Temperature Dependent Phase Transformation Kinetics of Reverted Austenite during Tempering in 13Cr Supermartensitic Stainless Steel

Abstract

:1. Introduction

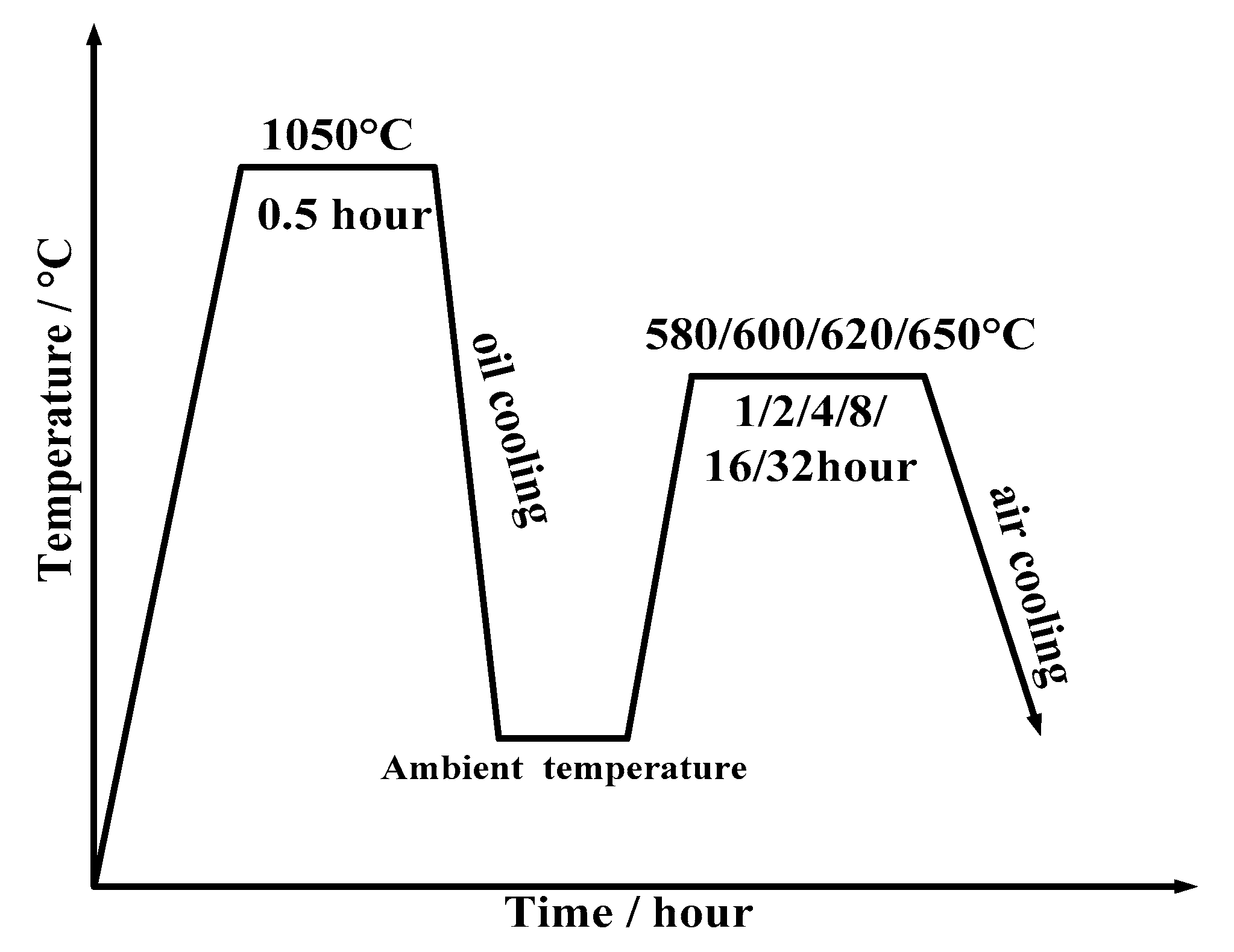

2. Materials and Methods

3. Results and Discussion

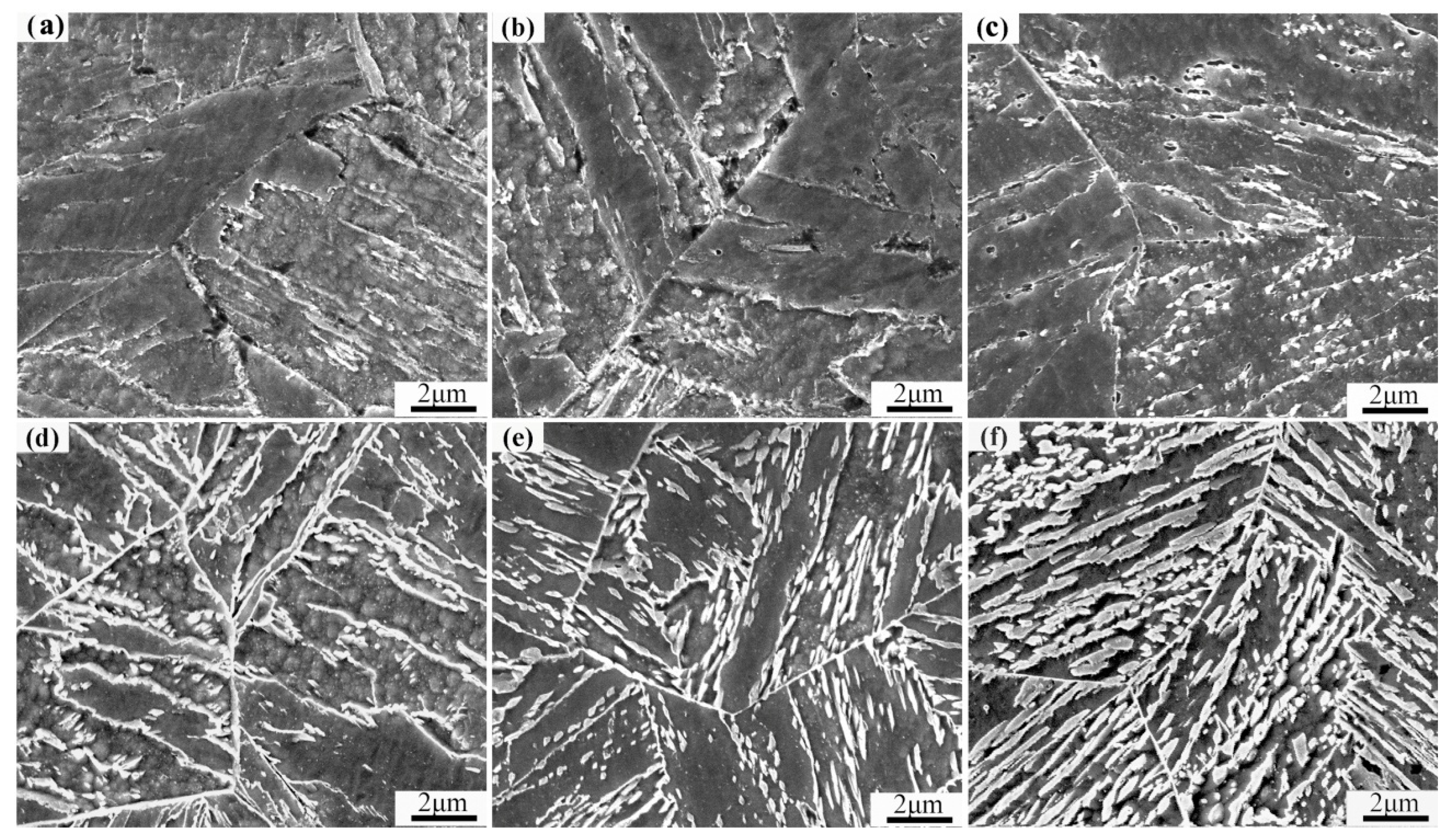

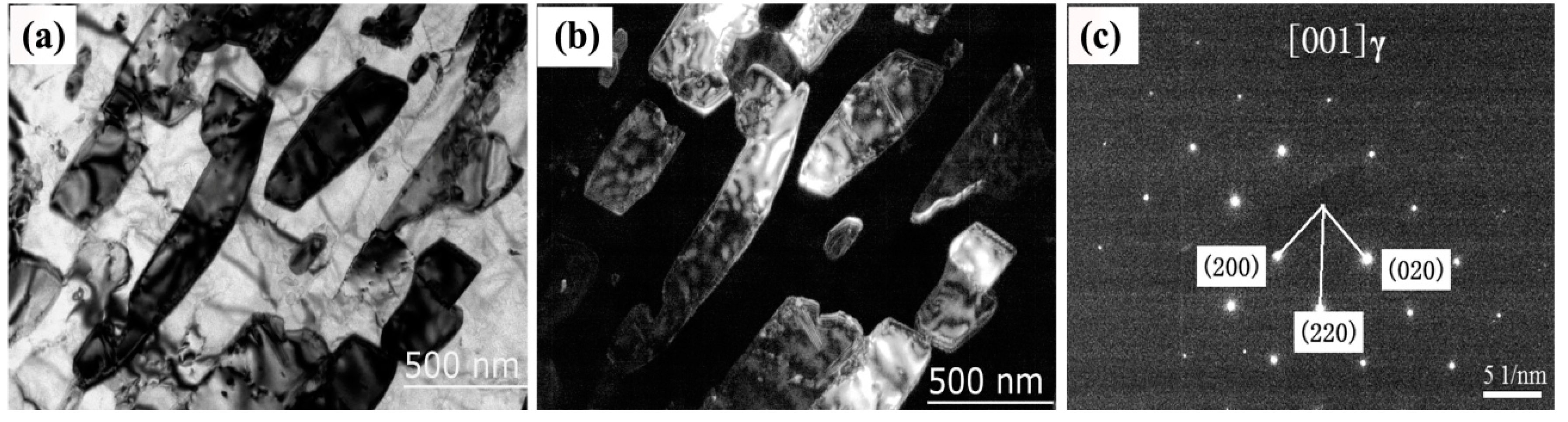

3.1. Tempered Microstructure Characterization

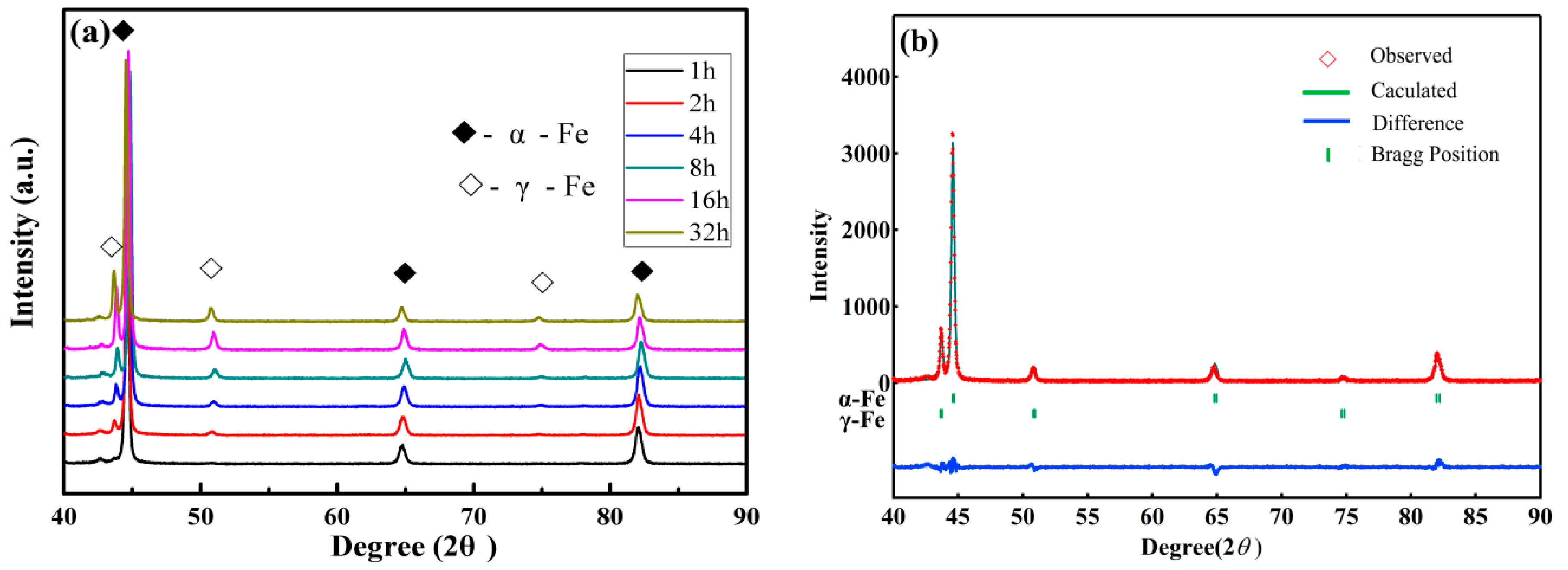

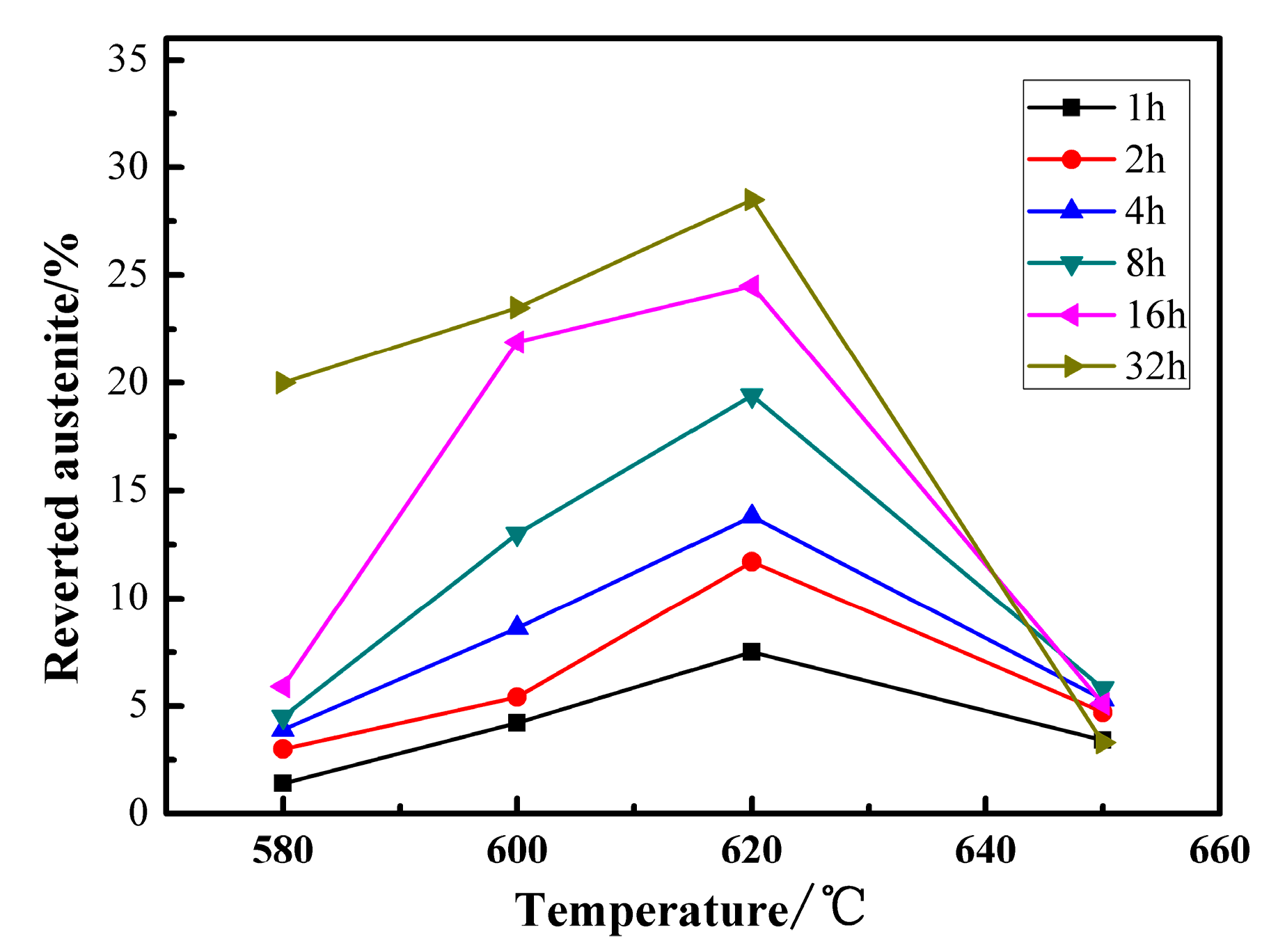

3.2. Variations in Amounts of Reverted Austenite with Tempering Time

4. Discussion

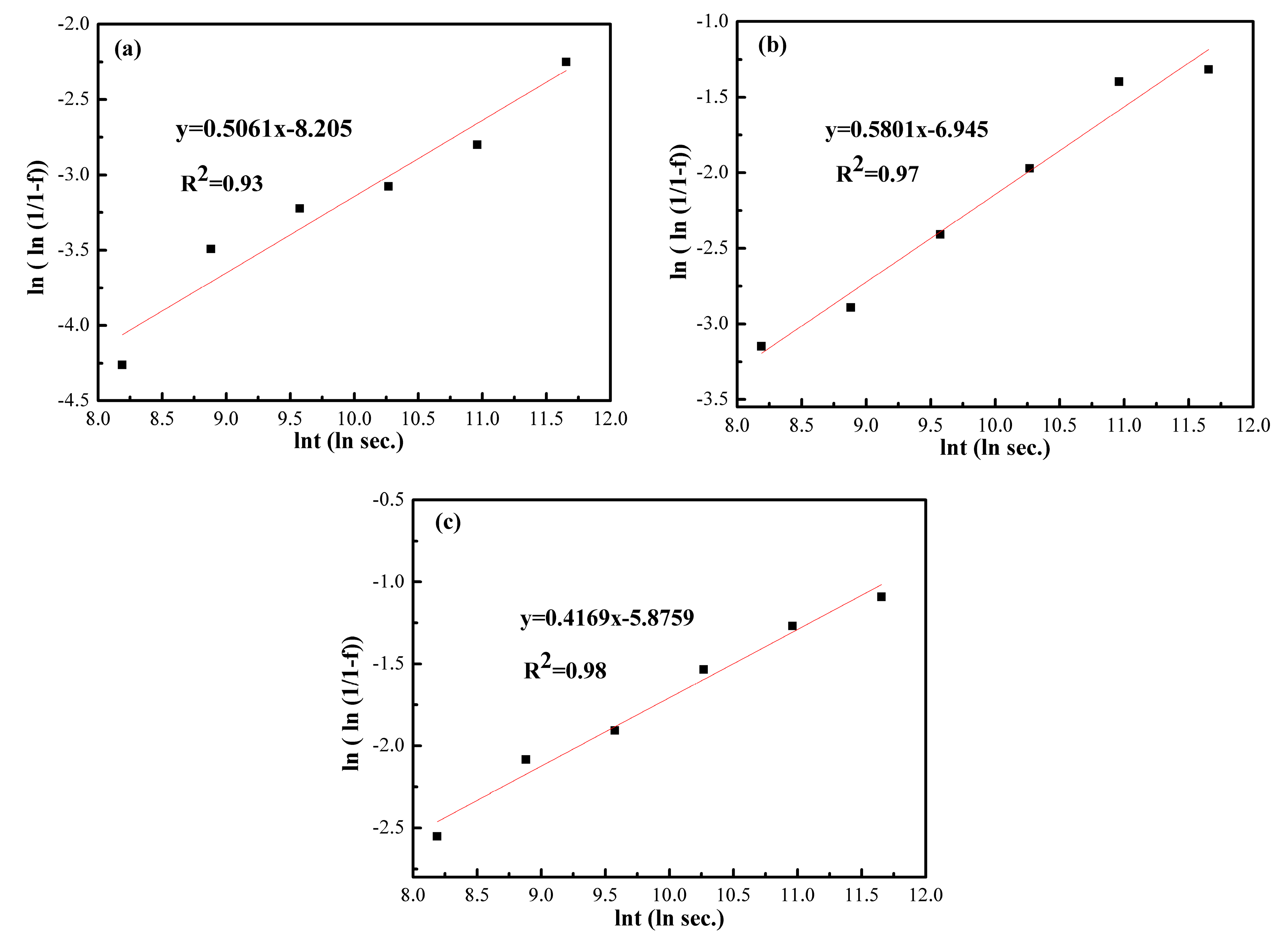

4.1. The Transformation Kinetic Parameters and Tansformation Activation Energy

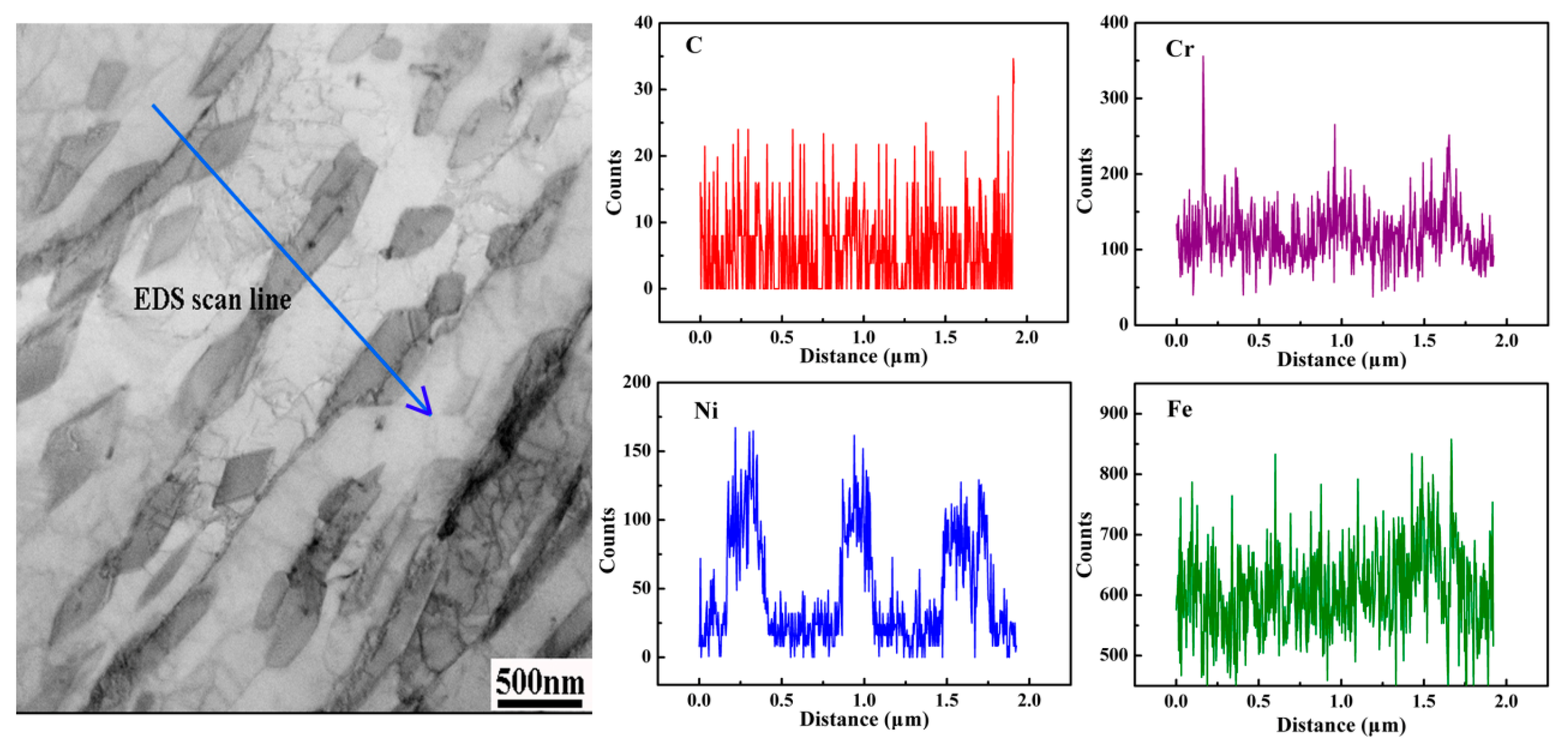

4.2. The Transformation Mechanism of Reverted Austenite During Tempering

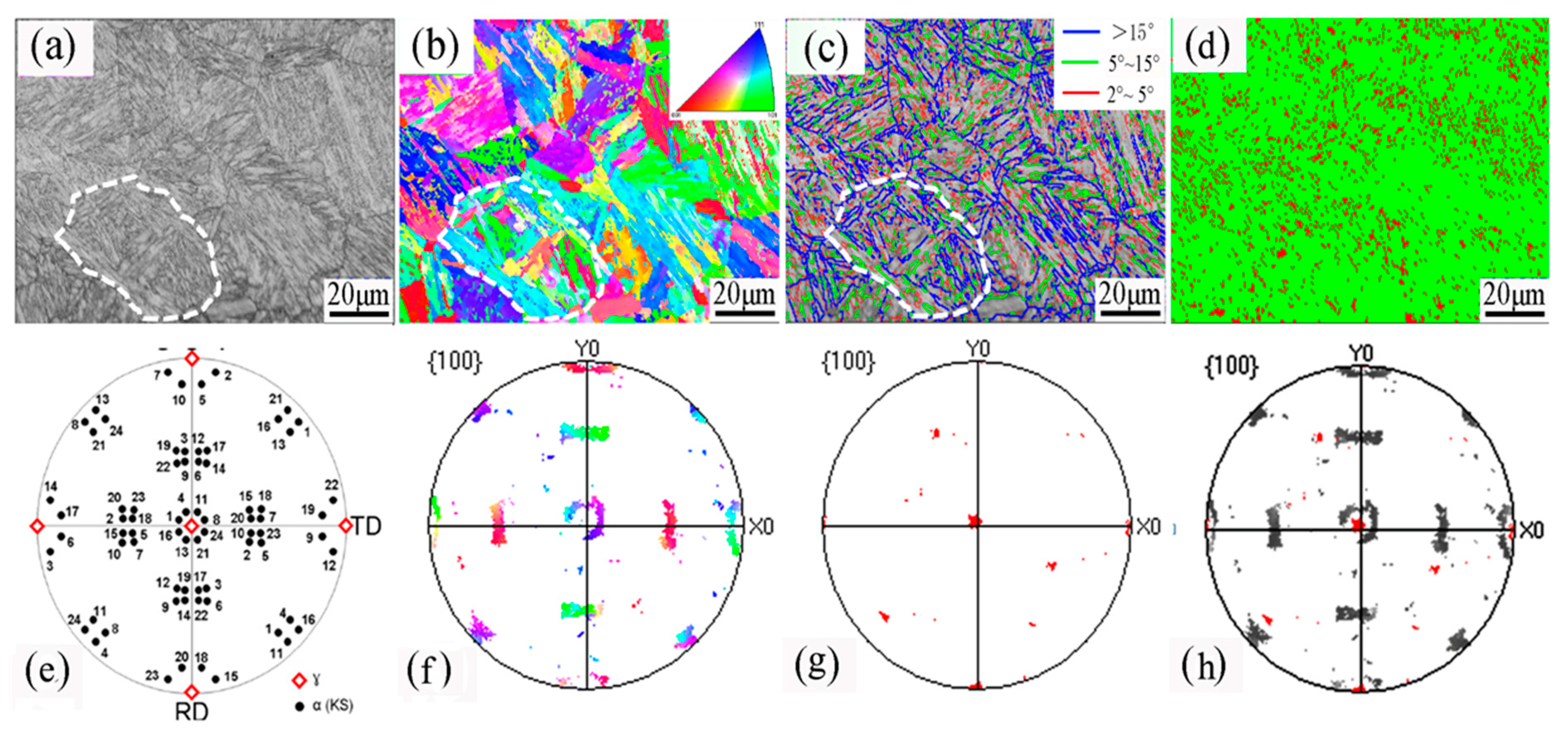

4.3. EBSD Analysis of the Orientation Relationship

5. Conclusions

