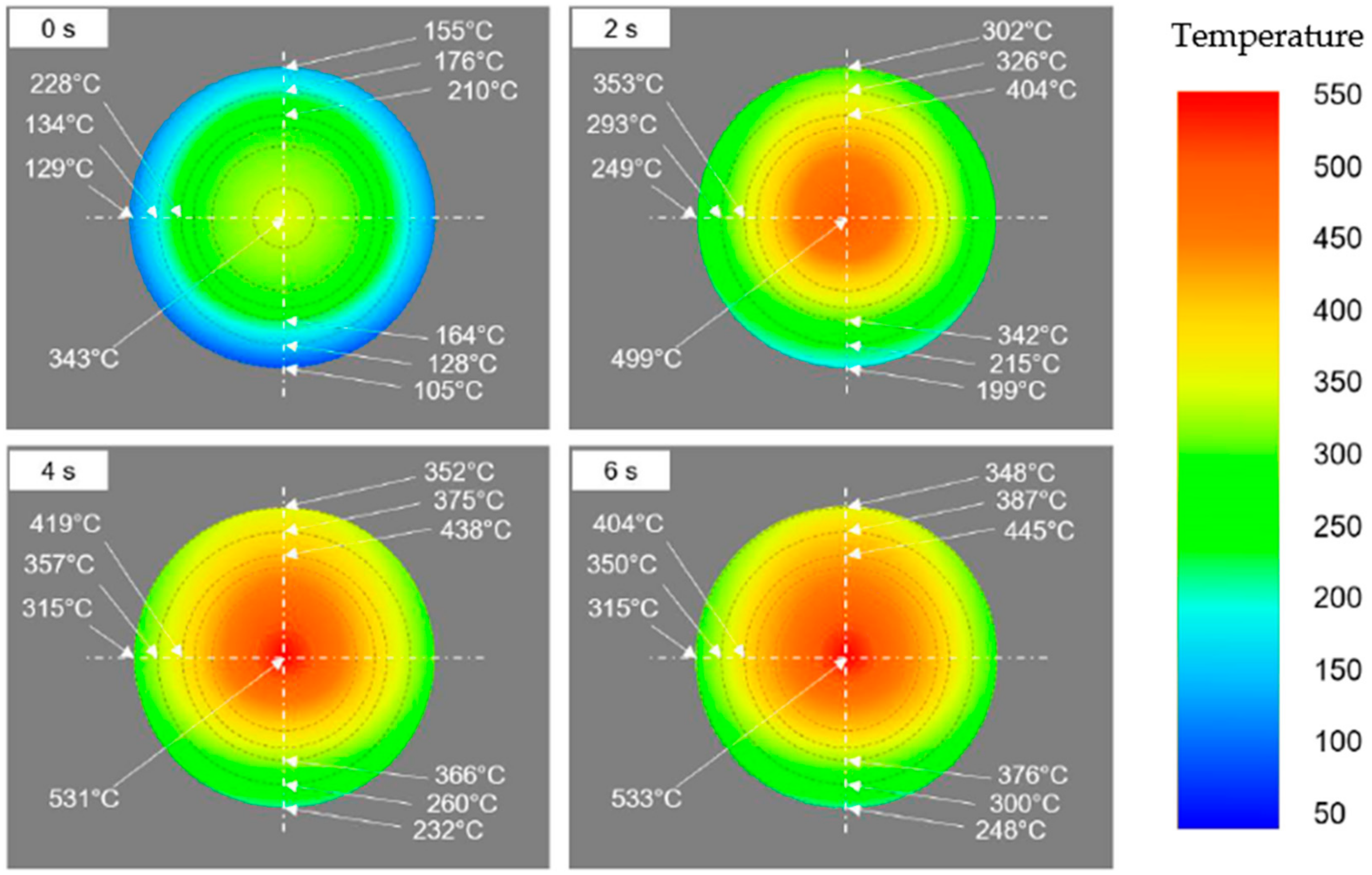

Figure 2 shows the temperature curve at the welding stud for the four residence times. All samples show a similar heating and cooling behavior, but the maximum temperature rises up to 4 s dwell time. From 4 to 6 s, no further increase of the maximum temperature can be recorded, which has already been shown in the tests for parameter determination. However, this diagram can be used to explain why the samples with a residence time of 6 s were noticeably warmer, as the samples were kept at the maximum temperature for longer due to the longer residence time.