- The microstructure was tempered martensite and reverted austenite in the 13Cr supermartensitic stainless steel, and the reverted austenite as a plate-like precipitated at the blocks, sub-blocks, laths and prior austenite grain boundaries. The amount of the reverted austenite increased with the tempering time at the same tempering temperature. Due to the stability of reverted austenite, the amount of the reverted austenite was decreased when the tempering temperature was above 620 °C.

- The model of the kinetics transformation of the reverted austenite was explored by the formula of Johnson–Mehl–Avrami. The value of Avrami exponent n was 0.5, and the activation energy Q was 369 kJ/mol. The Avrami exponent shows that the reverted austenite grew in thickness through the diffusion of Ni austenization element. The reverted austenite precipitated within the prior austenite grain uniformly. The morphologies of the reverted austenite proved the above kinetics model. It was determined that the growth of reverted austenite was controlled by the diffusion of substitution Ni elements during tempering process.

- The result shows that reverted austenite and martensite met the K-S orientation relationship from the (100) pole figure. The martensite reverted to austenite with the same crystallographic orientation as that of the prior austenite. The orientation relationships minimized the strain energy of the phase transformation by reducing the crystallographic mismatch between phases.

Author Contributions

Funding

Conflicts of Interest

References

- Zepon, G.; Nogueira, R.P.; Kiminami, C.S.; Botta, W.J.; Bolfarini, C. Electrochemical corrosion behavior of spray-formed boron-modified supermartensitic stainless steel. Metall. Mater. Trans. A 2017, 48, 2077–2089. [Google Scholar] [CrossRef]