In the FSSBW study, the influence of glass beads on strength and material flow should be considered, which is why tests with and without glass beads are carried out. The glass beads have a diameter of 0.25 mm.

Table 4 shows the experimental design for the FSSBW study.

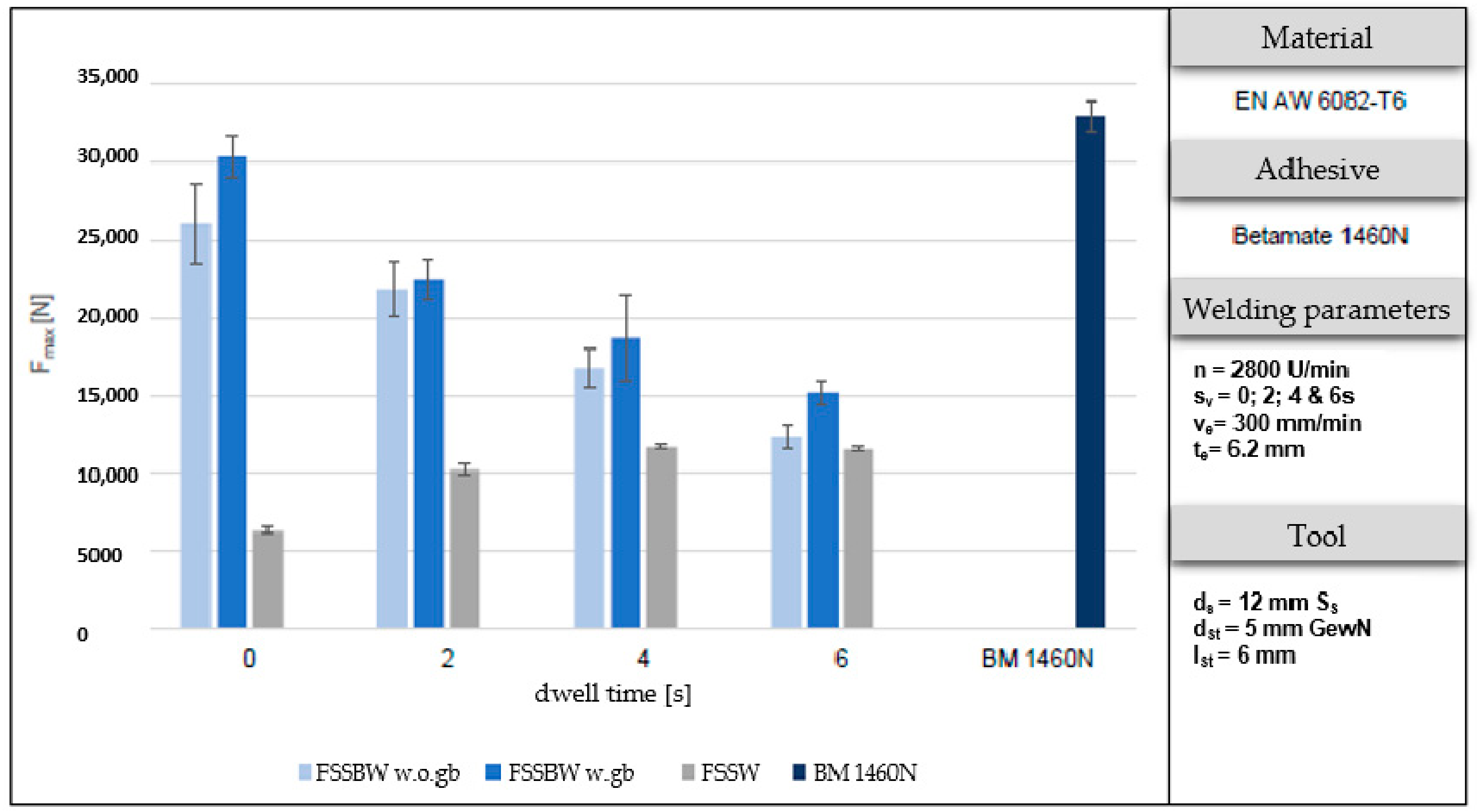

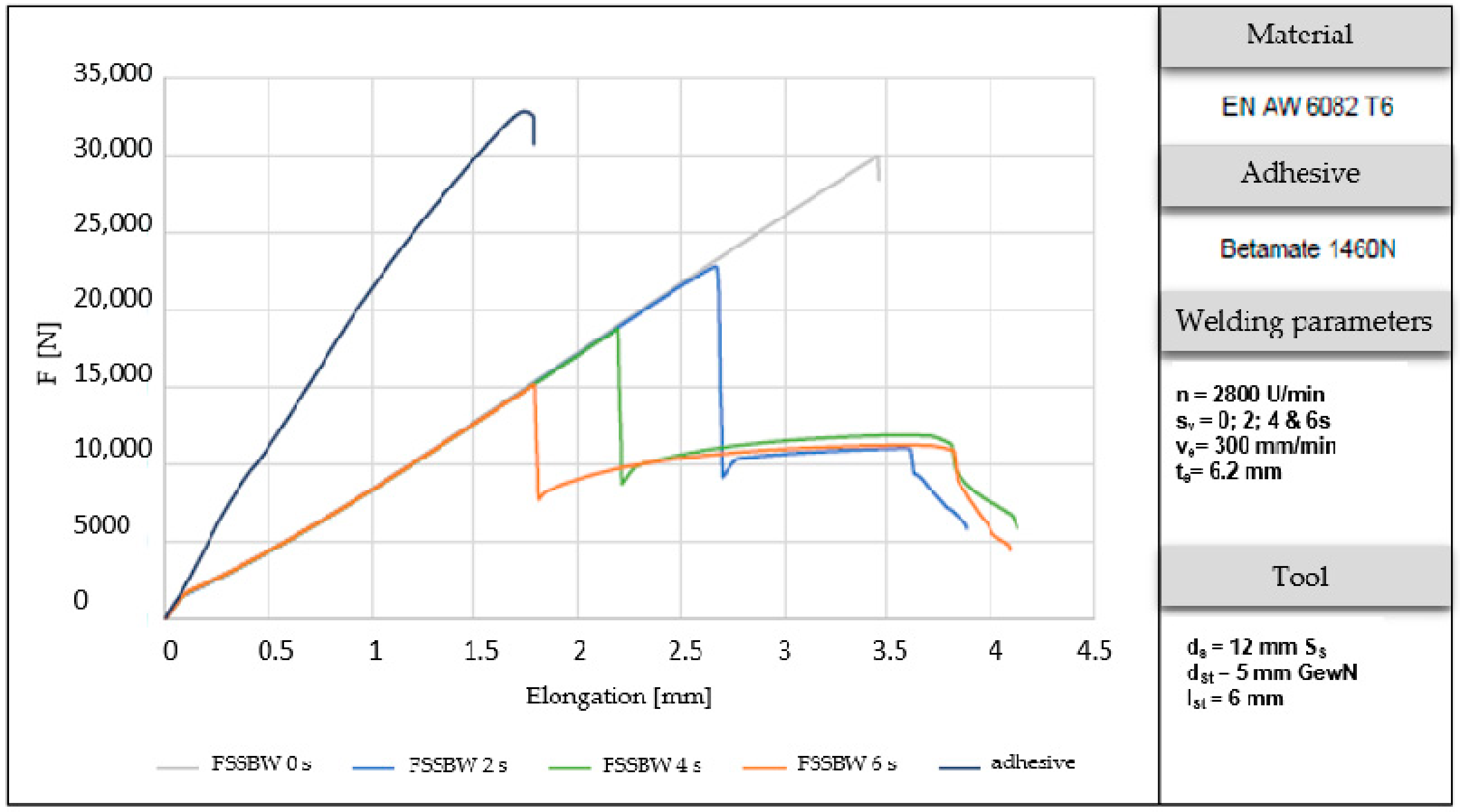

The results of the tensile shear test of the FSSBW specimens with and without glass beads are shown in

Figure 3 and compared with the results of the purely friction stir welded and purely bonded specimens. On the one hand, it can be observed that the FSSBW specimens with glass beads achieve higher tensile shear forces than the FSSBW specimens without glass beads. The reason for this is probably the displacement of the adhesive from the adhesive joint. To verify this assumption, the cross sections and fracture patterns are examined below. For all FSSBW specimens, a greater dispersion of the tensile force can be observed compared to the FSSW specimens, presumably caused by the different characteristics of the adhesive layer.

If the tensile strength of the purely bonded and purely friction-welded specimens is compared, the weld points achieve higher strengths. With a maximum tensile force of 11.7 kN and a weld spot area of 93.5 mm2, the tensile strength is 125 MPa. The purely bonded specimens withstand a tensile force of 32.9 kN with an adhesive surface of 1575 mm2, which corresponds to a tensile strength of 20.9 MPa. On the other hand, all FSSBW specimens have a lower tensile force than the purely bonded specimens. In addition, the shear forces decrease with increasing residence time, which can probably be attributed to the strength-reducing adhesive burn-up. The difference in shear forces between the FSSW and FSSBW specimens also decreases with increasing residence time, suggesting that the adhesive layer contributes less to the overall strength of the joint. With a residence time of 0 s, on the other hand, it can be assumed that the high joint strength is almost exclusively based on the adhesive strength, since the FSSW specimens have significantly lower weld spot strengths due to the lower heat input and thus insufficient plasticization of the material.

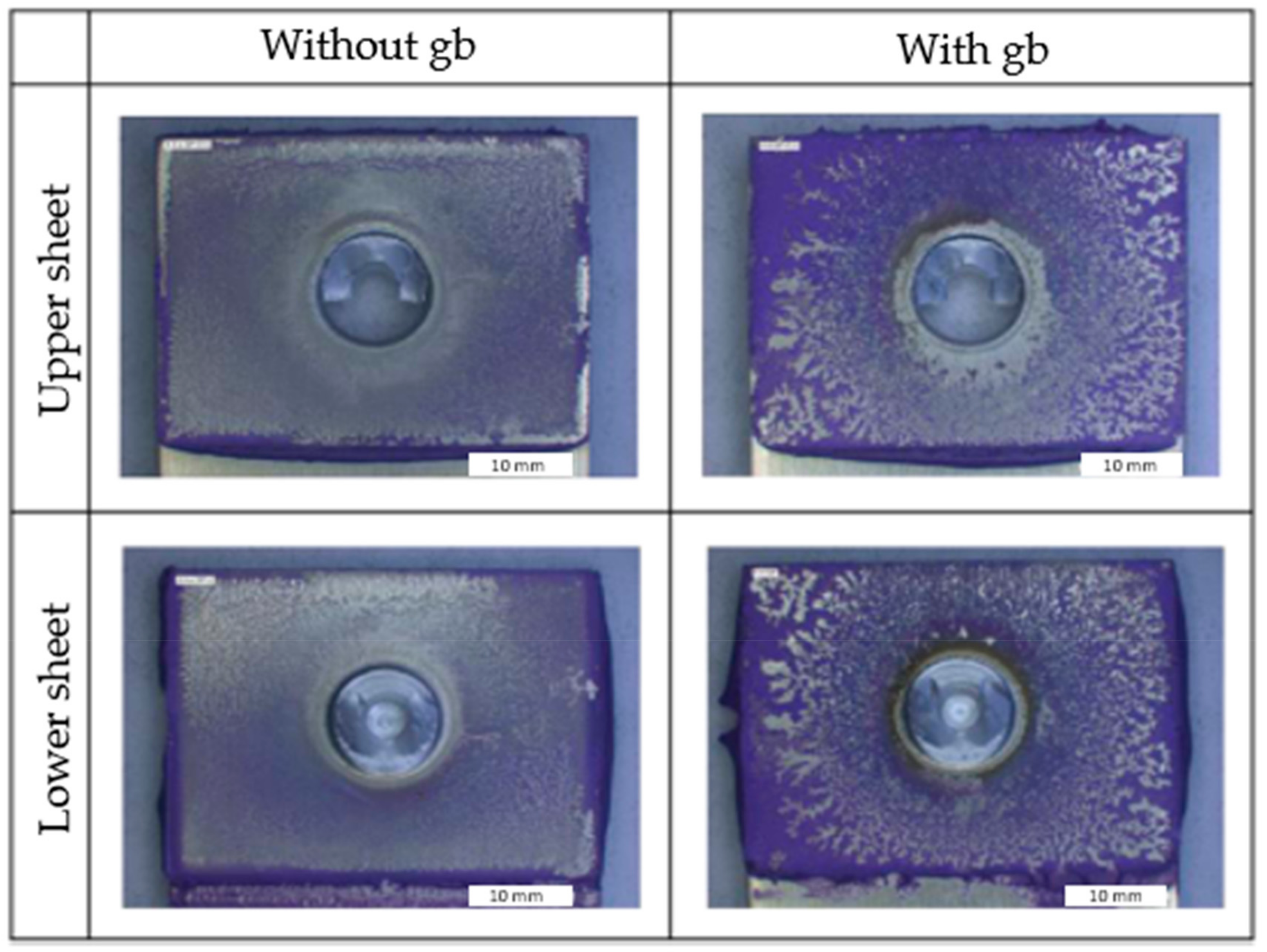

Figure 4 shows the fracture patterns of the RRPSK specimens with and without glass beads at a residence time of 4 s. The specimens without glass beads have a smaller residual amount of adhesive in the overlap area. When the tool is immersed, forces of more than 20 kN occur in the axial direction. When the tool is immersed, the glass beads prevent large parts of the adhesive from being displaced from the adhesive joint. Nevertheless, the adhesive has been displaced from the adhesive joint in these samples as well, which is indicated by the fracture pattern. On the one hand, the pattern is created by the displacement of the adhesive due to the application of force and the subsequent contraction of the adhesive during relief. Since the adhesive has already been pressed out of the adhesive joint, it can no longer be completely filled. On the other hand, the adhesive is decomposed and reduced in quantity because of the heat input. Due to the residual moisture in the adhesive, gases can be produced during heating, which can also contribute to the formation of this pattern. Additionally, the adhesive layer is damaged around the welding point.

No difference is visible regarding the type of failure of the weld spot. Both specimens show a mixed fracture with about half of the spot weld being pulled out. This type of failure also occurs with the purely friction stir welded specimens, so that it can be stated that the adhesive has no influence on the failure behavior of the weld spot. Whether the glass beads and the adhesive have an influence on the RZ can be better assessed on the basis of the cross-section images. Both specimens show a cohesion fracture. This is a sign of a high-quality bond and indicates a good bond between the joining part material EN AW 6082-T6 and the adhesive Betamate 1460 N. The bond between the two materials is also good.