- Anselmo, N.; May, J.E.; Mariano, N.A.; Nascente, P.A.P.; Kuri, S.E. Corrosion behavior of supermartensitic stainless steel in aerated and CO2-saturated synthetic seawater. Mater. Sci. Eng. A 2006, 428, 73–79. [Google Scholar] [CrossRef]

- Song, Y.; Li, X.; Rong, L.; Li, Y. The influence of tempering temperature on the reversed austenite formation and tensile properties in Fe–13%Cr–4%Ni–Mo low carbon martensite stainless steels. Mater. Sci. Eng. A 2011, 528, 4075–4079. [Google Scholar] [CrossRef]

- Qin, B.; Wang, Z.Y.; Sun, Q.S. Effect of tempering temperature on properties of 00Cr16Ni5Mo stainless steel. Mater. Charact. 2008, 59, 1096–1100. [Google Scholar] [CrossRef]

- Escobar, J.D.; Faria, G.A.; Wu, L.; Oliveira, J.P.; Mei, P.R.; Ramirez, A.J. Austenite reversion kinetics and stability during tempering of a Ti-stabilized supermartensitic stainless steel: Correlative in situ synchrotron x-ray diffraction and dilatometry. Acta Mater. 2017, 138, 92–99. [Google Scholar] [CrossRef]