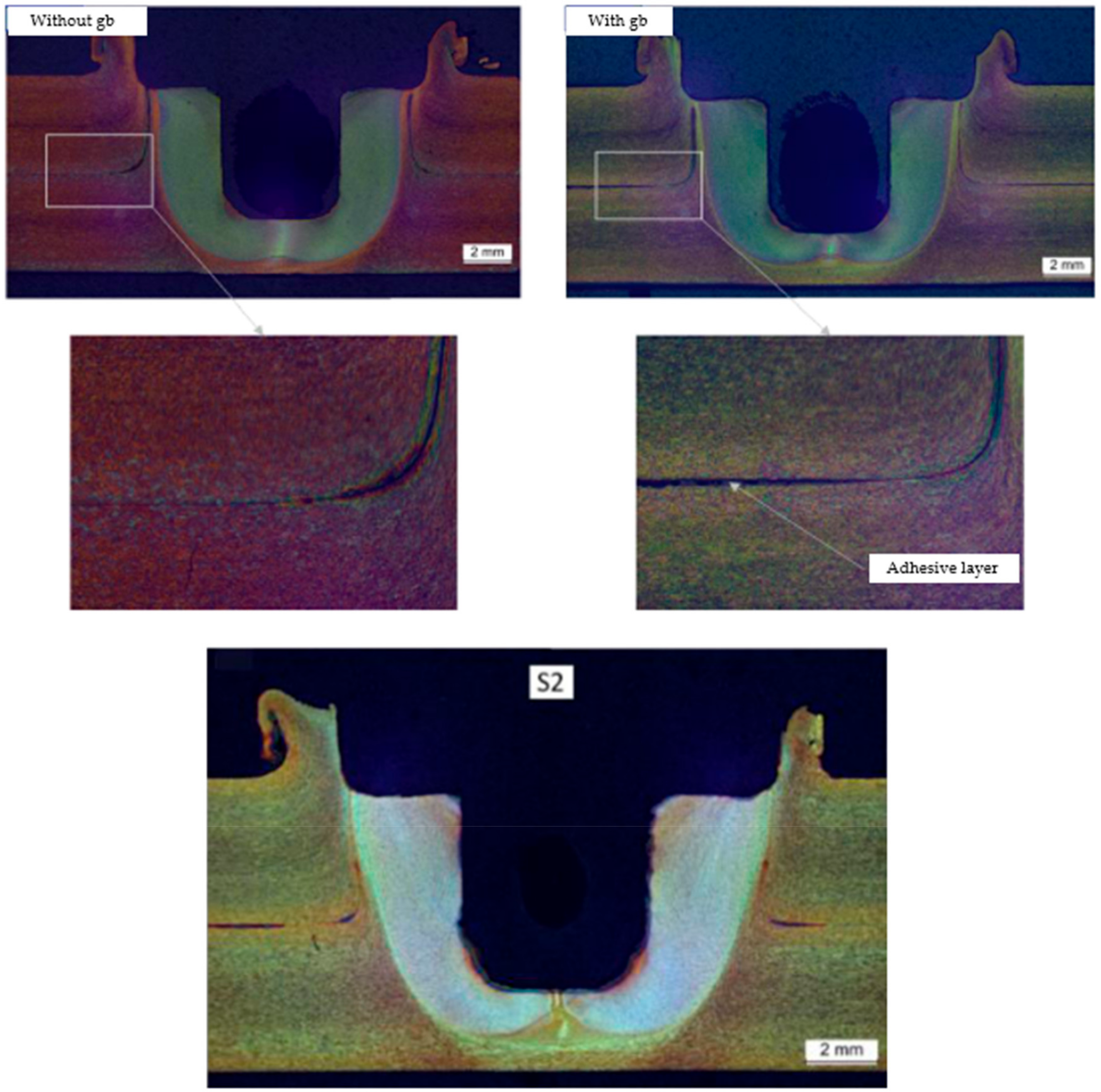

The cross-section images in

Figure 5 confirm that the adhesive is largely displaced from the adhesive joint in the specimens without glass beads. In the glass bead specimen, on the other hand, a defined adhesive layer is visible immediately behind the shoulder impression. The displacement of the adhesive below the shoulder diameter confirms that the adhesive has no effect on the material flow and the stirring zone. The geometry and shape of the stirring zone of the FSSBW samples are similar to those of the FSSW samples. Under the complete shoulder impression, these samples show a stirring zone and a steep hook running along the stirring zone to the outer edge of the shoulder impression (see sample S2 in

Figure 5). A closer look at the FSSBW cross sections also reveals the onion rings. Complete glass beads, on the other hand, are not visible in the RZ. These are probably broken into fine fragments around the welding spot due to the high axial forces or are simply not in the plane of the cut.

The shear forces of the FSSBW specimens decrease by almost 50% with increasing residence time. The fracture patterns of the FSSBW specimens with glass beads are shown in ascending residence time in

Figure 6. The temperature runs for this area were modelled from the data of the thermocouple in the welding stud and the three thermocouples each placed around the welding spot and graphically shown in

Figure 6. For this purpose, the local maximum temperature values of the sensors during the welding process were used for the different dwell times. Since only punctual values were recorded, this distribution has to be considered qualitatively. While at a residence time of 0 s no adhesive burn-off can be observed, but only a displacement of the adhesive around the weld spot, increasing adhesive burn-off can be observed at a residence time of 2 s and longer. Adhesive burn-off is shown by the yellow-brown discoloration around the weld spot and is greatest at the longest dwell time. This result is not surprising when the temperature curves in

Figure 6 are considered.

The samples at 4 s and 6 s reach almost identical maximum temperatures at the welding stud and show a similar temperature distribution, but the heat input at 6 s is higher. At a residence time of 0 s, temperatures of around 200 °C occur at the internal sensors, which does not damage the adhesive. As the residence time increases, temperatures more than 350 °C or 430 °C are recorded, which damage the adhesive in this area.

Based on the fracture pattern of the specimen (

Figure 7) with a residence time of 0 s, it can be confirmed that the high joint strength is based almost exclusively on the adhesive strength, since the adhesive layer is hardly damaged, and the weld spot fails in the shear fracture, which is attributable to the low heat input. With increasing residence time, the fracture behavior changes to a mixed fracture with tearing of up to about half of the weld spot.

Figure 8 shows a force-elongation diagram of the FSSBW specimens with glass beads and the purely bonded specimen. It becomes clear that with the FSSBW, the elongation at break can be increased considerably. The increase is over 150%. Furthermore, the time-delayed failure of the weld spot can be observed based on this diagram. After the maximum force has been reached by the adhesive layer, the tensile force drops abruptly. There, the weld spot takes hold and considerably increases the elongation at break. Even though the maximum tensile force decreases steadily with increasing residence time, the specimens achieve similar elongations, which is attributable to the changed fracture behavior. The weld spot, thus, contributes to an increased energy absorption, which is particularly desirable for car body components. A high plastic elongation is advantageous for crash-relevant components, as the impact energy is absorbed more efficiently, and less acceleration change occurs. A further advantage is that safety-relevant components deform plastically before final failure and are therefore easy to identify optically.

However, the selection of the optimum parameters must be adapted to the specific application. The welding parameters of the test series (dwell time 2 s) are characterized by good weld spot formation and justifiable heat input, since a minimum input of heat is necessary to form a large stirring zone and thus achieve high weld spot strength with simultaneous low adhesive layer damage. Although the weld spot strength increases by 14% from 2 s to 4 s dwell time (see

Figure 3), the overall strength of the hybrid joint decreases due to adhesive burn-up. The tensile strength is highest at 0 s, but this is mainly due to the adhesive layer and not to the weld spot. This is particularly disadvantageous with cyclically loaded components.

In summary, it can be said that the adhesive has no influence on the material flow and the type of failure. In addition, the use of glass beads is recommended as the glass beads reduce the displacement of the adhesive from the adhesive joint. The FSSBW specimens show both high shear forces and high plastic deformability and are suitable for the application of crash-relevant components. Only after the complete failure of the adhesive layer does the spot weld failure occur, whereby the spot weld serves as additional protection. However, it is important to consider the specific application and to adapt the parameters to it.