- Escobar, J.D.; Poplawsky, J.D.; Faria, G.A.; Rodriguez, J.; Oliveira, J.P.; Salvador, C.A.F.; Mei, P.R.; Babu, S.S.; Ramirez, A.J. Compositional analysis on the reverted austenite and tempered martensite in a Ti-stabilized supermartensitic stainless steel: Segregation, partitioning and carbide precipitation. Mater. Des. 2018, 140, 95–105. [Google Scholar] [CrossRef]

- Della Rovere, C.A.; Ribeiro, C.R.; Silva, R.; Baroni, L.F.S.; Alcântara, N.G.; Kuri, S.E. Microstructural and mechanical characterization of radial friction welded supermartensitic stainless steel joints. Mater. Sci. Eng. A 2013, 586, 86–92. [Google Scholar] [CrossRef]

- De Sanctis, M.; Lovicu, G.; Valentini, R.; Dimatteo, A.; Ishak, R.; Migliaccio, U.; Montanari, R.; Pietrangeli, E. Microstructural features affecting tempering behavior of 16Cr-5Ni supermartensitic steel. Metall. Mater. Trans. A 2015, 46, 1878–1887. [Google Scholar] [CrossRef]

- Ma, X.P.; Wang, L.J.; Qin, B.; Liu, C.M.; Subramanian, S.V. Effect of N on microstructure and mechanical properties of 16Cr5Ni1Mo martensitic stainless steel. Mater. Des. 2012, 34, 74–81. [Google Scholar] [CrossRef]

- Rodrigues, C.A.D.; Bandeira, R.M.; Duarte, B.B.; Tremiliosi-Filho, G.; Jorge, A.M. Effect of phosphorus content on the mechanical, microstructure and corrosion properties of supermartensitic stainless steel. Mater. Sci. Eng. A 2016, 650, 75–83. [Google Scholar] [CrossRef]

- Li, X.; Lu, K. Improving sustainability with simpler alloys. Science 2019, 364, 733–734. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Lu, S.P.; Xiao, N.M.; Li, D.Z.; Li, Y.Y. Effect of delta ferrite on impact properties of low carbon 13Cr–4Ni martensitic stainless steel. Mater. Sci. Eng. A 2010, 527, 3210–3216. [Google Scholar] [CrossRef]

- Ma, X.P.; Wang, L.J.; Liu, C.M.; Subramanian, S.V. Role of Nb in low interstitial 13Cr super martensitic stainless steel. Mater. Sci. Eng. A 2011, 528, 6812–6818. [Google Scholar] [CrossRef]

- Rodrigues, C.A.D.; Lorenzo, P.L.D.; Sokolowski, A.; Barbosa, C.A.; Rollo, J.M.D.A. Titanium and molybdenum content in supermartensitic stainless steel. Mater. Sci. Eng. A 2007, 460, 149–152. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.-X.; Sun, G.-S.; Xie, H.; Misra, R.D.K. The determining role of reversed austenite in enhancing toughness of a novel ultra-low carbon medium manganese high strength steel. Scripta Mater. 2015, 104, 87–90. [Google Scholar] [CrossRef]

- Liu, Y.; Ye, D.; Yong, Q.; Su, J.; Zhao, K.; Jiang, W. Effect of heat treatment on microstructure and property of Cr13 super martensitic stainless steel. J. Iron Steel Res. Int. 2011, 18, 60–66. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Lv, C.; Tan, L.; Yuan, X.; Li, S. Effect of carbon partition in the reverted austenite of supermartensitic stainless steel. Mater. Res. Express 2019, 6, 086518. [Google Scholar] [CrossRef]

- Jiang, W.; Zhao, K.; Ye, D.; Li, J.; Li, Z.; Su, J. Effect of heat treatment on reversed austenite in Cr15 super martensitic stainless steel. J. Iron Steel Res. Int. 2013, 20, 61–65. [Google Scholar] [CrossRef]

- Haidemenopoulos, G.N.; Grujicic, M.; Olson, G.B.; Cohen, M. Thermodynamics-based alloy design criteria for austenite stabilization and transformation toughening in the Fe-Ni-Co system. J. Alloys Compd. 1995, 220, 142–147. [Google Scholar] [CrossRef]

- Gruber, M.; Ressel, G.; Méndez Martín, F.; Ploberger, S.; Marsoner, S.; Ebner, R. Formation and growth kinetics of reverted austenite during tempering of a high Co-Ni steel. Metall. Mater. Trans. A 2016, 47, 5932–5941. [Google Scholar] [CrossRef]

- Zuo, D.; Han, Y.; Zhang, W.; Fang, X. Influence of tempering process on mechanical properties of 00Cr13Ni4Mo supermartensitic stainless steel. J. Iron Steel Res. Int. 2010, 17, 50–54. [Google Scholar]

- Zhang, Q.; Zhao, B.; Fang, M.; Liu, C.; Hu, Q.; Fang, F.; Sun, D.; Ouyang, L.; Zhu, M. (Nd(1.5)Mg(0.5))Ni7-based compounds: Structural and hydrogen storage properties. Inorg. Chem. 2012, 51, 2976–2983. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, C.; Yuan, X.; Li, D.; Yin, Y.; Li, S. Microstructure evolution and orientation relationship of reverted austenite in 13Cr supermartensitic stainless steel during the tempering process. Materials 2019, 12, 589. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Li, X.; Rong, L.; Li, Y. Anomalous phase transformation from martensite to austenite in Fe-13%Cr-4%Ni-Mo martensitic stainless steel. J. Mater. Sci. Technol. 2010, 26, 823–826. [Google Scholar] [CrossRef]

- Ye, D.; Li, S.; Li, J.; Jiang, W.; Su, J.; Zhao, K. Study on the crystallographic orientation relationship and formation mechanism of reversed austenite in economical Cr12 super martensitic stainless steel. Mater. Charact. 2015, 109, 100–106. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, P.; Li, D.; Li, Y. Investigation of the evolution of retained austenite in Fe–13%Cr–4%Ni martensitic stainless steel during intercritical tempering. Mater. Des. 2015, 84, 385–394. [Google Scholar] [CrossRef]

- Park, E.S.; Yoo, D.K.; Lee, J.H.; Sung, J.H.; Sung, J.H.; Kang, C.Y. Formation of reversed austenite during tempering of 14Cr−7Ni−0.3Nb−0.7Mo−0.03C super martensitic stainless steel. Met. Mater. Int. 2004, 10, 521–525. [Google Scholar] [CrossRef]

- Leem, D.S.; Lee, Y.D.; Jun, J.H.; Choi, C.S. Amount of retained austenite at room temperature after reverse transformation of martensite to austenite in an Fe–13%Cr–7%Ni–3%Si martensitic stainless steel. Scr. Mater. 2001, 45, 767–772. [Google Scholar] [CrossRef]

- Lee, Y.K.; Shin, H.C.; Leem, D.S.; Choi, J.Y.; Jin, W.; Choi, C.S. Reverse transformation mechanism of martensite to austenite and amount of retained austenite after reverse transformation in Fe-3Si-13Cr-7Ni (wt. %) martensitic stainless steel. Mater. Sci. Technol. 2003, 19, 393–398. [Google Scholar] [CrossRef]

- Mittemeijer, E.J. Review—Analysis of the kinetics of phase transformations. J. Mater. Sci. 1992, 27, 3977–3987. [Google Scholar] [CrossRef]

- Guo, Z.; Sha, W.; Li, D. Quantification of phase transformation kinetics of 18 wt. % Ni C250 maraging steel. Mater. Sci. Eng. A 2004, 373, 10–20. [Google Scholar] [CrossRef]

- Isobe, S.; Okabe, M. Kinetics of reverted austenite formation and its effects on the properties of 17-4PH stainless steel. Denki Seiko 1983, 54, 253–264. [Google Scholar] [CrossRef]

- Rajasekhara, S.; Ferreira, P.J. Martensite→austenite phase transformation kinetics in an ultrafine-grained metastable austenitic stainless steel. Acta Mater. 2011, 59, 738–748. [Google Scholar] [CrossRef]

- Nakada, N.; Tsuchiyama, T.; Takaki, S.; Miyano, N. Temperature dependence of austenite nucleation behavior from lath martensite. ISIJ Int. 2011, 51, 299–304. [Google Scholar] [CrossRef]

- Song, P.C.; Liu, W.B.; Zhang, C.; Liu, L.; Yang, Z.G. Reversed austenite growth behavior of a 13%Cr-5%Ni stainless steel during intercritical annealing. ISIJ Int. 2016, 56, 148–153. [Google Scholar] [CrossRef]

- Song, Y.Y.; Ping, D.H.; Yin, F.X.; Li, X.Y.; Li, Y.Y. Microstructural evolution and low temperature impact toughness of a Fe–13%Cr–4%Ni–Mo martensitic stainless steel. Mater. Sci. Eng. A 2010, 527, 614–618. [Google Scholar] [CrossRef]

- Bojack, A.; Zhao, L.; Morris, P.F.; Sietsma, J. In situ thermo-magnetic investigation of the austenitic phase during tempering of a 13Cr6Ni2Mo supermartensitic stainless steel. Metall. Mater. Trans. A 2014, 45, 5956–5967. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Danilchenko, V.E.; L’Heritier, P.; Shabashov, V.A. The structure and properties of Fe–Ni alloys with a nanocrystalline austenite formed under different conditions of γ–α–γ transformations. Mater. Sci. Eng. A 2002, 337, 146–159. [Google Scholar] [CrossRef]

- Yun, W. Microstructural Characterization and Mechanical Properties of Super 13% Cr Steel. Ph.D. Thesis, The University of Sheffield, Sheffield, UK, 2005. [Google Scholar]

- Bojack, A.; Zhao, L.; Morris, P.F.; Sietsma, J. Austenite formation from martensite in a 13Cr6Ni2Mo supermartensitic stainless steel. Metall. Mater. Trans. A 2016, 47, 1996–2009. [Google Scholar] [CrossRef]

- Song, Y.Y.; Li, X.Y.; Rong, L.J.; Ping, D.H.; Yin, F.X.; Li, Y.Y. Formation of the reversed austenite during intercritical tempering in a Fe–13%Cr–4%Ni–Mo martensitic stainless steel. Mater. Lett. 2010, 64, 1411–1414. [Google Scholar] [CrossRef]

- Karlsen, M.; Hjelen, J.; Grong, Ø.; Rørvik, G.; Chiron, R.; Schubert, U.; Nilsen, E. SEM/EBSD based in situ studies of deformation induced phase transformations in supermartensitic stainless steels. Mater. Sci. Technol. 2013, 24, 64–72. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhara, T.; Maki, T.; Hansen, N. The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Sicupira, F.L.; Sandim, M.J.R.; Sandim, H.R.Z.; Santos, D.B.; Renzetti, R.A. Quantification of retained austenite by X-ray diffraction and saturation magnetization in a supermartensitic stainless steel. Mater. Charact. 2016, 115, 90–96. [Google Scholar] [CrossRef]

- Nakada, N.; Tsuchiyama, T.; Takaki, S.; Hashizume, S. Variant selection of reversed austenite in lath martensite. ISIJ Int. 2007, 47, 1527–1532. [Google Scholar] [CrossRef]

- Sato, M.; Matsumoto, S.; Miyamoto, G.; Furuhara, T. Microstructure of reverted austenite in Fe-0.3N martensite. Scripta Mater. 2018, 156, 85–89. [Google Scholar] [CrossRef]

- Brandl, D.; Lukas, M.; Stockinger, M.; Ploberger, S.; Ressel, G. Evidence of austenite memory in PH 15-5 and assessment of its formation mechanism. Mater. Des. 2019, 176, 107841. [Google Scholar] [CrossRef]

- Abbasi, M.; Nelson, T.W.; Sorensen, C.D.; Wei, L. An approach to prior austenite reconstruction. Mater. Charact. 2012, 66, 1–8. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yin, Y.; Li, D.; Ma, P.; Liu, Q.; Yuan, X.; Li, S. Temperature Dependent Phase Transformation Kinetics of Reverted Austenite during Tempering in 13Cr Supermartensitic Stainless Steel. Metals 2019, 9, 1203. https://doi.org/10.3390/met9111203

Zhang Y, Yin Y, Li D, Ma P, Liu Q, Yuan X, Li S. Temperature Dependent Phase Transformation Kinetics of Reverted Austenite during Tempering in 13Cr Supermartensitic Stainless Steel. Metals. 2019; 9(11):1203. https://doi.org/10.3390/met9111203

Chicago/Turabian StyleZhang, Yiwei, Yuande Yin, Diankai Li, Ping Ma, Qingyun Liu, Xiaomin Yuan, and Shengzhi Li. 2019. "Temperature Dependent Phase Transformation Kinetics of Reverted Austenite during Tempering in 13Cr Supermartensitic Stainless Steel" Metals 9, no. 11: 1203. https://doi.org/10.3390/met9111203

APA StyleZhang, Y., Yin, Y., Li, D., Ma, P., Liu, Q., Yuan, X., & Li, S. (2019). Temperature Dependent Phase Transformation Kinetics of Reverted Austenite during Tempering in 13Cr Supermartensitic Stainless Steel. Metals, 9(11), 1203. https://doi.org/10.3390/met9111203